1. Introduction

Electrical engineering education has been benefited by including experiential methodologies and competency-based learning at different levels. Industry partnership has shown an excellent alternative for students who want to integrate collaborative teams in solving real-world challenges. Industry participation in engineering education has grown in recent years due to the need for competent engineers who could join company groups without requiring a lot of additional training. The concept of practical training, which gained popularity in the 1980s, now is being complemented with an interesting alternative for both universities and industries. Unfortunately, higher education institutions involve training partners from the industry to participate in the teaching process of students when a thesis is required to graduate a student for a bachelor’s degree, in internships, or at the level of developing research and development when a postgraduate student participates in building a new product or service. Due to the above, recently in our institution, we have incorporated the “Innovation Semester” (i-Semester). This consists of an activity that involves, for a period of one semester, very exhaustive planning teamwork between university faculty and industry practicing engineers to define a challenge project for undergraduate engineering students. Proposals for the solution to this challenge require engineering students of different disciplines, and therefore, TEC offers this i-Semester to many undergraduate engineering programs. The student also benefits from the multidisciplinary nature of the vast majority of challenges and projects available today in the automotive and instrumentation industry.

Problem-based learning, project-based learning, experiential learning, and challenge-based learning have been applied with interesting results that give students additional motivation and promote important engagement to real-world problem solving using theoretical content. Examples of contributions in challenge-based learning and experiential learning in higher education are given as follows. Using challenge-based learning for medical device design has provided additional advantages over the traditional education format because it allows students to focus on design factors to make a product [

1]. Comparing traditional education with challenge-based-learning strategies was performed at the University of Washington, having aerospace industrial partners with an 8 h introductory course for company employees [

2]. In this case, outcomes show a significantly higher number of interactions among participants of the challenge-based group; in addition, participants performed better in activities requiring concept synthesis [

2]. In another example, biomedical engineering students had opportunities for establishing connections among different complex concepts with active and adaptive strategies [

3]; specifically, in this study, students participated in a biomechanics 4-week project-based learning experience, in which they showed higher self-confidence, enhanced their self-directed research, and provided better projection into their life-long learning skills [

3]. Information technologies and software engineering education have benefited from challenged-based methodologies to deliver high-quality projects, therefore increasing maturity in software engineering competencies, and outcomes [

4]. This strategy can provide important advances in the learning process for information technologies and software engineering in the years to come. Likewise, engineering education in lean manufacturing has provided an example of a learning model that incorporates professional competencies, resources, and cutting-edge methods for industrial engineering students at TEC [

5]; this learning model presents a very interesting lean-thinking-learning space that augments the possibilities of real-world experience opportunities to students and applies competence-based learning in parallel to the challenge-based approach [

5]. As a result, this study reported a significant increase in competency acquisition using this learning model. Other educational models suggest a further increment in the collaboration between industrial partners and universities via practical training, industrial clinics, joint projects, and the development of a multidisciplinary approach to social community projects [

6,

7,

8,

9,

10]. Moreover, the use of technology via interactive education and videos has developed a new trend in high-level education that engages students into user-friendly platforms that develop creativity and reinforce theoretical contents in traditional engineering and science courses [

11,

12,

13,

14,

15,

16,

17]. Experiential pedagogy has been addressed by researchers at Universidad de País Vasco and the University of Deusto in Spain [

18], where the methodology approach of value-added in-service learning is the main educational model for engineering and science education. In the business and management fields, at the University of Chile, experiential learning has been also applied to marketing courses with a very successful development where the students perform much better than traditional courses [

19].

As a tendency, during the last 10 years, engineering students’ learning at the university level has been oriented toward professional outcome and competency acquisition [

20]. This process has been developed using conceptual, procedural, and value contents from different levels of science and engineering. However, the pure traditional class exposition has been questioned due to different factors such as:

- a.

Lack of student interest in certain non-dominant courses within its major study program.

- b.

Excess in activities and other working duties that the student is immersed in during his/her university experience.

- c.

Obsolescence in course contents especially in technology-related courses.

- d.

Mismatch in student learning style versus professor teaching style and lack of communication from professor to students and vice versa.

- e.

Lack of a connection between course content and real-life problems that excite the interest of students.

Regarding the management of university education in conjunction with the incorporation of the Sustainable Development Goals (SDGs) for the long-term improvement of curricular plans, the United Nations has proposed as a high priority for administrators and policy makers the challenge to consolidate learning innovation in universities [

21]. As an example, TEC has shown preliminary ideas for incorporating the SDGs into the university mission [

21]. Likewise, the University of Huelva [

22] and the RMIT University [

23] show other examples of including the SDGs in the study plans of undergraduate programs; however, according to a study in Finland, from the educational perspective, this country currently requires many activities to incorporate the SDGs into the curricula of undergraduate programs at universities [

24]. This finding is surprising because, according to the Organization for Economic Cooperation for Development (OECD), Finland is among the best educational countries in the world [

25]. Now, from the perspective of describing plausible efforts to integrate educational activities in higher education programs for the subject of the SDGs, it is possible to observe the following examples: At the University of Guadalajara, learning outside the classroom was carried out to conduct experiments in laboratories related to chemistry and sustainability classes taking students to the industry of the region [

26]. In TEC, different examples of ODS have been shown on how to teach through problem-based learning the relationship between air pollution and the thermal inversion problem present in large cities in a physics course to teach modeling of damped harmonic motion experiments [

27]. Similarly, there was a study of teaching by a method based on challenges, which included the activity of having students participate in a competition to build a small-scale car that has motion control through chemical kinetics and basic electronics to teach the use of clean energy in an efficient and affordable way to move a car [

28]. Another example is the application of challenge-based learning in an e-learning course where students must propose a solution to solve a problem related to the SDGs [

29]. Recently, TEC has reported on an implementation study of an Emergency First Response course aimed at all undergraduate programs to arrive at a solution for the prevention of accidents present in the home or work environment or related to the mobility of people; thus, this initiative is directly associated with the goal of good health and well-being [

30]. Consequently, most of these SDG educational activity areas were oriented with the vision of enhancing competency-based education. Nonetheless, considering this literature review, very few contributions were found where educational research methods—either quantitative, qualitative, or mixed methods—have been used to evaluate and compare performance evaluation of competency-based higher engineering education of specific fields and included the technical skills, or transversal skills. This lack of studies that analyzed competency-based education is also present in the incorporation of the SDG objectives in undergraduate and postgraduate programs. As a result, in order to remedy the current need to carry out studies based on the importance of evaluating competencies in STEM fields in higher education, as well as to contribute to providing education oriented to the SDG, in this study, a comparison was shown in a group of engineering students enrolled in an electronics engineering “traditional course” and another group of engineering students taking a course that has an “industrial partner” where the experiential-challenge-based learning scheme is implemented.

Thus, the main objectives of this study are described below:

- a.

Evaluate the main competency, which includes SDGs as part of the attitudinal content, in the applied electronics course which is a fundamental core subject for many electrical, computer, biomedical, and robotics engineering undergraduate programs.

- b.

Compare two groups, one using the traditional applied electronics teaching and the other using the applied electronics module with an industrial partner that proposed the challenge project to solve during the semester. Thus, this comparison will contribute to determining if there is a significant difference in both groups regarding the level of the domain on the competency taught.

In

Section 2, the materials and methods are described, and thus this section describes the framework of the i-Semester project, the industrial partnership, the subject and challenge of the project, methodology, activities, purpose, research design, participants, data collection, rubrics, analysis, and the quintuple helix of innovation as a framework of the study. In

Section 3, the results are described.

Section 4 includes the discussion and limitations of the study. Finally,

Section 5 describes the conclusions and recommendations.

2. Materials and Methods

2.1. Framework of the i-Semester Project

The industrial partnership requires some initial planning to establish the challenge-based platform for the group of students taking the course using this scheme. To briefly describe this process, the following list discusses the activities developed before the semester initiates.

The planning team, professors, and leading engineers from a participating company define:

- I.

The main field of involvement (for example, hardware, software, or both) to consider a challenge to be developed and solved by engineering students.

- II.

The broad description of the challenge.

- III.

The competencies and outcomes that the students develop when solving the challenge.

- IV.

The modules (or course work) that the faculty will provide to the students and will contribute to achieving a reasonable solution to the challenge.

- V.

The activities that the students will develop in order to reach the required competence and outcome levels.

- VI.

The rubrics to establish the evaluation of the student’s performance during the semester.

This research describes the experience with automotive electronics systems where the challenge was defined by automotive industry engineers and faculty of TEC during the following semesters: Fall 2017, Fall 2018, Spring 2019, and Fall 2019. The main topic of the i-Semester was “Embedded Automotive Technology” and was offered to junior and senior students of the following engineering programs: Mechatronics Engineering, Digital Systems and Robotics Engineering, Biomedical Engineering, and Other Engineering such as Innovation Engineering.

2.2. The Challenge, Industrial Partnership, and Subjects of the Project

A challenging definition for the “Embedded Technology” instructional team formed by industry engineers and university faculty describes a company’s real need that consists of developing technology devices (base prototypes), personalizing a graphical interface of the automobile instrument cluster, consolidating electric vehicle models in graphical programming environments to test advanced sensorless controllers, and the development of an embedded flight computer model for an AWES (airborne wind energy system) power drone system. This was performed assuming the professional social responsibility of not only having a reliable design in terms of hardware and embedded software for the high standards of the automotive industry but also communicating and document reliable information about simulation runs and developed designs. The project integrates the product design cycle that includes:

- a.

Establishing client’s requirements.

- b.

Hardware and software design.

- c.

Embedded software coding.

- d.

Hardware and software testing using high-performance technological tools.

Industry partners for the “Embedded Technology” challenges are worldwide leading companies in developing instrumentation systems for the automotive industry such as harnesses, instrument clusters, test equipment hardware, and software. From the faculty side, experienced professors in embedded software, microcontrollers, mechatronics design, and applied electronics are available as experts that will form the instructional team with the hardware and software engineers from the company. Moreover,

Table 1 illustrates the module contents for three participating engineering programs at TEC.

Table 1 includes a module in ethics that covers many communities’ development issues where the students, faculty, and company engineers integrate a team to discover community concerns and propose solutions related to the sustainable development of communities, industries, and universities. An example of this was the initiative to improve the ecology of the communities close to the main industry campuses where ecology issues were addressed, and park preservation proposals were posted to the citizens for further authority implementation. Consequently, this subject teaches students how to be involved with the society in participating in initiatives not only in SDG issues for one’s close community but also in working with SDGs in a formal research and development project with the industry as was the case in the “i-Semester”.

2.3. Methodology Description

During the period of 2017 to 2020, several challenging projects were developed, three of them for the automotive instrumentation industry and one for research in the automated instrumentation of renewable energy systems. Students participate in one of the following four projects:

The student develops electronic instrumentation for both embedded hardware and software according to client requirements and the graphic indicators of the new instrument clusters for leading car manufacturing brands.

The students perform multidisciplinary work to successfully develop a technological solution following the standards and methodologies provided by a leading automotive electronic instrumentation company.

The students perform hardware-in-the-loop (HIL) simulations to test advanced controllers in electric power drives for electric vehicles of different operating characteristics.

The students perform a simulation and instrumentation development for flight computers of power drones in AWES (airborne wind energy system) that use a ground generation system platform.

Therefore, these projects are also related to the SDG objectives: affordable and clean energy, industry innovation and infrastructure, and sustainable cities and communities with the development of efficient mobility. This is in addition to other ecological proposals made by the team formed from the integration of students, faculty, and company engineers.

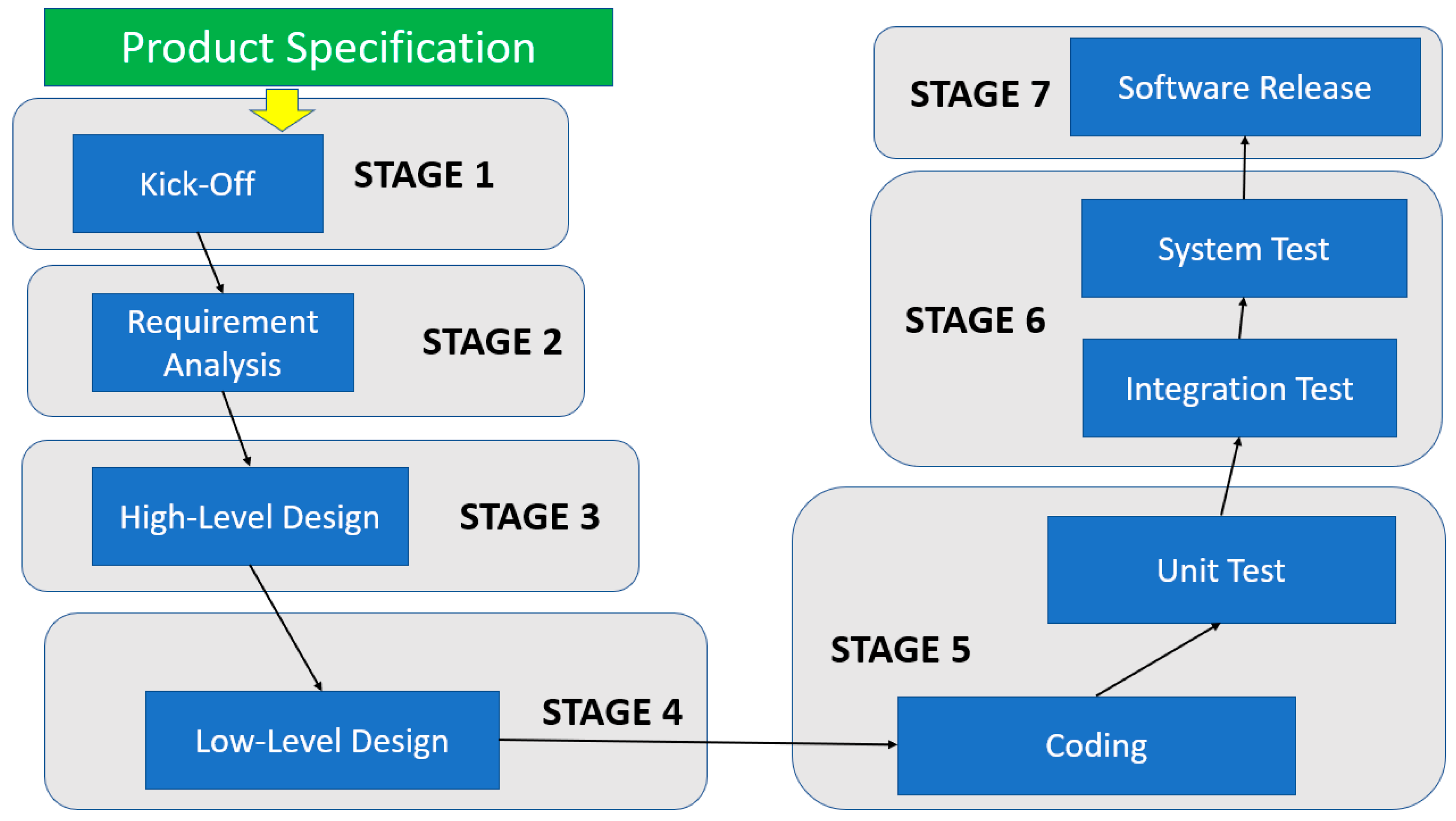

Each semester, teams of 3 to 4 students are formed to work in collaborative teams to develop a prototype design as a term product. The project advances will be presented to the hardware and software engineers during the semester in order to receive feedback at every time using the company’s Q&A (question and answer) methodology. At the end of the semester, they present the prototype to the hardware and software managers. The students are evaluated individually during the semester considering outcomes in the challenge and progress in the modules. The design methodology uses a U process shown in

Figure 1, and it is very similar to the V design cycle used by the automotive industry for years [

31,

32,

33] when device prototypes are developed. The 7 stages represent particular milestones that students achieve and when they receive feedback from both practicing engineers and faculty. In the challenge-based learning unit, the U design cycle shown in

Figure 1 is simplified for the students but includes the following aspects:

- a.

Product specification and project kick-off.

- b.

Requirement analysis.

- c.

High-level design.

- d.

Low-level design.

- e.

Software coding.

- f.

Unit testing.

- g.

Integration test.

- h.

System test.

- i.

Presentation and prototype refinements.

2.4. Activities

Research in engineering education has shown studies of learning effectiveness at the undergraduate level and focused on specific limited disciplines such as engineering science [

34]. However, more multidisciplinary studies where knowledge is learned in multiple majors with industry partnership are necessary and have not been discussed yet. In the Embedded Automotive Technology semester, the students are exposed to activities that integrate specific modules comprehending engineering concepts from disciplines that would be covered in the traditional format. The interaction of the company partnership allows the student to connect the concepts learned with a challenging project embedded in a real-world situation. Therefore, this study performed a comparison on the evaluation of the main competency, “creation of technological solutions for electronic devices” for students in two different learning scenarios: traditional applied electronics course and i-Semester Embedded Automotive Technology. In addition, the study provides an initial description of activities, rubrics, and evaluation of conceptual content to different engineering majors whose main goal is to develop a working prototype that solves the requirements of the challenge proposed by both industrial partners and faculty. Different activities were performed during the semester for selected topics in applied electronics. The topics are:

Introduction to data acquisition systems.

Introduction to op-amps and linear signal conditioning.

Fundamentals of active filters and filter configurations.

Comparator circuits and sample and hold amplifier.

D-A and A-D signal conversion.

Sinewave oscillators and multivibrators.

Voltage and current regulation.

Three evaluations during the process, final presentation, and report documentation.

2.5. Purpose

The purpose of this research was to determine the domain level of students from two well-defined sample groups, which were:

- (1)

Traditional class of applied electronics and

- (2)

Module of applied electronics in the i-Semester of Embedded Automotive Technology with an industrial partner at TEC.

Thus, this domain level corresponds to the development of the “

creation of technological solutions for electronic devices” competency during the semester. This outcome includes collaborative work in solving multidisciplinary electronics projects and report documentation development for electronic prototypes. The “i-Semester with industrial partner” project promotes student and faculty participation [

13,

35,

36,

37] with an industrial educational partner and facilitates training and collaboration using advanced high-performance tools to disseminate engineering education in communities. The participating students were junior undergraduates from Mechatronics Engineering, Digital Systems Engineering, and Biomedical Engineering programs at TEC. In addition, the students enrolled in the i-Semester program took content in the ethics and citizenship class where the course includes the topics of the 17 SDGs and in which the tree-planting activity was carried out in joint participation with the government, the industry, and citizenship.

This research was guided by the following research questions:

R.Q.1. What relationship exists between the final-grade performance and the “creation of technological solutions for electronic devices” competency acquisition by undergraduate students from the standpoint of preliminary domain levels?

R.Q.2. Considering students from 4 different engineering programs, what initial differentiation exists between domain levels 1, 2, and 3 when students from traditional programs are compared to students from “i-Semester with industrial partner”?

For this study, domain level 1 corresponds to the lowest level, and domain level 3 corresponds to the mature high-performance level.

2.6. Research Design

A sequential quantitative method design was selected to conduct this research as shown in

Figure 2 [

38]. The sequential design allowed the researchers to elaborate and expand the conclusions about the evaluation of the “creation of technological solutions for electronic devices” competency at different domain levels for both students taking applied electronics in the traditional way and students taking applied electronics with an industrial partner in the “i-Semester” scheme. All students and the domain level were reported during the quantitative results data collection using different instruments: self-study quizzes, quick-experiment (QE) reports, exams, videos, and term project grades. By comparing the quantitative results in both groups, it is possible to find and further explain the possible impact of the industrial partner to acquire the “creation of technological solutions for electronic devices” competency domain levels. Subsequently, the parametric statistical Student’s

t-test was carried out to prove the null hypothesis and the alternative to prove if there is a significant difference in both courses to obtain better results with the evaluated competency “creation of technological solutions for electronic devices”.

2.7. Participants

The student population groups for this research were:

Figure 3 and

Figure 4 show the distribution in different areas of study in engineering:

Mechatronics Engineering.

Digital Systems and Robotics Engineering.

Biomedical Engineering.

Other Engineering programs.

Figure 3 and

Figure 4 show that the traditional sections have a larger size of Mechatronics Engineering students compared to Digital Systems and Robotics. In the industrial partner sections, the predominance of Digital Systems and Robotics Engineering students is apparent.

2.8. Data Collection

This research used several elements as evidence to measure participants’ competency of “creation of technological solutions for electronic devices” The evidence used to measure the competence was:

Self-study quizzes about conceptual contents (SSQ).

Quick-experiment (QE) activity realization.

Quick-experiment (QE) report.

Comprehensive examination (Ex).

Video review about precise concepts.

Term project report and presentation (PG).

The developed term project consisted of a capstone activity that consolidates the student collaborative work during the semester. This design or proposal includes the procedural and attitudinal concepts for the students. For the students having “i-Semester” industry partners, the term project consists of the capstone development project with specific added interest of searching a solution for the industrial partner. Evaluation rubrics were created to evaluate QE and term-project activities, and they provide an exhaustive verification of different development phases, previously mentioned, that include requirements, high-level design, low-level design, simulation execution, unit test, integration test, and final system test. Reports on QE and term project are delivered as evidence, individually and by teams. In addition, each student completes mid-term/final examinations to consolidate the understanding of conceptual and procedural contents during the semester.

2.9. Rubric

The competency “creation of technological solutions for electronic devices” is evaluated according to the criteria that provide the domain level achieved by the student.

Table 3 illustrates a rubric with the criterion used to evaluate the competency.

2.10. Data Analysis

The data were collected over an educational platform (such as Blackboard or Canvas) with all evidence (having 116 students). Results were analyzed using descriptive statistics and a simple analysis to classify participants into domain levels. The average grade obtained in all evidence for both groups of students was obtained to determine the corresponding competence’s domain level. Using the exam grade (Ex), project grade (PG), self-study quizzes grade (Self), and quick-experiment (QE) activity reports, a final grade (FG) was calculated for each student. FG was used as indicator for the three domain levels illustrated in

Table 3 and defined as follows for the Applied Electronics Module in the i-Semester with having industrial partner.

- a.

Domain Level 3,

- b.

Domain Level 2,

- c.

Domain Level 1,

- d.

Non-Certified,

In addition, FG

T was used as indicator for the three domain levels illustrated in

Table 3 and defined as follows for the Applied Electronics Module using the traditional teaching scheme.

- a.

Domain Level 3,

- b.

Domain Level 2,

- c.

Domain Level 1,

- d.

Non-Certified,

For the industrial partner group, results from 55 students were collected and analyzed, and for the traditional applied electronics course without the industrial partner, data from 61 students were also collected and analyzed. As before, simple statistical analysis was used to identify the students’ self-efficacy in the “creation of technological solutions for electronic devices” competency following those evidence’s indicators.

2.11. Quality Considerations

For the industry partner groups (55 students), an adapted version of the comprehensive exams was used to test the students about the project being developed during the semester. About 8 different exams per group were designed; thus, the execution of this study took place from 2017 through 2020 to test the students’ competency. In addition, quick-experiment practice verification was also evaluated by the instructor using the evaluation rubric. This was done to revise the clarity of instructions and possible students’ interpretation during the experiment realization [

39].

2.12. Quintuple Innovation Helix Framework Model Applied in This Study

In this study, as it is observed from the previous sections, a synergy of collaborative work was implemented between different sectors, which were the university, government, industry, society, and the natural environmental area within the educational program of the i-Semester. As a result, the quintuple innovation helix model was implemented in the competency-based education model (A detailed description of the quintuple helix innovation model is incorporated in

Appendix A).

In our competency assessment study “creation of technological solutions for electronic devices” with and without an industry training partner, the quintuple helix model was used as described in

Figure 5. In detail, the figure shows information in relation to the interactions that the five helices had. For example, the figure shows in its boxes in gray and diagonally the description of the participating agents for each helix. Likewise, each column and row when crossing within the figure describes the interactions and or activities that took place between the respective helices or entities in this study. As an example, the following is described in the box that crosses between the government–industry interaction: “The industry conducts research in accordance with government regulations. Likewise, between government and industry, the activity is structured to invite society to plant trees, and permits are released for their execution”. Similarly, the other relationships between the different helices are described in the other boxes in

Figure 5. Consequently,

Figure 5 shows the different levels of cooperation and participation that each helix has among them.

3. Results

In evaluating the “creation of technological solutions for electronic devices” competency, the expected outcomes for the students in the group with external participation of the industrial partner (55 students) include:

- I.

The Applied Electronics Module evaluation counts toward 50% of the final grade.

- a.

Comprehensive partial exams (Ex) (25%);

- b.

Quick-experiment (QE1) individual realization (30%);

- c.

Quick-experiment (QE2) group reporting and videos (25%);

- d.

Self-study quizzes (SSQs) (15%);

- e.

Student assistance (SA) (5%).

- II.

The challenge project solution product and presentation for the capstone project to support the “creation of technological solutions for electronic devices” proposed to the industry partner counts toward the other 50% of the final-grade module evaluation. This is expressed as follows.

where PPG stands for the final grade in the module evaluation. For the “traditional applied electronics group” (61 students) the “creation of technological solutions for electronic devices” competency was evaluated as follows:

- a.

Comprehensive partial exams (Ex) (45%);

- b.

Quick-experiment (QE) individual realization and group reporting (20%);

- c.

Self-study quizzes (SSQs) (10%);

- d.

Term project individual demonstration and report (PG) (25%).

In this case, the final “competence evaluation grade”,

, is obtained as:

Figure 6 and

Figure 7 describe the results for the sample of 116 students in both groups. In detail, it is shown in

Figure 6 that the sample population for the “industrial partner group” (55 students) obtains a mean of 88.7/100 in the

FG with a standard deviation of 6.57. Additionally, there is a 95% of confidence in the interval for the mean obtained from 87.98 and 91.5, which means that most students are in the competence domain levels 2 and 3 for the group having an industrial partner.

Figure 7 shows that the sample population for the “traditional group” (61 students) obtains a mean of 82.9/100 in the

grade with a standard deviation of 7.07. Moreover, the data show a 95% confidence interval for the mean obtained from 81.12 and 84.74, which means that, in this case, most students are in the competence domain level 2. The final-grade evaluation for the “creation of technological solutions for electronic devices” competency is obtained for each group separately using the scale factors illustrated by Equations (1)–(4).

Figure 6 and

Figure 7 suggest that most students in the “industrial partner group” have competence domain levels 2 and 3, and in the “traditional applied electronics group”, most students show a solid domain level of 2.

Figure 8 and

Figure 9 show the distribution of students in terms of domain levels for both the “industrial partner” group and the “traditional group”, respectively. Specifically,

Figure 8 shows that the “industrial partner” group has a range between 2.33 and 2.68 in the domain level (also a median range between levels 2 and 3) with a 95% confidence interval for the mean. In addition,

Figure 9 shows that the “traditional applied electronics group” has a range between 1.68 and 2.0 in the domain level (also a median just at 2.0) with a 95% confidence interval for the mean.

Due to the fact that the student participants were associated with four engineering categories according to the undergraduate programs described in the methodology, those engineering students took this course in both formats: traditional way and using the industrial partner embedded in the i-Semester format. The following analysis complements and tests the emerging theory that their field of study does not affect necessarily their performance evaluation in the “creation of technological solutions for electronic devices” competency evaluation whatsoever [

7,

14].

Figure 10 shows a 3D plot for the final grade (FG) versus engineering category (y-axis) and domain level (x-axis) in the “industry partner applied electronics group”. This graph shows that the variation of the FG with respect to the engineering programs 1, 2, or 3 is essentially negligible for the “creation of technological solutions for electronic devices” competency. However, other engineering programs show a slight decrease in performance due, perhaps, to the lack of solid fundamentals in circuit analysis. For instance, students in engineering innovation sometimes must work harder to comprehend the fundamentals of electronics engineering which is not one of their core subjects in their basic preparation during their sophomore or junior years.

Furthermore, in the analysis in the evaluation of “creation of technological solutions for electronic devices” competency, in

Figure 11, a 3D plot for the final grade (

) versus engineering category (y-axis) and domain level (x-axis) is shown.

Figure 11 describes the “traditional applied electronics student group” data; specifically, slightly better performance is observed in

for engineering programs 2 and 3 with negligible variation in “creation of technological solutions for electronic devices” competency level. However, engineering programs 1 and 4 show a slight decrease in performance.

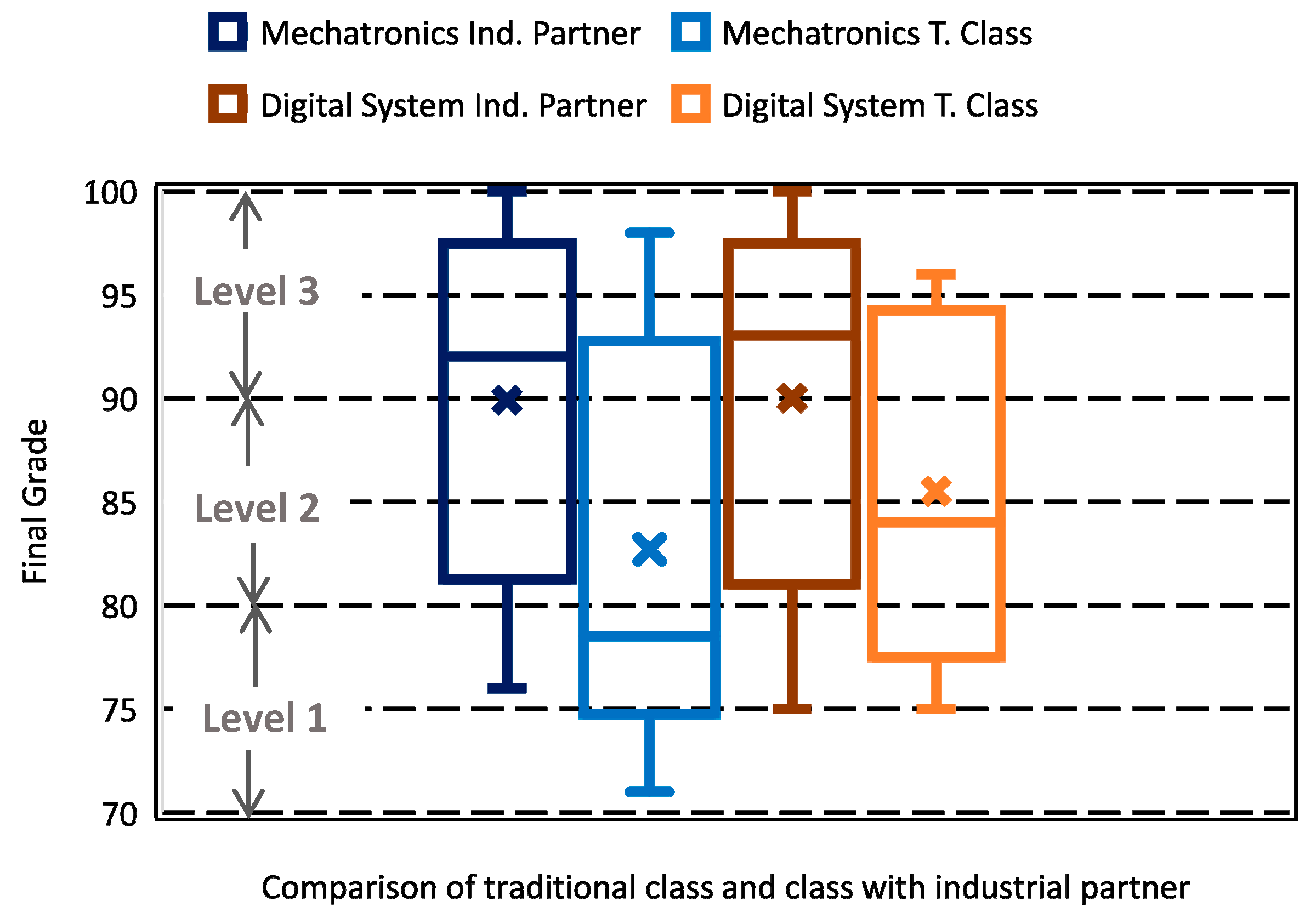

An analysis in the comparison of the two applied teaching methods, such as working with an industrial partner involved in the teaching process or teaching in a traditional way without linking strategic partners, can be carried out in engineering degree programs. In this sense,

Figure 12 and

Figure 13 describe the results of the final grades vs. engineering undergraduate programs of the two teaching methods.

In

Figure 12, better performance is shown on the final-grade results obtained with the i-Semester class with the industrial partner with respect to the traditional class for the Mechatronics and Digital System undergraduate programs. In a similar way,

Figure 13 describes better results on final graduate data in the class with an industrial partner with respect to the performance results on the traditional-way teaching method for the Biomedical and Others Engineering programs. Nonetheless, in

Figure 13, more variation is observed in the distribution of the students’ final grades when the course was delivered in a traditional way; this final-grade distribution remains roughly similar for both methods of teaching when the analysis considered is only for the Mechatronics and Digital Systems undergraduate programs as is shown in

Figure 12. Indeed, the average final grade in Mechatronics and Digital Systems remains approximately the same on the order of 90 when taught with an industrial partner. This result provides better performance for these grades than when taught in a traditional way without an industrial partner; moreover, the distribution of grades is in the range of 100 to 75 for both undergraduate engineering programs.

In

Figure 13, it is observed that, in the case of the results of the students in the undergraduate program of Biomedical Engineering, there is a slight decrease in the distribution with respect to the undergraduate programs in Digital Systems Engineering and Mechatronics of final grades between 77 to 98; this observation also remains for the teaching program linking the industrial partner. On the other hand, the results obtained from students in other engineering programs such as Innovation Engineering (other engineering) is only a final grade of 81 for the teaching modality with an industrial partner. A preliminary conclusion is that the competence of “creation of technological solutions for electronic devices” is independent of the engineering program if the main field of study includes the fundamental principles of electronic engineering, such as electronic circuits theory.

The comparative analysis of the final qualifications of the undergraduate programs of different engineering can also be observed in

Figure 12 and

Figure 13 when the course was carried out in a “traditional way”. For instance, the results show an average value in the final grades of the Mechatronics, Digital Systems, and Biomedical Engineering undergraduate programs; particularly in the Biomedical Engineering undergraduate program, the highest value, 100, is shown in the final graduation obtained by some students. As a result, this traditional course (no industrial partner linkage) is slightly biased (not much) by Biomedical Engineering undergraduate students, who show very strong fundamentals of electronic engineering. The preliminary conclusion, again, is that the “creation of technological solutions for electronic devices” competence is relatively independent of the engineering program as long as it includes a good background in electronic engineering in electronic circuit theory, in the traditional teaching modality [

40]. On the other hand,

Figure 13 shows little data on the other undergraduate engineering programs (other engineering), where the final grades in this sector are much less distributed for a traditional course. Here the best results are not good enough to obtain level 3 in the “creation of technological solutions for electronic devices” competency, but similarly, the worst final grades in these engineering programs are not below the worst final grades reported by Mechatronics, Digital Systems, or Biomedical Engineering for a traditional course.

4. Discussion

The population of 116 engineering students with several majors of undergraduate programs at TEC in this research reported a high domain level in the “creation of technological solutions for electronic devices” competency after completing either the applied electronics course with an “industrial partner” in the “i-Semester” or the traditionally applied electronics course at TEC. In addition, the students consolidated their abilities to perform practical engineering and innovation in support of the “creation of technological solutions for electronic devices” competency in the industry.

A t-distribution statistical analysis was performed to compare the mean values of both samples the group of “i-Semester applied electronics with industrial partner” and the group of “traditional applied electronics”. The samples have a different number of students (55 for the “i-Semester group”, and 61 for the “traditional group”) and the test was performed for the final grade, FG, considering that the samples are independent with normal distributions. Observing that the difference between sample means is 6.83 (

), the standard deviations of “i-Semester group” and “traditional” samples are 6.57 and 7.08, respectively, and the proposed hypothesis test for the percentage difference between means is

, which is a very conservative value (

.

Table 4 shows the hypothesis criteria and the main equation to be used for comparing the means of the two sample populations.

The common variance and standard deviation are obtained as follows:

Given that

(critical region limit or confidence parameter), sample sizes of

, and the critical t-distribution values from the standard tables [

41] are

.

Table 5 illustrates the results for this mean comparison experiment.

Given that 2.23 from

Table 5 is within the critical region of

, the null hypothesis is rejected as

. Consider that

P is the probability that

2.23 where

is the t-student distribution for the combined sample of 55 + 61 = 116. Using standard Student’s

t-test statistical table [

41], and making a double interpolation, the distribution value is obtained as follows:

Therefore, with the basis of this statistical experiment, we conclude that the difference between the means of the FG in the “i-Semester” and “traditional” groups is statistically greater than four and discernible with the Student’s t-test distribution having a value of p = 0.0163. In other words, the Student’s t-test describes that the methodology associated with the industrial partner in the course is significantly relevant in the overall result of the competency “creation of technological solutions for electronic devices”, evaluated among the students.

Figure 14 illustrates the process interactions required to perform this study. The figure shows three dominant engineering student majors—Mechatronics, Digital Systems and Robotics, and Biomedical—that participate in the instruction of applied electronics with and without an industrial partner. The figure also illustrates that they enter the i-Semester according to the pre-requisite requirements, and their genuine interest is in spending the whole semester with an industrial partner liaison. Recall that the student also receives credit for the other four or five subjects of his/her degree plan. The challenge project includes not only embedded technologies and electronics engineering but also proposals to enhance sustainable development goals (SDGs) in communities nearby the company campus. This combination technological challenge method receives students, university professors (faculty), and practicing engineers that collaborate as industrial partners and consolidated teams to propose decision-making and alternative solutions. These three groups of human resources work together the whole semester, and the students receive credit for subjects of their degree plan. Of course, there will be some guidelines, specifications, and requirements provided by the industrial partner or an external client, as there is the need to sign confidentiality agreements for the development of intellectual property projects.

Finally,

Figure 14 also shows the output of this team interaction where the conceptual content for the applied electronics is posted. The lower feedback loop of

Figure 14 shows the instructional aspects of the course development during the semester where the applied electronics contents help to give solutions to the challenge proposed by the industrial partner whatsoever.

Regarding outcome performance, most students achieved the highest domain levels 2 and 3 in the “creation of technological solutions for electronic devices”competence. The opportunity areas to improve the structure and details of the “industry–university” liaison during the semester were addressed by faculty and industry supervising engineers year by year since the fall of 2017. This will allow much better performance from students performing domain level 1 and trying to jump to domain levels 2 and 3. This new and more realistic perception of their “creation of technological solutions for electronic devices” competency was related to a noticeable change in participants’ behavior and attitudes when performing the practical experiments and interactions with company engineers; therefore, by adjusting their approach to the product prototype, participants were able to develop even more their competency up to the point that some of them could reach the highest domain level of 3 during the final project presentations. More on the subject has been observed in the interaction among students, practicing engineers, and faculty from mechatronics and electrical engineering, computer science and information technologies [

8], the development of technology-driven applications [

9], and the participation of industrial partners [

10], in which they provide a very fertile multidisciplinary environment to promote innovation opportunities [

6].

Limitations of the Study

This research should be viewed as the application of a new instructional model of engineering education to colleges and universities implementing competency-based, challenge-based, and experience-based degree programs with a robust interaction from “industrial partners” in student education. This study shows that the required domain level of different competencies can be achieved by students during their four years of education and when the study focuses on the integration of ““creation of technological solutions for electronic devices” into the students’ life plan of activities. Therefore, by including the “industrial partner” in the education process of the “

creation of technological solutions for electronic devices”, the outcome includes automotive manufacturing and instrumentation hardware companies. As a result, this reinforces the commitment to integrate the community’s instructional teams that participate in the whole educational process. This strategy of including committed “industrial partners” plays a key role in the successful completion of the competence-based education that is presented in this electronics engineering education’s example. This joint-venture experience with the automotive and the instrumentation hardware industries was so successful that the continuation of the project was authorized for many years to come. Thus, this study shows a particular partnership between TEC and the automotive hardware industry partnership that generated participation of more than 55 new students since 2017. Considering resources, faculty dedication, and overall implementation issues,

Table 6 shows the advantages and disadvantages of using the industrial-partner “i-Semester” scheme as a major high engineering educational drive for intermediate learning in junior students.

5. Conclusions and Recommendations

This research contributes to the engineering education competencies by encouraging students to build their “creation of technological solutions for electronic devices” into their day-to-day life professional activities. This research initiated a reflection about questions R.Q.1. and R.Q.2. Even though some answers have been discussed through the paper, a quick review answer to each one is presented as follows.

R.Q.1. What relationship exists between the final grade performance and the “creation of technological solutions for electronic devices” competency acquisition by engineering undergraduate students from the standpoint of preliminary domain levels?

Quick Review Answer to R.Q.1. From a population of 116, the mean final grades FG and were 88.7/100 with a standard deviation of 6.57 and 82.9/100 with a standard deviation of 7.07, respectively. In addition, the median ranges were 88.57 to 94 for the industrial partner group and 80 to 84.59 for the traditional applied electronics group, indicating domain levels between 2 and 3 of the “creation of technological solutions for electronic devices” competency in the “industrial partner applied electronics group”. However, students in the “traditional applied electronics group” developed predominantly a solid domain level 2 considering the evaluation performed and verified by the applied electronics professors.

R.Q.2. Considering students from four different engineering programs, what initial differentiation exists between domain levels 1, 2, and 3 when students from traditional programs are compared to students from “i-Semester with industrial partner”?

Quick Review Answer to R.Q.2. The study shows some independence in the engineering program, as long as the major field of study has fundamental principles of electric and electronic circuit theory. The variation between both teaching methods shows that most students reached higher performance in the domain level associated with the “creation of technological solutions for electronic devices” competency according to the final grades when the course was taught with an industrial partner. Likewise, a higher distribution was observed in the final grades in the traditional applied electronics class for biomedical engineering and other engineering programs; however, this final-grade distribution remains roughly the same for Mechatronics and Digital System undergraduate programs regardless of the teaching methodology applied. Therefore, it can be inferred that the course taught with an industrial partner not only reflects better results among students but also that the performance among students is a little more uniform. Likewise, with the basis of the statistical Student’s t-test method, we proved that the difference between the means of the FG in “i-Semester” and “traditional” groups is statistically greater than four and discernible with the Student’s t-test distribution having a value of p = 0.0163. In other words, the Student’s t-test describes that the methodology associated with the industrial partner in the course is significantly relevant in the overall result of the competency “creation of technological solutions for electronic devices” evaluated in the students. Consequently, the quality or effectiveness of the course with an industrial partner is more suitable for structuring educational dynamics that strengthen cognitive processes to incorporate new topics, as well as execute better levels of competency in the “creation of technological solutions for electronic devices”. Furthermore, the industrial partner method emulates better professional life after the university education process is finished.

Finally, an important observation is to highlight that teaching through competency-based learning showed better results than content-based learning, as reflected in some studies [

22,

29,

41,

42,

43]. However, at the level of the educational system, even though interdisciplinarity in individuals is important to promote creative thinking and critical thinking and to obtain innovative and disruptive results (complex thinking processes), there is up to now a behavior that demerits these practices, as it is reflected in the study by Christensen et al. [

44]. Therefore, the indications of the study by Christensen et al. [

44] promote that the best way to obtain interdisciplinary knowledge is through teaching by challenge-based learning methods and in a collaborative way, then it is possible to infer that this experience can be catalyzed to reach better results when we take advantage of sustainable learning as it is with the participation of an industrial partner in the university education. In this way, it is evidenced that students obtain learning that is closer to the work environment and through the development and evaluation of competencies that are needed to meet the challenges of the SDGs in a faster way; in fact, the trend goes toward that path since when analyzing the benefits of providing higher education based on competencies and emulating professional life in an “even more global way to deal with more complex problems”, it can be observed that, for these cases, it is necessary to develop education more robust in meta-competencies such as the complex thinking competency [

45,

46,

47,

48]; thus, when these major challenges are presented due to their complexities, the innovation models of multiple helices that incorporate different entities according to the need can and should be applied; these required helices to strengthen a synergy collaboration that corresponds to the academia, the economic sector, local and federal governments, social organizations of all kinds, the media, and the natural environment, among others [

49,

50,

51,

52,

53,

54,

55,

56].

Future Work

Future research should be conducted to consolidate the evaluation and validation of disciplinary competencies in all engineering/science programs in semesters beyond 2021. Qualitative and mixed educational innovation research methods [

57,

58,

59] are also required to be applied in this case to consider a more exhaustive evaluation of the student’s engagement with the educational process. Video-integration flipped classroom and distance/home flexible instruction are some of the additional strategies to be addressed by competency-based learning in engineering programs [

6,

11,

12,

15]. Additional contributions and other evidence are also necessary to be integrated into the overall evaluation rubrics to perform a very exhaustive differentiation in the declared domain levels and considering other engineering programs.