Analysis of Reasons for the Structural Collapse of Historic Buildings

Abstract

:1. Introduction

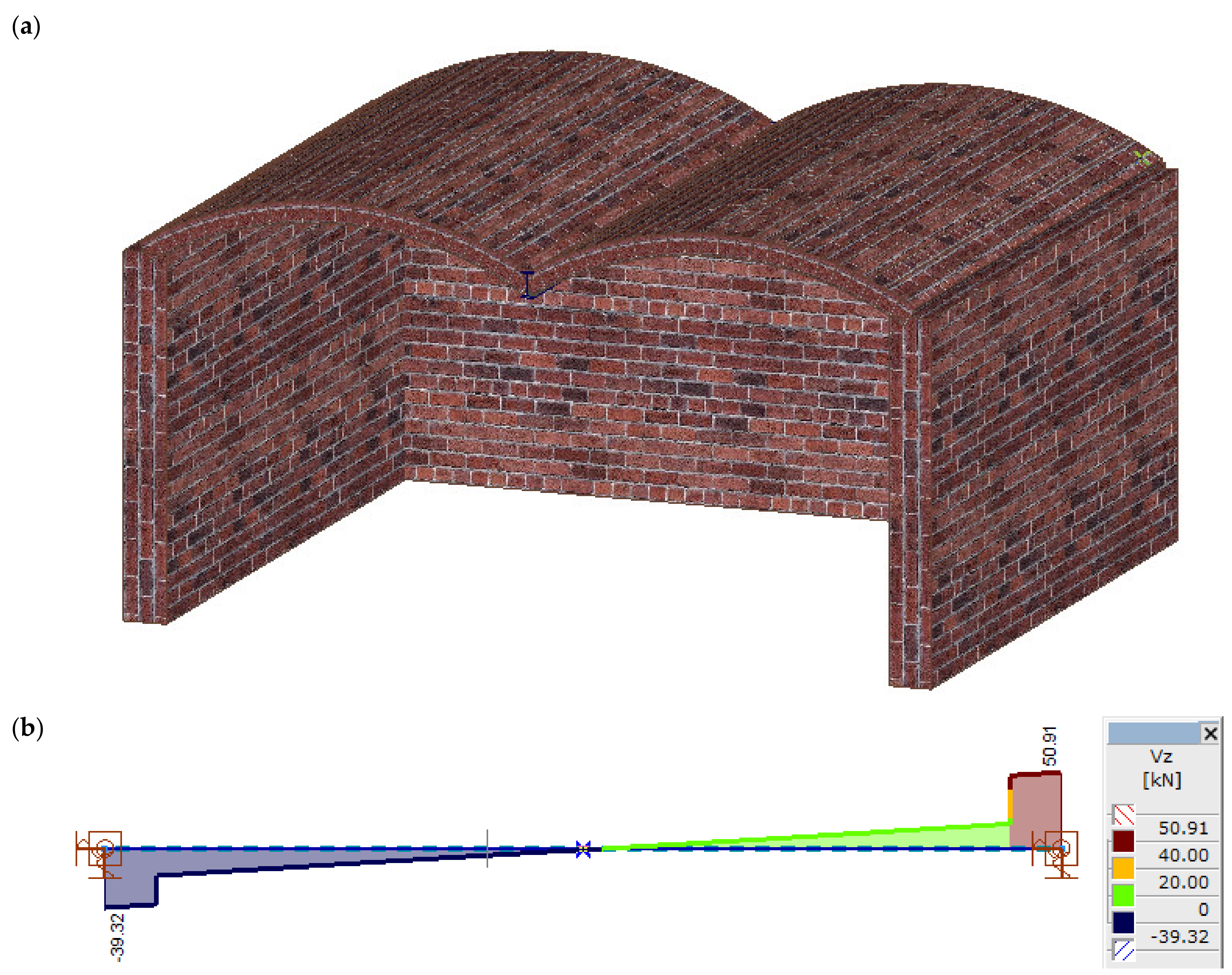

2. The Structural Collapse Induced by Faulty Design

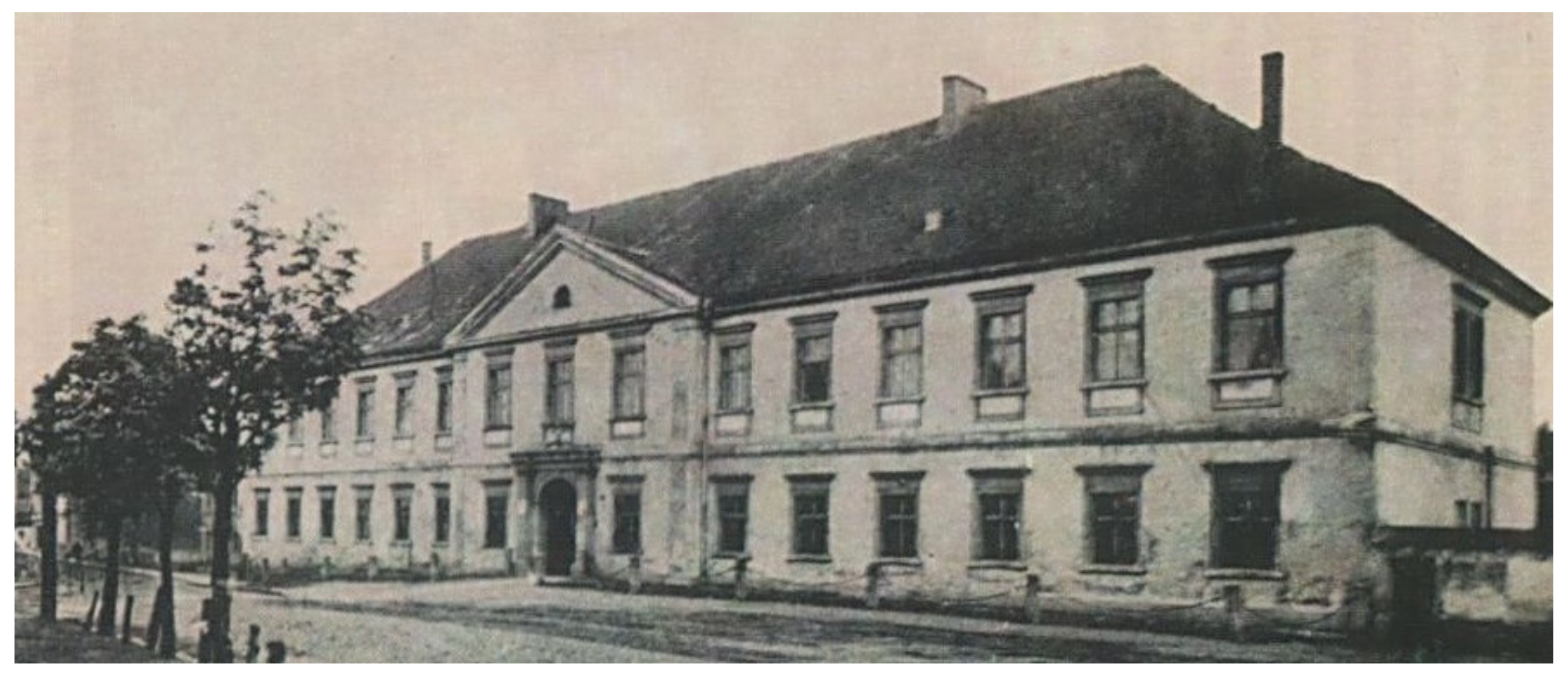

2.1. Description of the Building

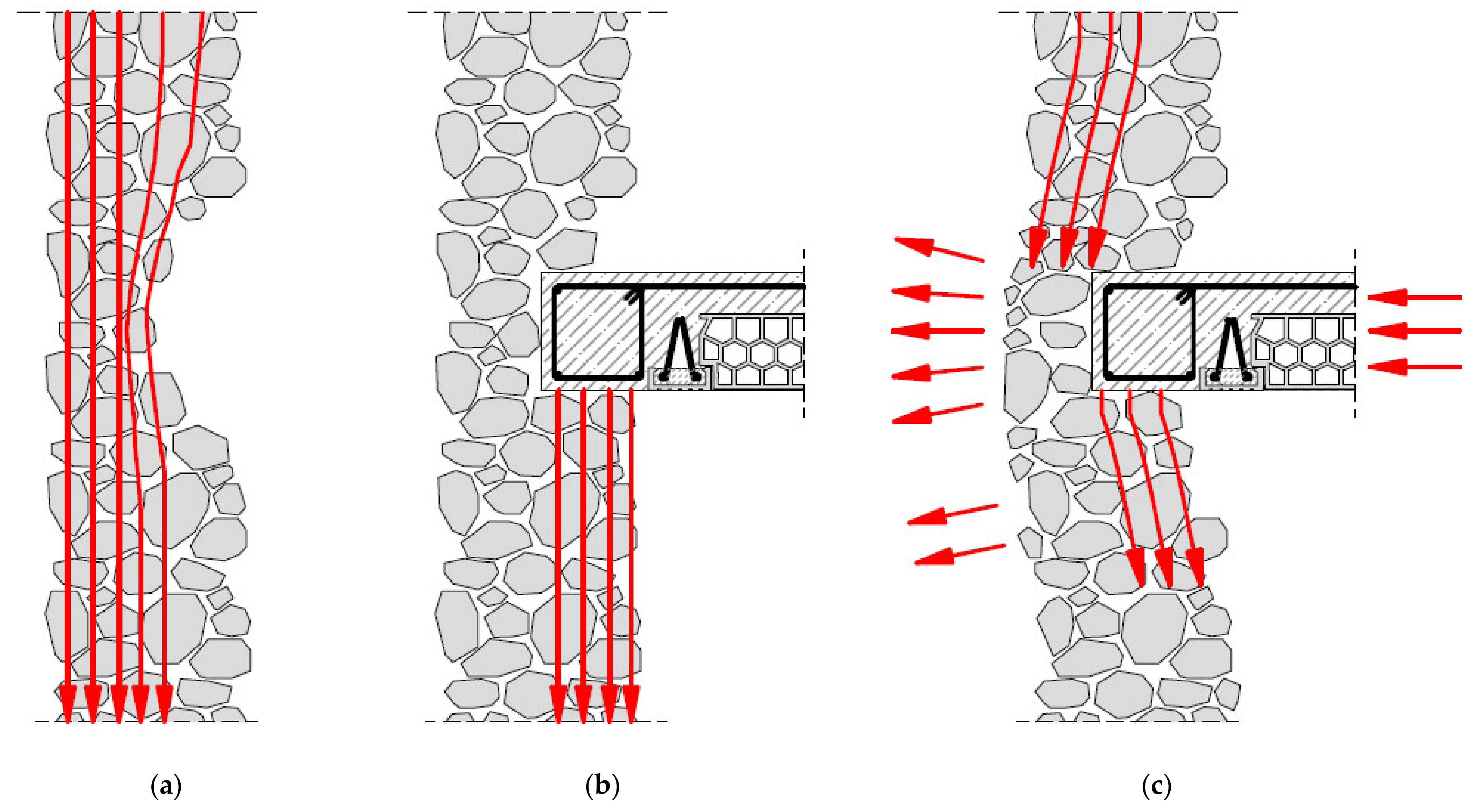

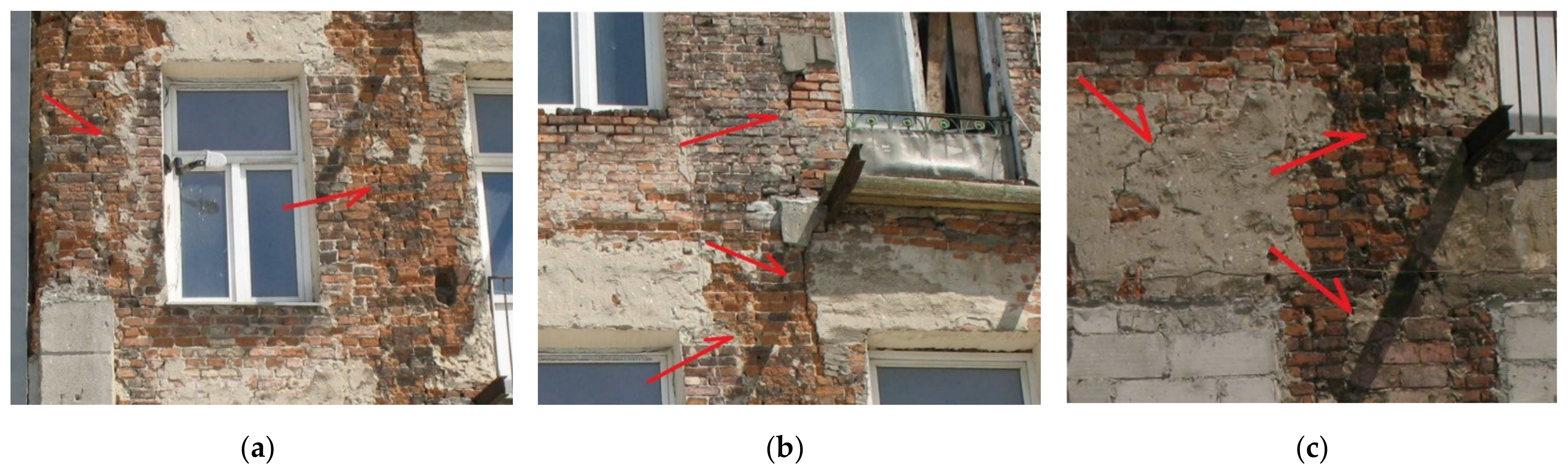

2.2. Structural Collapse

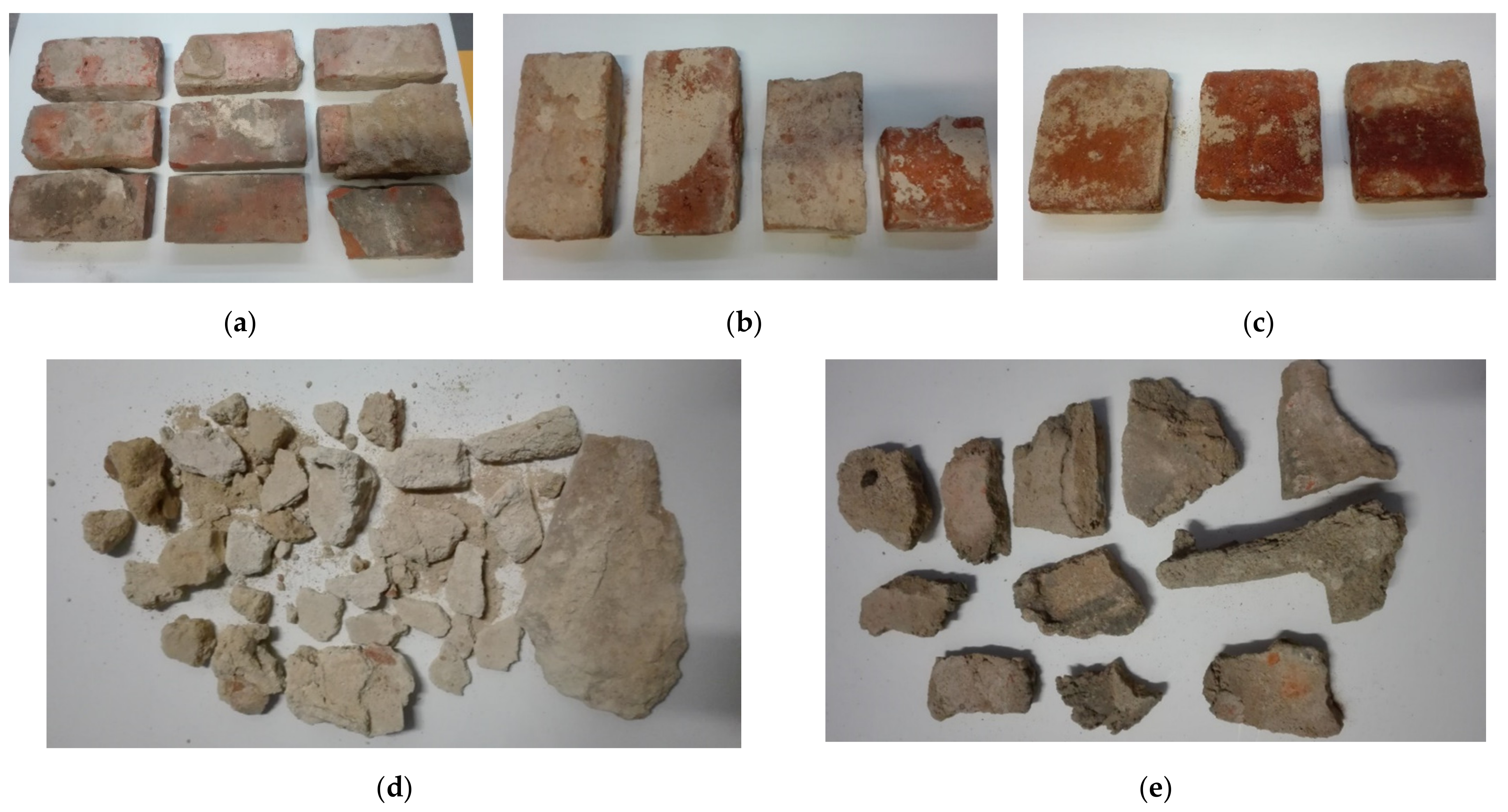

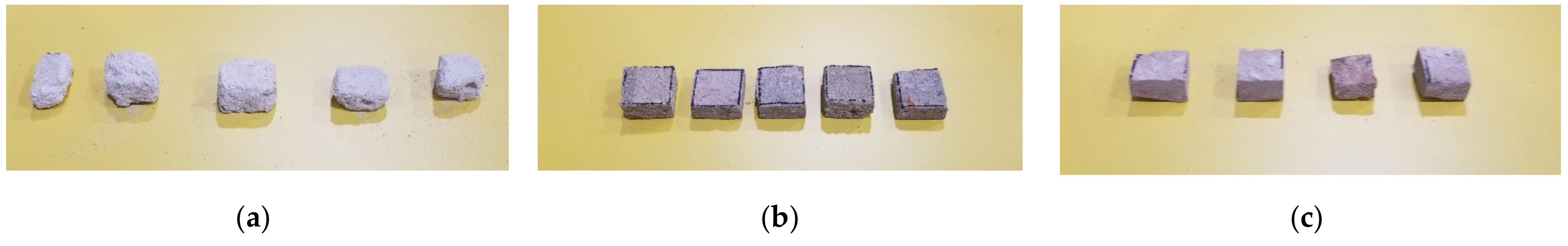

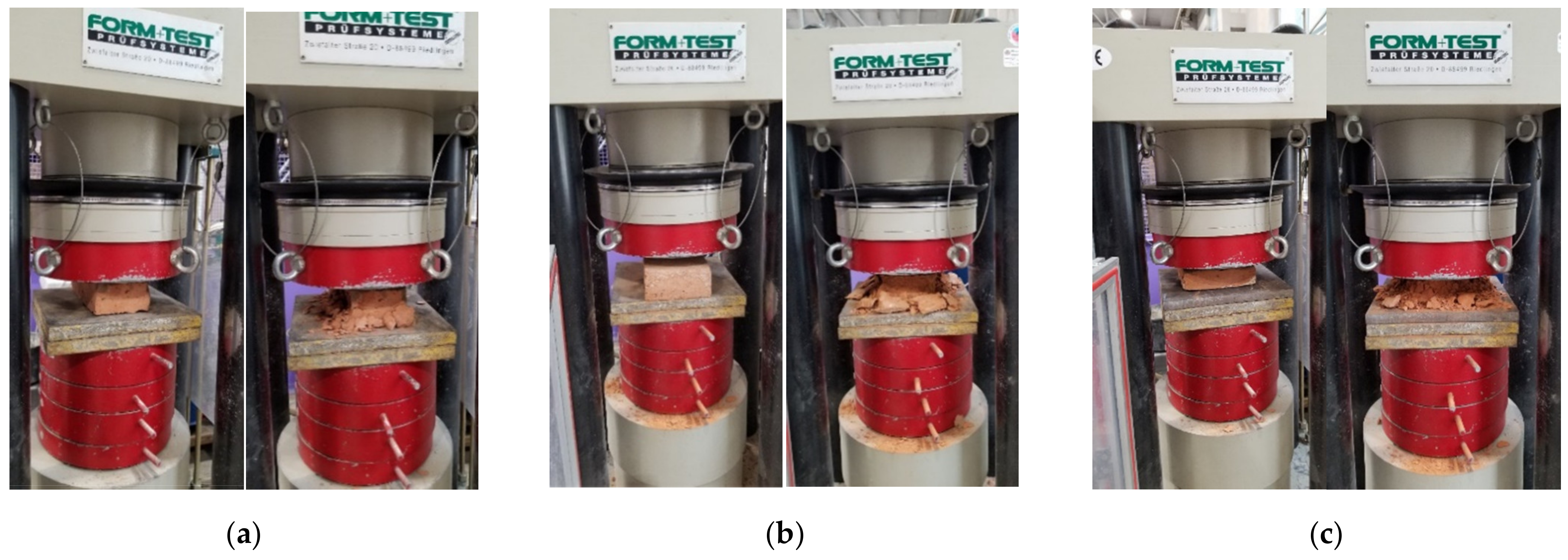

2.3. Tests Performed

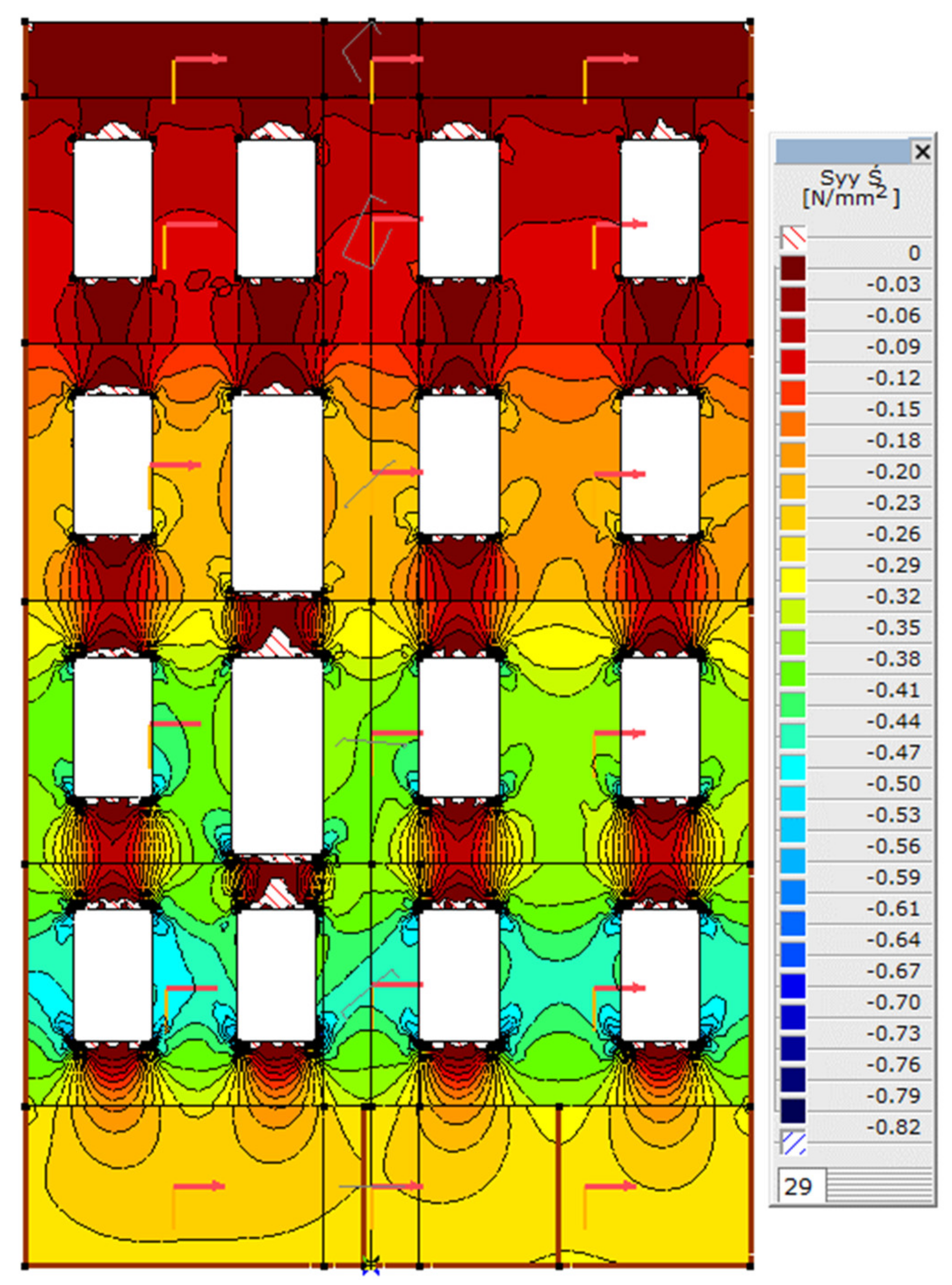

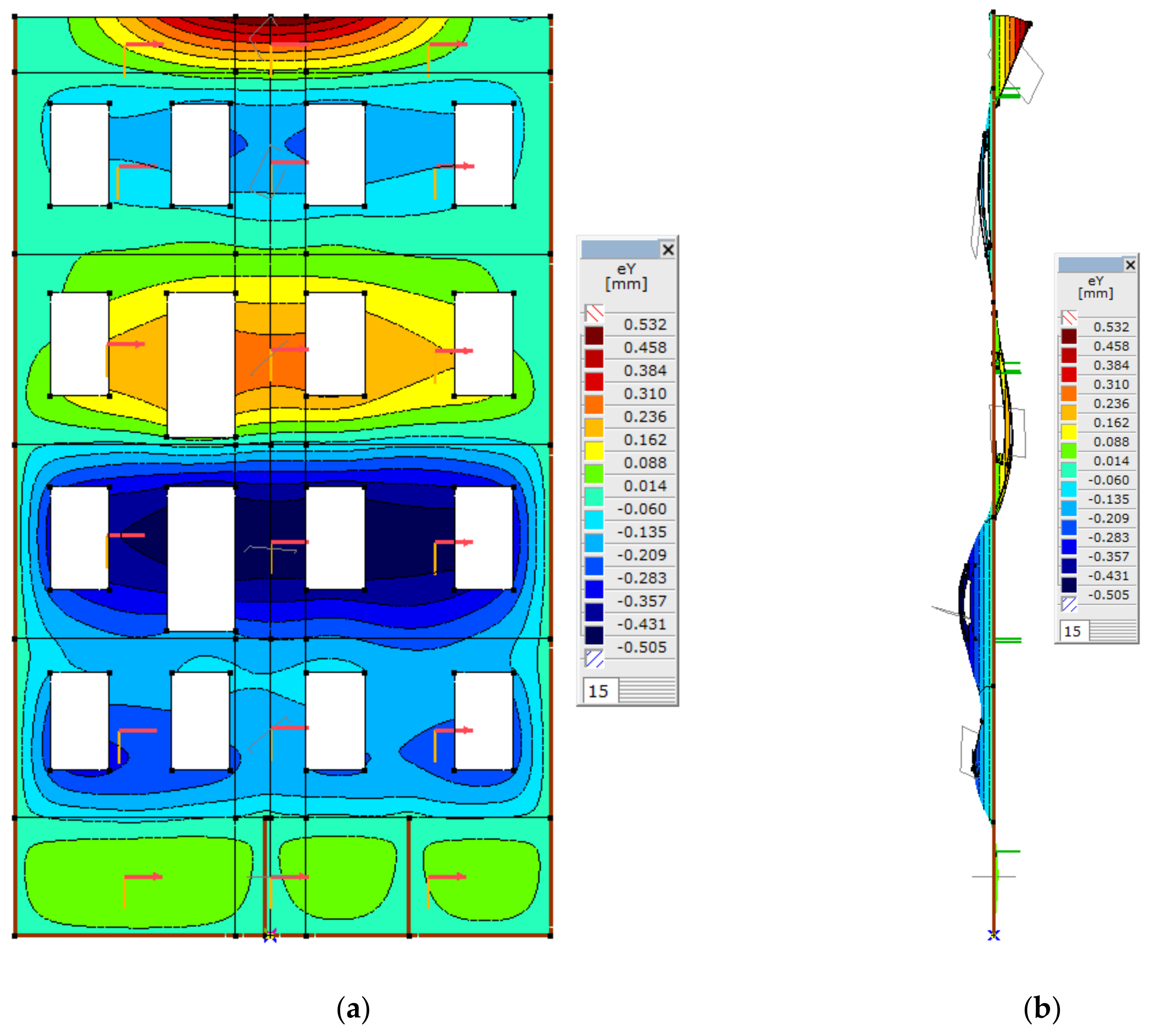

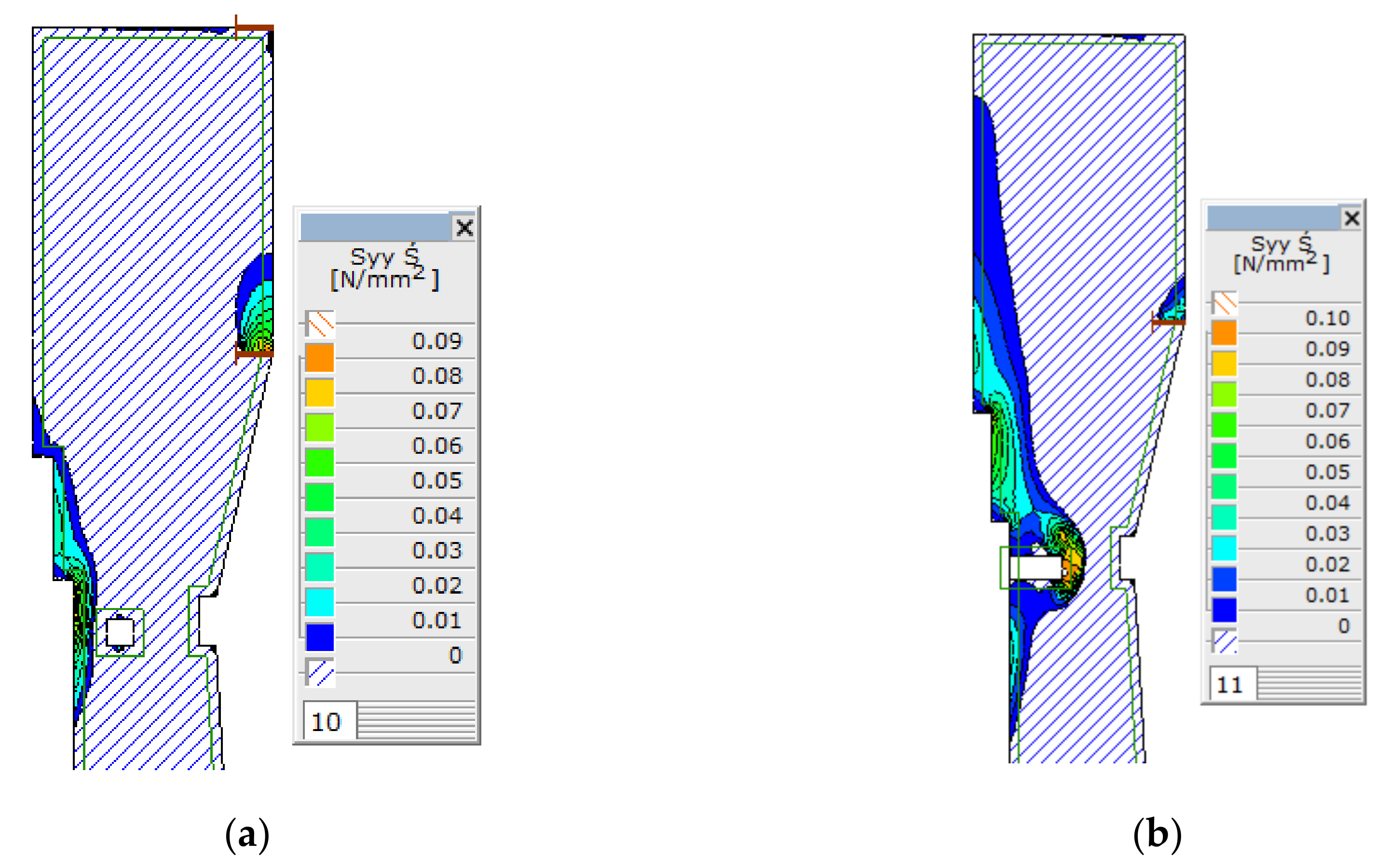

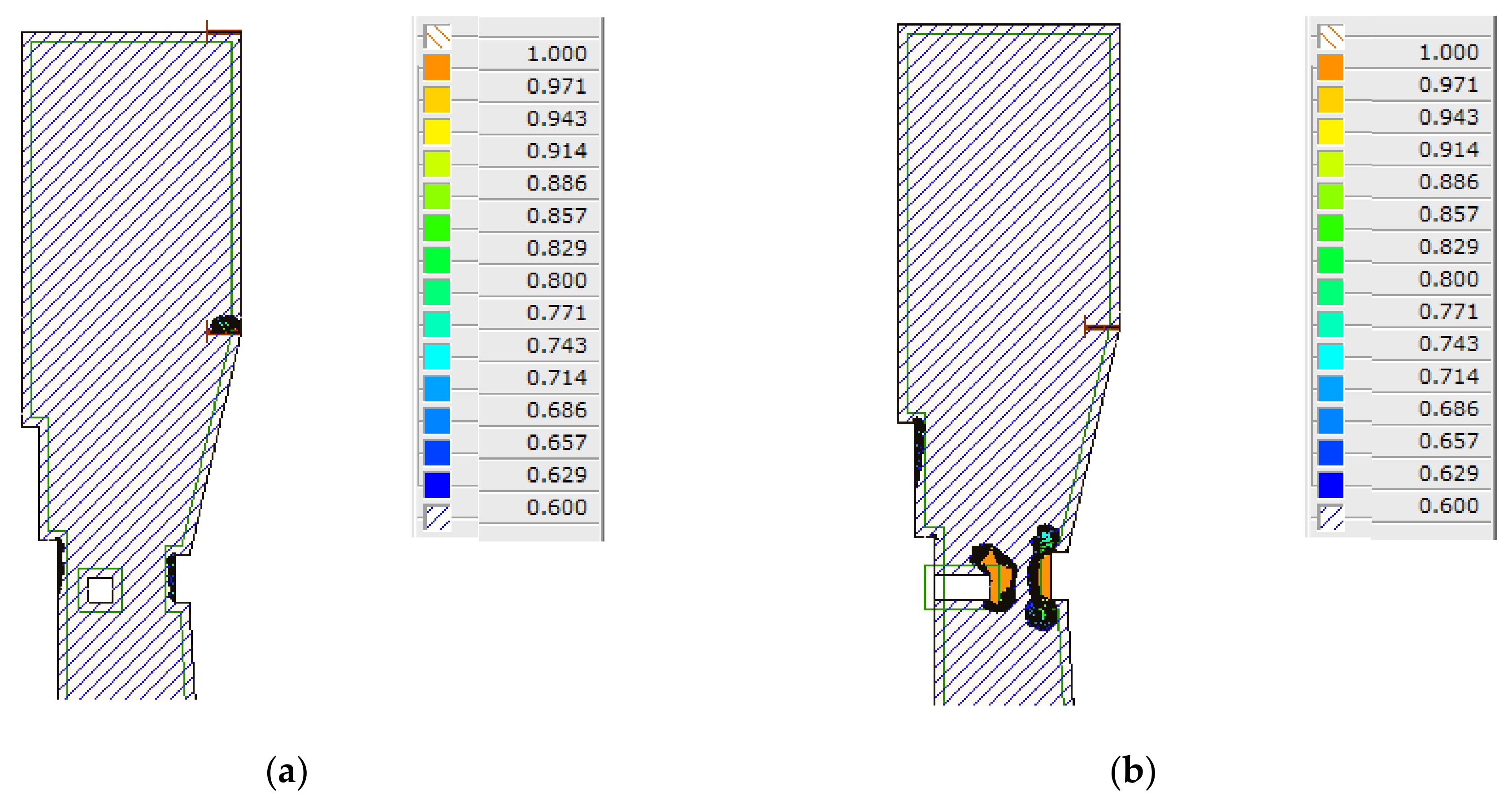

2.4. Damage Causes

3. An Example of the Collapse Caused by Faulty Performance

3.1. Description of the Building

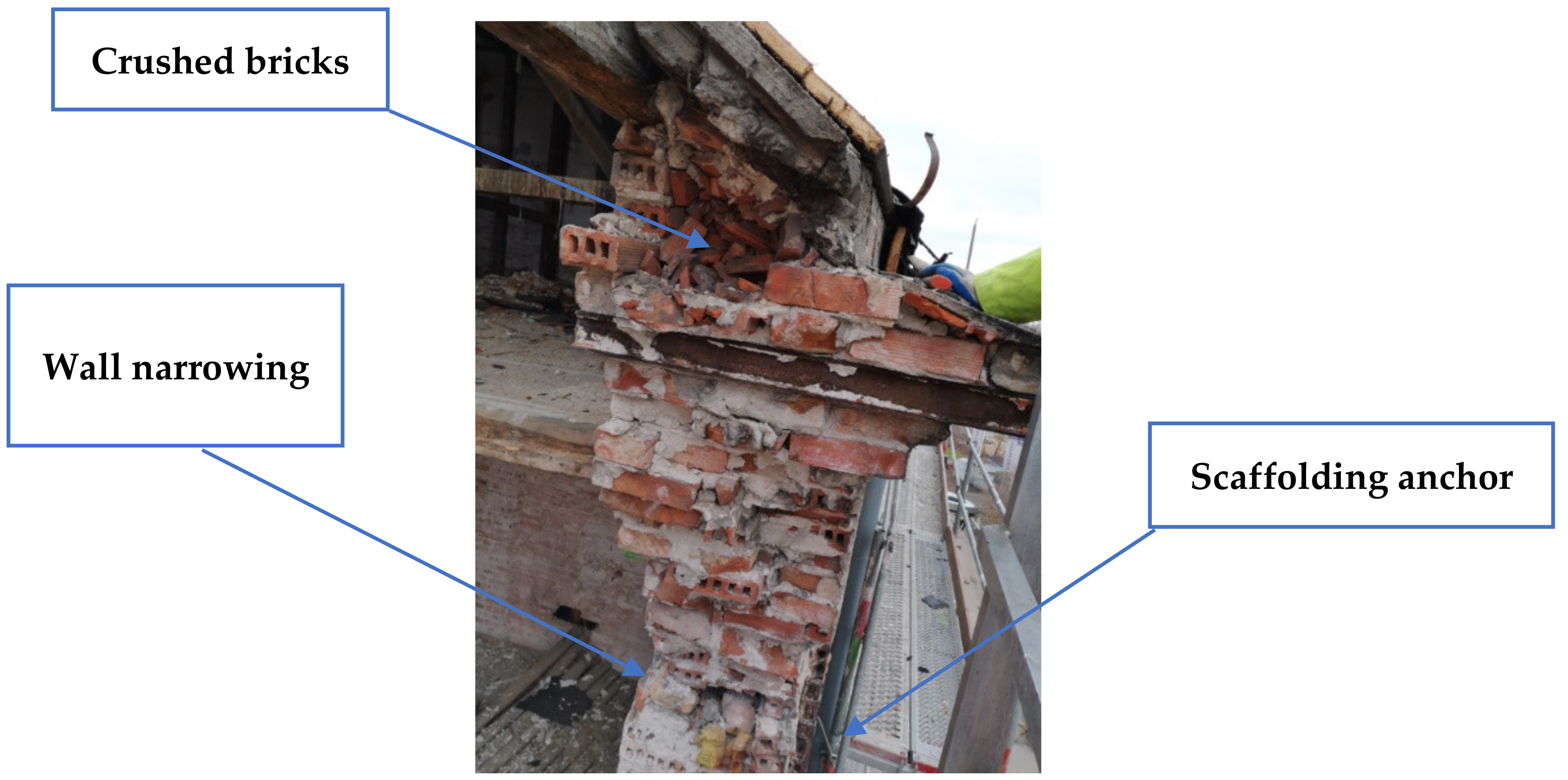

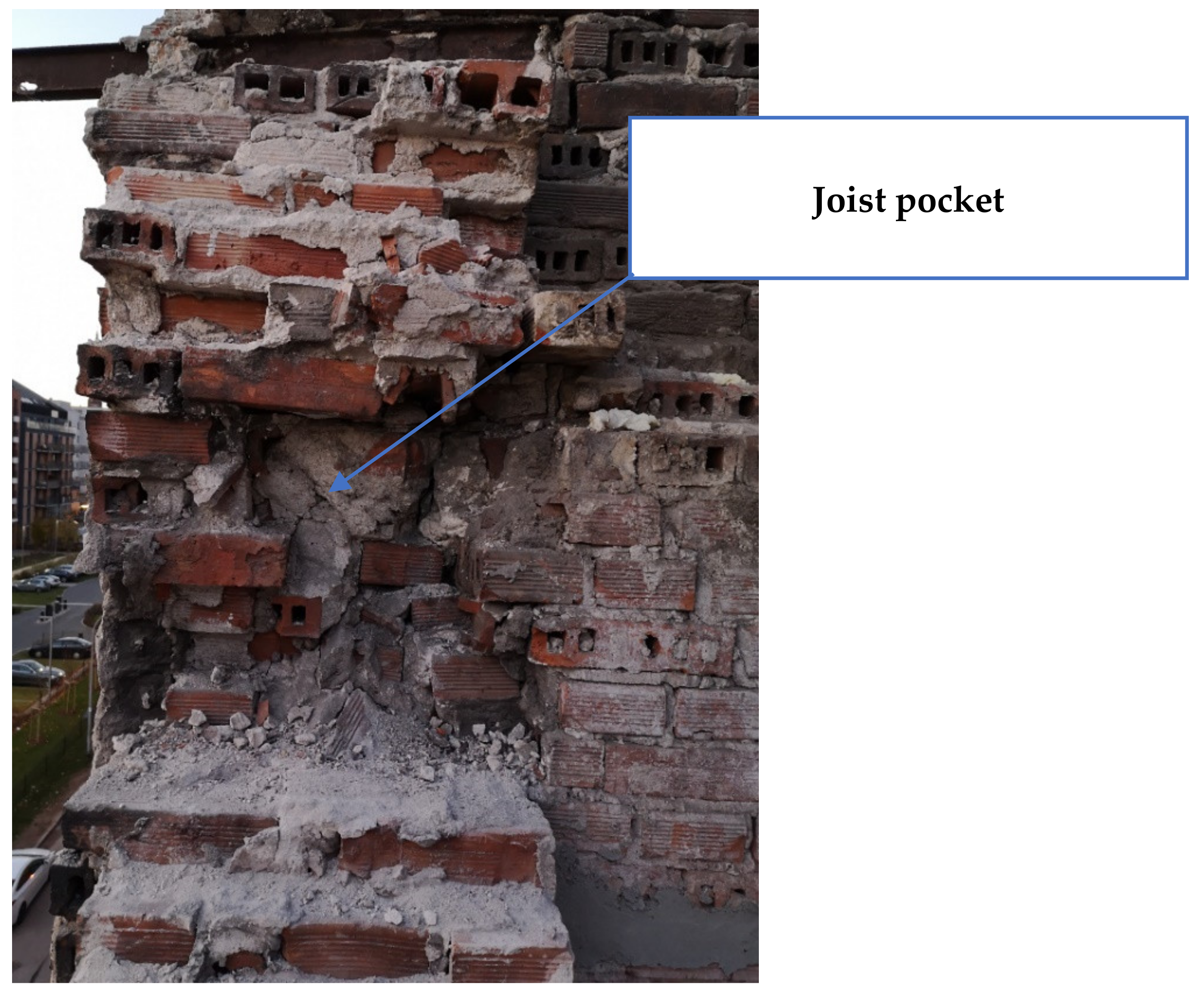

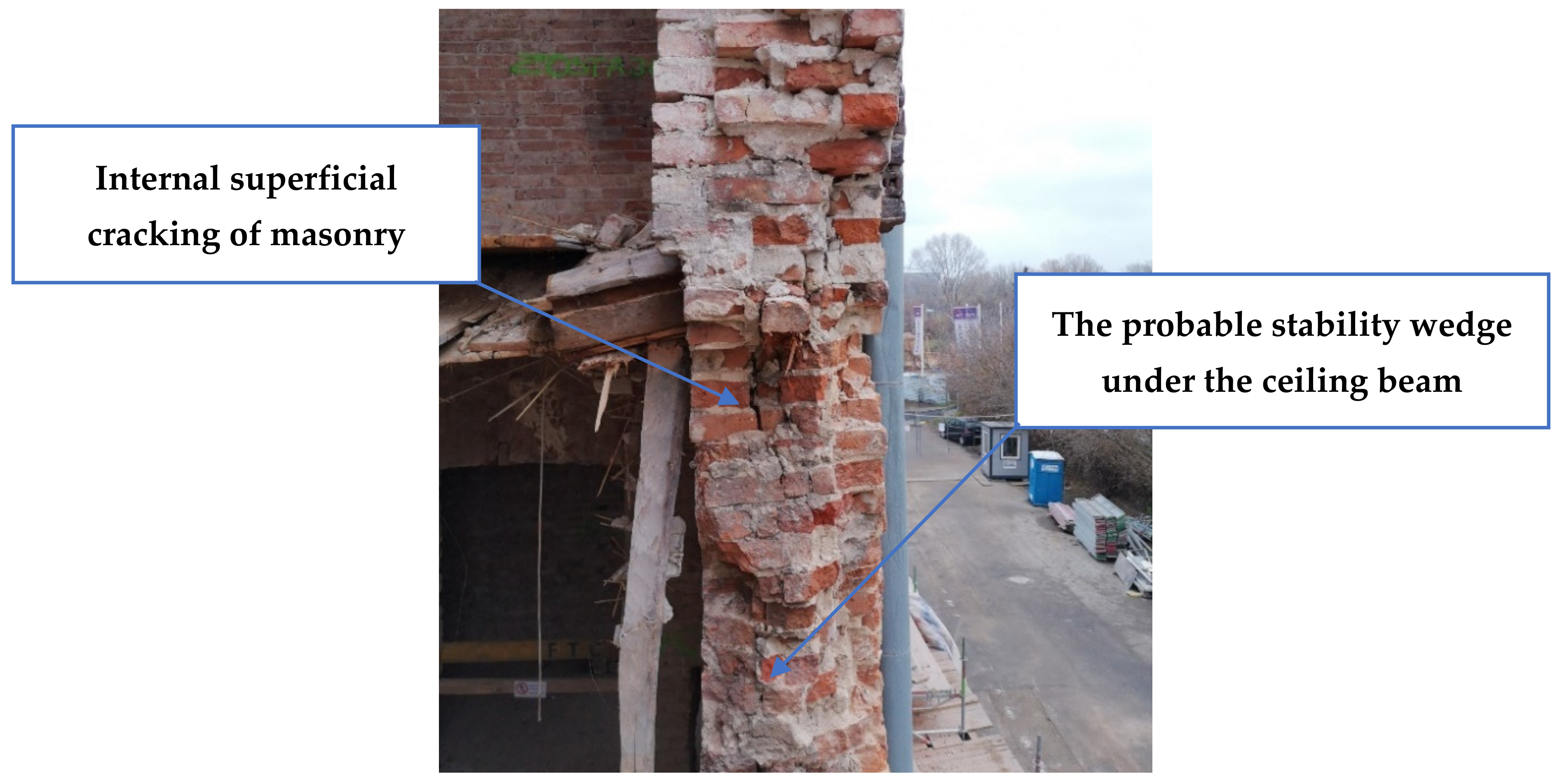

3.2. Structural Collapse

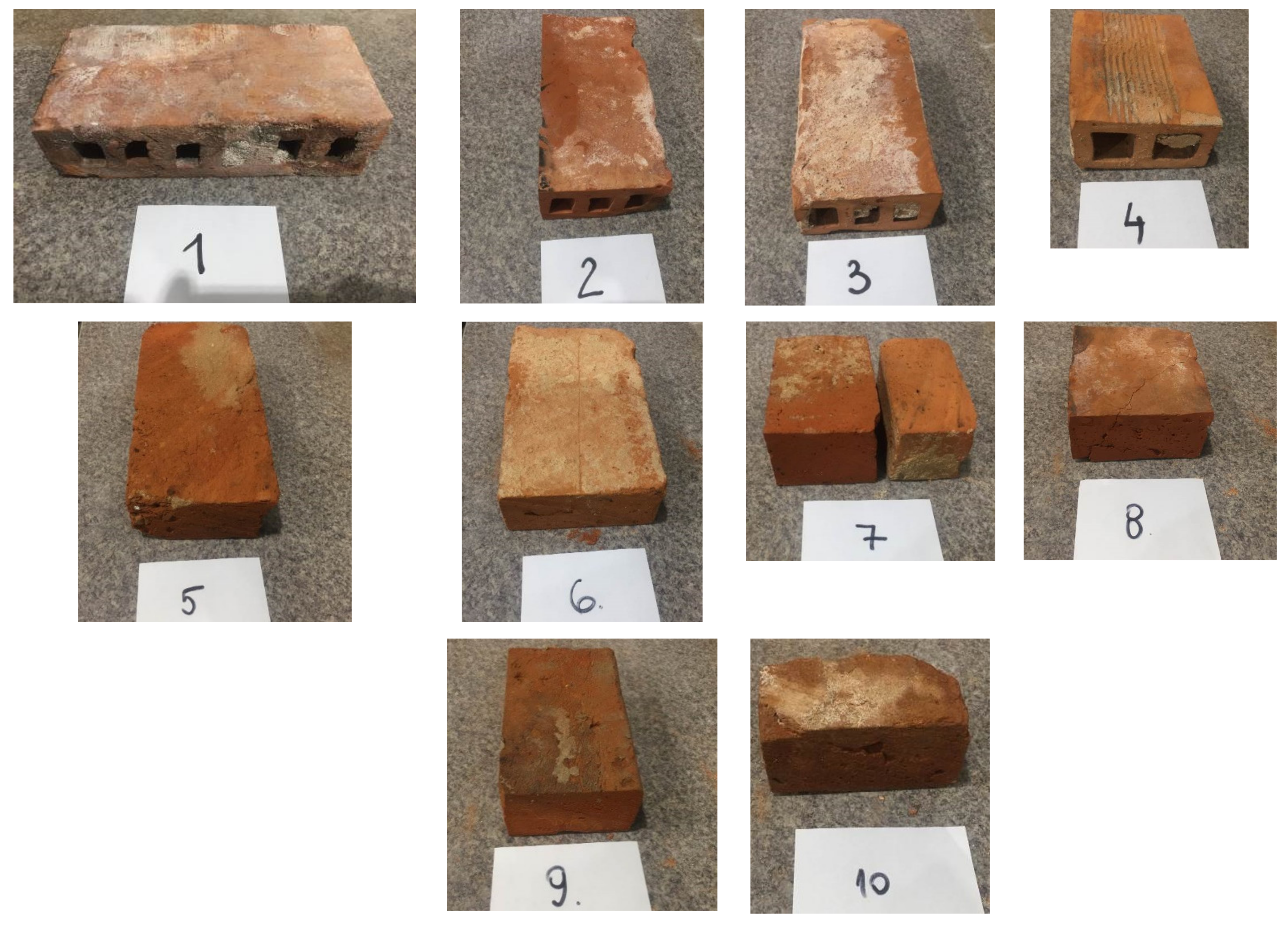

3.3. Tests Performed

3.4. Analysis of Recordings from Surveillance Cameras

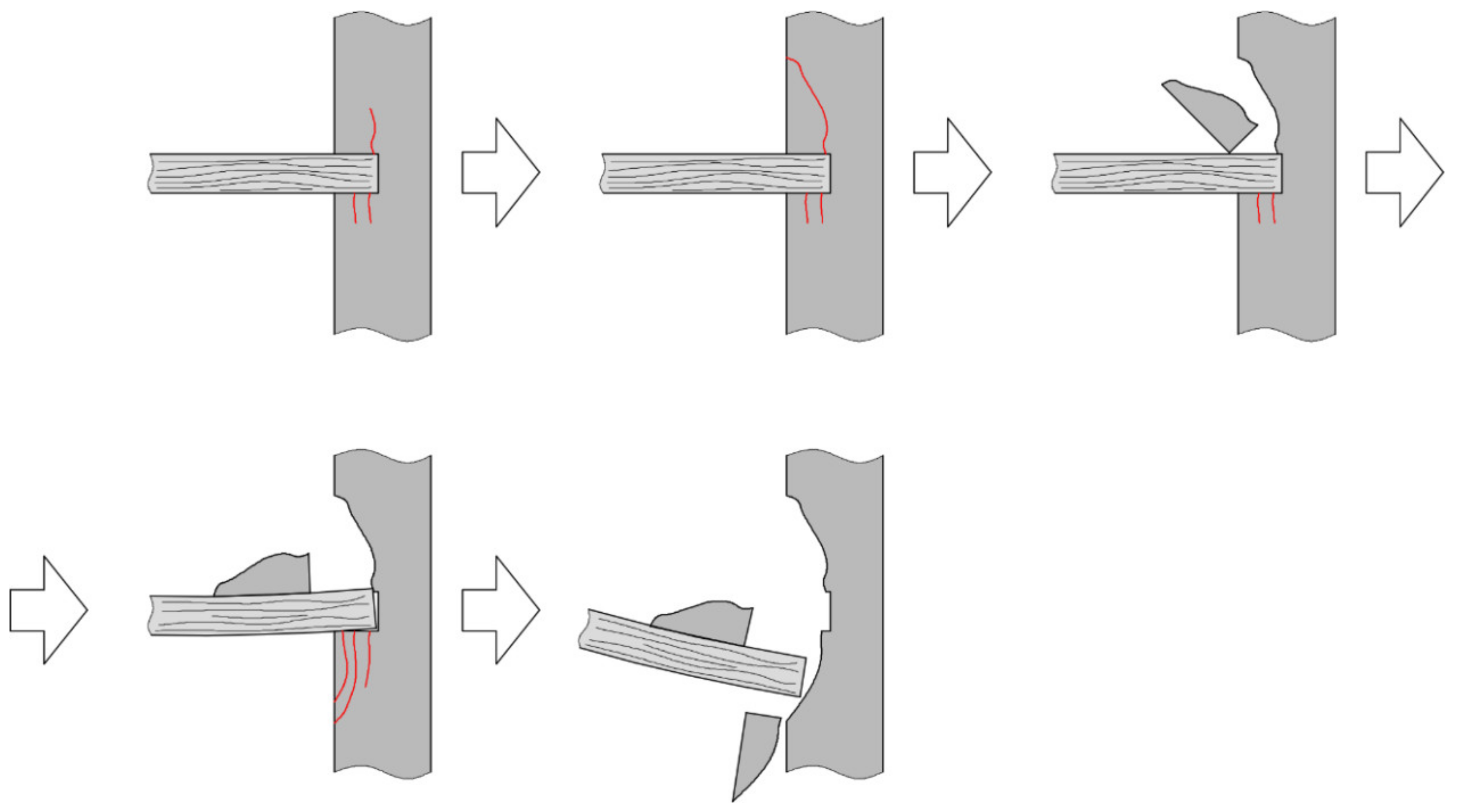

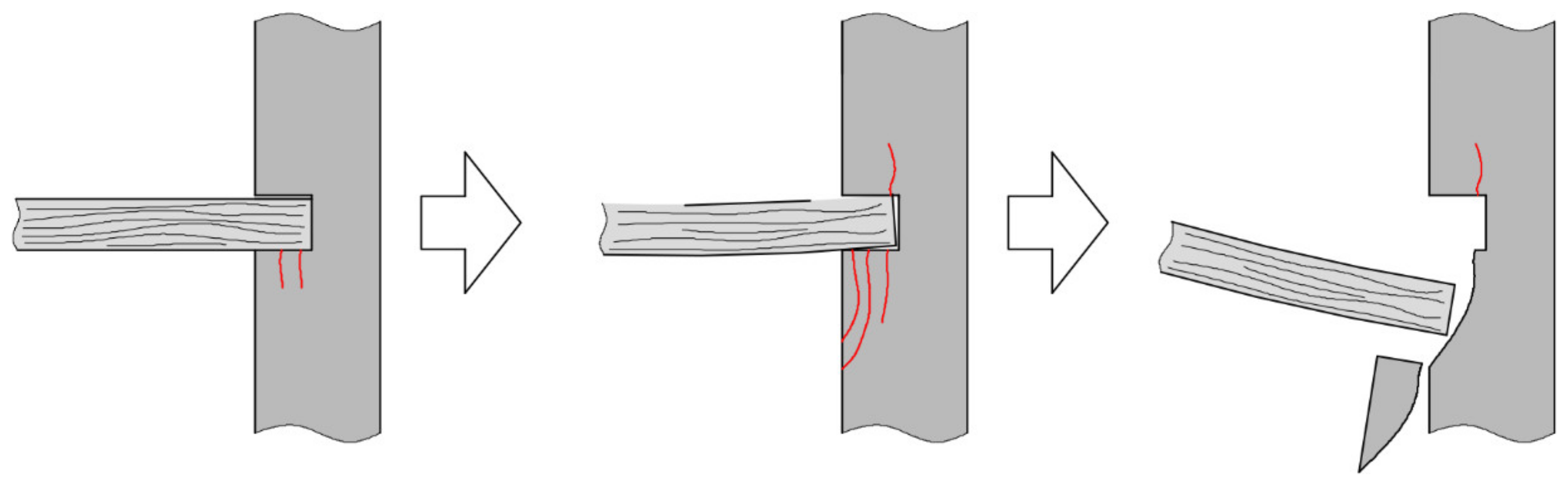

3.5. Collapse Causes

4. An Example of the Collapse Caused by Faulty Operation

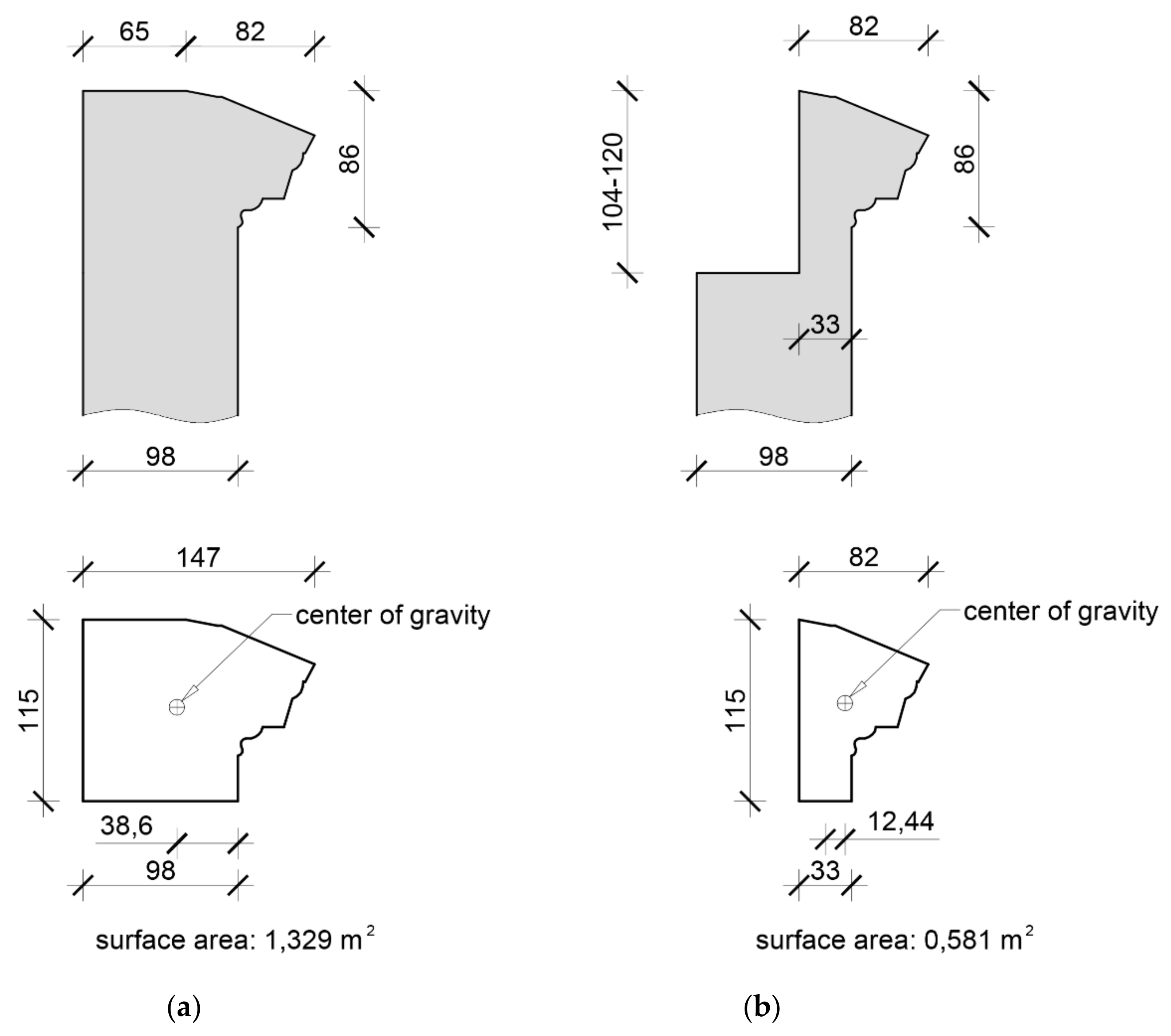

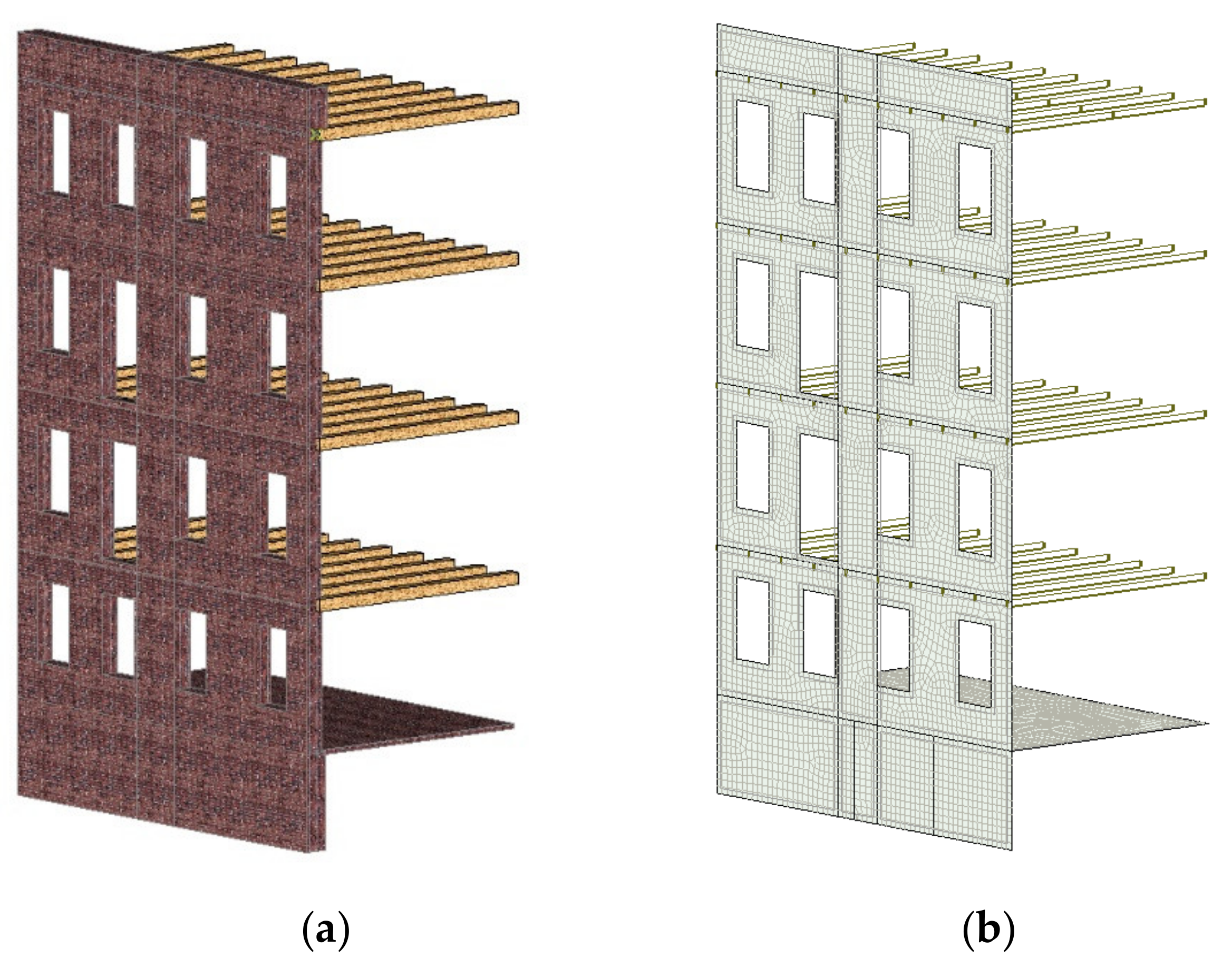

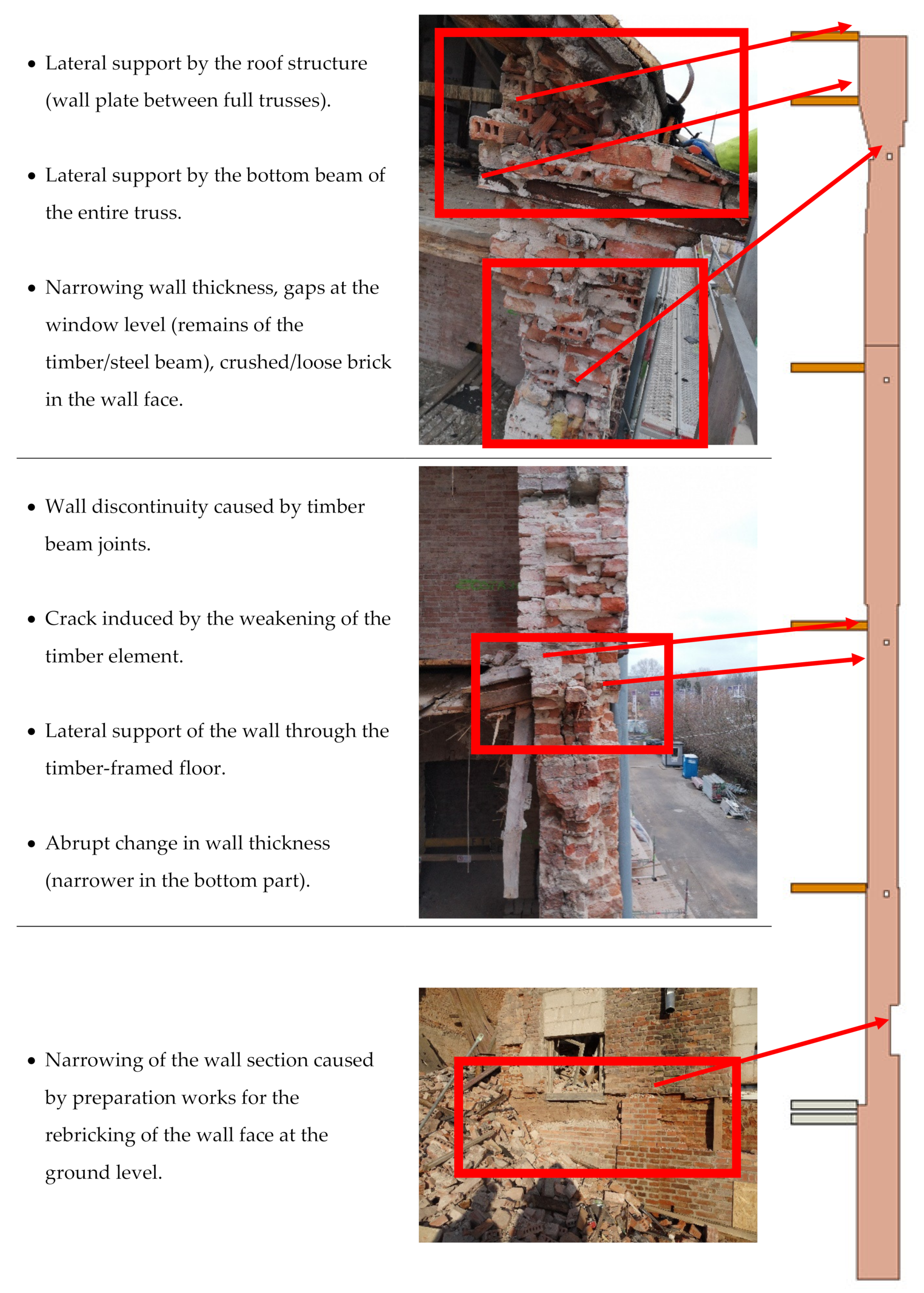

4.1. Description of the Building

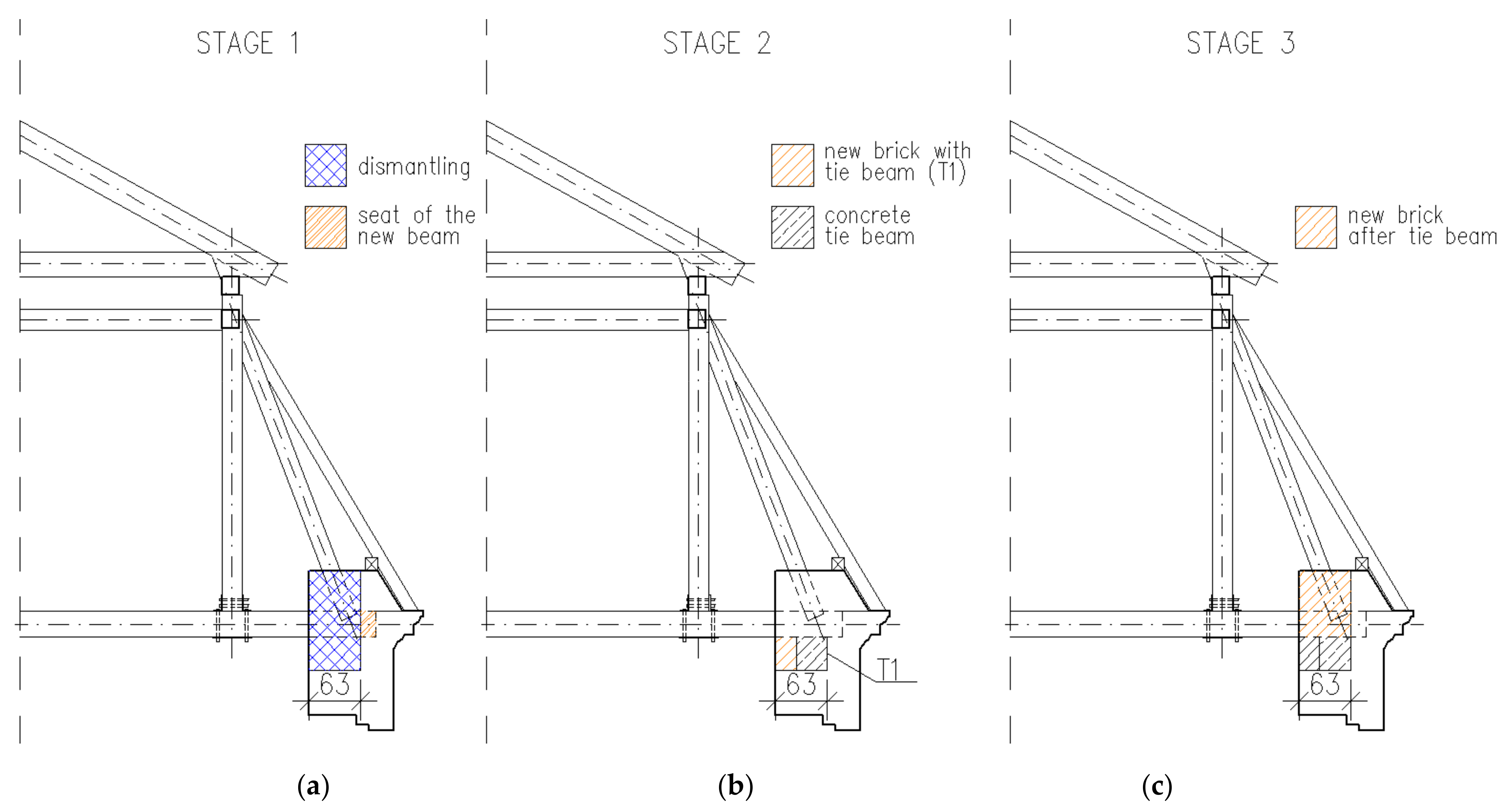

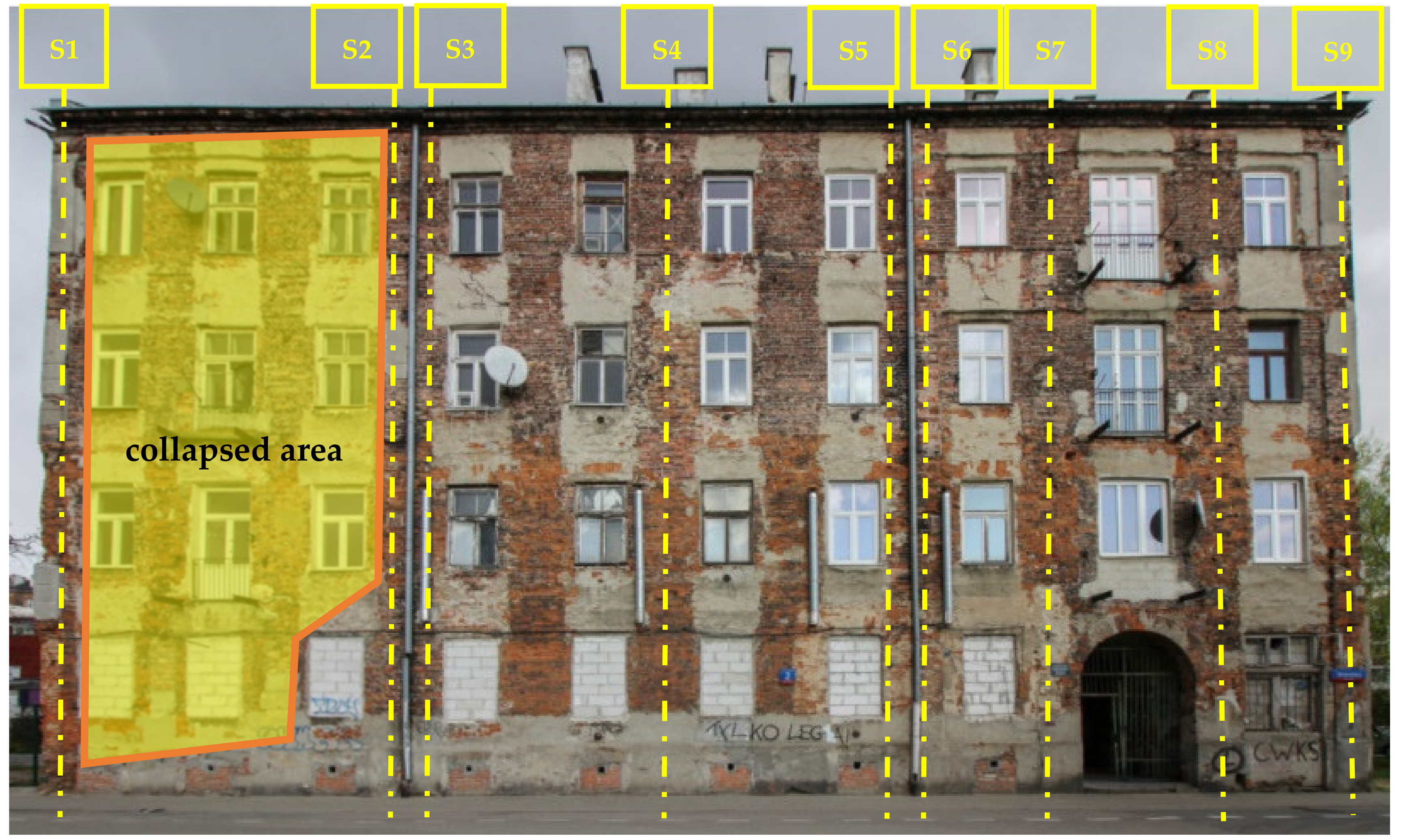

4.2. Structural Collapse

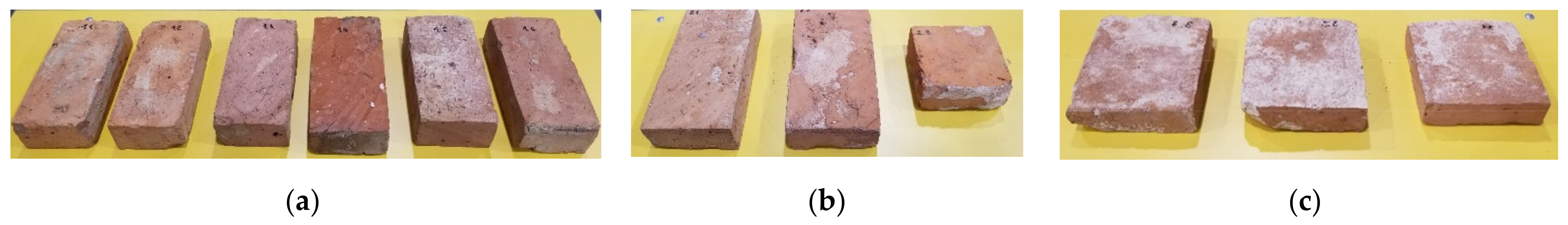

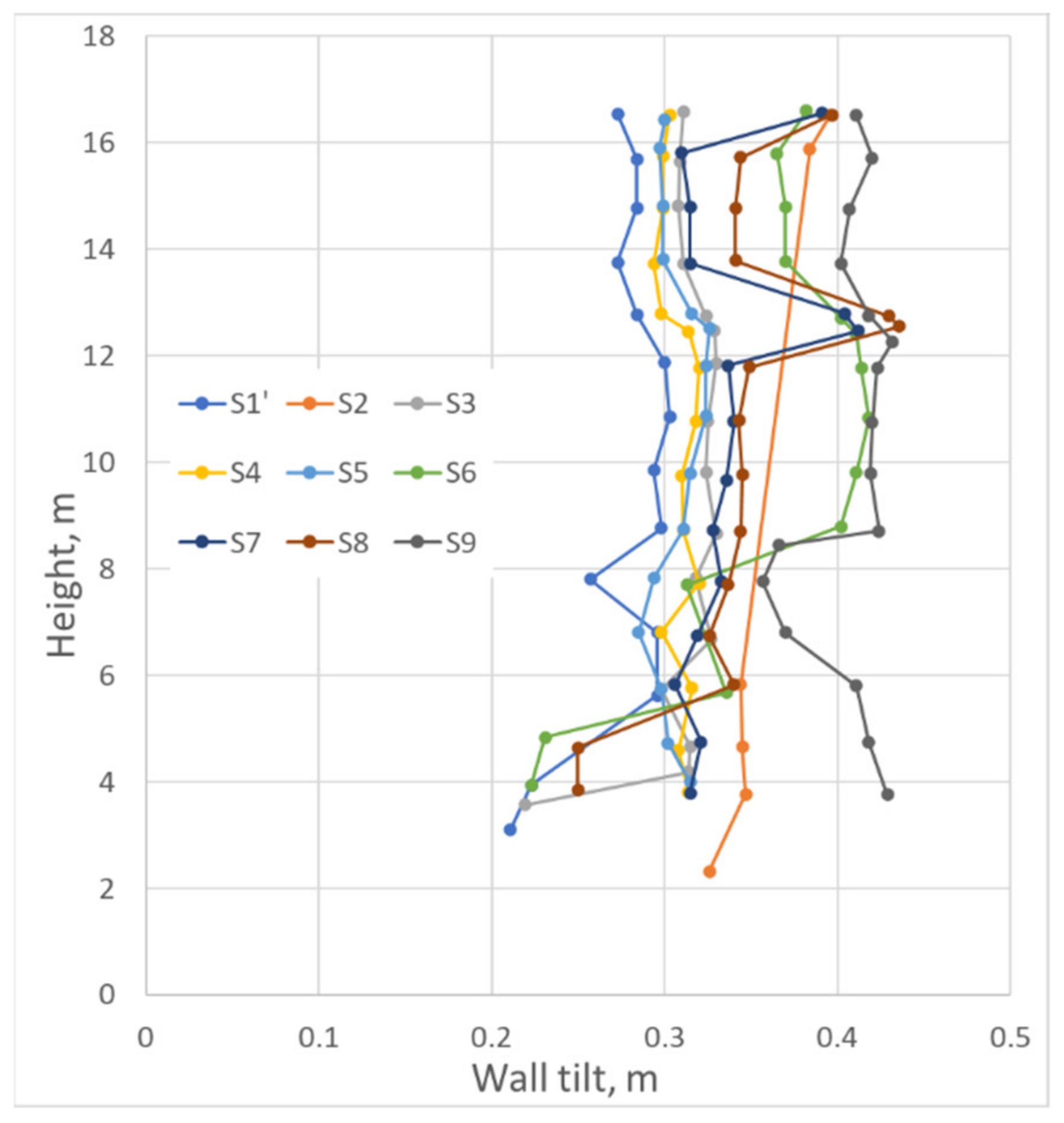

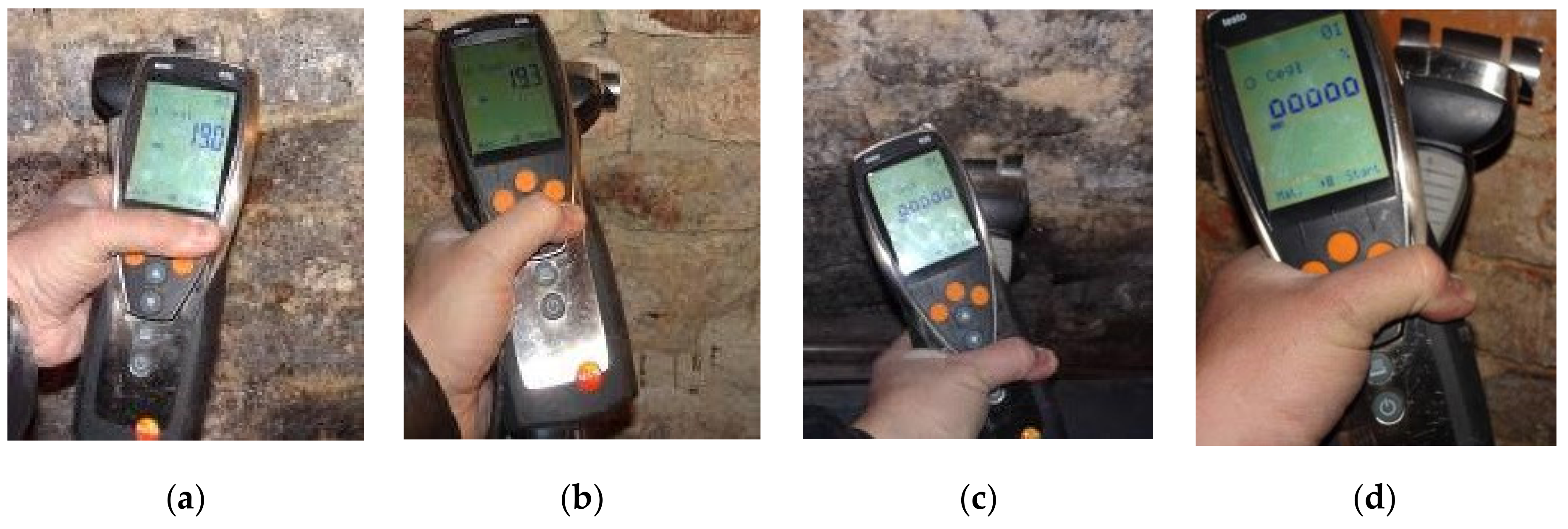

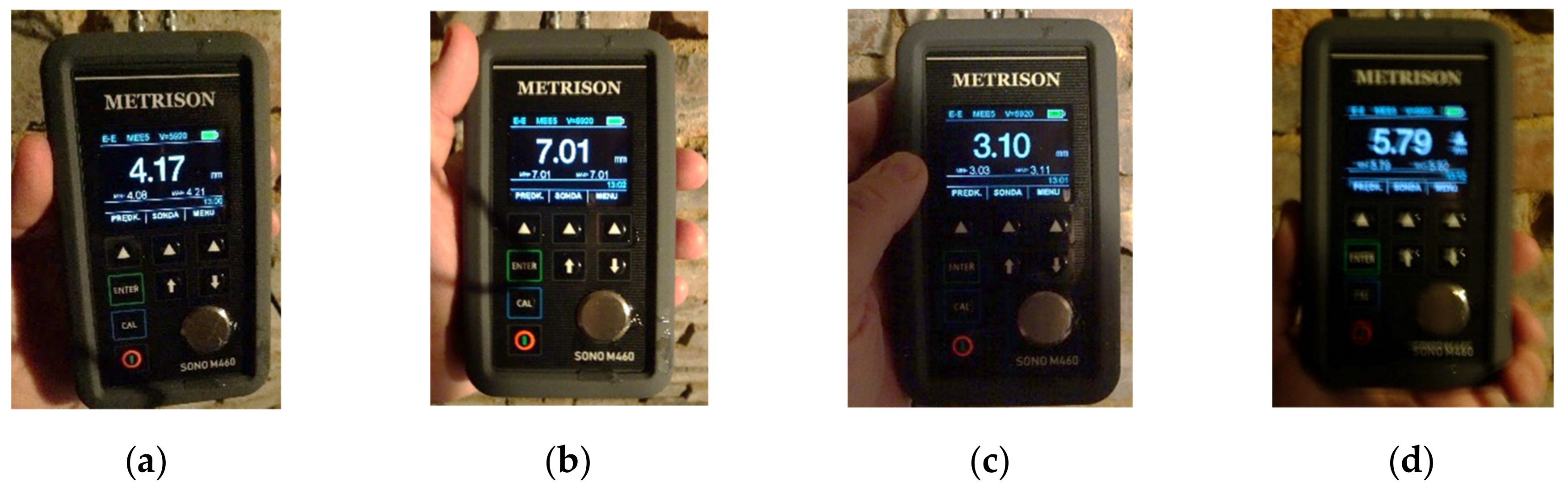

4.3. Tests Performed

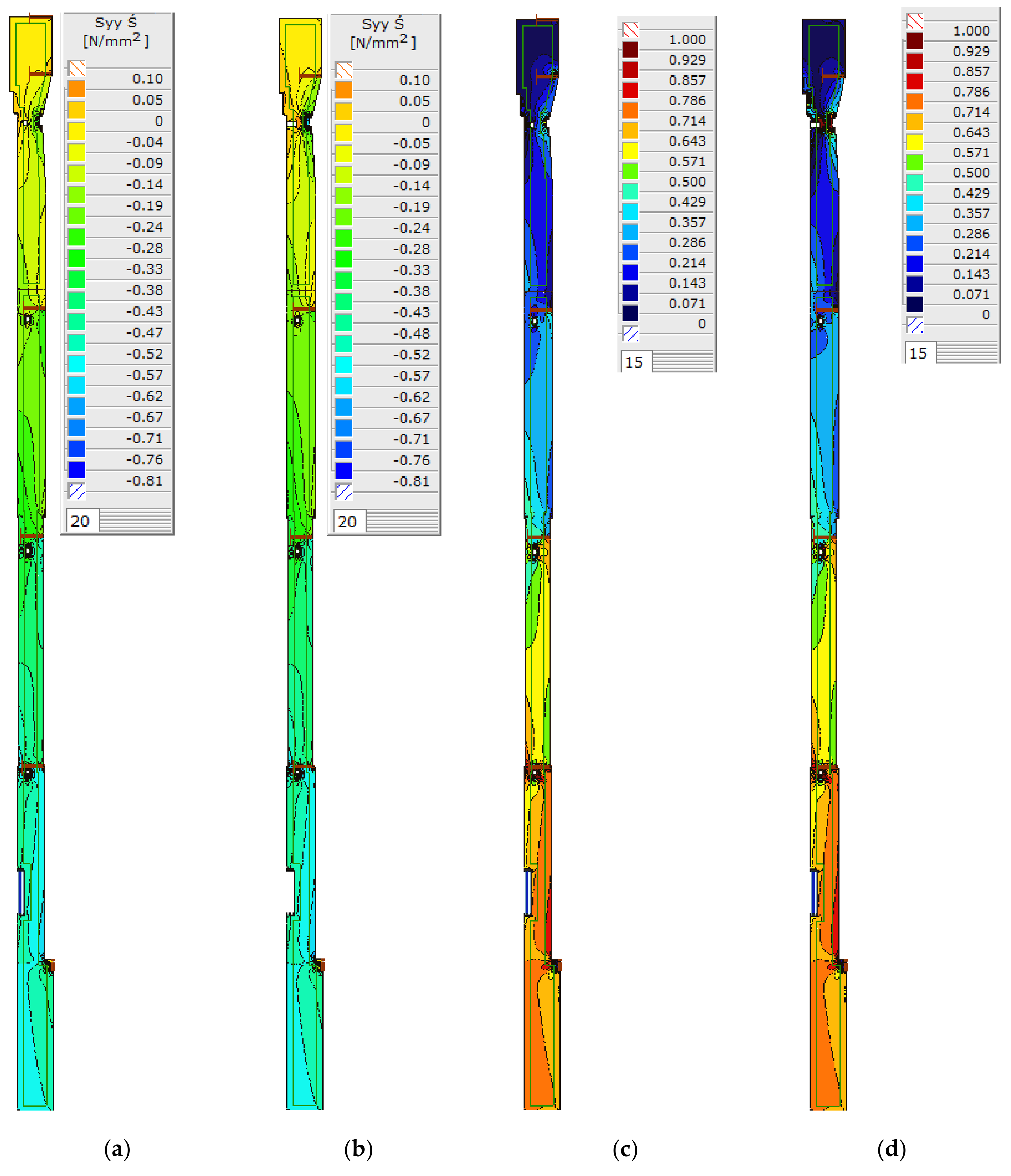

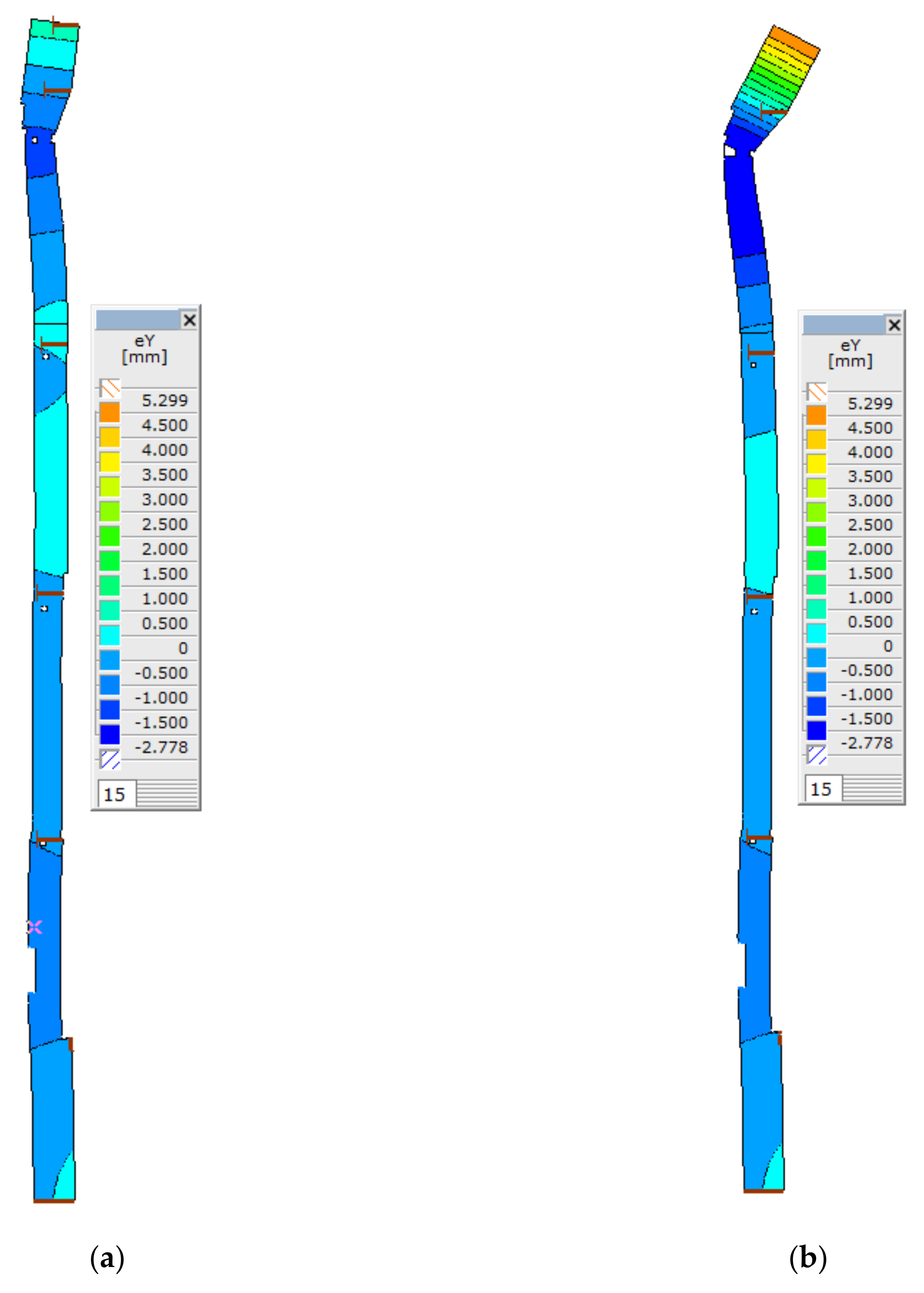

4.4. Collapse Causes

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Borri, A.; Corradi, M. Architectural Heritage: A Discussion on Conservation and Safety. Heritage 2019, 2, 631–647. [Google Scholar] [CrossRef] [Green Version]

- Cardani, G.; Belluco, P. Reducing the Loss of Built Heritage in Seismic Areas. Buildings 2018, 8, 19. [Google Scholar] [CrossRef] [Green Version]

- Nowogońska, B. Consequences of Abandoning Renovation: Case Study—Neglected Industrial Heritage Building. Sustainability 2020, 12, 6441. [Google Scholar] [CrossRef]

- Du, F.; Okazaki, K.; Ochiai, C.; Kobayashi, H. Post-disaster building repair and retrofit in a disaster-prone historical villageinChina: A case study in Shangli, Sichuan. Int. J. Disaster Risk Reduct. 2016, 16, 142–157. [Google Scholar] [CrossRef]

- Ruggiero, G.; Marmo, R.; Nicolella, M. A Methodological Approach for Assessing the Safety of Historic Buildings’ Façades. Sustainability 2021, 13, 2812. [Google Scholar] [CrossRef]

- Binda, L.; Saisi, A.; Tiraboschi, C. Investigation procedures for the diagnosis of historic masonries. Constr. Build. Mater. 2000, 14, 199–233. [Google Scholar] [CrossRef]

- Rodrigues, F.; Matos, R.; Di Prizio, M.; Costac, A. Conservation level of residential buildings: Methodology evolution. Constr. Build. Mater. 2018, 172, 781–786. [Google Scholar] [CrossRef]

- Konior, J.; Rejment, M. Correlation between Defects and Technical Wear of Materials Used in Traditional Construction. Materials 2021, 14, 2482. [Google Scholar] [CrossRef] [PubMed]

- Kroftova, K. Most Frequent Problems of Building Structures of Urban Apartment Buildings from 2nd Half of 19th Century and the Start of 20th Century. Buildings 2021, 11, 27. [Google Scholar] [CrossRef]

- Drobiec, Ł. Limitation of cracking in AAC masonry under the window zone. Mauerwerk 2017, 21, 332–342. [Google Scholar] [CrossRef]

- Drobiec, Ł. Study of impact of bed joint reinforcement on load-carrying capacity and crack resistance of masonry walls made of calcium silicate units. J. Build. Eng. 2021, 33, 101841. [Google Scholar] [CrossRef]

- Drobiec, Ł. Analysis of AAC walls subjected to vertical load. Mauerwerk 2019, 23, 387–403. [Google Scholar] [CrossRef]

- Kania, T.; Derkach, V.; Nowak, R. Testing Crack Resistance of Non-Load-Bearing Ceramic Walls with Door Openings. Materials 2021, 14, 1379. [Google Scholar] [CrossRef]

- Corradi, M.; Borri, A.; Castori, G.; Coventry, K. Experimental Analysis of Dynamic Effects of FRP Reinforced Masonry Vaults. Materials 2015, 8, 8059–8071. [Google Scholar] [CrossRef] [Green Version]

- Jasieńko, J.; Raszczuk, K.; Frąckiewicz, P.; Kleszcz, K.; Bednarz, Ł. Strengthening of masonry rings with composite materials. Herit. Sci. 2021, 9, 1–9. [Google Scholar] [CrossRef]

- Nowak, R.; Orłowicz, R. Testing of Chosen Masonry Arched Lintels. Int. J. Archit. Herit. 2020. [Google Scholar] [CrossRef]

- Drobiec, Ł.; Jasiński, R.; Mazur, W. Accuracy of eddy-current and radar methods used in reinforcement detection. Materials 2019, 12, 1168. [Google Scholar] [CrossRef] [Green Version]

- Łątka, D.; Matysek, P. Determination of Mortar Strength in Historical Brick Masonry Using the Penetrometer Test and Double Punch Test. Materials 2020, 13, 2873. [Google Scholar] [CrossRef]

- Nuzzo, M.; Faella, G. The Carmine Maggiore Bell Tower: An Inclusive and Sustainable Restoration Experience. Sustainability 2021, 13, 1445. [Google Scholar] [CrossRef]

- Nowak, R.; Orłowicz, R.; Rutkowski, R. Use of TLS (LiDAR) for Building Diagnostics with the Example of a Historic Building in Karlino. Buildings 2020, 10, 24. [Google Scholar] [CrossRef] [Green Version]

- Rucka, M.; Wojtczak, E.; Zielińska, M. Integrated Application of GPR and Ultrasonic Testing in the Diagnostics of a Historical Floor. Materials 2020, 13, 2547. [Google Scholar] [CrossRef] [PubMed]

- Wang, N.; Zhao, X.; Zhao, P.; Zhang, Y.; Zou, Z.; Ou, J. Automatic damage detection of historic masonry buildings based on mobile deep learning. Autom. Constr. 2019, 103, 53–66. [Google Scholar] [CrossRef]

- Borri, A.; Castori, G.; Corradi, M. Determination of shear strength of masonry panels through dierent tests. Int. J. Archit. Herit. 2015, 9, 913–927. [Google Scholar] [CrossRef]

- Matysek, P.; Witkowski, M. A comparative study on the compressive strength of bricks from different historical periods. Int. J. Archit. Herit. 2016, 10, 396–405. [Google Scholar] [CrossRef]

- EN-1996-1-1:2009. Eurocode 6—Design of Masonry Structures. Part 1-1: General Rules for Reinforced and Unreinforced Masonry Structures; CEN Comité Européen De Normalisation: Brussels, Belgium, 2009. [Google Scholar]

- Borri, A.; Corradi, M.; De Maria, A. The Failure of Masonry Walls by Disaggregation and the Masonry Quality Index. Heritage 2020, 3, 1162–1198. [Google Scholar] [CrossRef]

- De Velasco Machardo, L.; de Oliveira, U.R. Analysis of failures in the accessibility of university buildings. J. Build. Eng. 2021, 33, 101654. [Google Scholar] [CrossRef]

- Municipal Museum Museums in Poland. Available online: https://wodzislaw_slaski.fotopolska.eu/1620,foto.html?o=b846 (accessed on 9 June 2021).

- EN 772-1:2011+A1:2015. Methods of Test for Masonry Units. Determination of Compressive Strength; CEN Comité Européen De Normalisation: Brussels, Belgium, 2015. [Google Scholar]

- EN 1015-11:2019. Methods of Test for Mortar for Masonry. Determination of Flexural and Compressive Strength of Hardened Mortar; CEN Comité Européen De Normalisation: Brussels, Belgium, 2019. [Google Scholar]

- EN 1991-1-4:2005. Actions on Structures. Part 1-4: General Actions—Wind Actions; CEN Comité Européen De Normalisation: Brussels, Belgium, 2005. [Google Scholar]

- EN-1993-1-1:2005. Design of Steel Structures—Part 1-1: General Rules and Rules for Buildings; CEN Comité Européen De Normalisation: Brussels, Belgium, 2005. [Google Scholar]

| Specimen | Width, mm | Length, mm | Height, mm | Ultimate Force, kN | Strength fB, N/mm2 | Strength Mean fB, N/mm2 | |

|---|---|---|---|---|---|---|---|

| Type | Number | ||||||

| I—contemporary brick | 1.1 | 115 | 246 | 63.6 | 1079 | 38.14 | 30.29 |

| 1.2 | 113.6 | 251 | 62.7 | 919.1 | 32.23 | ||

| 1.3 | 116.3 | 248 | 62.1 | 996.7 | 34.56 | ||

| 1.4 | 122 | 262 | 62.5 | 520.3 | 16.28 | ||

| 1.5 | 117.5 | 245 | 68 | 796.2 | 27.66 | ||

| 1.6 | 114.4 | 254 | 62 | 955.7 | 32.89 | ||

| II—18th-century brick | 2.1 | 144.5 | 306 | 65.5 | 290.3 | 6.57 | 7.54 |

| 2.2 | 153.5 | 304 | 66.5 | 397.2 | 8.51 | ||

| 2.3 | 155.5 | 157.5 | 64.8 | 199.7 | 8.15 | ||

| III—14th-century brick | 3.1 | 124 | 192.5 | 49.5 | 506 | 21.20 | 16.09 |

| 3.2 | 178.6 | 207.2 | 53.2 | 432.9 | 11.70 | ||

| 3.3 | 125.5 | 206.5 | 52 | 398.7 | 15.38 | ||

| Specimen Type | Mean Strength, MPa | Mean Shape Factor δ | Standardized Mean Strength fb, N/mm2 | Class of Masonry Unit |

|---|---|---|---|---|

| I | 30.29 | 0.83 | 25.1 | 25 |

| II | 7.54 | 0.75 | 5.7 | 5 |

| III | 30.29 | 0.72 | 11.6 | 10 |

| Specimen | Width, mm | Length, mm | Height, mm | Ultimate Force, kN | Strength f, N/mm2 | Strength Mean fm, N/mm2 | |

|---|---|---|---|---|---|---|---|

| Type | Number | ||||||

| Lime mortar | 1.1 | 40 | 37 | 30 | 0.56 | 0.38 | 0.35 |

| 1.2 | 40 | 35 | 30 | 0.49 | 0.35 | ||

| 1.3 | 40 | 34 | 23 | 0.39 | 0.29 | ||

| 1.4 | 35 | 31 | 28 | 0.38 | 0.35 | ||

| 1.5 | 40 | 27 | 21 | 0.39 | 0.36 | ||

| Cement–lime mortar with coarse aggregate | 2.1 | 40 | 40 | 28 | 24.65 | 15.41 | 15.5 |

| 2.2 | 40 | 40 | 28 | 24.36 | 15.23 | ||

| 2.3 | 40 | 40 | 24 | 25.9 | 16.19 | ||

| 2.4 | 40 | 40 | 23 | 22.7 | 14.19 | ||

| 2.5 | 40 | 40 | 21 | 26.35 | 16.47 | ||

| Cement–lime mortar | 3.1 | 40 | 40 | 31 | 17.37 | 10.86 | 10.2 |

| 3.2 | 40 | 40 | 29 | 16.32 | 10.20 | ||

| 3.3 | 40 | 40 | 28 | 15.32 | 9.58 | ||

| 3.4 | 40 | 40 | 26 | 16.37 | 10.23 | ||

| Mortar | Lime Mortar | Cement–Lime Mortar with Coarse Aggregate | Cement–Lime Mortar | |

|---|---|---|---|---|

| Brick | ||||

| Type I Contemporary brick | not applicable | 7.83 | 6.91 | |

| Type II 18th century brick | 0.88 | not applicable | not applicable | |

| Type III 14th century brick | 1.45 | not applicable | not applicable | |

| Specimen | Width, mm | Length, mm | Height, mm | Ultimate force, kN | Compressive Strength fB, N/mm2 | Mean Strength fB, mean N/mm2 | |

|---|---|---|---|---|---|---|---|

| Type | Number | ||||||

| I Hollow clay brick | 1 | 270 | 135 | 65 | 395.7 | 10.86 | - |

| 2 | 240 | 118 | 65 | 305.6 | 10.79 | ||

| 3 | 257 | 125 | 67 | 231.7 | 7.21 | ||

| 4 | 165 | 125 | 67 | 94.4 | 4.58 | ||

| II Solid brick | 5 | 270 | 135 | 67 | 321.8 | 8.83 | - |

| 6 | 235 | 140 | 65 | 321.8 | 9.78 | ||

| 7.1 | 132 | 92 | 67 | 82.7 | 6.81 | 6.37 | |

| 7.2 | 129 | 70 | 67 | 53.6 | 5.94 | ||

| 8 | 130 | 120 | 65 | 286.6 | 18.37 | - | |

| 9 | 162 | 100 | 62 | 222.6 | 13.74 | ||

| 10 | 130 | 70 | 65 | 31.8 | 3.49 | ||

| Specimen No. | Strength fB, N/mm2 | Mean Shape Factor δ | Standardized Mean Strength fb, N/mm2 | Class of Masonry Unit |

|---|---|---|---|---|

| 1 | 10.86 | 0.780 | 8.47 | 5 |

| 2 | 10.79 | 0.814 | 8.78 | 5 |

| 3 | 7.21 | 0.820 | 5.91 | 5 |

| 4 | 4.58 | 0.820 | 3.75 | 2.5 |

| 5 | 8.83 | 0.800 | 7.06 | 5 |

| 6 | 9.78 | 0.770 | 7.53 | 5 |

| 7 | 5.78 | 0.886 and 0.930 | 5.78 | 5 |

| 8 | 18.37 | 0.810 | 14.88 | 10 |

| 9 | 13.74 | 0.810 | 11.13 | 10 |

| 10 | 3.49 | 0.910 | 3.18 | 2.5 |

| Specimen | Width, mm | Length, mm | Height, mm | Force Ultimate Force, kN | Strength f, MPa | Strength Average fm, MPa (Coefficient of Variation, %) | |

|---|---|---|---|---|---|---|---|

| Type | Number | ||||||

| Lime mortar | 5.1 | 24 | 28 | 15 | 0.4 | 0.60 | 0.70 (23%) |

| 5.2 | 32 | 27 | 15 | 0.74 | 0.86 | ||

| 5.3 | 22 | 22 | 15 | 0.38 | 0.79 | ||

| 5.4 | 26 | 22 | 15 | 0.34 | 0.59 | ||

| 5.5 | 25 | 19 | 15 | 0.24 | 0.51 | ||

| 5.6 | 24 | 22 | 15 | 0.5 | 0.95 | ||

| 5.7 | 25 | 25 | 15 | 0.4 | 0.64 | ||

| 6.1 | 26 | 30 | 10 | 0.45 | 0.58 | 0.64 | |

| 6.2 | 25 | 25 | 13 | 0.44 | 0.70 | ||

| Cement–lime mortar | 3.1 | 26 | 30 | 19 | 0.62 | 0.79 | 0.80 (7.2%) |

| 3.2 | 28 | 28 | 19 | 0.59 | 0.75 | ||

| 3.3 | 40 | 32 | 19 | 0.95 | 0.74 | ||

| 3.4 | 26 | 30 | 20 | 0.66 | 0.85 | ||

| 3.5 | 25 | 22 | 19 | 0.48 | 0.87 | ||

| Specimen No. | Standardized Strength of Masonry Units fb, MPa | Compressive Strength of Mortar fm, MPa | Characteristic Compressive Strength of Masonry fk, MPa | Designed Compressive Strength of Masonry fd, MPa |

|---|---|---|---|---|

| 1 | 8.47 | 0.80 | 1.00 * | 0.46 |

| 2 | 8.78 | 0.80 | 1.03 * | 0.47 |

| 3 | 5.91 | 0.80 | 0.78 | 0.35 |

| 4 | 3.75 | 0.80 | 0.57 * | 0.26 |

| 5 | 7.06 | 0.70 | 1.27 | 0.58 |

| 6 | 7.53 | 0.64 | 1.29 | 0.59 |

| 7 | 5.78 | 0.69 | 1.10 ** | 0.50 |

| 8 | 14.88 | 0.69 | 2.13 ** | 0.97 |

| 9 | 11.13 | 0.69 | 1.74 ** | 0.79 |

| 10 | 3.18 | 0.69 | 0.72 ** | 0.33 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Drobiec, Ł.; Grzyb, K.; Zając, J. Analysis of Reasons for the Structural Collapse of Historic Buildings. Sustainability 2021, 13, 10058. https://doi.org/10.3390/su131810058

Drobiec Ł, Grzyb K, Zając J. Analysis of Reasons for the Structural Collapse of Historic Buildings. Sustainability. 2021; 13(18):10058. https://doi.org/10.3390/su131810058

Chicago/Turabian StyleDrobiec, Łukasz, Krzysztof Grzyb, and Jakub Zając. 2021. "Analysis of Reasons for the Structural Collapse of Historic Buildings" Sustainability 13, no. 18: 10058. https://doi.org/10.3390/su131810058

APA StyleDrobiec, Ł., Grzyb, K., & Zając, J. (2021). Analysis of Reasons for the Structural Collapse of Historic Buildings. Sustainability, 13(18), 10058. https://doi.org/10.3390/su131810058