A continuous increase in global population is demanding more development and industrialization, which leads to the production of various waste such as municipal wastewater, agricultural waste, industrial waste, medical waste, electronic wastes, etc. [1,2,3]. Waste management is important to maintain human health and the sustainability of the environment [4,5]. Various technologies have been reported to manage various kinds of wastes and produce valuable products [6,7,8,9]. Wastewater is produced from households and the textile, municipal, dairy, and pharmaceutical industries [10]. Management of wastewater is a challenging task as it is rich in nutrients and its release in the open may cause eutrophication and pose a threat to the environment. Generally, wastewater is treated using various physical and chemical methods, but these methods are costly and often result in sludge production and secondary water pollution. The use of microbe-based biowaste to bioenergy conversion technology can provide an economic way to manage wastewater and produce bioenergy simultaneously. Various microbe-mediated methods like anaerobic digestion (AD), microbial fuel cells (MFC), dark fermentation, etc. can be used for resource recovery from wastewater and energy production. Wastewater to bioenergy is a hot topic and many articles have been published in this area and the number is continuously increasing with each passing year.

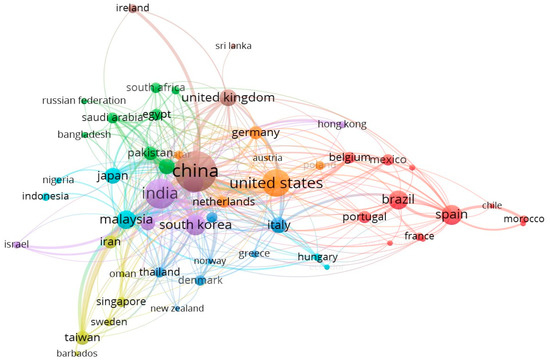

According to the Scopus database, 1354 articles were found published during 2016–2021 using the search keywords wastewater and bioenergy. In terms of number of publications, China (433), India (213), the United States (173), South Korea (83), and Australia (73) make up the top five list. Figure 1 illustrates the visualization network of countries involved in this research area. Distinct clusters can be identified with different colors assigned to the individual country. The size of the circle corresponds to the frequency of publications while the thickness of the lines represents the co-authorship link and relative strength.

Figure 1.

Co-occurrence mapping based on publication numbers (min. number of occurrences: three). The map was generated using Vosviewer.

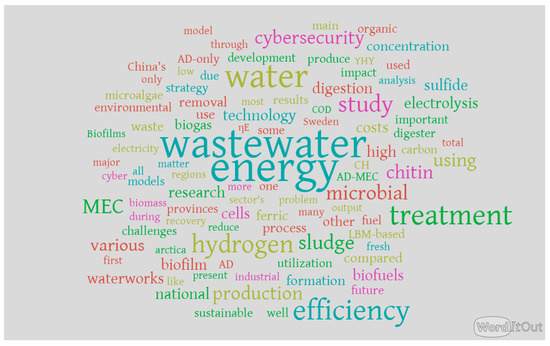

The editorial aim of this editorial is to highlight the key aspects of all contributions and provide an update to a broader scientific audience. In this Special Issue, we are publishing ten studies, which include six research articles and four review articles (Figure 2 provides a word cloud of published articles).

Figure 2.

Word cloud of articles published in the Special Issue. The most frequent words are displayed with a larger font. The image was generated using worditout.com.

The review article contributed to this Special Issue by Bhatia et al. provides an overall overview of renewable energy products produced through wastewater valorization technologies [11]. Wastewaters were categorized into fifteen types based on their source. Wastewater from industrial effluent contains a significant quantity of harmful chemicals and heavy metals and lower biological content as compared to household wastewater. Different strategies reported for resource recovery from wastewater such as anaerobic digestion (AD), fermentation, microbial fuel cell (MFC), combustion, gasification, and pyrolysis of sludge for bioenergy production were reviewed in brief. The need for integrated wastewater treatment with benefits and challenges was also discussed.

Wastewater treatment cost is also an issue for proper wastewater management. Gallego-valero et al. prepared a bibliometric analysis of publications on wastewater treatment cost from Web of Science published in the period 1950–2020 [12]. This study concluded that leading countries involved in wastewater research include China, the USA, India, Spain, and the UK based on the number of publications. The leading research institutes in terms of the number of related articles are the Chinese Academy of Sciences, China (561), followed by the Indian Institute of Technology (445). Different technologies are in fashion for resource recovery from wastewater and bioenergy production. Contribution by Jeyaseelan et al. discussed algal system utilization in wastewater treatment and bioenergy production [13]. Algae have high photosynthetic activity, are more effective in carbon dioxide capture, and produce 5–10 times more biomass compared to terrestrial plants. Algae are able to accumulate fatty acids up to 40–50% of their biomass and are used for biodiesel production. Microalgae like Chlorella are highly efficient in the removal of nutrients and are able to remove nitrogen and phosphorus up to 98% and 89%, respectively. Still, the use of this technology for biodiesel production is a challenge as algae cultivation and harvesting is costly. Residual algal biomass after oil extraction can also be used for bioenergy production using anaerobic digestion and fermentation processes. Microbial fuel cells (MFC) are also getting attention for wastewater treatment and bioelectricity production. Microorganisms biodegrade and oxidize the organic materials in the anodic chamber and produce electrons and protons that travel through external circuits and proton exchange membranes, respectively, to the cathode, producing current. Gurav et al. explored seafood processing chitin waste as a raw material for Oceanisphaera aractica YHY01 to produce electricity in MFC [14]. Microbial fuel cells demonstrated stable electricity generation until 216 h (0.228 mA/cm2). N-acetyl-D-glucosamine (GlcNAc) was the major by-product and other organic acids such as lactate, acetate, propionate, and butyrate were the main metabolites produced in MFC. Cyclic voltammetry (CV) showed the role of outer membrane-bound cytochrome in the electron transfer mechanism. Biohydrogen is a clean and renewable source of energy. Wastewater can be used as a feedstock for hydrogen production using microbial electrolysis cells (MEC). In the MEC process, microbes are used in anodic chambers, which utilize organic material and convert chemical energy into electrical energy and produce energy that is subsequently used in cathodic parts to produce hydrogen. Dange et al. discuss the thermodynamics and electrochemistry of hydrogen-producing MEC technology in their contribution [15]. The MEC reactor architecture, materials used in electrode preparation, and various factors that affect hydrogen production are also discussed. The authors conclude that high MEC manufacturing cost, high internal resistance, methanogenesis, and membrane/cathode biofouling are the main limiting factors in the scale-up of this technology. To increase hydrogen production Hassanein et al., combined MEC technology with anaerobic digestion [16]. A comparative study between MEC and AD-MEC was conducted, and it was concluded that cumulative H2 and CH4 production and COD removal were higher in AD-MEC as compared to AD-only. During the AD process, biogas is produced by the digestion of organic material by methanogenic bacteria. Most of the substrates are rich in sulfur content and methanogenic microbes reduce it into hydrogen sulfide, which negatively affect methanogens activity and poison the digester. Ferric salt is used in AD to remove hydrogen sulfide production. Persson et al. used ferric oxide containing waterworks sludge in the AD process and reported a reduction in operational cost up to 50% [17]. This technology is one step closer to the circular economy as it helps to replace the use of virgin chemicals with the by-product waterworks sludge and reduces the carbon footprint of the waterworks. Biofilm is important for MFC wastewater treatment but is also related to problems such as infections, food contamination, and equipment corrosion. However, biofilm production is a complex process due to the interaction among physicochemical and biological processes. In the contribution by Delavar et al., (2021) an overview of advanced numerical modeling techniques using the lattice Boltzmann method (LBM) for prediction of biofilm formation and growth of microbial community structure is provided [18]. The main features and drawbacks of LBM-based biofilm models from the ecological and biotechnological perspective with challenges and future directions are also discussed. With industrial development and economic growth, environmental problems caused by excessive energy consumption become prominent. Improvement of efficiency of energy utilization can help to solve this problem. Huang et al. used a data envelopment analysis (DEA) model considering various input factors like labor force, capital stock, energy consumption and carbon emission to calculate the energy utilization efficiency of China’s provinces [19]. This study concluded that urbanization openness and industrial structure have a negative effect on energy efficiency, while marketization has a significant positive impact. Water and wastewater treatment is an important lifeline for the economic development of any country, and it is very important to secure these sectors. Malatji et al. has provided a report on South Africa’s cybersecurity strategy aimed at addressing cyber terrorism and cybercriminal activities [20]. In this study, they found that along with the National Cybersecurity Policy Framework, the Electronic Communications and Transactions Act, Critical Infrastructure Protection Act, and other supporting legislation, a wastewater sector’s computer security incident response team can be established without the need to propose any new laws or amend existing ones.

Considering the content of various articles contributed to this Special Issue, it is clear that wastewater-based microbial biorefinery for bioenergy production is an emerging field and has the potential to meet the challenge of wastewater treatment and increased energy demands. Keeping in view the present status of the coronavirus pandemic, it is very important to treat wastewater. There is an essential need to increase research activity in this area to make wastewater to bioenergy technologies more efficient and economic. The main aim of various articles included in this Special Issue is to reach a broad readership and develop understanding in researchers and stakeholders related to wastewater to bioenergy technology.

Author Contributions

Conceptualization, writing—original draft preparation, visualization, writing—review and editing, S.K.B. The author has read and agreed to the published version of the manuscript.

Funding

This study was supported by the Research Program to solve social issues of the National Research Foundation of Korea (NRF)s funded by the Ministry of Science and ICT (grant number 2021R1F1A1050325).

Acknowledgments

The authors would like to acknowledge the KU Research Professor Program of Konkuk University, Seoul, South Korea.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Bhatia, S.K.; Joo, H.-S.; Yang, Y.-H. Biowaste-to-bioenergy using biological methods—A mini-review. Energy Convers. Manag. 2018, 177, 640–660. [Google Scholar] [CrossRef]

- Duan, Y.; Pandey, A.; Zhang, Z.; Awasthi, M.K.; Bhatia, S.K.; Taherzadeh, M.J. Organic solid waste biorefinery: Sustainable strategy for emerging circular bioeconomy in China. Ind. Crop. Prod. 2020, 153, 112568. [Google Scholar] [CrossRef]

- Saratale, G.D.; Bhosale, R.; Shobana, S.; Banu, J.R.; Pugazhendhi, A.; Mahmoud, E.; Sirohi, R.; Bhatia, S.K.; Atabani, A.; Mulone, V.; et al. A review on valorization of spent coffee grounds (SCG) towards biopolymers and biocatalysts production. Bioresour. Technol. 2020, 314, 123800. [Google Scholar] [CrossRef] [PubMed]

- Arora, K.; Kaur, P.; Kumar, P.; Singh, A.; Patel, S.K.S.; Li, X.; Yang, Y.-H.; Bhatia, S.K.; Kulshrestha, S. Valorization of Wastewater Resources Into Biofuel and Value-Added Products Using Microalgal System. Front. Energy Res. 2021, 9, 119. [Google Scholar] [CrossRef]

- Bhatia, S.K.; Gurav, R.; Choi, T.-R.; Kim, H.J.; Yang, S.-Y.; Song, H.-S.; Park, J.Y.; Park, Y.-L.; Han, Y.-H.; Choi, Y.-K.; et al. Conversion of waste cooking oil into biodiesel using heterogenous catalyst derived from cork biochar. Bioresour. Technol. 2020, 302, 122872. [Google Scholar] [CrossRef] [PubMed]

- Ginni, G.; Kavitha, S.; Kannah, Y.; Bhatia, S.K.; Kumar, A.; Rajkumar, M.; Kumar, G.; Pugazhendhi, A.; Chi, N.T.L. Valorization of agricultural residues: Different biorefinery routes. J. Environ. Chem. Eng. 2021, 9, 105435. [Google Scholar] [CrossRef]

- Bhatia, S.K.; Palai, A.K.; Kumar, A.; Bhatia, R.K.; Patel, A.K.; Thakur, V.K.; Yang, Y.-H. Trends in renewable energy production employing biomass-based biochar. Bioresour. Technol. 2021, 340, 125644. [Google Scholar] [CrossRef] [PubMed]

- Bhatia, S.K.; Otari, S.V.; Jeon, J.-M.; Gurav, R.; Choi, Y.-K.; Bhatia, R.K.; Pugazhendhi, A.; Kumar, V.; Banu, J.R.; Yoon, J.-J.; et al. Biowaste-to-bioplastic (polyhydroxyalkanoates): Conversion technologies, strategies, challenges, and perspective. Bioresour. Technol. 2021, 326, 124733. [Google Scholar] [CrossRef] [PubMed]

- Kumar, G.; Ponnusamy, V.K.; Bhosale, R.R.; Shobana, S.; Yoon, J.-J.; Bhatia, S.K.; Banu, R.; Kim, S.-H. A review on the conversion of volatile fatty acids to polyhydroxyalkanoates using dark fermentative effluents from hydrogen production. Bioresour. Technol. 2019, 287, 121427. [Google Scholar] [CrossRef] [PubMed]

- Bhatia, S.K.; Mehariya, S.; Bhatia, R.K.; Kumar, M.; Pugazhendhi, A.; Awasthi, M.K.; Atabani, A.E.; Kumar, G.; Kim, W.; Seo, S.-O.; et al. Wastewater based microalgal biorefinery for bioenergy production: Progress and challenges. Sci. Total Environ. 2021, 751, 141599. [Google Scholar] [CrossRef] [PubMed]

- Bhatia, R.K.; Sakhuja, D.; Mundhe, S.; Walia, A. Renewable Energy Products through Bioremediation of Wastewater. Sustainability 2020, 12, 7501. [Google Scholar] [CrossRef]

- Gallego-Valero, L.; Moral-Parajes, E.; Román-Sánchez, I.M. Wastewater Treatment Costs: A Research Overview through Bibliometric Analysis. Sustainability 2021, 13, 5066. [Google Scholar] [CrossRef]

- Jayaseelan, M.; Usman, M.; Somanathan, A.; Palani, S.; Muniappan, G.; Jeyakumar, R.B. Microalgal Production of Biofuels Integrated with Wastewater Treatment. Sustainability 2021, 13, 8797. [Google Scholar] [CrossRef]

- Gurav, R.; Bhatia, S.K.; Choi, T.-R.; Kim, H.-J.; Lee, H.-J.; Cho, J.-Y.; Ham, S.; Suh, M.-J.; Kim, S.-H.; Kim, S.-K.; et al. Seafood Processing Chitin Waste for Electricity Generation in a Microbial Fuel Cell Using Halotolerant Catalyst Oceanisphaera arctica YHY1. Sustainability 2021, 13, 8508. [Google Scholar] [CrossRef]

- Dange, P.; Pandit, S.; Jadhav, D.; Shanmugam, P.K.; Gupta, P.; Kumar, S.; Kumar, M.; Yang, Y.-H.; Bhatia, S. Recent Developments in Microbial Electrolysis Cell-Based Biohydrogen Production Utilizing Wastewater as a Feedstock. Sustainability 2021, 13, 8796. [Google Scholar] [CrossRef]

- Hassanein, A.; Witarsa, F.; Lansing, S.; Qiu, L.; Liang, Y. Bio-electrochemical Enhancement of Hydrogen and Methane Production in a Combined Anaerobic Digester (AD) and Microbial Electrolysis Cell (MEC) from Dairy Manure. Sustainability 2020, 12, 8491. [Google Scholar] [CrossRef]

- Persson, T.; Persson, K.M.; Åström, J. Ferric Oxide-Containing Waterworks Sludge Reduces Emissions of Hydrogen Sulfide in Biogas Plants and the Needs for Virgin Chemicals. Sustainability 2021, 13, 7416. [Google Scholar] [CrossRef]

- Delavar, M.A.; Wang, J. Lattice Boltzmann Method in Modeling Biofilm Formation, Growth and Detachment. Sustainability 2021, 13, 7968. [Google Scholar] [CrossRef]

- Huang, G.; Pan, W.; Hu, C.; Pan, W.-L.; Dai, W.-Q. Energy Utilization Efficiency of China Considering Carbon Emissions—Based on Provincial Panel Data. Sustainability 2021, 13, 877. [Google Scholar] [CrossRef]

- Malatji, M.; Marnewick, A.L.; Solms, S.V. Cybersecurity Policy and the Legislative Context of the Water and Wastewater Sector in South Africa. Sustainability 2021, 13, 291. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).