Towards Comparable Carbon Credits: Harmonization of LCA Models of Cellulosic Biofuels

Abstract

:1. Introduction

2. Key Global Initiatives for Decarbonization of the Transport Sector

3. Methods

3.1. Comparison of LCA Models—The Case of 2G Ethanol Production

3.2. Harmonization of LCA Models

4. Results and Discussion

4.1. Comparison of Key Assumptions, Parameters, and Calculation Procedures of the LCA Models

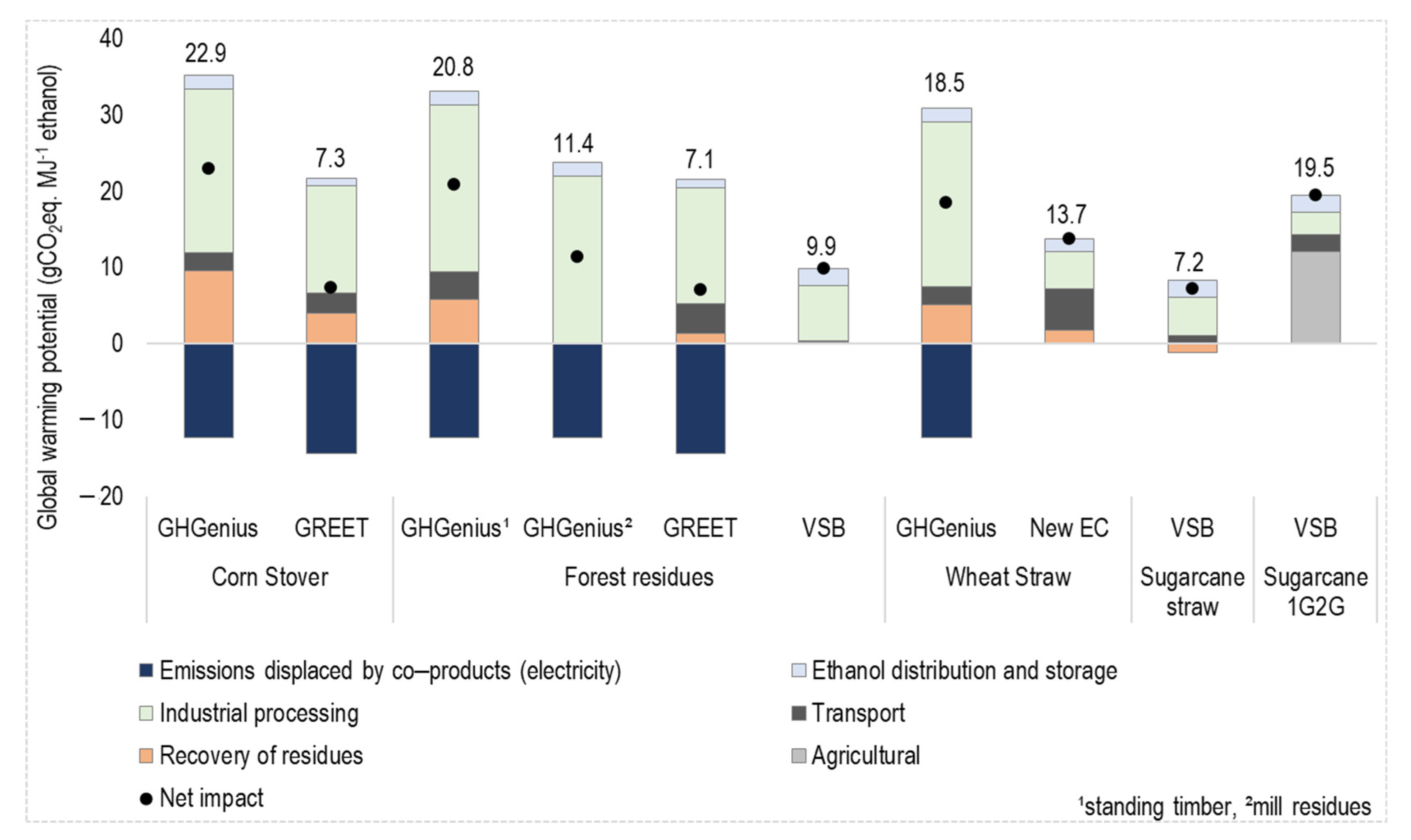

4.2. Comparison of Greenhouse Gases Emissions Calculated with the Different LCA Models

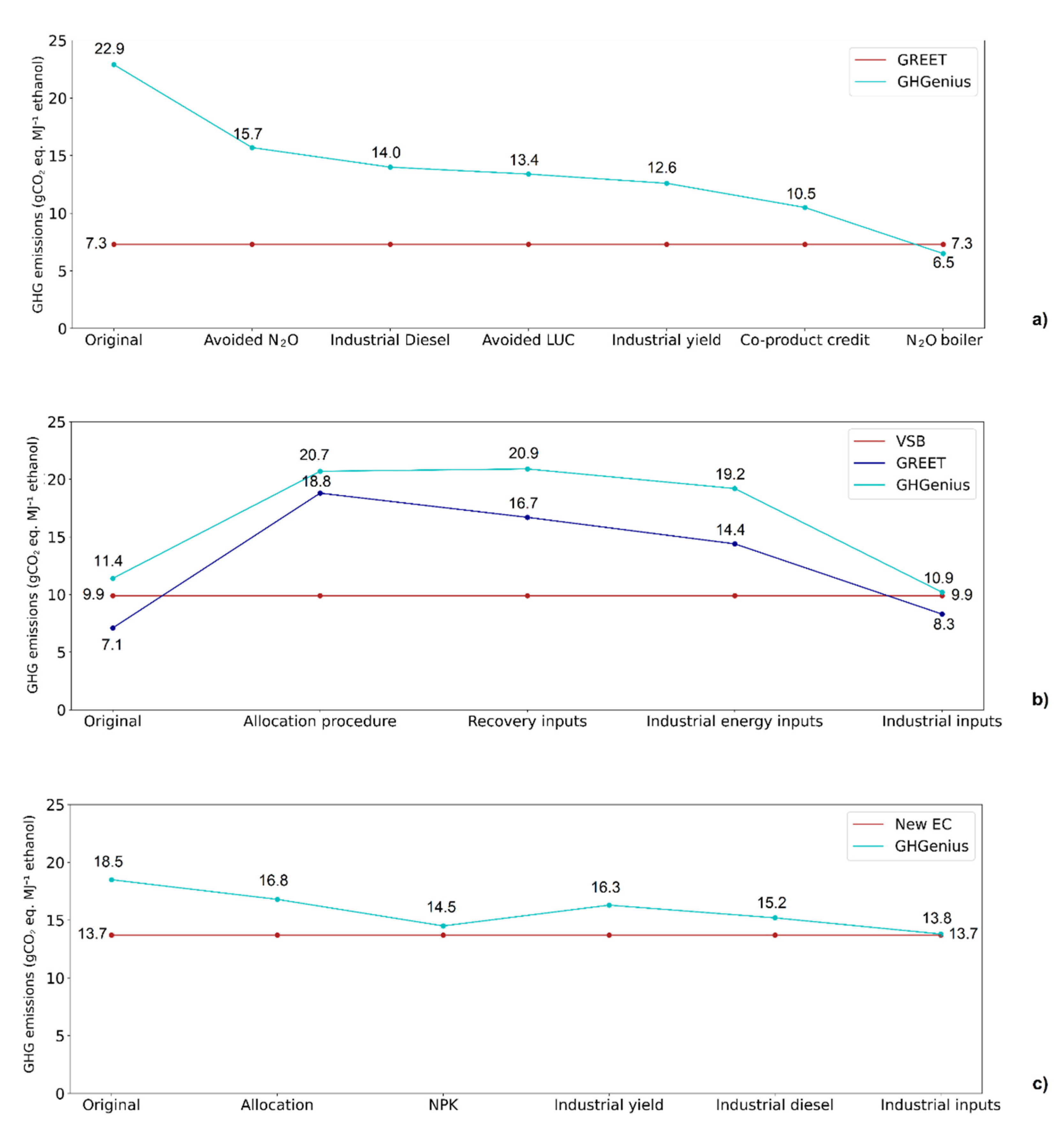

4.3. Harmonization of Greenhouse Gases Emissions of 2G Ethanol Pathways

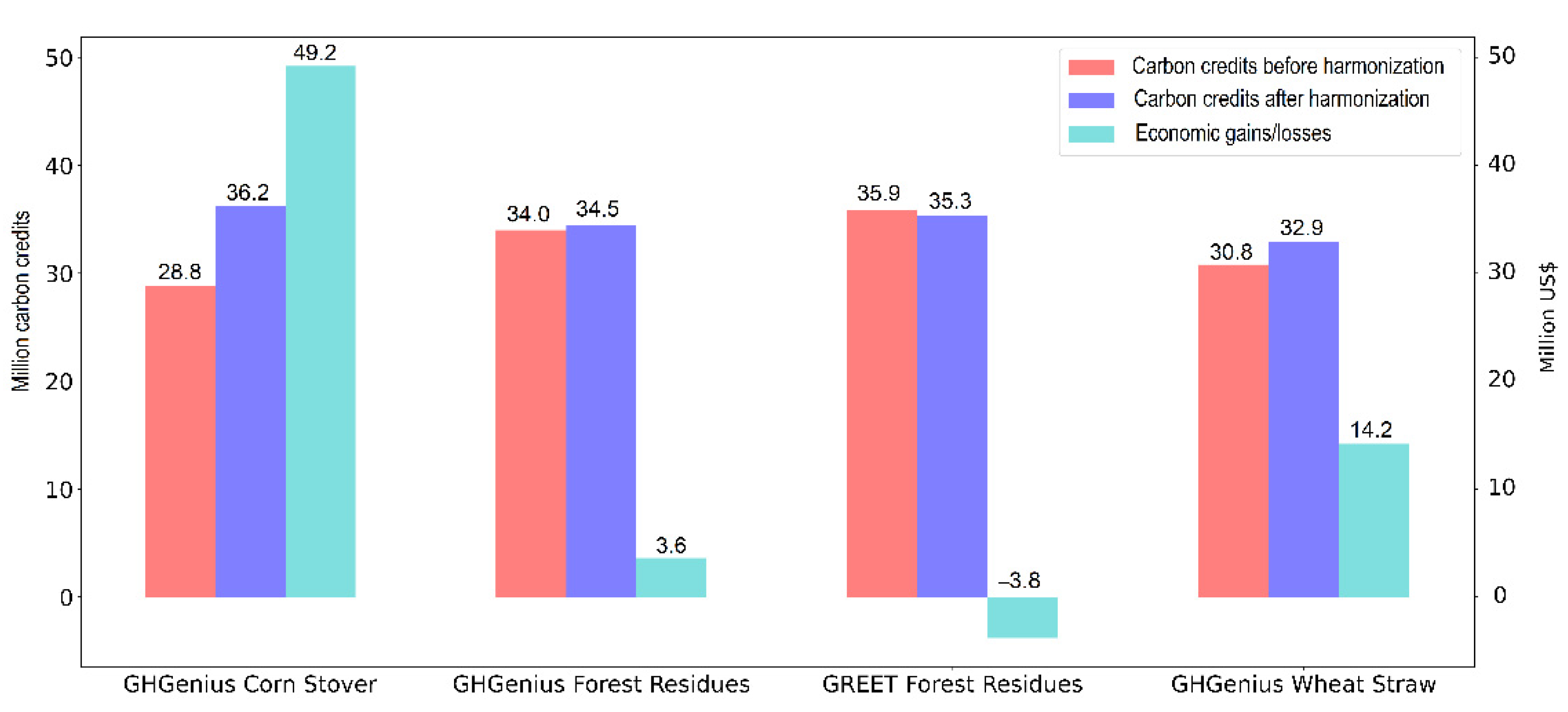

4.4. Implications and Opportunities for Harmonization of LCA Models

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| 1G | First-generation ethanol |

| 1G2G | Integrated first and second-generation ethanol |

| 2G | Second-generation or lignocellulosic ethanol |

| BC-LCFS | Low Carbon Fuel Standard from British Columbia |

| CA-LCFS | Low Carbon Fuel Standard from California |

| CARBOB | California Reformulated Gasoline Blendstock for Oxygenate Blending |

| CBIO | Carbon credit from the RenovaBio program |

| CHP | Combined heat and power generation |

| GHG | Greenhouse gases |

| GTAP-AEZ-EF | Global Trade Analysis Project/Agro-ecological zone emission factor model |

| GWP | Global warming potential for a time horizon of 100 years |

| JRC | Joint Research Centre|European Commission |

| LCA | Life Cycle Assessment |

| LCIA | Life Cycle Impact Assessment |

| LNBR/CNPEM | Brazilian Biorenewables National Laboratory, Brazilian Center for Research in Energy and Materials |

| LUC | Land use change |

| RED | Renewable Energy Directive |

| USA | United States of America |

| VSB | Virtual Sugarcane Biorefinery |

References

- Daioglou, V.; Doelman, J.; Wicke, B.; Faaij, A.; van Vuuren, D. Integrated assessment of biomass supply and demand in climate change mitigation scenarios. Glob. Environ. Chang. 2019, 54, 88–101. [Google Scholar] [CrossRef] [Green Version]

- Hanssen, S.V.; Daioglou, V.; Steinmann, J.N.Z.; Frank, S.; Popp, A.; Brunelle, T.; Lauri, P.; Hasewaga, T.; Huijbregts, M.A.J.; van Vuuren, D.P. Biomass residues as twenty-first century bioenergy feedstock—A comparison of eight integrated assessment models. Clim. Chang. 2019, 163, 1569–1586. [Google Scholar] [CrossRef] [Green Version]

- OECD/IEA. Technology Roadmap Delivering Sustainable Bioenergy. 2017. Available online: https://www.ieabioenergy.com/publications/technology-roadmap-delivering-sustainable-bioenergy/ (accessed on 20 July 2020).

- Slade, R.; Bauen, A.; Gross, R. Global bioenergy resources. Nat. Clim. Chang. 2014, 4, 99–105. [Google Scholar] [CrossRef]

- Adebayo, T.S.; Awosusi, A.A.; Oladipupo, S.D.; Agyekum, E.B.; Jayakumar, A.; Kumar, N.M. Dominance of fossil fuels in Japan′s national energy mix and implications for environmental sustainability. Int. J. Environ. Res. Public Health 2021, 18, 7347. [Google Scholar] [CrossRef]

- Baeyens, J.; Kang, Q.; Appels, L.; Dewil, R.; Lv, Y.; Tan, T. Challenges and opportunities in improving the production of bio-ethanol. Prog. Energy Combust. Sci. 2015, 47, 60–88. [Google Scholar] [CrossRef]

- Lynd, L.R.; Liang, X.; Biddy, M.J.; Allee, A.; Cai, H.; Foust, T.; Himmel, M.E.; Laser, M.S.; Wang, M.; Wyman, C.E. Cellulosic ethanol: Status and innovation. Curr. Option Biotechnol. 2017, 45, 202–211. [Google Scholar] [CrossRef] [Green Version]

- Wang, M.; Han, J.; Dunn, J.B.; Cai, H.; Elgowainy, A. Well-to-wheels energy use and greenhouse gas emissions of ethanol from corn, sugarcane and cellulosic biomass for US use. Environ. Res. Lett. 2012, 7, 045905. [Google Scholar] [CrossRef] [Green Version]

- Zabed, H.; Sahu, J.N.; Suely, A.; Boyce, A.N.; Faruq, G. Bioethanol production from renewable sources: Current perspectives and technological progress. Renew. Sustain. Energy Rev. 2017, 71, 475–501. [Google Scholar] [CrossRef]

- Zhao, Y.; Damgaard, A.; Christensen, T.H. Bioethanol from corn stover: A review and technical assessment of alternative biotechnologies. Prog. Energy Combust. Sci. 2018, 67, 275–291. [Google Scholar] [CrossRef] [Green Version]

- Jaiswal, D.; de Souza, A.; Larsen, S.; LeBauer, D.S.; Miguez, F.; Sparovek, G.; Bollero, G.; Buckeridge, M.S.; Long, S.P. Brazilian sugarcane ethanol as an expandable green alternative to crude oil use. Nat. Clim. Chang. 2017, 7, 788–791. [Google Scholar] [CrossRef]

- Prasad, S.; Singh, A.; Korres, N.E.; Rathore, D.; Sevda, S.; Pant, D. Sustainable utilization of crop residues for energy generation: A life cycle assessment (LCA) perspective. Bioresour. Technol. 2020, 303, 122964. [Google Scholar] [CrossRef]

- World Bioenergy Association. WBA Global Bioenergy Statistics. 2016. Available online: https://worldbioenergy.org/uploads/WBA%20Global%20Bioenergy%20Statistics%202016.pdf (accessed on 20 July 2020).

- SCOPE. Bioenergy & Sustainability: Bridging the Gaps; Souza, G.M., Victoria, R.L., Joly, C.A., Verdade, L.M., Eds.; SCOPE: Paris, France, 2012; ISBN 978-2-9545557-0-6. [Google Scholar]

- CGEE. Sustainability of Sugarcane Bioenergy. Brasília, DF, Brasil. 2012. Available online: http://livroaberto.ibict.br/bitstream/1/910/1/Sustainability_sugarcane_bioenergy.pdf (accessed on 20 July 2020).

- Manochio, C.; Andrade, B.R.; Rodriguez, R.P.; Moraes, B.S. Ethanol from biomass: A comparative overview. Renew. Sustain. Energy Rev. 2017, 80, 743–755. [Google Scholar] [CrossRef]

- Cavalett, O.; Chagas, M.F.; Junqueira, T.L.; Watanabe, M.D.B.; Bonomi, A. Environmental impacts of technology learning curve for cellulosic ethanol in Brazil. Ind. Crop. Prod. 2017, 106, 31–39. [Google Scholar] [CrossRef]

- Junqueira, T.L.; Chagas, M.F.; Gouveia, V.L.; Rezende, M.; Watanabe, M.D.B.; Jesus, C.; Cavalett, O.; Milanez, A.; Bonomi, A. Techno-economic analysis and climate change impacts of sugarcane biorefineries considering different time horizons. Biotechnol. Biofuels 2017, 10, 50. [Google Scholar] [CrossRef] [Green Version]

- California Air Resource Board. Low Carbon Fuel Standard. 2020. Available online: https://ww2.arb.ca.gov/our-work/programs/low-carbon-fuel-standard (accessed on 14 July 2021).

- British Columbia. Greenhouse Gas Reduction (Renewable and Low Carbon Fuel Requirements) Act Renewable and Low Carbon Fuel Requirements Regulation B.C. Reg. 394/2008. Consolidation current to August 7, 2020. Available online: https://www.bclaws.ca/civix/document/id/crbc/crbc/394_2008 (accessed on 13 November 2020).

- EU. Directive (EU) 2018/2001 of the European Parliament and of the Council of 11 December 2018. 2018. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=uriserv:OJ.L_.2018.328.01.0082.01.ENG&toc=OJ:L:2018:328:TOC (accessed on 13 November 2020).

- ANP. Agência Nacional do Petróleo, Gás Natural e Biocombustíveis. RenovaBio. 2020. Available online: http://www.anp.gov.br/producao-de-biocombustiveis/renovabio (accessed on 13 November 2020).

- Peña, C.; Civit, B.; Gallego-Schmid, A.; Druckman, A.; Caldeira-Pires, A.; Weidema, B.; Mieras, E.; Wang, F.; Fava, J.; Canals, L.M.; et al. Using life cycle assessment to achieve a circular economy. Int. J. Life Cycle Assess. 2021, 26, 215–220. [Google Scholar] [CrossRef]

- Gerbrandt, K.; Chu, P.L.; Simmonds, A.; Mullins, K.A.; MacLean, H.L.; Griffin, M.W.; Saville, B.A. Life cycle assessment of lignocellulosic ethanol: A review of key factors and methods affecting calculated GHG emissions and energy use. Curr. Opin. Biotechnol. 2016, 38, 63–70. [Google Scholar] [CrossRef]

- Pereira, L.G.; Cavalett, O.; Bonomi, A.; Zhang, Y.; Warner, E.; Chum, H.L. Comparison of biofuel life-cycle GHG emissions assessment tools: The case studies of ethanol produced from sugarcane, corn, and wheat. Renew. Sustain. Energy Rev. 2019, 110, 1–12. [Google Scholar] [CrossRef]

- Bonomi, A.; Cavalett, O.; Cunha, M.P.; Lima, M.A.P. Virtual Biorefinery—An Optimization Strategy for Renewable Carbon Valorization; Springer International Publishing: Kamm, Switzerland, 2016. [Google Scholar]

- Cherubini, F.; Strømman, A.H.; Ulgiati, S. Influence of allocation methods on the environmental performance of biorefinery products—A case study. Resour. Conserv. Recycl. 2011, 55, 1070–1077. [Google Scholar] [CrossRef]

- Cherubini, F.; Fuglestvedt, J.; Gasser, T.; Reisinger, A.; Cavalett, O.; Huijbregts, M.A.J.; Levasseur, A. Bridging the gap between impact assessment methods and climate science. Environ. Sci. Policy 2016, 64, 129–140. [Google Scholar] [CrossRef] [Green Version]

- Hoefnagels, R.; Smeets, E.; Faaij, A. Greenhouse gas footprints of different biofuel production systems. Renew. Sustain. Energy Rev. 2010, 14, 1661–1694. [Google Scholar] [CrossRef]

- RFA. Renewable Fuel Associations—Statistics Annual World Fuel Ethanol Production (Mil. Gal.). 2021. Available online: https://ethanolrfa.org/statistics/annual-ethanol-production/ (accessed on 13 August 2021).

- CARB. California Air Resource Board. LCFS Basics with Notes. 2020. Available online: https://ww2.arb.ca.gov/sites/default/files/2020-09/basics-notes.pdf (accessed on 14 July 2021).

- CARB. California Air Resource Board. CA-GREET3.0 Supplemental Document and Tables of Changes. 2018. Available online: https://ww2.arb.ca.gov/sites/default/files/classic//fuels/lcfs/ca-greet/cagreet_supp_doc_clean.pdf (accessed on 14 July 2021).

- OR. Oregon′s Clean Fuels Program. Fuel Pathways—Carbon Intensity Values. 2021. Available online: https://www.oregon.gov/deq/ghgp/cfp/Pages/Clean-Fuel-Pathways.aspx (accessed on 28 January 2021).

- British Columbia. Renewable & Low Carbon Fuel Requirements Regulation. 2020. Available online: https://www2.gov.bc.ca/gov/content/industry/electricity-alternative-energy/transportation-energies/renewable-low-carbon-fuels (accessed on 13 November 2020).

- British Columbia. Using GHGenius in B.C. 2017. Available online: https://www2.gov.bc.ca/assets/gov/farming-natural-resources-and-industry/electricity-alternative-energy/transportation/renewable-low-carbon-fuels/rlcf010_-_using_ghgenius_for_bc.pdf (accessed on 13 November 2020).

- California. Clean Fuel Standard. 2020. Available online: https://www.canada.ca/en/environment-climate-change/services/managing-pollution/energy-production/fuel-regulations/clean-fuel-standard.html (accessed on 14 July 2021).

- California. Clean Fuel Standard: Proposed Regulatory Approach. 2020. Available online: https://www.canada.ca/en/environment-climate-change/services/managing-pollution/energy-production/fuel-regulations/clean-fuel-standard/regulatory-approach.html#toc55 (accessed on 14 July 2021).

- EU. Directive 2009/28/EC of the European Parliament and of the Council of 23 April 2009. 2009. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:32009L0028&from=EN (accessed on 13 November 2020).

- Edwards, R.; O′Connell, A.; Padella, M.; Giuntoli, J.; Koeble, R.; Bulgheroni, C.; Marelli, L.; Lonza, L. Definition of Input Data to Assess GHG Default Emissions from Biofuels in EU Legislation. Version 1d. 2019. Available online: https://ec.europa.eu/jrc/en/publication/definition-input-data-assess-ghg-default-emissions-biofuels-eu-legislation (accessed on 13 November 2020).

- CNPEM. Relatório Anual 2019 Partes II e III. 2019. Available online: https://cnpem.br/wp-content/uploads/2019/09/RelatorioCG-2019-Parte-IIeIII.pdf (accessed on 13 November 2020).

- Klein, B.C.; Chagas, M.F.; Watanabe, M.D.B.; Bonomi, A.; Maciel Filho, R. Low carbon biofuels and the New Brazilian National Biofuel Policy (RenovaBio): A case study for sugarcane mills and integrated sugarcane-microalgae biorefineries. Renew. Sustain. Energy Rev. 2018, 115, 109365. [Google Scholar] [CrossRef]

- Matsuura, M.I.S.F.; Scachetti, M.T.; Chagas, M.F.; Seabra, J.; Moreira, M.M.R.; Bonomi, A.; Bayma, G.; Picoli, J.F.; Morandi, M.A.B.; Ramos, N.P.; et al. RenovaCalcMD: Método e Ferramenta Para a Contabilidade da Intensidade de Carbono de Biocombustíveis no Programa RenovaBio. 2018. Available online: http://www.anp.gov.br/images/Consultas_publicas/2018/n10/CP10-2018_Nota-Tecnica-Renova-Calc.pdf (accessed on 20 July 2020).

- (S&T)2 Consultants Inc. GHGenius Model 5.0c. 2018. Available online: https://ghgenius.ca/index.php/downloads (accessed on 20 July 2020).

- ANL. GREET Model. 2018. Available online: https://greet.es.anl.gov/ (accessed on 20 July 2020).

- Edwards, R.; Padella, M.; Giuntoli, J.; Koeble, R.; O’Connell, A.; Bulgheroni, C.; Marelli, L. Biofuels Pathways. Input Values and GHG Emissions. Database (COM(2016)767). European Commission, Joint Research Centre (JRC) [Dataset]. 2016. Available online: http://data.europa.eu/89h/jrc-alf-bio-biofuels_jrc_annexv_com2016-767_v1_july17 (accessed on 20 July 2020).

- Bonomi, A.; Cavalett, O.; Klein, B.C.; Chagas, M.F.; Souza, N.R.D. Technical Report—Comparison of Biofuel Life Cycle Analysis Tools, Phase 2, Part 2: Comparison of LCA Models for Biochemical Second Generation (2G) Ethanol Production and Distribution. IEA Bioenergy. Task 39—Commercializing Liquid Biofuels. 2020. Available online: http://task39.sites.olt.ubc.ca/files/2020/01/Task-39-Phase-2.2-Ethanol-2G-Comparison-of-Biofuel-Life-Cycle-Analysis-Tools.pdf (accessed on 10 July 2021).

- IPCC. Climate Change 2007—The Physical Science Basis. Contribution of Working Group I to the Fourth Assessment Report of the IPCC; Cambridge University Press: Cambridge, UK, 2007; ISBN 978 0521 88009-1. [Google Scholar]

- Obnamia, J.A.; Dias, G.M.; MacLean, H.L.; Saville, B.A. Comparison of U.S. Midwest corn stover ethanol greenhouse gas emissions from GREET and GHGenius. Appl. Energy 2019, 235, 591–601. [Google Scholar] [CrossRef]

- Edwards, R.; Padella, M.; Giuntoli, J.; Koeble, R.; O’Connell, A.; Bulgheroni, C.; Marelli, L. Appendix 1—Outcomes of Stakeholders Consultations. Definition of Input Data to Assess GHG Default Emissions from Biofuels in EU Legislation, Version 1c—July 2017, EUR 28349 EN; Publications Office of the European Union: Luxembourg, 2017; ISBN 978-92-79-66185-3. [Google Scholar] [CrossRef]

- Humbird, D.; Davis, R.; Tao, L.; Kinchin, C.; Hsu, D.; Aden, A.; Schoen, P.; Lukas, J.; Olthof, B.; Worley, M.; et al. Process Design and Economics for Biochemical Conversion of Lignocellulosic Biomass to Ethanol. NREL. 2011. Available online: https://www.nrel.gov/docs/fy11osti/47764.pdf (accessed on 20 July 2020).

- Wu, M.; Wang, M.; Huo, H. Fuel-Cycle Assessment of Selected Bioethanol Production Pathways in the United States. 2006. Available online: https://greet.es.anl.gov/files/2lli584z (accessed on 20 July 2020.).

- Johnson, E. Integrated enzyme production lowers the cost of cellulosic ethanol. Biofuels Bioprod. Biorefining 2016. [Google Scholar] [CrossRef] [Green Version]

- Bonomi, A.; Klein, B.C.; Chagas, M.F.; Souza, N.R.D. Technical Report—Comparison of Biofuel Life Cycle Analysis Tools. Phase 2, Part 1: FAME and HVO/HEFA. IEA Bioenergy. Task 39—Commercializing Liquid Biofuels. 2019. Available online: http://task39.sites.olt.ubc.ca/files/2019/08/Task-39-CTBE-biofuels-LCA-comparison-Final-Report-Phase-2-Part-1-2019.pdf (accessed on 10 July 2021).

- B3. Renda Fixa. Dados Por Ativo. 2021. Available online: http://www.b3.com.br/pt_br/market-data-e-indices/servicos-de-dados/market-data/historico/renda-fixa/ (accessed on 21 January 2021).

- 26 U.S. Code § 45Q—Credit for Carbon Oxide Sequestration. Available online: https://www.law.cornell.edu/uscode/text/26/45Q (accessed on 20 August 2021).

| BC-LCFS | CA-LCFS | RED | RenovaBio | |

|---|---|---|---|---|

| Geographical representation | British Columbia/Canada | California/USA | Europe Union | Brazil |

| Calculator | GHGenius | CA-GREET 3.0 | No standard tool 1 | RenovaCalc |

| Carbon intensity calculation methodology | LCA | LCA | LCA | LCA |

| Use of default values | Allowed in case of data gap | Producers must provide specific values for ethanol | Use of total default values and disaggregated default values, actual data and combinations of these last two are possible | Use of default values are penalized |

| Functional unit | gCO2eq. MJ−1 | gCO2eq. MJ−1 | gCO2eq. MJ−1 | gCO2eq. MJ−1 |

| Approach | Attributional LCA | Attributional LCA | Attributional LCA | Attributional LCA |

| Boundaries | Well-to-wheels | Well-to-wheels | Well-to-wheels | Well-to-wheels |

| Characterization factor | GWP 100 AR4 IPCC | GWP 100 AR4 IPCC 2 | GWP 100 AR4 IPCC | GWP100 AR5 IPCC |

| Allocation procedure | Displacement of coproducts emissions | Mass and energetic. Displacement of coproducts emissions | Energetic | Energetic |

| Fuel pathways |

|

|

|

|

| Biomass production | Account for land use change emissions, modelled with GHGenius. | Account for land use change emissions, modelled with GTAP/AEZ-EF. | Protection of land with high biodiversity and high-carbon stock. Penalty for biomass produced in areas that were not agriculture in January 2008 and from severely degraded land. | No suppression of native vegetation. Brazilian farms must be registered in Cadastro Ambiental Rural (CAR). Sugarcane AgroEcological zoning and Palm AgroEcological Zoning. |

| Considered biomasses |

|

|

|

|

| Considered residues |

|

|

|

|

| GHGenius | GREET | New EC | VSB | |

|---|---|---|---|---|

| Model version | 5.0c (2018) | 2018 | 2017 | 2019 |

| Geographical representation | Canada | USA | Europe | Brazil |

| Developed for regulatory use | No 1 | No | Yes | No |

| Global warming gases included | CO2, CH4, N2O, CO, VOC, NOx, fluorinated compounds | CO2, CH4, N2O | CO2, CH4, N2O | CO2, CH4, N2O |

| Lifecycle data | Internal | Internal | Internal | Ecoinvent database |

| Functional units | km, MJ | km, mile Btu, MJ | MJ | km, MJ |

| Default allocation | Substitution | Substitution | Energy | Economic |

| Land use change | - | CCLUB | C stocks | - |

| System boundaries | Well-to-wheel | Well-to-wheel | Well-to-pump | Well-to-wheel |

| IPCC GWP method | 1995, 2001, 2007, 2013 | 2013 | 2007 | 2007 |

| Default characterization factors for GWP100 | CO2: 1; CH4: 25; N2O: 298 | CO2: 1; CH4: 30; N2O: 265 | CO2: 1; CH4: 25; N2O: 298 | CO2: 1; CH4: 25; N2O: 298 |

| GHGenius | GREET | New EC | VSB | |

|---|---|---|---|---|

| Corn stover | X | X | ||

| Forest residues | X | X | X | |

| Wheat straw | X | X | ||

| Sugarcane straw | X | |||

| Sugarcane bagasse and straw | X |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rinke Dias de Souza, N.; Colling Klein, B.; Ferreira Chagas, M.; Cavalett, O.; Bonomi, A. Towards Comparable Carbon Credits: Harmonization of LCA Models of Cellulosic Biofuels. Sustainability 2021, 13, 10371. https://doi.org/10.3390/su131810371

Rinke Dias de Souza N, Colling Klein B, Ferreira Chagas M, Cavalett O, Bonomi A. Towards Comparable Carbon Credits: Harmonization of LCA Models of Cellulosic Biofuels. Sustainability. 2021; 13(18):10371. https://doi.org/10.3390/su131810371

Chicago/Turabian StyleRinke Dias de Souza, Nariê, Bruno Colling Klein, Mateus Ferreira Chagas, Otavio Cavalett, and Antonio Bonomi. 2021. "Towards Comparable Carbon Credits: Harmonization of LCA Models of Cellulosic Biofuels" Sustainability 13, no. 18: 10371. https://doi.org/10.3390/su131810371

APA StyleRinke Dias de Souza, N., Colling Klein, B., Ferreira Chagas, M., Cavalett, O., & Bonomi, A. (2021). Towards Comparable Carbon Credits: Harmonization of LCA Models of Cellulosic Biofuels. Sustainability, 13(18), 10371. https://doi.org/10.3390/su131810371