Two-Year Non-Destructive Evaluation of Eco-Efficient Concrete at Ambient Temperature and after Freeze-Thaw Cycles

Abstract

:1. Introduction

2. Method

2.1. Materials and Mixes

2.2. Test Methods

3. Results at Ambient Temperature

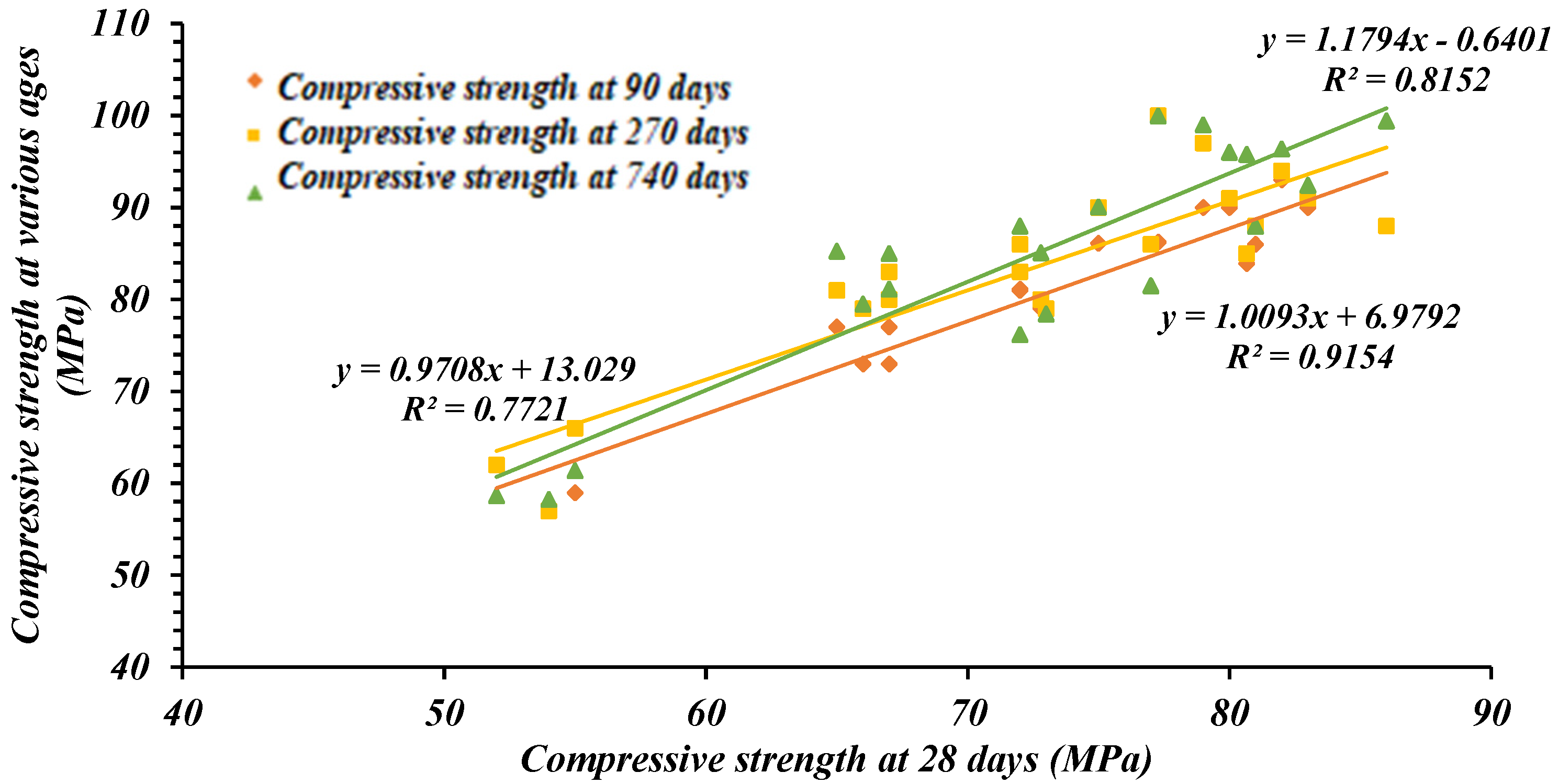

3.1. Compressive Strength

3.2. Rebound Values (RVs)

3.3. Ultrasonic Pulse Velocity (UPV)

4. Results after Exposure to Freeze–Thaw Cycles

4.1. Relative Residual Compressive Strength

4.2. Relative Residual Rebound Values (RVs)

4.3. Relative Residual Ultrasonic Pulse Velocity (UPV)

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Sandanayake, M.; Zhang, G.; Setunge, S. Estimation of environmental emissions and impacts of building construction–A decision making tool for contractors. J. Build. Eng. 2018, 21, 173–185. [Google Scholar] [CrossRef]

- Thives, L.P.; Ghisi, E. Asphalt mixtures emission and energy consumption: A review. Renew. Sustain. Energy Rev. 2017, 72, 473–484. [Google Scholar] [CrossRef]

- Mikulčić, H.; Klemeš, J.J.; Vujanović, M.; Urbaniec, K.; Duić, N. Reducing greenhouse gasses emissions by fostering the deployment of alternative raw materials and energy sources in the cleaner cement manufacturing process. J. Clean. Prod. 2016, 136, 119–132. [Google Scholar] [CrossRef]

- Bai, G.; Zhu, C.; Liu, C.; Liu, B. An evaluation of the recycled aggregate characteristics and the recycled aggregate concrete mechanical properties. Constr. Build. Mater. 2020, 240, 117978. [Google Scholar] [CrossRef]

- Bungey, J.H.; Millard, S.G.; Grantham, M.G. Testing of Concrete in Structures, 4th ed.; CRC Press, Taylor & Francis: Abingdon, UK, 2018. [Google Scholar]

- Hack, R.; Huisman, M. Estimating the Intact Rock Strength of a Rockmass by Simple Means, in: Engineering Geology for Developing Countries. In Proceedings of the 9th Congress of the International Association for Engineering Geology and the Environment (IAEG), Durban, South Africa, 16–20 September 2002. [Google Scholar]

- Breccolotti, M.; Bonfigli, M.F.; Materazzi, A. Influence of carbonation depth on concrete strength evaluation carried out using the SonReb method. NDT E Int. 2013, 59, 96–104. [Google Scholar] [CrossRef]

- Breysse, D. Nondestructive evaluation of concrete strength: An historical review and a new perspective by combining NDT methods. Constr. Build. Mater. 2012, 33, 139–163. [Google Scholar] [CrossRef]

- Craeye, B.; van de Laar, H.; van der Eijk, J.; Gijbels, W.; Lauriks, L. On-site strength assessment of limestone based concrete slabs by combining non-destructive techniques. J. Build. Eng. 2017, 13, 216–223. [Google Scholar] [CrossRef]

- Mohammed, T.U.; Rahman, N. Effect of types of aggregate and sand-to-aggregate volume ratio on UPV in concrete. Constr. Build. Mater. 2016, 125, 832–841. [Google Scholar] [CrossRef]

- Tchamdjou, W.H.J.; Cherradi, T.; Abidi, M.L.; Pereira-De-Oliveira, L.A. Mechanical properties of lightweight aggregates concrete made with cameroonian volcanic scoria: Destructive and non-destructive characterization. J. Build. Eng. 2018, 16, 134–145. [Google Scholar] [CrossRef]

- Kazemi, M.; Madandoust, R.; de Brito, J. Compressive strength assessment of recycled aggregate concrete using Schmidt rebound hammer and core testing. Constr. Build. Mater. 2019, 224, 630–638. [Google Scholar] [CrossRef]

- Al-Mufti, R.L.; Fried, A. The early age non-destructive testing of concrete made with recycled concrete aggregate. Constr. Build. Mater. 2012, 37, 379–386. [Google Scholar] [CrossRef]

- Soares, D.; de Brito, J.; Ferreira, J.; Pacheco, J. In situ materials characterization of full-scale recycled aggregates concrete structures. Constr. Build. Mater. 2014, 71, 237–245. [Google Scholar] [CrossRef]

- Kou, S.-C.; Poon, C.S.; Agrela, F. Comparisons of natural and recycled aggregate concretes prepared with the addition of different mineral admixtures. Cem. Concr. Compos. 2011, 33, 788–795. [Google Scholar] [CrossRef]

- Kurda, R.; De Brito, J.; Silvestre, J.D. Indirect evaluation of the compressive strength of recycled aggregate concrete with high fly ash ratios. Mag. Concr. Res. 2018, 70, 204–216. [Google Scholar] [CrossRef]

- Khatib, J. Properties of concrete incorporating fine recycled aggregate. Cem. Concr. Res. 2005, 35, 763–769. [Google Scholar] [CrossRef]

- Justnes, H. How to Make Concrete More Sustainable. J. Adv. Concr. Technol. 2015, 13, 147–154. [Google Scholar] [CrossRef] [Green Version]

- Revilla-Cuesta, V.; Skaf, M.; Faleschini, F.; Manso, J.M.; Ortega-López, V. Self-compacting concrete manufactured with recycled concrete aggregate: An overview. J. Clean. Prod. 2020, 262, 121362. [Google Scholar] [CrossRef]

- BS EN 196-2. Method of Testing Cement. Chemical Analysis of Cement; BSI: London, UK, 2013. [Google Scholar]

- Abed, M.; Nemes, R. Mechanical Properties of Recycled Aggregate Self-Compacting High Strength Concrete Utilizing Waste Fly Ash, Cellular Concrete and Perlite Powders. Period. Polytech. Civ. Eng. 2019, 63, 266–277. [Google Scholar] [CrossRef] [Green Version]

- EFNARC. The European Guidelines for Self-Compacting Concrete Specification, Production, and Use, International Association of Experts for Specialised Construction and Concrete Systems, Europe; EFNARC: Flums, Switzerland, 2005. [Google Scholar]

- BS EN 12390-3. Testing hardened Concrete. Compressive Strength of Test Specimens; BSI: London, UK, 2009. [Google Scholar]

- BS EN 12504-2. Testing Concrete in Structures. Non-Destructive Testing. Determination of Rebound Number; BSI: London, UK, 2012. [Google Scholar]

- ASTM C597-97. Standard Test Method for Pulse Velocity Through Concrete; ASTM International: West Conshohocken, PA, USA, 1997. [Google Scholar]

- PD CEN/TR 15177. Testing the Freeze-Thaw Resistance of Concrete. Internal Structural Damage; BSI: London, UK, 2006. [Google Scholar]

- Elhakam, A.A.; Mohamed, A.E.; Awad, E. Influence of self-healing, mixing method and adding silica fume on mechanical properties of recycled aggregates concrete. Constr. Build. Mater. 2012, 35, 421–427. [Google Scholar] [CrossRef]

- Kou, S.; Poon, C.S. Enhancing the durability properties of concrete prepared with coarse recycled aggregate. Constr. Build. Mater. 2012, 35, 69–76. [Google Scholar] [CrossRef]

- Bui, N.K.; Satomi, T.; Takahashi, H. Effect of mineral admixtures on properties of recycled aggregate concrete at high temperature. Constr. Build. Mater. 2018, 184, 361–373. [Google Scholar] [CrossRef]

- Makul, N.; Sua-Iam, G. Effect of granular urea on the properties of self-consolidating concrete incorporating untreated rice husk ash: Flowability, compressive strength and temperature rise. Constr. Build. Mater. 2018, 162, 489–502. [Google Scholar] [CrossRef]

- Yu, L.-H.; Ou, H.; Lee, L.-L. Investigation on pozzolanic effect of perlite powder in concrete. Cem. Concr. Res. 2003, 33, 73–76. [Google Scholar] [CrossRef]

- Kou, S.-C.; Poon, C.S. Long-term mechanical and durability properties of recycled aggregate concrete prepared with the incorporation of fly ash. Cem. Concr. Compos. 2013, 37, 12–19. [Google Scholar] [CrossRef]

- Gyurkó, Z.; Szijártó, A.; Nemes, R. Cellular concrete waste as an economical alternative to traditional supplementary cementitious materials. J. Therm. Anal. Calorim. 2019, 138, 947–961. [Google Scholar] [CrossRef] [Green Version]

- Poon, C.; Shui, Z.; Lam, L.; Fok, H.; Kou, S. Influence of moisture states of natural and recycled aggregates on the slump and compressive strength of concrete. Cem. Concr. Res. 2004, 34, 31–36. [Google Scholar] [CrossRef]

- Hamood, A.; Khatib, J.; Williams, C. The effectiveness of using Raw Sewage Sludge (RSS) as a water replacement in cement mortar mixes containing Unprocessed Fly Ash (u-FA). Constr. Build. Mater. 2017, 147, 27–34. [Google Scholar] [CrossRef]

- Szilágyi, K.; Borosnyói, A.; Zsigovics, I. Rebound surface hardness of concrete: Introduction of an empirical constitutive model. Constr. Build. Mater. 2011, 25, 2480–2487. [Google Scholar] [CrossRef]

- Nicolas, R.S.; Cyr, M.; Escadeillas, G. Performance-based approach to durability of concrete containing flash-calcined metakaolin as cement replacement. Constr. Build. Mater. 2014, 55, 313–322. [Google Scholar] [CrossRef]

- Kovler, K.; Wang, F.; Muravin, B. Testing of concrete by rebound method: Leeb versus Schmidt hammers. Mater. Struct. 2018, 51, 138. [Google Scholar] [CrossRef]

- Kim, J.-K.; Kim, C.-Y.; Yi, S.-T.; Lee, Y. Effect of carbonation on the rebound number and compressive strength of concrete. Cem. Concr. Compos. 2009, 31, 139–144. [Google Scholar] [CrossRef]

- BS EN 13795. Assessment of In-Situ Compressive Strength in Structures and Precast Concrete Components; BSI: London, UK, 2019. [Google Scholar]

- Saint-Pierre, F.; Philibert, A.; Giroux, B.; Rivard, P. Concrete Quality Designation based on Ultrasonic Pulse Velocity. Constr. Build. Mater. 2016, 125, 1022–1027. [Google Scholar] [CrossRef]

- Chu, S. Effect of paste volume on fresh and hardened properties of concrete. Constr. Build. Mater. 2019, 218, 284–294. [Google Scholar] [CrossRef]

- Tesinova, P. (Ed.) Advances in Composite Materials-Analysis of Natural and Man-Made Materials; InTech: London, UK, 2011. [Google Scholar]

- Evangelista, L.; Guedes, M.; de Brito, J.; Ferro, A.C.; Pereira, M. Physical, chemical and mineralogical properties of fine recycled aggregates made from concrete waste. Constr. Build. Mater. 2015, 86, 178–188. [Google Scholar] [CrossRef]

- Gesoğlu, M. Influence of steam curing on the properties of concretes incorporating metakaolin and silica fume. Mater. Struct. 2009, 43, 1123–1134. [Google Scholar] [CrossRef]

- Rao, A.; Jha, K.N.; Misra, S. Use of aggregates from recycled construction and demolition waste in concrete. Resour. Conserv. Recycl. 2007, 50, 71–81. [Google Scholar] [CrossRef]

- Vergara, L.; Miralles, R.; Gosálbez, J.; Juanes, F.; Ullate, L.; Anaya, J.; Hernández, M.; Izquierdo, M. NDE ultrasonic methods to characterise the porosity of mortar. NDT E Int. 2001, 34, 557–562. [Google Scholar] [CrossRef]

- Abed, M.; de Brito, J. Evaluation of high-performance self-compacting concrete using alternative materials and exposed to elevated temperatures by non-destructive testing. J. Build. Eng. 2020, 32, 101720. [Google Scholar] [CrossRef]

- Bogas, J.A.; de Brito, J.; Ramos, D. Freeze–thaw resistance of concrete produced with fine recycled concrete aggregates. J. Clean. Prod. 2016, 115, 294–306. [Google Scholar] [CrossRef]

- Hao, L.; Liu, Y.; Wang, W.; Zhang, J.; Zhang, Y. Effect of salty freeze-thaw cycles on durability of thermal insulation concrete with recycled aggregates. Constr. Build. Mater. 2018, 189, 478–486. [Google Scholar] [CrossRef]

- Abed, M.; Nemes, R.; Tayeh, B.A. Properties of self-compacting high-strength concrete containing multiple use of recycled aggregate. J. King Saud Univ.-Eng. Sci. 2018, 32, 108–114. [Google Scholar] [CrossRef]

- Li, X. Recycling and reuse of waste concrete in China. Resour. Conserv. Recycl. 2008, 53, 36–44. [Google Scholar] [CrossRef]

- Abed, M.A. Indirect Evaluation of the Compressive Strength of Recycled Aggregate Concrete at Long Ages and after Exposure to Freezing or Elevated Temperatures. Russ. J. Nondestruct. Test. 2021, 57, 195–202. [Google Scholar] [CrossRef]

- Abed, M.; Nemes, R. Long-term durability of self-compacting high-performance concrete produced with waste materials. Constr. Build. Mater. 2019, 212, 350–361. [Google Scholar] [CrossRef]

- Ebrahimi, K.; Daiezadeh, M.J.; Zakertabrizi, M.; Zahmatkesh, F.; Korayem, A.H. A review of the impact of micro- and nanoparticles on freeze-thaw durability of hardened concrete: Mechanism perspective. Constr. Build. Mater. 2018, 186, 1105–1113. [Google Scholar] [CrossRef]

| Measured Property | CEM I | WFA | WPP | WCC |

|---|---|---|---|---|

| Density (g/cm3) | 3.02 | 2.15 | 2.33 | 1.96 |

| Specific surface area (cm2/g) | 3326 | 4323 | 2501 | 2513 |

| Loss on ignition | 3.0 | 1.95 | 2.0 | 9.25 |

| SiO2 | 19.33 | 43.02 | 73.5 | 54.28 |

| CaO | 63.43 | 15.07 | 1.38 | 22.81 |

| MgO | 1.45 | 3.14 | 0.155 | 1.15 |

| Fe2O3 | 3.42 | 14.17 | 2.58 | 2.16 |

| Al2O3 | 4.67 | 15.6 | 15.2 | 5.09 |

| SO3 | 2.6 | 3.56 | - | 4.90 |

| Chloride content | 0.04 | 0.02 | - | 0.02 |

| Free CaO | 0.71 | 0.37 | - | - |

| K2O | 0.78 | - | 3.8 | - |

| Na2O | 0.33 | - | 2.08 | - |

| TiO2 | - | - | 0.087 | - |

| Insoluble part in dilute hydrochloric acid and sodium carbonate | 0.26 | 49.72 | 89.13 | 33.02 |

| Physical Tests | NA | RA |

|---|---|---|

| Water absorption (%) | 1.0 | 5.6 |

| Los Angeles wear (%) | 26.3 | 36.1 |

| Density (kg/m3) | 2640 | 2612 |

| Mix designation | Contents in kg/m3 | Slump Flow in cm | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| CEM I 42.5 N | WCC | WFA | WPP | Sand | Coarse Aggregate | Superplasticizer | Water | |||

| NA | RA | |||||||||

| 0/4 | 4/16 | |||||||||

| Series I: 0% RA | ||||||||||

| RA0 | 500 | 0 | 0 | 0 | 783 | 939 | 0 | 1.5 | 175 | 69.8 |

| F15RA0 | 425 | 0 | 75 | 0 | 767 | 920 | 0 | 2 | 175 | 73 |

| F30RA0 | 350 | 0 | 150 | 0 | 751 | 901 | 0 | 3 | 175 | 73.5 |

| P15RA0 | 425 | 0 | 0 | 75 | 774 | 928 | 0 | 3 | 175 | 62.5 |

| P30RA0 | 350 | 0 | 0 | 150 | 766 | 918 | 0 | 3.75 | 175 | 59 |

| C15RA0 | 425 | 75 | 0 | 0 | 766 | 919 | 0 | 1.7 | 175 | 65.5 |

| C30RA0 | 350 | 150 | 0 | 0 | 750 | 899 | 0 | 3.25 | 175 | 60 |

| Series II: 25% RA replacement | ||||||||||

| RA25 | 500 | 0 | 0 | 0 | 783 | 704 | 230 | 1.5 | 175 | 68 |

| F15RA25 | 425 | 0 | 75 | 0 | 767 | 690 | 226 | 2 | 175 | 73.5 |

| F30RA25 | 350 | 0 | 150 | 0 | 751 | 475 | 221 | 3 | 175 | 72 |

| P15RA25 | 425 | 0 | 0 | 75 | 774 | 697 | 228 | 3 | 175 | 61.5 |

| P30RA25 | 350 | 0 | 0 | 150 | 766 | 688 | 225 | 3.75 | 175 | 59 |

| C15RA25 | 425 | 75 | 0 | 0 | 766 | 690 | 225 | 1.7 | 175 | 65.5 |

| C30RA25 | 350 | 150 | 0 | 0 | 750 | 674 | 220 | 3.25 | 175 | 58 |

| Series III: 50% RA replacement | ||||||||||

| RA50 | 500 | 0 | 0 | 0 | 783 | 470 | 460 | 1.5 | 175 | 67.5 |

| F15RA50 | 425 | 0 | 75 | 0 | 767 | 460 | 251 | 2 | 175 | 72 |

| F30RA50 | 350 | 0 | 150 | 0 | 751 | 451 | 442 | 3 | 175 | 72.8 |

| P15RA50 | 425 | 0 | 0 | 75 | 774 | 464 | 455 | 3 | 175 | 60.8 |

| P30RA50 | 350 | 0 | 0 | 150 | 766 | 459 | 450 | 3.75 | 175 | 57.5 |

| C15RA50 | 425 | 75 | 0 | 0 | 766 | 459 | 451 | 1.7 | 175 | 65.5 |

| C30RA50 | 350 | 150 | 0 | 0 | 750 | 451 | 442 | 3.25 | 175 | 58 |

| Target Test | Type of Test | Measurements | Specimens | Ages of Test | Number of Specimens for Each Mix | |

|---|---|---|---|---|---|---|

| Type | Number | |||||

| Compressive strength | Non-destructive | RVs | Cubes, 150 × 150 × 150 mm | 3 | 28, 90, 270, 740 days | 12 |

| UPV | ||||||

| Destructive | Compressive strength test | |||||

| Freeze–thaw resistance | Non-destructive | Relative residual RVs | Cubes, 150 × 150 × 150 mm | 9 | 270 days | 9 |

| Relative residual UPV | ||||||

| Destructive | Relative residual compressive strength | |||||

| Total | 21 | |||||

| Mix | 28 Days | 90 Days | 270 Days | 740 Days |

|---|---|---|---|---|

| RA0 | 81 | 86 | 88 | 88 |

| F15RA0 | 73 | 79 | 80 | 85 |

| F30RA0 | 67 | 77 | 80 | 81 |

| C15RA0 | 73 | 79 | 79 | 78 |

| C30RA0 | 52 | 62 | 62 | 59 |

| P15RA0 | 82 | 93 | 94 | 96 |

| P30RA0 | 66 | 73 | 79 | 80 |

| RA25 | 75 | 86 | 90 | 90 |

| F15RA25 | 72 | 81 | 86 | 88 |

| F30RA25 | 81 | 84 | 85 | 96 |

| C15RA25 | 72 | 81 | 83 | 76 |

| C30RA25 | 55 | 59 | 66 | 61 |

| P15RA25 | 83 | 90 | 91 | 92 |

| P30RA25 | 80 | 90 | 91 | 96 |

| RA50 | 79 | 90 | 97 | 99 |

| F15RA50 | 77 | 86 | 100 | 100 |

| F30RA50 | 86 | 88 | 88 | 99 |

| C15RA50 | 77 | 86 | 86 | 82 |

| C30RA50 | 54 | 57 | 57 | 58 |

| P15RA50 | 67 | 73 | 83 | 85 |

| P30RA50 | 65 | 77 | 81 | 85 |

| Mix | 0 Cycles | 50 Cycles | 150 Cycles | Mix | 0 Cycles | 50 Cycles | 150 Cycles | Mix | 0 Cycles | 50 Cycles | 150 Cycles |

|---|---|---|---|---|---|---|---|---|---|---|---|

| RA0 | 100 | 106 | 109 | RA25 | 100 | 105 | 94 | RA50 | 100 | 95 | 90 |

| F15RA0 | 100 | 97 | 71 | F15RA25 | 100 | 103 | 87 | F15RA50 | 100 | 99 | 92 |

| F30RA0 | 100 | 81 | 72 | F30RA25 | 100 | 91 | 83 | F30RA50 | 100 | 89 | 75 |

| C15RA0 | 100 | 92 | 66 | C15RA25 | 100 | 78 | 67 | C15RA50 | 100 | 74 | 67 |

| C30RA0 | 100 | 62 | 36 | C30RA25 | 100 | 54 | 42 | C30RA50 | 100 | 47 | 28 |

| P15RA0 | 100 | 102 | 91 | P15RA25 | 100 | 93 | 77 | P15RA50 | 100 | 93 | 80 |

| P30RA0 | 100 | 92 | 72 | P30RA25 | 100 | 86 | 70 | P30RA50 | 100 | 88 | 73 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abed, M.A.; Tayeh, B.A.; Abu Bakar, B.H.; Nemes, R. Two-Year Non-Destructive Evaluation of Eco-Efficient Concrete at Ambient Temperature and after Freeze-Thaw Cycles. Sustainability 2021, 13, 10605. https://doi.org/10.3390/su131910605

Abed MA, Tayeh BA, Abu Bakar BH, Nemes R. Two-Year Non-Destructive Evaluation of Eco-Efficient Concrete at Ambient Temperature and after Freeze-Thaw Cycles. Sustainability. 2021; 13(19):10605. https://doi.org/10.3390/su131910605

Chicago/Turabian StyleAbed, Mohammed A., Bassam A. Tayeh, B. H. Abu Bakar, and Rita Nemes. 2021. "Two-Year Non-Destructive Evaluation of Eco-Efficient Concrete at Ambient Temperature and after Freeze-Thaw Cycles" Sustainability 13, no. 19: 10605. https://doi.org/10.3390/su131910605

APA StyleAbed, M. A., Tayeh, B. A., Abu Bakar, B. H., & Nemes, R. (2021). Two-Year Non-Destructive Evaluation of Eco-Efficient Concrete at Ambient Temperature and after Freeze-Thaw Cycles. Sustainability, 13(19), 10605. https://doi.org/10.3390/su131910605