Innovative Olive Tree Leaves Shredder Prototype for the Valorization of Wasted Leaves: An Application to High-Quality Compost Production

Abstract

:1. Introduction

2. Materials and Methods

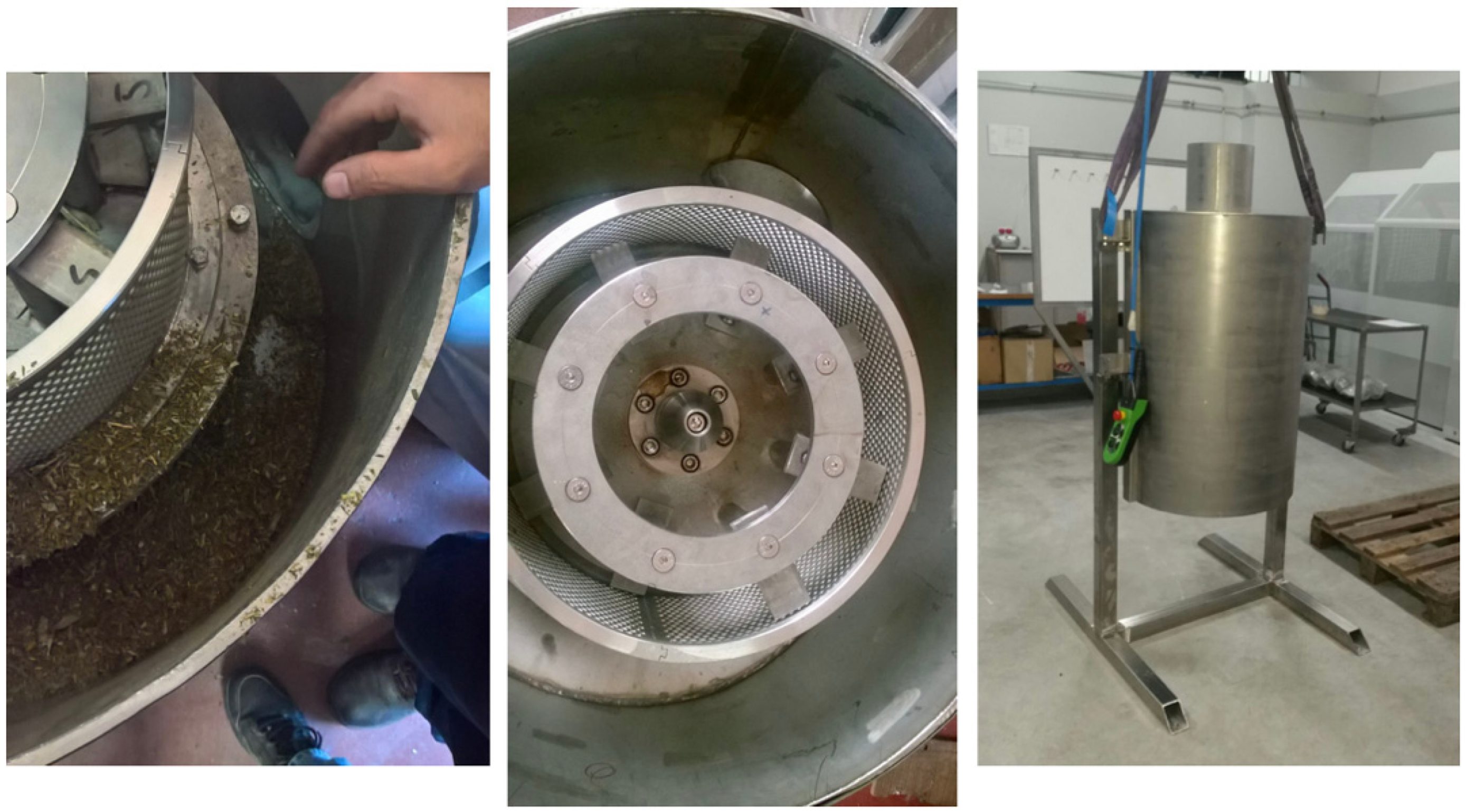

2.1. Prototype Description

- -

- ((volume of fresh olive tree leaves − volume of minced olive tree leaves)/volume of fresh olive tree leaves) × 100

2.2. Compost Formulation

2.3. Sampling and Compost Analyses

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Altieri, R.; Esposito, A. Olive orchard amended with two experimental olive mill wastes mixtures: Effects on soil organic carbon, plant growth and yield. Bioresour. Technol. 2008, 99, 8390–8393. [Google Scholar] [CrossRef] [PubMed]

- European Commission. Olive Oil: An Overview of the Production and Marketing of Olive Oil in the EU. 2020. Available online: https://ec.europa.eu/info/food-farming-fisheries/plants-and-plant-products/plant-products/olive-oil (accessed on 15 June 2021).

- Espadas-Aldana, G.; Vialle, C.; Belaud, J.P.; Vaca-Garcia, C.; Sablayrolles, C. Analysis and trends for Life Cycle Assessment of olive oil production. Sustain. Prod. Consum. 2019, 19, 216–230. [Google Scholar] [CrossRef] [Green Version]

- Masella, P.; Angeloni, G.; Spadi, A.; Guerrini, L.; Cappelli, A.; Parenti, A.; Baldi, F.; Cini, E. An artificial neural network model to predict olive mechanical harvesting: A first approach based on metadata. In VI International Symposium on Applications of Modelling as an Innovative Technology in the Horticultural Supply Chain Model-IT. Acta Hortic. 2021, 1311, 355–359. [Google Scholar] [CrossRef]

- Beghi, R.; Giovenzana, V.; Tugnolo, A.; Guidetti, R. Visible/near infrared spectroscopy for horticulture: Case studies from preharvest to postharvest. In VI International Symposium on Applications of Modelling as an Innovative Technology in the Horticultural Supply Chain Model-IT. Acta Hortic. 2021, 1311, 123–130. [Google Scholar] [CrossRef]

- Tugnolo, A.; Giovenzana, V.; Beghi, R.; Grassi, S.; Alamprese, C.; Casson, A.; Casiraghi, E.; Guidetti, R. A diagnostic visible/near infrared tool for a fully automated olive ripeness evaluation in a view of a simplified optical system. Comput. Electron. Agric. 2021, 180, 105887. [Google Scholar] [CrossRef]

- Cappelli, A.; Parretti, C.; Cini, E.; Citti, P. Development of a new washing machine in olive oil extraction plant: A first application of usability-based approach. J. Agric. Eng. 2019, 50, 134–142. [Google Scholar] [CrossRef] [Green Version]

- Russo, C. A new membrane process for the selective fractionation and total recovery of polyphenols, water and organic substances from vegetation waters (VW). J. Membr. Sci. 2007, 288, 239–246. [Google Scholar] [CrossRef]

- Ahmad-Qasem, M.H.; Ahmad-Qasem, B.H.; Barrajón-Catalán, E.; Micol, V.; Cárcel, J.A.; García-Pérez, J.V. Drying and storage of olive leaf extracts. Influence on polyphenols stability. Ind. Crop. Prod. 2016, 79, 232–239. [Google Scholar] [CrossRef]

- Castaño-Martínez, T.; Olivares-Vicente, M.; Barrajón-Catalan, E.; Encinar, J.A.; Micol, V.; Herranz-López, M. Olive leaf polyphenols alleviate oxidative stress and improve mitochondrial function in high glucose-induced 3T3-L1 hypertrophic adipocytes. Free Radic. Biol. Med. 2017, 108, S94. [Google Scholar] [CrossRef]

- Alburquerque, J.A.; Gonzálvez, J.; García, D.; Cegarra, J. Effects of a compost made from the solid by-product (“alperujo”) of the two-phase centrifugation system for olive oil extraction and cotton gin waste on growth and nutrient content of ryegrass (Lolium perenne L.). Bioresour. Technol. 2007, 98, 940–945. [Google Scholar] [CrossRef] [PubMed]

- ISO. UNI EN ISO 5667-13. Water Quality—Sampling—Part 13, 2011: Guide for Sludge Sampling; ISO: Geneva, Switzerland, 2011. [Google Scholar]

- AOAC International. Official Methods of Analysis, 17th ed.; AOAC International: Gaithersburg, MD, USA, 2005. [Google Scholar]

- Chiumenti, A.; Da Borso, F.; Rodar, T.; Chiumenti, R. Swine manure composting by means of experimental turning equipment. Waste Manag. 2007, 27, 1774–1782. [Google Scholar] [CrossRef] [PubMed]

- Charisiou, N.D.; Goula, M.A. Composting Process of Olive Tree Prunings: Assessment of Nitrogen and Carbon Losses. In Proceedings of the ATHENS 2014, Athens, Greece, 2–5 September 2014. [Google Scholar]

- Garcia-Gomez, A.; Bernal, R.M.P. Composting of the solid fraction of olive mill wastewater with olive leaves: Organic matter degradation and biological activity. Bioresour. Technol. 2003, 86, 59–64. [Google Scholar] [CrossRef]

- Manios, V.I.; Tsikalas, P.E.; Syminis, C.I. Phytotoxicity of olive tree leaf compost in relation to the organic acid concentration. Biol. Wastes 1989, 27, 307–317. [Google Scholar] [CrossRef]

| Parameters | Sample 1 | Sample 2 | Sample 3 |

|---|---|---|---|

| pH | 4.71 ± 0.10 | 6.96 ± 0.55 | 9.69 ± 0.25 |

| Dry matter (g/100 g) | 41.50 ± 0.28 | 45.55 ± 3.75 | 43.95 ± 4.45 |

| Ashes (g/100 g) | 2.25 ± 0.21 | 2.55 ± 0.07 | 4.85 ± 0.78 |

| Humification index (HI) | 0.54 ± 0.02 | 0.51 ± 0.01 | 0.50 ± 0.01 |

| Organic carbon (%) | 29.65 ± 4.60 | 31.10 ± 3.54 | 31.82 ± 1.95 |

| Total nitrogen (%) | 10.40 ± 0.01 | 10.95 ± 0.35 | 4.65 ± 0.07 |

| Total phosphorus (%) | 3.67 ± 0.52 | 3.98 ± 0.39 | 3.93 ± 0.32 |

| Pb (mg/kg) | 8.45 ± 1.77 | 5.85 ± 0.49 | 7.55 ± 1.34 |

| Cu (mg/kg) | 12.05 ± 3.32 | 10.35 ± 0.07 | 13.75 ± 6.86 |

| Cd (mg/kg) | <1 | <1 | <1 |

| Hg (mg/kg) | <0.5 | <0.5 | <0.5 |

| Ni (mg/kg) | 12.05 ± 3.32 | 7.45 ± 1.63 | 7.11 ± 1.06 |

| Zn (mg/kg) | 14.45 ± 0.07 | 10.60 ± 0.28 | 14.05 ± 3.58 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cappelli, A.; Menditto, N.; Cini, E. Innovative Olive Tree Leaves Shredder Prototype for the Valorization of Wasted Leaves: An Application to High-Quality Compost Production. Sustainability 2021, 13, 9421. https://doi.org/10.3390/su13169421

Cappelli A, Menditto N, Cini E. Innovative Olive Tree Leaves Shredder Prototype for the Valorization of Wasted Leaves: An Application to High-Quality Compost Production. Sustainability. 2021; 13(16):9421. https://doi.org/10.3390/su13169421

Chicago/Turabian StyleCappelli, Alessio, Nicola Menditto, and Enrico Cini. 2021. "Innovative Olive Tree Leaves Shredder Prototype for the Valorization of Wasted Leaves: An Application to High-Quality Compost Production" Sustainability 13, no. 16: 9421. https://doi.org/10.3390/su13169421

APA StyleCappelli, A., Menditto, N., & Cini, E. (2021). Innovative Olive Tree Leaves Shredder Prototype for the Valorization of Wasted Leaves: An Application to High-Quality Compost Production. Sustainability, 13(16), 9421. https://doi.org/10.3390/su13169421