1. Introduction

Over the past 40 years of reform and development of the Chinese economy, the country has made remarkable advancements; however, the rapid development of the economy has been at the expense of ecosystem health and sustainability due to high energy consumption and high pollution. China accounts for 26.1% of the global primary energy consumption and 57.4% of the energy consumption in the Asia Pacific region. The energy consumption in 2020 was 2.1% higher than that in 2019, with a growth rate of 3.8% per annum from 2009 to 2019 [

1]. The primary energy source is fossil fuels; their consumption leads to the release of pollutants, such as waste gases and dust. The contradiction between high-speed economic growth and environmental pollution is increasingly discernible. The economic losses associated with environmental pollution are estimated to be CNY 511.8 billion (approximately USD 79.94 billion), accounting for 3.05% of the annual GDP [

2], which highlights the significant costs of environmental pollution. To address the emerging environmental problems and achieve sustainable development, the Chinese government stipulates via the “14th Five-Year Plan” that the energy consumption per CNY 10,000 of GDP will be reduced by 13.5% in 2025 compared with that in 2020, and that the total emissions of major pollutants will continue to decline [

3].

To achieve the above goals, the Chinese Government has proposed several related environmental regulation policies, which increases the cost of controlling pollutant emissions by enterprises. The costs incurred in the process of controlling pollution are known as environmental regulation costs, which are an important issue that the government must consider in ensuring that the environmental regulation policies formulated are reasonable and feasible. Environmental regulation costs associated with enterprises can be evaluated from different perspectives. Studies have assessed such costs from an economic perspective using the Pigou tax approach [

4,

5,

6], with the premise that the government levies taxes on enterprises that produce pollutants in the market. The amount of tax should be equivalent to the gap between the cost to the enterprise and the social cost. Conversely, the government subsidizes enterprises that do not pollute; consequently, their costs are reduced to be equivalent to the social cost. Other studies have measured the cost of such environmental regulations to enterprises based on an output perspective, that is, the relative output reductions caused by environmental regulations [

7,

8,

9,

10]. The perspective of opportunity costs (output losses) can be divided into two categories. Some studies have adopted the weak disposability of an unfavorable output approach, which considers the variability in output (under strong and weak output disposability) as the cost of environmental regulation [

11,

12,

13,

14]. In addition, some scholars refer to the reduction in output under emission reduction constraints as the shadow price of pollutants [

15,

16,

17,

18,

19,

20,

21], which can be interpreted as the desirable (favorable) output given up by reducing an additional unit of undesirable (unfavorable) output.

This study proposes a novel concept based on an energy cost perspective that is different from the economic cost or opportunity cost perspectives adopted in current literature. In the presented energy cost concept, the costs of environmental regulations are evaluated by estimating the energy consumption associated with reducing pollutant emissions. For example, SO

2 (sulfur dioxide) production is mainly reduced by using desulfurization processes. The installed capacity of desulfurization units in thermal power plants increased from 82.6% in 2010 to 96% in 2015. (The data are from

http://news.bjx.com.cn/html/20160113/700672.shtml, accessed on 12 September 2021. This is a Chinese web page. Readers can access the website address through Google Chrome and translate the content into English by right clicking and selecting the “translate to English” option.) The SO

2 removal rates are increasing annually, which implies increased energy consumption associated with the desulfurization process. Consequently, the simultaneous achievement of “energy saving” and “emission reduction” goals, especially in low-energy-efficiency regions (the energy efficiency in this paper is based on the concept of input–output efficiency, which can be defined as the ratio of GDP to energy input (the reciprocal of the energy intensity defined as the energy consumption per unit of GDP)), is a challenge. During the “Eleventh Five-Year Plan” period, China’s energy consumption decreased by 19.1%, and the goal of achieving a 20% reduction in energy consumption was not achieved. The above insights highlight the challenge of simultaneously achieving energy conservation and emission reduction.

Therefore, in this study, we estimated the costs of environmental regulations based on an energy consumption perspective and investigated whether SO2 emission reduction incurs high energy costs. From 2006 to 2015, industrial SO2 emissions accounted for 87.1% of China’s total SO2 emissions on average; therefore, we focused on industrial SO2 here. Determining the energy cost of reducing SO2 emission could enhance our understanding of the interaction between “energy savings” and “emission reduction” and facilitate the formulation of rational and sustainable energy conservation and emission reduction targets. Furthermore, the findings of such studies could prompt jurisdictions with high emission reduction costs to improve their energy structures and promote green technology innovations.

The key contributions of the proposed study are as follows: first, it proposes a novel perspective for estimating the costs of environmental regulations. We developed directional distance functions based on an environmental production model to estimate optimal energy inputs with and without environmental constraints, which allowed us to explore the costs of SO2 emission reductions from an energy consumption perspective. Second, we compared the energy costs of SO2 removal across 30 provinces in and across four major economic zones to investigate the degree of discrepancy between energy savings and emission reductions among different economic zones and analyzed the reasons for the differences. Finally, we present specific recommendations for improving energy efficiency in underdeveloped areas.

3. Results and Discussion

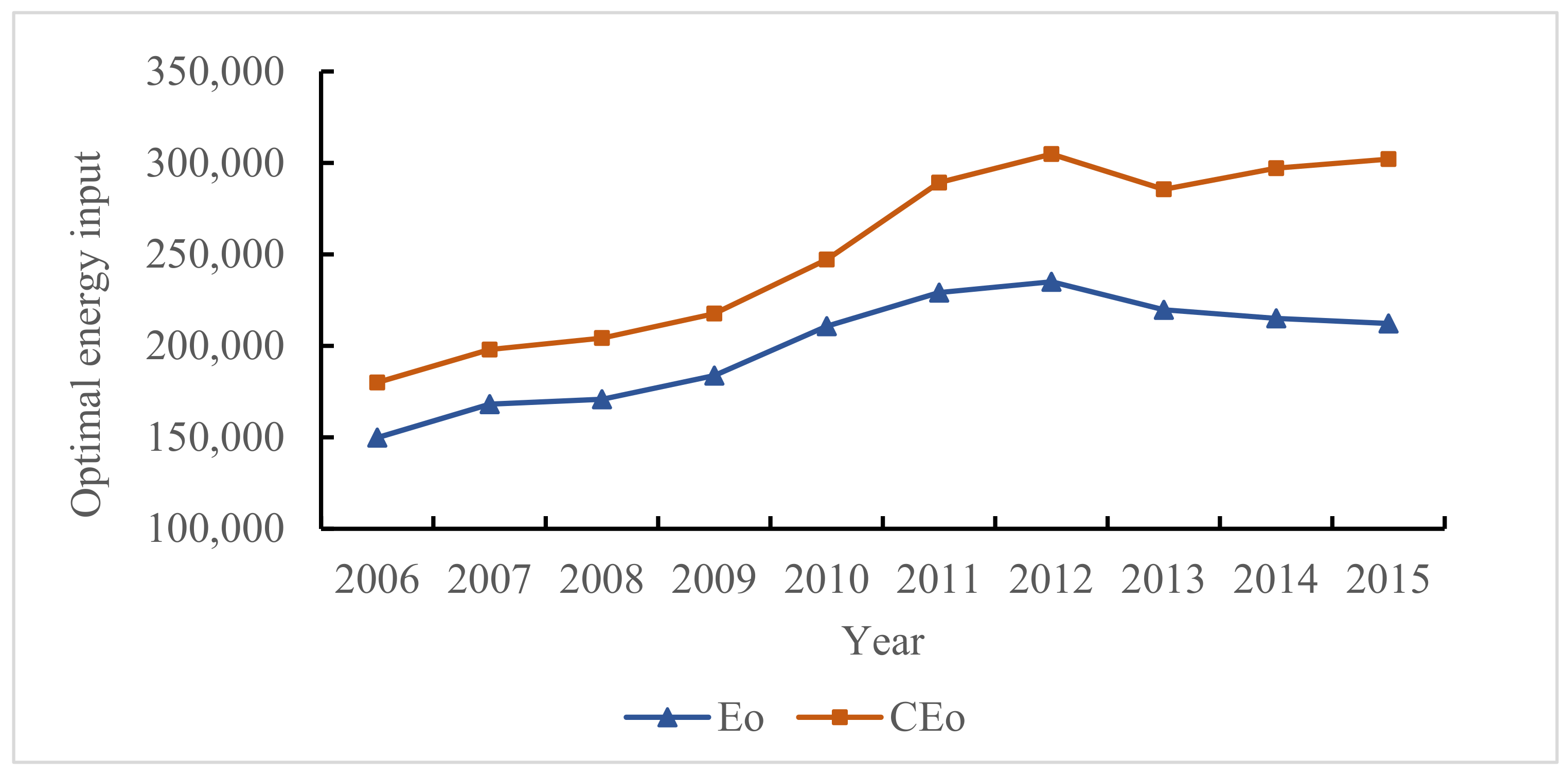

Based on Equations (7) and (8), we calculated the two sets of optimal energy inputs,

Eo and

CEo, in China’s 30 provincial regions from 2006 to 2015. The

Eo and

CEo trends are illustrated in

Figure 2. The x-axis represents the year, and the y-axis represents the optimal energy input, where

Eo represents the optimal energy input without emission reduction constraints and

CEo represents the optimal energy input with emission reduction constraints. According to

Figure 2,

CEo was significantly higher than

Eo in 2006–2015, revealing that high energy amounts are consumed in the SO

2 removal process. In addition, according to

Figure 2, the gap between

CEo and

Eo was increasing gradually, which is consistent with the actual status in China. In 2005, China began to give more importance to environmental issues and put forward clear emission reduction requirements in the “11th and 12th Five-Year Plans”. With an increase in emission reduction, highly polluting enterprises have gradually appreciated the importance of green production and started to adopt or develop tail gas treatment technologies, resulting in the gradual increase in energy consumption for emission reduction activities.

The energy costs for industrial SO

2 emission reduction are listed in

Table 2. The annual average emission reduction for SO

2 in 2006–2015 was 39.82 million tons, and the average yearly energy consumption for SO

2 emission reduction was 532.43 million tons of standard coal. Overall, the energy consumption for emission reduction increased markedly from 301.29 million tons in 2006 to 903.1330 million tons in 2015, with an average annual growth rate of 14.59%. Similarly, the amount of SO

2 emission reduction also increased from 16.53 million tons in 2006 to 56.23 million tons in 2015. Based on the ECSR, 13.40 tons of standard coal would be consumed to reduce SO

2 emissions by 1 ton. Similarly, the removal of 1 ton of SO

2 “crowds out” the energy-saving space of 13.40 tons of standard coal. In addition to the absolute amount of energy consumed to reduce emissions increasing annually (excluding 2007), the proportion of energy consumed to reduce emissions from the total energy input exhibited an upward trend. In 2011–2015, on average, 16.89% of the energy input was used to reduce emissions; this value was significantly higher than that observed in 2006–2010 (9.67%).

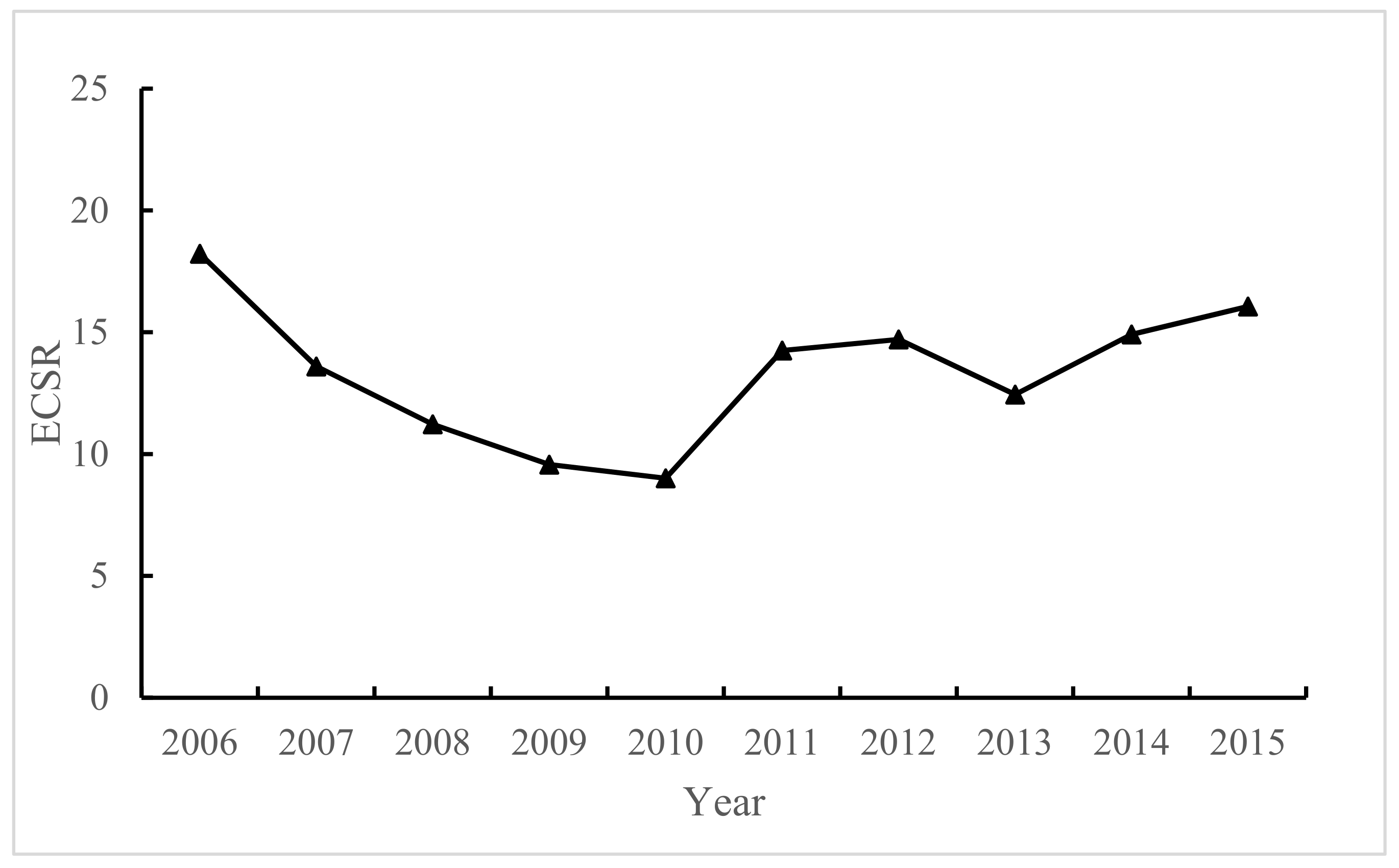

In

Figure 3, the

x-axis represents the year and the

y-axis represents the energy cost per unit of SO

2 emission reduction (ECSR).

Figure 3 shows the trend of ECSR from 2006 to 2015, which can be divided into two stages. The first stage represents the 2006–2010 period. The average energy consumed to reduce SO

2 emissions in the five years was 326.77 million tons, accounting for 9.65% of the total energy input. ECSR exhibited a noticeable decline from 2006 to 2010, with an average of 12.33, indicating that, in the five years, 12.33 tons of standard coal was required to reduce SO

2 emissions by a ton on average. ECSR had a downward trend in 2006–2010, which is mainly attributed to the strict environmental regulations in the period. The environmental protection indicators defined under the 10th Five-Year Plan (2000–2005) were not achieved adequately. The total emissions of SO

2 and industrial SO

2 did not decline but rebounded. According to statistics from the Ministry of Ecology and Environment of the People’s Republic of China, in 2005, the national SO

2 emissions increased by 27% compared to the emissions in 2000 (Data were obtained from

http://www.mee.gov.cn/home/ztbd/gzhy/hbdh/hjbhdh/xgbd/200604/t20060419_75928.shtml, accessed on 12 September 2021) [

27]. Therefore, during the “11th Five-Year Plan” period (2006–2010), the central government proposed a 10% reduction of the total amount of pollutants discharged as a binding indicator. To achieve this goal, on the premise that desulfurization facilities would be installed in new coal-fired power plants during the 11th Five-Year Plan period, 4.9 million tons of SO

2 in active thermal power units would be reduced through engineering measures so that the installed desulfurization capacity of existing thermal power units would reach 213 million kW. The desulfurization capacity of steel sintering machine flue gas desulfurization projects would be 300,000 tons (Circular of the State Council on printing and distributing the 11th Five Year Plan for national environmental protection.

http://www.mee.gov.cn/zcwj/gwywj/201811/t20181129_676435.shtml, accessed on 12 September 2021) [

28]. The accountability system and the “one-vote veto system” were also implemented, (In 2007, the State Council approved and transmitted the implementation plan and method for the statistical monitoring and assessment of energy conservation and emission reduction formulated by the national development and Reform Commission, the National Bureau of Statistics and the General Administration of Environmental Protection. The plan and method include two parts: the energy consumption per unit of GDP and total emission reduction for major pollutants. In the plan and method, if energy conservation and emission reduction fail to pass the assessment, the leaders of local governments and important enterprises will face accountability and “one vote veto”) reinforcing the environmental regulations.

To achieve the emission reduction standards, industrial enterprises need to develop and improve desulfurization technologies. Desulfurization technologies are generally divided into fuel desulfurization, combustion desulfurization, and flue gas desulfurization technologies, corresponding to prior desulfurization, mid-desulfurization, and post-desulfurization treatments, respectively. In the beginning, most industrial enterprises adopted flue gas desulfurization, which implies the desulfurization of the flue gas produced after coal combustion. The flue gas desulfurization technology is divided into a dry method and a wet method. The dry method mainly involves placing limestone and dolomite in high-temperature furnaces, which react with SO

2 to produce solid sulfur. Conversely, the wet method consists of washing the flue gas with an alkaline slurry, thereby removing the SO

2 from the flue gas [

29]. The two methods have some limitations. The dry method has low absorption efficiency, and the long-term use of the wet method leads to equipment corrosion and deformation [

29]. To address the challenges, various equipment manufacturers have developed second- and third-generation limestone desulfurization technologies. In addition, many manufacturers have developed absorption and regeneration techniques that process the liquid that has absorbed SO

2 into sulfuric acid and other products and removed SO

2 for recycling [

30]. Combustion desulfurization is similar to flue gas desulfurization, and it is gradually being improved with the reinforcement of environmental regulations. Fuel desulfurization is used to transform coal with a higher sulfur elimination of 50 million kW of small thermal content into clean energy using sulfur-fixation methods before combustion. Sulfur-fixation methods are divided into physical, chemical, and biological methods. The physical method has been applied extensively in China; however, the physical method has major limitations and cannot remove organic sulfur from coal. Conversely, the chemical method requires complex equipment and consumes high energy amounts; therefore, its use is currently impractical. In contrast, the biological method is associated with mild reaction conditions, simple equipment requirements, and low cost. Today, many equipment manufacturers in China are developing and researching equipment for the biological method [

31]. Overall, desulfurization technology is continuously improving; according to statistics from the Ministry of Environmental Protection, technological progress facilitated up to 66% SO

2 emission reductions during the “11th Five-Year Plan” [Data were obtained from “

http://www.chinanews.com/ny/2011/06-22/3129223.shtml, accessed on 12 September 2021”] [

32]. With the developments and advancements in methods and equipment for desulfurization tail gas treatment, the energy consumed in SO

2 emission reduction activities has decreased along with the ECSR.

The second stage of the ECSR estimation represents the 2011–2015 period. As illustrated in

Figure 2, the gap between E

o and CE

o was slightly larger, which implies that more energy was invested toward reducing SO

2. The average amount of energy consumed to reduce emissions in the five years was 738.09 million tons (

Table 2), accounting for 16.93% of the total energy input and being 2.26-fold that of the previous five years. The average ECSR (14.48) was also higher than that of the first phase, showing that the average ECSR increased. Considering the technological advancements that have taken place over the study period, such findings are not promising.

A potential explanation for the ECSR rebound in the second phase is a slowdown in the shutdown plan for China’s small thermal power units. The power generation industry has always produced high SO2 emissions. In 2005, the power generation industry emitted 11.67 million tons of SO2, accounting for 58.935% of the total emissions of 39 industrial industries (19.805 million tons) [Data from “2006 China Statistical Yearbook”]. Therefore, the power generation industry bears most of the brunt of China’s SO2 emission reduction efforts. In addition to relying on the advancements in desulfurization technologies to reduce SO2 emissions, the government has taken steps to shut down small thermal power units. Small thermal power units are mainly found in small thermal power plants, whose owners are unwilling to install desulfurization equipment due to a lack of funds or limited production scales. Consequently, their SO2 emissions exceed the national standards.

For the sustainable development of China’s industry, the government required the power units during the 11th Five-Year Plan period (2005–2010). The goal was surpassed, as 76.83 million kW of small thermal power units were eventually taken off the grid during the 11th Five-Year Plan period (Data from “

http://www.bjnews.com.cn/finance/2011/10/25/159896.html, accessed on 12 September 2021”) [

33]. However, the rapid and arbitrary shutdown of small power plants has introduced numerous challenges, such as the employment of many laid-off employees and corporate debt problems [

34]. Consequently, the shutdown of small thermal power units slowed down gradually during the 12th Five-Year Plan period.

The “12th Five-Year Plan for Energy Conservation and Emission Reduction” targeted the elimination of small thermal power units that produced a total of 20 million kW in 2010–2015 [Data from “

http://www.chinanews.com/ny/2012/08-28/4138090.shtml, accessed on 12 September 2021”] [

35]. The target represented only a quarter of the number of shutdowns during the “11th Five-Year Plan” period. Under such a policy environment, many small thermal power units were shut down during the 11th Five-Year Plan period, which reduced SO

2 emissions without energy consumption. Therefore, although small thermal power units continued to shut down over the 12th Five-Year Plan period, the shutdown rate was reduced because many shutdowns had occurred during the 11th Five-Year Plan period. Therefore, the reduction in SO

2 emissions due to the shutting down of small thermal power units decreased, while the proportion of SO

2 emissions was reduced when the use of desulfurization equipment increased under augmented energy consumption, resulting in a rebound in ECSR.

To further explore the energy consumption of emission reduction efforts in various areas, we divided mainland China into Northeast, East, Central, and West zones [The Northeast includes Liaoning Province, Jilin Province and Heilongjiang Province; the East includes Beijing, Tianjin, Hebei Province, Shanghai, Jiangsu Province, Zhejiang Province, Fujian Province, Shandong Province, Guangdong Province and Hainan Province; the Central includes Shanxi Province, Anhui Province, Jiangxi Province, Henan Province, Hubei Province and Hunan Province; the West includes the Inner Mongolia Autonomous Region, the Guangxi Zhuang Autonomous Region, Chongqing, Sichuan Province, Guizhou Province, Yunnan Province, Shaanxi Province, Gansu Province, Qinghai Province, the Ningxia Hui Autonomous Region and the Xinjiang Uygur Autonomous Region]. According to the Eo, CEo, and energy inputs in the provincial regions, we first calculated the energy costs of SO2 emission reduction in each province-level region. We then used the average values as the energy costs of SO2 emission reductions in the separate zones.

Table 3 lists the ECSRs in four zones in China. The eastern region had the lowest ECSR, with an average value of 9.91. Meanwhile, the western region had the highest ECSR, with an average value of 18.63. The ECSRs in the northeast and central regions were relatively close at 10.41 and 10.70, respectively. The energy costs of reducing SO

2 emissions were the lowest in the eastern regions because the economies of the eastern regions are relatively developed and can introduce and upgrade desulfurization units. Therefore, the eastern regions have a high desulfurization efficiency, implying that more SO

2 can be removed per unit of energy consumed (Data were obtained from

https://www.cec.org.cn/detail/index.html?3-138643; https://

www.cec.org.cn/detail/index.html?3-151148, accessed on 12 September 2021) [

36]. The reason that the western region exhibits the highest ECSR is that, due to the high terrain, long freezing periods, and severe drought in that region, desulfurization methods that do not require much water are adopted as much as possible and anti-freeze measures are required following wet desulfurization. Therefore, the western region is more suitable for applying the dry desulfurization method [

37,

38]. Although the dry desulfurization method does not require water, and the process is relatively simple, desulfurization itself is not efficient. When a high amount of desulfurization is required, more energy is consumed; therefore, the highest energy costs for emission reduction are observed in the western region. The northeast and central regions adopt combinations of dry and wet desulfurization methods, which is not considerably different from the desulfurization technology adopted in the east. Therefore, the energy costs of emission reduction in the northeast and central regions are only slightly higher than those in the east.

The energy costs of SO2 emission reductions reflect the inconsistency between energy conservation and emission reduction, and the differences in ECSR among different regions reflect the different degrees of inconsistency. The findings could guide government policy formulation activities for rational environmental policies in different regions.

Table 4 lists the E

o, CE

o, and ECSR across the different provinces. Among them, ECSR = 0 in Tianjin and Guangzhou indicates that the energy costs of removing SO

2 were very low [For ECSR = 0, here, we do not understand it as a mathematical zero. Since DEA calculates the relative efficiency based on the input–output of each decision-making unit, the zero here can be understood as the energy costs of pollution reduction in these two regions being lower than those for other regions]. The provinces with ECSR values <5 are Hebei, Jiangsu, Zhejiang, Anhui, Fujian, and Hubei; most of these are located in eastern China and are at the forefront of economic development in China. Conversely, Jilin, Guangxi, Hainan, Guizhou, and Shaanxi had high ECSRs (>20), which indicated that the local desulfurization technologies are relatively outdated and consume high amounts of energy when processing SO

2. In addition to the difference in desulfurization technology, another reason for the large variations in ECSR could be that the energy structures of the areas are diverse. According to the Bureau of Statistics, China’s electricity consumption accounts for an average of 14.32% of the total energy consumption. Zhejiang’s electricity consumption accounts for the highest proportion (20.86%). China’s coal consumption accounts for an average of 65.74% of the total energy consumption, and Beijing’s coal consumption accounts for the lowest proportion (25.35%). There are only six provinces in China with coal consumption accounting for less than 50% of the total energy consumption in the province, namely, Beijing, Tianjin, Shanghai, Zhejiang, Guangdong, and Fujian (with an average of 40.40%). Provinces and cities with superior energy structures (a high proportion of electricity consumption and a low proportion of coal consumption) are largely concentrated in the eastern region. In the two provinces with the lowest ECSRs (Tianjin and Guangdong), electricity consumption accounted for 18.11% and 19.61% of the total energy consumption, respectively, while coal consumption accounted for 49.38% and 42.03% of the energy consumption, respectively. Conversely, in the three provinces with the highest ECSRs (Shaanxi, Guizhou, and Guangxi), the electricity consumption accounted for 8.42%, 11.19%, and 12.58% of the total energy consumption, respectively, while coal consumption accounted for 79.10%, 69.55%, and 64.34%, respectively [Coal and electricity consumption data for each region were obtained from

https://data.stats.gov.cn/easyquery.htm?cn=E0103, accessed on 12 September 2021. We converted the electricity consumption into standard coal according to the conversion coefficient for electricity (0.1229 kg of standard coal/kWh)] [

39]. Provinces and cities with superior energy structures exhibit lower ECSRs (and vice versa) because, under high coal consumption, SO

2 emissions are relatively high. Therefore, to meet the environmental standards set by the government, the energy consumed in emission reduction efforts is higher, which leads to higher ECSRs.

4. Conclusions

Previous studies on the costs of SO2 emission reduction have mainly focused on economic cost or opportunity cost perspectives, for example, accounting for the shadow price of SO2 or relative output reductions caused by sulfur dioxide emission reduction constraints. In fact, environmental regulations often include the dual goals of energy conservation and emission reduction, and there is an internal inconsistency between the goals. However, there are a few studies in this field. Differently from previous studies, we developed directional distance functions to explore the energy costs of SO2 emission reduction. This is a new perspective for not only estimating the costs of environmental regulations, but also exploring the extent of inconsistency between emission reduction and energy saving, which has not been pointed out in previous studies.

An analytical framework is proposed herein for evaluating the energy costs of reducing SO2 emissions in China’s provincial regions from 2006 to 2015 by developing non-parametric directional distance functions, with and without emission reduction constraints. The input variables are employment, capital, and standard coal consumption. The desirable output is the industrial GDP, and the undesirable output is the industrial SO2 emissions. The empirical results are provided below.

The annual average emission reduction for SO2 was 39.82 million tons. The average yearly energy consumption for emission reduction was 532.43 million tons of standard coal (ECSR = 13.40), which implies that reducing SO2 emissions by 1 ton would consume 13.40 tons of standard coal. From 2006 to 2015, the energy consumption and emission reduction for SO2 increased, while the ECSR decreased from 2006 to 2010 and then exhibited an upward trend from 2011 to 2015.

In terms of economic zones, the energy cost per unit of SO2 removed was the highest in West China (an average of 18.63), while that in eastern China was the lowest (9.91). This shows that a more developed economy with a considerable number of technology-intensive industrial enterprises will show an augmented upgradation rate for technologies, a higher efficiency for SO2 treatment, and reduced energy costs for SO2 removal.

In each provincial region, there was a considerable gap in ECSR among different regions. In some areas, especially the economically developed eastern regions such as Jiangsu and Zhejiang, the energy costs of SO2 emission reduction were relatively low. In Tianjin and Guangdong, ECSR = 0, which indicated that using advanced desulfurization technologies or cleaner production technologies could reduce SO2 emissions or eliminate them from the source. Therefore, the energy consumption of SO2 removal could be reduced to very low amounts, indicating that energy conservation can be achieved simultaneously with emission reduction. However, numerous regions (especially economically underdeveloped provinces and cities in Northeast, Central, and Western China) with high ECSRs indicated that the energy consumed for emission reductions in the areas was high, and the discrepancy between energy conservation and emission reduction was more prominent. Overall, China’s cost for managing pollutants still has a lot of room for improvement.