A Methodological Framework to Support the Sustainable Innovation Development Process: A Collaborative Approach

Abstract

:1. Introduction

- What are the dimensions characterizing the concept of sustainable innovation?

- How can actors’ collaboration across the supply chain be supported during the process of sustainable innovation development?

2. Theoretical Background

2.1. The Concept of Sustainable Innovation

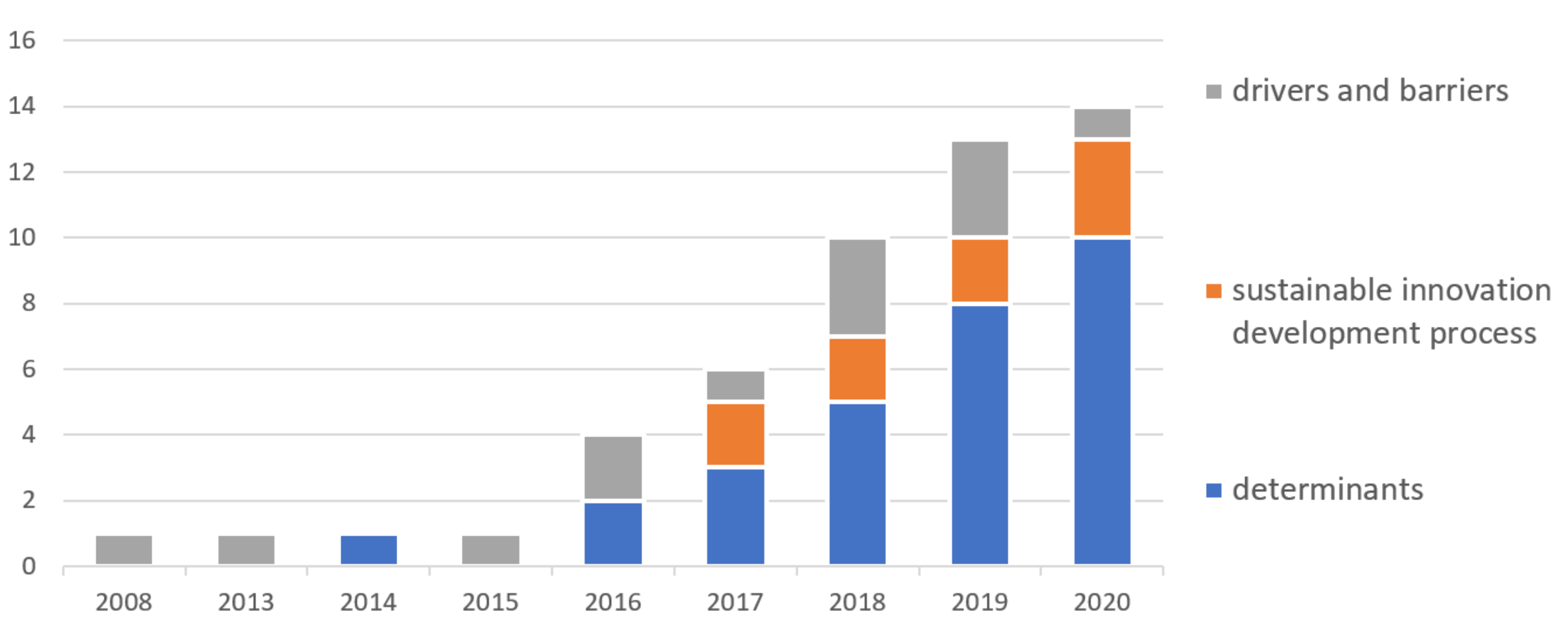

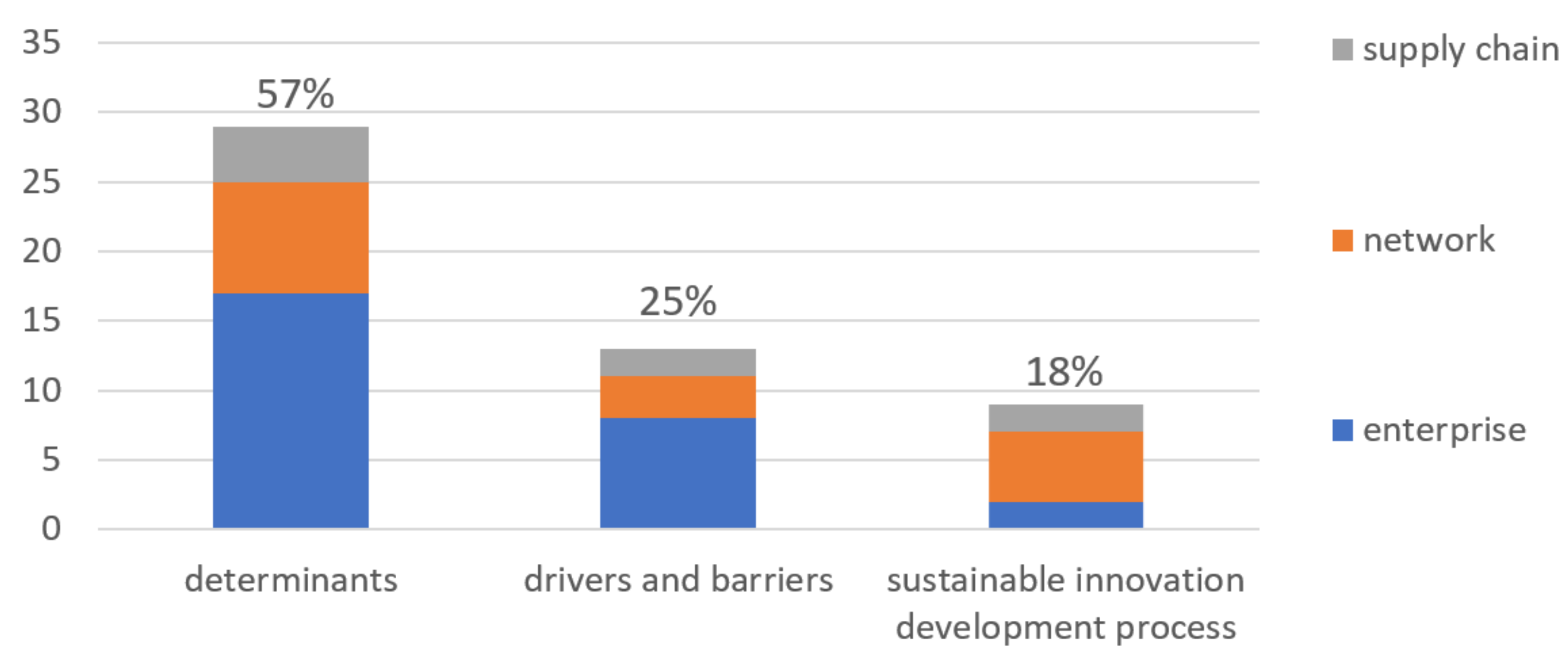

2.2. Thematic Analysis of the Sustainable Innovation Literature

2.3. Sustainable Innovation Development Process

3. Materials and Methods

3.1. Qualitative Study

- Internal actors: Thirteen interviews were performed with key actors from the departments of purchasing (project leader), prescription, sustainable development, human resources, research and development (R&D), and the operational employees (users of the safety clothes).

- External actors: seven interviews were carried out with actors from the entire supply chain, involving clothes manufacturers , logistics providers, washing service providers, and end-of-life service providers. Moreover, non-economic actors (social organizations) were integrated to the project with the aim at identifying further sustainable-oriented opportunities.

3.2. Quantitative Study

4. Results and Discussion

4.1. Case Study Context

4.2. Qualitative Study

4.2.1. Setting Actors’ Motivations and Expectations

4.2.2. Criteria Definition

- (E) Economics: this dimension focuses on reducing the purchasing costs, and developing new market niches in France based on circular economy strategies throughout the transformation of the waste clothing into new resources.

- (N) Environmental: implementing an environmental management plan over the entire system of safety clothing, focusing on supplier management and waste treatment policies.

- (S) Social: guaranteeing the respect of the human rights in the manufacturing countries (of safety clothing), decent conditions of employment, and development of the French economy.

- (R) Relational: establishing long-term relationships with providers, sharing responsibilities, and promoting collaboration for innovation development.

- (F) Functional: improving the lifespan of the safety clothes, establishing a system based on the clothes availability to use, rather than the traditional product reprovisioning.

4.2.3. Alternative Definition with Suppliers

- (BOL) Beginning of life: the main decision concerns the type of fibre used to manufacture the safety clothes. A critical aspect for the providers in terms of sustainability is the country of production, hence, a mix between Asian, North African, and European production was considered. After a brainstorming session integrating providers capabilities and EDF criteria for the future model, three fibre options were retained: poly-cotton, organic cotton, and tencel (eucalyptus-based fibre).

- (MOL) Middle of life: decisions in this stage focus on the washing system (localised or centralised) and on the type of technology used for ensuring clothes traceability (RFID tag or bar code).

- (EOL) End of life: decisions concern the system for waste upgrading and the opportunities to develop new markets in France by using the wasted textile. Three options resulted from the providers interviews: new product, second-life safety clothing, energy recovery (i.e., from incineration).

4.3. Quantitative Study

- Eco-efficiency: when adopting this profile, EDF is willing to reduce environmental impacts only if the economic expenses are kept at least stable with respect to the current model. Concerning the relationship with the suppliers, EDF adopts a prescriptive positioning rather than collaborative, e.g., the purchasing function asks for eco-innovative products to the providers.

- Societal: this profile supposes a strong internal transformation of EDF’s purchasing practices. For instance, the roles of sustainable development and human resources departments gain in importance in the definition of the purchasing strategy. Moreover, the purchasing department should be able to cooperate with the providers of the entire supply chain in order to accomplish sustainability goals from a normative perspective. Such a collaboration should be a common effort to transform the supply chain practices.

- Triple bottom line (TBL): in this case, EDF is willing to pay a higher price for the safety clothing (i.e., degradation of economic dimension) if this reduces the environmental and social impacts, and guarantees the tracking and the quality of the product (i.e., improvement of environmental, social, and functional dimensions).

5. Conclusions and Implications

5.1. Theoretical Implications

5.2. Managerial Implications

5.3. Limits and Future Research

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Nielsen, K.R. Policymakers’ views on sustainable end-user innovation: Implications for sustainable innovation. J. Clean. Prod. 2020, 254, 120030. [Google Scholar] [CrossRef]

- Klewitz, J.; Hansen, E.G. Sustainability-oriented innovation of SMEs: A systematic review. J. Clean. Prod. 2014, 65, 57–75. [Google Scholar] [CrossRef]

- Rohrbeck, R.; Konnertz, L.; Knab, S. Collaborative business modelling for systemic and sustainability innovations. Int. J. Technol. Manag. 2013, 63, 4–23. [Google Scholar] [CrossRef]

- Berkowitz, H. Meta-organizing firms’ capabilities for sustainable innovation: A conceptual framework. J. Clean. Prod. 2018, 175, 420–430. [Google Scholar] [CrossRef]

- Adams, R.; Jeanrenaud, S.; Bessant, J.; Denyer, D.; Overy, P. Sustainability-oriented innovation: A systematic review. Int. J. Manag. Rev. 2016, 18, 180–205. [Google Scholar] [CrossRef]

- Aboelmaged, M.; Hashem, G. Absorptive capacity and green innovation adoption in SMEs: The mediating effects of sustainable organisational capabilities. J. Clean. Prod. 2019, 220, 853–863. [Google Scholar] [CrossRef]

- Anttonen, M.; Halme, M.; Houtbeckers, E.; Nurkka, J. The other side of sustainable innovation: Is there a demand for innovative services? J. Clean. Prod. 2013, 45, 89–103. [Google Scholar] [CrossRef] [Green Version]

- Foxon, T.; Pearson, P. Overcoming barriers to innovation and diffusion of cleaner technologies: Some features of a sustainable innovation policy regime. J. Clean. Prod. 2008, 16, 148–161. [Google Scholar] [CrossRef]

- Pinto, M.M.A.; Kovaleski, J.L.; Yoshino, R.T.; Pagani, R.N. Knowledge and Technology Transfer Influencing the Process of Innovation in Green Supply Chain Management: A Multicriteria Model Based on the DEMATEL Method. Sustainability 2019, 11, 3485. [Google Scholar] [CrossRef] [Green Version]

- Huang, J.W.; Li, Y.H. Green innovation and performance: The view of organizational capability and social reciprocity. J. Bus. Ethics 2017, 145, 309–324. [Google Scholar] [CrossRef]

- Mousavi, S.; Bossink, B.A. Firms’ capabilities for sustainable innovation: The case of biofuel for aviation. J. Clean. Prod. 2017, 167, 1263–1275. [Google Scholar] [CrossRef]

- Ferigotti, C.M.; Cunha, S.K.; Fernandes, B.H.R. Managerial competencies for requirements of sustainable innovation: The case of Electrolux of Brazil S/A. Int. J. Innov. Sustain. Dev. 2016, 10, 160–176. [Google Scholar] [CrossRef]

- Brix, J. Building capacity for sustainable innovation: A field study of the transition from exploitation to exploration and back again. J. Clean. Prod. 2020, 268, 122381. [Google Scholar] [CrossRef]

- Kuokkanen, A.; Uusitalo, V.; Koistinen, K. A framework of disruptive sustainable innovation: An example of the Finnish food system. Technol. Anal. Strateg. Manag. 2019, 31, 749–764. [Google Scholar] [CrossRef]

- Neutzling, D.M.; Land, A.; Seuring, S.; do Nascimento, L.F.M. Linking sustainability-oriented innovation to supply chain relationship integration. J. Clean. Prod. 2018, 172, 3448–3458. [Google Scholar] [CrossRef]

- Reficco, E.; Gutiérrez, R.; Jaén, M.H.; Auletta, N. Collaboration mechanisms for sustainable innovation. J. Clean. Prod. 2018, 203, 1170–1186. [Google Scholar] [CrossRef]

- Aka, K.G. Actor-network theory to understand, track and succeed in a sustainable innovation development process. J. Clean. Prod. 2019, 225, 524–540. [Google Scholar] [CrossRef]

- Mercado-Caruso, N.; Segarra-Oña, M.; Ovallos-Gazabon, D.; Peiró-Signes, A. Identifying endogenous and exogenous indicators to measure eco-innovation within clusters. Sustainability 2020, 12, 6088. [Google Scholar] [CrossRef]

- Cheng, C.C. Sustainability orientation, green supplier involvement, and green innovation performance: Evidence from diversifying green entrants. J. Bus. Ethics 2020, 161, 393–414. [Google Scholar] [CrossRef]

- Wang, J.; Xue, Y.; Sun, X.; Yang, J. Green learning orientation, green knowledge acquisition and ambidextrous green innovation. J. Clean. Prod. 2020, 250, 119475. [Google Scholar] [CrossRef]

- Abbas, J.; Sağsan, M. Impact of knowledge management practices on green innovation and corporate sustainable development: A structural analysis. J. Clean. Prod. 2019, 229, 611–620. [Google Scholar] [CrossRef]

- Seman, N.A.A.; Govindan, K.; Mardani, A.; Zakuan, N.; Saman, M.Z.M.; Hooker, R.E.; Ozkul, S. The mediating effect of green innovation on the relationship between green supply chain management and environmental performance. J. Clean. Prod. 2019, 229, 115–127. [Google Scholar] [CrossRef]

- Soewarno, N.; Tjahjadi, B.; Fithrianti, F. Green innovation strategy and green innovation. Manag. Decis. 2019, 57, 3061–3078. [Google Scholar] [CrossRef]

- Tariq, A.; Badir, Y.F.; Safdar, U.; Tariq, W.; Badar, K. Linking firms’ life cycle, capabilities, and green innovation. J. Manuf. Technol. Manag. 2019, 31, 284–305. [Google Scholar] [CrossRef]

- Wang, C.H. How organizational green culture influences green performance and competitive advantage. J. Manuf. Technol. Manag. 2019, 30, 666–683. [Google Scholar] [CrossRef]

- de Medeiros, J.F.; Vidor, G.; Ribeiro, J.L.D. Driving factors for the success of the green innovation market: A relationship system proposal. J. Bus. Ethics 2018, 147, 327–341. [Google Scholar] [CrossRef]

- Saunila, M.; Ukko, J.; Rantala, T. Sustainability as a driver of green innovation investment and exploitation. J. Clean. Prod. 2018, 179, 631–641. [Google Scholar] [CrossRef]

- Cuerva, M.C.; Triguero-Cano, Á.; Córcoles, D. Drivers of green and non-green innovation: Empirical evidence in Low-Tech SMEs. J. Clean. Prod. 2014, 68, 104–113. [Google Scholar] [CrossRef]

- Weidner, K.; Nakata, C.; Zhu, Z. Sustainable innovation and the triple bottom-line: A market-based capabilities and stakeholder perspective. J. Mark. Theory Pract. 2021, 29, 141–161. [Google Scholar] [CrossRef]

- Dyck, B.; Silvestre, B.S. Enhancing socio-ecological value creation through sustainable innovation 2.0: Moving away from maximizing financial value capture. J. Clean. Prod. 2018, 171, 1593–1604. [Google Scholar] [CrossRef]

- WCED, S.W.S. World commission on environment and development. Our Common Future 1987, 17, 1–91. [Google Scholar]

- Pope, J.; Morrison-Saunders, A.; Annandale, D. Applying sustainability assessment models. Impact Assess. Proj. Apprais. 2005, 23, 293–302. [Google Scholar] [CrossRef]

- Vezzoli, C.; Manzini, E. Design for Environmental Sustainability; Springer: London, UK, 2008. [Google Scholar]

- Bond, A.; Morrison-Saunders, A.; Pope, J. Sustainability assessment: The state of the art. Impact Assess. Proj. Apprais. 2012, 30, 53–62. [Google Scholar] [CrossRef]

- ISO 14001. Environmental Management System: Requirements with Guidance for Use; International Organization for Standardization: Geneva, Switzerland, 2015. [Google Scholar]

- ISO 26000. Guidance on Social Responsibility; International Organization for Standardization: Geneva, Switzerland, 2010. [Google Scholar]

- Carrillo-Hermosilla, J.; del Río, P.; Könnölä, T. Diversity of eco-innovations: Reflections from selected case studies. J. Clean. Prod. 2010, 18, 1073–1083. [Google Scholar] [CrossRef]

- Barile, S.; Grimaldi, M.; Loia, F.; Sirianni, C.A. Technology, value Co-Creation and innovation in service ecosystems: Toward sustainable Co-Innovation. Sustainability 2020, 12, 2759. [Google Scholar] [CrossRef] [Green Version]

- Brown, P.; Bocken, N.; Balkenende, R. Why do companies pursue collaborative circular oriented innovation? Sustainability 2019, 11, 635. [Google Scholar] [CrossRef] [Green Version]

- Delmas, M.A.; Pekovic, S. Corporate sustainable innovation and employee behavior. J. Bus. Ethics 2018, 150, 1071–1088. [Google Scholar] [CrossRef] [Green Version]

- Van de Wetering, R.; Mikalef, P.; Helms, R. Driving organizational sustainability-oriented innovation capabilities: A complex adaptive systems perspective. Curr. Opin. Environ. Sustain. 2017, 28, 71–79. [Google Scholar] [CrossRef]

- Abdullah, M.; Zailani, S.; Iranmanesh, M.; Jayaraman, K. Barriers to green innovation initiatives among manufacturers: The Malaysian case. Rev. Manag. Sci. 2016, 10, 683–709. [Google Scholar] [CrossRef]

- Huang, X.x.; Hu, Z.p.; Liu, C.s.; Yu, D.j.; Yu, L.f. The relationships between regulatory and customer pressure, green organizational responses, and green innovation performance. J. Clean. Prod. 2016, 112, 3423–3433. [Google Scholar] [CrossRef]

- Zailani, S.; Govindan, K.; Iranmanesh, M.; Shaharudin, M.R.; Chong, Y.S. Green innovation adoption in automotive supply chain: The Malaysian case. J. Clean. Prod. 2015, 108, 1115–1122. [Google Scholar] [CrossRef]

- Costa, J.; Matias, J.C. Open innovation 4.0 as an enhancer of sustainable innovation ecosystems. Sustainability 2020, 12, 8112. [Google Scholar] [CrossRef]

- Zhou, M.; Govindan, K.; Xie, X. How fairness perceptions, embeddedness, and knowledge sharing drive green innovation in sustainable supply chains: An equity theory and network perspective to achieve sustainable development goals. J. Clean. Prod. 2020, 260, 120950. [Google Scholar] [CrossRef]

- Awan, U.; Sroufe, R.; Kraslawski, A. Creativity enables sustainable development: Supplier engagement as a boundary condition for the positive effect on green innovation. J. Clean. Prod. 2019, 226, 172–185. [Google Scholar] [CrossRef]

- Maletič, M.; Maletič, D.; Dahlgaard, J.J.; Dahlgaard-Park, S.M.; Gomišček, B. Effect of sustainability-oriented innovation practices on the overall organisational performance: An empirical examination. Total Qual. Manag. Bus. Excell. 2016, 27, 1171–1190. [Google Scholar] [CrossRef] [Green Version]

- Cantele, S.; Moggi, S.; Campedelli, B. Spreading sustainability innovation through the co-evolution of sustainable business models and partnerships. Sustainability 2020, 12, 1190. [Google Scholar] [CrossRef] [Green Version]

- Goodman, J.; Korsunova, A.; Halme, M. Our collaborative future: Activities and roles of stakeholders in sustainability-oriented innovation. Bus. Strategy Environ. 2017, 26, 731–753. [Google Scholar] [CrossRef]

- Melane-Lavado, A.; Álvarez-Herranz, A. Cooperation Networks as a Driver of Sustainability-Oriented Innovation. Sustainability 2020, 12, 2820. [Google Scholar] [CrossRef] [Green Version]

- Inigo, E.A.; Ritala, P.; Albareda, L. Networking for sustainability: Alliance capabilities and sustainability-oriented innovation. Ind. Mark. Manag. 2020, 89, 550–565. [Google Scholar] [CrossRef]

- Chen, X.; Yi, N.; Zhang, L.; Li, D. Does institutional pressure foster corporate green innovation? Evidence from China’s top 100 companies. J. Clean. Prod. 2018, 188, 304–311. [Google Scholar] [CrossRef]

- Gupta, H.; Barua, M.K. Supplier selection among SMEs on the basis of their green innovation ability using BWM and fuzzy TOPSIS. J. Clean. Prod. 2017, 152, 242–258. [Google Scholar] [CrossRef]

- Hernandez-Vivanco, A.; Bernardo, M.; Cruz-Cázares, C. Sustainable innovation through management systems integration. J. Clean. Prod. 2018, 196, 1176–1187. [Google Scholar] [CrossRef]

- Lee, D. Implementation of collaborative activities for sustainable supply chain innovation: An analysis of the firm size effect. Sustainability 2019, 11, 3026. [Google Scholar] [CrossRef] [Green Version]

- Ghassim, B.; Bogers, M. Linking stakeholder engagement to profitability through sustainability-oriented innovation: A quantitative study of the minerals industry. J. Clean. Prod. 2019, 224, 905–919. [Google Scholar] [CrossRef]

- Rauter, R.; Perl-Vorbach, E.; Baumgartner, R.J. Is open innovation supporting sustainable innovation? Findings based on a systematic, explorative analysis of existing literature. Int. J. Innov. Sustain. Dev. 2017, 11, 249–270. [Google Scholar] [CrossRef]

- Eisenhardt, K.M. Building Theories from Case Study Research. Acad. Manag. Rev. 1989, 14, 532–550. [Google Scholar] [CrossRef]

- Yin, R.K. Case Study Research and Applications: Design and Methods; Sage Publications: Los Angeles, CA, USA, 2017. [Google Scholar]

- Miles, M.B.; Huberman, A.M.; Saldaña, J. Qualitative Data Analysis: A Methods Sourcebook, 3rd ed.; SAGE Publications: Thousand Oaks, CA, USA, 2014. [Google Scholar]

- Saaty, T.L. Decision making—The analytic hierarchy and network processes (AHP/ANP). J. Syst. Sci. Syst. Eng. 2004, 13, 1–35. [Google Scholar] [CrossRef]

- Dos Santos, P.H.; Neves, S.M.; Sant’Anna, D.O.; de Oliveira, C.H.; Carvalho, H.D. The analytic hierarchy process supporting decision making for sustainable development: An overview of applications. J. Clean. Prod. 2019, 212, 119–138. [Google Scholar] [CrossRef]

- Karthik, T.; Rathinamoorthy, R. Sustainable synthetic fibre production. In Sustainable Fibres and Textiles; Elsevier: Amsterdam, The Netherlands, 2017; pp. 191–240. [Google Scholar]

- Boons, F.; Lüdeke-Freund, F. Business models for sustainable innovation: State-of-the-art and steps towards a research agenda. J. Clean. Prod. 2013, 45, 9–19. [Google Scholar] [CrossRef]

| Reference | Research Design | Research Methodology | Contribution Type | Collaboration Level | |

|---|---|---|---|---|---|

| Qualitative | Mixed | ||||

| [13] | case study | x | conceptualization | enterprise | |

| [49] | case study | x | case analysis | network | |

| [17] | case study | x | method proposal | network | |

| [14] | multi case study | x | conceptualization | enterprise | |

| [15] | multi case study | x | conceptualization | supply chain | |

| [16] | multi case study | x | conceptualization | network | |

| [50] | case study | x | conceptualization | network | |

| [54] | experts consulting | x | method proposal | supply chain | |

| Internal Actors | Date | Function | Duration |

|---|---|---|---|

| 1 | 31 October 2017 | Purchasing department (group interview) | 01:34:23 |

| 2 | 31 October 2017 | Indirect purchasing | 00:47:39 |

| 3 | 31 October 2017 | Purchasing—distribution | 00:48:19 |

| 4 | 31 October 2017 | Purchasing—nuclear safety clothing | 00:49:01 |

| 5 | 14 November 2017 | Sustainable development direction | 00:56:25 |

| 6 | 14 November 2017 | R&D engineering | 00:40:10 |

| 7 | 14 November 2017 | Sustainable development direction | 00:47:44 |

| 8 | 14 November 2017 | Prescription—industrial safety | 00:51:39 |

| 9 | 14 November 2017 | Human Resources | 01:38:48 |

| 10 | 14 November 2017 | Prescription | 00:45:52 |

| 11 | 14 November 2017 | Prescription—waste management | 01:41:46 |

| 12 | 27 November 2017 | Social dialogue direction—CSR | 00:39:53 |

| 13 | 4 December 2017 | Human resources—normative expert | 00:30:28 |

| External Actors | |||

| 14 | 5 December 2017 | Clothes manufacturer | 00:44:55 |

| 15 | 5 December 2017 | Logistics provider | 00:40:17 |

| 16 | 5 December 2017 | Washing service provider | 00:45:18 |

| 17 | 5 December 2017 | Logistics, washing and location service provider | 00:46:55 |

| 18 | 5 December 2017 | Waste management—energy recovery | 00:18:30 |

| 19 | 19 December 2017 | Recycling organisation | 01:42:21 |

| 20 | 17 December 2017 | Security service provider | 00:46:00 |

| SI Dimension | Criterion | Sense | Description |

|---|---|---|---|

| Environmental | Environmental quality of the fibre | + | It includes a multiple-criteria evaluation taking into account: the country of production, the feasibility of production, the possibility to recycle the fibre, the emissions to the air due to the transport of raw materials, water consumption, the use of chemical products, energy consumption, and the price per kg of fibre. |

| Environmental performance of providers | + | Provider performance category according to the auditory score (bad, acceptable, good, very good). | |

| Carbon footprint | – | Corresponds to the quantity of equivalent emitted to the air in the activities of transportation (from producer to the customer) and washing. | |

| Chemical use | – | Quantity of chemical used during the washing process, generating water pollution, and possible health damages. | |

| Recycling capability | + | Capability of the system to enable recycling expressed as the percentage of recycled material at the end of life. | |

| Economic | Life cycle costs | – | Expected costs of the entire life cycle, including the cost of waste transformation. |

| Purchasing cost | – | Cost to acquire a product or a service, including indirect costs. | |

| Social | Social performance of providers | + | Provider category assignment according to the auditory (bad, acceptable, good, very good). |

| New job generation | + | Number of new jobs in relation to the new system implementation (entire supply chain/life cycle of the offer). | |

| Employees resistance to change | + | Percentage of employees rejecting the new safety clothing system. | |

| Responsible purchasing | + | Percentage services purchased to socially-engaged organisations in France (Secteur Adapté et Protégé (French)). | |

| Relational | Contribution to the brand image | + | Level of the positive impact on the image of EDF in relation to the adoption of sustainable alternatives. |

| Level of innovation sharing | + | New knowledge (in terms of processes and competencies) acquired through the collaboration: high, medium, low, none. | |

| Functional | Guarantee of the fibre quality | + | Level of mechanic resistance of the fibre monitored through different type of tests (simulation, real-life). |

| Availability of safety clothing | + | Level of service provided during the process of distribution. | |

| Guarantee of lifespan | + | Number of washing according to historical data from service providers at MOL. | |

| Comfort | + | Related to the ergonomics of safety clothes verified during the execution of the corresponding activities: breathability, adapted to weather conditions, adapted to activity, meeting the employees’ needs. | |

| Efficiency level of the tracking | + | Level of service provided during the washing process. Considering the historical data with ancient providers. | |

| Waste upgrading level | + | Capability to dismantle the safety clothing and use it as a resource for a new production cycle, measured as the percentage of recovered material. |

| Users | Date | Function | Time (hh/mm/ss) |

|---|---|---|---|

| 1 | 17 September 2018 | Project management—environment | 00:34:45 |

| 2 | 17 September 2018 | Mechanic team managerment | 00:22:16 |

| 3 | 17 September 2018 | National preventor | 00:26:57 |

| 4 | 17 September 2018 | Operator—renewable energy | 00:20:41 |

| 5 | 17 September 2018 | Operator—renewable energy | 00:31:41 |

| 6 | 17 September 2018 | Operator—Enedis | 00:24:21 |

| 7 | 01 October 2018 | Operator—Electricité de Strasbourg | 00:22:30 |

| 8 | 08 October 2018 | Operator—EDF group | 00:30:00 |

| External Actors | |||

| 9 | 11 December 2018 | Clothes manufacturer A | 00:30:00 |

| 10 | 11 December 2018 | Clothes manufacturer B | 00:30:00 |

| 11 | 11 December 2018 | Clothes manufacturer C | 00:30:00 |

| 12 | 11 December 2018 | Clothes manufacturer D | 00:30:00 |

| 13 | 11 December 2018 | Clothes manufacturer E | 00:30:00 |

| 14 | 11 December 2018 | Clothes manufacturer F | 00:30:00 |

| 15 | 11 December 2018 | Clothes manufacturer G | 00:30:00 |

| 16 | 11 December 2018 | Clothes manufacturer H | 00:30:00 |

| 17 | 11 December 2018 | Logistics service provider | 00:30:00 |

| 18 | 11 December 2018 | Recycling organisation | 00:30:00 |

| Criterion | A1 | A2 | A3 | A4 | A5 | A6 | A7 | A8 | A9 | AIP |

|---|---|---|---|---|---|---|---|---|---|---|

| Environmental | 45% | 15% | 42% | 31% | 40% | 27% | 44% | 34% | 32% | 35% |

| Fibre quality | 75% | 50% | 50% | 75% | 83% | 83% | 25% | 50% | 83% | 64% |

| Providers env. performance | 25% | 50% | 50% | 25% | 17% | 17% | 75% | 50% | 17% | 36% |

| Social | 28% | 21% | 15% | 19% | 21% | 49% | 25% | 22% | 32% | 26% |

| Providers soc. performance | 88% | 75% | 50% | 17% | 83% | 83% | 17% | 88% | 17% | 57% |

| User resistance | 12% | 25% | 50% | 83% | 17% | 17% | 83% | 12% | 83% | 43% |

| Functional | 4% | 34% | 27% | 33% | 11% | 10% | 4% | 15% | 7% | 16% |

| Fibre quality | 83% | 50% | 83% | 88% | 75% | 25% | 88% | 75% | 13% | 64% |

| Availability | 17% | 50% | 17% | 12% | 25% | 75% | 12% | 25% | 87% | 36% |

| Relational | 14% | 25% | 8% | 5% | 18% | 6% | 19% | 22% | 12% | 14% |

| Brand image | 50% | 83% | 50% | 88% | 50% | 50% | 88% | 83% | 50% | 66% |

| Innovation | 50% | 17% | 50% | 12% | 50% | 50% | 12% | 17% | 50% | 34% |

| Economic | 10% | 5% | 8% | 12% | 9% | 9% | 8% | 7% | 17% | 9% |

| Life cycle costs | 83% | 88% | 50% | 88% | 50% | 88% | 88% | 88% | 75% | 77% |

| Purchasing cost | 17% | 12% | 50% | 12% | 50% | 12% | 12% | 12% | 25% | 23% |

| Alternative | A1 | A2 | A3 | A4 | A5 | A6 | A7 | A8 | A9 | AIP |

|---|---|---|---|---|---|---|---|---|---|---|

| Tencel | 56% | 48% | 35% | 35% | 45% | 43% | 55% | 36% | 43% | 44% |

| Poly-cotton | 21% | 36% | 38% | 37% | 27% | 29% | 14% | 20% | 25% | 28% |

| Organic cotton | 23% | 16% | 27% | 28% | 28% | 28% | 31% | 44% | 32% | 28% |

| Criterion | A1 | A2 | A3 | A4 | A5 | A6 | A7 | A8 | A9 | A10 | A11 | A12 | AIP |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Environmental | 49% | 21% | 41% | 16% | 25% | 49% | 53% | 19% | 38% | 30% | 22% | 6% | 31% |

| Carbon footprint | 50% | 50% | 50% | 83% | 17% | 83% | 88% | 13% | 90% | 50% | 83% | 50% | 59% |

| Chemicals use | 50% | 50% | 50% | 17% | 83% | 17% | 12% | 87% | 10% | 50% | 17% | 50% | 41% |

| Social | 24% | 31% | 32% | 12% | 24% | 28% | 18% | 25% | 10% | 27% | 49% | 55% | 28% |

| Local jobs | 45% | 24% | 14% | 43% | 49% | 45% | 28% | 24% | 11% | 45% | 35% | 33% | 33% |

| User resistance | 9% | 28% | 49% | 14% | 37% | 9% | 6% | 21% | 11% | 9% | 9% | 33% | 20% |

| Responsible purchasing | 45% | 48% | 37% | 43% | 14% | 45% | 66% | 55% | 78% | 45% | 6% | 33% | 43% |

| Functional | 4% | 23% | 9% | 42% | 17% | 5% | 4% | 19% | 28% | 27% | 9% | 6% | 16% |

| Lifespan | 26% | 14% | 45% | 13% | 33% | 66% | 21% | 49% | 20% | 44% | 7% | 33% | 31% |

| Comfort | 63% | 33% | 45% | 75% | 33% | 19% | 55% | 37% | 60% | 39% | 64% | 33% | 46% |

| Traceability | 11% | 53% | 10% | 12% | 34% | 15% | 24% | 14% | 20% | 17% | 29% | 34% | 23% |

| Economic | 12% | 5% | 10% | 26% | 11% | 12% | 10% | 16% | 13% | 8% | 14% | 25% | 14% |

| Relational | 12% | 21% | 8% | 4% | 23% | 5% | 14% | 19% | 12% | 9% | 5% | 6% | 12% |

| Brand image | 25% | 50% | 88% | 83% | 50% | 13% | 88% | 17% | 13% | 75% | 75% | 50% | 52% |

| Innovation | 75% | 50% | 13% | 17% | 50% | 88% | 13% | 83% | 88% | 25% | 25% | 50% | 48% |

| Alternative | A1 | A2 | A3 | A4 | A5 | A6 | A7 | A8 | A9 | A10 | A11 | A12 | AIP |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Local washing | 67% | 79% | 58% | 80% | 59% | 54% | 74% | 73% | 88% | 54% | 73% | 47% | 68% |

| Centralised washing | 33% | 21% | 42% | 20% | 41% | 46% | 26% | 27% | 12% | 37% | 23% | 53% | 32% |

| Criterion | A1 | A2 | A3 | A4 | A5 | A6 | A7 | A8 | AIP |

|---|---|---|---|---|---|---|---|---|---|

| Environmental | 46% | 53% | 21% | 41% | 20% | 49% | 17% | 16% | 33% |

| Carbon footprint | 17% | 17% | 17% | 17% | 17% | 17% | 17% | 17% | 17% |

| Recycling | 83% | 83% | 83% | 83% | 83% | 83% | 83% | 83% | 83% |

| Social | 20% | 13% | 12% | 38% | 20% | 7% | 54% | 40% | 26% |

| Local job | 63% | 66% | 41% | 72% | 7% | 45% | 18% | 41% | 44% |

| User resistance | 11% | 16% | 11% | 8% | 7% | 9% | 70% | 11% | 18% |

| Responsible purchasing | 26% | 19% | 48% | 19% | 7% | 45% | 11% | 48% | 28% |

| Economic | 10% | 5% | 21% | 8% | 20% | 20% | 19% | 22% | 16% |

| Functional | 4% | 15% | 41% | 6% | 20% | 18% | 5% | 12% | 15% |

| Relational | 20% | 13% | 5% | 6% | 20% | 7% | 5% | 10% | 11% |

| Brand image | 25% | 50% | 83% | 17% | 50% | 50% | 83% | 50% | 51% |

| Innovation | 75% | 50% | 17% | 83% | 50% | 50% | 17% | 50% | 49% |

| Alternative | A1 | A2 | A3 | A4 | A5 | A6 | A7 | A8 | AIP |

|---|---|---|---|---|---|---|---|---|---|

| Other product | 65% | 37% | 60% | 27% | 39% | 39% | 39% | 37% | 43% |

| New clothing | 18% | 49% | 12% | 61% | 51% | 29% | 39% | 46% | 38% |

| Energy recovery | 17% | 14% | 28% | 12% | 10% | 32% | 22% | 17% | 19% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Orellano, M.; Lambey-Checchin, C.; Medini, K.; Neubert, G. A Methodological Framework to Support the Sustainable Innovation Development Process: A Collaborative Approach. Sustainability 2021, 13, 9054. https://doi.org/10.3390/su13169054

Orellano M, Lambey-Checchin C, Medini K, Neubert G. A Methodological Framework to Support the Sustainable Innovation Development Process: A Collaborative Approach. Sustainability. 2021; 13(16):9054. https://doi.org/10.3390/su13169054

Chicago/Turabian StyleOrellano, Martha, Christine Lambey-Checchin, Khaled Medini, and Gilles Neubert. 2021. "A Methodological Framework to Support the Sustainable Innovation Development Process: A Collaborative Approach" Sustainability 13, no. 16: 9054. https://doi.org/10.3390/su13169054

APA StyleOrellano, M., Lambey-Checchin, C., Medini, K., & Neubert, G. (2021). A Methodological Framework to Support the Sustainable Innovation Development Process: A Collaborative Approach. Sustainability, 13(16), 9054. https://doi.org/10.3390/su13169054