Development of Road Freight Transport Indicators Focused on Sustainability to Assist Shippers: An Analysis Conducted in France through the FRET 21 Programme

Abstract

:1. Introduction

2. Literature Review

2.1. Models Proposing Sustainable Transportation Indicators

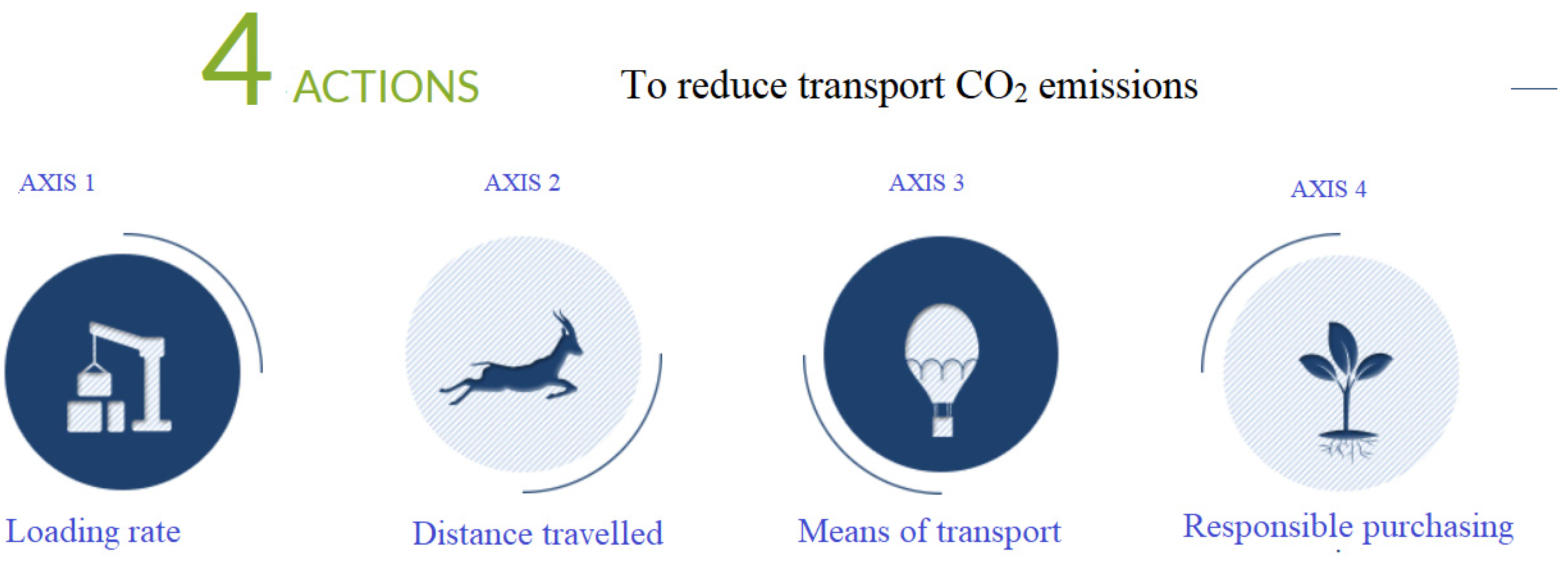

2.2. Main Decision Variables Identified to Set Up Concrete Sustainable Transport Indicators

2.2.1. Volume Optimisation

2.2.2. Distances Optimisation

2.2.3. Alternative Transport Modes

2.2.4. Fuel Consumption Reduction

2.2.5. Technological Innovation/Tool Implementation

2.2.6. Internal Management Practices

2.2.7. External Management Practices (Carriers)

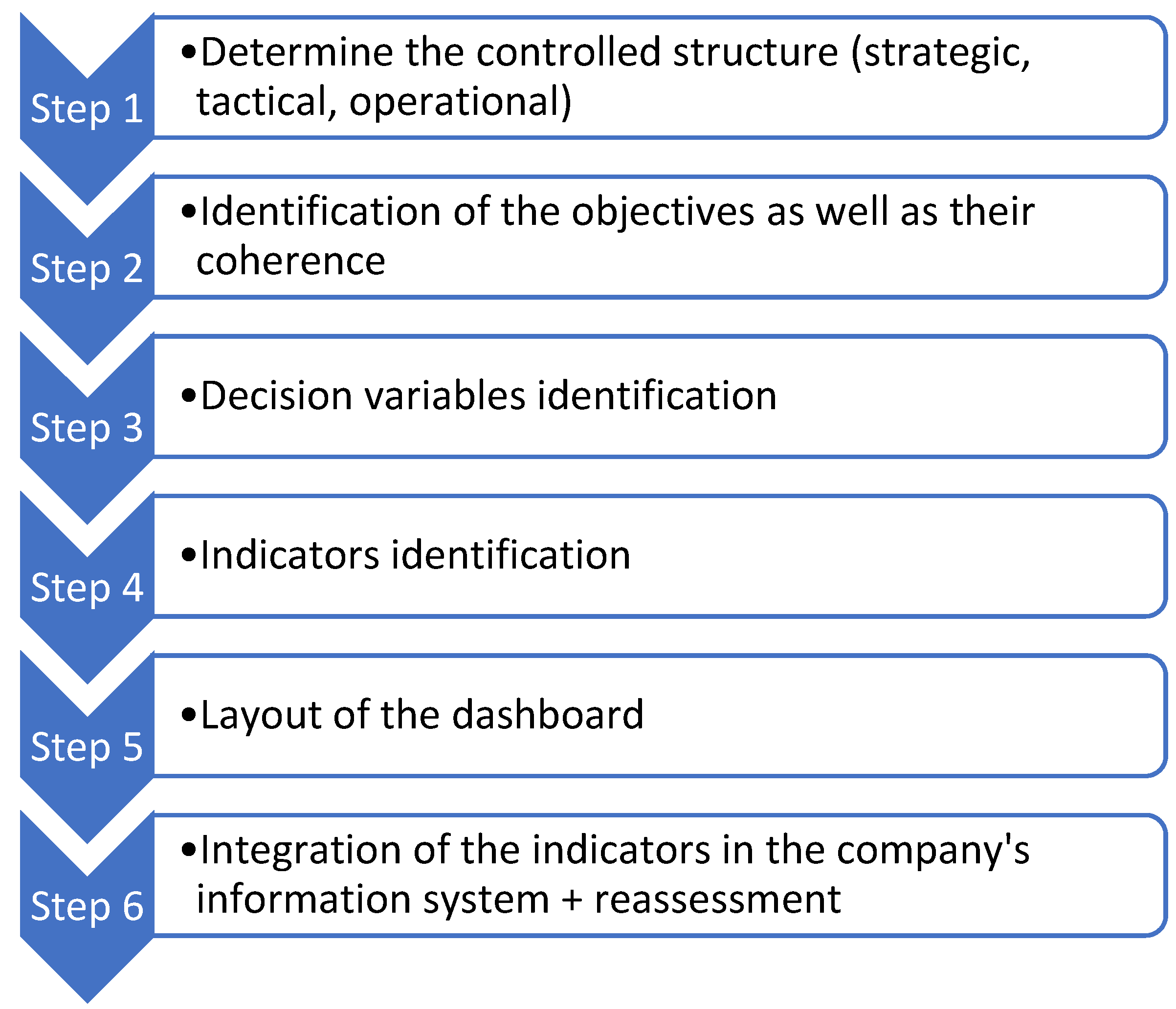

3. Methodology

3.1. Indicators Set Up through an Extensive Literature Review

3.2. Selection of the Respondents

3.3. Modalities to Submitting the Indicator Grids

3.4. Data Analysis

4. Results

4.1. Most Relevant Decision Variables

4.2. Preferred Indicators by Order of Relevancy

4.3. Preferred Indicators by Order of Feasibility

5. Conclusions

Author Contributions

Funding

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Teixeira, A.C.; Machado, P.G.; Mendes de Almeida Collaço, F.; Mouette, D. Alternative Fuel Technologies Emissions for Road Heavy-Duty Trucks: A Review. Environ. Sci. Pollut. Res. 2021, 28, 20954–20969. [Google Scholar] [CrossRef]

- Luthra, S.; Govindan, K.; Kannan, D.; Mangla, S.K.; Chandra Prakash, G. An Integrated Framework for Sustainable Supplier Selection and Evaluation in Supply Chains. J. Clean. Prod. 2017, 140, 1686–1698. [Google Scholar] [CrossRef]

- Jackson, R.W.; Lester, A.N.; Dale, A.L. An empirical investigation of the differences in goods and services as perceived by organizational buyers. Ind. Mark. Manag. 1995, 24, 99–108. [Google Scholar] [CrossRef]

- Evangelista, P.; Santoro, L.; Hallikas, J.; Kähkönen, A.K.; Lintukangas, K. Greening Logistics Outsourcing: Reasons, Actions and Influencing Factors. Int. J. Logist. Syst. Manag. 2019, 34, 269. [Google Scholar] [CrossRef]

- Touratier-Muller, N.; Ortas, E. Factors driving shippers’ compliance with a voluntary sustainable freight programme in France. J. Clean. Prod. 2021, 318, 128397. [Google Scholar] [CrossRef]

- Bask, A.; Rajahonka, M.; Laari, S.; Solakivi, T.; Töyli, J.; Ojala, L. Environmental Sustainability in Shipper-LSP Relationships. J. Clean. Prod. 2018, 172, 2986–2998. [Google Scholar] [CrossRef]

- Jazairy, A.; Von Haartman, R. Analysing the Institutional Pressures on Shippers and Logistics Service Providers to Implement Green Supply Chain Management Practices. Int. J. Logist. Res. Appl. 2020, 23, 44–84. [Google Scholar] [CrossRef] [Green Version]

- Rogerson, S. Influence of Freight Transport Purchasing Processes on Logistical Variables Related to CO2 Emissions: A Case Study in Sweden. Int. J. Logist. Res. Appl. 2017, 20, 604–623. [Google Scholar] [CrossRef]

- Van den Berg, R.; De Langen, P.W. Environmental Sustainability in Container Transport: The Attitudes of Shippers and Forwarders. Int. J. Logist. Res. Appl. 2017, 20, 146–162. [Google Scholar] [CrossRef]

- Lafkihi, M.; Pan, S.; Ballot, E. Freight Transportation Service Procurement: A Literature Review and Future Research Opportunities in Omnichannel E-Commerce. Transp. Res. Part E Logist. Transp. Rev. 2019, 125, 348–365. [Google Scholar] [CrossRef]

- Roy, S.A.; Ali, S.M.; Kabir, G.; Enayet, R.; Suhi, S.A.; Haque, T.; Hasan, R. A Framework for stainable Supplier Selection with Transportation Criteria. Int. J. Sustain. Eng. 2020, 13, 77–92. [Google Scholar] [CrossRef]

- Govindan, K.; Rajendran, S.; Sarkis, J.; Murugesan, P. Multi Criteria Decision Making Approaches for Green Supplier Evaluation and Selection: A Literature Review. J. Clean. Prod. 2015, 98, 66–83. [Google Scholar] [CrossRef]

- Large, R.O.; Kramer, N.; Hartmann, R.K. Procurement of logistics services and sustainable development in Europe: Fields of activity and empirical results. J. Purch. Supply Manag. 2013, 19, 122–133. [Google Scholar] [CrossRef]

- Touratier-Muller, N.; Machat, K.; Jaussaud, J. Impact of French Governmental Policies to Reduce Freight Transportation CO2 Emissions on Small- and Medium-Sized Companies. J. Clean. Prod. 2019, 215, 721–729. [Google Scholar] [CrossRef]

- Fulzele, V.; Shankar, R. Performance Measurement of Sustainable Freight Transportation: A Consensus Model and FERA Approach. Ann. Oper. Res. 2021. [Google Scholar] [CrossRef]

- Anttonen, M.; Halme, M.; Houtbeckers, E.; Nurkka, J. The Other Side of Sustainable Innovation: Is There a Demand for Innovative Services? J. Clean. Prod. 2013, 45, 89–103. [Google Scholar] [CrossRef] [Green Version]

- Bitton, M. Méthode de Conception et D’implantation de Systèmes de Mesures de Performances Pour Organisations Industrielles. Ph.D. Thesis, Université de Bordeaux I, Bordeaux, France, 1990; 220p. [Google Scholar]

- Doumeingts, G.; Clave, F.; Ducq, Y. ECOGRAI—A method to design and to implement Performance Measurement Systems for industrial organizations—Concepts and application to the Maintenance function. In Benchmarking—Theory and Practice; Rolstadås, A., Ed.; IFIP Advances in Information and Communication Technology; Springer: Boston, MA, USA, 1995. [Google Scholar]

- Moad, K. Modélisation et Optimisation Multi-Niveaux du Transport Forestier. Master’s Thesis, Gestion et management, Université de Bordeaux, Bordeaux, France, 2016. [Google Scholar]

- Talbot, D. Les Stratégies Climatiques et les Pratiques de Légitimation des Grands Émetteurs Industriels: Une Approche Qualitative; Doctorat en sciences de l’administration; Université de Laval: Quebec City, QC, Canada, 2015. [Google Scholar]

- McKinnon, A.C.; Edwards, J. The role of government in promoting green logistics. In Green Logistics: Improving the Environmental Sustainability of Logistics, 3rd ed.; McKinnon, A.C., Cullinane, A., Whiteing, A., Browne, M., Eds.; Kogan Page: London, UK, 2015. [Google Scholar]

- Martinsen, U.; Huge-Brodin, M. Greening the offerings of logistics service providers. In Proceedings of the 22th Annual NOFOMA Conference: Logistics and Supply Chain Management, Kolding, Denmark, 10–11 June 2010; pp. 959–984. [Google Scholar]

- Martinsen, U.; Huge-Brodin, M. Environmental Practices as Offerings and Requirements on the Logistics Market. Logist. Res. 2014, 7, 115. [Google Scholar] [CrossRef] [Green Version]

- Sarkis, J. A Strategic Decision Framework for Green Supply Chain Management. J. Clean. Prod. 2003, 11, 397–409. [Google Scholar] [CrossRef]

- Litman, T. Developing Indicators for Sustainable and Livable Transport Planning; Victoria Transport Policy Institute: Victoria, BC, Canada, 2016. [Google Scholar]

- Touratier-Muller, N.; Andersson, D. Environmental Considerations When Purchasing Transport Services: A Comparison of Management Approaches between Swedish and French Shipper; Cross-Cultural Challenges in International Management; Routledge: New York, NY, USA, 2020; pp. 193–208. [Google Scholar]

- Caplice, C.; Sheffi, Y. A Review and Evaluation of Logistics Metrics. Int. J. Logist. Manag. 1994, 5, 11–28. [Google Scholar] [CrossRef]

- Dobranskyte-Niskota, A.; Perujo, A.; Pregl, M. Indicators to Assess Sustainability of Transport Activities Part 1: Review of the Existing Transport Sustainability Indicators Initiatives and Development of an Indicator Set to Assess Transport Sustainability Performance; OPOCE, European Commission, Joint Research Centre: Ispra, Italy, 2007. [Google Scholar]

- McIntyre, K.; Smith, H.; Henham, A.; Pretlove, J. Environmental Performance Indicators for Integrated Supply Chains: The Case of Xerox Ltd. Supply Chain Manag. Int. J. 1998, 3, 149–156. [Google Scholar] [CrossRef]

- McKinnon, A. Performance Measurement in Freight Transport: Its Contribution to the Design, Implementation and Monitoring of Public Policy; International Transport Forum: Queretaro, Mexico, 2015. [Google Scholar]

- Garcia, I.V.; Wang, K.; Babinsky, H. Aerodynamic shape optimization of double-deck trucks. In Proceedings of the Third International Conference in Numerical and Experimental Aerodynamics of Road Vehicles and Trains, Milan, Italy, 13–15 June 2018. [Google Scholar]

- McClelland, D.; McKinnon, A. Use of Vehicle Telematics Systems for the Collection of Key Performance Indicator Data in Road Freight Transport; Heriot-Watt University: Edinburgh, UK, 2004. [Google Scholar]

- Hirsch, P. Minimizing Empty Truck Loads in Round Timber Transport with Tabu Search Strategies. Int. J. Inf. Syst. Supply Chain Manag. (IJISSCM) 2011, 4, 15–41. [Google Scholar] [CrossRef] [Green Version]

- McKinnon, A. The Potential of Economic Incentives to Reduce CO2 Emissions from Goods Transport. In Proceedings of the 1st International Transport Forum on ‘Transport and Energy: The Challenge of Climate Change’, Leipzig, Germany, 28–30 May 2008. [Google Scholar]

- Peignier, I. Gestion des Risques Reliés au Transport de Matières Dangereuses au Québec: Un Outil d’aide à la Décision Pour le Choix des Transporteurs; Université de Montréal: Montréal, QC, Canada, 2010. [Google Scholar]

- Touratier-Muller, N. Le Rôle et la Responsabilité des “Achats de Transport” dans la Prise en Compte des Critères Environnementaux et des Émissions CO2 en France. Ph.D. Thesis, Université de Pau et des Pays de l’Adour (UPPA), Pau, France, 2018. [Google Scholar]

- Bachok, S.; Ponrahono, Z.; Osman, M.M.; Jaafar, S.; Ibrahim, M.; Mohamed, M. A preliminary Study of Sustainable Transport Indicators in Malaysia: The Case Study of Klang Valley Public Transportation. Procedia Environ. Sci. 2015, 28, 464–473. [Google Scholar] [CrossRef] [Green Version]

- Forinash, C. Sustainable Transportation Performance Measures; EPA Office of Sustainable Communities: Austin, TX, USA, 2011. [Google Scholar]

- Gnap, J.; Poliak, M.; Semanova, S. The Issue of a Transport Mode Choice from the Perspective of Enterprise Logistics. Open Eng. 2019, 9, 374–383. [Google Scholar] [CrossRef]

- Rostamzadeh, R.; Govindan, K.; Esmaeili, A.; Sabaghi, M. Application of fuzzy VIKOR for evaluation of green supply chain management practices. Ecol. Indic. 2015, 49, 188–203. [Google Scholar] [CrossRef]

- Weijers, S.; Glöckner, H.H.; Pieters, R. Logistic service providers and sustainable physical distribution. In Scientific Journal of Logistics Edition; HAN University of Applied Sciences: Arnhem, The Netherlands, 2012. [Google Scholar]

- Zegras, C. Sustainable Transportation Indicators and assessment methodologies. In Proceedings of the Biannual conference and Exhibit of the Clean Air Initiative for Latin American Cities, São Paulo, Brazil, 25–27 July 2006. [Google Scholar]

- Pinchasik, D.R.; Hovi, I.B.; Bø, E.; Mjøsund, C.S. Can Active Follow-Ups and Carrots Make Eco-Driving Stick? Findings from a Controlled Experiment among Truck Drivers in Norway. Energy Res. Soc. Sci. 2021, 75, 102007. [Google Scholar] [CrossRef]

- Kumar, A. Transition Management Theory-Based Policy Framework for Analyzing Environmentally Responsible Freight Transport Practices. J. Clean. Prod. 2021, 294, 126209. [Google Scholar] [CrossRef]

- Shah, N. Green Purchasing: The Issue of Responsible Supply Chain Management for Improving the Environmental Performance; HCS Consulting: Report written from a Master thesis; Illinois Institute of Technology: Chicago, IL, USA, 2010. [Google Scholar]

- Marino, C.; Monterosso, C.; Nucara, A.; Panzera, M.F. Analysis of the Reduction of Pollutant Emissions by the Vehicle Fleet of the City of Reggio Calabria Due to the Introduction of Ecological Vehicles. Sustainability 2020, 12, 2877. [Google Scholar] [CrossRef] [Green Version]

- Aronsson, H.; Huge Brodin, M. The Environmental Impact of Changing Logistics Structures. Int. J. Logist. Manag. 2006, 17, 394–415. [Google Scholar] [CrossRef]

- Wang, Y.; Boggio-Marzet, A. Evaluation of Eco-Driving Training for Fuel Efficiency and Emissions Reduction According to Road Type. Sustainability 2018, 10, 3891. [Google Scholar] [CrossRef] [Green Version]

- Eng-Larsson, F.; Kohn, C. Modal Shift for Greener Logistics—The Shipper’s Perspective. Int. J. Phys. Distrib. Logist. Manag. 2012, 42, 36–59. [Google Scholar] [CrossRef]

- Bonvoisin, F. Evaluation de la Performance des Blocs Opératoires: Du Modèle aux Indicateurs; Discipline: Automatique Spécialité: Automatique et Génie Informatique. Master’s Thesis, Université de Valenciennes et du Hainaut-Cambresis, Valenciennes, France, 2011. [Google Scholar]

- Robin, V.; Sperandio, S.; Blanc, S.; Girard, P. Interactions Modelling between Factors Influencing Management of Design System Evolution. In Proceedings of the 15th International Conference on Engineering Design, ICED 2005, Melbourne, Australia, 15–18 August 2005. [Google Scholar]

- Achhal, Y. Cadre Méthodologique Pour la Conception D’indicateurs de Performance de Développement Durable (Maîtrise en Génie Mécanique); Université de Laval: Quebec City, QC, Canada, 2013. [Google Scholar]

- Ducq, Y.; Vallespir, B. Definition and aggregation of a Performance Measurement System in three aeronautical workshops using the ECOGRAI Method. Int. J. Prod. Plan. Control 2005, 16, 163–177. [Google Scholar] [CrossRef]

- El Mahmedi, A.; Addouche, S.A.; Dafaoui, E.M. Identification des Relations Entre Inducteurs et Indicateurs de Performance des Processus D’entreprise; Conception et Production Intégrées: Casablanca, Morocco, 2005. [Google Scholar]

- Carmines, E.G.; McIver, J.P. Analyzing models with unobserved variables. In Social Measurement: Current Issues; Bohrnstedt, G.W., Borgatta, E.F., Eds.; Sage: Beverly Hills, CA, USA, 1981. [Google Scholar]

- Demeuse, M. Introduction aux Théories et aux Méthodes de la Mesure en Sciences Psychologiques et en Sciences de L’éducation; Licence en Sciences de L’éducation: Liège, Belgique, 2004. [Google Scholar]

- Symon, G.; Cassell, C. Qualitative Methods and Analysis in Organizational Research: A Practical Guide; SAGE: London, UK, 1998. [Google Scholar]

- Baumler, I.; Kotzab, H. Intelligent transportation system development, main influences and key technologies. In Proceedings of the Nofoma Conference, Lund, Sweden, 8–9 June 2017. [Google Scholar]

| Technical and Operational Dimension | Decision variables |

| 1. Volume optimisation | |

| 2. Distance optimisation | |

| 3. Alternative transport modes | |

| 4. Fuel consumption reduction | |

| 5. Technological innovations / tools implementation | |

| Managerial Dimension | Decision variables |

| 6. Internal management practices | |

| 7. External management practices (carriers, clients, other companies) |

| Main Decision Variables Identified and Retained | References |

|---|---|

| 1. Volume optimisation | [14,19,28,29,35] |

| 2. Distance optimisation | [22,25]; Indicators set-up by the private organisation TK’Blue * |

| 3. Alternative modes of transportation | [13,21,30,37,38]; EEA report (2008) |

| 4. Reduction in fuel consumption | [20,25,40,42,44]; EEA report (2008) |

| 5. Technological innovations/ implementation of tools | [25,28,40]; The Responsible Purchasing Observatory (2011) |

| 6. Internal management practices | [22,44] |

| 7. External management practices | [5,13,14,25,28,40,49]; indicators set up by the private organisation TK’Blue |

| 1. Volume Optimisation |

| 1. Loading rate of trucks carrying the shipper’s goods |

| 2. Double-deck loading rate |

| 3. Weight of goods loaded per pallet and then per truck |

| 4. Number of empty kilometres for trucks carrying no goods |

| 2. Distance optimization |

| 5. Average number of kilometres travelled by road concerning shippers’ finished goods |

| 6. Average kilometres travelled by road transport for each product reference: |

| 3. Alternative modes of transportation |

| 7. Percentage of volumes managed by transport mode (road, rail, waterways) |

| 4. Reduction in fuel consumption |

| 8. Fuel consumption per truck per km |

| 9. Consumption per “standard haul” |

| 10. Consumption per driver |

| 11. Percentage of journeys carried out using alternative energy sources (biofuels, biomethane, hybrid vehicles, gas) |

| 5. Technological innovations/ implementation of tools |

| 12. Percentage of pallets ‘received’ and ‘loaded’ on Euro 5 and Euro 6 standards vehicles |

| 13. Percentage of carriers equipped with telematics technology |

| 6. Internal management practices |

| 14. Frequency of training for transport buyers |

| 15. Frequency of meetings with other divisions on environmental issues |

| 7. External management practices |

| 16. Percentage of pallets received and loaded via carriers with ISO 14001 certification |

| 17. Percentage of pallets received and loaded via “CO2-chartered” carriers |

| 18. Percentage of pallets received and sent via carriers with the “CO2 label” |

| 19. Percentage of carriers complying with the decree 2011-1336 |

| 20. Percentage of drivers who received eco-driving training during the preceding two years |

| 21. Frequency of meetings with carriers on environmental issues |

| Company | Industrial Sector | Size | Country of Origin | Our Main Interlocutor for this Research |

|---|---|---|---|---|

| Air products | Petrochemicals | Large | USA | Supply Chain Manager |

| Carrefour | Mass distribution | Large | France | Sustainable Supply Chain and Transportation Manager |

| Coca-Cola | Food industry | Large | USA | Sustainable Supply Chain Manager |

| Ferrero | Food industry | Large | France | Transportation Purchasing Manager |

| Fleury Michon | Food industry | Large | France | Transportation Purchasing Manager |

| Hénaff | Food industry | Medium-sized | France | Transportation Purchasing Manager |

| Orrion Chemicals Orgaform | Chemicals | Small | France | Transportation Purchasing Manager |

| SCA Hygien Products | Hygiene sector | Large | Sweden | Supply Chain Director (SCA Incontinence Care, South Division) |

| Saint-Gobain (Placoplatre) | Building materials | Large | France | Supply Chain Director, and 2 Transportation Buyers |

| Renault | Automotive | Large | France | Environment Supply Chain Director |

| Order of Relevancy | Indicators Obtaining the Best Score from the Companies Interviewed | Decision Variables |

|---|---|---|

| 1 | Loading ratio of the trucks transporting shippers’ goods | Optimising volume |

| 2 | Percentage of volumes managed by transport mode (road, rail, waterways) | Mode choice and intermodal transport |

| 3 | Percentage of journeys carried out using alternative energy sources (biofuels, biomethane, hybrid vehicles, gas) | Fuel consumption |

| 4 | Frequency of environmental meetings with carriers | External management |

| 5 | Percentage of carriers equipped with telematics | Technological innovations |

| 6 | Shippers’ goods average number of kilometres travelled | Optimising distances |

| 7 | Frequency of meetings with other divisions (Production, Purchasing, R&D) regarding environmental issues | Internal management |

| 8 | Percentage of drivers who received eco-driving training during the preceding two years | External management |

| 9 | Percentage of pallets received and loaded by carriers who signed up to the FRET21 charter | External management |

| 10 | Number of empty kilometres for trucks carrying no goods | Optimising volume |

| 11 | Percentage of carriers who obtained the “Objective CO2” certification | External management |

| 12 | Fuel consumption per truck per km | Fuel consumption |

| Order of Feasibility | Indicators Obtaining the Best Score from the Companies Interviewed | Decision Variables |

|---|---|---|

| 1 | Percentage of carriers who obtained the “Objective CO2” certification | External management |

| 2 | Loading ratio of the trucks transporting shippers’ goods | Optimising volumes |

| 3 | Frequency of meetings with other divisions (Production, Purchasing, R&D) regarding environmental issues | Internal management |

| 4 | Frequency of training for transport buyers | Internal management |

| 5 | Percentage of pallets received and loaded by carriers who signed up to the FRET 21 charter | External management |

| 6 | Frequency of environmental meetings with carriers | External management |

| 7 | Percentage of drivers who received eco-driving training during the preceding two years | External management |

| 8 | Percentage of volumes managed by transport mode (road, rail, waterways) | Mode choice and intermodal transport |

| 9 | Percentage of carriers equipped with telematics | Technological innovations |

| 10 | Percentage of pallets received and loaded via carriers with ISO 14001 certification | External management |

| 11 | Weight of goods loaded per pallet and then per truck | Optimising volumes |

| 12 | Number of empty kilometres for trucks carrying no goods | Fuel consumption |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Touratier-Muller, N.; Jaussaud, J. Development of Road Freight Transport Indicators Focused on Sustainability to Assist Shippers: An Analysis Conducted in France through the FRET 21 Programme. Sustainability 2021, 13, 9641. https://doi.org/10.3390/su13179641

Touratier-Muller N, Jaussaud J. Development of Road Freight Transport Indicators Focused on Sustainability to Assist Shippers: An Analysis Conducted in France through the FRET 21 Programme. Sustainability. 2021; 13(17):9641. https://doi.org/10.3390/su13179641

Chicago/Turabian StyleTouratier-Muller, Nathalie, and Jacques Jaussaud. 2021. "Development of Road Freight Transport Indicators Focused on Sustainability to Assist Shippers: An Analysis Conducted in France through the FRET 21 Programme" Sustainability 13, no. 17: 9641. https://doi.org/10.3390/su13179641

APA StyleTouratier-Muller, N., & Jaussaud, J. (2021). Development of Road Freight Transport Indicators Focused on Sustainability to Assist Shippers: An Analysis Conducted in France through the FRET 21 Programme. Sustainability, 13(17), 9641. https://doi.org/10.3390/su13179641