Exploring the Causes of Design Changes in Building Construction Projects: An Interpretive Structural Modeling Approach

Abstract

:1. Introduction

- Theoretical contribution, arising from developing a systematic hierarchy model to explore the underlying influences among causes;

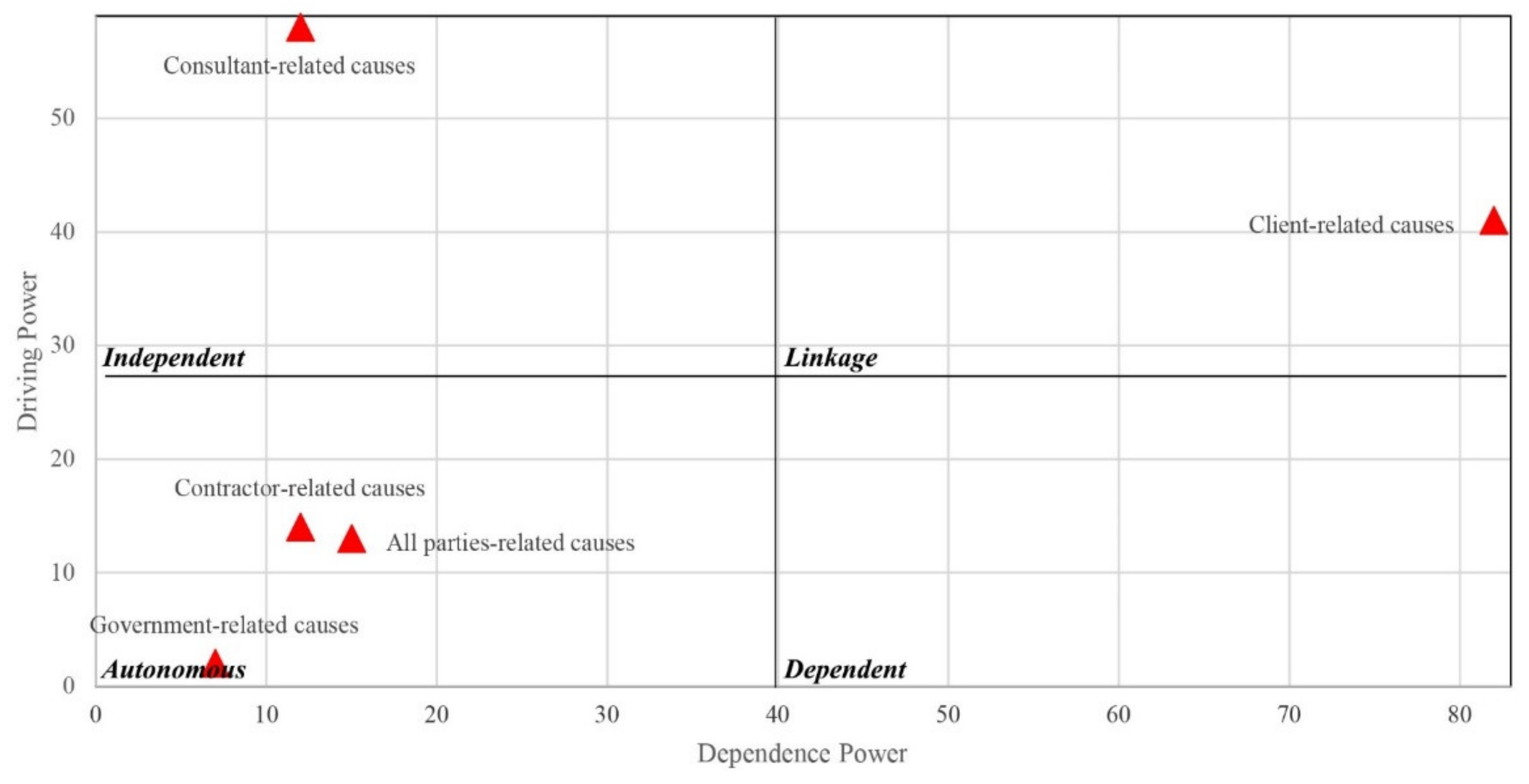

- Empirical contribution, arising from the determination of the driving and dependence power of each cause in connection with others;

- Identifying the most important management areas on which stakeholders and decision-makers should concentrate;

- Identifying and proposing remedies based on the position of causes in the developed hierarchical model and their dependence/driving power.

2. Literature Review

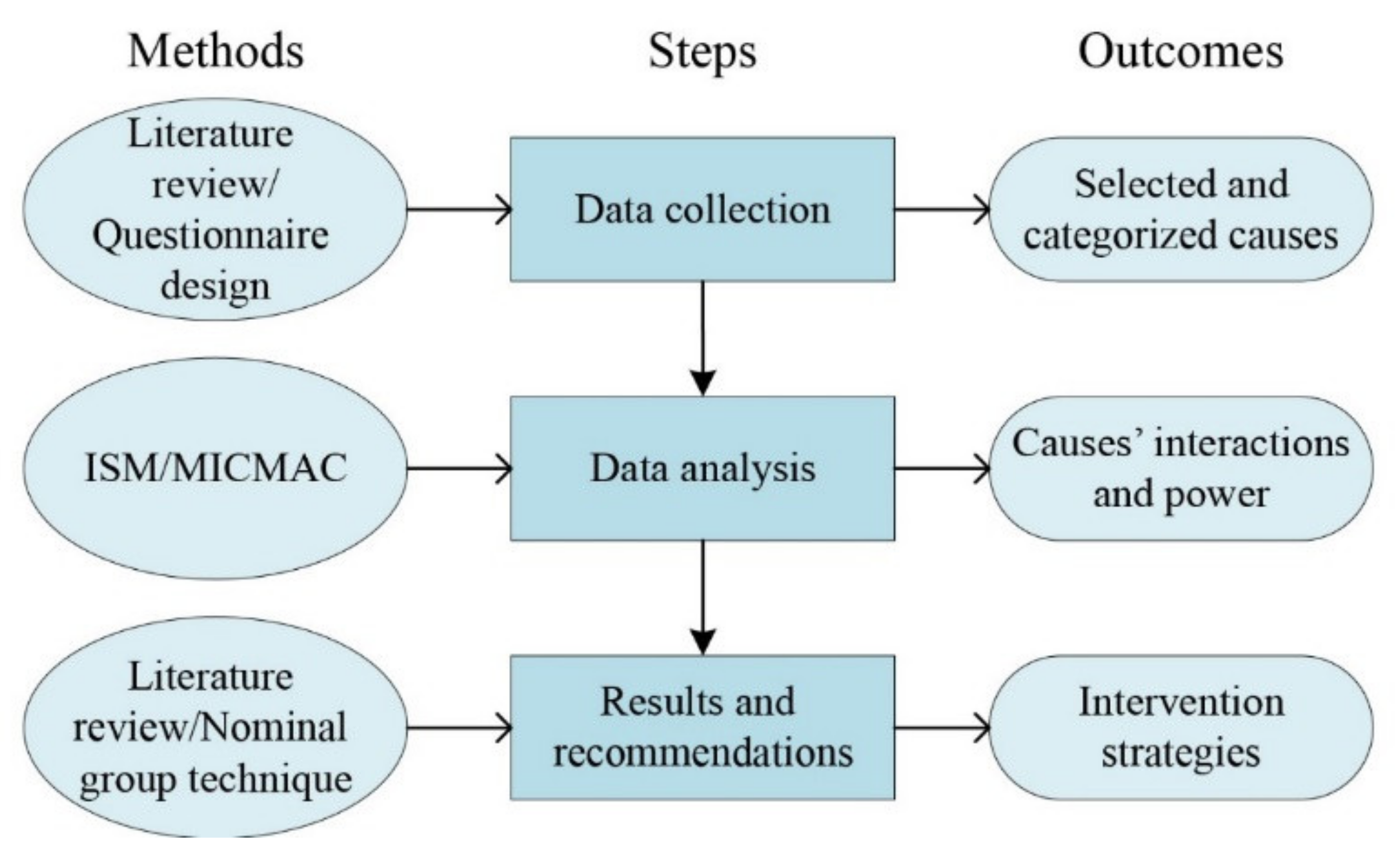

3. Research Methods

- In the first stage, in order to complete the initial list of causes identified through a comprehensive literature review and to customize them for the Iranian context, a panel of twenty professionals was surveyed. The Relative Importance Index (RII) was employed for this purpose.

- Having determined the most contributing causes, in the second step, the interrelationships between causes were assessed using the nominal group technique, in which group interviews were conducted in a way that ensured the interviewees addressed issues independently, free from any interference by other participants [28]. To do so, another panel of experts consisting of five experts was applied. The ISM approach was employed to visualize the interrelationships between the causes. The causes and management areas associated with causes were also categorized based on their driving and dependence power and illustrated using MICMAC diagrams.

- Finally, in the last stage, the results were discussed and through another brainstorming session with experts and conducting the literature review, some recommendations to alleviate the critical causes were also presented.

3.1. Data Collection

3.2. Data Analysis

- V indicates factor i affects factor j;

- A indicates factor j affects factor i;

- X indicates factors i and j have a mutual impact on each other;

- O indicates there is no relation between i and j.

4. Results and Recommendations

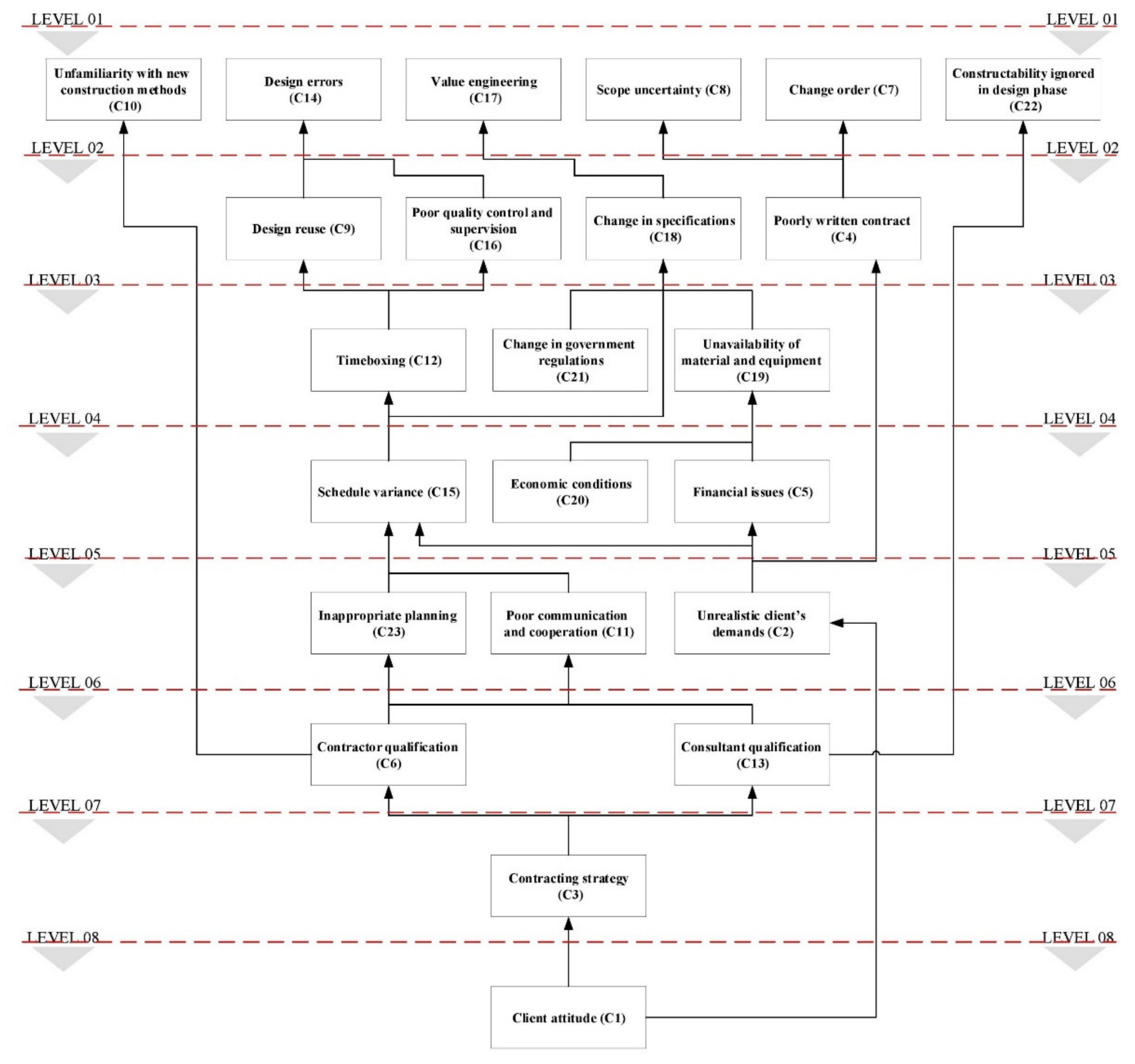

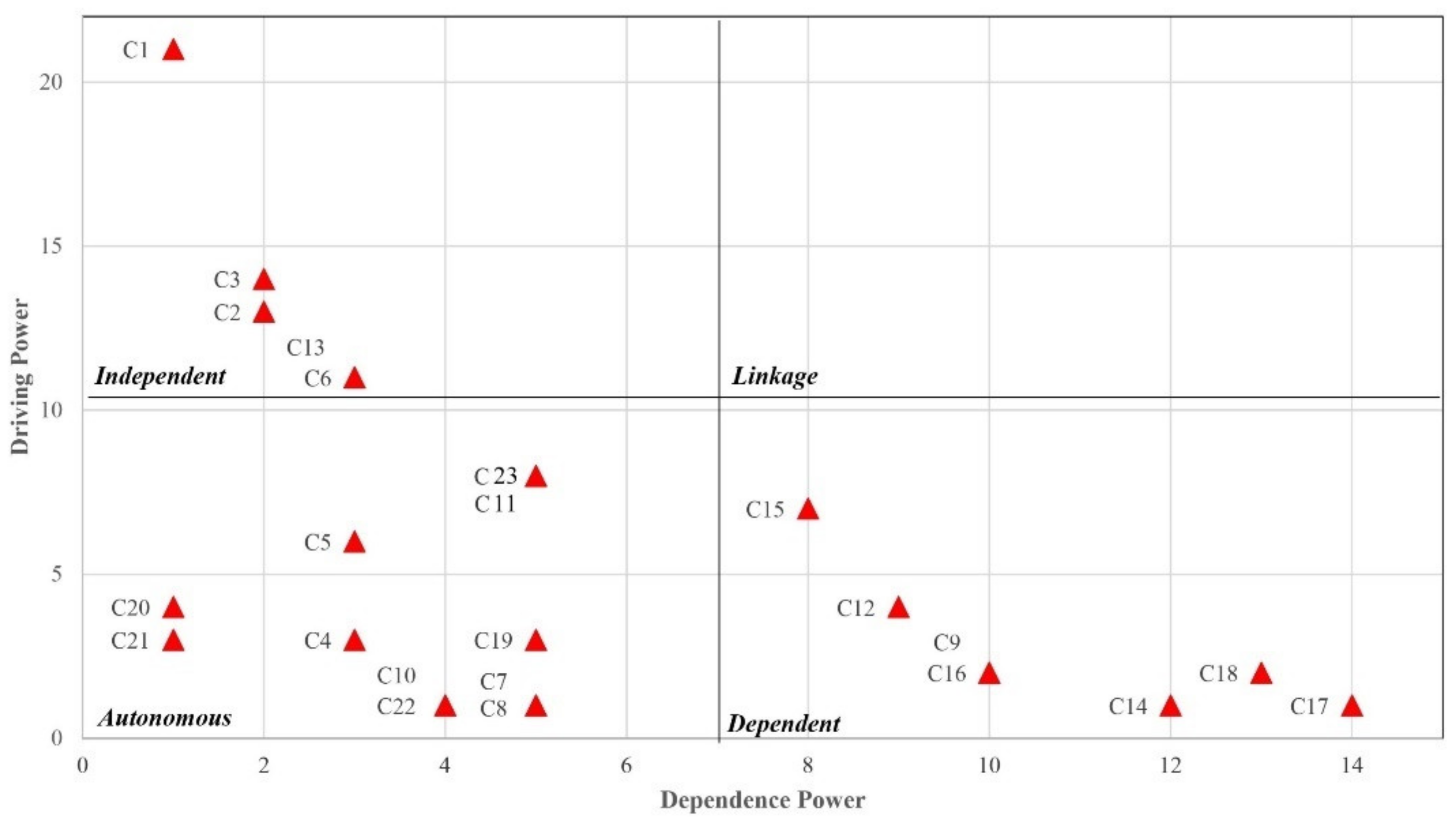

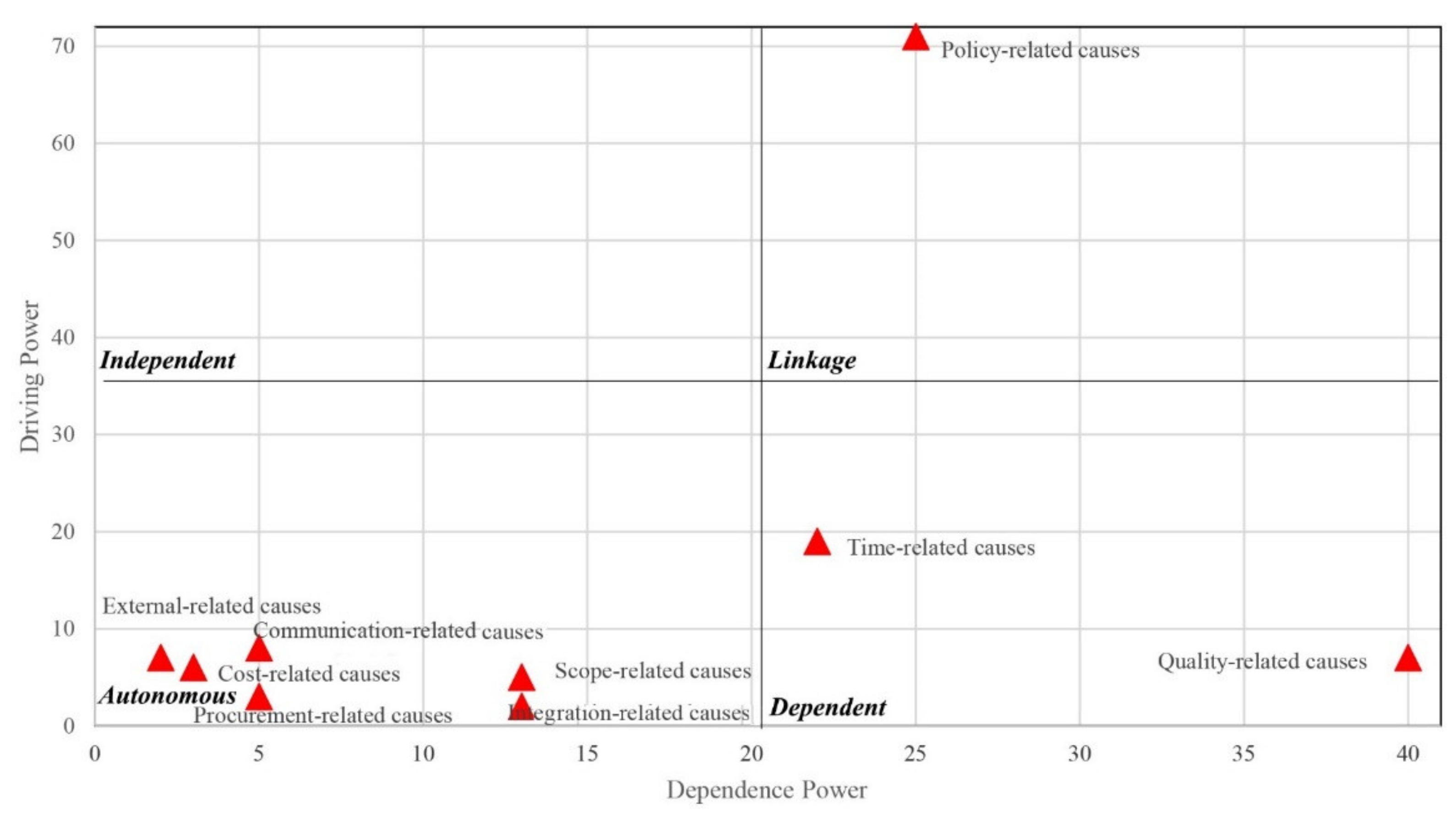

4.1. Results of ISM and MICMAC Analyses

4.2. Proposing Recommendations to Overcome Design Changes

4.2.1. Strategies to Address Independent Causes

4.2.2. Strategies to Address Dependent Causes

4.2.3. Strategies to Address Autonomous Causes

5. Discussions

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| MICMAC | Matrice d’Impacts Croisés Multiplication Appliquée à un Classement |

| ISM | Interpretive Structural Modeling |

| GDP | Gross Domestic Product |

| ANN | Artificial Neural Network |

| IPMA | International Project Management Association |

| CNBR | Co-operative Network for Building Researchers |

| RII | Relative Importance Index |

| PPP | Public–Private Partnership |

| SSIM | Structural Self-Interaction Matrix |

| DrP | Driving Power |

| DeP | Dependence Power |

| DE | Digital Engineering |

| BIM | Building Information Modeling |

| AR | Augmented Reality |

| VR | Virtual Reality |

Appendix A

| ID | Causes | Source |

|---|---|---|

| C01 | Clients’ attitude and experience | [42] |

| C02 | Unrealistic client’s demands | [27] |

| C03 | Contracting strategy | [19] |

| C04 | Poorly written contract | [25] |

| C05 | Financial issues | [24] |

| C06 | Contractor qualification | [27] |

| C07 | Change order | [25] |

| C08 | Scope uncertainty | [19] |

| C09 | Design reuse | [42] |

| C10 | Unfamiliarity with new construction methods | [19] |

| C11 | Poor communication and co-operation | [24] |

| C12 | Timeboxing | [42] |

| C13 | Consultant qualification | [42] |

| C14 | Design errors | [2] |

| C15 | Schedule variance | [10] |

| C16 | Poor quality control and supervision | [42] |

| C17 | Value engineering | [4] |

| C18 | Change in specifications | [10] |

| C19 | Unavailability of materials and equipment | [2] |

| C20 | Economic conditions | [27] |

| C21 | Change in government regulations | [24] |

| C22 | Constructability ignored in design process | [4] |

| C23 | Inappropriate planning | [19] |

| C24 | Slow decision-making | [62] |

| C25 | Change of use of building | [4] |

| C26 | Insufficient soil investigation prior to design | [4] |

| C27 | The expensiveness of current design | [27] |

| C28 | Non-compliance with authority requirements | [63] |

| C29 | Compliance to new quality requirements | [64] |

| C30 | Unforeseen ground conditions | [4] |

| C31 | Site safety considerations | [65] |

| C32 | Undetected underground utilities | [4] |

| C33 | Clashes with adjacent structures | [4] |

| C34 | Problem with adjacent properties | [4] |

| C35 | Local authority planning permission requirements | [64] |

| C36 | Outdated design | [66] |

| C37 | Incomplete drawings | [2] |

| C38 | Skill shortage in certain trades | [67] |

References

- Myers, D. Construction Economics: A New Approach, 4th ed.; Routledge: London, UK, 2016; pp. 221–249. [Google Scholar]

- Gharaibeh, L.G.; Matarneh, S.T.; Arafeh, M.; Sweis, G. Factors leading to design changes in Jordanian construction projects. Int. J. Product. Perform. Manag. 2020, 70, 893–915. [Google Scholar] [CrossRef]

- Parvan, K.; Rahmandad, H.; Haghani, A. Estimating the impact factor of undiscovered design errors on construction quality. In Proceedings of the 30th International Conference of the System Dynamics Society, St. Gallen, Switzerland, 22–26 July 2012; pp. 1–16. [Google Scholar]

- Yap, J.B.H.; Skitmore, M. Investigating design changes in Malaysian building projects. Archit. Eng. Des. Manag. 2018, 14, 218–238. [Google Scholar] [CrossRef]

- Hanna, A.S.; Camlic, R.; Peterson, P.A.; Lee, M.-J. Cumulative effect of project changes for electrical and mechanical construction. J. Constr. Eng. Manag. 2004, 130, 762–771. [Google Scholar] [CrossRef]

- Olawale, Y.A.; Sun, M. Cost and time control of construction projects: Inhibiting factors and mitigating measures in practice. Constr. Manag. Econ. 2010, 28, 509–526. [Google Scholar] [CrossRef]

- Sunday, D.O.; Afolarin, A.O. Causes, effects and remedies of errors in Nigerian construction documents. Organ. Technol. Manag. Constr. An. Int. J. 2013, 5, 676–686. [Google Scholar] [CrossRef]

- Alnuaimi, A.S.; Taha, R.A.; al Mohsin, M.; Al-Harthi, A.S. Causes, effects, benefits, and remedies of change orders on public construction projects in Oman. J. Constr. Eng. Manag. 2010, 136, 615–622. [Google Scholar] [CrossRef]

- Khanh, H.D. Factors causing design changes in Vietnamese residential construction projects: An evaluation and comparison. J. Sci. Technol. Civil. Eng. 2020, 14, 151–166. [Google Scholar] [CrossRef]

- Yap, J.B.H.; Skitmore, M.; Gray, J.; Shavarebi, K. Systemic view to understanding design change causation and exploitation of communications and knowledge. Proj. Manag. J. 2019, 50, 288–305. [Google Scholar] [CrossRef] [Green Version]

- Shoar, S.; Nasirzadeh, F.; Zarandi, H.R. Quantitative assessment of risks on construction projects using fault tree analysis with hybrid uncertainties. Constr. Innov. 2019, 19, 48–70. [Google Scholar] [CrossRef]

- Yana, A.A.G.A.; Rusdhi, H.A.; Wibowo, M.A. Analysis of factors affecting design changes in construction project with Partial Least Square (PLS). Procedia Eng. 2015, 125, 40–45. [Google Scholar] [CrossRef] [Green Version]

- Assaf, S.A.; Al-Hejji, S. Causes of delay in large construction projects. Int. J. Proj. Manag. 2006, 24, 349–357. [Google Scholar] [CrossRef]

- Ameh, O.J.; Soyingbe, A.A.; Odusami, K.T. Significant factors causing cost overruns in telecommunication projects in Nigeria. J. Constr. Dev. Ctries. 2010, 15, 49–67. [Google Scholar]

- Le-Hoai, L.; Lee, Y.D.; Lee, J.Y. Delay and cost overruns in Vietnam large construction projects: A comparison with other selected countries. KSCE J. Civil. Eng. 2008, 12, 367–377. [Google Scholar] [CrossRef]

- Owalabi, J.D.; Amusan, L.M.; Oloke, C.O. Causes and effects of delay on project construction delivery time. Int. J. Educ. Res. 2014, 2, 197–208. [Google Scholar]

- Gamil, Y.; Abdul Rahman, I. Assessment of critical factors contributing to construction failure in Yemen. Int. J. Constr. Manag. 2020, 20, 429–436. [Google Scholar] [CrossRef]

- Annamalaisami, C.D.; Kuppuswamy, A. Reckoning construction cost overruns in building projects through methodological consequences. Int. J. Constr. Manag. 2019. [Google Scholar] [CrossRef]

- Aslam, M.; Baffoe-Twum, E.; Saleem, F. Design changes in construction projects—causes and impact on the cost. Civil. Eng. J. 2019, 5, 1647–1655. [Google Scholar] [CrossRef] [Green Version]

- Parchami Jalal, M.; Shoar, S. A hybrid framework to model factors affecting construction labour productivity: Case study of Iran. J. Financ. Manag. Prop. Constr. 2019, 24, 630–654. [Google Scholar] [CrossRef]

- Samarghandi, H.; Tabatabaei, S.M.M.; Taabayan, P.; Hashemi, A.M.; Willoughby, K. Studying the reasons for delay and cost overrun in construction projects: The case of Iran. J. Constr. Dev. Ctries. 2016, 21, 51–84. [Google Scholar] [CrossRef]

- Heravi, G.; Mohammadian, M. Investigating cost overruns and delay in urban construction projects in Iran. Int. J. Constr. Manag. 2021, 21, 958–968. [Google Scholar] [CrossRef]

- Parchami Jalal, M.; Shoar, S. A hybrid SD-DEMATEL approach to develop a delay model for construction projects. Eng. Constr. Archit. Manag. 2017, 24, 629–651. [Google Scholar] [CrossRef]

- Yap, J.B.H.; Abdul-Rahman, H.; Wang, C.; Skitmore, M. Exploring the underlying factors inducing design changes during building production. Prod. Plan. Control. 2018, 29, 586–601. [Google Scholar] [CrossRef] [Green Version]

- Bassa, M. Causes and effects of design change in building construction projects in three selected southern Ethiopia zones. Int. J. Eng. Res. Technol. 2020, 8, 757–761. [Google Scholar] [CrossRef]

- Saad, D.A.; Gharib, F.; El-Said, M. Simulation of design changes impact in healthcare construction projects using system dynamics. Can. J. Civil. Eng. 2021, 48, 554–569. [Google Scholar] [CrossRef]

- Afsharghotli, A.; Yitmen, I. ANN model for assessment of design changes in gas–oil and petrochemical projects. Arab. J. Sci. Eng. 2020, 45, 4273–4284. [Google Scholar] [CrossRef]

- Janes, F.R. Interpretive structural modelling: A methodology for structuring complex issues. Trans. Inst. Meas. Control 1988, 10, 145–154. [Google Scholar] [CrossRef]

- Abowitz, D.A.; Toole, T.M. Mixed method research: Fundamental issues of design, validity, and reliability in construction research. J. Constr. Eng. Manag. 2010, 136, 108–116. [Google Scholar] [CrossRef]

- Yin, R.K. Case Study Research: Design and Methods; Sage: Thousand Oaks, CA, USA, 1994. [Google Scholar]

- Riege, A.M. Validity and reliability tests in case study research: A literature review with “hands-on” applications for each research phase. Qual. Market. Res. An. Int. J. 2003, 6, 75–86. [Google Scholar] [CrossRef] [Green Version]

- Lucko, G.; Rojas, E.M. Research validation: Challenges and opportunities in the construction domain. J. Constr. Eng. Manag. 2010, 136, 127–135. [Google Scholar] [CrossRef]

- Yu, T.; Liang, X.; Wang, Y. Factors affecting the utilization of big data in construction projects. J. Constr. Eng. Manag. 2020, 146, 04020032. [Google Scholar] [CrossRef]

- Iyer, K.C.; Sagheer, M. Hierarchical structuring of PPP risks using interpretative structural modeling. J. Constr. Eng. Manag. 2010, 136, 151–159. [Google Scholar] [CrossRef] [Green Version]

- Pidd, M. Why modelling and model use matter. J. Oper. Res. Soc. 2010, 61, 14–24. [Google Scholar] [CrossRef]

- Landry, M.; Oral, M. In search of a valid view of model validation for operations research. Eur. J. Oper. Res. 1993, 66, 161–167. [Google Scholar] [CrossRef]

- El-Diraby, T.E.; O’Connor, J.T. Lessons learned in designing research methodology in field-based construction research. J. Prof. Issues Eng. Educ. Pract. 2004, 130, 109–114. [Google Scholar] [CrossRef]

- Lopez, C.; Salmeron, J.L. Dynamic risks modelling in ERP maintenance projects with FCM. Inf. Sci. 2014, 256, 25–45. [Google Scholar] [CrossRef]

- Khanzadi, M.; Nasirzadeh, F.; Dashti, M.S. Fuzzy cognitive map approach to analyze causes of change orders in construction projects. J. Constr. Eng. Manag. 2018, 144, 04017111. [Google Scholar] [CrossRef]

- Shrivas, A.; Singla, H.K. Analysis of interaction among the factors affecting delay in construction projects using interpretive structural modelling approach. Int. J. Constr. Manag. 2020. [Google Scholar] [CrossRef]

- Prakash, A.; Phadtare, M. Exploration of logic in project marketing using interpretive structural modeling. J. Constr. Eng. Manag. 2019, 145, 04019066. [Google Scholar] [CrossRef]

- Assaf, S.; Hassanain, M.A.; Abdallah, A. Review and assessment of the causes of deficiencies in design documents for large construction projects. Int. J. Build. Pathol. Adapt. 2018, 36, 300–317. [Google Scholar] [CrossRef]

- Sushil. Interpreting the interpretive structural model. Glob. J. Flex. Syst. Manag. 2012, 13, 87–106. [Google Scholar] [CrossRef]

- Tavakolan, M.; Etemadinia, H. Fuzzy weighted interpretive structural modeling: Improved method for identification of risk interactions in construction projects. J. Constr. Eng. Manag. 2017, 143, 04017084. [Google Scholar] [CrossRef]

- Kannan, G.; Pokharel, S.; Kumar, P.S. A hybrid approach using ISM and fuzzy TOPSIS for the selection of reverse logistics provider. Resour. Conserv. Recycl. 2009, 54, 28–36. [Google Scholar] [CrossRef]

- Mandal, A.; Deshmukh, S.G. Vendor selection using interpretive structural modelling (ISM). Int. J. Oper. Prod. Manag. 1994, 14, 52–59. [Google Scholar] [CrossRef]

- Malone, D.W. An introduction to the application of interpretive structural modeling. Proc. IEEE 1975, 63, 397–404. [Google Scholar] [CrossRef]

- Lopez, R.; Love, P.E.D.; Edwards, D.J.; Davis, P.R. Design error classification, causation, and prevention in construction engineering. J. Perform. Constr. Facil. 2010, 24, 399–408. [Google Scholar] [CrossRef]

- Love, P.E.D.; Edwards, D.J.; Irani, Z. Forensic project management: An exploratory examination of the causal behavior of design-induced rework. IEEE Trans. Eng. Manag. 2008, 55, 234–247. [Google Scholar] [CrossRef]

- Abdul-rahman, H.; Wang, C.; Yap, J.B.H. Impacts of design changes on construction project performance: Insights from literature review. J. Quant. Surv. Constr. Bus. 2017, 7, 31–54. [Google Scholar]

- Suleiman, I.J.; Luvara, V.G.M. Factors influencing change of design of building projects during construction Stage in Dar-es-Salaam Tanzania. Int. J. Constr. Eng. Manag. 2016, 5, 93–101. [Google Scholar]

- Love, P.E.D.; Irani, Z.; Edwards, D.J. A rework reduction model for construction projects. IEEE Trans. Eng. Manag. 2004, 51, 426–440. [Google Scholar] [CrossRef] [Green Version]

- Nazari, A.; Vandadian, S.; Abdirad, H. Fuzzy AHP model for prequalification of engineering consultants in the Iranian public procurement system. J. Manag. Eng. 2017, 33, 04016042. [Google Scholar] [CrossRef]

- Love, P.E.D.; Edwards, D.J. Forensic project management: The underlying causes of rework in construction projects. Civil. Eng. Environ. Syst. 2004, 21, 207–228. [Google Scholar] [CrossRef]

- Hosseini, M.R.; Jupp, J.; Papadonikolaki, E.; Mumford, T.; Joske, W.; Nikmehr, B. Position paper: Digital engineering and building information modelling in Australia. Smart Sustain. Built Environ. 2020. [Google Scholar] [CrossRef]

- Pour Rahimian, F.; Chavdarova, V.; Oliver, S.; Chamo, F. OpenBIM-Tango integrated virtual showroom for offsite manufactured production of self-build housing. Autom. Constr. 2019, 102, 1–16. [Google Scholar] [CrossRef]

- Shen, L.; Song, X.; Wu, Y.; Liao, S.; Zhang, X. Interpretive Structural Modeling based factor analysis on the implementation of Emission Trading System in the Chinese building sector. J. Clean. Prod. 2016, 127, 214–227. [Google Scholar] [CrossRef]

- Elghaish, F.; Matarneh, S.; Talebi, S.; Kagioglou, M.; Hosseini, M.R.; Abrishami, S. Toward digitalization in the construction industry with immersive and drones technologies: A critical literature review. Smart Sustain. Built Environ. 2020. [Google Scholar] [CrossRef]

- Pour Rahimian, F.; Seyedzadeh, S.; Oliver, S.; Rodriguez, S.; Dawood, N. On-demand monitoring of construction projects through a game-like hybrid application of BIM and machine learning. Autom. Constr. 2020, 110, 103012. [Google Scholar] [CrossRef]

- Moshtaghian, F.; Golabchi, M.; Noorzai, E. A framework to dynamic identification of project risks. Smart Sustain. Built Environ. 2020, 9, 375–393. [Google Scholar] [CrossRef]

- Makadok, R.; Burton, R.; Barney, J. A practical guide for making theory contributions in strategic management. Strateg. Manag. J. 2018, 39, 1530–1545. [Google Scholar] [CrossRef]

- Muller, R.; Smith, E.; Lillah, R. The impact of employee engagement on organizational performance: A balanced score-card approach. Int. J. Econ. Financ. Stud. 2018, 10, 22–39. [Google Scholar]

- Nel, D. Allocation of risk in public private partnerships in information and communications technology. Int. J. eBusiness eGovernment Stud. 2020, 12, 1–16. [Google Scholar] [CrossRef] [Green Version]

- Shoar, S.; Payan, S. A qualitative system dynamics approach to modeling the causes and effects of design deficiencies in construction projects. J. Facil. Manag. 2021. [Google Scholar] [CrossRef]

- Erol, M. Occupational health and work safety systems in compliance with industry 4.0: Research directions. Int. J. eBusiness eGovernment Stud. 2019, 11, 121–133. [Google Scholar] [CrossRef]

- Sardari, M.; Bavar, S. Introducing the innovative course of architecture modeling and rendering (RSVP). J. Res. Sci. Eng. Technol. 2017, 5, 1–5. [Google Scholar] [CrossRef]

- Orando, M.; Isabirye, A.K. Construction workers’ skill development: A strategy for improving capacity and productivity in South Africa. Int. J. Econ. Financ. Stud. 2018, 10, 66–80. [Google Scholar]

| Validation | Description | Designed Questions | Mean Value of Experts’ Agreement | Final Value of Experts’ Agreement |

|---|---|---|---|---|

| Conceptual validity | It is concerned with the degree of relevance and accuracy of the scope, and level of detail underlying the conceptual model. | Is the conceptual model an accurate representation of the system under investigation? | 4.6 | 4.7 |

| Does the conceptual model contain all necessary details? | 4.8 | |||

| Experimental validity | It is concerned with the degree of efficiency and accuracy of obtained results. | Are the results of the research sufficiently accurate and efficient? | 4.4 | 4.45 |

| Are the results achieved from the analysis of the model in agreement with what has been witnessed during the project? | 4.6 | |||

| Are the immediate causes of design changes identified by the analysis, the most prevalent causes witnessed during the project? | 4.6 | |||

| Does managing the identified root causes of design changes result in mitigating the occurrence of design changes? | 4.2 | |||

| Operational validity | It is concerned with the quality and applicability of the proposed intervention strategies. | How do you evaluate the usefulness and applicability of the proposed strategies for managing and decreasing the occurrence of design changes in construction projects? | 4.4 | 4.4 |

| External validity | It is concerned with the generalizability of research findings to different settings. | Does the causal model contain critical factors that could lead to design changes in building construction projects within different settings? | 4.5 | 4.437 |

| Are the causal relationships found within this study generalizable to building construction projects in different settings? | 4.25 | |||

| Based on your experience, could the consideration of the proposed strategies be of benefit to tackling design changes in your own setting? | 4.375 | |||

| Are the findings of this study congruent with, connected to, or confirmatory of previous knowledge in this field? | 4.625 |

| ID | Causes | Responsible Stakeholders | Management Area | Source |

|---|---|---|---|---|

| C01 | Clients’ attitude and experience | Client | Policy | [42] |

| C02 | Unrealistic client’s demands | Client | Policy | [27] |

| C03 | Contracting strategy | Client | Policy | [19] |

| C04 | Poorly written contract | Client | Scope | [25] |

| C05 | Financial issues | Client | Cost | [24] |

| C06 | Contractor qualification | Client | Policy | [27] |

| C07 | Change order | Client | Scope | [25] |

| C08 | Scope uncertainty | Client | Scope | [19] |

| C09 | Design reuse | Consultant | Quality | [42] |

| C10 | Unfamiliarity with new construction methods | Contractor | Quality | [19] |

| C11 | Poor communication and co-operation | All parties | Communication | [24] |

| C12 | Timeboxing | Consultant | Time | [42] |

| C13 | Consultant qualification | Client | Policy | [42] |

| C14 | Design errors | Consultant | Quality | [2] |

| C15 | Schedule variance | All parties | Time | [10] |

| C16 | Poor quality control and supervision | Consultant | Quality | [42] |

| C17 | Value engineering | Client | Policy | [4] |

| C18 | Change in specifications | Consultant | Integration | [10] |

| C19 | Unavailability of materials and equipment | Contractor | Procurement | [2] |

| C20 | Economic conditions | Government | External | [27] |

| C21 | Change in government regulations | Government | External | [24] |

| C22 | Constructability ignored in design process | Consultant | Quality | [4] |

| C23 | Inappropriate planning | Contractor | Time | [19] |

| C1 | C2 | C3 | C4 | C5 | C6 | C7 | C8 | C9 | C10 | C11 | C12 | C13 | C14 | C15 | C16 | C17 | C18 | C19 | C20 | C21 | C22 | C23 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| C1 | 1 | 1 | 1 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| C2 | 0 | 1 | 0 | 1 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| C3 | 0 | 0 | 1 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| C4 | 0 | 0 | 0 | 1 | 0 | 0 | 1 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| C5 | 0 | 0 | 0 | 0 | 1 | 0 | 1 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 1 | 0 | 0 | 0 | 0 |

| C6 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 1 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 |

| C7 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| C8 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| C9 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| C10 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| C11 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| C12 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 1 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| C13 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 1 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 1 |

| C14 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| C15 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 1 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 |

| C16 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| C17 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 |

| C18 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 1 | 0 | 0 | 0 | 0 | 0 |

| C19 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 1 | 0 | 0 | 0 | 0 |

| C20 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 1 | 0 | 0 | 0 |

| C21 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 1 | 0 | 0 |

| C22 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 |

| C23 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 |

| C1 | C2 | C3 | C4 | C5 | C6 | C7 | C8 | C9 | C10 | C11 | C12 | C13 | C14 | C15 | C16 | C17 | C18 | C19 | C20 | C21 | C22 | C23 | DrP | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| C1 | 1 | 1 | 1 | 1 | 1 * | 1 * | 1 * | 1 * | 1 * | 1 * | 1 | 1 * | 1 * | 1 * | 1 * | 1 * | 1 * | 1 * | 1 * | 0 | 0 | 1 * | 1 * | 21 |

| C2 | 0 | 1 | 0 | 1 | 1 | 0 | 1 * | 1 * | 1 * | 0 | 0 | 1 * | 0 | 1 * | 1 * | 1 * | 1 * | 1 * | 1 * | 0 | 0 | 0 | 0 | 13 |

| C3 | 0 | 0 | 1 | 0 | 0 | 1 | 0 | 0 | 1 * | 1 * | 1 * | 1 * | 1 | 1 * | 1 * | 1 * | 1 * | 1 * | 0 | 0 | 0 | 1 * | 1 * | 14 |

| C4 | 0 | 0 | 0 | 1 | 0 | 0 | 1 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 3 |

| C5 | 0 | 0 | 0 | 0 | 1 | 0 | 1 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 1 * | 1 | 0 | 0 | 0 | 0 | 6 |

| C6 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 1 * | 1 | 1 | 1 * | 0 | 1 * | 1 * | 1 | 1 * | 1 * | 0 | 0 | 0 | 0 | 1 | 11 |

| C7 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 |

| C8 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 |

| C9 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 2 |

| C10 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 |

| C11 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 * | 0 | 1 | 1 * | 0 | 1 * | 1 | 1 * | 1 * | 1 * | 0 | 0 | 0 | 0 | 0 | 8 |

| C12 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 1 | 0 | 1 * | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 4 |

| C13 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 * | 0 | 1 | 1 * | 1 | 1 | 1 * | 1 * | 1 * | 1 * | 0 | 0 | 0 | 1 | 1 | 11 |

| C14 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 |

| C15 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 * | 0 | 0 | 1 | 0 | 1 * | 1 | 1 * | 1 * | 1 | 0 | 0 | 0 | 0 | 0 | 7 |

| C16 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 2 |

| C17 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 1 |

| C18 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 1 | 0 | 0 | 0 | 0 | 0 | 2 |

| C19 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 * | 1 | 1 | 0 | 0 | 0 | 0 | 3 |

| C20 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 * | 1 * | 1 | 1 | 0 | 0 | 0 | 4 |

| C21 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 * | 1 | 0 | 0 | 1 | 0 | 0 | 3 |

| C22 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 1 |

| C23 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 * | 0 | 0 | 1 * | 0 | 1 * | 1 | 1 * | 1 * | 1 * | 0 | 0 | 0 | 0 | 1 | 8 |

| DeP | 1 | 2 | 2 | 3 | 3 | 3 | 5 | 5 | 10 | 4 | 5 | 9 | 3 | 12 | 8 | 10 | 14 | 13 | 5 | 1 | 1 | 4 | 5 | _ |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shoar, S.; Chileshe, N. Exploring the Causes of Design Changes in Building Construction Projects: An Interpretive Structural Modeling Approach. Sustainability 2021, 13, 9578. https://doi.org/10.3390/su13179578

Shoar S, Chileshe N. Exploring the Causes of Design Changes in Building Construction Projects: An Interpretive Structural Modeling Approach. Sustainability. 2021; 13(17):9578. https://doi.org/10.3390/su13179578

Chicago/Turabian StyleShoar, Shahab, and Nicholas Chileshe. 2021. "Exploring the Causes of Design Changes in Building Construction Projects: An Interpretive Structural Modeling Approach" Sustainability 13, no. 17: 9578. https://doi.org/10.3390/su13179578

APA StyleShoar, S., & Chileshe, N. (2021). Exploring the Causes of Design Changes in Building Construction Projects: An Interpretive Structural Modeling Approach. Sustainability, 13(17), 9578. https://doi.org/10.3390/su13179578