Abstract

The closed-loop supply chain considers conceptually the possibility of reverse logistics with the use of recycling, remanufacturing and disposal centers. This study contributes for the first time a green closed-loop supply chain framework for the ventilators, which are highly important in the case of the COVID-19 pandemic. The proposed model simulates a case study of Iranian medical ventilator production. The proposed model includes environmental sustainability to limit the carbon emissions as a constraint. A novel stochastic optimization model with strategic and tactical decision making is presented for this closed-loop supply chain network design problem. To make the proposed ventilator logistics network design more realistic, most of the parameters are considered to be uncertain, along with the normal probability distribution. Finally, to show the managerial dimensions under the COVID-19 pandemic for our proposed model, some sensitivity analyses are performed. Results confirm the high impact of carbon emissions and demand variations on the optimal solution in the case of COVID-19.

1. Introduction

Supply chain network design (SCND) [1,2,3,4,5] is defined as providing a conceptual network for the operations of supply chains and logistics [6,7,8,9,10] with regards to information management [11,12,13,14,15], facility location planning [16,17,18,19,20], flow of products and inventory management [21,22,23,24,25]. A common method for modeling the SCND is to consider the forward logistics in which the flow of products is simulated from suppliers to the customers [26,27,28]. However, an interesting and valuable research that has hardly been addressed in recent studies is the modeling of SCND in an integrated forward and reverse logistics [29,30,31,32].

Reverse logistics are highly important in recent times. Governments and international comities encourage the managers of SCND to add the possibility of recycling and remanufacturing for their used products [33,34,35,36,37]. The reverse logistics started from customers and then created added value across the SCND [38]. Meanwhile, one of the effective ways to increase profitability and competitiveness is to enhance the profits from the reverse logistics [9,10,11,12,13]. An efficient design for the SCND model indirectly affects the profitability of companies by reducing risks [7], improving public images [15,18], persuading non-governmental groups and media, satisfying activists’ requirements [13,34] and maintaining customer loyalty [27]. Although there are many studies in the area of SCND, the ventilator production which has a key factor in the case of the COVID-19 pandemic has not been studied [17]. In addition, recent studies in the area of COVID-19 response confirm that different health strategies have been used by different countries to battle COVID-19 (e.g., social distancing, wearing masks, working remotely, reduction of certain activities, etc.) and an efficient SCND is highly important to reduce the effects of COVID-19 on society [16,21,39]. It goes without saying that before the COVID-19 pandemic, governors and healthcare practitioners had not significantly considered the ventilator supply chain. After the COVID-19 pandemic, the demand for ventilators increased significantly [28]. This makes the assessment of a closed-loop supply chains for the ventilators important. Such a tendency motivates this effort to develop a stochastic optimization model for the case of ventilator logistics network design [39,40,41,42,43,44,45].

Additionally, SCND is a decision-making process which involves three decisions: strategic, tactical and operational decisions [6,37]. It is worth noting that there are many uncertain parameters in these decisions that compromise the flexibility of facility performance [23,25,45]. To tackle such uncertainties, many studies select different modeling methods given the presence or absence of historical data [19,46]. However, Turken et al. [40] argues that the various sources of uncertainties are a serious issue, which significantly reduces flexibility of decisions, and there are only few studies selecting modeling methods with a consideration of the complexity of uncertainty sources [5,44].

All in all, this study contributes to the Iranian medical ventilator logistics for the COVID-19 pandemic. This pandemic has a high impact on the supply chain activities such as transportation and delivery of the products, the demand of customers and the reverse logistics. This study considers both forward and reverse flows as a closed-loop supply chain (CLSC) in the case of pandemic. The environmental emissions are limited by an allowable bound to reduce the carbon emissions. This study develops a novel stochastic programming approach to evaluate an efficient SCND under the COVID-19 pandemic for a closed-loop Iranian medical ventilator supply chain for the first time.

This study attempts to answer the following research questions of a closed-loop SCND:

- Where are the optimal locations of production facilities?

- How to allocate production resources efficiently among facilities?

- How to select the optimal production technology for each facility?

- How to optimize the location-routing decisions of business profitability and environmental pollution?

- How to maintain a resilient and green supply chain to cope with a disruptive occurrence, e.g., COVID-19?

The framework of this paper is as follows: Section 2 is the literature review with a survey on the recent and relevant studies finding the research gaps. Section 3 addresses the proposed problem and its model formulation. Section 4 illustrates the case study with details and our analyses to generate managerial insights for controlling and managing the COVID-19 pandemic. Finally, the conclusion, a summary of this research with findings as well as the future research directions, is provided in Section 5.

2. Literature Review

The field of SCND is an active research topic with a growing concern of CLSC impacts with regards to social and environmental responsibility [39,40,41,42,44,45,46]. Pishvaee et al. [34] proposed a social responsibility SCND by using a robust possibilistic programming approach. Devika et al. [6] developed a sustainable closed-loop SCND and tested with a case of glass industry in Iran. Alshamsi and Diabat [1] proposed an optimization model for the reverse SCND by jointly considering economic, environmental and social goals. Keyvanshokooh, et al. [24] developed a hybrid robust and stochastic programming approach for the SCND by employing an accelerated bender decomposition method. Sahebjamnia et al. [38] employed a CLSC in the Iranian tire industry and solved the problem using the hybrid metaheuristics algorithm. Fathollahi-Fard et al. [11] developed a two-stage stochastic programming model for a closed-loop SCND with a consideration of social impacts and proposed four metaheuristic algorithms to solve the problem. Aiming at water supply chain network, Fathollahi-Fard et al. [12] developed an adaptive Lagrangian heuristic by considering wastewater collection and recycling and further proposed a SCND with a multi-objective, two-stage stochastic model [10]. Finally, a sustainable reverse logistics network design was proposed by Mojtahedi et al. [29] who applied an adaptive memory search combining social engineering optimizer for solving this optimization model.

The literature of SCND is summarized in Table 1, and the model of this study is listed in the last raw for comparison. The literature is selected from Scopus (Scopus is Elsevier’s abstract and citation database launched in 2004, which allows users to search, sort and filter publications by desired criteria, e.g., author, publication date, citation, relevance, etc.) by citation and publication year (after 2006), and summarized by product flow (forward and/or reverse), decision variables (location and allocation, production technology and different transportation system) and modeling methodology (robust programming, robust-stochastic programming, fuzzy programming, simulation and optimization and hybrid chance constraint and cost function method).

Table 1.

A survey of the relevant literature from 2006 to 2021.

Further insights can be drawn from the literature summary (Table 1):

- The decision of location and allocation (L&A) is very common in the literature of SCND that all the studies consider the optimization of location and allocation.

- To the best of our knowledge, there is not any other model in the literature jointly considering the decisions of location and allocation (L&A), production technology (PT) and multiple transportation systems (MTS).

- No study applies the ventilator logistics in a CLSC under the case of the COVID-19 pandemic.

This study designs an integrated closed-loop supply chain network using stochastic programming under chance constraints while considering ventilator logistics. A wide range of parameters is adopted and tested for fixed and variable costs, market demand and the minimum requirement of product recycling. Despite facility location and resource allocation, this study further incorporates the factors of production technology and transportation modes.

3. Proposed Problem

A ventilator, also known as a respirator or breathing machine, is a medical device that provides a patient with oxygen when they are unable to breathe on their own. The ventilator gently pumps air into the lungs and allows it to come back out such as the lungs would typically do when they are able. This happens when patients are too ill to breathe by themselves. This often happen due to trauma, infection, or another problem. The production of ventilators has to meet high-standard medical requirements to ensure the high functionality, reliability and process stability of the ventilators’ production. It goes without saying that the demand for medical ventilators has been growing significantly in the presence of COVID-19. Prior to the pandemic, the market size of ventilators was 77,000 globally in 2019 [23]; however, in April 2020, New York City alone forecasted a need for 30,000 more plants for ventilator production (https://www.hamiltonmedical.com/en_US/Products.html?gclid=Cj0KCQiAyJOBBhDCARIsAJG2h5f7C9gmbe5j5EigjgJis2FoUOP0L5jMnzdga2t0IdzC7Ib-YFsL2IaApLKEALw_wcB (accessed on 18 May 2020)). Moreover, the demand for artificial respiration devices in Iran also skyrocketed after the outbreak of SARS-COV-2 [19]. Therefore, a resilient supply chain network is urgently needed for artificial respiration devices to handle intensive fluctuations in demand.

In response to the challenge of volatile market, a wide range of parameters, especially market demand, is adopted in the integrated sustainable network, which is composed of plants, maintenance units, customers (i.e., medical science universities) and disposal centers (DCs). Given that some units require different treatments in the multi-echelon system, products are divided into three groups: new product, product to be disposed and product to be dismantled. Additionally, factories usually have options of a variety of production technologies and transportation modes (e.g., truck, train, airplane, ship, etc.) in the business practices. The goals of the network design are summarized as follows:

- Optimize facility locations;

- Optimize resource flow between facilities;

- Determine the optimal production technology for each factory;

- Determine the optimal transportation mode between facilities;

- Control the emission of greenhouse gases in the process of production, storage, disassembling and reproduction;

- Handle the disposal products;

- Improve SC resilience for fluctuating demand.

The proposed mixed-integer nonlinear programming (MINLP) model follows the following assumptions:

- The model is single-period with a fixed time interval of 3 months.

- Shortage is not allowed for all customer demands. The main reason is related to the emergency cases of COVID-19, and we must satisfy the demand of ventilator products to the customers at the earliest convenience.

- The following parameters are assumed to be stochastic: fixed costs of facility construction, variable costs of product flow between facilities, transportation and storage costs, costumer demands, the limit of greenhouse gas emission, the proportion of product units to be collected from customers and the proportion to be dismantled and shipped from DCs.

- Two technologies in the form of two ventilator products, including portable and ICU (Intensive Care Unit) medical ventilator production, are considered, based on a real case study in Iran.

- There are several transportation options available, including land (truck), rail (train), sea (ship), air (airplane), etc.

Notations of this study are summarized below:

| Notations | |

| Sets | |

| I: | Set of manufacturing facilities i ∈{1,2,…,I} |

| J: | Set of warehouses j ∈ {1,2,…,J} |

| K: | Set of customers k ∈ {1,2,…,K} |

| L: | Set of DCs l ∈{1,2,…,L} |

| M: | Set of transportation options from/to the manufacturing plants m ∈ {1,2,…,M} |

| N: | Set of transportation options from/to warehouses n ∈ {1,2,…,N} |

| O: | Set of transportation options from/to customers o ∈ {1,2,…,O} |

| V: | Set of transportation options from/to DCs v ∈ {1,2,…,V} |

| U: | Set of production technologies or ventilator product types u ∈ {1,2,…,U} |

| Parameters | |

| : | Fixed cost for building the manufacturing facility i ∈ I with the technology u and with the mean ucpi,u and variance σ2cpi,u |

| : | Fixed cost for building the warehouse j ∈ J with the mean ucwj and variance σ2cwj |

| : | Fixed cost for building the DC l ∈ L with the mean ucdl and variance σ2cdl |

| : | Variable cost per product unit in the manufacturing plant i ∈ I with the technology u and with the mean uc′pi,u and variance σ2c′pi,u |

| : | Inventory handling cost per unit in the warehouse j ∈ J with the mean uc′hj and variance σ2c′hj |

| : | Collecting cost per unit of product from the customer k ∈ K with the mean uc′ck and variance σ2c′ck |

| : | Disassembling cost per unit of product disposed in the DC l ∈ L with the mean uc′dl and variance σ2c′dl |

| : | Reproduction cost per unit of product in the manufacturing plant i ∈ I with the technology u and the mean uc′ri,u and variance σ2c′ri,u |

| : | Shortage cost per unit of product for the customer k ∈ K with the mean uc′qk and variance σ2c′qk |

| Transportation cost per unit of product from the factory i to the warehouse j with the transportation method m, the mean uc″pi,jm and variance σ2c″pi,jm | |

| Transportation cost per unit of product from the warehouse j to the customer k with the transportation method n, the mean uc″wj,kn and variance σ2c″wj,kn | |

| : | Transportation cost per unit of product from the customer k to the DC l with the transportation method o, the mean uc″ck,lo and variance σ2c″ck,lo |

| : | Transportation cost per unit of product from the DC l to the manufacture i with the transportation method v, the mean uc″dl,iv and variance σ2c″dl,iv |

| : | The rate of CO2 emission per unit of product in the manufacturing plant i and with the production technology u |

| : | The rate of CO2 emission per unit of disassembled product in the DC l |

| : | The rate of CO2 emission per unit of remanufactured product in the manufacturing facility i and with technology u |

| : | The rate of CO2 emission from transporting a unit of product from facility to warehouse per unit distance |

| : | The rate of CO2 emission from transporting a unit of product from warehouse to customer per unit distance by transportation method n |

| : | The rate of CO2 emission to handle and storage a unit of product in the warehouse j |

| : | The rate of CO2 emission by the transportation method o to collect a unit of product to be recycled from customer to DC per unit distance |

| : | The rate of CO2 emission by the transportation method v to ship a unit of product to be dismantled from DC to the manufacturing plant per unit distance |

| : | Maximum production capacity of the manufacturing facility i, with production technology u |

| : | Maximum storage, handling and processing capacity of the warehouse j |

| : | Maximum disassembly capacity of DC l |

| : | Maximum reproduction capacity of the manufacturing facility i with production technology u |

| : | Transportation rate from the manufacturing facility i to the warehouse j with the transportation method m |

| : | Transportation rate from the warehouse j to the customer k with the transportation method n |

| : | Transportation rate for collecting a unit of product from the customer k to DC l with the transportation method o |

| : | Distance between the manufacturing facility i and the warehouse j |

| : | Distance between the warehouse j and the customer k |

| : | Distance between the customer k and the DC l |

| : | Distance between the DC l and the manufacturing facility i |

| : | Minimum proportion of product unit recycled from a customer with the mean and variance . |

| : | Minimum proportion of product unit dissembled in a DC with the mean and variance . |

| : | Demand from the customer k with the mean and variance . |

| : | The regulated limit of CO2 emission with the mean and variance |

| : | The maximum number of products to be disposed. |

| : | The probability of rejecting a solution that does not satisfy the constraints. |

| : | The lower critical point of the standard normal distribution used for a () chance constraint of the solution obtained. |

| Decision Variables: | |

| : | 1 if the factory i with production technology u is established, 0 otherwise |

| : | 1 if the warehouse j is established, 0 otherwise |

| : | 1 if DC l is established, 0 otherwise |

| : | Amount of unit product shipped from the factory i with the production technology u to the warehouse j with the transportation method m |

| : | Amount of unit product shipped from the warehouse j to the customer k with the transportation method n |

| : | Amount of unit product to be disposed and collected from the customer k to DC l with the transportation method o |

| : | Amount of unit product to be dismantled and from DC l to the factory i with the production technology u and the transportation method v |

In order to enhance supply chain resilience under an uncertain environment, we developed a stochastic programming model with a hybrid of the cost-objective function and chance constraints. The objective function of cost minimization is provided in Equation (1) as follows, which incorporates construction, production, inventory handling, product collecting, dissembling and reproduction and transportation costs incurred in/between manufacturing facilities, warehouses and DCs (see following papers as examples to support the feasibility of the objectives: [6,38]).

Given that the emission amount of greenhouse gas is assumed to be uncertain to better reflect the reality, the greenhouse gas emission constraints (i.e., from production, reproduction, strong, disassembling and transportation) are modeled as chance-constraints in Equation (2), indicating that the probability of violation of the regulated emission limit must be kept (to support the feasibility of this formula, see [14] for more details).

Demand is also assumed to be stochastic, and the demand constraint is modeled as given in Equations (3) and (4) to have a (1 − β) chance to fulfill the demand.

Similarly, the amount of products recycled, collected and dismantled through the reverse supply chain network is also assumed to be uncertain and formulated as chance constraints, shown in Equations (5) and (6), to have a (1 − γ)% chance to meet the minimum requirements of collection and dismantling (see following papers for examples to check the feasibility of these formulas: [3,14].

The final model is as follows:

s.t.

Equation (7) presents the expected cost which incorporates construction, production, inventory handling, product collecting, dissembling, reproduction and transportation costs incurred in/between manufacturing facilities, warehouses and DCs.

The environmental dimension of the sustainable supply chain network is modeled as a constraint in Equation (8) to control the emission of greenhouse gas under the regulated limit throughout the business process (i.e., forward and reverse) and supply chain network (i.e., manufacturing facility, warehouse and DC). Equation (8) is converted from the stochastic from of Equation (2) by employing the Z score of the desired α, and the given mean and variance of greenhouse emission. Equation (9) is a disposal constraint to comply with the regulated disposal limit. Equations (10), (11) and (12) are capacity constraints for the production and reproduction of manufacturing facilities, strong warehouses and disassembly of DCs, respectively. Equation (13) is respecting the demand satisfaction for customers. The constraint of Equation (14) states that demand is always satisfied by supply, and Equation (15) reveals that total recycled products exceed customer demand. Both Equations (16) and (17) employ the stochastic conversion technique similarly to Equation (8) based on the Z score of desired β, and the given mean and variance of demand to convert Equations (3) and (4) to the deterministic form. Equations (18) and (19), on the other hand, convert the chance constraints of recycling collection and dismantling Equations (5) and (6) to deterministic forms. Equation (20) is a binary constraint for the decision variables of manufacturing facilities, warehouses and DC. Equation (21) is a non-negative constraint for the decision variables of product flow along the supply chain network.

4. Computational Results

In this section, we resort to the real case to testify our proposed solution approach and evaluate its efficiency and performance. In particular, the data of medical ventilators are collected from a coherent network of production and distribution. Our client is an Iranian medical equipment manufacturer company who intends to urgently fulfill the demand of the respiratory patients for medical ventilators through its supply chain network.

Like many other countries worldwide, Iran encounters a severe shortage of ventilator amid the pandemic. Its network is composed of facilities in some designated zones in Iran. To this end, the company can build a maximum of three manufacturing plants, three warehouses and three disassembling centers. Figure 1 shows the map of Iran and our case study. Each manufacturing plant can select only one of the ICU and portable technologies for the production of the medical ventilator. In addition, eight major areas of COVID-19 outbreaks have been identified by a team of experts. To fulfill the demand from each customer zone more swiftly, three forms of transportation methods (i.e., truck, train and air) between each facility, especially air transport, are considered. It should be noted that the simulated data are generated regarding the recent benchmarks [12,14,28].

Figure 1.

Map of our case study.

The production technology in each production plant, the way each of the facilities is allocated to each other and various transportation modes are considered [37]. In order to solve the model, the CPLEX solver is used. To design our network for the medical ventilator, the optimal value of the mean of the total cost is 931,859.945 million Rial.

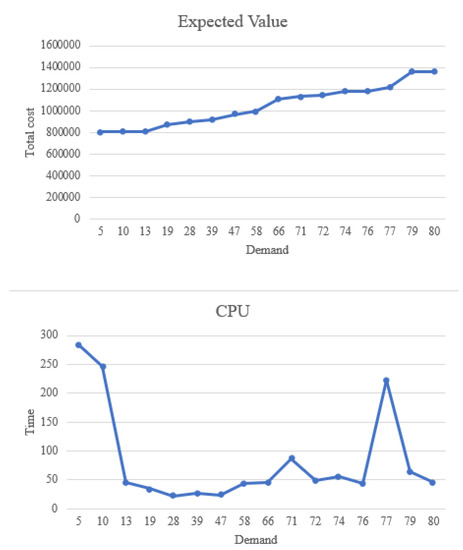

For sensitivity analyses, we examined the effect of changing the amount of some effective and critical parameters, including the customer demand and the upper bound of greenhouse gas emissions. As depicted in Figure 2, with increasing the expected value of demands, the expected costs were increased to cover the demand growth.

Figure 2.

Sensitivity analysis on the growth of the demand in the objective function.

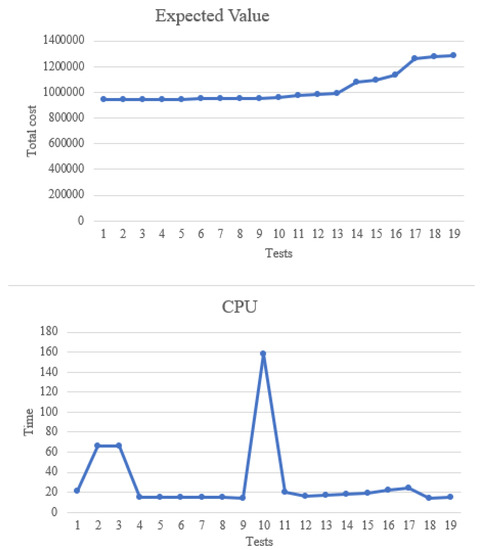

In view of Figure 3, some sensitivity analyses by an increase in the upper bound of around 5 percent per test are conducted, and the value of the expected value and CPU time were studied. Reducing the value of the upper bound of the released carbon would further affect the function of the mean of the costs. For the upper bound of carbon emission, its lowest value is set as 328,503 kg.

Figure 3.

Sensitivity analysis on the CO2 upper bound.

To derive useful managerial insights, sensitivity analyses were conducted via extensive numerical studies as shown above. It is revealed that enforcing the constraint with imposing strict policies for environmental issues could greatly increase the expected value and the variance of the costs monotonically. Another important managerial insight is shifting a ventilator supply chain to a green closed-loop supply chain for the ventilator production which highlights the relationship between environmental protection and pollution goals and the ventilator supply chain. It is also an introduction for reverse logistics and closed-loop supply chains in the case of the COVID-19 pandemic. It goes without saying that the use of a stochastic optimization model controls the impacts of uncertainty factors for the COVID-19 pandemic.

5. Conclusions and Future Research Work

Before the COVID-19 pandemic, governors and healthcare practitioners were not significantly considering the ventilator supply chain. After the outbreak of the COVID-19 pandemic, the demand for ventilators has increased significantly. This makes the assessment of closed-loop supply chains for the ventilators important. In this research, we developed a novel stochastic optimization model for the design of a closed-loop supply chain network. To the best of our knowledge, this is the first study to develop a chance-constrained programming approach to design ventilator logistics. The performance and application of the proposed model is examined through an integrated network of medical ventilators. To obtain the managerial implications, sensitivity analyses were conducted. It is showed that adopting strict policies for environmental issues could greatly increase the mean and variance of the costs. Results confirm the high impact of carbon emissions and demand variations on the optimal solution in the case of COVID-19.

A novel issue that could affect the structure of the proposed model is the consideration of restrictions for each form of transportation between facilities. Since the proposed model covers a variety of hypotheses, future studies could focus on medium- and large-scale solution methods, such as heuristic and meta-metaheuristic algorithms, and exact decomposition methods. The proposed model should be integrated with blockchain technologies and the Internet of things [30]. Uncertain parameters such as demand could be predicted using grey models [20].

Author Contributions

Conceptualization, L.P. and S.-M.S.-H.; methodology, L.P.; software, S.-M.S.-H.; validation, L.P., S.-M.S.-H. and A.J.; formal analysis, L.P.; investigation, L.P.; resources, L.P.; data curation, L.P.; writing—original draft preparation, L.P.; writing—review and editing, L.P.; visualization, L.P.; supervision, L.P.; project administration, L.P.; funding acquisition, S.-M.S.-H. All authors have read and agreed to the published version of the manuscript.

Funding

The authors declare that there is no funding for this research.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Alshamsi, A.; Diabat, A. A reverse logistics network design. J. Manuf. Syst. 2015, 37, 589–598. [Google Scholar] [CrossRef]

- Altiparmak, F.; Gen, M.; Lin, L.; Paksoy, T. A genetic algorithm approach for multi-objective optimization of supply chain networks. Comput. Ind. Eng. 2006, 51, 196–215. [Google Scholar] [CrossRef]

- Baptista, S.; Barbosa-Póvoa, A.P.; Escudero, L.F.; Gomes, M.I.; Pizarro, C. On risk management of a two-stage stochastic mixed 0–1 model for the closed-loop supply chain design problem. Eur. J. Oper. Res. 2019, 274, 91–107. [Google Scholar] [CrossRef]

- Chalmardi, M.K.; Camacho-Vallejo, J.-F. A bi-level programming model for sustainable supply chain network design that considers incentives for using cleaner technologies. J. Clean. Prod. 2019, 213, 1035–1050. [Google Scholar] [CrossRef]

- Costa, A.; Cannella, S.; Corsini, R.R.; Framinan, J.M.; Fichera, S. Exploring a two-product unreliable manufacturing system as a capacity constraint for a two-echelon supply chain dynamic problem. Int. J. Prod. Res. 2020, 56, 1–29. [Google Scholar] [CrossRef]

- Devika, K.; Jafarian, A.; Nourbakhsh, V. Designing a sustainable closed-loop supply chain network based on triple bottom line approach: A comparison of metaheuristics hybridization techniques. Eur. J. Oper. Res. 2014, 235, 594–615. [Google Scholar] [CrossRef]

- Eskandarpour, M.; Dejax, P.; Miemczyk, J.; Péton, O. Sustainable supply chain network design: An optimization-oriented review. Omega 2015, 54, 11–32. [Google Scholar] [CrossRef]

- Fallahpour, A.; Nayeri, S.; Sheikhalishahi, M.; Wong, K.Y.; Tian, G.; Fathollahi-Fard, A.M. A hyper-hybrid fuzzy decision-making framework for the sustainable-resilient supplier selection problem: A case study of Malaysian Palm oil industry. Environ. Sci. Pollut. Res. 2021, 43, 1–21. [Google Scholar]

- Fathollahi-Fard, A.M.; Hajiaghaei-Keshteli, M. A stochastic multi-objective model for a closed-loop supply chain with environmental considerations. Appl. Soft Comput. 2018, 69, 232–249. [Google Scholar] [CrossRef]

- Fathollahi-Fard, A.M.; Ahmadi, A.; Mirzapour Al-e-Hashem, S.M.J. Sustainable closed-loop supply chain network for an integrated water supply and wastewater collection system under uncertainty. J. Environ. Manag. 2020, 275, 111277. [Google Scholar] [CrossRef]

- Fathollahi-Fard, A.M.; Hajiaghaei-Keshteli, M.; Mirjalili, S. Multi-objective stochastic closed-loop supply chain network design with social considerations. Appl. Soft Comput. 2018, 71, 505–525. [Google Scholar] [CrossRef]

- Fathollahi-Fard, A.M.; Hajiaghaei-Keshteli, M.; Tian, G.; Li, Z. An adaptive Lagrangian relaxation-based algorithm for a coordinated water supply and wastewater collection network design problem. Inf. Sci. 2020, 512, 1335–1359. [Google Scholar] [CrossRef]

- Fathollahi-Fard, A.M.; Woodward, L.; Akhrif, O. Sustainable distributed permutation flow-shop scheduling model based on a triple bottom line concept. J. Ind. Inf. Integr. 2021, 24, 100233. [Google Scholar]

- Gonela, V.; Salazar, D.; Zhang, J.; Osmani, A.; Awudu, I.; Altman, B. Designing a sustainable stochastic electricity generation network with hybrid production strategies. Int. J. Prod. Res. 2019, 57, 2304–2326. [Google Scholar] [CrossRef]

- Ghadami, N.; Gheibi, M.; Kian, Z.; Faramarz, M.G.; Naghedi, R.; Eftekhari, M.; Fathollahi-Fard, A.M.; Dulebenets, M.A.; Tian, G. Implementation of solar energy in smart cities using an integration of artificial neural network, photovoltaic system and classical Delphi methods. Sustain. Cities Soc. 2021, 74, 103149. [Google Scholar] [CrossRef]

- Huynh, T.L.D. Does culture matter social distancing under the COVID-19 pandemic? Saf. Sci. 2020, 130, 104872. [Google Scholar] [CrossRef] [PubMed]

- Huge-Brodin, M.; Sweeney, E.; Evangelista, P. Environmental alignment between logistics service providers and shippers—A supply chain perspective. Int. J. Logist. Manag. 2020, 34, 234–252. [Google Scholar] [CrossRef]

- Ivanov, D. Viable supply chain model: Integrating agility, resilience and sustainability perspectives—Lessons from and thinking beyond the COVID-19 pandemic. Ann. Oper. Res. 2020, 13, 1–21. [Google Scholar] [CrossRef]

- Ivanov, D.; Dolgui, A. Viability of intertwined supply networks: Extending the supply chain resilience angles towards survivability. A position paper motivated by COVID-19 outbreak. Int. J. Prod. Res. 2020, 58, 2904–2915. [Google Scholar] [CrossRef] [Green Version]

- Islam, M.R.; Ali, S.M.; Fathollahi-Fard, A.M.; Kabir, G. A novel particle swarm optimization-based grey model for the prediction of warehouse performance. J. Comput. Des. Eng. 2021, 8, 705–727. [Google Scholar] [CrossRef]

- Jaja, I.F.; Anyanwu, M.U.; Iwu Jaja, C.J. Social distancing: How religion, culture and burial ceremony undermine the effort to curb COVID-19 in South Africa. Emerg. Microbes Infect. 2020, 9, 1077–1079. [Google Scholar] [CrossRef] [PubMed]

- Jamshidi, R.; Ghomi, S.F.; Karimi, B. Multi-objective green supply chain optimization with a new hybrid memetic algorithm using the Taguchi method. Sci. Iran. 2012, 19, 1876–1886. [Google Scholar] [CrossRef] [Green Version]

- Kaplan, E.H. OM Forum—COVID-19 Scratch models to support local decisions. Manuf. Serv. Oper. Manag. 2020, 22, 645–655. [Google Scholar] [CrossRef]

- Keyvanshokooh, E.; Ryan, S.M.; Kabir, E. Hybrid robust and stochastic optimization for closed loop supply chain network design using accelerated benders decomposition. Eur. J. Oper. Res. 2016, 249, 76–92. [Google Scholar] [CrossRef] [Green Version]

- Krug, Z.; Guillaume, R.; Battaïa, O. Exploring the opportunities in establishing a closed-loop supply chain under uncertainty. Int. J. Prod. Res. 2020, 43, 1–20. [Google Scholar] [CrossRef]

- Mardan, E.; Govindan, K.; Mina, H.; Gholami-Zanjani, S.M. An accelerated benders decomposition algorithm for a bi-objective green closed loop supply chain network design problem. J. Clean. Prod. 2019, 235, 1499–1514. [Google Scholar] [CrossRef]

- Mehrotra, S.; Rahimian, H.; Barah, M.; Luo, F.; Schantz, K. A model of supply-chain decisions for resource sharing with an application to ventilator allocation to combat COVID-19. Nav. Res. Logist. 2020, 67, 303–320. [Google Scholar] [CrossRef]

- Mohammadi, A.S.; Alemtabriz, A.; Pishvaee, M.S.; Zandieh, M. A multi-stage stochastic programming model for sustainable closed-loop supply chain network design with financial decisions: A case study of plastic production and recycling supply chain. Sci. Iran. 2020, 27, 377–395. [Google Scholar] [CrossRef] [Green Version]

- Mojtahedi, M.; Fathollahi-Fard, A.M.; Tavakkoli-Moghaddam, R.; Newton, S. Sustainable Vehicle Routing Problem for Coordinated Solid Waste Management. J. Ind. Inf. Integr. 2021, 23, 100220. [Google Scholar]

- Moosavi, J.; Naeni, L.M.; Fathollahi-Fard, A.M.; Fiore, U. Blockchain in supply chain management: A review, bibliometric, and network analysis. Environ. Sci. Pollut. Res. 2021, 21, 1–15. [Google Scholar]

- Nurjanni, K.P.; Carvalho, M.S.; Costa, L. Green supply chain design: A mathematical modeling approach based on a multi-objective optimization model. Int. J. Prod. Econ. 2017, 183, 421–432. [Google Scholar] [CrossRef]

- Paksoy, T.; Pehlivan, N.Y.; Ozceylan, E. Fuzzy multi-objective optimization of a green supply chain network with risk management that includes environmental hazards. Hum. Ecol. Risk Assess Int. J. 2012, 18, 1120–1151. [Google Scholar] [CrossRef]

- Pasha, J.; Dulebenets, M.A.; Fathollahi-Fard, A.M.; Tian, G.; Lau, Y.Y.; Singh, P.; Liang, B. An integrated optimization method for tactical-level planning in liner shipping with heterogeneous ship fleet and environmental considerations. Adv. Eng. Inform. 2021, 48, 101299. [Google Scholar] [CrossRef]

- Pishvaee, M.S.; Razmi, J.; Torabi, S.A. Robust possibilistic programming for socially responsible supply chain network design: A new approach. Fuzzy Sets Syst. 2012, 206, 1–20. [Google Scholar] [CrossRef]

- Quan, J.; Wang, X.; Wang, X.; Xia, D.; Yang, J.B. Performance optimization of supply chain based on cooperative contract with disappointment-aversion strategic consumers. Flex. Serv. Manuf. J. 2021, 13, 1–21. [Google Scholar]

- Rezaei, M.; Chaharsooghi, S.K.; Kashan, A.H.; Babazadeh, R. Optimal design and planning of biodiesel supply chain network: A scenario-based robust optimization approach. Int. J. Energy Environ. Eng. 2020, 11, 111–128. [Google Scholar] [CrossRef] [Green Version]

- Safaeian, M.; Fathollahi-Fard, A.M.; Tian, G.; Li, Z.; Ke, H. A multi-objective supplier selection and order allocation through incremental discount in a fuzzy environment. J. Intell. Fuzzy Syst. 2019, 37, 1435–1455. [Google Scholar] [CrossRef]

- Sahebjamnia, N.; Fathollahi-Fard, A.M.; Hajiaghaei-Keshteli, M. Sustainable tire closed-loop supply chain network design: Hybrid metaheuristic algorithms for large-scale networks. J. Clean. Prod. 2018, 196, 273–296. [Google Scholar] [CrossRef]

- Xie, K.; Liang, B.; Dulebenets, M.A.; Mei, Y. The impact of risk perception on social distancing during the COVID-19 pandemic in China. Int. J. Environ. Res. Public Health 2020, 17, 6256. [Google Scholar] [CrossRef]

- Turken, N.; Cannataro, V.; Geda, A.; Dixit, A. Nature inspired supply chain solutions: Definitions, analogies, and future research directions. Int. J. Prod. Res. 2020, 58, 4689–4715. [Google Scholar] [CrossRef]

- Tsao, Y.-C.; Thanh, V.-V.; Lu, J.-C.; Yu, V. Designing sustainable supply chain networks under uncertain environments: Fuzzy multi-objective programming. J. Clean. Prod. 2018, 174, 1550–1565. [Google Scholar] [CrossRef]

- Theophilus, O.; Dulebenets, M.A.; Pasha, J.; Lau, Y.Y.; Fathollahi-Fard, A.M.; Mazaheri, A. Truck Scheduling Optimization at a Cold-Chain Cross-Docking Terminal with Product Perishability Considerations. Comput. Ind. Eng. 2021, 156, 107240. [Google Scholar] [CrossRef]

- Seuring, S.; Müller, M. From a literature review to a conceptual framework for sustainable supply chain management. J. Clean. Prod. 2008, 16, 1699–1710. [Google Scholar] [CrossRef]

- Xu, X.; Lee, S.D.; Kim, H.S.; You, S.S. Management and optimization of chaotic supply chain system using adaptive sliding mode control algorithm. Int. J. Prod. Res. 2020, 6, 1–17. [Google Scholar]

- Zhang, Y.; Che, A.; Chu, F. Improved model and efficient method for bi-objective closed-loop food supply chain problem with returnable transport items. Int. J. Prod. Res. 2020, 73, 1–18. [Google Scholar]

- Zhang, Z.J.; Srivastava, P.R.; Eachempati, P.; Yu, Y. An intelligent framework for analyzing supply chain resilience of firms in China: A hybrid multicriteria approach. Int. J. Logist. Manag. 2021, 43, 1–54. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).