Addressing Nutrient Depletion in Tanzanian Sisal Fiber Production Using Life Cycle Assessment and Circular Economy Principles, with Bioenergy Co-Production

Abstract

1. Introduction

2. Materials and Methods

2.1. Circular Economy in Tanzania—Identifying Potential Cosubstrates and Nutrient Balances

2.2. LCA of Sisal Production, including Mass Balances to Assess Nutrient Depletion

3. Results and Discussion

3.1. Circular Economy in Tanzania—Potential Cosubstrates and Nutrient Balances

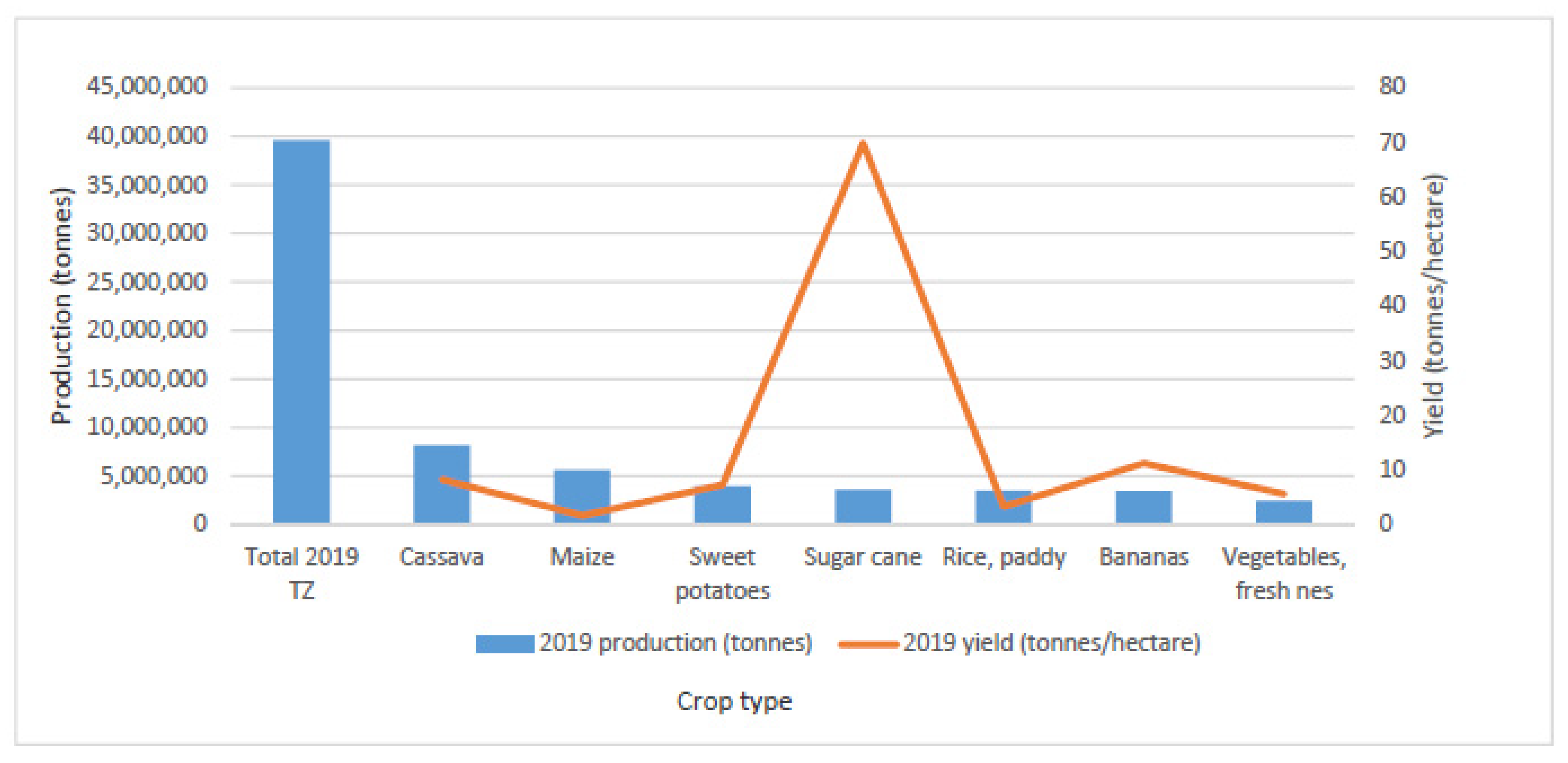

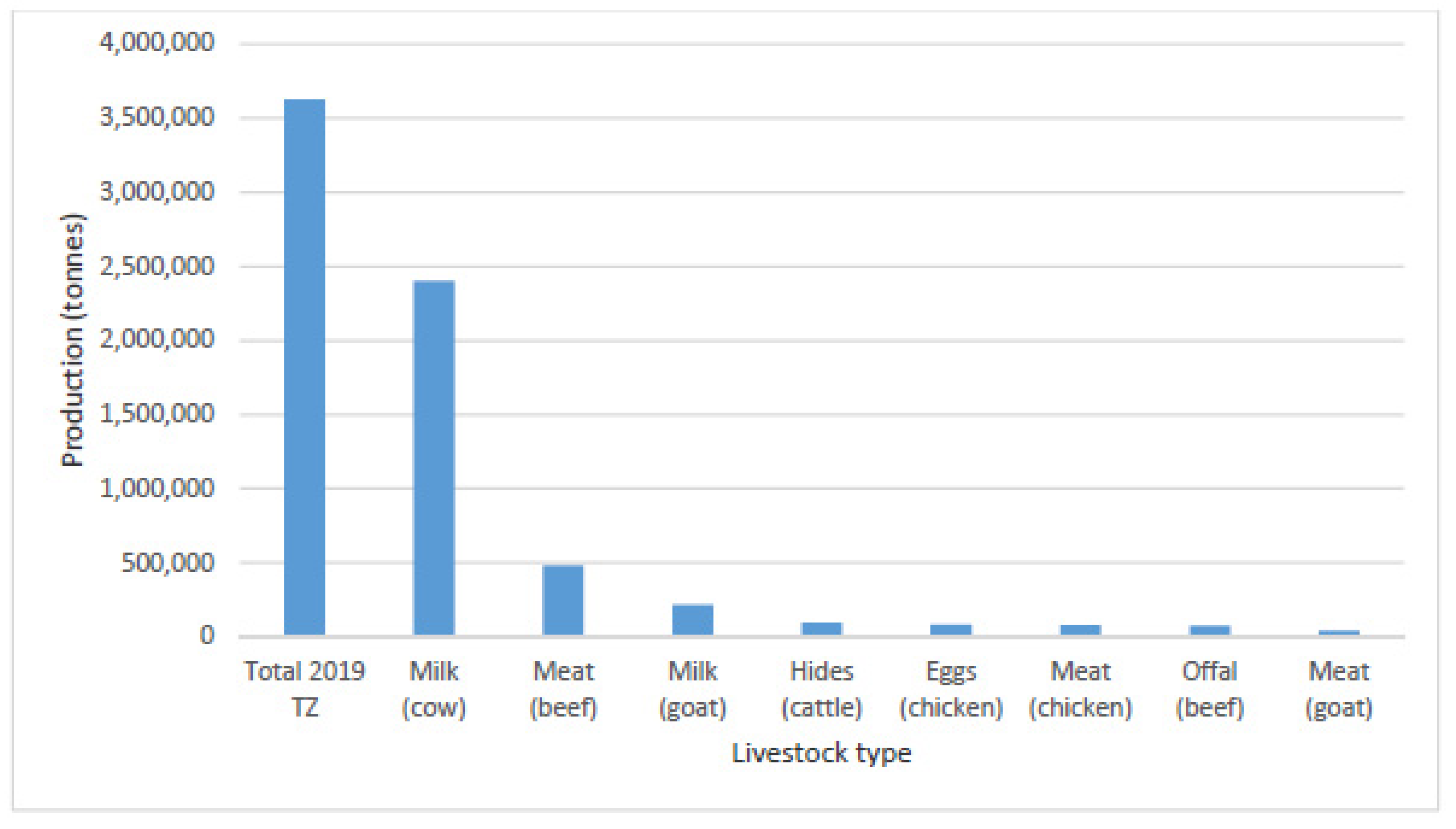

3.1.1. Potential Nutrient Sources from within the Tanzanian Economy

3.1.2. Nutrient Balances of Cosubstrates

3.2. LCA Results

3.2.1. Nutrient Balances of Current Operation

3.2.2. Nutrient Balances of Current Operation with Cosubstrates Added

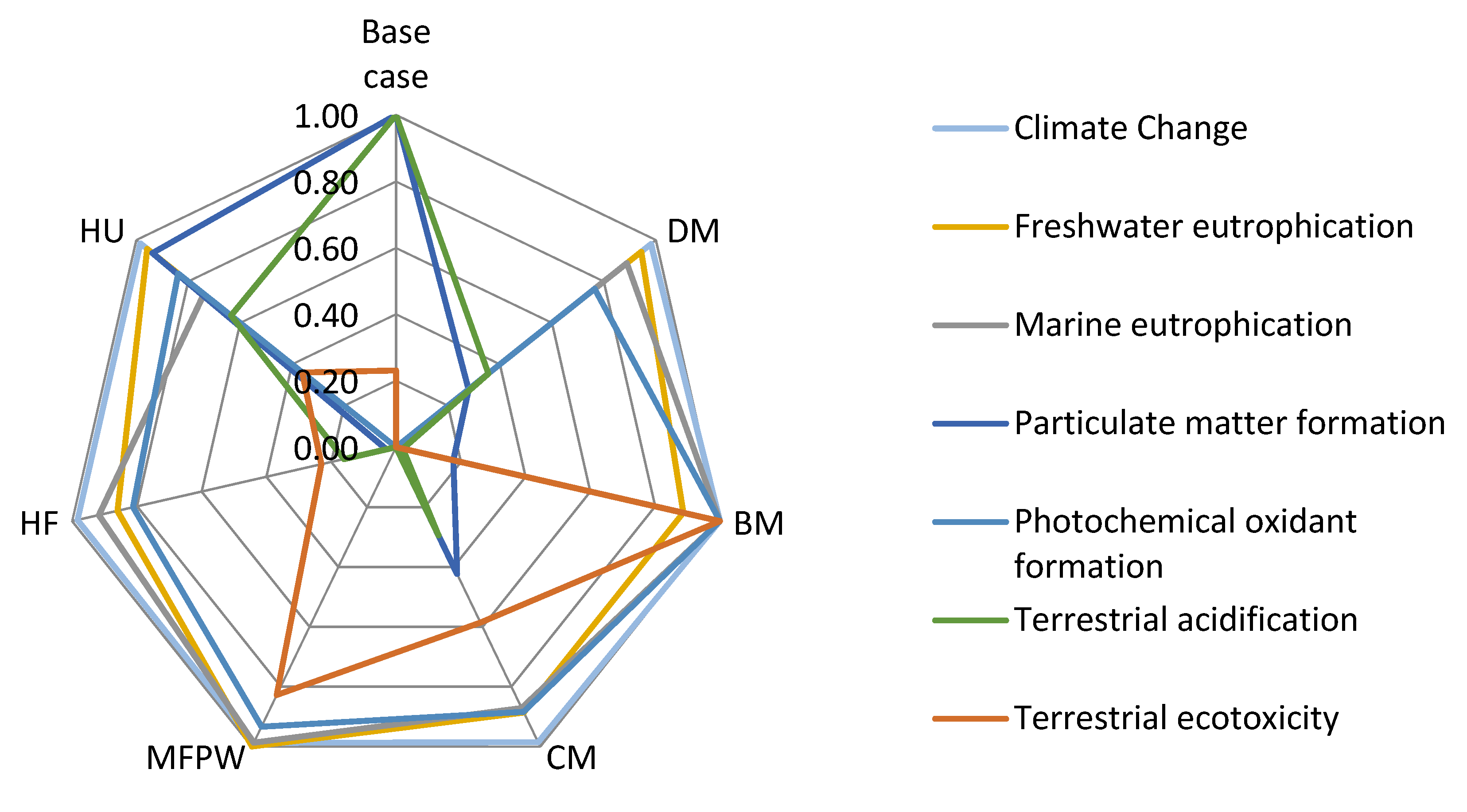

3.2.3. LCA Results of Current Base Case

3.2.4. Results for the IAS Biodigester/Generator Scenarios

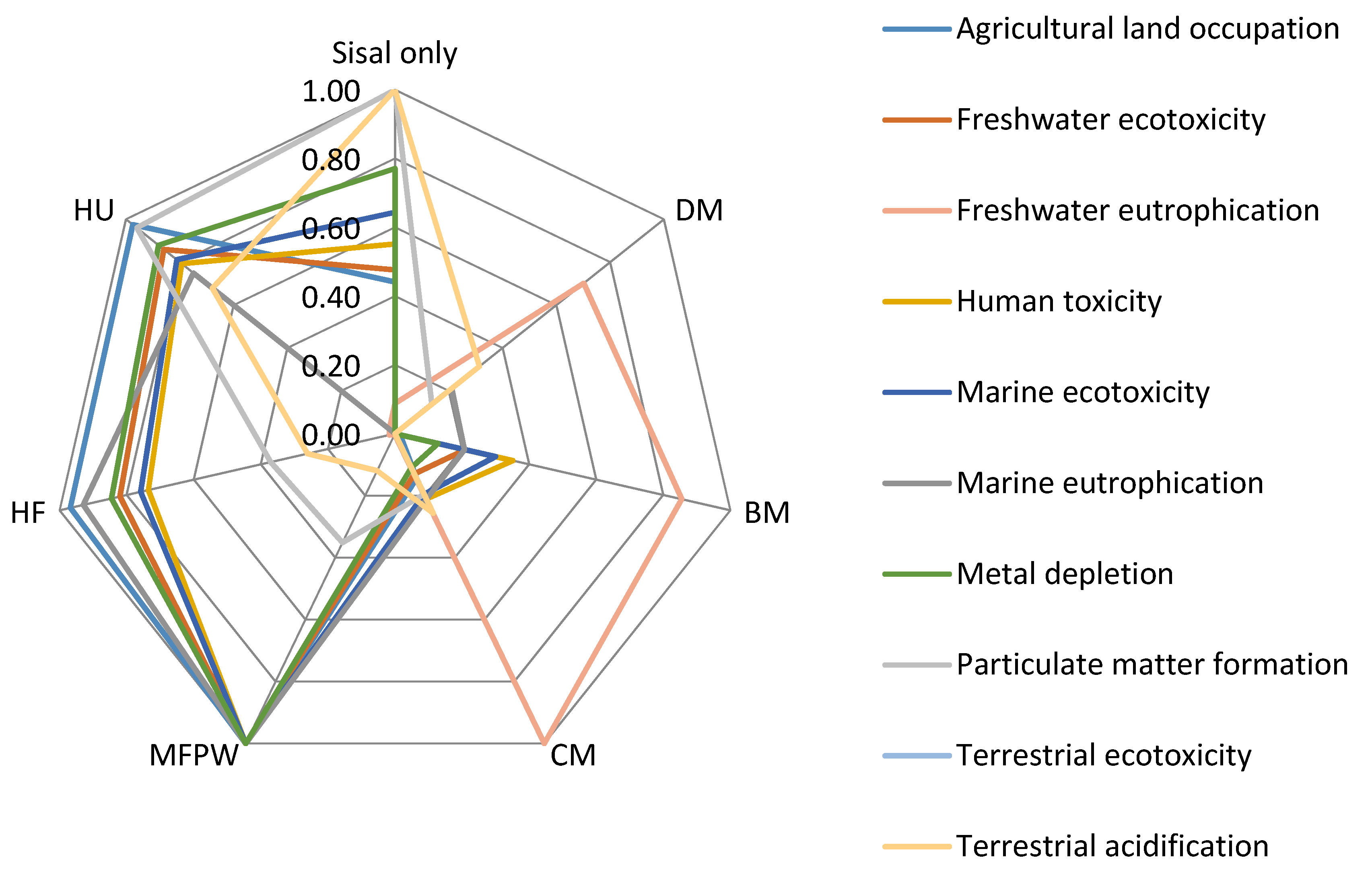

3.2.5. Results for the IAS with Current Beneficial Reuse of Agricultural Cosubstrate and No Current Beneficial Reuse for Non-agricultural Waste Cosubstrate

3.2.6. Significant Processes Contributing to MIC for the IAS

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A. Background Information on Sisal

Appendix A.1. Sisal Production Methods in Tanzania

Appendix A.2. Historical Sisal Fiber Use

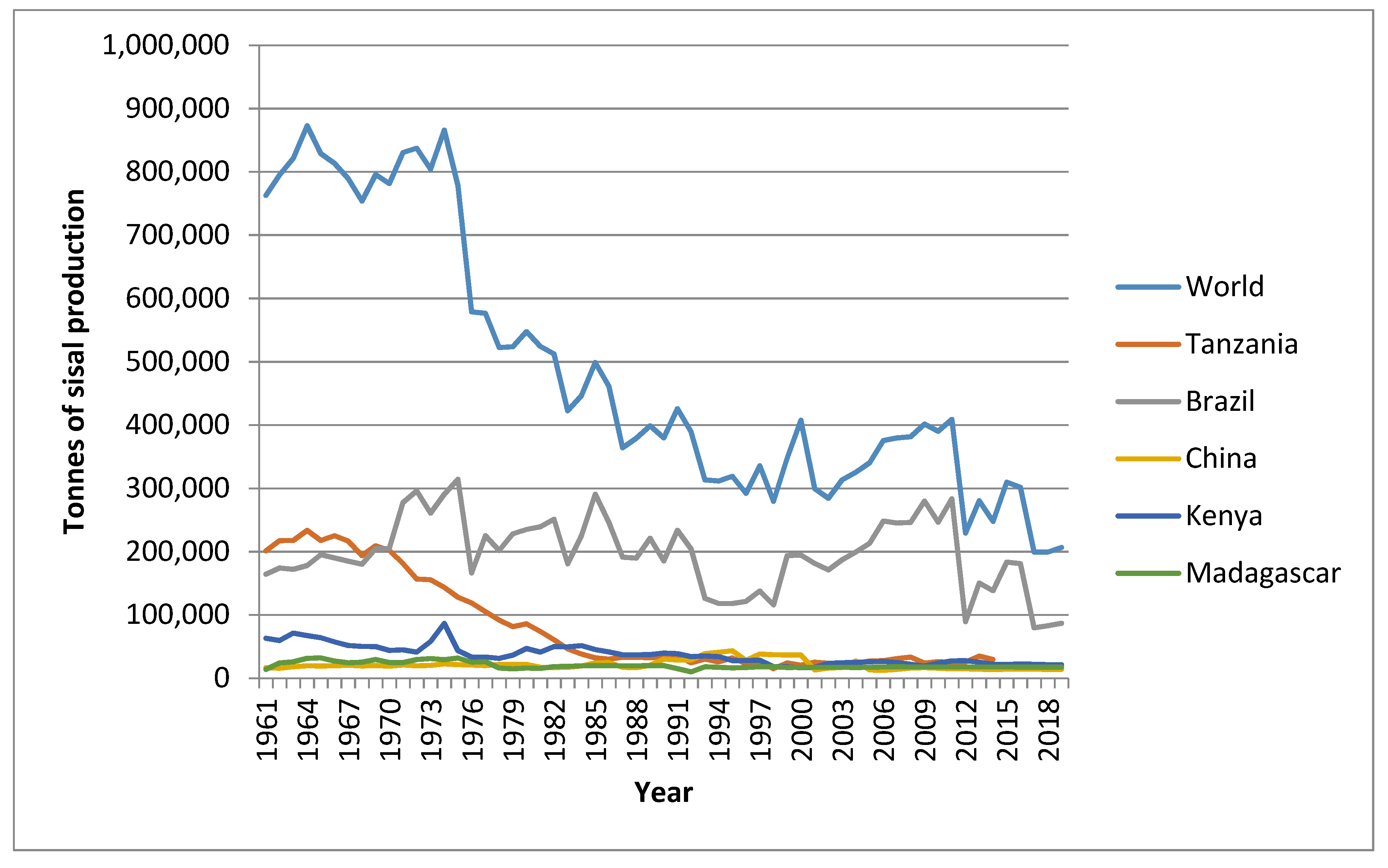

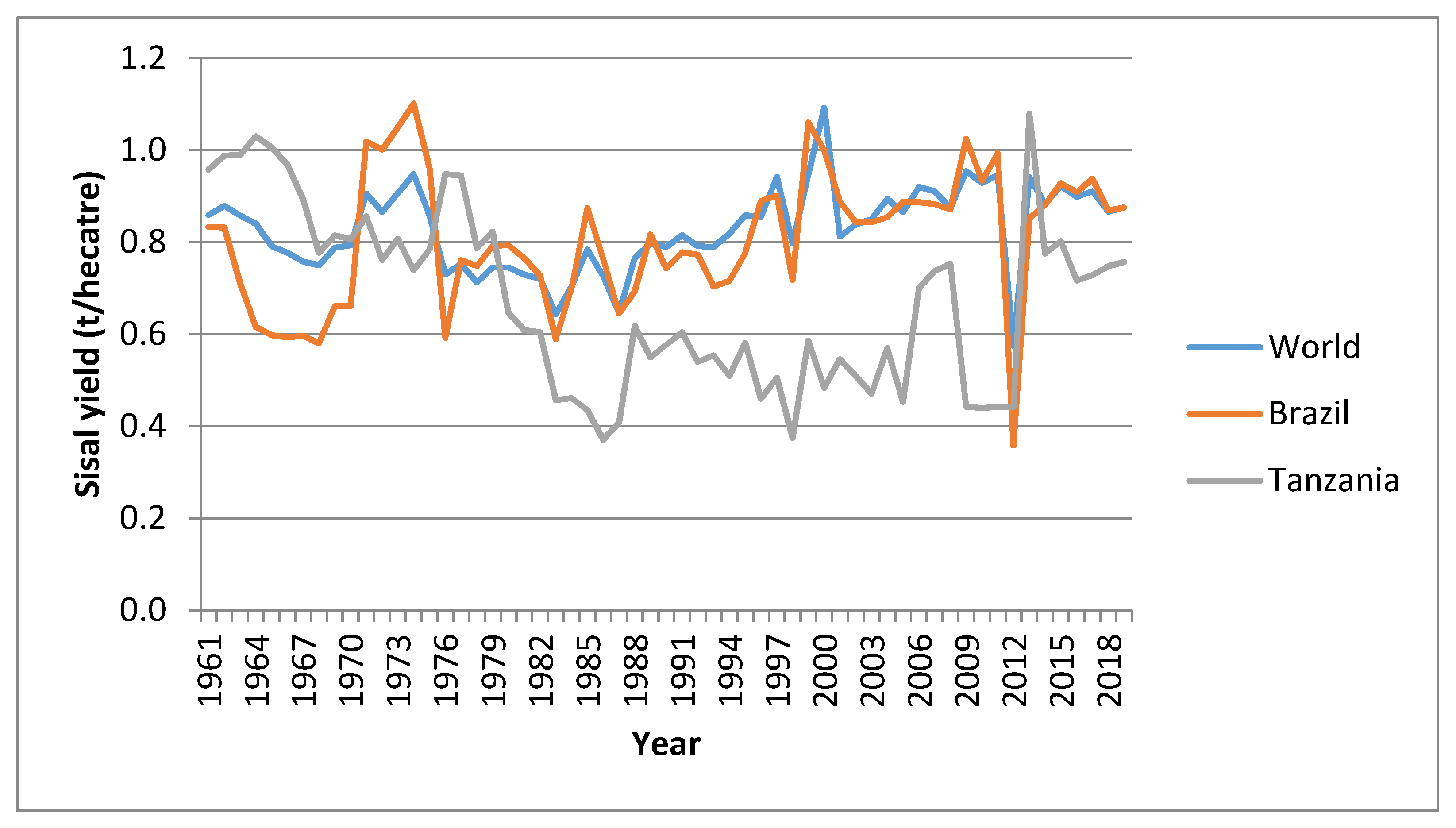

Appendix A.3. Historical Global Sisal Production Rates and Yield from FAO Data

Appendix A.4. Sisal Composition

| Nutrient | Nursery Leaves a | Plantation Leaves b | ||

|---|---|---|---|---|

| Weight % | Ratio vs. N | Weight % | Ratio vs. N | |

| Calcium | 0.44 | 2.7 | 0.32 | 3.5 |

| Magnesium | 0.06 | 0.4 | 0.09 | 1.3 |

| Nitrogen | 0.16 | 1 | 0.12 | 1 |

| Phosphorus | 0.05 | 0.3 | 0.01 | 0.15 |

| Potassium | 0.18 | 1.1 | 0.14 | 1.5 |

| Nutrient | Agave Sisalana | Hybrid 11648 | ||

|---|---|---|---|---|

| kg Removed/ha.t Fiber | Relative to N | kg Removed/ha.t Fiber | Relative to N | |

| Calcium | 70 | 2.6 | 82 | 3.2 |

| Magnesium | 34 | 1.3 | 31 | 1.2 |

| Nitrogen | 27 | 1.00 | 26 | 1.0 |

| Phosphorus | 7 | 0.26 | 3.5 | 0.13 |

| Potassium | 69 | 2.6 | 44 | 1.7 |

Appendix B

| Process | Flow | BPS | IAS | Ecoinvent Process Used/Reference | |

|---|---|---|---|---|---|

| |||||

| Growing time (years) | 1.5 | ||||

| Bulbil planting density (#/ha) | 100,000 | 80,000 | |||

| Weight of bulbil (kg) | 0.06 | Estimated from seedling size (9 cm vs. 35 cm) | |||

| Bulbil loss rate | 10% | [1] | |||

| Glyphosate use (kg/ha) | 2–3 | 0 | |||

| Glyphosate in roundup (g/L) | 360 | n/a | glyphosate | market for glyphosate | ||

| # Applications of roundup (#/growing cycle) | 1 | 0 | application of plant protection product, by field sprayer | application of plant protection product, by field sprayer | ||

| Fraction of glyphosate to soil | 75% | [72] | |||

| Fraction of glyphosate to air | 25% | [72] | |||

| Ploughing: wheel tractor—diesel L/ha | 10 | 8–10 | modified Ecoinvent process—tillage, harrowing, by rotary harrow|tillage, harrowing, by rotary harrow|APOS, U (TZ 1) | ||

| Leveling: wheel tractor, harrow—diesel L/ha | 10 | 8–10 | modified Ecoinvent process—tillage, ploughing|tillage, ploughing [APOS, U (TZ1)—RoW] | ||

| Occupation, arable, non-irrigated | Reusing existing land, not clearing new land | ||||

| Agricultural lime use (kg/ha) | 100 | 0 | limestone, crushed, washed|market for limestone, crushed, washed | ||

| Calcium mass % in agricultural limestone | 40% | n/a | |||

| # Applications of agricultural lime (#/growing cycle) | 1 | 0 | done at same time as Muriate of potash | ||

| Muriate of potash use (kg/ha) | 5–9 | 0 | potassium chloride, as K2O|market for potassium chloride, as K2O | ||

| # Applications of muriate of potash (#/growing cycle) | 1 | 0 | fertilizing, by broadcaster|fertilizing, by broadcaster | ||

| Potassium mass % in muriate of potash | 50% | ||||

| Potassium mass % in K2O | 83% | ||||

| Distance—Dar es Salem port to nursery for inputs (km) | 300 | 356 | |||

| Transport inputs—road—(glyphosate, lime, potash) (tkm) | 32.85 | 0 | transport, freight, lorry 16–32 metric ton, EURO3|market for transport, freight, lorry 16–32 metric ton, EURO3 | ||

| Output | Weight of seedling ready for planting (kg) | 0.25 | |||

| Seedlings produced per hectare | 90,000 | 72,000 | |||

| |||||

| Land preparation | |||||

| Brush cutting (L diesel used/hectare)—clearing | 44 | 25 | Modified Ecoinvent process—mowing, by rotary mower|mowing, by rotary mower (TZ 2 clear) | ||

| Burning of biomass material (25 t biomass/hectare, 10.4 GJ/t, green and air dried wood)—N2O emissions 0.004 kg N2O released/GJ biomass burnt, methane emission 0.028 kg methane released/GJ biomass burnt | Data from Table 2.2.2, p80, carbon dioxide not counted [73] | ||||

| Ploughing of burnt biomass material into soil, caterpillar with plough—diesel use (L) per hectare | 36 | 0 | Modified Ecoinvent process: tillage, ploughing|tillage, ploughing|APOS, U (TZ 2)—RoW | ||

| Leveling: Caterpillar with harrowing | 33 | 0 | Modified Ecoinvent process: tillage, harrowing, by rotary harrow|tillage, harrowing, by rotary harrow|APOS, U (TZ 2) | ||

| Leveling: Wheel tractor | 0 | 18 | Modified Ecoinvent process: tillage, harrowing, by rotary harrow|tillage, harrowing, by rotary harrow|APOS, U (TZ 2) | ||

| Distance, nursery to plantation (km) | 7 | 5 | transport, tractor and trailer, agricultural | market for transport, tractor and trailer, agricultural | ||

| Distance, plantation to fiber processing (km) | 10 | 7 | transport, freight, lorry, all sizes, EURO3 to generic market for transport, freight, lorry, unspecified|transport, freight, lorry, unspecified | APOS, S—RoW | ||

| Seedling planting density (#/ha) | 5000 | 4000 | |||

| Growing cycle (years) | 10–12 | 10–12 | |||

| Year of first harvest | 3–4 | 3 | |||

| Years of harvesting per growing cycle | 8–10 | 8–10 | |||

| Agricultural lime use (kg/ha) | 5000 | 0 | limestone, crushed, washed|market for limestone, crushed, washed | ||

| Calcium mass % in agricultural limestone | 40% | ||||

| # Applications of agricultural lime (#/growing cycle) | 1 | 0 | |||

| Triple Superphosphate (TSP) use (kg/ha) | 100–125 | 0 | phosphate fertilizer, as P2O5|triple superphosphate production | ||

| Phosphorus mass % in TSP | 20% | ||||

| Calcium mass % in TSP | 15.5% | ||||

| # Applications of TSP (#/growing cycle) | 2 | 0 | fertilizing, by broadcaster|fertilizing, by broadcaster | ||

| Composted sisal residue use (kg/ha) | 300 | 0 | |||

| # Applications of composted sisal residues (#/growing cycle) | 2 | 0 | |||

| Weeding—times, years 0–3 | 6 | 6 | Modified Ecoinvent process—tillage, harrowing, by spring tine harrow|tillage, harrowing, by spring tine harrow|APOS, U (TZ 2)—RoW | ||

| Weeding—times, years 4–6 | 4 | 6 | Modified Ecoinvent process—mowing, by rotary mower | mowing, by rotary mower (TZ 2 mow) | ||

| Carbon dioxide uptake by plant material | Calculation based on 42% C in fiber [74] | ||||

| Mass of sisal ball at end of growing cycle (kg) | 20 | 20 | Included in biomass material burnt as part of field prep | ||

| Distance—to Dar es Salaam from South Africa for TSP (km) | 3100 | n/a | |||

| Distance—Port to plantation (km) | 70 | 356 | Note—different port to fiber export for BPS | ||

| Occupation, arable, non-irrigated (ha.a) | 1× growing cycle | Reusing existing land, not clearing new land | |||

| |||||

| Yield, total fiber per hectare for year (t/year) | 1.6 | 0.6 | A—[4] | ||

| Total fiber fraction in sisal leaves | 4% | 2.5% | B—assumed value | ||

| Export fiber percent of total fiber | 92% | 59% | C—[4] | ||

| Net export fiber yield (t/ha.year) | 1.5 | 0.35 | D = A x C | ||

| Off-spec fiber yield (t/ha.year)—included as a negative input | 0.1 | 0.25 | A–D—entered as jute fiber|market for jute fiber | ||

| Sisal leaf production (t/ha.year) | 40 | 24 | E = A/B | ||

| Sisal leaf production (t/ha.growing cycle) | 340 | 204 | F = E x years of harvesting | ||

| Export fiber yield (t/ha.growing cycle) | 12.5 | 3.0 | G = D x years of harvesting | ||

| Water usage, L/ton dry fiber | 112,000 | 100,000 | |||

| Electricity use (kWh/t fiber) (refer to Appendix D for details on BPS) | 615 | 343 | BPS based on metered data, includes biogas plant, in theory should only be 30% higher than ordinary plant. IAS based on diesel genset (200L diesel to process 2.5 t fiber, assume 40% electrical efficiency) | ||

| Note that estates will measure the tonnes of final product and estimate the weight of sisal leaves, so this is an area of potential data improvement | |||||

| Water content of total fiber entering drying process | 60% | ||||

| Water content of total fiber leaving drying process | 10–15% | ||||

| Ratio of sisal fiber residue to sisal export fiber | 19 | 19 | |||

| Distance to port for sisal export grade fiber (km) | 300 | 356 | |||

| |||||

| Depth of ponds | 1.5–3 m | ||||

| Engine electrical efficiency, biogas use | 35% | - | |||

| PLACE | # | kW | h/Day | kWh/Day (Calculated) | Subtotal | % of A or B | % of Total | ||

|---|---|---|---|---|---|---|---|---|---|

| A+B | BPS + biogas plant | Total | 2896.0 | ||||||

| A | BPS | Subtotal | 2047.2 | 71% | |||||

| A.1 | CORONA | Corona motor | 1 | 90 | 10 | 900 | |||

| Rope system motor | 1 | 7.5 | 10 | 75 | |||||

| Feed table motor | 1 | 3.75 | 10 | 37.5 | |||||

| Lamps | 5 | 0.085 | 12 | 5.1 | |||||

| 1018 | 50% | 35% | |||||||

| A.2 | BRUSHING ROOM | Brushing machine motor | 3 | 7.5 | 12 | 270 | |||

| Brushing machine motor | 2 | 8 | 12 | 198 | |||||

| Lamp | 7 | 0.085 | 12 | 7.14 | |||||

| 475 | 23% | 16% | |||||||

| A.3 | BALING | Press pump motor | 1 | 12 | 8 | 96 | |||

| Lamp | 4 | 0.085 | 8 | 2.72 | |||||

| 99 | 5% | 3% | |||||||

| A.4 | WORKSHOP | Motors | 2 | 7.5 | 12 | 180 | |||

| Motor | 1 | 5 | 12 | 60 | |||||

| Lamp | 2 | 0.085 | 2 | 0.34 | |||||

| 240 | 12% | 8% | |||||||

| A.5 | PUMP STATION | Pump motor | 1 | 15.5 | 12 | 186 | |||

| Lamp | 3 | 0.085 | 12 | 3.1 | |||||

| 189 | 9% | 7% | |||||||

| A.6 | OFFICE | Lamp | 18 | 0.085 | 2 | 3.1 | |||

| A.7 | SECURITY LAMP | 4 | 0.085 | 12 | 4.1 | ||||

| A.8 | Workers Houses | Room Lamps | 120 | 0.02 | 4 | 9.6 | |||

| Security Lamp | 40 | 0.02 | 12 | 9.6 | |||||

| B | BIOGAS PLANT | Subtotal | 849 | 29% | |||||

| B.1 | CONVEYORS | Conveyor Motor | 3 | 1.5 | 10 | 45 | |||

| Conveyor Motor | 1 | 5.5 | 10 | 55 | |||||

| Lamp | 2 | 0.085 | 12 | 2.0 | |||||

| B.2 | SQUEEZER | Squeezer motor | 1 | 18.5 | 10 | 185 | |||

| B.3 | CAGE | Cage motor | 1 | 7.5 | 10 | 75 | |||

| B.4 | COLLECTION TANK | Collection tank stirrer motor | 1 | 5.5 | 10 | 55 | |||

| Feed Pump | 1 | 5 | 10 | 50 | |||||

| B.5 | HYDROLYSIS | Stirrer motor | 1 | 4 | 6 | 24 | |||

| Feed Pump | 1 | 15 | 6 | 90 | |||||

| B.6 | DIGESTER | Stirrer motor | 1 | 15 | 6 | 90 | |||

| B.7 | FERTILIZER TANK | Stirrer motor | 1 | 15 | 6 | 90 | |||

| B.8 | H2S CLEANER | Water pump | 1 | 1.5 | 1 | 1.5 | |||

| B.9 | CHP | Water circulation pump | 2 | 3 | 10 | 60 | |||

| B.10 | COOLING TOWER | Blower motor | 1 | 1.5 | 10 | 15 | |||

| B.11 | MeS Office | Lamp | 12 | 0.038 | 2 | 0.9 | |||

| B.12 | MeS Security lamp | Lamp | 11 | 0.038 | 12 | 5.0 | |||

| Computers | Computers | 2 | 0.02 | 6 | 0.2 | ||||

| Refrigerator | Refrigerator | 1 | 0.3 | 12 | 3.6 | ||||

| Oven | Oven | 1 | 0.3 | 5 | 1.5 | ||||

| Assumptions | Unit | BPS | IAS |

|---|---|---|---|

| Harvest years per growing cycle | years | 8.5 | 8.5 |

| Total fiber fraction of the leaves | % | 4 | 2.5 |

| Total fiber yield (export + off-spec) | t/ha/year | 1.6 | 0.6 |

| Export fiber yield | % total fiber yield | 92 | 59 |

| Calculated values | |||

| Total weight leaves grown | t/ha/year | 40 | 24 |

| t/ha/growing cycle | 340 | 204 | |

| Total export fiber | t/ha/growing cycle | 12.5 | 3.0 |

| Total off-spec fiber | t/ha/growing cycle | 1.1 | 2.1 |

| Unit | Sisal Pulp a | Sisal Wastewater b | Combined Sisal Waste | |

|---|---|---|---|---|

| Mass per t sisal fiber | kg | 15,490 | 121,472 | 136,962 |

| % of total mass | 11% | 89% | ||

| Total solids (TS) | % of M | 9% | 1.6% | 2.4% |

| Mass of TS | kg | 1394 | 1944 | 3338 |

| Volatile solids (VS) | % of TS | 87.5% | 47.7% | 64% |

| Mass of VS | kg | 1220 | 927 | 2147 |

| Organic carbon (OC) | % | 49% | 39.3% | 40% |

| Mass of OC | kg | 683 | 364 | 1047 |

| Total nitrogen (TN) | % of TS | 1.08% | 2.60% | 1.97% |

| Mass of TN | kg | 15.1 | 50.5 | 65.6 |

| N partitioning c | % | 23% | 77% | |

| Mass of TN | kg | From mass balance of sisal leaves | 24.5 | |

| C:N ratio | 59 | |||

| Goal |

|

| Scope |

|

Appendix C. Circular Economy in Tanzania—Identification of Potential Cosubstrates

Appendix D. Life Cycle Impact Assessment Results (Note—Red Indicates Highest Value (Worst), Green Lowest (Best), Blue is the Second Lowest (Second Best)

| BPS | Cosubstrate with No Current Beneficial Reuse | Sink | Source | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Impact Category (17) | Reference Unit | Current | DM | DM | CM | MFPW | HF | HU | ||

| Agricultural land occupation | m2*a | −6.0 | −45 | −50 | −46 | −46 | −45 | −45 | 7 | 0 |

| Climate change | kg CO2-eq | 29,945 | −3198 | −3533 | −3277 | −3309 | −3229 | −3246 | 6 | 1 |

| Fossil depletion | kg oil eq | −1473 | −1105 | −1227 | −1136 | −1149 | −1118 | −1124 | 7 | 0 |

| Freshwater ecotoxicity | kg 1,4-DB eq | −1.2 | −6.8 | −9.9 | −8.4 | −9.1 | −7.5 | −7.8 | 7 | 0 |

| Freshwater eutrophication | kg P eq | 3.2 | 3.7 | 3.8 | 3.6 | 3.6 | 3.6 | 3.6 | 0 | 7 |

| Human toxicity | kg 1,4-DB eq | −31 | −133 | −255 | −201 | −229 | −160 | −175 | 7 | 0 |

| Ionizing radiation | kg U235 eq | −14 | −86 | −114 | −99 | −105 | −91 | −94 | 7 | 0 |

| Marine ecotoxicity | kg 1,4-DB eq | −0.92 | −3.6 | −7.6 | −5.9 | −6.8 | −4.5 | −5.0 | 7 | 0 |

| Marine eutrophication | kg N eq | 15 | −43 | −50 | −42 | −49 | −45 | −33 | 6 | 1 |

| Metal depletion | kg Fe eq | −2.9 | −11 | −24 | −19 | −21 | −14 | −16 | 7 | 0 |

| Natural land transformation | m2 | −0.12 | −0.85 | −0.99 | −0.90 | −0.92 | −0.87 | −0.89 | 7 | 0 |

| Ozone depletion | kg CFC-11 eq | −0.00004 | −0.0003 | −0.00036 | −0.00033 | −0.00034 | −0.00031 | −0.00032 | 7 | 0 |

| Particulate matter formation | kg PM10 eq | 2.0 | 2.7 | 3.3 | 2.9 | 3.6 | 3.5 | 2.2 | 0 | 7 |

| Photochemical oxidant formation | kg NMVOC | 11 | −6.7 | −9.5 | −8.1 | −8.7 | −7.2 | −7.6 | 6 | 1 |

| Terrestrial acidification | kg SO2 eq | 18 | 34 | 44 | 39 | 45 | 42 | 32 | 0 | 7 |

| Terrestrial ecotoxicity | kg 1,4-DB eq | −0.04 | −0.08 | −0.29 | −0.21 | −0.26 | −0.13 | −0.16 | 7 | 0 |

| Water depletion | m3 | −1763 | −14,581 | −14,708 | −14,097 | −13,900 | −14,390 | −14,284 | 7 | 0 |

| Worst | 14 | 0 | 1 | 0 | 2 | 0 | 0 | |||

| Best | 3 | 0 | 14 | 0 | 0 | 0 | 0 | |||

| Sink | 11 | 14 | 14 | 14 | 14 | 14 | 14 | 95 | ||

| Source | 6 | 3 | 3 | 3 | 3 | 3 | 3 | 24 | ||

| BPS | Cosubstrate with Current Beneficial Reuse | Sink | Source | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Impact Category (17) | Reference Unit | Current | DM | BM | CM | MFPW | HF | HU | ||

| Agricultural land occupation | m2*a | −6.0 | −2.2 | −3.1 | −8.9 | −16 | 1.3 | −22 | 6 | 1 |

| Climate Change | kg CO2-eq | 29,945 | −2656 | −2903 | −2738 | −2739 | −2616 | −2858 | 6 | 1 |

| Fossil depletion | kg oil eq | −147 | −1023 | −1131 | −1051 | −1069 | −1015 | −1070 | 7 | 0 |

| Freshwater ecotoxicity | kg 1,4-DB eq | −1.2 | −0.03 | −2.0 | −1.3 | −2.6 | 1.2 | −3.3 | 6 | 1 |

| Freshwater eutrophication | kg P eq | 3.2 | 14 | 16 | 18 | 8.4 | 26 | 6.9 | 0 | 7 |

| Human toxicity | kg 1,4-DB eq | −31 | 33 | −60 | −23 | −73 | 59 | −67 | 5 | 2 |

| Ionizing radiation | kg U235 eq | −14 | −61 | −84 | −72 | −82 | −57 | −79 | 7 | 0 |

| Marine ecotoxicity | kg 1,4-DB eq | −0.92 | 3.0 | −0.02 | 0.98 | −0.54 | 3.8 | −0.67 | 4 | 3 |

| Marine eutrophication | kg N eq | 15 | 1.8 | 2.2 | 1.9 | 2.1 | 2.1 | 1.6 | 0 | 7 |

| Metal depletion | kg Fe eq | −2.9 | 26 | 20 | 21 | 16 | 33 | 9.8 | 1 | 6 |

| Natural land transformation | m2 | −0.12 | −0.77 | −0.90 | −0.82 | −0.85 | −0.77 | −0.83 | 7 | 0 |

| Ozone depletion | kg CFC-11 eq | −0.00004 | −0.00027 | −0.00032 | −0.00029 | −0.00030 | −0.00027 | −0.00029 | 7 | 0 |

| Particulate matter formation | kg PM10 eq | 2.0 | 3.6 | 4.4 | 3.9 | 4.4 | 4.8 | 2.8 | 0 | 7 |

| Photochemical oxidant formation | kg NMVOC | 11 | −5.4 | −7.9 | −6.8 | −7.4 | −5.7 | −6.7 | 6 | 1 |

| Terrestrial acidification | kg SO2 eq | 18 | 37 | 48 | 42 | 48 | 45 | 34 | 0 | 7 |

| Terrestrial ecotoxicity | kg 1,4-DB eq | −0.04 | 0.32 | 0.13 | 0.10 | −0.05 | 0.27 | 0.02 | 2 | 5 |

| Water depletion | m3 | −1763 | −13,903 | −13,909 | −13,342 | −13,312 | −13,426 | −13,878 | 7 | 0 |

| Worst | 8 | 1 | 1 | 0 | 0 | 7 | 0 | |||

| Best | 5 | 0 | 7 | 0 | 2 | 0 | 3 | |||

| Sink | 11 | 9 | 11 | 10 | 12 | 7 | 11 | 71 | ||

| Source | 6 | 8 | 6 | 7 | 5 | 10 | 6 | 48 | ||

| IAS—Fusion | Cosubs with No Current Bene. Reuse | Cosubs with Current Bene. Reuse | Sink | Source | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Impact Category | Reference Unit | Current | MFPW | HF | HU | DM | BM | CM | ||

| Agricultural land occupation | m2*a | 0 | −63 | −59 | −60 | 49 | 48 | 33 | 3 | 3 |

| Climate Change | kg CO2 eq | 41,049 | −4458 | −4256 | −4300 | −2807 | −3426 | −3005 | 6 | 1 |

| Fossil depletion | kg oil eq | 0 | −1548 | −1468 | −1485 | −1229 | −1502 | −1297 | 6 | 1 |

| Freshwater ecotoxicity | kg 1,4-DB eq | 0 | −12 | −7.9 | −8.8 | 11 | 6.1 | 7.9 | 3 | 3 |

| Freshwater eutrophication | kg P eq | 8.2 | 3.4 | 4.1 | 3.6 | 29 | 35 | 41 | 0 | 7 |

| Human toxicity | kg 1,4-DB eq | 0 | −297 | −122 | −160 | 365 | 133 | 226 | 3 | 3 |

| Ionizing radiation | kg U235 eq | 0 | −139 | −106 | −113 | −28 | −86 | −56 | 6 | 0 |

| Marine ecotoxicity | kg 1,4-DB eq | 0 | −8.8 | −2.8 | −4.1 | 16 | 8.5 | 11 | 3 | 3 |

| Marine eutrophication | kg N eq | 39 | −126 | −114 | −85 | 4.2 | 4.8 | 4.2 | 3 | 4 |

| Metal depletion | kg Fe eq | 0 | −28 | −9.1 | −13 | 93 | 78 | 80 | 3 | 3 |

| Natural land transformation | m2 | 0 | −1.2 | −1.1 | −1.1 | −0.86 | −1.2 | −0.98 | 6 | 0 |

| Ozone depletion | kg CFC-11 eq | 0 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 6 | 0 |

| Particulate matter formation | kg PM10 eq | 6.6 | 10 | 10 | 6.8 | 12 | 12 | 11 | 0 | 7 |

| Photochemical oxidant formation | kg NMVOC | 17 | −11 | −7.8 | −8.6 | −3.0 | −9.6 | −6.6 | 6 | 1 |

| Terrestrial acidification | kg SO2 eq | 50 | 103 | 94 | 69 | 91 | 110 | 95 | 0 | 7 |

| Terrestrial ecotoxicity | kg 1,4-DB eq | 0 | −0.33 | 0.00 | −0.07 | 1.1 | 0.65 | 0.58 | 2 | 3 |

| Water depletion | m3 | 0 | −18,877 | −20,118 | −19,847 | −18,883 | −18,899 | −17,458 | 6 | 0 |

| Worst | 8 | 0 | 0 | 0 | 6 | 2 | 1 | |||

| Best | 2 | 14 | 1 | 0 | 0 | 0 | 0 | |||

| Sink | 0 | 14 | 13 | 14 | 7 | 7 | 7 | 62 | ||

| Source | 6 | 3 | 4 | 3 | 10 | 10 | 10 | 46 | ||

| Process Unit → | Electricity, High Voltage, Production Mix|Electricity, High Voltage|APOS, S–TZ | Treatment of Scrap Steel, Municipal Incineration|Scrap Steel|APOS, U–RoW | SRM–Fish Waste (RF = 1t Sisal Export Fiber] | Treatment of Brake Wear Emissions, Lorry|Brake Wear Emissions, Lorry|APOS, U–RoW | |

|---|---|---|---|---|---|

| Impact Category ↓ | |||||

| Agricultural land occupation | m2*a | −47 | |||

| % | −101% | ||||

| Climate change | kg CO2 eq | −33,452 | |||

| % | −101% | ||||

| Fossil depletion | kg oil eq | −1162 | |||

| % | −101% | ||||

| Freshwater ecotoxicity | kg 1,4-DB eq | −9.4 | |||

| % | −103% | ||||

| Freshwater eutrophication | kg P eq | 3.7 | |||

| % | 102% | ||||

| Human toxicity | kg 1,4-DB eq | −2417 | 5.1 | ||

| % | −105% | 2.2% | |||

| Ionizing radiation | kg U235 eq | −108 | |||

| % | −103% | ||||

| Marine ecotoxicity | kg 1,4-DB eq | −7.4 | 0.1 | ||

| % | −106% | 2.0% | |||

| Marine eutrophication | kg N eq | −49 | |||

| % | −99% | ||||

| Metal depletion | kg Fe eq | −23 | |||

| % | −106% | ||||

| Natural land transformation | m2 | −0.94 | |||

| % | −102% | ||||

| Ozone depletion | kg CFC-11 eq | −0.00035 | |||

| % | −102% | ||||

| Particulate matter formation | kg PM10 eq | −4.5 | 8.0 | ||

| % | −127% | 224% | |||

| Photochemical oxidant | kg NMVOC | −9.0 | |||

| formation | % | −103% | |||

| Terrestrial acidification | kg SO2 eq | −16. | 61 | ||

| % | −37% | 136% |

References

- Common Fund for Commodities and UNIDO. Sisal: Past Research Results and Present Production Practices, Amsterdam, 8. 2001. Available online: http://common-fund.org/fileadmin/user_upload/Publications/Technical/Hard_Fibres/CFC_Technical_Paper_No._8.pdf (accessed on 19 January 2017).

- FAO. Sisal Production, 1961–2019. 2019. Available online: http://www.fao.org/faostat/en/#data/QC (accessed on 8 July 2021).

- Lock, G.W. Sisal, 2nd ed.; Longmans: London, UK, 1969. [Google Scholar]

- Broeren, M.L.M.; Dellaert, S.N.C.; Cok, B.; Patel, M.K.; Worrell, E.; Shen, L. Life cycle assessment of sisal fibre–Exploring how local practices can influence environmental performance. J. Clean. Prod. 2017, 149, 818–827. [Google Scholar] [CrossRef]

- Nandra, S.S. The Role of Chemical Analysis in Determining the Fertilizer Requirements of Crops, Research Bulletin No. 56; Mlingano: Tanga, Tanzania, 1971. [Google Scholar]

- Nandra, S.S. Soil fertility status of the sisal growing areas in Tanzania. African Soils 1977, XIX, 58–66. [Google Scholar]

- Van Kekem, A.J.; Kimaro, D.N. Soils of Amboni Sisal Estate and Their Potential for Sisal Growing. Site Evaluations and Appraisal Studies S4; Mlingano: Tanga, Tanzania, 1986. [Google Scholar]

- Kimaro, D.N.; Van Kekem, A.J. Soils of Kikwetu Sisal Estate and Their Potential for Sisal and Alternative Crops (Reconnaissance Soil Survey Report R4); Mlingano: Tanga, Tanzania, 1987. [Google Scholar]

- Kips, P.A.; Mbongoni, J.D.J.; Ndondi, P.M. Soils of Kwafungo Estate and Their Suitability for Selected Fruit Crops and Hybriud Sisal Cultivation. Semi-Detailed Soil Survey Report D17; Mlingano: Tanga, Tanzania, 1989. [Google Scholar]

- Ngailo, J.A.; Ndondi, P.M.; Kips, P.A. Soil Conditions and Agricultural Potential for Hybrid Sisal and Selected Fruit Crops at Kwamgwe Estate, Site Evaluations and Appraisal Studies S14; Mlingano: Tanga, Tanzania, 1990. [Google Scholar]

- Hartemink, A.E.E.; Van Kekem, A.J. Nutrient depletion in Ferralsols under hybrid sisal cultivation in Tanzania. Soil Use Manag. 1994, 10, 103–107. [Google Scholar] [CrossRef]

- Hartemink, A.E.; Wienk, J.F. Sisal Production and Soil Fertility Decline in Tanzania. Outlook Agric. 1995, 24, 91–96. Available online: http://www.alfredhartemink.nl/PDF/1995-SisalproductionTanzania.pdf (accessed on 19 January 2017). [CrossRef]

- Hartemink, A.E.; Osborne, J.F.; Kips, P.A. Soil Fertility Decline and Fallow Effects in Ferralsols and Acrisols of Sisal Plantations in Tanzania. Expl. Agric. 1996, 32, 173–184. Available online: http://www.alfredhartemink.nl/PDF/1996-Falloweffectsandsoilfertilitydecline.pdf (accessed on 19 January 2017). [CrossRef]

- Hartemink, A.E. Input and output of major nutrients under monocropping sisal in Tanzania. Land Degrad. Dev. 1997, 8, 305–310. [Google Scholar] [CrossRef]

- Hartemink, A.E. Soil fertility decline in some Major Soil Groupings under permanent cropping in Tanga Region, Tanzania. Geoderma 1997, 75, 215–229. Available online: http://www.alfredhartemink.nl/PDF/1997-SisalTanzania.pdf (accessed on 19 January 2017). [CrossRef]

- FAO. The Future of Food and Agriculture—Alternative Pathways to 2050, Rome. 2018. Available online: http://www.fao.org/3/I8429EN/i8429en.pdf (accessed on 14 January 2019).

- United Nations. World Population Prospects: The 2015 Revision, Key Findings and Advance Tables; United Nations: New York, NY, USA, 2015. [Google Scholar] [CrossRef]

- International Energy Agency (IEA). World Energy Outlook 2019, 2019th ed.; International Energy Agency: Washington, DC, USA, 2019; ISBN 978-92-64-97300-8. [Google Scholar]

- International Energy Agency (IEA), IEA Country Profile—Tanzania, Country Profiles. 2019. Available online: https://www.iea.org/countries/tanzania (accessed on 8 July 2021).

- Terrapon-Pfaff, J.C.; Fischedick, M.; Monheim, H. Energy potentials and sustainability—The case of sisal residues in Tanzania. Energy Sustain. Dev. 2012, 16, 312–319. [Google Scholar] [CrossRef]

- Kivaisi, A.; Rubindamayugi, M.S.T. The potential of agro-indsutrial residues for production of biogas and electricity in Tanzania. Renew. Energy 1996, 9, 917–921. [Google Scholar] [CrossRef]

- Jungersen, G.; Kivaisi, A.; Rubindamayugi, M. Bioenergy from Sisal Residues-Experimental Results and Capacity Building Activities (EFP-95 Project); 1998. Available online: https://www.etde.org/etdeweb/servlets/purl/632768/?type=download (accessed on 19 January 2017).

- Geissdoerfer, M.; Morioka, S.N.; de Carvalho, M.M.; Evans, S. Business models and supply chains for the circular economy. J. Clean. Prod. 2018, 190, 712–721. [Google Scholar] [CrossRef]

- Bocken, N.M.P.; de Pauw, I.; Bakker, C.; van der Grinten, B. Product design and business model strategies for a circular economy. J. Ind. Prod. Eng. 2016, 33, 308–320. [Google Scholar] [CrossRef]

- Ellen MacArthur Foundation, Circular Economy Overview. 2015. Available online: https://www.ellenmacarthurfoundation.org/circular-economy (accessed on 17 January 2017).

- FAO. FAOSTAT, Crops and Livestock Products. 2019. Available online: http://www.fao.org/faostat/en/#data/TP (accessed on 25 January 2019).

- Mshandete, A.; Kivaisi, A.; Rubindamayugi, M.; Mattiasson, B. Anaerobic batch co-digestion of sisal pulp and fish wastes. Bioresour. Technol. 2004, 95, 19–24. [Google Scholar] [CrossRef] [PubMed]

- Hills, D.J.; Roberts, D.W. Anaerobic digestion of dairy manure and field crop residues. Agric. Wastes 1981, 3, 179–189. Available online: http://production.datastore.cvt.dk/filestore?oid=532e0a01f36b9a657d0a263f&targetid=5326f8cdea081d6c09086cf7 (accessed on 12 January 2017). [CrossRef]

- EC-JRC. (ILCD) Handbook: General Guide for Life Cycle Assessment—Detailed Guidance; Publications Office of the European Union: Luxembourg, 2010. [Google Scholar] [CrossRef]

- Hauschild, M.Z.; Rosenbaum, R.K.; Olsen, S.I.; Bjørn, A.; Owsianiak, M.; Molin, C.; Laurent, A.; Ryberg, M.W.; Moltesen, A.; Corona, A.; et al. Life Cycle Assessment: Theory and Practice, 1st ed.; Hauschild, M.Z., Rosenbaum, R.K., Olsen, S.I., Eds.; Springer: Cham, Switzerland, 2017; ISBN 9783319564753. [Google Scholar]

- Rockström, J.; Steffen, W.; Noone, K.; Persson, Å.; Chapin, F.S.; Lambin, E.; Lenton, T.M.; Scheffer, M.; Folke, C.; Schellnhuber, H.J.; et al. Planetary boundaries: Exploring the safe operating space for humanity. Ecol. Soc. 2009, 461, 4. [Google Scholar] [CrossRef]

- Steffen, W.; Richardson, K.; Rockström, J.; Cornell, S.E.; Fetzer, I.; Bennett, E.M.; Biggs, R.; Carpenter, S.R.; De Vries, W.; De Wit, C.A.; et al. Planetary boundaries: Guiding human development on a changing planet. Science 2015, 347. [Google Scholar] [CrossRef]

- Nemecek, T.; Kagi, T. Life Cycle Inventories of Agricultural Production Systems, Ecoinvent Report No. 15. Final Rep. Ecoinvent V2.0 2007, 1–360. Available online: http://www.upe.poli.br/~cardim/PEC/EcoinventLCA/ecoinventReports/15_Agriculture.pdf (accessed on 17 January 2017).

- Muthangya, M.; Hashim, S.O.; Amana, J.M.; Mshandete, A.M.; Kivaisi, A.K.; Mutemi, M. Auditing and Characterisation of Sisal Processing Waste: A Bioresource for Value Addition. ARPN J. Agric. Biol. Sci. 2013, 8, 518–524. Available online: www.arpnjournals.com (accessed on 11 January 2017).

- UNIDO and Common Fund for Commodities. Feasibility Study for the Generation of Biogas and Electricity from Sisal Waste—Construction and Ooperations Manual (Project No. US/URT/09/006-1151 and FB/URT/09/A04-1151); Common Fund for Commodities: Amsterdam, The Netherlands, 2010. [Google Scholar]

- Stoorvogel, J.J.; Smaling, E.M.A. Volume III: Literature review and description of land use. In Assessment of Soil Nutrient Depletion in Sub Saharan Africa: 1983–2000; The Winand Staring Centre for Integrated Land, Soil and Water Research: Wageningen, The Netherlands, 1990. [Google Scholar]

- Parker, G.G. Throughfall and stemflow in the forest nutrient cycle. Adv. Ecol. Res. 1983, 13, 57–133. [Google Scholar]

- Nitrogen Deposition, Critical Loads and Biodiversity; Sutton, M.A., Mason, K.E., Sheppard, L.J., Sverdrup, H., Haueber, R., Hicks, W.K., Eds.; Springer: Berlin/Heidelberg, Germany; New York, NY, USA; London, UK, 2014; ISBN 9789400779389. [Google Scholar]

- Cosme, N.; Hauschild, M.Z. Characterization of waterborne nitrogen emissions for marine eutrophication modelling in life cycle impact assessment at the damage level and global scale. Int. J. Life Cycle Assess 2017. [Google Scholar] [CrossRef]

- Nerini, F.F.; Andreoni, A.; Bauner, D.; Howells, M. Powering production. The case of the sisal fibre production in the Tanga region, Tanzania. Energy Policy 2016, 98, 544–556. [Google Scholar] [CrossRef]

- Salum, A.; Hodes, G. Leveraging CDM to Scale-Up Sustainable Biogas Production from Sisal Waste. Available online: https://backend.orbit.dtu.dk/ws/portalfiles/portal/4044107/Salum_paper.pdf (accessed on 13 March 2017).

- Mshandete, A.; Björnsson, L.; Kivaisi, A.K.; Rubindamayugi, M.S.T.; Mattiasson, B. Effect of particle size on biogas yield from sisal fibre waste. Renew. Energy 2006, 31, 2385–2392. [Google Scholar] [CrossRef]

- Mshandete, A.; Bjornsson, L.; Kivaisi, A.; Rubindamayugi, M.; Mattiasson, B. Performance of a sisal fibre fixed-bed anaerobic digester for biogas production from sisal pulp waste. Tanzania J. Sci. 2005, 31, 41–52. [Google Scholar] [CrossRef]

- Muthangya, M.; Mshandete, A.M.; Kivaisi, A.K. Enhancement of Anaerobic Digestion of Sisal Leaf Decortication Residues By Biological Pre-Treatment. ARPN J. Agric. Biol. Sci. 2009, 4, 66–73. [Google Scholar]

- Mshandete, A.; Björnsson, L.; Kivaisi, A.K.; Rubindamayugi, S.T.; Mattiasson, B. Enhancement of anaerobic batch digestion of sisal pulp waste by mesophilic aerobic pre-treatment. Water Res. 2005, 39, 1569–1575. [Google Scholar] [CrossRef] [PubMed]

- Mshandete, A.M.; Björnsson, L.; Kivaisi, A.K.; Steven, M.; Rubindamayugi, T.; Mattiasson, B. Effect of aerobic pre-treatment on production of hydrolases and volatile fatty acids during anaerobic digestion of solid sisal leaf decortications residues. African J. Biochem. Res. 2008, 2, 111–119. Available online: http://www.academicjournals.org/AJBR (accessed on 13 March 2017).

- Gumisiriza, R.; Mshandete, A.M.; Thomas, M.S.; Kansiime, F.; Kivaisi, A.K. Nile perch fish processing waste along Lake Victoria in East Africa: Auditing and characterization. African J. Environ. Sci. Technol. 2009, 3, 13–20. [Google Scholar] [CrossRef]

- Foo, K. Value-added utilization of maize cobs waste as an environmental friendly solution for the innovative treatment of carbofuran. Process Saf. Environ. Prot. 2016, 1, 295–304. [Google Scholar] [CrossRef]

- Ali Abro, S.; Tian, X.; Wang, X.; Wu, F.; Esther Kuyide, J. Decomposition characteristics of maize (Zea mays. L.) straw with different carbon to nitrogen (C/N) ratios under various moisture regimes. African J. Biotechnol. 2011, 10, 10149–10156. [Google Scholar] [CrossRef]

- Kamolmanit, N.; Reungsang, A. Effect of carbon to ntirogen ratio on the composting of cassava pulp with swine manure. J. Water Environ. Technol. 2006, 4, 18. Available online: https://www.jstage.jst.go.jp/article/jwet/4/1/4_1_33/_pdf (accessed on 17 January 2017).

- Suthar, S.; Mutiyar, P.K.; Singh, S. Vermicomposting of milk processing industry sludge spiked with plant wastes. Bioresour. Technol. 2012, 116, 214–219. [Google Scholar] [CrossRef] [PubMed]

- Rusinamhodzi, L.; Murwira, H.K.; Nyamangara, J. Effect of cotton-cowpea intercropping on C and N mineralisation patterns of residue mixtures and soil. Aust. J. Soil Res. 2009, 47, 190–197. [Google Scholar] [CrossRef]

- Esteban, M.B.; García, A.J.; Ramos, P.; Márquez, M.C. Evaluation of fruit–vegetable and fish wastes as alternative feedstuffs in pig diets. Waste Manag. 2006, 27, 193–200. [Google Scholar] [CrossRef] [PubMed]

- Muñoz, I.; i Canals, L.M.; Clift, R.; Doka, G. A simple model to include human excretion and wastewater treatment in life cycle assessment of food products. Cent. Environ. Strateg. Univ. Surrey 2007, 1–46. Available online: http://www.doka.ch/CEShumanExcretion07.pdf (accessed on 13 March 2017).

- Rose, C.; Parker, A.; Jefferson, B.; Cartmell, E. The Characterization of Feces and Urine: A Review of the Literature to Inform Advanced Treatment Technology. Crit. Rev. Environ. Sci. Technol. 2015, 45, 1827–1879. [Google Scholar] [CrossRef] [PubMed]

- Strauss, M. Health Aspects of Nightsoil and Sludge Use in Agriculture and Aqua- Culture. Part II: Pathogen Survival (04/85); International Reference Centre for Waste Disposal (IRCWD): Duebendorf, Switzerland, 1985. [Google Scholar]

- Felix, M. Status update on LCA studies and networking in Tanzania. Int. J. Life Cycle Assess. 2016, 21, 1825–1830. [Google Scholar] [CrossRef]

- Lock, G.W. Sisal: Twenty-Five Years’ Sisal Research; Tropical, S., Ed.; Longmans, Green: London, UK, 1962. [Google Scholar]

- Common Fund for Commodities. Discover Natural Fibres. 2009. Available online: http://www.fao.org/3/i0709e/i0709e00.htm (accessed on 19 January 2017).

- Cantalino, A.; Torres, E.A.; Silva, M.S. Sustainability of Sisal Cultivation in Brazil Using Co-Products and Wastes. J. Agric. Sci. 2015, 7, 64–74. Available online: http://citeseerx.ist.psu.edu/viewdoc/summary?doi=10.1.1.958.7749 (accessed on 11 January 2017). [CrossRef][Green Version]

- Kimaro, D.N.; Msanya, B.M. Review of sisal production and research in Tanzania. Afr. Study Monogr. 1994, 15, 227–242. [Google Scholar]

- Tambyrajah, D.; Patel, D.M.; Faaij, P.A. A Blueprint for a Sustainability Certification Scheme for The Hard Fibers Sector; Common Fund for Commodities: Amsterdam, The Netherlands, 2012; Available online: http://common-fund.org/fileadmin/user_upload/Projects/FIGHF/FIGHF_32FT/Final_Report_August_2012.pdf (accessed on 23 February 2017).

- FAO and Common Fund for Commodities. Alternative Applications for Sisal and Henequen. In Technical Paper 14; 2001; p. 121. Available online: http://common-fund.org/fileadmin/user_upload/Publications/Technical/Hard_Fibres/Technical_Paper_No._14.pdf (accessed on 18 January 2017).

- Common Fund for Commodities, “Product and Market Development of Sisal and Henequen,” Amsterdam. 2005. Available online: http://common-fund.org/fileadmin/user_upload/Publications/Technical/Hard_Fibres/CFC_FIGHF_07.pdf (accessed on 23 February 2017).

- Magoggo, J.P. Cleaner Integral Utilization of Sisal Waste for Biogas and Biofertilizers; Common Fund for Commodities: Tanga, Tanzania, 2011; Available online: http://www.jpfirstlab.com (accessed on 3 February 2017).

- Andrade, W. Feasibility Evaluation for Utilization of Sisal Liquid Waste (Juice) for the Production of Pesticides and Veterinary Drugs. Sindifibras, Brazil. 2012. Available online: http://common-fund.org/fileadmin/user_upload/Projects/FIGHF/FIGHF_30FT/Final_Report_2012.pdf (accessed on 19 January 2017).

- Fortucci, P.; Mbabaali, S. Impact Evaluation of a CFC Funded Cluster of Sisal Projects; Common Fund for Commodities: Amsterdam, The Netherlands, 2015. [Google Scholar]

- FAOSTAT. 2014 Sisal Production; FAO: Rome, Italy, 2014. [Google Scholar]

- Hopkinson, D.; Wienk, J.F. Agave Hybrid Evaluations. In Tanganyika Sisal Growers’ Association Annual Report 1965/1966; Tanganyika Sisal Growers’ Association: Tanga, Tanzania, 1966. [Google Scholar]

- Muller, A. Health status of sisal plants (Agave sisalana) as related to soils and the mineral composition of their leaves. J. Sci. Food Agric. 1964, 15, 129–132. [Google Scholar] [CrossRef]

- Osborne, J.F. Some Preliminary Estimates of Nutrient Removal by Agave Crops; Tanganyika Sisal Growers’ Association: Mlingano, Tanzania, 1967. [Google Scholar]

- Neto, B.; Dias, A.C.; Machado, M. Life cycle assessment of the supply chain of a Portuguese wine: From viticulture to distribution. Int. J. Life Cycle Assess. 2013, 18, 590–602. [Google Scholar] [CrossRef]

- Department of the Environment and Energy. National Greenhouse Accounts Factors, Australian National Greenhouse Accounts; ACT: Canberra, Australia, 2016. Available online: www.environment.gov.au (accessed on 3 March 2017).

- Salazar, V.L.P.; Leao, A.L. Biodegradation of coconut and sisal fibers applied in the automotive industry (in Portugese). Energy Agric. Botucatu 2006, 21, 99–133. [Google Scholar]

| TN h % | TKN h % | TOC h % | Non-Lignin TOC% | TOC:TN | TOC:TKN | nlTOC:TKN | |

|---|---|---|---|---|---|---|---|

| Maize cobs a | 1.99 | 48.77 | 25 | ||||

| Maize straw b | 0.86 | 42 | 49 | ||||

| Cassava pulp c | 0.45 | 51.5 | 118 | ||||

| Rice hulls d | 0.69 | 32.9 | 22.5 | 48 | 33 | ||

| Rice straw d | 0.39 | 33.6 | 28.9 | 86 | 74 | ||

| Sugar cane trash e | 2.52 | 49.15 | 15.5 | ||||

| Cowpea residue f | 2.7 | 43.1 | 16.0 | ||||

| Grass clippings d | 3.25 | 40.8 | 38.4 | 12.6 | 11.8 | ||

| Dairy manure (DM) d | 2.14 | Table | 29.6 | 19.1 | 13.8 | ||

| Beef manure (BM) d | 2.1 | 38.5 | 30 | 18 | 14 | ||

| Chicken manure (CM) d | 6.87 | 31.7 | 30.3 | 4.6 | 4.4 | ||

| Pig manure d | 3.67 | 44.3 | 39.7 | 12.1 | 10.8 | ||

| Pig manure c | 2.47 | 26.16 | 10.6 | ||||

| Milk proc sludge e | 5.68 | 37.9 | 5.06 | ||||

| Marine fish waste (MFPW) g | 5.85 | 51 | 9 |

| Unit | DM a | BM a | CM a | MFPW b | HF c | HU c,d | |

|---|---|---|---|---|---|---|---|

| Mass required | kg | 22,500 | 19,700 | 8150 | 2220 | 16,850 | 13,650 |

| Equivalent animals or people/day | 407 | 886 | 69,150 | 6343 e | 69,342 | 9613 | |

| Nutrient input from cosubstrates | |||||||

| Calcium | kg | 44 | 43 | 167 | 34 | 77 | 2 |

| Magnesium | kg | 19 | 17 | 18 | 1.0 | 15 | 1.9 |

| Nitrogen | kg | 113 | 132 | 110 | 130 | 118 | 87 |

| Phosphorus | kg | 25 | 31 | 37 | 12 | 56 | 8 |

| Potassium | kg | 77 | 73 | 41 | 4 | 64 | 17 |

| Unit | DM | BM | CM | MFPW | HF | HU | |

|---|---|---|---|---|---|---|---|

| C:N ratio | 6.2 | 8.9 | 5.8 | 8.7 | 7.1 | 0.8 | |

| Mass required | kg | 8900 | 7750 | 3200 | 875 | 6650 | 5400 |

| Equivalent animals or people/day | 161 | 349 | 27,134 | 2500 | 27,366 | 3808 | |

| Nutrient input from cosubstrates | |||||||

| Calcium | kg | 17 | 17 | 65 | 13 | 30 | 0.7 |

| Magnesium | kg | 8 | 7 | 7 | 0.4 | 6 | 0.8 |

| Nitrogen | kg | 45 | 52 | 43 | 51 | 47 | 35 |

| Phosphorus | kg | 10 | 12 | 15 | 5 | 22 | 3 |

| Potassium | kg | 30 | 29 | 16 | 2 | 25 | 7 |

| Best Practice Site (BPS) | Industry Average Site (IAS) | ||||||

|---|---|---|---|---|---|---|---|

| Nutrient | Unit | Nursery | Plantation | Total | Nursery | Plantation | Total |

| Calcium | kg | −0.74 | 56 | 55 | −7.1 | −276 | −283 |

| Magnesium | kg | −0.18 | −29 | −30 | −0.38 | −68 | −68 |

| Nitrogen | kg | −0.52 | −19 | −19 | −1.3 | −36 | −37 |

| Phosphorus | kg | −0.26 | −1.6 | −1.9 | −0.83 | −7.3 | −8.1 |

| Potassium | kg | −0.80 | −35 | −36 | −3.0 | −84 | −87 |

| Unit | DM | BM | CM | MFPW | HF | HU | Initial Depletion | |

|---|---|---|---|---|---|---|---|---|

| Calcium | kg | 128 | 128 | 252 | 118 | 161 | 86 | −283 |

| Magnesium | kg | 50 | 48 | 49 | 32 | 46 | 33 | −68 |

| Total Nitrogen (TN) | kg | 137 | 157 | 135 | 154 | 142 | 112 | −37 |

| Phosphorus | kg | 29 | 35 | 41 | 15 | 60 | 12 | −8 |

| Potassium | kg | 113 | 109 | 77 | 40 | 100 | 53 | −87 |

| Unit | DM | BM | CM | MFPW | HF | HU | Initial Depletion | |

|---|---|---|---|---|---|---|---|---|

| Calcium | kg | 102 | 102 | 150 | 98 | 115 | 85 | 55 |

| Magnesium | kg | 39 | 38 | 38 | 32 | 37 | 32 | −30 |

| Nitrogen | kg | 69 | 79 | 68 | 76 | 71 | 59 | −19 |

| Phosphorus | kg | 14 | 16 | 18 | 8.3 | 26 | 6.9 | −1.9 |

| Potassium | kg | 67 | 65 | 52 | 38 | 62 | 43 | −36 |

| IAS | Reference Unit | Current Base Case | Cosubstrate with no Current Beneficial Reuse | Current Base Case | Cosubstrate with Current Beneficial Reuse | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Impact Category (17) | DM | BM | CM | MFPW | HF | HU | DM | BM | CM | MFPW | HF | HU | |||

| Agricultural land occupation | m2*a | 0 | −58 | −71 | −61 | −63 | −59 | −60 | 0 | 49 | 48 | 33 | 14 | 59 | −1.7 |

| Climate Change | kg CO2 eq | 41049 | −4178 | −5027 | −4376 | −4458 | −4256 | −4300 | 41049 | −2807 | −3426 | −3005 | −3013 | −2703 | −3318 |

| Fossil depletion | kg oil eq | 0 | −1437 | −1746 | −1515 | −1548 | −1468 | −1485 | 0 | −1229 | −1502 | −1297 | −1344 | −1207 | −1347 |

| Freshwater ecotoxicity | kg 1,4-DB eq | 0 | −6.3 | −14 | −10 | −12 | −7.9 | −8.8 | 0 | 11 | 6.1 | 7.9 | 4.6 | 14 | 2.5 |

| Freshwater eutrophication | kg P eq | 8.2 | 3.7 | 4.0 | 4.0 | 3.4 | 4.1 | 3.6 | 8.2 | 29 | 35 | 41 | 16 | 61 | 12 |

| Human toxicity | kg 1,4-DB eq | 0 | −54 | −362 | −226 | −297 | −122 | −160 | 0 | 365 | 133 | 226 | 100 | 431 | 111 |

| Ionizing radiation | kg U235 eq | 0 | −93 | −162 | −126 | −139 | −106 | −113 | 0 | −28 | −86 | −56 | −82 | −19 | −74 |

| Marine ecotoxicity | kg 1,4-DB eq | 0 | −0.53 | −11 | −6.4 | −8.8 | −2.8 | −4.1 | 0 | 16 | 8.5 | 11 | 7.2 | 18 | 6.7 |

| Marine eutrophication | kg N eq | 39 | −109 | −128 | −107 | −126 | −114 | −84 | 39 | 4.2 | 4.8 | 4.2 | 4.7 | 4.6 | 3.3 |

| Metal depletion | kg Fe eq | 0 | −1.8 | −34 | −20 | −28 | −9.0 | −13 | 0 | 93 | 78 | 80 | 67 | 110 | 51 |

| Natural land transformation | m2 | 0 | −1.1 | −1.4 | −1.2 | −1.2 | −1.1 | −1.1 | 0 | −0.86 | −1.2 | −0.98 | −1.0 | −0.86 | −1.0 |

| Ozone depletion | kg CFC-11 eq | 0.0 | −0.00035 | −0.00052 | −0.00042 | −0.00045 | −0.00038 | −0.00040 | 0.0 | −0.00027 | −0.00042 | −0.00033 | −0.00037 | −0.00028 | −0.00034 |

| Particulate matter formation | kg PM10 eq | 6.6 | 9.3 | 9.7 | 8.8 | 10 | 10 | 6.8 | 6.6 | 12 | 12 | 11 | 13 | 13 | 8.3 |

| Photochemical oxidant formation | kg NMVOC | 17 | −6.4 | −13 | −10 | −11 | −7.8 | −8.6 | 17 | −3.03 | −9.6 | −6.6 | −8.2 | −3.8 | −6.4 |

| Terrestrial acidification | kg SO2 eq | 50 | 84 | 101 | 87 | 102 | 94 | 69 | 50 | 91 | 110 | 95 | 110 | 103 | 74 |

| Terrestrial ecotoxicity | kg 1,4-DB eq | 0 | 0.13 | −0.42 | −0.19 | −0.33 | 0.00 | −0.07 | 0 | 1.1 | 0.65 | 0.58 | 0.19 | 1.0 | 0.38 |

| Water depletion | m3 | 0 | −20598 | −20930 | −19380 | −18877 | −20118 | −19847 | 0 | −18883 | −18899 | −17458 | −17385 | −17676 | −18821 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Colley, T.A.; Valerian, J.; Hauschild, M.Z.; Olsen, S.I.; Birkved, M. Addressing Nutrient Depletion in Tanzanian Sisal Fiber Production Using Life Cycle Assessment and Circular Economy Principles, with Bioenergy Co-Production. Sustainability 2021, 13, 8881. https://doi.org/10.3390/su13168881

Colley TA, Valerian J, Hauschild MZ, Olsen SI, Birkved M. Addressing Nutrient Depletion in Tanzanian Sisal Fiber Production Using Life Cycle Assessment and Circular Economy Principles, with Bioenergy Co-Production. Sustainability. 2021; 13(16):8881. https://doi.org/10.3390/su13168881

Chicago/Turabian StyleColley, Tracey Anne, Judith Valerian, Michael Zwicky Hauschild, Stig Irving Olsen, and Morten Birkved. 2021. "Addressing Nutrient Depletion in Tanzanian Sisal Fiber Production Using Life Cycle Assessment and Circular Economy Principles, with Bioenergy Co-Production" Sustainability 13, no. 16: 8881. https://doi.org/10.3390/su13168881

APA StyleColley, T. A., Valerian, J., Hauschild, M. Z., Olsen, S. I., & Birkved, M. (2021). Addressing Nutrient Depletion in Tanzanian Sisal Fiber Production Using Life Cycle Assessment and Circular Economy Principles, with Bioenergy Co-Production. Sustainability, 13(16), 8881. https://doi.org/10.3390/su13168881