A Study on the Application of the Safety Practice Index to Reduce Safety Accidents in the Manufacturing Industry

Abstract

:1. Introduction

2. Methods of Research

2.1. Selection of the Research Target Industry

2.2. Safety Activity Group Selection and Safety Activity Index (SAI) Calculation

2.3. Risk Management Group Selection and Risk Management Index (RMI) Calculation

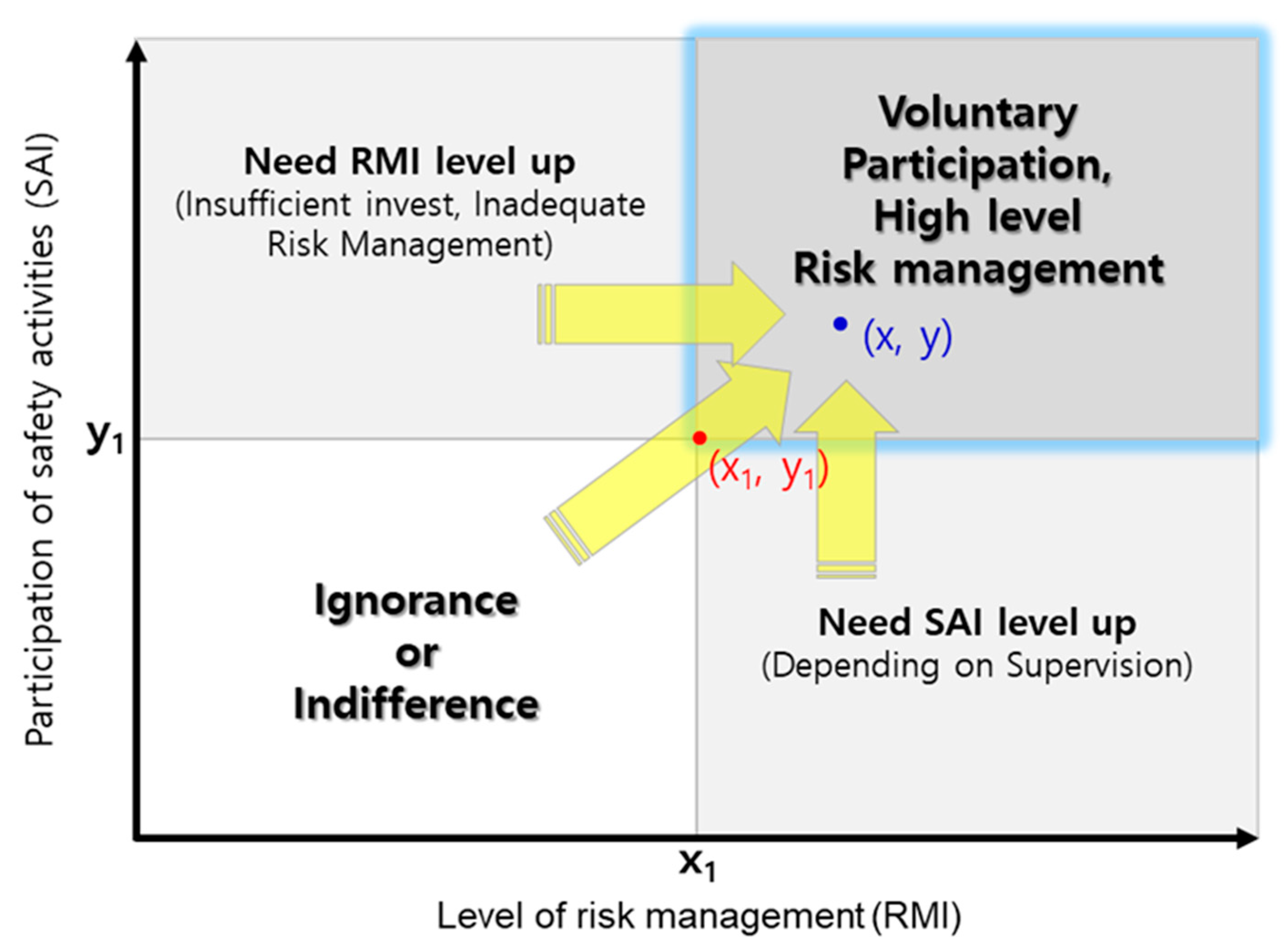

2.4. Safety Practice Index (SPI) Calculation

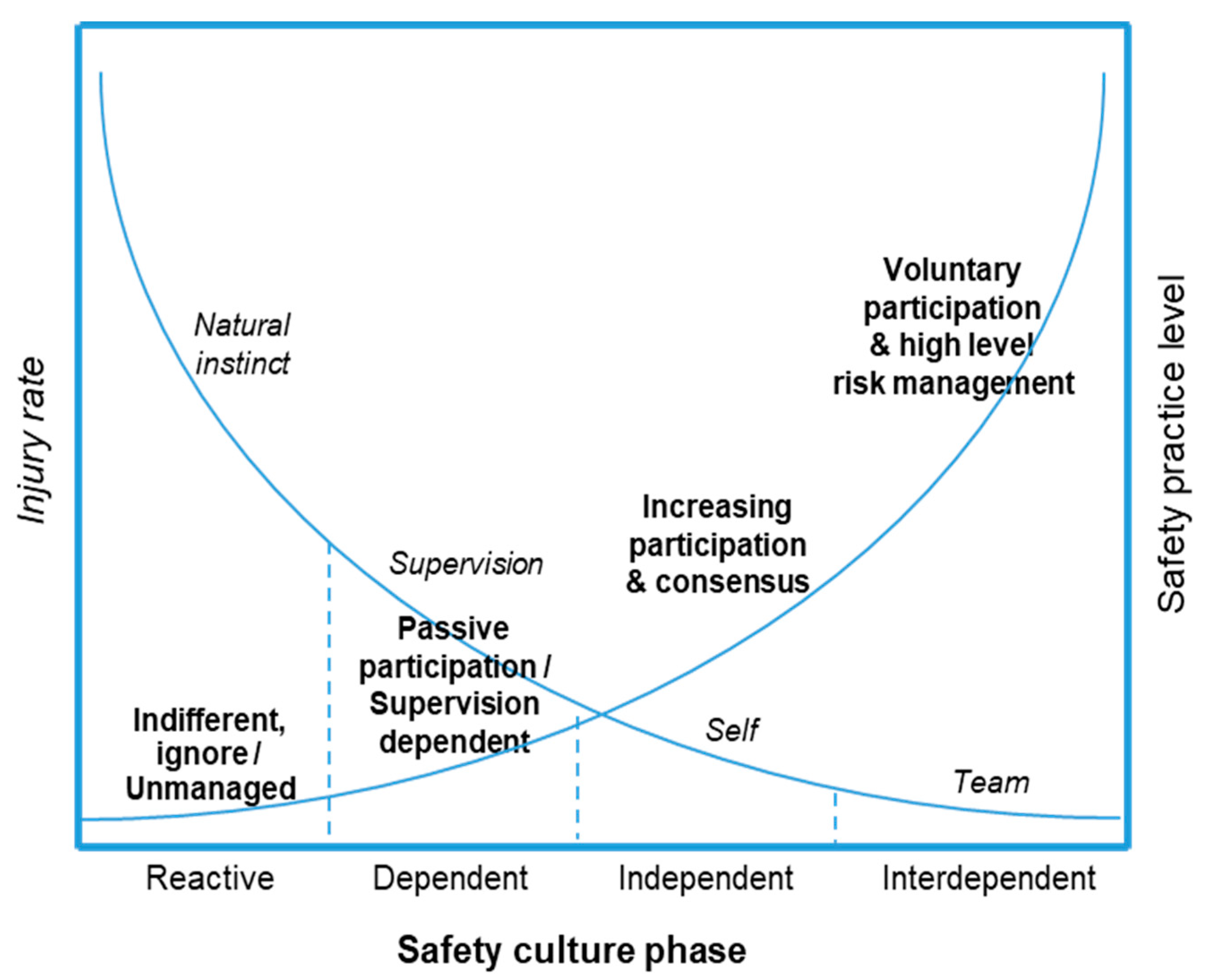

2.5. Safety Practice Level (SPL) Grading

3. Consideration of Application Cases

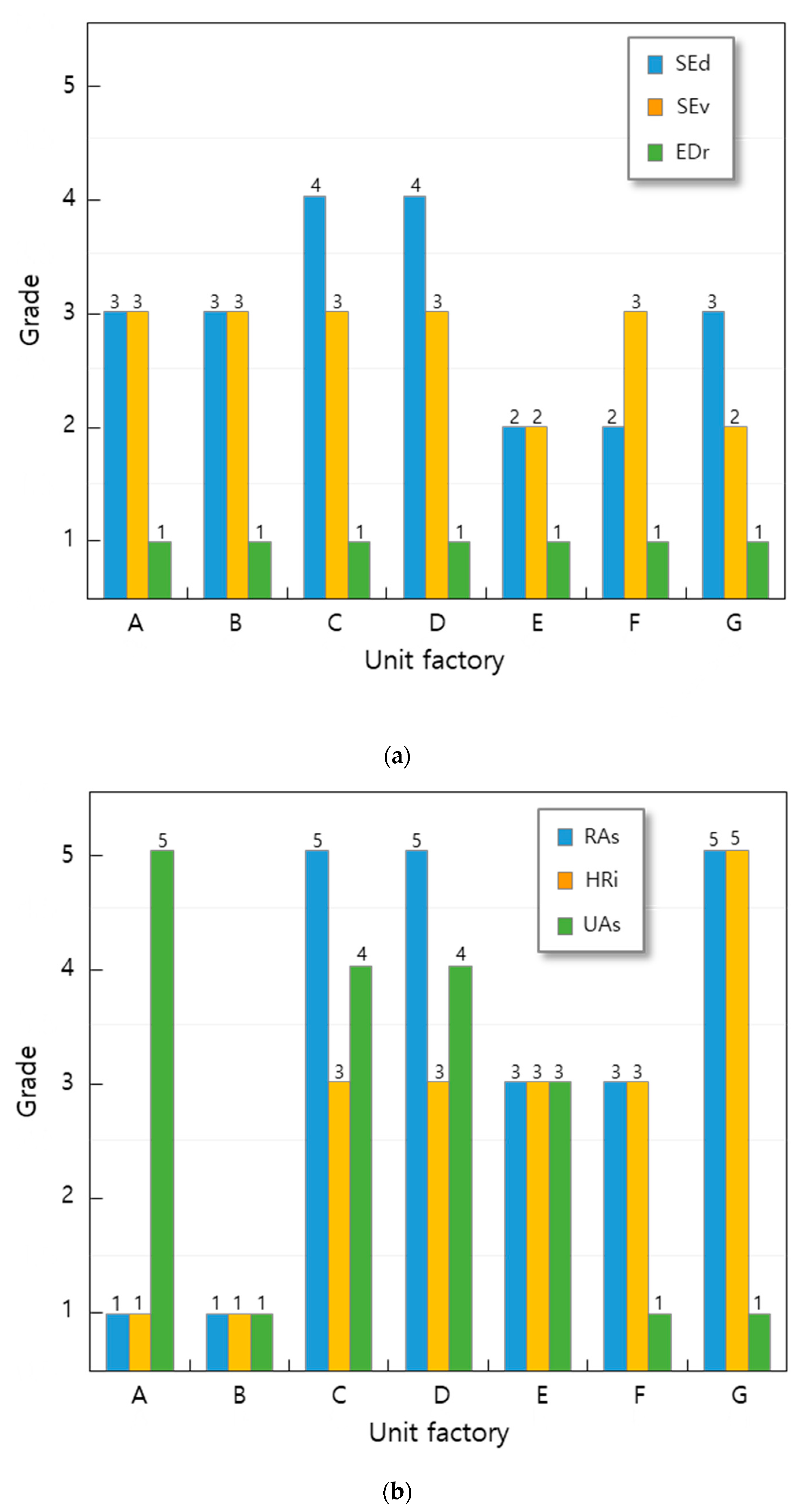

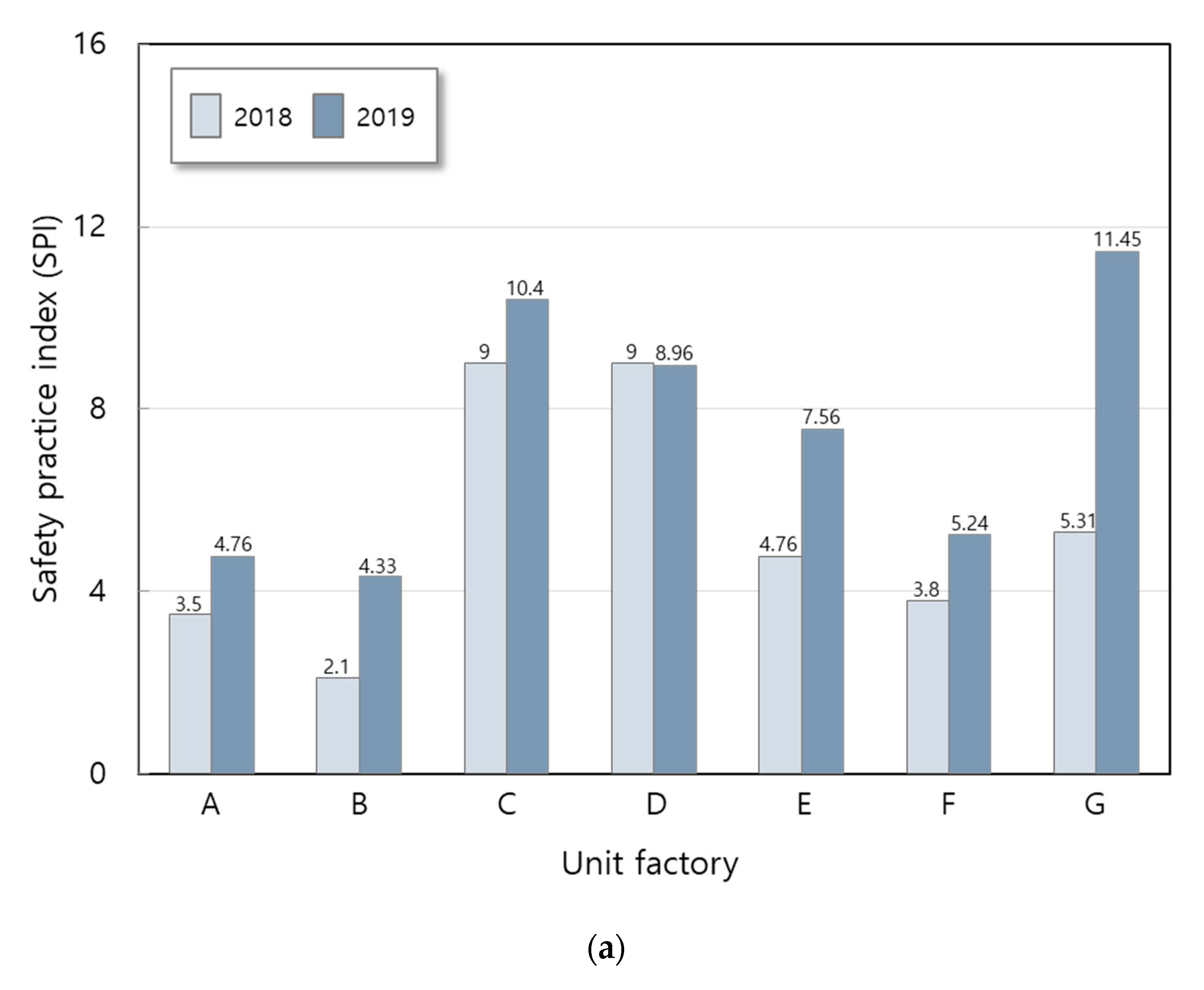

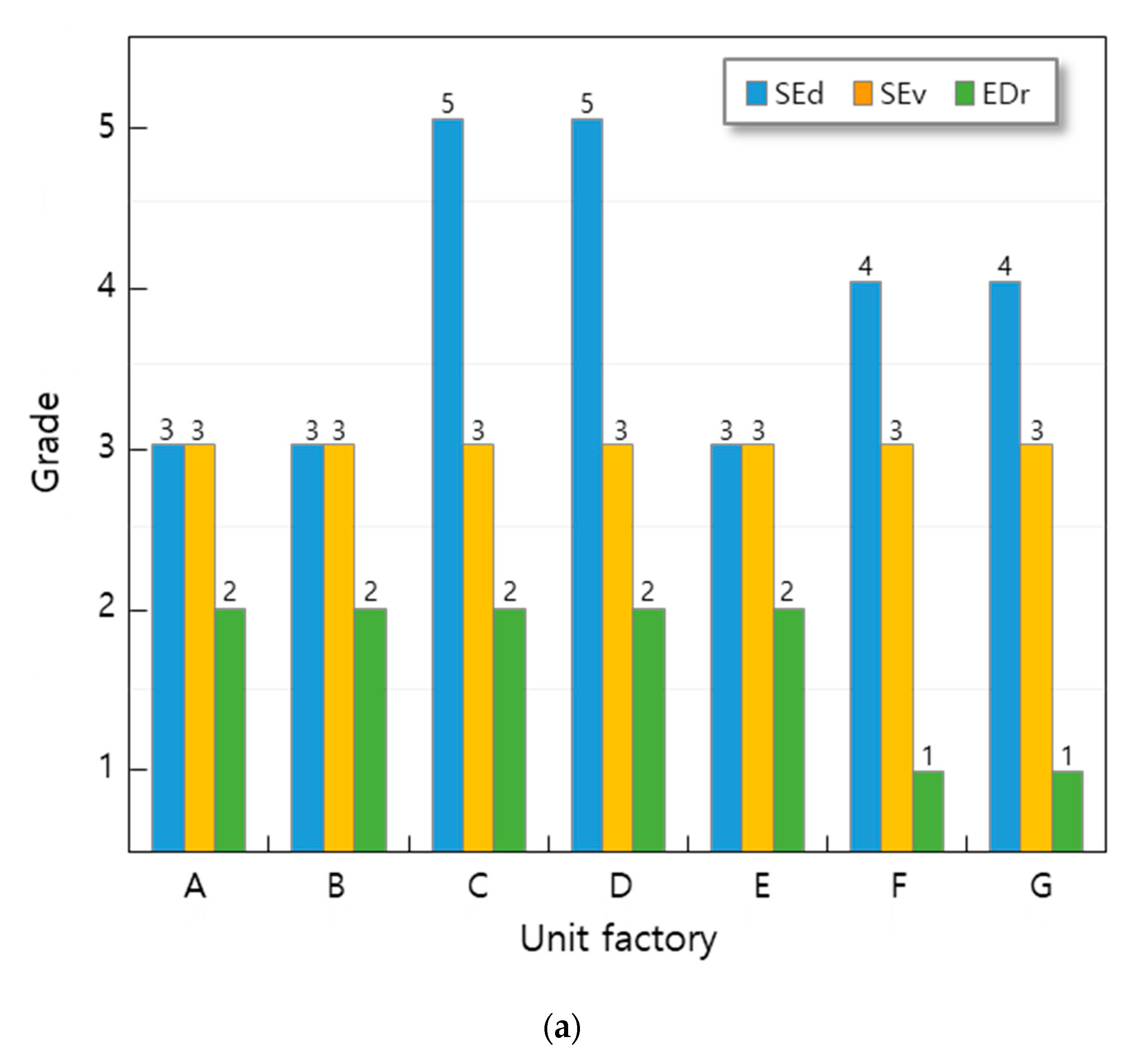

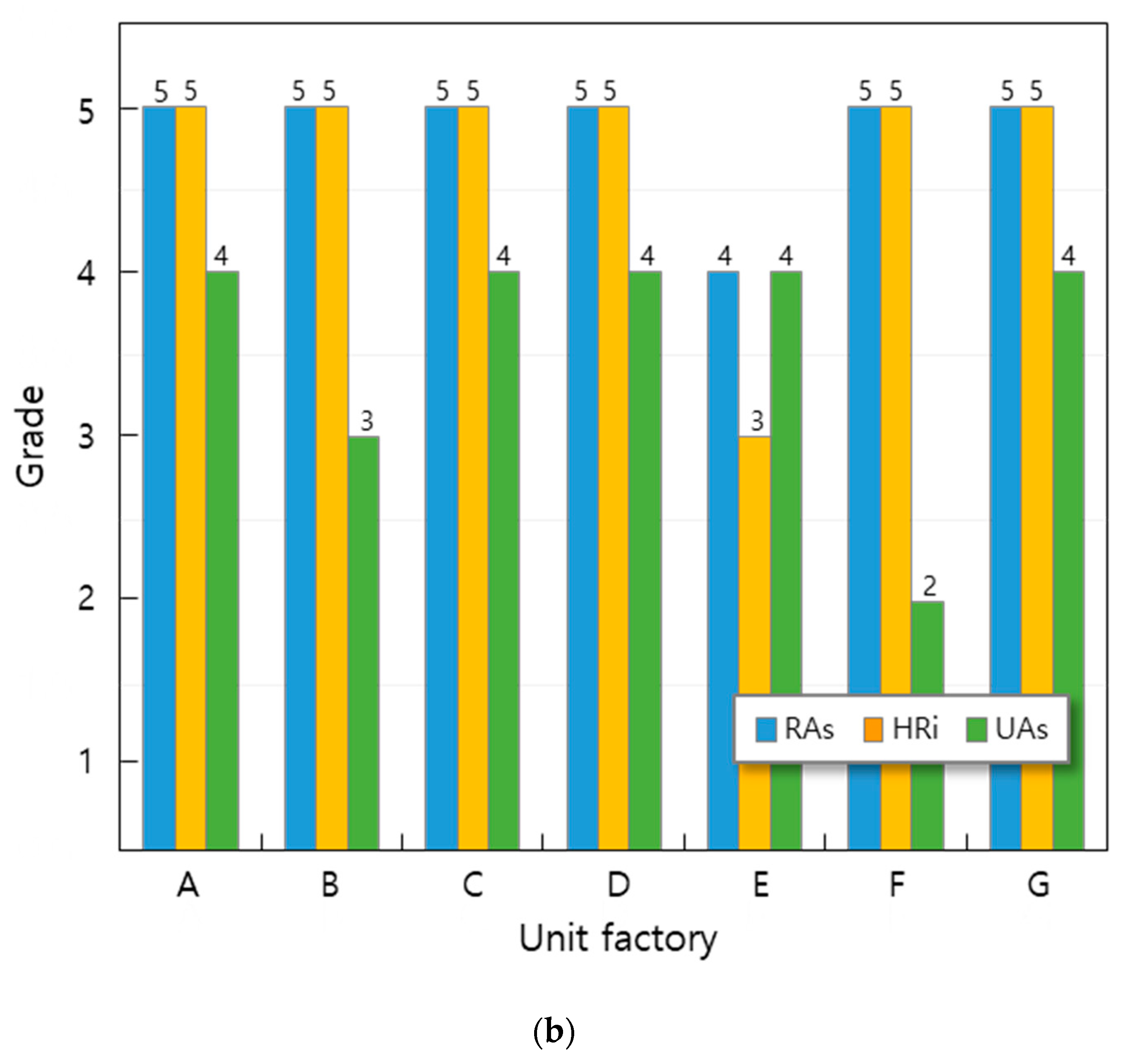

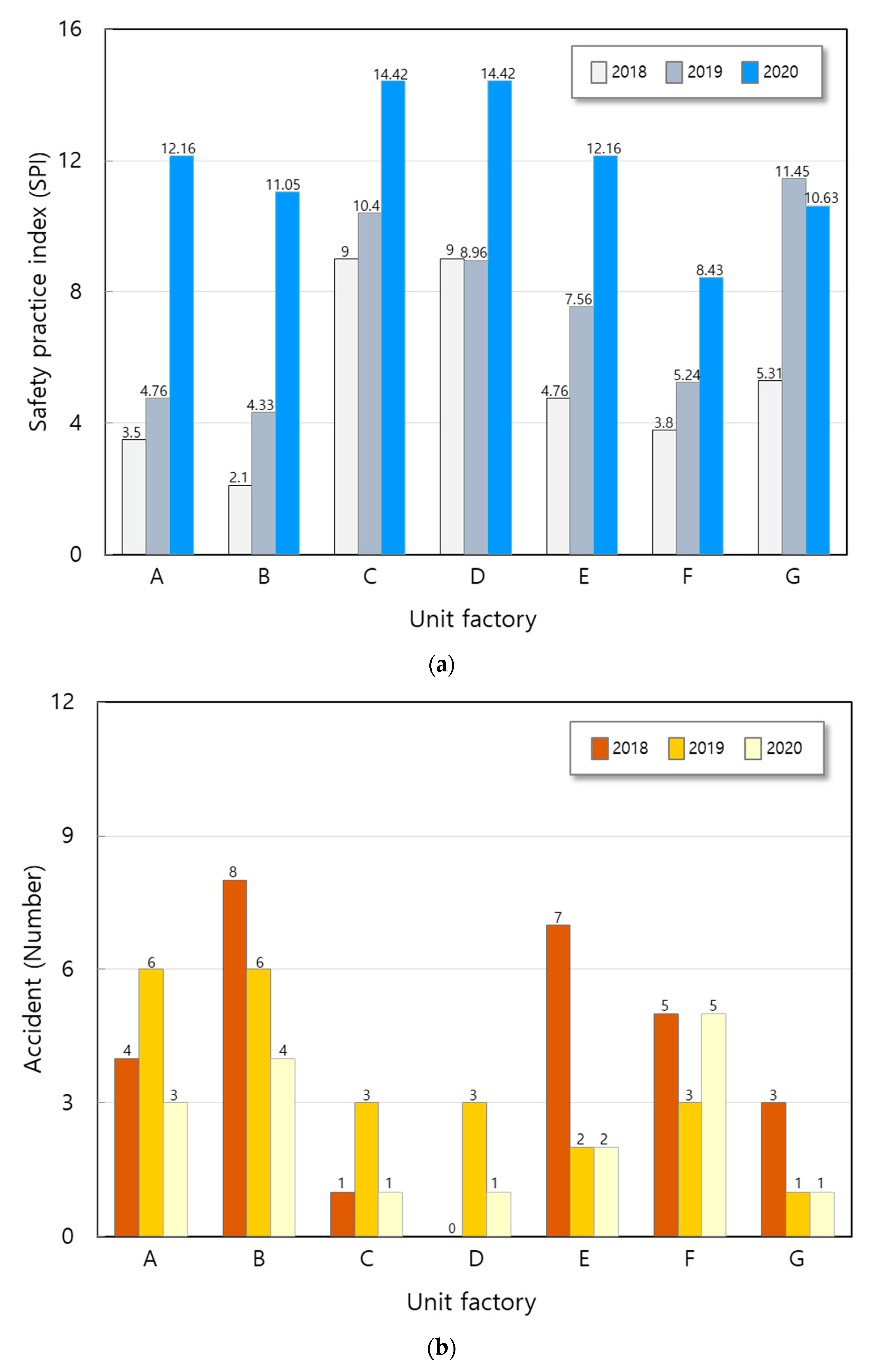

3.1. ’18 Safety Practice Index (SPI)

- SAI = = = 2.01

- RMI = = = 2.89

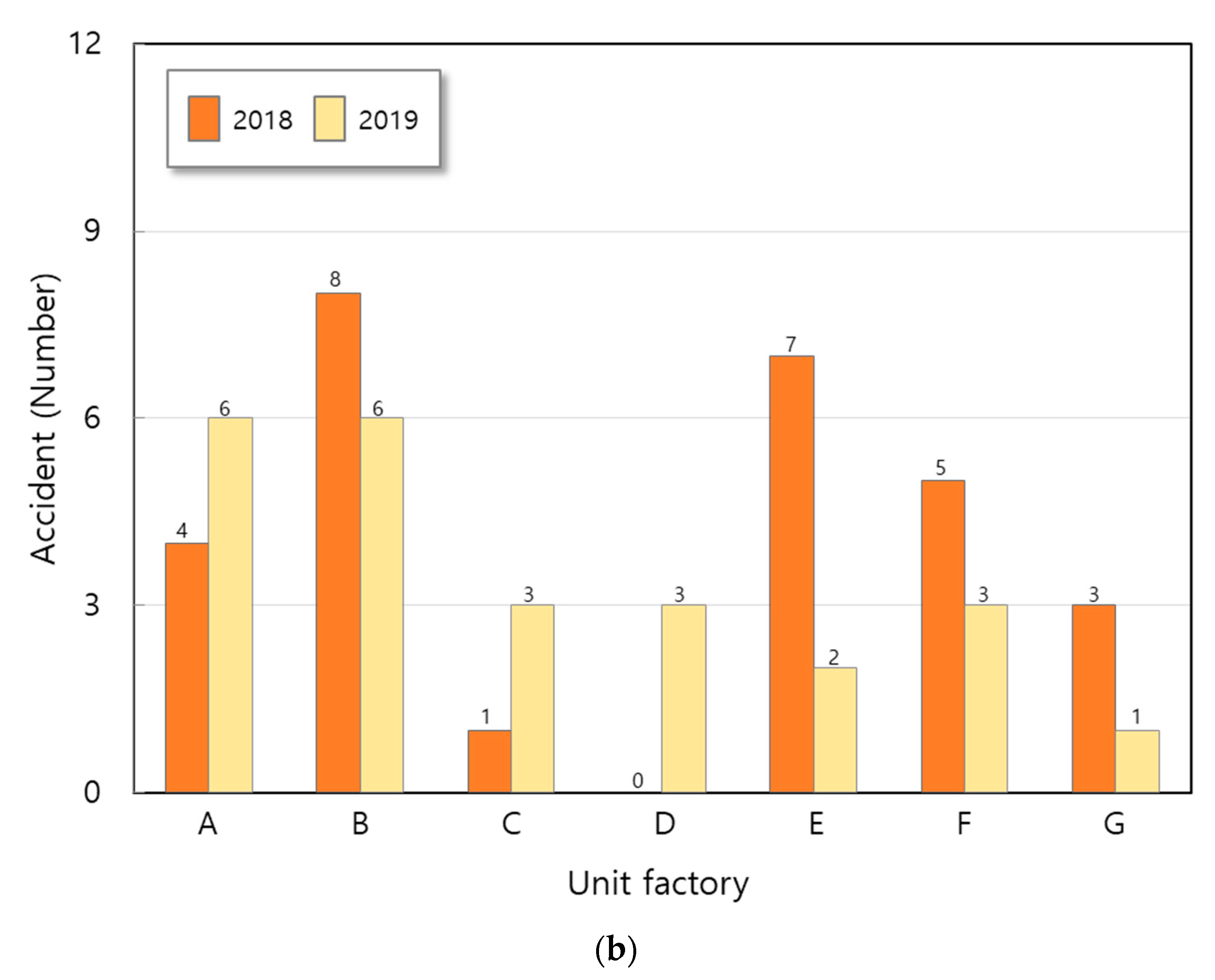

3.2. ’19 Safety Practice Index (SPI)

- SAI = = = 2.2

- RMI = = = 3.47

3.3. ’20 Safety Practice Index (SPI)

- Conduct emergency scenario and drill evaluation with the presence of the safety department to increase each unit factory’s participation rate in emergency drills.

- Strengthening periodic inspections through safety meetings to increase high risk improvement.

- SAI = = = 2.63

- RMI = = = 4.34

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Worst World Economy. How Ranked Is the Korean Economy? Financial News. Available online: http://www.fnnews.com/news/202105181435424202 (accessed on 20 May 2021).

- The Analysis of Industrial Injury, 2017~2019. Available online: http://www.kosha.or.kr (accessed on 15 July 2021).

- Comparison of Industrial Safety Penalties between Korea and G5, Global Insight. Available online: http://www.fki.or.kr (accessed on 30 April 2021).

- Bae, J.H. Corporate Social Responsibility and Occupational Safety & Health. Research Paper; Kangwon National University: Kangwon, Korea, 2010; Volume 649, p. 180. [Google Scholar]

- The Analysis of Industrial Injury Status. 2019. Available online: http://www.kosha.or.kr (accessed on 15 July 2021).

- DSS Bradley Curve Infographic. 2021. Available online: http://www.consultdss.com/bradley-curve-infographic/ (accessed on 2 July 2021).

- Terry, L. Mathis. Behind the Bradley Curve. EHS Today 2016, 9, 8–9. [Google Scholar]

- Sutherland, M.B. Safety culture idea & advice from the safety trenches. Prof. Saf. 2020, 65, 28–30. [Google Scholar]

- Terry, L. Mathis. Safety Excellence Maturity Model. EHS Today 2019, 12, 5–6. [Google Scholar]

- Kim, Y.S. A Study on the Difference in Recognition of Safety Culture between Construction Industry and Manufacturing Industry. Master’s Thesis, Songwon University, Chungcheongbuk, Korea, 2019; pp. 25–26. [Google Scholar]

- Li, L.; Hovsepian, J.H. A Proposed Safety Culture Development Model. Prof. Saf. 2020, 65, 53–54. [Google Scholar]

- Jones, S.; Kirchsteiger, C.; Bjerke, W. The Importance of Near Miss Reporting to Further Improve Safety. J. Loss Prev. Process Ind. 1999, 12, 59–67. [Google Scholar] [CrossRef]

- Chen, J.R.; Yang, Y.T. A Predictive Risk Index for Safety Performance in Process Industries. J. Loss Prev. Process Ind. 2004, 17, 233–242. [Google Scholar] [CrossRef]

- Fruggiero, F.; Riemma, S.; Ouazene, Y.; Macchiaroli, R.; Guglielmi, V. Incorporating the Human Factor within Manufacturing Dynamics. IFAC-Pap. Online 2016, 49, 1691–1696. [Google Scholar] [CrossRef]

- Hong, I.G.; Baek, J.B. Towards an Effective Assessment of Safety Culture. J. Korean Soc. Saf. 2016, 31, 118–125. [Google Scholar] [CrossRef] [Green Version]

- Nazaripour, E.; Halvani, G.; Jahangiri, M.; Fallahzadeh, H.; Mohammadzadeh, M. Safety Performance evaluation in a Steel Industry: A Short-term Time Series Approach. Saf. Sci. 2018, 110 Pt A, 285–290. [Google Scholar] [CrossRef]

- Center for Chemical Process Safety. Process Safety Metrics—Guide for Selecting Leading and Lagging Indicators; Center for Chemical Process Safety, American Institute of Chemical Engineers, 2018; Version 3.2; Available online: http://www.aiche.org/ccps (accessed on 15 July 2021).

- Walaski, P. The Role of Leading & Lagging Indicators in OSH Performance Management. Prof. Saf. 2020, 65, 29–35. [Google Scholar]

- Hopkins, A. Thinking about process safety indicators. Saf. Sci. 2009, 47, 460–465. [Google Scholar]

- Manuele, F.A. Leading and lagging indicators: Do they add value to the practice of safety? Prof. Saf. 2009, 54, 28–33. [Google Scholar]

- Susca, P.T. Measuring up: Evaluating effectiveness rather than results. Prof. Saf. 2019, 64, 22–24. [Google Scholar]

- Chiri, K.; Jansz, J. Examining the Relationship between Safety Culture and Safety Climate and the Role Leading Safety Indicators Play in Enhancing Safety Performance in the Oil and Gas Industry. World Saf. J. 2016, XXV, 4–14. [Google Scholar]

- Kim, B.S.; Jin, S.; Chang, S.R. Measurement of Incident-reporting Rate for Developing a Leading Indicator of Safety Culture. J. Korean Soc. Saf. 2018, 33, 93–101. [Google Scholar]

- Reiman, T.; Pietikäinen, E. Leading Indicators of System Safety—Monitoring and Driving the Organizational Safety Potential. Saf. Sci. 2012, 50, 1993–2000. [Google Scholar] [CrossRef]

- Math Encyclopedia. Available online: http://www.kms.or.kr/ (accessed on 28 February 2021).

- Brigham, E.F.; Houston, J.F. Fundamental of Financial Management, 4th ed.; Harcourt College: Fort Worth, TX, USA, 2021. [Google Scholar]

- Kim, H.S.; Kim, J.I.; Rie, D.H. A Study on the Utilization of Safety Practice Index to Increase the Effectiveness of Safety Management. J. Korean Soc. Saf. 2021, 36, 44–49. [Google Scholar]

| Punishment | Korea | UK | France | Germany | Japan | USA |

|---|---|---|---|---|---|---|

| Imprisonment (personal) | 7 years or less | 2 years or less | 1 year or less | 1 year or less | 6 months or less | 10 years or less |

| Fines (corporate) | KRW 1 billion or less | 10% or less of sales | EUR 30,000 or less | EUR 5000 or less | JPY 500,000 or less | USD 7000 or less |

| Punishment | Korea | UK |

|---|---|---|

| Imprisonment (personal) | 1 year or more, 1 billion or less | - |

| Fines (corporate) | KRW 5 billion or less | Unlimited (usually 10% of annual sales) |

| Original responsibility | Same way as subcontractors | When there is an actual command |

| Ranking | Industry | Number of Disaster Victims | Number of Workers | Industry Applied to This Study |

|---|---|---|---|---|

| 1 | Manufacturing of metal and mechanical products | 11,280 | 1,462,709 | A |

| 2 | Manufacturing of chemical and rubber products | 2675 | 452,800 | B |

| 3 | Manufacturing of food | 2638 | 316,021 | C |

| 4 | Manufacturing of wood and paper products | 1451 | 116,466 | Exception (<300,000) |

| 5 | Manufacturing of electrical machinery and electronic products | 1431 | 906,585 | D |

| Workplace | Education | Drill | Event | Traffic Enforcement | Safety Proposal | Mentoring |

|---|---|---|---|---|---|---|

| A | ○ | ○ | ○ | ○ | - | - |

| B | ○ | ○ | ○ | - | ○ | - |

| C | ○ | ○ | ○ | - | - | ○ |

| D | ○ | ○ | ○ | - | ○ | - |

| Item | Measurement Item | Ratio (%) |

|---|---|---|

| Safety education (SEd) | Ratio of implementation Ratio of participation | Implementation/target count participants/target person |

| Safety event (SEv) | Ratio of participation | Participants/number of trials |

| Emergency drill (EDr) | Ratio of implementation Ratio of good times | Implementation/target count good times/number of checks |

| Grade | Safety Education | Safety Event | Emergency Drill |

|---|---|---|---|

| 5 | 100% | 100% | 100% |

| 4 | 90~100% | 90~100% | 90~100% |

| 3 | 80~90% | 80~90% | 80~90% |

| 2 | 70~80% | 70~80% | 70~80% |

| 1 | less than 70% | less than 70% | less than 70% |

| Workplace | Risk Assessment | High Risk Improvement | Unsafe Act | Labor Joint Inspection | Subcontractor Joint Inspection | My Safety Check |

|---|---|---|---|---|---|---|

| A | ○ | ○ | ○ | ○ | - | - |

| B | ○ | ○ | ○ | ○ | - | - |

| C | ○ | ○ | ○ | - | ○ | - |

| D | ○ | ○ | ○ | - | - | ○ |

| Item | Measurement Item | Ratio (%) |

|---|---|---|

| Risk assessment (RAs) | Ratio of risk assessment | Number of assessment/work procedure |

| High-risk improvement (HRi) | Ratio of improvement | Number of improvement/high risk |

| Unsafe act (UAc) | Ratio of unsafe act | Number of unsafe act/work cases |

| Grade | Risk Assessment | High Risk Improvement | Unsafe Act |

|---|---|---|---|

| 5 | 100% | 100% | 0~5% |

| 4 | 95~100% | 90~100% | 5~10% |

| 3 | 90~95% | 80~90% | 10~15% |

| 2 | 85~90% | 70~80% | 15~20% |

| 1 | less than 85% | less than 70% | more than 20% |

| Grade | SPI | Safety Practice Level (SPL) | Remark (Bradley Curve) |

|---|---|---|---|

| IV | 12~16 | Voluntary participation and high-level risk management | Interdependent |

| III | 8~12 | Increasing participation and consensus | Independent |

| II | 4~8 | Passive participation/supervision dependent | Dependent |

| I | 0~4 | Indifferent and ignorant of safety activities/unmanaged risk | Reactive |

| Unit Factory | A | B | C | D | E | F | G |

|---|---|---|---|---|---|---|---|

| Employees | 80 | 83 | 72 | 86 | 72 | 67 | 121 |

| Product | Intermediary steel material | Finished steel product | |||||

| Index | Category | Unit A | Unit B | Unit C | Unit D | Unit E | Unit F | Unit G | Average | |

|---|---|---|---|---|---|---|---|---|---|---|

| SAI | SEd (safety education) | 3 | 3 | 4 | 4 | 2 | 2 | 3 | 3 | |

| score | 89.2 | 81.3 | 96.7 | 92.5 | 75.0 | 76.7 | 87.1 | 85.5 | ||

| SEv (safety event) | 3 | 3 | 3 | 3 | 2 | 3 | 2 | 2.71 | ||

| score | 84.8 | 82.2 | 85.2 | 85.7 | 78.7 | 84.3 | 74.0 | 82.1 | ||

| EDr (education drill) | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | ||

| score | 41.7 | 43.3 | 58.3 | 40.0 | 38.3 | 56.7 | 35.3 | 44.8 | ||

| RMI | RAs (risk assessment) | 1 | 1 | 5 | 5 | 3 | 3 | 5 | 3.29 | |

| score | 82.4 | 82.4 | 100 | 100 | 91.2 | 91.2 | 100 | 92.5 | ||

| HRi (high-risk improvemt) | 1 | 1 | 3 | 3 | 3 | 3 | 5 | 2.71 | ||

| score | 40 | 40 | 84.6 | 84.6 | 81.7 | 81.7 | 100 | 73.2 | ||

| UAc (unsafe act) | 5 | 1 | 4 | 4 | 3 | 1 | 1 | 2.71 | ||

| score | 4.1 | 22.4 | 6.0 | 8.1 | 13.8 | 26.5 | 31.1 | 16 | ||

| SPI | 3.5 | 2.1 | 9.0 | 9.0 | 4.8 | 3.8 | 5.3 | 5.81 | ||

| Accident | 4 | 8 | 1 | 0 | 7 | 5 | 3 | 28 | ||

| Index | Category | Unit A | Unit B | Unit C | Unit D | Unit E | Unit F | Unit G | Average | |

|---|---|---|---|---|---|---|---|---|---|---|

| SAI | SEd (safety education) | 3 | 3 | 5 | 4 | 3 | 3 | 5 | 3.7 | |

| Score | 85 | 85 | 100 | 95.4 | 85 | 85 | 100 | 90.8 | ||

| SEv (safety event) | 3 | 3 | 3 | 3 | 3 | 2 | 3 | 2.9 | ||

| Score | 80.3 | 83.5 | 81.7 | 81.3 | 80.3 | 78.5 | 80.3 | 80.8 | ||

| EDr (education drill) | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | ||

| Score | 33.3 | 45 | 45 | 36.7 | 33.3 | 30 | 33.3 | 36.7 | ||

| RMI | RAs (risk assessment) | 3 | 3 | 5 | 5 | 4 | 4 | 5 | 4.1 | |

| Score | 91.2 | 91.2 | 100 | 100 | 98.3 | 98.3 | 100 | 97 | ||

| HRi (high-risk improvemt) | 1 | 1 | 3 | 3 | 3 | 3 | 5 | 2.7 | ||

| Score | 60 | 60 | 84.6 | 84.6 | 81.7 | 81.7 | 100 | 78.9 | ||

| UAc (unsafe act) | 4 | 3 | 5 | 4 | 4 | 2 | 4 | 3.7 | ||

| Score | 8.1 | 12.2 | 4.2 | 7.1 | 7.5 | 15.8 | 6.1 | 8.7 | ||

| SPI | 4.8 | 4.3 | 10.4 | 9.0 | 7.6 | 5.2 | 11.4 | 7.63 | ||

| Accident | 6 | 6 | 3 | 3 | 2 | 3 | 1 | 24 | ||

| Index | Category | Unit A | Unit B | Unit C | Unit D | Unit E | Unit F | Unit G | Average | |

|---|---|---|---|---|---|---|---|---|---|---|

| SAI | SEd (safety education) | 3 | 3 | 5 | 5 | 3 | 4 | 4 | 3.86 | |

| Score | 86.7 | 81.7 | 100 | 100 | 85 | 90 | 91.7 | 91.0 | ||

| SEv (safety event) | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3.0 | ||

| Score | 87.1 | 87.5 | 85.8 | 85.8 | 80.3 | 87.9 | 86.7 | 87.0 | ||

| EDr (education Drill) | 2 | 2 | 2 | 2 | 1 | 1 | 1 | 1.57 | ||

| Score | 71.7 | 70.0 | 76.7 | 78.3 | 33.3 | 43.3 | 73.3 | 69.3 | ||

| RMI | RAs (risk assessment) | 5 | 5 | 5 | 5 | 4 | 5 | 5 | 4.9 | |

| Score | 100 | 100 | 100 | 100 | 98.3 | 100 | 100 | 99.8 | ||

| HRi (high-risk improvemt) | 5 | 5 | 5 | 5 | 3 | 5 | 5 | 4.7 | ||

| Score | 100 | 100 | 100 | 100 | 81.7 | 100 | 100 | 97.4 | ||

| UAc (unsafe act) | 4 | 3 | 4 | 4 | 4 | 2 | 4 | 3.6 | ||

| Score | 5.6 | 11.4 | 5.2 | 6 | 7.2 | 15.2 | 5.8 | 8.1 | ||

| SPI | 12.16 | 11.05 | 14.42 | 14.42 | 12.16 | 8.43 | 10.63 | 11.41 | ||

| Accident | 3 | 4 | 1 | 1 | 2 | 5 | 1 | 17 | ||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, H.; Kim, J.; Rie, D. A Study on the Application of the Safety Practice Index to Reduce Safety Accidents in the Manufacturing Industry. Sustainability 2021, 13, 10990. https://doi.org/10.3390/su131910990

Kim H, Kim J, Rie D. A Study on the Application of the Safety Practice Index to Reduce Safety Accidents in the Manufacturing Industry. Sustainability. 2021; 13(19):10990. https://doi.org/10.3390/su131910990

Chicago/Turabian StyleKim, Heonseok, Jongin Kim, and Dongho Rie. 2021. "A Study on the Application of the Safety Practice Index to Reduce Safety Accidents in the Manufacturing Industry" Sustainability 13, no. 19: 10990. https://doi.org/10.3390/su131910990

APA StyleKim, H., Kim, J., & Rie, D. (2021). A Study on the Application of the Safety Practice Index to Reduce Safety Accidents in the Manufacturing Industry. Sustainability, 13(19), 10990. https://doi.org/10.3390/su131910990