1. Introduction

Human-error-induced accidents have become the primary source of accidents in complex socio-technical systems. Statistics have shown that more than 60% of casualties and accidents that occur around the world every year are associated with human error. Moreover, the proportion of major disasters caused by such events can reach 80% or more, a number that continues to increase annually, especially in high-risk fields, such as nuclear plants, aerospace, and maritime fields [

1,

2]. A ship’s navigational system is also a complex human–machine system (HMS) comprising people, machines, and the operating environment, where human factors play a vital role in ship navigational safety. According to statistics, human-error-related maritime traffic accidents account for 80% or more of maritime accidents; moreover, the proportion of human-error-related accidents can be as high as 95% in collisions [

3]. Maritime traffic accidents not only result in potentially huge personnel and property losses but also cause irreversible damage to the environment [

4]. An ordered logistic regression model has been used to reflect the relationship between these factors and the severity of marine accidents using the worldwide accident investigation reports during the period 2010–2019. Regarding aspects related to human factors, the results showed that insufficient manning of the ship, invalid or incomplete ship certificate(s), and seafarers lacking in theoretical knowledge and seafaring experience to be factors most inclined to be the cause of accidents, often with severe consequences [

5]. Rothblum emphasized that the prevention of human error should not be underestimated because, in addition to ship collisions, human error could cause tanker accidents, vessel groundings, fires, and explosions [

6].

In terms of human error, human–computer interaction (HCI) plays a leading role as humans exhibit relatively large plasticity and uncontrollability due to their physical, psychological, social, and spiritual characteristics [

7]. The complexity of HCI can also affect human error in many ways:

- (a)

A decrease in situational awareness (SA). An operator’s complete understanding of the system and environment serves as the basis for making correct operational decisions. However, the absence of SA is one of the main causes of human error and operational accidents [

8]. SA [

9] relates to continuously obtaining information from the environment and integrating it with existing knowledge to form a complete and unified mental representation of the situation at any point in time. The operator then uses this mental representation to determine how to obtain information for the next step and to predict the event(s) that may occur. Cognitive processes that shape SA during ship navigation include identifying signals, understanding their meanings, integrating information, predicting system status, and so on. This is a process involving complex mental processing, which can be affected by a variety of cognitive factors, where processes such as attention, perception, and memory all play an important role [

10].

- (b)

An increase in time pressure due to prompt communication and feedback failure. The ship crew follow a duty system, which exhibits significant timeliness. At night—especially during the period when the second officer (2/O) and chief officer (C/O) are on duty—the crew on duty are more likely to feel fatigued and sleepy due to their biorhythms, potentially leading to navigational accidents [

11]. In emergency situations, risk information needs to be obtained from the crew on duty through telephone communication; in this case, there may be delays in communicating such information. If there is insufficient knowledge to solve this complex task, it may create time pressure for the operator, serving to increase the complexity of the task.

- (c)

An increase in the cognitive load due to onboard human machine interaction (OHMI) management tasks and operation control tasks [

12]. Cumbersome cockpit management tasks require the operator to filter, screen, reorganize, and integrate a large volume of information, which may increase the operator’s cognitive load and may result in the misjudgment or missing of crucial information. Moreover, the physical environment for HCI—such as the weather, wind, waves, temperature, noise, and other factors—may also affect the HCI quality and outcomes [

13].

As the scale of systems becomes more complex and human–machine interactions become more important, the behavior of system operators becomes increasingly critical for the entire human–machine system [

14]. However, previous researchers in the maritime field have focused their maritime traffic safety research primarily on the development of advanced equipment, the optimization of the navigational environment, and legal and regulatory constraints, emphasizing the reduction of the accident occurrence rate by improving technologies [

15,

16]. Research into the human factors involved has been relatively scarce and biased toward the studying of psychological factors and performing static assessments. There have been few studies on dynamic risk assessments. As a result, this field of research faces many challenges:

HCI has not been sufficiently associated with safety issues in the field of ship transportation.

Current human factor research in the ship transportation industry has not employed precise and detailed probability analysis methods.

In daily navigational processes, the mechanism(s) of cognitive-based information flow and task completion processes among the crews remain unclear.

This study aims to fill this research gap and promote the research of human error in the interaction processes with complex systems from descriptive and predictive perspectives. This work includes:

(a) Based on the IDAC model, a knowledge-based ship HCI framework architecture is established; (b) a proposed maritime accident dynamics simulation (MADS) method, enhanced by HCI based on cognition, decision making, and operational models, a method that can predict possible event(s) and probabilities that may lead to decision-making errors in scenarios of knowledge-driven task failures; and (c) the building of a related simulation verification platform, the delivery of a HCI performance assessment tool and multiple interaction strategies, the performing of a preliminary decision-making reliability test, and the provision of viable solutions for ship collision avoidance.

The remainder of the paper is organized as follows.

Section 2 briefly introduces the relationships between HCI, human error, human reliability, and dynamic probability analysis, and also reviews and summarizes related work.

Section 3 establishes a ship HCI framework for knowledge-based complex tasks.

Section 4 explains the approach of the MADC-IDAC method for daily navigation tasks.

Section 5 performs simulation verification for the decision-making reliability of collision avoidance in a two-ship encounter scenario on the MADS-IDAC system, as well as discussing and analyzing the case study. The conclusions are summarized in

Section 6.

2. Literature Review

2.1. HCI Based on the Cognitive Process

HCI refers to a process whereby operators obtain information from a system, make decisions accordingly, and then take related actions [

17]. This study started by understanding users and studying their usage habits by analyzing their cognitive processes as well as associated physical and psychological characteristics, so as to solve practical problems encountered by users in the HCI process.

The cognitive process refers to the information processing process of an individual’s cognitive activities. In cognitive psychology, this process is regarded as an information processing system, consisting of continuous cognitive operational behavior—such as acquiring information, encoding, storing, extracting, and using it [

18]. The human information processing model proposed by Wickens [

19] focuses on the perception, thinking and decision-making, and response processes by calling on working memory (WM) and long-term memory (LM). This process depends on the user’s psychological or cognitive resources, describing the human cognitive behavior from an information flow perspective. When a user acquires, accepts, and uses information, they have to go through a series of cognitive processes—such as feeling, perception, attention, thinking, and memorizing—before performing information filtering, memorizing, and problem solving. All of these factors may affect every aspect of the interaction process. Sohn and Doane [

20] pointed out that both short-term and long-term WM play a role in complex HCI tasks, and their importance varies with the user’s degree of professionalism. Short-term WM plays an important role in the early stages of learning a task; once proficiency is reached in terms of task execution, long-term WM takes over. In short, in the HCI process, multiple processing stages are linked together under the intermediate effects of long-term WM; consequently, new information can be integrated with information already obtained to continuously enrich SA and related cognitive processes, finally forming a complete cognition of the HMS [

21]. The focus in HCI is the feelings and processes generated during the interaction processes, which are the result of continuous interaction and the mutual influences between the HMS and the surrounding environment.

2.2. Human Error in HCI

As HMS complexity continued to increase, people began to realize the negative effects of human error in the 1940s. In the late 1960s, substantial research had been conducted on such errors. Traditional human errors were mostly studied from an individual perspective, where a method of experimental psychology was adopted to analyze the impact of an individual’s error, WM, and other cognitive factors, as well as physiological factors, and the specific microenvironment on their performances [

22]. By the 1990s, research on human error had been steered in a new direction. Through studies of organizational behavior, researchers found that accidents were not simply caused by individual factors but also resulted from organizational systems to a large extent because an individual’s behavior could be greatly affected by organizational behavior [

23]. Reason proposed the concept of

Latent Failures—which specifically referred to management failures—in his book “Human Error”, where he believed that the root cause of accidents could be traced back to latent failures and organization error resulting from internal system problems [

24]. Catherine et al. [

25] reviewed studies on human factors in ship transportation safety and determined that the impact of individual and organizational factors were the most noteworthy factors affecting the occurrence of accidents in ship transportation. The specific influencing factors included the nine aspects of fatigue, stress, health, environment, collaborative operation, decision making, information, automatic control, and safety culture.

The application and development of digital technologies have made HCI more convenient and effective, which has improved system reliability and personnel performance [

26]. Moreover, the role of the operator in the HMS has changed, having been transformed from being the executor and monitor in charge of “monitoring + operation” previously, to today’s supervisor and manager who performs “monitoring + judgment + decision making + operations”. As a result, in the subsequent interaction processes, the operator not only has to perform tasks that directly monitor the system operation, but also needs to obtain more information to perform the interface management tasks. Such tasks occupy and require more attention, thereby increasing the operator’s cognitive load. This role change requires more sophisticated individuals, and thus objectively increases the possible occurrence of human error [

27].

The causes of human error comprise many complex factors, which are of random and uncertain nature [

28]. In many systems, the principle of crew operation is often adopted to compensate for individual errors—that is, in a crew, members will support each other and supervise the correctness of each other’s actions. In this way, the system will not be affected by individual problems, thereby improving its reliability [

29]. However, an operator often needs to complete abnormal and demanding tasks when handling accidents, which plays a vital role in the safety of the entire system. Human behavior may lead to the occurrence of abnormal accidents or exacerbate the consequences of accidents; however, it may also be possible to restore a system to its normal status or alleviate the consequences of accidents through the correct intervention behavior.

2.3. Probability Risk Analysis

Probability risk analysis (PRA) [

30] is a quantitative risk assessment technique and logical analysis method. It uses the event tree (ET), fault tree, and other methods in a comprehensive manner to construct a risk event chain model. Qualitative assessment and quantitative calculations are combined to perform model quantification and uncertainty analysis, thereby realizing the reasonable prediction of a system’s risk level as well as an analysis of the key factors affecting the risk.

PRA integrates reliability analysis, human reliability assessment (HRA), and uncertainty analysis. However, as PRA research depends on the professional knowledge of analysts, it can sometimes lead to incomplete risk settings for major accident scenarios. Consequently, researchers have proposed various dynamic PRA methods.

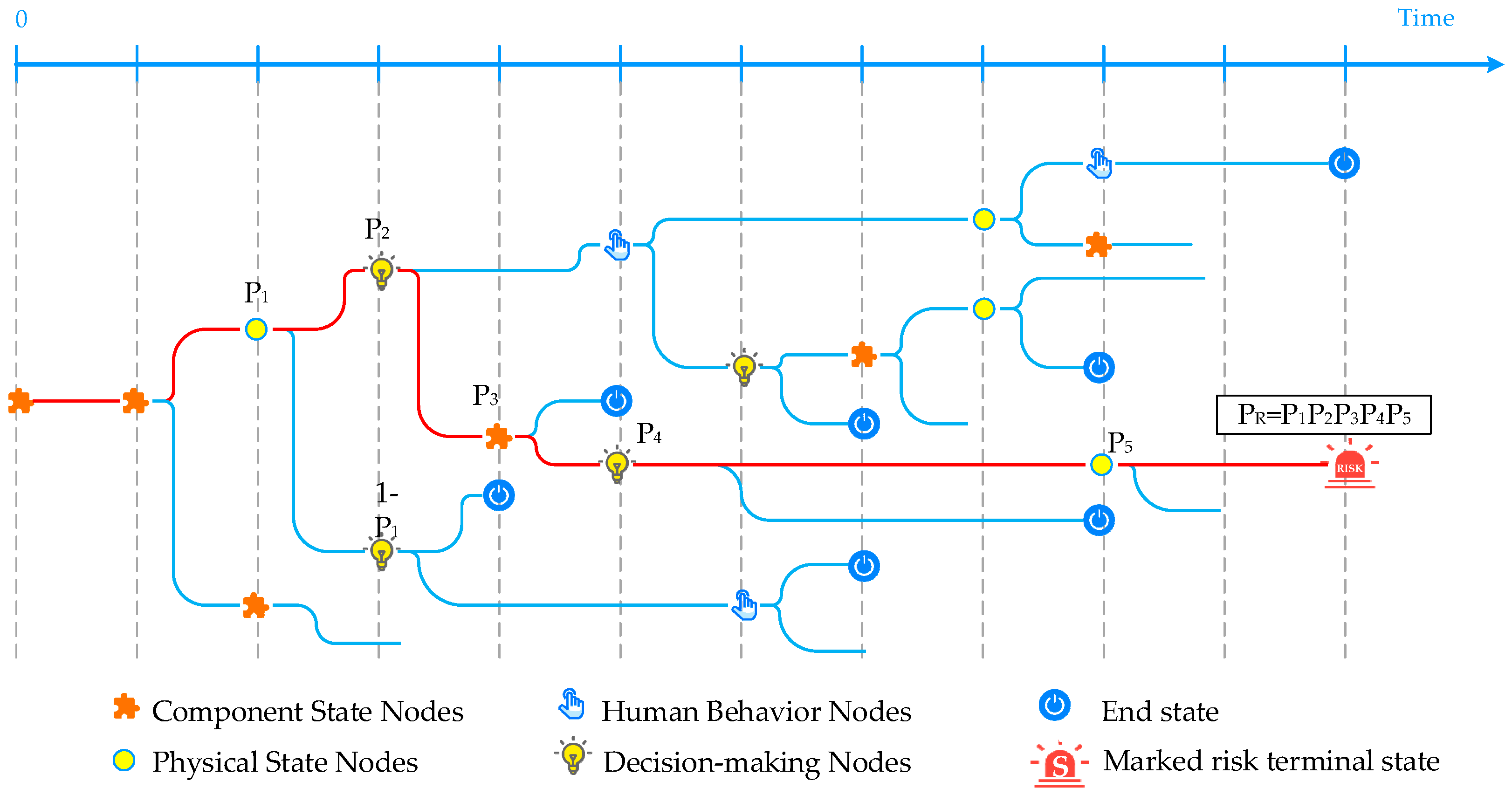

Dynamic PRA can be divided into two categories, namely continuous-time and discrete-time. In terms of the convenience for computer simulation and solutions, discrete dynamic PRA—such as the dynamic discrete event tree (DDET) model [

31]—has seen wider adoption. The DDET method dynamically generates an ET and performs calculations based on a time-dependent system evolution model and various branch conditions. Essentially, all discrete dynamic PRA methods use a simulation engine, the main function of which is to generate branches under each user-specified time step or conditions and related probabilities, and calculate the probability of each branch node. This dynamic simulation analysis method has provided a natural framework for the design safety analysis of complex human–machine–environment systems. It includes a physical model of the operating environment, a mechanical model of hardware failures, and a behavioral model of the operator’s cognitive process. A typical example is the MADS-IDAC method [

32], as shown in

Figure 1, where the standards for generating branch nodes include the system hardware status, changes in physical quantities, human decisions and operations, software failures or preset end states, and so on. The final ET that is dynamically generated through system simulation is the DDET. It can provide a quantitative and detailed analysis of the interactive responses between the system and human information, decisions, and actions, as well as the corresponding results. At present, it has been applied to the safety and reliability analysis of nuclear power plants and the HRA of the remote control center in intelligent ships.

Accordingly, a DDET-based probabilistic simulation engine (MADS) was proposed, which was combined with the crew’s cognitive decision-making model (IDAC) to form a dynamic risk analysis system of maritime accidents, that is, the MADS-IDAC system. Its main function is to simulate the accident development process through driving a ship physical simulator and a crew’s decision-making model for a preset scenario, and dynamically generating the ET branches, so as to obtain the event development processes and probabilities for different results in the preset scenario.

2.4. Human Reliability Assessment Method and IDAC Model

The HRA discipline in relation to PRA has gone through an evolutionary process [

33]. HRA studies the ways in which people obtain information from the outside world, the representation of information in the human brain and how it is transformed into knowledge, the storage of such knowledge, and how it is used to guide people’s attention and behavior. The core research work is the qualitative and quantitative analysis and assessment of human reliability, and the research objective is to analyze, predict, reduce, and prevent human error [

34]. The first generation of HRA methods assumed that human behavior could be decomposed like a hardware system. These models were highly dependent on expert analyses. The second generation focused on the modeling and analysis of human cognitive mechanisms, and the third generation was dynamic and based on cognitive simulation models, that is, the IDAC model.

The IDAC model was proposed by Chang YHJ and Mosleh A. (researchers at the University of Maryland) based on the IDA model, a computational model for aircrew operation reliability analysis. The IDAC model was developed based on numerous relevant findings from cognitive psychology, behavioral science, neuroscience, human factors, social science, field observations, and various first- and second-generation HRA methodologies [

35]. The IDA analysis method was based mainly on simulations of the specific operating behavior of an individual under given operating conditions, whereas the IDAC method quantifies the human reliability at each operating stage through cognitive modeling and analysis. Compared with other cognitive reliability models, the IDAC model exhibits the following distinct differences:

In the IDAC model, thorough consideration was given to the individual performing an operation, the environmental impact factors of the current operation were also analyzed, and the performance-influencing factor (PIF) was introduced to analyze the reliability relationships at the cognitive stage.

A flow chart for the transmission of operational information was also established in this model, and the MADS program was used to simulate the cognitive response process of the operator during their specific operating process.

IDAC models the individual and group behavior of the operating crew. Currently, three generic types of operator can be modeled, each with somewhat different roles and responsibilities [

35]. The operator responds to system abnormalities and interacts with the system based on organizational specifications. The MADS code simulates an accident scenario and generates information about the external environment—that is, the system state and environmental variables. This information can then be used as input to the crew model (i.e., the IDAC model), which, in turn, simulates the various types of operator responses, including operations on the system. Each individual operator model includes elements of the IDAC cognitive architecture—that is, PIFs, memory architecture, etc.—and a model of the cognitive process (e.g., the information processing model) [

36].

The IDAC method has been widely applied to the reliability simulation analysis of nuclear power plants but has not been widely employed in other fields to date. Consequently, this study extends its application to the ship transportation field.

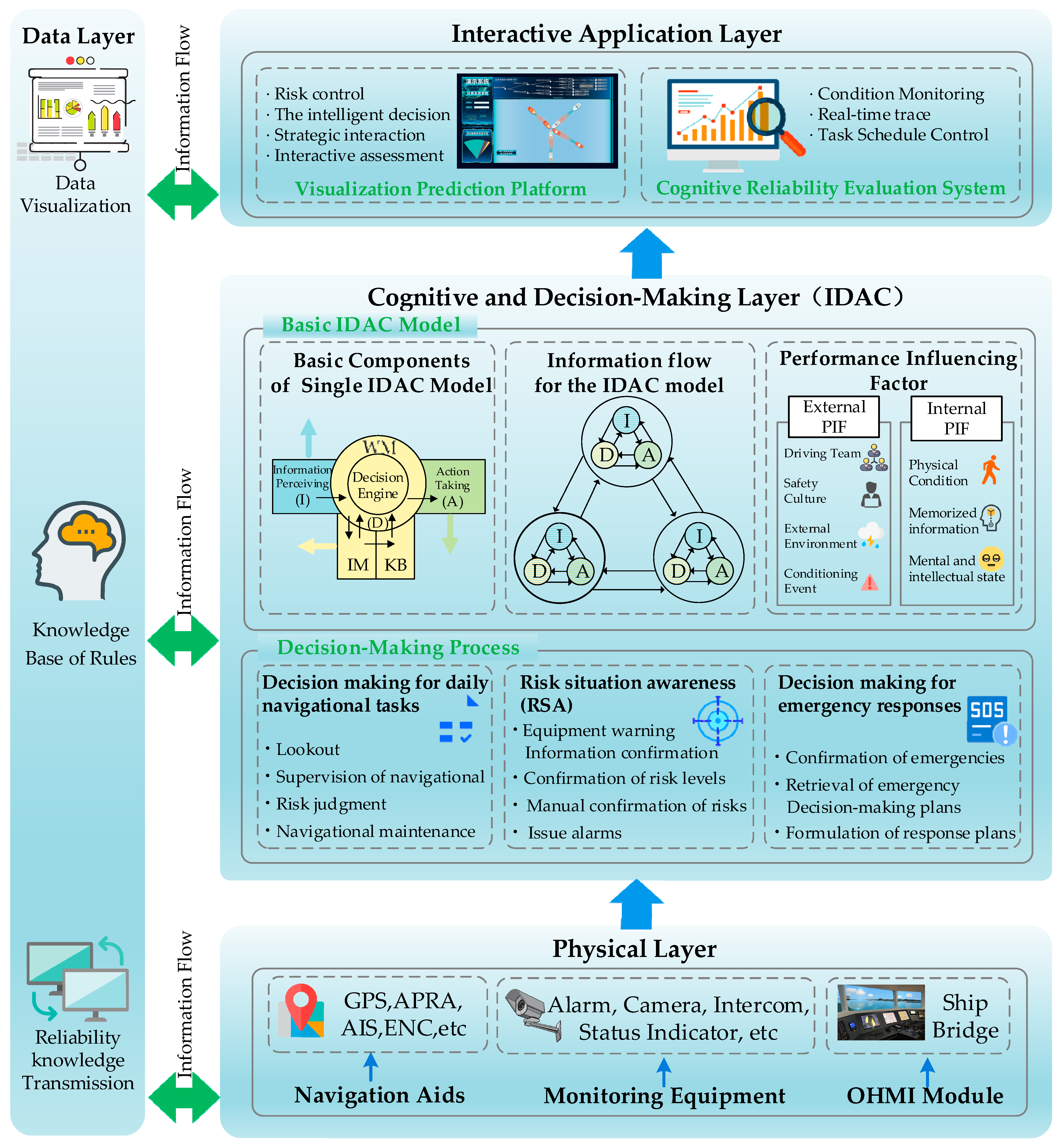

3. Methodology: Knowledge-Based Ship HCI Framework Architecture

Ships engage in a labyrinth of communication tasks as well as prompts and operations based on multi-source information during navigation, which require frequent interactions between humans and machines. Based on the literature review and related theoretical analysis, this paper proposes an HCI framework architecture in the context of handling complex tasks, as shown in

Figure 2. The overall architecture consists of four layers, namely the physical, cognitive decision-making, interaction application, and data layers.

3.1. The Physical Layer

The physical layer consists of navigational aids, including an automatic identification system (AIS), for sending locations, speed, and headings at set times, as well as sharing information; an automatic radar plotting aid (APRA) radar, for sending alerts upon contact; an electronic chart (ENC), for sharing geological locations with other ships; a Baidu GPS, for self-positioning navigational information, a bridge management software, etc.; internal and external monitoring equipment, including alarms, intercoms, running status indicators, cameras, etc.; and a OHMI module, which is used to perform the human–machine interaction in the ship bridge and engine room.

The physical layer is responsible for serving operations, risk perceptions, real-time monitoring, and information sharing for humans, machines, and the environment. The crew will be immersed in an environment of continuous perception and participate in cognitive decision-making tasks with a large number of risk reminders and data. The officer on watch (OOW) can collect current navigational status information and make preliminary judgments on scenarios through the ship’s navigational aid system. The OOW receives the captain’s instructions and performs all interactions with ship operations through the OHMI module. The real-time communication during the interaction is realized with assistance from the cockpit management equipment. Depending on the existing real-time information transmission and risk warning data, various sensing and operational equipment are configured to realize interconnection and mutual sensing between physical resources, thereby ensuring the real-time accuracy of multi-source information as well as a reliable understanding of safety risks during navigation. The digital monitoring of the system requires obtaining complete data about it and its environment during the entire navigational process through various data acquisition methods, either directly or with the aid of other sensors and equipment.

3.2. The Cognitive Decision-Making Layer

The cognitive decision-making layer acts as the core layer of the entire architecture, which includes a basic IDAC model and a decision-making process. The basic IDAC model part starts from a human cognitive behavior perspective and models the cognitive process of the crew’s perception of their environment and risks during ship navigation. Each operator’s cognitive activities can be divided into three phases: information perception (I), diagnosis selecting and decision making (D), and action taking (A) [

37]. A set of cognitive rules are defined and applied for each operator’s cognitive activity of these three phases. The operator’s behavior—such as changes in memory, changes in mental state, and behavior in a synchronized dynamic environment—is regulated by cognitive rules. The IDAC cognitive model constructed includes working memory (WM), intermediate memory (IM), knowledge base (KB)/long-term memory (LM), and indications of the operator’s mental state. The most recent perceived information is stored in the WM, which is of relatively limited capacity, similar to that of an operator’s short-term memory. The information residing in the WM is transferred to the IM for later retrieval. It is assumed that the intermediate storage is unlimited, but the information may be forgotten (or decay) over time. The KB is a collection of all the information (including collision-avoidance procedures, current internal and external facts, and past experience) that the operator has regarding the hardware system and accidents. In this memory model, IM acts as a buffer between the WM and the KB [

37]. The static and dynamic influencing factors—the PIFs—are the core elements of the IDAC. The PIFs discussed here refer to the ones that play an effective role in changing the event process by affecting the operator’s responses. Therefore, the PIFs that take a long time to be effective (such as learning-related factors) are not considered.

The decision-making process part consists of daily navigational task decisions, risk situation awareness (RSA), and emergency response decision making. By combining the information perception and the IDAC model, the operator can predict the risk situation and make corresponding decisions. The specific details of the IDAC model are elaborated on in

Section 4.

3.3. The Interactive Application Layer

The interactive application layer is driven by information from the physical layer as well as data from the IDAC model of the cognitive decision-making layer, where a visual prediction MADS-IDAC platform and a cognitive reliability assessment system are established. The MADS-IDAC model comprises MADS—a probabilistic simulation engine based on the DDET method—and IDAC—a cognitive decision-making model of the crew and the intelligent system. It can simulate the HCI and the ship’s hydrodynamic performance during real navigation through driving the ship’s physical simulator and the crew decision-making model. It can dynamically generate ET branches when human- or physical-factor-induced events—such as crew decision making, operations, and collisions—occur during the event development process. Moreover, it can further simulate various subsequent scenarios with or without event occurrences along the branch, thereby obtaining the event development logic and the occurrence probability of each scenario for different results under a preset scenario. The cognitive reliability assessment system includes visual information acquisition (via camera) in the cockpit and background data assessment. It can provide real-time and accurate feedback based on the real operational situation in the cockpit. The system exhibits the advantages of integrated risk avoidance and assessment, risk control, and real-time process traceability. It can also assist and participate in the quality assessment of the HMS and select the optimal navigational strategy. A specific case is expanded on in

Section 5.

3.4. The Data Layer

The data layer provides immediately available services—such as a reliability knowledge base, data integration rule base, and resource knowledge base—for the operation of the entire interaction framework from a data, information, and knowledge perspective. Equipped with navigation aids (e.g., GPS or sensor), machines and workstations realize a preliminary perception of the environment. Massive raw data reflecting the real scenario is generated. Multi-source heterogeneous data collected from various sensors describe the real scenario and acts as connectors among different modules. The information data layer serves as the interface between the operator model and the machines through information digitization, transmission, and reception.

4. The Approach of the MADC-IDAC Method for Daily Navigation Task

4.1. Cognition-Based Task Execution Process

In the IDAC method, the operator’s cognitive process is divided into three phases: information perception and processing (information, I), decision making (decision, D), and action taking (action, A). These cognitive processes are supported by a memory model composed of three different units [

35].

In the MADS-IDAC system, the current crew model of the ship includes a decision maker (captain) and two actors (OOWs). Similar to an actual collision-avoidance scenario, each operator assumes their unique role and responsibilities. Among them, the captain selects a high-level objective(s) and sends instructions to the actors. The OOWs collect current navigational status information through the ship navigational aid system and make preliminary judgments on the current scenario. The OOWs receive the captain’s instructions and interact with the ship maneuvering model through the OHMI module of the MADS-IDAC system. The current system supports three high-level objectives in the analysis of ship collision accidents: maintaining normal navigation, the timing of collision avoidance, and collision-avoidance decision making. The selection of specific objectives and strategies is based on the current risk situation perceived by the operator and their PIFs.

The current version of the MADS-IDAC system only considers the stage from risk detection to collision-avoidance decision making and does not involve the rescue and repair stage after the collision itself.

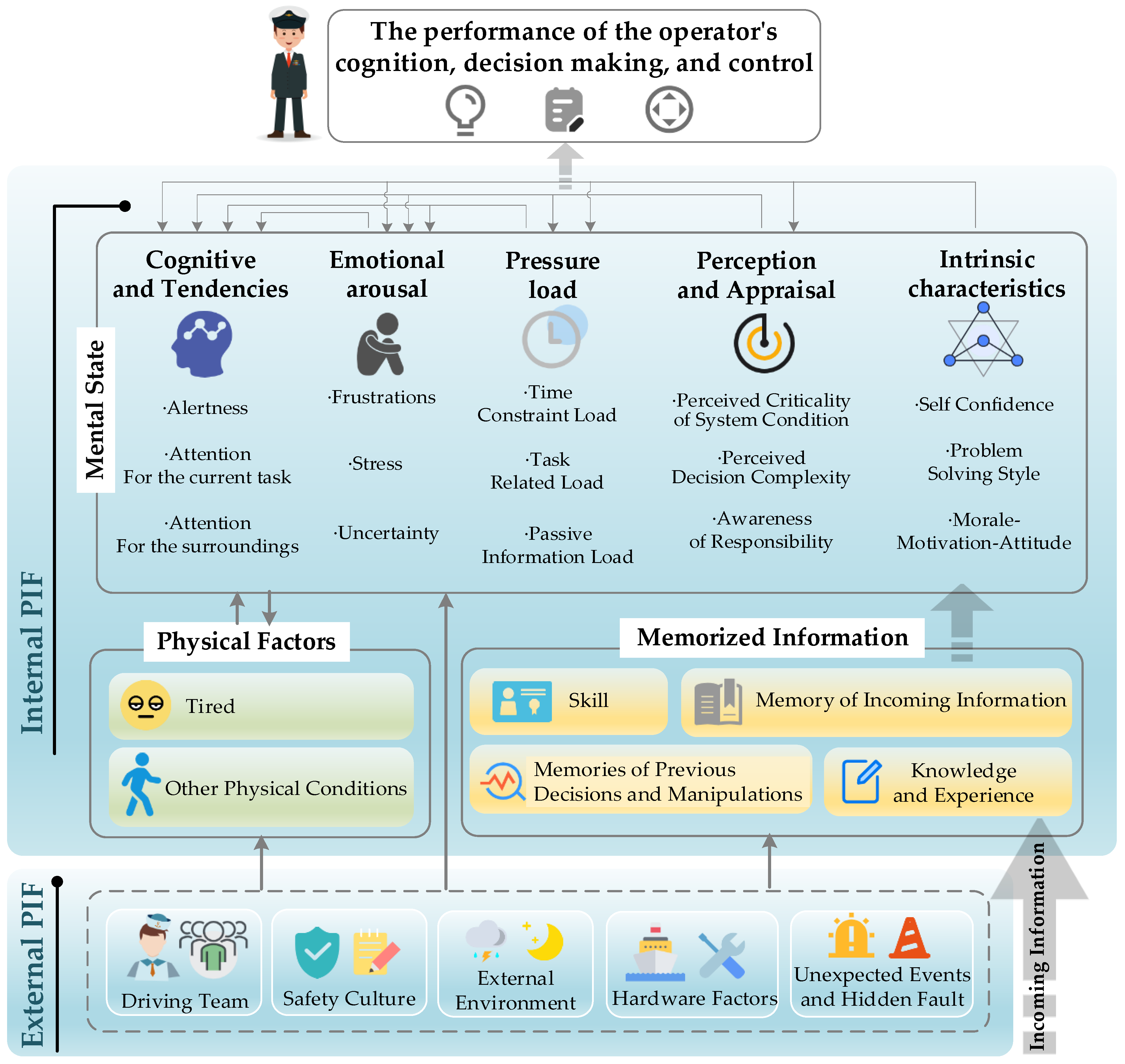

4.2. Performance-Influencing Factors (PIFs) for the Crews’ Response to Daily Navigation Task

When encountering an abnormal event during navigation, the natural responses of the operator usually include physical, cognitive, and emotional responses, all of which can affect each other. In addition to these internal factors, some external factors also play a role—for example, organizational factors.

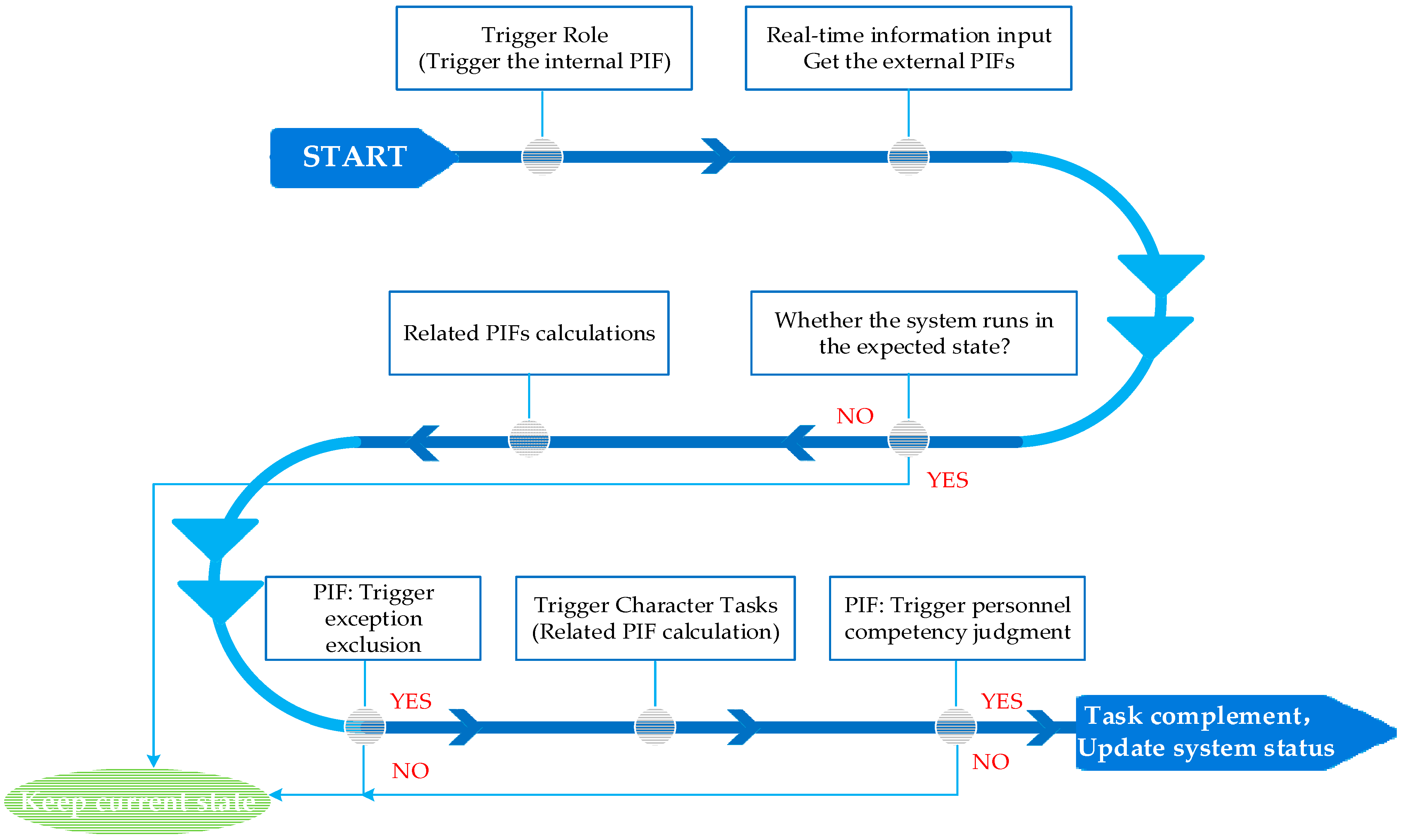

The operator’s behavior is affected by static and dynamic PIFs, which have captured both internal and external factors that may affect cognitive performance. In the current version of the MADS-IDAC system, the PIFs are divided into two groups and seven classes in the ship’s IDAC model. The states of the PIFs determine the operator’s mental state and affect their cognitive behavior. In the system, such an effect is manifested as an influence on the probabilities of nodes in the DDET.

When running the MADS-IDAC model, the PIFs are manifested as influences on the state-change probability of the IDAC model.

Figure 3 shows the task completion flowchart of a role, where the PIF exhibits an important effect, such that the deterministic decision-making process and the influencing factors of uncertainties are unified to present the entire decision-making process in a more complete form.

At the human cognition and decision-making level, PIFs show the interactions between human, machine, and environment, as well as the internal impact logic on decision makers’ and operators’ behavior. The hierarchical structures and influence paths of these PIFs are shown in

Figure 4.

Figure 4 shows that external PIFs refer to the external influence factors experienced by the crew during the cognitive process, which includes both the influence from the team and organization on the crew’s personal status and the real-time information obtained regarding the internal and external navigational status. The external PIFs affect the behavior of the crew by activating internal PIFs.

The degree of influence of physical factors, memory information, and mental and intellectual status varies for crews in different posts. For example, an OOW’s work is more dependent on the stability of their mental and intellectual state, whereas the performance of a crew member is mainly affected by physical factors. The captain’s post has the most demanding requirements for long-term memory information. A unique variation model, parameter system, and influence path can be assigned to each of these PIFs when constructing the IDAC model; they can have either a positive or negative impact on different links in the cognitive decision-making process.

5. Case Study

5.1. Introduction of the MADS-IDAC Risk Analysis Platform and Simulation Scenario Construction

5.1.1. Introduction of the MADS-IDAC Risk Analysis Platform

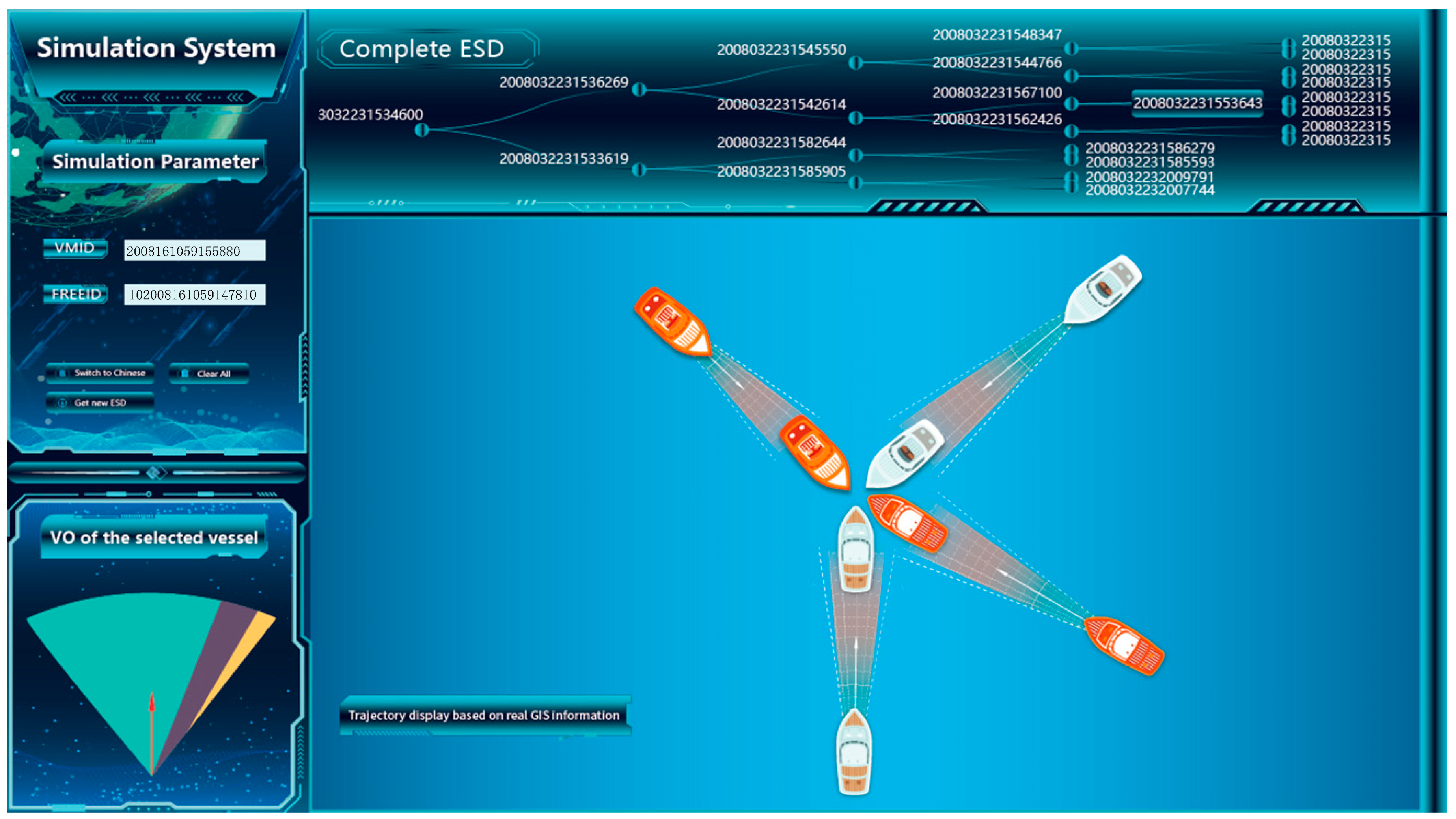

The MADS-IDAC system comprises the MADS system and IDAC model, where MADS is a general simulation engine for maritime accidents, and IDAC is a simulation object for a specific verification scenario—that is, the decision-making scenario for ship collision avoidance in this case. The web interface of the collision-avoidance decision-making simulation system developed for the two-ship encountering scenario is shown in

Figure 5. In this interface, users can easily traverse the entire ET and query the ship’s navigational status at every simulation node. In

Figure 5, the section for simulation system parameters on the upper-left-hand side can be used to call all the stored virtual machines (VMs) and ETs through the ID of the simulation VM or ET. The lower-left-hand side shows the risk situation calculated using the speed–obstacle method for the currently selected ship, where the green sector represents the safe navigational area. The entire ET for the current scene is shown on the upper-right-hand side. Next to each node is the ID of the simulation VM that the node is running. By clicking on any node, the scenario development trajectory during the period of the node can be displayed in the map below. By continuously clicking on the ET sequence from the initial event to any node, a complete development trajectory for a certain scenario can be plotted. The bottom-right-hand area shows the navigational history trajectory based on the map. Accordingly, the user needs to specify the specific longitude and latitude coordinates of the accident in the initial-state settings. For simulation convenience, a wide sea area east of the Shanghai Yangshan Port was selected as the experimental waters for a multi-ship collision-avoidance scenario in this section.

5.1.2. Input Information and Requirements of the MADS-IDAC System

(1) OHMI module

In the ship model, the operator performs information perception and operation through the OHMI module. The control scheme resembles an actual ship cockpit or engine room. The MADS-IDAC OHMI module—as the information interface between the operator and the ship’s mechanical model—displays four types of information:

The navigational status of the current ship and the other ships displayed on navigational aids (the AIS, ARPA, GPS systems, etc.) during actual navigation, including real-time position, speed, heading, etc.

The navigational status of the current ship displayed on the dashboard during actual navigation, including the current speed, heading, and rudder angle of the ship.

The operational status of the main propulsion and steering equipment such as the main engine and steering engine of the ship.

Alarm: alarm for collision risk(s) regarding the current navigational status or alarm for the failure of instruments and mechanical equipment regarding the ship status.

The information input to the OHMI module by the crew includes speed and heading information. The incoming information is used to represent the operating activities of the crew, which, through the ship’s hardware and hydrodynamics modules, will be reflected as actual changes in the ship’s speed and heading.

(2) Crew’s experience and knowledge base

In the MADS-IDAC system, each individual operator possesses a unique knowledge base and operational file to guide and regulate their behavior. The knowledge base includes: operational procedures and emergency plans for different accident scenarios; interactions between each link and the OHMI module, including information that needs to be queried, its processing methods, and the operational content that needs to be output; the position of the current post relative to the entire team, upstream and downstream posts of the information; and the response and processing of alarm information. In addition, uncertain factors that affect the operator’s performance are also included.

(3) System schedule module

When running the MADS-IDAC system, a new accident sequence will be generated when a branching rule is activated. To simplify the scenario and control the number of branches of the DDET, in the current version of the MADS-IDAC system, new branches will only be generated when the navigational status of the physical ship changes. Factors that can change the ship’s navigational status include:

The decision-based operational behavior of the human-factor system.

The ship’s hardware failure and mechanical failure events.

The safe collision-avoidance process or collision of the ship.

The simulation of a large number of sequences usually requires many computing resources and much time. Consequently, it is often necessary to terminate or truncate sequences of no research significance. The number of branches in the MADS-IDAC system is controlled by increasing the step length of the time series generated by the branch; however, a set of rules for terminating or truncating accident sequences (such as sequences with a termination probability below a certain small threshold value) are formulated.

5.1.3. Output Information and Requirements

Many output data files are generated from running the MADS-IDAC system. The DDET sequences are described by these files to identify the influencing factors that would lower the safety of the ship collision-avoidance scenario, thereby verifying the reliability of the ship collision-avoidance decision. This output information can either be visually displayed on the web interface developed for the MADS-IDAC system, or output as a JSON database file.

- (1)

DDET information: All the information needed to construct a graphical representation of the DDET is provided by the MADS-IDAC system output. The specific output of each branch event includes:

The type of branch event (initial event and subsequent events, post-decision events, safe scenario results, and collisions), the number of subsequent branches, and corresponding probabilities.

The activation time of branch events.

The sequence identifier associated with the branch event.

Based on the above data, the web interface can draw a complete dynamic event sequence tree for the ship collision accident. In addition to the data required to reconstruct the DDET, the MADS-IDAC system also provides a list of sequence summaries and a complete narrative description for each sequence. In a sequence summary, all event sequences generated during the simulation, the related sequence probabilities, termination times, and reasons for the sequence results are listed. In the sequence narrative, all OHMI module alarms, inter-crew communications, the time history of the interaction between the operator and the OHMI module, etc., are described.

- (2)

Cognition and decision-making information from the human cognitive system: The MADS-IDAC system has a built-in OHMI module scanning function for active information acquisition. During each scanning cycle, the system can output all the query information, received alarm information, decision content, and operational instructions of the human cognitive system contained in the scanning queue, as well as a list of the PIF parameters and related priorities at each time point. In the MADS-IDAC system, the output data of the cognitive and decision-making process of the human cognitive system includes:

The PIF status, such as human fatigue and continuous error accumulation.

Acquired information, such as navigational aid alarms, the ship’s current navigational status, and the information of the ship(s) encountered in the scenario.

Perception and understanding of the current scenario, such as the risk–value calculation of the scenario, and the prediction of the future status of the target ship.

Response strategies for the current scenario, such as making decisions for manual ship steering or gear shifting.

- (3)

Ship status data: In general, ships of different types have different hydrodynamic parameters, thus exhibiting different response characteristics to human operations. This affects the outcomes of collision avoidance and the PIFs (the hardware factors) of the human factor intelligent system. Therefore, to determine the influence of a specific set of ship hardware system configurations on the ship collision-avoidance process, the comprehensive time history records of a specific sequence of all OHMI module data streams, ship navigational status, and controller input values were provided in the MADS-IDAC system. The output information was stored in a JSON database file, and the navigational status information could also be visually displayed on the web interface developed for the MADS-IDAC system. Together with the preset ship hydrodynamic parameters, this information could be used to perform a comprehensive analysis on the influence of the ship’s status on the consequences of a collision.

5.2. Case Simulation and Results

5.2.1. Simulation Scenario Construction

In this section, a simulation of collision-avoidance decision making was performed in a two-ship encounter scenario. Real geographic environment information was adopted for physical modeling and simulation. This case was set in a wide water area in the sea east of the Zhoushan Islands, the location being approximately 123° E, 30.9° N. The specific initial-state settings of the ship are listed in

Table 1.

5.2.2. Simulation Experiment and Results

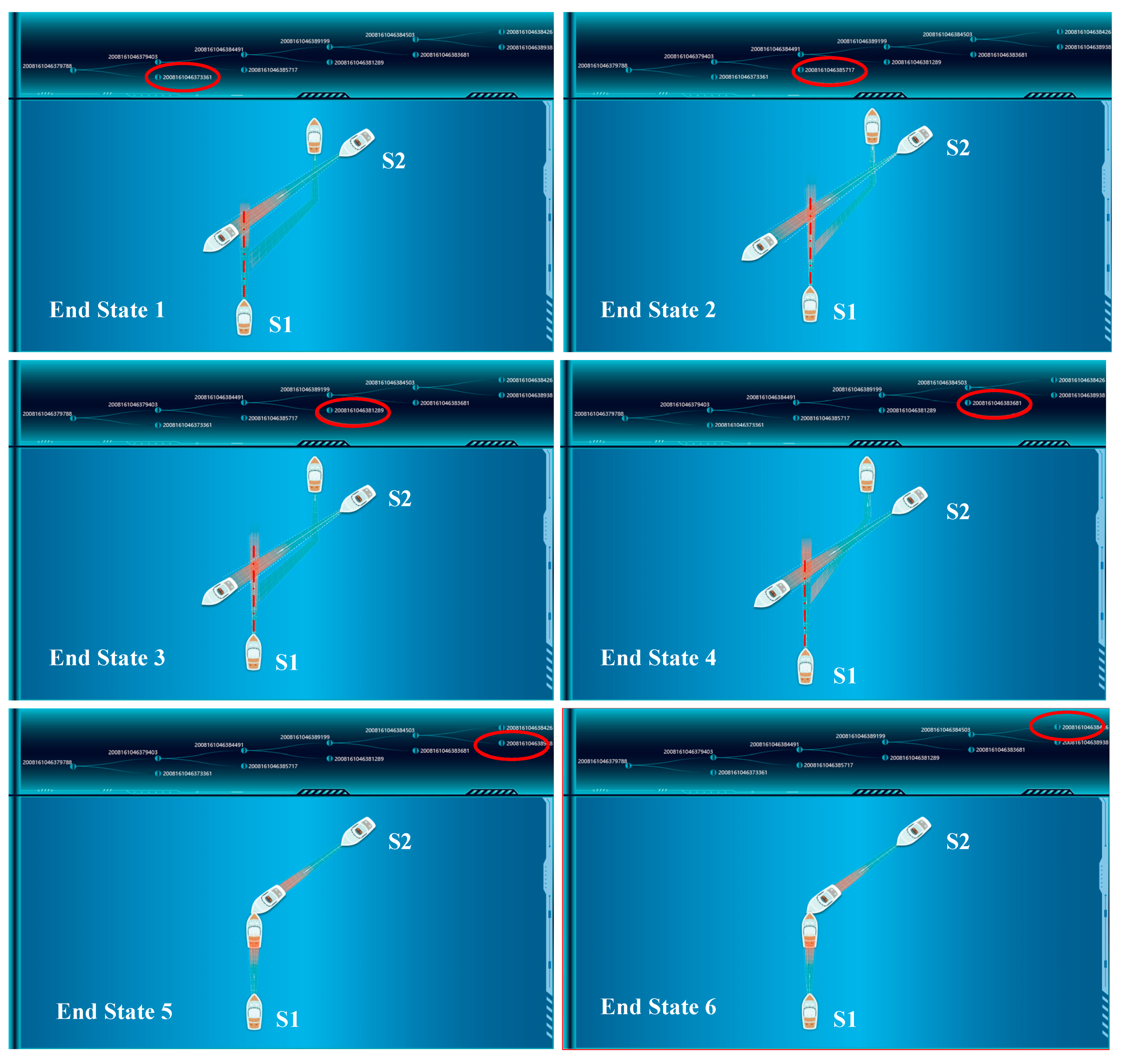

In this case study, two ships were selected from the multi-ship collision-avoidance scenario to perform a decision-making reliability test for collision avoidance in the encounter scenario. By running the system, a total of six different end states—including taking no collision-avoidance measures—were obtained; among them were four security end states and two collision scenarios. The specific calculation results are shown in

Table 2.

In this experiment, the branch generation scan step for the DDET was set to 6 min in the scenario control module of the MADS-IDAC system; that is, after every 6 min cycle of running the physical scenario, the system would check whether a new branch had been generated or not. Until the collision between the two ships 30 min later, a total of six end states had been generated. Among them, end states 1 to 4 successfully avoided a collision, attributed to timely collision-avoidance decisions. In the final state, due to the ship giving way not having enough time to make a collision-avoidance decision and collision-avoidance maneuvers, a ship collision accident occurred. That is, as the entire collision-avoidance event was simulated, a set of six schemes were generated after achieving the objective, of which the interaction strategy of end states 1 to 4 could be adopted to successfully complete the collision-avoidance task.

Figure 6 shows the trajectories of the two ships for all six end states. The upper right corner of each subfigure of

Figure 6 represents the currently running Event Sequence Diagram (ESD) state. The small characters are the number of each node, which is detailed in the system ID in

Table 2. The end state corresponding to the current scenario is circled in the ET shown in the upper region of

Figure 6, a red dashed line being used to mark the route extension of the ship giving way. In the case where neither of the two ships make a decision, they will collide at the intersection. Based on this, the decision timing for end states 1 to 4 can be compared. It can be seen that even in end state 4—when the collision-avoidance risk of the two ships was already high—the ship giving way still had a chance to successfully avoid collision. Under the current settings, the probabilities of the six end states are listed in

Table 2.

5.3. Discussion

As the complexity of systems continue to increase, HCI has become increasingly more critical. People are also becoming more aware of the importance of the system operator’s behavior to the entire HMS performance. Our research results show that the established MADS-IDAC system can simulate and analyze a crew’s decision-making reliability in shipping risk scenarios, obtaining the probabilities of successful decision making at different timings as well as the logic of various influencing factors on the timing of decision making. By simulating a real risk scenario, an exhaustive set of interaction strategies was predicted. In the process of achieving the safety objective, the optimal strategy can be selected based on the developing changes in a situation. At the same time, in the interaction strategy of a failure scenario, the risk probability of the problem node can also be adjusted to establish the weak link(s) in the interaction process. The top-level interaction layer searches for risk problems in the cognitive decision-making layer and physical layer (e.g., risk accidents caused by human decision making or machine operations) from top to bottom, and identifies the causes.

This study proposed a relatively complete architecture of a ship HCI framework, including a physical layer, a cognitive decision-making layer, an interaction layer, and a data layer. Moreover, a dynamic simulation method for maritime accidents based on cognition, decision making, and operational models was proposed, and a dynamic risk analysis system for maritime accidents—that is, the MADS-IDAC system—was constructed. The interaction strategies predicted and generated in the simulation environment were found to improve a ship’s HCI capabilities, serving as an effective strategy generation tool for measuring HCI performance. In real scenarios, it could also generate prediction plans for safe collision avoidance through real-time simulation before encountering risks.

6. Conclusions

With the continuing development of ergonomics, cognitive engineering, and other disciplines, system engineers are paying increasing attention to human performance and human error analyses. A large number of practical HRA methods have been developed in the fields of reliability, safety engineering, and risk analysis. However, in the maritime field, there has been no predictive model that has considered the operator’s cognitive behavior, exhibiting both theoretical bases as well as experimental verifications. To fill this research gap, this study proposed an architecture for a knowledge-based ship HCI framework. By focusing on the cognitive process of the crew in the context of accident and risk handling during ship navigation, as well as the dynamic probability simulation, based on the IDAC model, MADS enhanced by HCI can effectively generate a strategy set of various outcomes in preset scenarios. The reliability of HCI on the ship can be improved effectively through these interaction strategies. This study has also provided a new research approach and interaction strategies for preventing human error, promoting the research of human error in the interaction process of complex systems from a descriptive and predictive perspective.

The main contributions of this paper can be summarized as follows:

A knowledge-based ship HCI framework was proposed, the proposed framework fully considering the interaction process in the cognitive-processing model of operating crew responses to daily navigational work on a cargo ship.

A dynamic simulation method of maritime accidents based on cognitive, decision making, and operational models was proposed from the perspective of HCI onboard aims at modeling the crew’s daily navigation task execution process. This method could simulate and analyze the crew’s decision-making reliability in risk scenarios for ships by generating a DDET through simulation, predicting and generating an exhaustive set of interaction strategies, as well as obtaining the probabilities of successful decision making at different timings.

This paper presents a method of human–machine interaction strategies based on a cognitive-process model. It provides a new method and thought for avoiding human error in crew interaction and to lower the risk of ship collision as well as effectively improving the reliability of human–computer interaction.

The MADS-IDAC was enhanced from the perspective of HCI structure and function design of the dynamic risk analysis platform for maritime accidents. The HCI-enhanced MADS-IDAC method provided both a theoretical basis and practical experience for the development of accident dynamic modeling, software reliability analysis, and HRA in the maritime and transportation fields.

Despite the abovementioned advantages, there are still limitations to this research. For instance, the development of the MADS-IDAC system is still in its infancy. At the current stage, it can only simulate ship collision scenarios in wide waters. In the future, further development efforts can be devoted to a more refined parameter library for the human reliability model, a more substantial algorithm library for the intelligent decision-making system, a more complete library for the ship’s hydrodynamic model, as well as a more comprehensive library for maritime accident scenarios.