Efficient Plastic Recycling and Remolding Circular Economy Using the Technology of Trust–Blockchain

Abstract

:1. Introduction

1.1. Classification of Plastics and Recycling Process

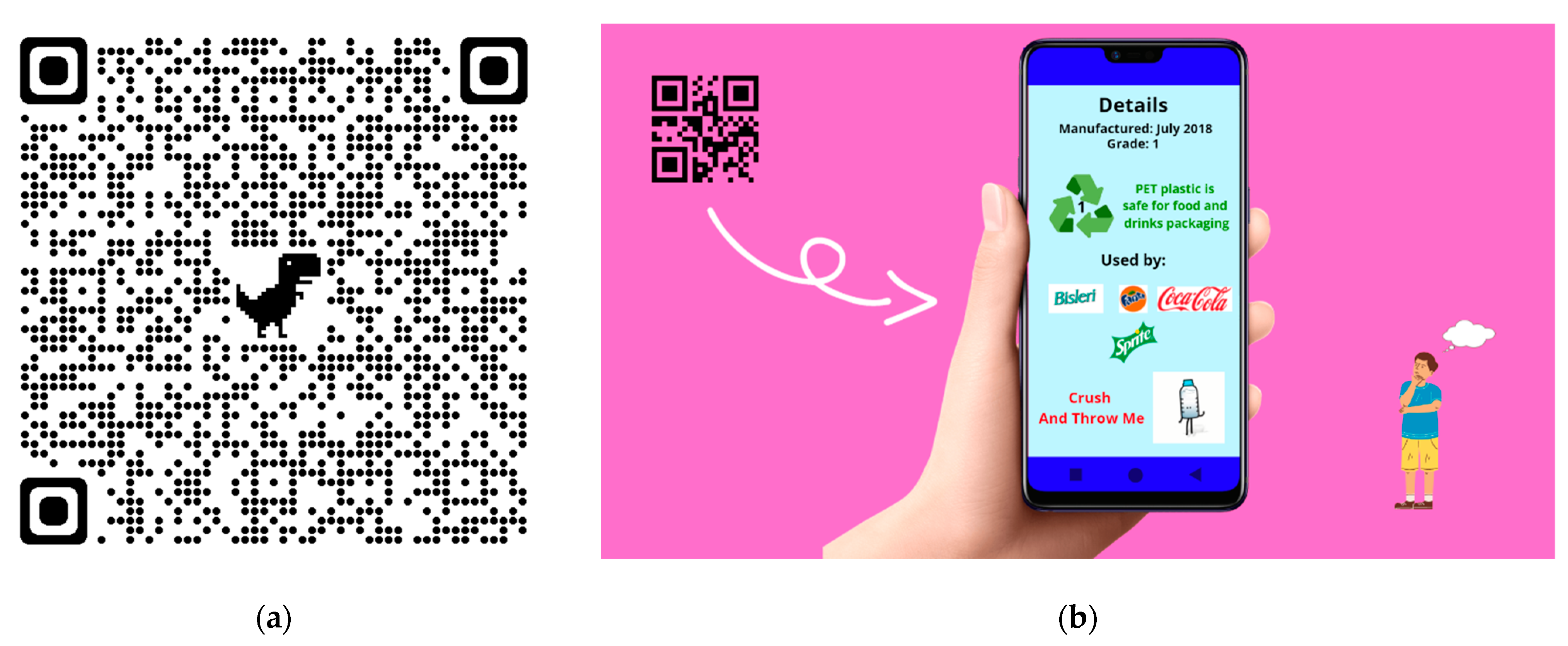

1.2. Blockchain-Based Technology for Plastic Recycling and Circular Economy

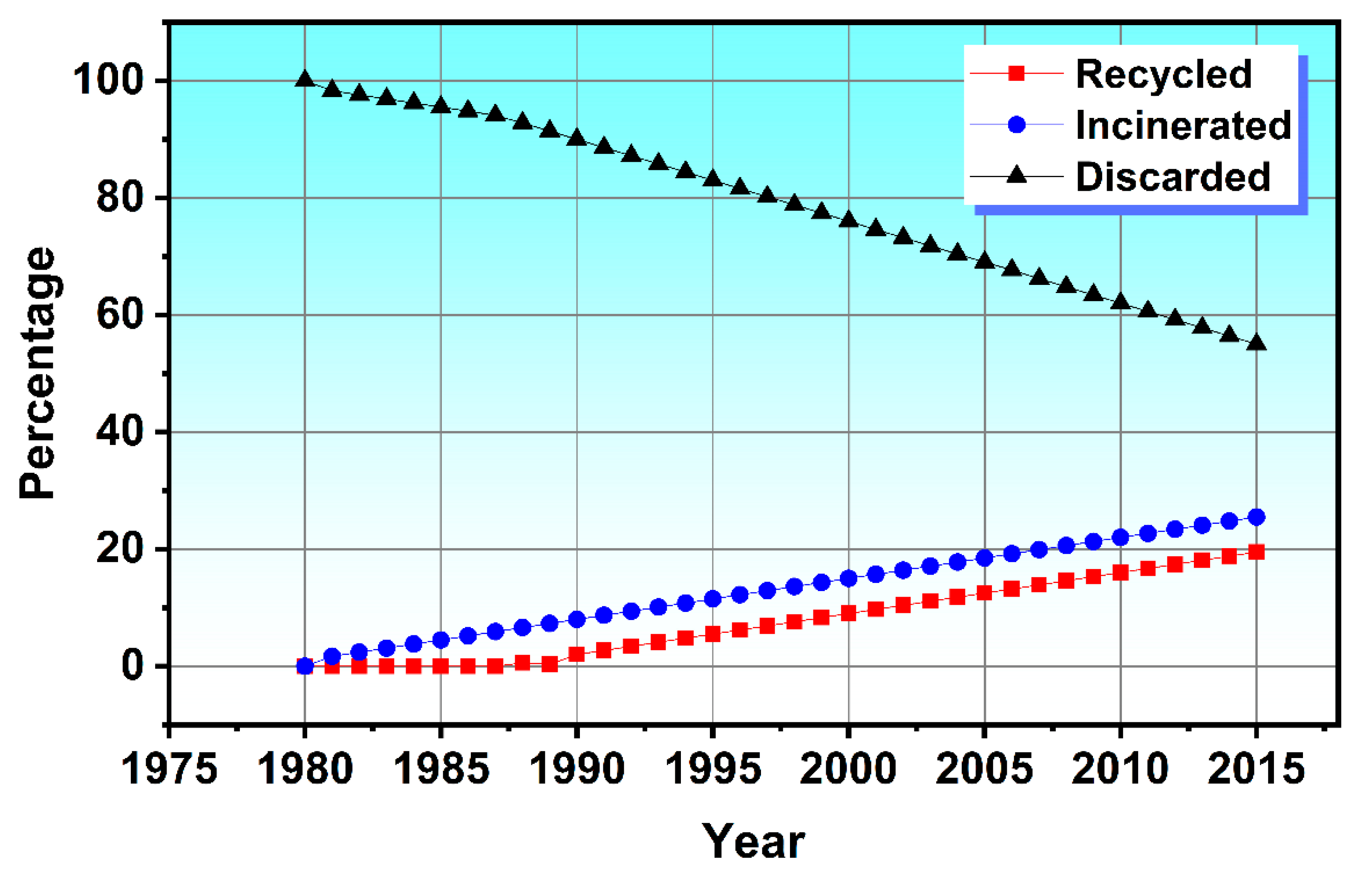

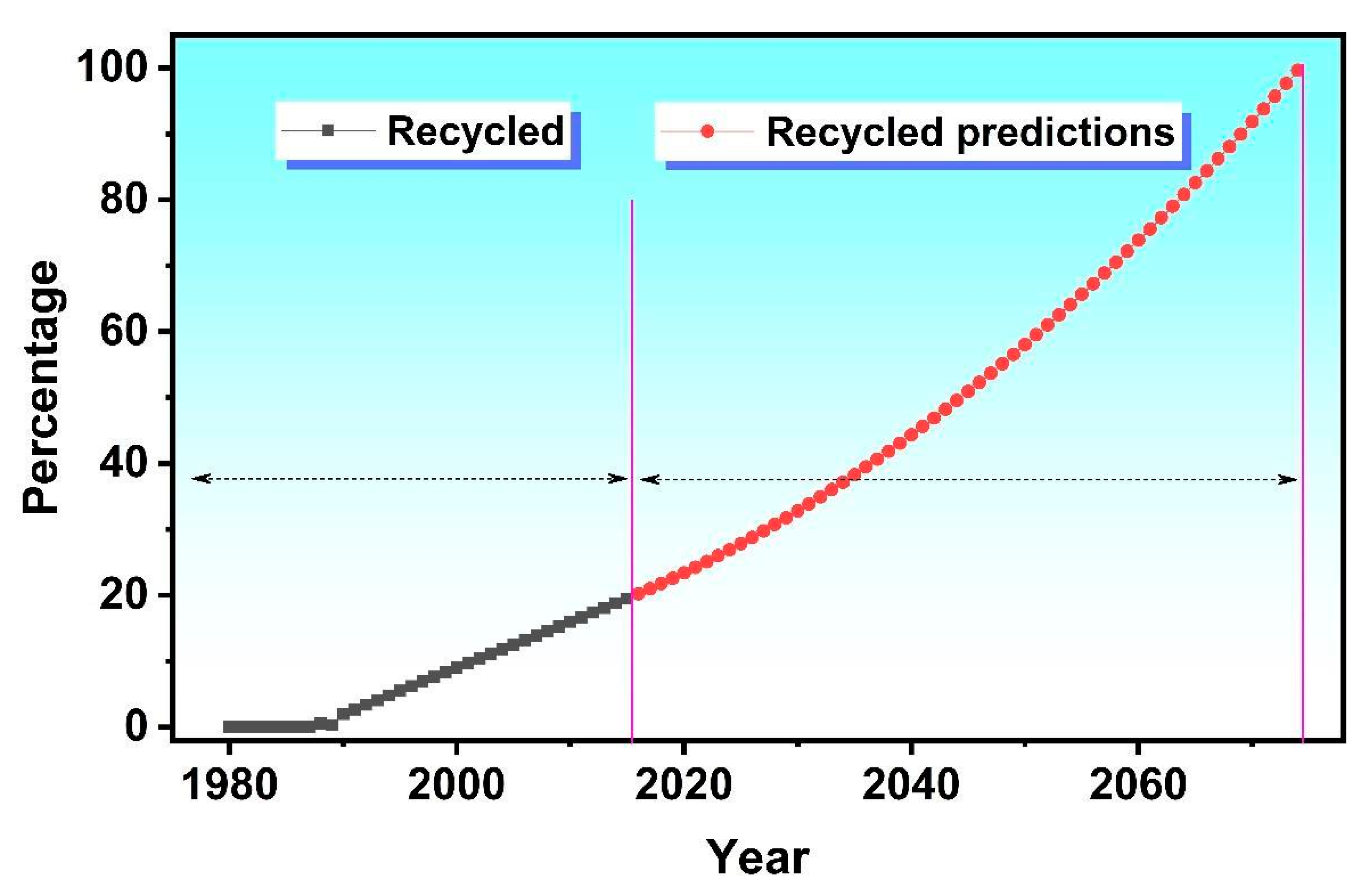

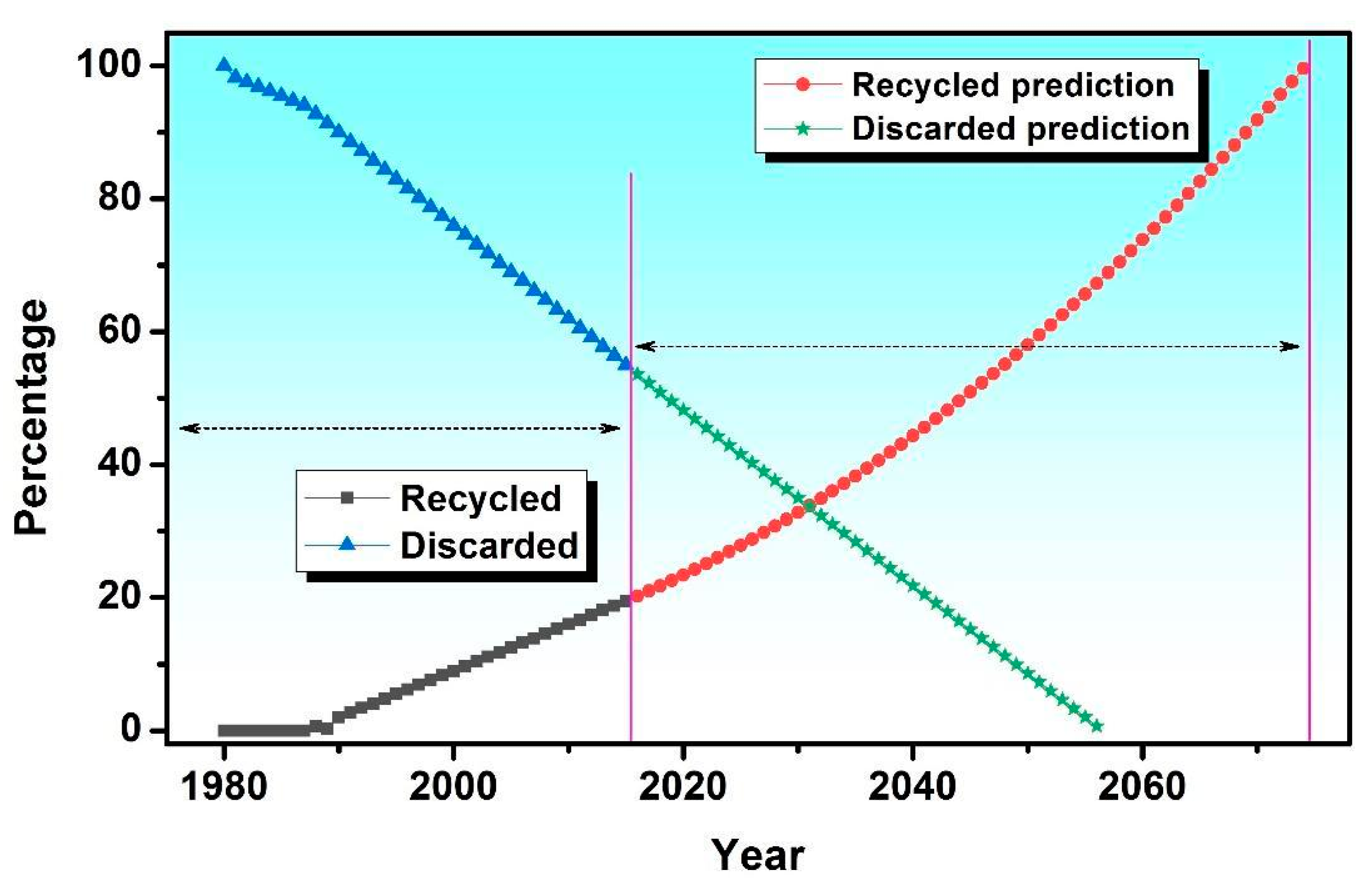

2. Statistics and Forecasting of the Plastic Waste Production Globally

3. Blockchain Technology and Circular Economy

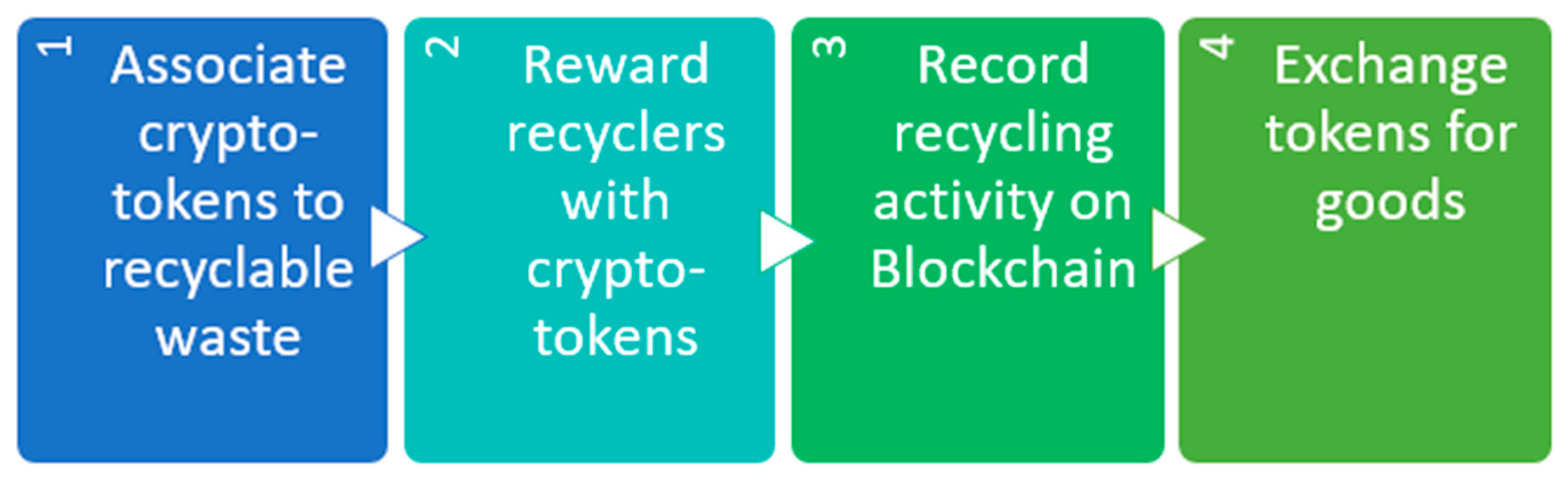

4. Prospective Proposal on Plastic Recycling and Blockchain Mechanism

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Thompson, R.C.; Moore, C.J.; Saal, F.S.V.; Swan, S. Plastics, the environment and human health: Current consensus and future trends. Philos. Trans. R. Soc. B Biol. Sci. 2009, 364, 2153–2166. [Google Scholar] [CrossRef]

- Winterstetter, A.; Grodent, M.; Kini, V.; Ragaert, K.; Vrancken, K. A Review of Technological Solutions to Prevent or Reduce Marine Plastic Litter in Developing Countries. Sustainability 2021, 13, 4894. [Google Scholar] [CrossRef]

- Cheang, C.C.; Ma, Y.; Fok, L. Occurrence and Composition of Microplastics in the Seabed Sediments of the Coral Communities in Proximity of a Metropolitan Area. Int. J. Environ. Res. Public Health 2018, 15, 2270. [Google Scholar] [CrossRef] [Green Version]

- Chen, Y.; Awasthi, A.K.; Wei, F.; Tan, Q.; Li, J. Single-use plastics: Production, usage, disposal, and adverse impacts. Sci. Total. Environ. 2020, 752, 141772. [Google Scholar] [CrossRef]

- Nezakati, T.; Seifalian, A.; Tan, A.; Seifalian, A. Conductive Polymers: Opportunities and Challenges in Biomedical Applications. Chem. Rev. 2018, 118, 6766–6843. [Google Scholar] [CrossRef]

- Xia, Q.; Chen, C.; Yao, Y.; Li, J.; He, S.; Zhou, Y.; Li, T.; Pan, X.; Yao, Y.; Hu, L. A strong, biodegradable and recyclable lignocellulosic bioplastic. Nat. Sustain. 2021, 4, 627–635. [Google Scholar] [CrossRef]

- Wang, C.; Liu, Y.; Chen, W.; Zhu, B.; Qu, S.; Xu, M. Critical review of global plastics stock and flow data. J. Ind. Ecol. 2021. [Google Scholar] [CrossRef]

- Wong, S.; Yeung, J.-K.-W.; Lau, Y.-Y.; So, J. Technical Sustainability of Cloud-Based Blockchain Integrated with Machine Learning for Supply Chain Management. Sustainability 2021, 13, 8270. [Google Scholar] [CrossRef]

- Xu, M.; Chen, X.; Kou, G. A systematic review of blockchain. Financ. Innov. 2019, 5, 27. [Google Scholar] [CrossRef] [Green Version]

- Chidepatil, A.; Bindra, P.; Kulkarni, D.; Qazi, M.; Kshirsagar, M.; Sankaran, K. From Trash to Cash: How Blockchain and Multi-Sensor-Driven Artificial Intelligence Can Transform Circular Economy of Plastic Waste? Adm. Sci. 2020, 10, 23. [Google Scholar] [CrossRef] [Green Version]

- Saberi, S.; Kouhizadeh, M.; Sarkis, J.; Shen, L. Blockchain technology and its relationships to sustainable supply chain man-agement. Int. J. Prod. Res. 2019, 57, 2117–2135. [Google Scholar] [CrossRef] [Green Version]

- Kouhizadeh, M.; Zhu, Q.; Sarkis, J. Blockchain and the circular economy: Potential tensions and critical reflections from practice. Prod. Plan. Control. 2019, 31, 950–966. [Google Scholar] [CrossRef]

- Komalavalli, C.; Saxena, D.; Laroiya, C. Overview of Blockchain Technology Concepts. In Handbook of Research on Blockchain Technology; Academic Press: Cambridge, MA, USA, 2020; pp. 349–371. [Google Scholar] [CrossRef]

- Katz, D. Plastic Bank: Recycling Ecosystems. Good Tech IBM, 1–5. 2021. Available online: https://www.ibm.com/blogs/corporate-social-responsibility/2020/04/plastic-bank-recycling-ecosystems/ (accessed on 12 February 2021).

- Park, A.; Li, H. The Effect of Blockchain Technology on Supply Chain Sustainability Performances. Sustainability 2021, 13, 1726. [Google Scholar] [CrossRef]

- Ghoreishi, M.; Happonen, A. New promises AI brings into circular economy accelerated product design: A review on supporting literature. E3S Web Conf. 2020, 158, 06002. [Google Scholar] [CrossRef]

- David, U.; Guerdat, P. Impact Tokens: A Blockchain-Based Solution for Impact Investing; IISDA: Winnipeg, MB, Canada, 2019; Available online: https://www.cabdirect.org/cabdirect/abstract/20208400105 (accessed on 13 February 2021).

- Forrest, A.; Giacovazzi, L.; Dunlop, S.; Reisser, J.; Tickler, D.; Jamieson, A.; Meeuwig, J.J. Eliminating Plastic Pollution: How a Voluntary Contribution From Industry Will Drive the Circular Plastics Economy. Front. Mar. Sci. 2019, 6, 627. [Google Scholar] [CrossRef]

- Source for Data Analysis. Available online: https://ourworldindata.org/faq-on-plastics#how-much-plastic-and-waste-do-we-produce (accessed on 13 February 2021).

- Commission Directive 97/69/EC of 5 December 1997 Adapting to Technical Progress for the 23rd Time Council Directive 67/548/EEC on the Approximation of the Laws, Regulations and Administrative Provisions Relating to the Classification, Packaging and Labelling of Dangerous Substances (Text with EEA Relevance)-Legislation-Legislation-VLEX 843169529. Available online: https://eu.vlex.com/vid/commission-directive-97-69-843169529 (accessed on 10 March 2021).

- Ahmad, R.W.; Salah, K.; Jayaraman, R.; Yaqoob, I.; Omar, M. Blockchain for Waste Management in Smart Cities: A Survey. 2021. Available online: https://doi.org/10.36227/techrxiv.14345534.v1 (accessed on 6 May 2021).

- LaZooz a Decentralized Uber. 13 May 2019. Available online: https://wearabletech.medium.com/lazooz-a-decentralized-uber-4fdbe1349d00 (accessed on 15 January 2021).

- Just around the Block—Blockchain and Revolutionizing Compilance in Supply Chains. 10 May 2021. Available online: https://fsc.org/en/newsfeed/just-around-the-block-blockchain (accessed on 20 May 2021).

- Energy Blockchain Labs: Facilitating Carbon Reduction with IBM Blockchain. 31 August 2017. Available online: https://mediacenter.ibm.com/media/Energy+Blockchain+LabsA+facilitating+carbon+reduction+with+IBM+Blockchain/1_j1cot0z5 (accessed on 20 May 2021).

- SMA Offers SolarCoin Crypto Cash to 260,000 PV Owners. 15 February 2019. Available online: https://www.greentechmedia.com/articles/read/sma-offers-solarcoin-crypto-cash-to-260000-pv-owners (accessed on 20 January 2021).

- Ghosh, J. The Blockchain: Opportunities for Research in Information Systems and Information Technology. J. Glob. Inf. Technol. Manag. 2019, 22, 235–242. [Google Scholar] [CrossRef] [Green Version]

- Vergne, J. Decentralized vs. Distributed Organization: Blockchain, Machine Learning and the Future of the Digital Platform. Organ. Theory 2020, 1, 2631787720977052. [Google Scholar] [CrossRef]

- Casino, F.; Dasaklis, T.K.; Patsakis, C. A systematic literature review of blockchain-based applications: Current status, classification and open issues. Telemat. Inform. 2019, 36, 55–81. [Google Scholar] [CrossRef]

- ShareRing, Crunchbase. 1 January 2018. Available online: https://www.crunchbase.com/organization/sharering (accessed on 18 March 2021).

- Foodchain Spa. 1 January 2016. Available online: https://www.chaineurope.org/blockchain-startups/foodchain-spa/ (accessed on 24 March 2021).

- Blockchain Technology Can Innovate the Business of Recycling. 16 April 2018. Available online: https://cycled.no/blockchain-technology-can-innovate-the-business-of-recycling (accessed on 19 February 2021).

- Environment and Climate Change. 13 June 2019. Available online: https://nature-coin.io/blog/environment-and-climate-change (accessed on 2 March 2021).

- World’s First “Global” Plastic-Offset Scheme Launched by BCDC. 14 November 2017. Available online: https://www.prnewswire.co.uk/news-releases/worlds-first-global-plastic-offset-scheme-launched-by-bcdc-657453793.html (accessed on 12 June 2021).

- Blockchain Development Company (BCDC.ONLINE LTD). 3 October 2018. Available online: https://www.bark.com/en/gb/company/blockchain-development-company-bcdconline-ltd/1kzgq/ (accessed on 10 June 2021).

- Indian Blockchain Project Swachhcoin. 6 June 2018. Available online: https://medium.com/@swachhcoin/indian-blockchain-project-swachhcoins-public-pre-sale-is-now-live-3c5461919a88 (accessed on 27 May 2021).

- Zwitter, A.J.; Gstrein, O.J.; Yap, E. Digital Identity and the Blockchain: Universal Identity Management and the Concept of the “Self-Sovereign” Individual. Front. Blockchain 2020, 3, 26. [Google Scholar] [CrossRef]

- Upadhyay, A.; Mukhuty, S.; Kumar, V.; Kazancoglu, Y. Blockchain technology and the circular economy: Implications for sustainability and social responsibility. J. Clean. Prod. 2021, 293, 126130. [Google Scholar] [CrossRef]

- D’Adamo, I.; Lupi, G. Sustainability and Resilience after COVID-19: A Circular Premium in the Fashion Industry. Sustainability 2021, 13, 1861. [Google Scholar] [CrossRef]

- Makridakis, S.; Christodoulou, K. Blockchain: Current Challenges and Future Prospects/Applications. Futur. Internet 2019, 11, 258. [Google Scholar] [CrossRef] [Green Version]

- Kosmarski, A. Blockchain Adoption in Academia: Promises and Challenges. J. Open Innov. Technol. Mark. Complex. 2020, 6, 117. [Google Scholar] [CrossRef]

| Application Category | Opportunities from Blockchain Technology | Examples | Reference |

|---|---|---|---|

| Resource Efficiency Enhancement | To make sharing economy models attractive by removing middlemen and/or creating a blockchain-based identity system. To enable direct financing of sustainable projects. | Sharing economy: Arcade City, Lazooz | [21] |

| Resource Tracking | To record transactions openly, indefinitely, and immutably, enhancing the transparency and trust in the information provided. To empower consumers in their consumer decisions. | Certification: PEFC (Programme for the Endorsement of Forest Certification) FSC (Forest Stewardship Council) and BHP Billiton Resource tracking: IBM collaboration with Nestlé, Unilever, and Walmart | [22] |

| Resource Pricing | To create more efficient credit management platforms. To create a cap-and-trade system considerably automatized with smart contracts against politicians chasing their political agendas. | Carbon credit management platform: IBM-Energy Blockchain Lab collaboration | [23] |

| Complementary Currency | To create financial accounting and macroeconomic systems with different rules from the current monetary systems. | Cryptocurrencies: Solar Coin, Eco Coin, Earth Dollar, BitNatura | [24] |

| Category of Application Functions | Blockchain Application | Provider (Country) | Target Materials | Reference |

|---|---|---|---|---|

| Resource Efficiency Enhancement | Excess Materials Exchange | Excess Materials Exchange (The Netherlands) | Any excess materials and under-used products | |

| ShareRing | ShareRing (Australia) | Any excess materials and under-used products | [28] | |

| IBM Blockchain Platform | IBM (US)/Plastic Bank (Canada) | Plastics | ||

| Resource Tracking | Circularise | Circularise (The Netherlands) | Waste electronic devices | |

| European waste transportation on blockchain | Dutch Ministry of Infrastructure & Water Management (The Netherlands) | Waste moved between Netherlands and Belgium | ||

| Foodchain | Foodchain Spa (Italy) | Food waste | [29] | |

| Troventum | Troventum Limited (Malta) | Solid recyclable household waste | ||

| IBM Blockchain Platform | IBM (US)/Plastic Bank (Canada) | Plastics | ||

| Resource Pricing | Cycled | Cycled (Norway) | Household waste | [30] |

| Complementary Currency | Augoraa Tech Lab | Ethereum Foundation (Switzerland) | Plastic waste | |

| Cycled | Cycled (Norway) | Household waste | ||

| Zafeplace Blockchain Platform | Zafeplace/Empower (Norway) | End-of-life plastics | ||

| NatureCoin | NatureCoin (Canada) | Disposable waste (including plastics, tins and cans) | [31] | |

| IBM Blockchain Platform | IBM (US)/Plastic Bank (Canada) | Plastics | [32] | |

| Recreum | Ethereum Foundation (Switzerland) | Glass, plastic, aluminum, used batteries, paper, wood | ||

| RecycleToCoin | BCDC.Online Limited (UK) | ‘Single-use’ plastic bottles and aluminum cans | [33] | |

| Swachhcoin | Swachhcoin (India) | Recyclable waste from households and industries | [34] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Khadke, S.; Gupta, P.; Rachakunta, S.; Mahata, C.; Dawn, S.; Sharma, M.; Verma, D.; Pradhan, A.; Krishna, A.M.S.; Ramakrishna, S.; et al. Efficient Plastic Recycling and Remolding Circular Economy Using the Technology of Trust–Blockchain. Sustainability 2021, 13, 9142. https://doi.org/10.3390/su13169142

Khadke S, Gupta P, Rachakunta S, Mahata C, Dawn S, Sharma M, Verma D, Pradhan A, Krishna AMS, Ramakrishna S, et al. Efficient Plastic Recycling and Remolding Circular Economy Using the Technology of Trust–Blockchain. Sustainability. 2021; 13(16):9142. https://doi.org/10.3390/su13169142

Chicago/Turabian StyleKhadke, Swikriti, Pragya Gupta, Shanmukh Rachakunta, Chandreswar Mahata, Suma Dawn, Mohit Sharma, Deepak Verma, Aniruddha Pradhan, Ambati Mounika Sai Krishna, Seeram Ramakrishna, and et al. 2021. "Efficient Plastic Recycling and Remolding Circular Economy Using the Technology of Trust–Blockchain" Sustainability 13, no. 16: 9142. https://doi.org/10.3390/su13169142

APA StyleKhadke, S., Gupta, P., Rachakunta, S., Mahata, C., Dawn, S., Sharma, M., Verma, D., Pradhan, A., Krishna, A. M. S., Ramakrishna, S., Chakrabortty, S., Saianand, G., Sonar, P., Biring, S., Dash, J. K., & Dalapati, G. K. (2021). Efficient Plastic Recycling and Remolding Circular Economy Using the Technology of Trust–Blockchain. Sustainability, 13(16), 9142. https://doi.org/10.3390/su13169142