Abstract

In recent years, because of outdoor ultrafine particles, residential heat recovery ventilators (HRVs) have been used with high efficiency filters by residents in Korea. However, as pre-filters are primarily used in residential HRVs, when a high-efficiency particulate air (HEPA) filter is installed, the filter pressure drop increases, reducing the airflow rate, which requires the fan to draw more power to maintain the airflow rate. Therefore, in this study, the change in power usage of HRVs installed in residential apartments in Korea with various air volumes and filters were analyzed. The results show that HEPA filters consumed 13.5–17.5% (16.1% on an average), 11.8–16.0% (13.8% on an average), and 16.8–41.3% (30.1% on an average) more power at 0.5, 1.0, and 1.5 air changes/h, respectively, than the pre-filter. These results indicate that unexpected power consumption increase could be caused if a pre-filter is replaced with a HEPA filter in residential small air-volume HRVs. This may lead to noise or failure due to fan overload. Thus, it is necessary to operate residential HRVs at the optimum air volume according to the fan performance.

1. Introduction

Generally, heating and cooling systems are not provided ventilation functions in Korean residential buildings. As indoor air quality became a social issue in the early 2000s, building permits for apartment complexes with 100 or more units have required the installation of ventilation facilities since 2006 [1]. Currently, the installation of ventilation facilities is required in complexes with more than 30 units [2].

Residential heat recovery ventilators (HRVs) have been widely employed because they achieve both ventilation and energy-saving effects. Recently, several studies regarding the improvement in indoor air quality have been conducted to determine when the concentration of external ultra-fine particulate matters reaches a level that threatens respiratory health [3,4]. An HRV consists of a fan, heat exchanger, damper, and supply filter, which cleans particulate air pollution. Various types of filters can be installed; however, a pre-filter is usually used for residential HRVs [5]. With the increasing issue of indoor air pollution caused by ultra-fine particulate matters, many apartment residents in Korea have replaced their HRV filters with high-efficiency particulate air (HEPA) filters [6].

For air-handling units applied in non-residential buildings, mechanical-facility engineers determine the fan specifications by considering the heating and cooling loads, and external and internal static pressure losses [7]. Therefore, the equipment could be designed in advance by anticipating existing problems such as energy and noise increase caused by the use of high-performance filters with ventilation fans. However, residential buildings generally install ready-made ventilation units with only ventilation function because traditional floor heating systems are installed in Korean apartments at the construction stage. If a resident arbitrarily installs a high-performance filter in this ready-made ventilation unit, various unexpected problems such as airflow decrease, noise and power consumption increase could occur [8]. Studies on not only the justification for installing a high-performance filter in a ventilation system of a residential building [9,10], but also the energy consumption of ventilation systems with high-performance filters have been conducted [11]. Theoretically, in the case of no fan speed control, installing a high-performance filter leads to a higher filter pressure drop and airflow decrease [12,13].

In addition, it has been reported that the fan power increases with an increase in the filter performance [8], and system energy including heating and cooling energy [14,15]. Conversely, other studies show that installing a high-performance filter in a residential heating, ventilating, and air conditioning system (HVAC) has a negligible increase in fan energy or that the overall increase in system energy is negligible [13,16,17,18].

These results show that system energy use may vary depending on the system’s performance. Some studies on Korean ventilation systems show that high-performance filter installation induced an approximate 20–30% air flow decrease and a 23% fan power draw decrease [8,19,20]. In practical use, the pressure drop may be larger than that of the research results, because the more polluted the filter, the greater the pressure drop [21,22,23]. According to the relevant literature review, studies on the increase in energy consumption when a high-performance filter is installed in a residential HVAC system increased from 2010 to 2015, but in the last 2–3 years the relevant studies have been limited [11]. Conversely, in Korea, related research has been increasing recently, because the domestic ultrafine dust problem has become more serious. Floor heating systems are installed during the construction phase in Korea and a separate air conditioning system can be installed according to the residents’ choice for cooling. As a result, ventilators without heating and cooling systems have been installed in Korean apartments.

Recently, there have been some studies on fan energy increase with HEPA filter installation in residential ventilators in Korea. However, most of them have been carried out in chambers [8,19,20], which could provide different results from those in a field experiment.

According to Korean standards, a 0.5 air change per hour (ACH) has been suggested as the minimum capacity for residential ventilators, which is insignificant compared with the air flow capacity of HVAC systems. Therefore, small-capacity fans are generally used for residential ventilators in Korea. When HEPA filters are installed in residential HRVs with a small air flow fan, the filter pressure drop increases, reducing the airflow rate, requiring the fan to draw significantly more power to maintain the required airflow rate.

After the Paris Agreement, Korea enacted a law requiring 20% or more of the primary energy consumption to be produced by the building itself in order to obtain a permit for buildings of a total floor area of 500 m2 or more from 2030 to reduce greenhouse gas emissions in the building sector [24]. To achieve this, a reduction in ventilation fan energy using electricity is also inevitable. Currently, most apartments in Korea are ventilating all rooms, but it is expected that room control will be applied in the near future to reduce fan energy [25]. For this reason, in this study, we analyzed the changes in fan power by assuming a case where room control was applied to an HRV with a HEPA filter installed in an apartment with a representative structure in Korea. In this study, analysis of dead zones and short circuits were excluded.

2. Materials and Methods

2.1. Experimental Methods

The leakage rate of an HRV can significantly affect the airflow rate/filter, thereby altering the power usage. Accordingly, the HRV used in this experiment was air-tight fabricated, and a best performance filter was installed to conduct a KS B 6879 standard test [26] to determine the net supply airflow rate ratio and the rated power draw.

An 84 m2 apartment unit, which is the representative size of Korean apartments [27], was selected as the test site and the HRV, duct system, variable air volume diffusers, and measurement equipment were installed to conduct the experiments.

The experimental conditions were specified according to the filter and room use, and the appropriate air volume was reviewed to determine the conditions. In addition, a room control system was built to obtain data under various conditions and volumes, allowing experimental conditions according to various room uses.

Under these experimental conditions, pressure differences observed for the filter and changes in the ventilator power usage were measured and analyzed. The instruments used for these measurements are described in Section 2.3.

2.2. Performance of Heat Recovery Ventilator

To verify the HRV performance, a test according to the KS B 6879 “Heat Recovery Ventilator” was conducted by the K-authorized testing institution.

The experiment was conducted at 150 m3/h (CMH) of test air volume in the chamber and 100 Pa of static pressure outside the HRV, as shown in Figure 1, when a HEPA (H13 grade) filter was installed. The heat exchanger in the HRV used in the test was a sensible heat exchanger, composed of polyethylene terephthalate, and the fan was of a brushless direct current forward type. An H13 grade filter was applied, which achieved a 99.97% dust-collection efficiency rate when using the total particle counting method according to EN 1822 [28]. Thus, in this study, we conducted an authorized test of KS B 6879 from a K testing institution located in Pyeongtaek, Gyeonggi-do for the ventilation unit with an H13 filter, which was conducted at the experimental apartment site.

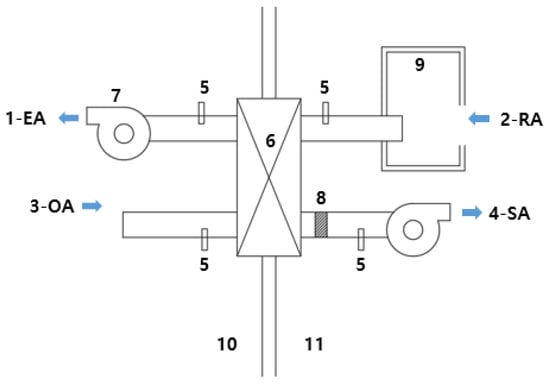

Figure 1.

Diagram of the test rig for air leakage rate test. (1: exhaust airflow (EA); 2: return airflow (RA); 3: outdoor airflow (OA); 4: supply airflow (SA); 5: tracer gas sampler; 6: Ventilator; 7: Fan; 8: air mixer; 9: tracer gas source; 10: outdoor test facility; 11: indoor test facility).

Under the KS B 6789 test condition, the effective ventilation of the ventilator was 98% (2% of air leakage rate), and the power usage at 100 Pa of external static pressure and 150 CMH of air volume was 72 W, as listed in Table 1.

Table 1.

HRV performance test results.

2.3. Test Site

The test site in this study was an 84 m2 unit, which consisted of a living room and three bedrooms. The living room and two rooms of the same size faced south, whereas the remaining room faced north (Figure 2a). External air was introduced via a ventilator (Figure 2b) installed in the main entrance hall and moved up to the diffuser (Figure 2c) along the supply airflow duct. The fan speed of the ventilator was controllable.

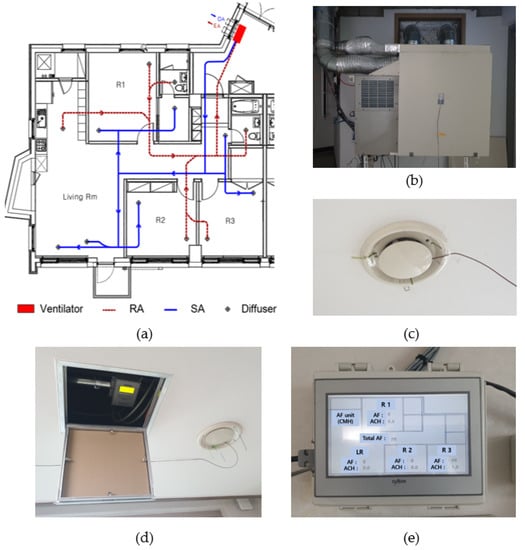

Figure 2.

Test-site plan with duct and diffusers for experiments; (a) duct work, (b) ventilator, (c) diffuser, (d) flow metering system (FMS), and (e) display of rooms’ airflow.

As the purpose of the study was to verify the changes in the power draw according to the pressure drop when using a HEPA filter in a residential HRV, the duct leakage was not checked. As air leakage may increase in a ventilator before and after a filter is installed, the air leakage in the ventilation unit was checked with chamber testing before installing the ventilator in the house. The air volume supplied to each room after the HEPA filter was installed was measured via a flow metering system (FMS; Airtron) located at the bottom of the duct (Figure 2d). According to the flow rate, the pressure difference was measured by a pitot probe embedded in the FMS, and then converted to an air volume and displayed in the monitor via power line communication (Figure 2e). As shown in Figure 2e, the ACH and air volume in each room were identified, and the fan’s power draw was checked using the power meter installed in the ventilator.

The applied diffuser was a motor diffuser to control the ventilation amount by controlling the opening rate. It could be fully closed and could block ventilation when ventilation was not needed.

Different filter pressure drops were measured with the differential pressure transmitter (DP100) found in the HRVs. An SJPM-C16 power meter was used to check the power draw of the HRV fan. Table 2 summarizes the measurement accuracies of the installed measurement instruments.

Table 2.

Measuring equipment accuracies.

2.4. Test Conditions

- (1)

- Experiment air filters

According to a previous study on 63 residential HRVs sold by 15 Korean companies, only a pre-filter was applied to most residential HRVs, of which approximately 70% did not provide information regarding filter performance [5]. However, most products applied HEPA filters to air cleaners to address the ultra-fine particulate matter problem [29]. Thus, in this study, we conducted tests by applying a HEPA filter (H13), a medium filter (E10), and a pre-filter, which have been generally used in residential HRVs [8]. The manufacturer filter specifications and test standards are summarized in Table 3. Medium filter and HEPA filter are 3 cm thick, and their size is 30 cm × 30 cm.

Table 3.

Air filter units for experiments.

This experiment targeted a clean filter whose length of use was less than 1 month.

With the application of a high-efficiency air filter, when the pressure drop across the filter rises, the system curve fluctuates, and the air volume decreases. Thus, to maintain the same air volume, a higher level of fan power is needed, which can vary depending on the fan characteristics or static pressure increase, making it difficult to estimate the required fan power accurately.

- (2)

- Air volumes for experiments

The minimum air flow rate for experiments was decided with the relevant rules and standards. According to the Rules on the Facility Standards of Buildings in Korea [2], a residential ventilator that satisfies 0.5 ACH should be used for mechanical ventilation systems installed in apartments, and should accommodate the minimum, optimum, and maximum steps of ventilation. In addition, according to the ASHRAE Standard 62.2, an 84 m2 apartment unit with 3 bedrooms and 1 living room needs to satisfy 28 L/s ventilation air flow rate requirement [31], which could be 100.8 m3/h and approximately 0.52 ACH in the apartment unit for experiments.

The maximum air flow rate for experiments was determined with the present CO2 concentration and standards for maintaining indoor air quality. The CO2 concentration of 416.5 ppm was recorded in May 2021 in Mauna Loa, Hawaii [32]. Considering the CO2 maintenance standard of 1000 ppm, which is used in several research [33,34] and the expiratory volume of 18 L/h at light work for one adult [35], a ventilation rate of 1.5 ACH is required for two people in a couple’s bedroom (R1). Therefore, the maximum was set to 1.5 ACH. Finally, as this ventilation system should be controlled in three stages, 1.0 ACH, in between 0.5 and 1.5 ACH, was set as the intermediate setting value.

Accordingly, the minimum ventilation rate for experiments was 0.5 ACH; thus, three levels of 0.5, 1.0, and 1.5 ACH were adopted for the three filter conditions.

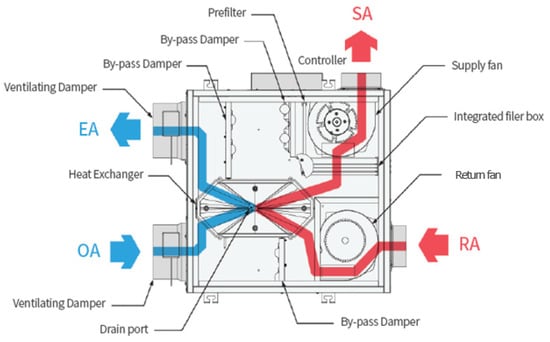

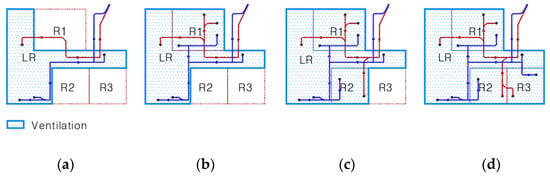

The mode was the heat recovery ventilation mode, as shown in Figure 3, and for the modes applied in winter and summer, the heat exchange element and filter were passed. Thus, the static pressure loss by the heat exchanger element and that by the filter were reflected in fan power. Additionally, because air volume varied according to the system pressure drop if only the living room and entire house were ventilated, the room control cases under various conditions were considered. As the living room is a family gathering space as well as a passage space, it was assumed to be ventilated in all cases. As shown in Figure 4, a total of four-room control cases were considered, indicating that there were 36 different test conditions.

Figure 3.

Heat recovery ventilation mode.

Figure 4.

Room ventilation cases for experiments. (a) LR; (b) LR + R1; (c) LR + R1 + R2; (d) all rooms.

The opening rate of the diffuser was controlled to apply the same ACH/room before the experiment. The ACH/room was displayed every second on the monitor shown in Figure 2e and was measured six times/s (by the FMS located at the bottom of the duct) and averaged (Figure 2d). Thus, testing, adjusting, and balancing were performed, and these aspects can be checked. The experimental cases were adjusted by fully closing and opening the diffuser in each room. Due to a lack of field experiments, ±0.1 of the target ACH was considered as satisfactory.

The power draw and pressure drop across the filters were measured at three ACH and under four-room control conditions with an installed pre-filter. The power usage was compared using the medium and HEPA filters to determine the level of power changes.

The pre-filter was installed first, for which the power and total air volume were measured when the target ACH was reached. The measured air volume slightly changed during the experiment because of certain variables, including eddies inside the duct at the same fan revolutions per minute (RPM) under the same condition while conducting the experiment. Thus, six measurements, one every 30 s for 3 min, were obtained, and the median value was used for the experiment.

3. Research Results and Discussion

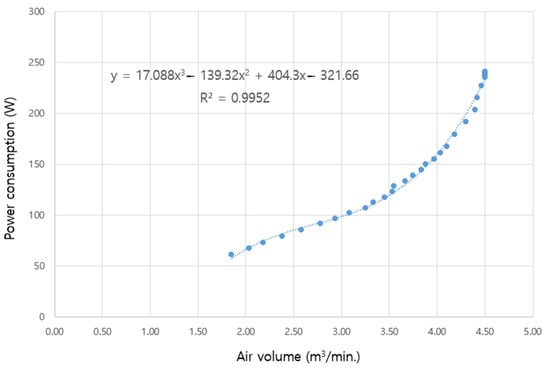

The initial test conducted to identify the fan’s performance verified that the fan performance exhibited the maximum air volume under the full room ventilation condition (Figure 3) when the HEPA filter installed was 4.5CMM (m3/min, 270 CMH), which led to the realization of a power consumption of 240.6 W.

Figure 5 shows the relationship between air volume and power consumption, in which the air volume does not increase, but power consumption increases even if the fan RPM increases at 4.5 CMM of air volume.

Figure 5.

Power consumption at the ventilation unit with a high-efficiency particulate air (HEPA) filter installed under full-room ventilation conditions.

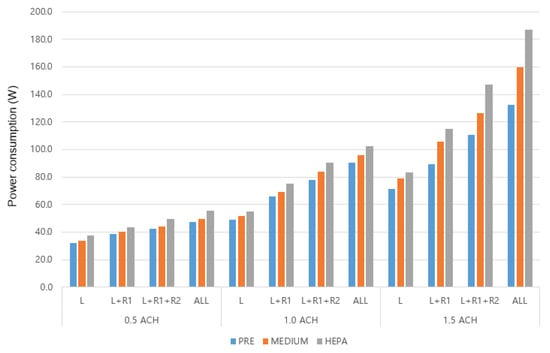

Table 4 and Figure 6 summarize the comparison results of rooms for ventilation and ACH by filter, whereas Table 5 presents the detailed results according to different filters, flow paths, and flow rates. When the medium or HEPA filters were installed, the power consumption exceeded that of the pre-filter at the same air volume. Under the same flow path and flow rate, power draws tended to increase with an increase in differential pressure. Meanwhile, under the same flow path and pressure loss conditions, power consumption tended to increase with an increasing flow rate.

Table 4.

Power draw comparison results.

Figure 6.

Power draw results according to different filters, flow paths, and flow rates (Note: HEPA: high-efficiency particulate air filter, Medium: medium filter, Pre: pre-filter, L: living room, R: room, All: all rooms (Figure 4d)).

Table 5.

Power draw results according to different filters, flow paths, and flow rates.

The results are as follows:

The medium and HEPA filters at the 0.5 ACH air volume condition consumed 3.5–5.0% (4.2% on an average) and 13.5–17.5% (16.1% on an average) more power than that of the pre-filter, respectively.

The medium and HEPA filters at 1.0 ACH air volume condition consumed 4.4–7.4% (5.9% on an average) and 11.8–16.0% (13.8% on an average) more power than that of the pre-filter, respectively.

Power consumption increased based on the filter change at 1.5 ACH air volume condition. Specifically, the medium and HEPA filters consumed 10.3–20.9% (16.1% on an average) and 16.8–41.3% (30.1% on an average) more power than pre-filter, respectively. Furthermore, for the full-room control when the required air volume was 235 CMH, the power consumption increased by 41.3% when the pre-filter was replaced with the HEPA filter.

4. Conclusions

In this study, the change in power consumption when a high-performance filter is installed in a residential ventilation system in Korea was analyzed through field experiments by reflecting the case of a room control mode in a standard apartment in Korea. Under 0.5 ACH and 1.0 ACH experiment conditions, the increase in power consumption showed a similar pattern in all filters. On the contrary, the 1.5 ACH test case and the combination of the high-performance filter tended to show a sharp increase in energy consumption, different from the other cases. For example, the HEPA filter case at a 1.5 ACH flow rate for all rooms resulted in a 41.3% increase in power draw, compared with the same pre-filter case. Under the HEPA filter case with a 1.0 ACH flow rate for all rooms, a 13.7% power draw increase was observed, compared with that under the same pre-filter case. This indicates that unexpected power consumption increases could be caused if a HEPA filter replaces a pre-filter in residential small air-volume HRV units. Furthermore, this experiment targeted a clean filter whose length of use was less than 1 month. Thus, if the filter becomes dirty and the differential pressure increases, power consumption will further increase.

A limitation of this study is that the results were obtained using one heat recovery ventilator installed in the field, and conditions were set based on the statutory ventilation frequency. Moreover, the analysis of required ventilation conditions according to actual resident behavior patterns was excluded. Nevertheless, this study is meaningful in that it analyzed the fan power via various ventilation routes and filters applied with room-specific control, which is not generally applied in residential buildings in Korea, through field experiments along with filter resistance. In future studies, indoor ultrafine dust conditions according to residents’ behavior patterns and climatic conditions will be carried out and the optimal ventilation volume will be analyzed accordingly. In addition, ventilation control strategies for each room will be researched to achieve the optimal air cleaning effect with minimum energy.

Author Contributions

K.C. performed the experiments, analyzed the data, and wrote the original draft; C.-U.C. and D.C. carried out the project administration and reviewed the paper: T.K. reviewed the paper. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the Korea Agency for Infrastructure Technology Advancement (KAIA) grant funded by the Ministry of Land, Infrastructure and Transport [grant number 21SHTD-B157018-02].

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data supporting the reported results in the present study will be available on request from the corresponding author or the first author.

Conflicts of Interest

The authors declare no conflict of interest.

References

- The Government of Korea. Ministry of Land, Infrastructure and Transport (MLIT), Presidential Decree No. 467, Rules on the Facility Standards of Buildings; The Government of Korea: Seoul, Korea, 2017.

- The Government of Korea. MLIT. Presidential Decree No. 715, Rules on the Facility Standards of Buildings; The Government of Korea: Seoul, Korea, 2020.

- Brook, R.D.; Rajagopalan, S.; Pope, C.A.; Brook, J.R.; Bhatnagar, A.; DiezRoux, A.V.; Holguin, F.; Hong, Y.; Luepker, R.V.; Mittleman, M.A.; et al. Particulate matter air pollution and cardiovascular disease. Circulation 2010, 121, 2331–2378. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Choe, J.; Lee, Y. A study on the impact of PM2.5 emissions on respiratory diseases. J. Environ. Policy Admin. 2015, 23, 155–172. [Google Scholar] [CrossRef]

- Kim, M.; Park, J.; Lee, J. Development of pre-filter system for improving particulate matter filtering performance of multi-unit heat recovery ventilation system. Korean Soc. Living Environ. 2019, 26, 641–648. [Google Scholar] [CrossRef]

- Song, Y. Evaluation of particulate matter removal rate according to filter type and thickness of total heat exchanger in apartment houses. LHI J. 2020, 11, 93–98. [Google Scholar]

- Won, K.; Kwak, R.; Huh, J. Evaluation of energy consumption of HVAC system of air filter pressure change in commercial buildings. Korean J. Air-Cond. Refrig. Eng. 2004, 16, 1227–1234. [Google Scholar]

- Kang, Y.; Kim, J.; Seo, J.; Jeon, B.; Ahn, Y. A study on the performance variations of an energy-recovery ventilator using a pre-filter and HEPA grade filters. Korean J. Air-Cond. Refrig. Eng. 2020, 32, 165–172. [Google Scholar]

- MacNeill, M.; Kearney, J.; Wallace, L.; Gibson, M.; Heroux, M.E.; Kuchta, J.; Guernsey, J.R.; Wheeler, A.J. Quantifying the contribution of ambient and indoor-generated fine particles to indoor air in residential environments. Indoor Air 2013, 24, 362–375. [Google Scholar] [CrossRef] [PubMed]

- Baxter, L.K.; Burke, J.; Lunden, M.; Turpin, B.J.; Rich, D.Q.; Thevenet-Morrison, K.; Hodas, N.; Ozkaynak, H. Influence of human activity patterns, particle composition, and residential air exchange rates on modeled distributions of PM2.5 exposure compared with central-site monitoring data. J. Expo. Sci. Environ. Epidemiol. 2013, 3, 241–247. [Google Scholar] [CrossRef] [PubMed]

- Alavy, M.; Siegel, J. IAQ and energy Implications of high efficiency filters in residential buildings: A review (RP-1649). Sci. Technol. Built Environ. 2019, 25, 261–271. [Google Scholar] [CrossRef] [Green Version]

- Noh, K.; Hwang, J. The effect of ventilation rate and filter performance on indoor particle concentration and fan power consumption in a residential housing unit. Indoor Built 2010, 19, 444–452. [Google Scholar] [CrossRef]

- Stephens, B.; Novoselac, A.; Seigel, J. The effects of filtration on pressure drop and energy consumption in residential HVAC systems. Sci. Technol. Built Environ. 2010, 16, 273–294. [Google Scholar]

- Zaatari, M.; Novoselac, A.; Siegel, J. The relationship between filter pressure drop, indoor air quality, and energy consumption in rooftop HVAC unit. Build. Environ. 2014, 73, 151–161. [Google Scholar] [CrossRef]

- Fazli, T.; Yeap, R.Y.; Stephens, B. Modeling the energy and cost impacts of excess static pressure in central forced-air heating and air-conditioning systems in single-family residences in the U.S. Energy Build. 2015, 107, 243–253. [Google Scholar] [CrossRef]

- Nassif, N. The impact of air filter pressure drop on the performance of typical air conditioning systems. Build. Simul. 2012, 5, 345–350. [Google Scholar] [CrossRef]

- Alavy, M.; Li, T.; Siegel, J.A. Energy use in residential buildings: Analyses of high-efficiency filters and HVAC fans. Energy Build. 2020, 209, 109697. [Google Scholar] [CrossRef]

- Walker, L.; Dickerhoff, D.; Faulkner, D.; Turner, J. System effects of high efficiency filters in homes. In Proceedings of the ASHRAE Annual Conference, Denver, CO, USA, 22–26 June 2013. [Google Scholar]

- Yang, S.; Ahn, T. A study on the airflow characteristics of an energy recovery ventilator according to the filter characteristics. In Proceedings of the Society of Air-Conditioning and Refrigeration Engineering Summer Conference, Yongpyeong, Korea, 19–21 June 2019. [Google Scholar]

- Jeong, Y.; Lee, S.; Park, B. Energy performance analysis according to filter pressure loss change of heat recovery ventilator. In Proceedings of the Society of Air-Conditioning and Refrigeration Engineering Summer Conference, Seoul, Korea, 22 November 2019. [Google Scholar]

- Montgomery, J.; Green, S.; Rogak, S.; Bartlett, K. Predicting the energy use and operation cost of HVAC air filters. Energy Build. 2012, 47, 643–650. [Google Scholar] [CrossRef]

- Kwak, R.; Won, G.; Jung, W.; Huh, J. Evaluation of energy saving and development of energy management system of AHU’s fan by air filter differential pressure in building. J. Arch. Inst. Korea 2004, 20, 204–211. [Google Scholar]

- Fisk, W.J.; Faulkner, D.; Palonen, J.; Seppanen, O. Performance and costs of particle air filtration technologies. Indoor Air 2002, 12, 223. [Google Scholar] [CrossRef] [Green Version]

- The Government of Korea. MLIT. The Second Plan for Green Buildings (20~24), Policy Report; The Government of Korea: Seoul, Korea, 2020.

- Lee, S. Application state of apartment ventilation system in Korea. Mag. SAREK 2021, 50, 56–62. [Google Scholar]

- Korea Standard. KS B 6879; Heat Recovery Ventilator; Korean Standard: Seoul, Korea, 2017.

- The Government of Korea. MLIT. Law for Apartment Housing; The Government of Korea: Seoul, Korea, 2020.

- British Standards (BS); European Standard (EN). BS EN 1822-1; Performance Testing, Marking. High Efficiency Air Filters (EPA, HEPA and ULPA); British Standards: London, UK, 2019. [Google Scholar]

- Song, S.; Shin, Y.; Kim, J. An experimental study on the differential pressure and speed of small air cleaner filter. In Proceedings of the KFMA Annual Meeting, Yeosu, Korea, 28–30 November 2018. [Google Scholar]

- American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE). Standard 52.2; Method of Testing General Ventilation Air-Cleaning Devices for Removal Efficiency by Particle Size; ASHRAE Inc.: Atlanta, GA, USA, 2017. [Google Scholar]

- ASHRAE. Standard 62.1; Ventilation for Acceptable Indoor Air Quality; ASHRAE Inc.: Atlanta, GA, USA, 2019. [Google Scholar]

- Global Monitoring Laboratory, Trends in Atmospheric Carbon Dioxide. Available online: https://gml.noaa.gov/ccgg/trends/global.html (accessed on 25 April 2021).

- Seong, N. Energy requirements of a multi-sensor based demand control ventilation system in residential buildings. In Proceedings of the 31st AIVC Conference, Low Energy and Sustainable Ventilation Technologies for Green Buildings, Seoul, Korea, 26–28 October 2010. [Google Scholar]

- Hesaraki, A.; Holmberg, S. Demand-controlled ventilation in new residential buildings: Consequences on indoor air quality and energy savings. Indoor Built Environ. 2015, 24, 162–173. [Google Scholar] [CrossRef] [Green Version]

- ASHRAE. Standard 62.2; Ventilation and Acceptable Indoor Air Quality in Residential Buildings; ASHRAE Inc.: Atlanta, GA, USA, 2019. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).