Abstract

Sustainability and environmental concerns have been important topics of discussion in recent decades. Green supply chain management assures the effectiveness of public and company policies in greening their operations, increasing the market share, improving the company image and reputation, and increasing profits. The objective of this article is to propose a conceptual framework that considers dimensions, categories, and practices in green supply chain management. After an extensive review of the literature, we identified models and a set of green dimensions, categories, and practices used for green supply chain management. From the analysis of the findings, we propose a conceptual framework that is organized into 3 environmental dimensions, 21 categories, and 64 green practices. The framework can contribute to the literature, given that empirical studies mostly select a limited set of dimensions to evaluate supply chain green practices. Finally, this study offers directions for future research.

1. Introduction

In the past few years, approximately 70% of the leading companies in their sectors have emphasized sustainability in their work agenda. Leading companies’ reports reinforce that the success of their sustainability efforts also depends on the collaboration with the supply chain (SC) actors [1,2]. In this context, green supply chain management (GSCM) has contributed to the effective implementation of eco-efficiency [3], renewable energy sources [4], and sustainable actions [5] in the SC, in innovation clusters [6] as well as in symbiotic industrial networks [7]. Green or sustainable supply chain management (SSCM) involves integrating environmental and economic objectives into the management of the operation strategy of the supply chain. Such integration helps reduce the carbon footprint while increasing financial return and profitability [8]. A wider concept is SSCM, which aims to maximize profitability and, at the same time, reduce the environmental impact and improve the social well-being of the various involved stakeholders [9]. Ahi and Searcy [10] identified 22 different definitions for GSCM and 12 for SSCM. In this article, we use the term GSCM, despite recognizing the alternative use of SSCM [11,12].

Bowen et al. [13], p. 176, define GSCM as the “Integration of the company’s purchase plans with the environmental activities in SCM, to improve the environmental performance of suppliers and customers.” GSCM also includes concerns about product design, use, reuse, disassembly, and final disposal [14], as well as warehousing, transportation, supplier development to meet green requirements in purchasing, and stimulus for the adoption of environmental certifications such as ISO 14000 [14,15]. Zhu and Sarkis [16] conceptualize GSCM as the integration of environmental thinking with operations management in the SC, starting with the product design and passing through the selection of raw materials, manufacturing processes, transportation and delivery, and the final consumer arriving at the final destination after use. Large and Thomsen [17] states that GSCM includes the design process, raw material selection, green procurement, the green manufacturing process, green distribution, and reverse logistics.

GSCM involves many functions within and outside organizations and a wide set of activities. However, a limited number of articles proposed GSCM models [18], most of them approaching the issue only partially [19]. A large number of empirical studies (case studies) published and a small number of GSCM models are cited by [18]. Other articles derive from case studies and mathematical and conceptual analyses [18,20,21,22], which characterizes a gap in the current research in GSCM. Therefore, the gap this article aims to bridge is to propose a structured model to guide GSCM analysis: a conceptual model framework that considers dimensions and categories to facilitate the discussion of green practices in GSCM.

This study poses the following research question: How do you organize green practices observed in GSCM in a model formed by dimensions and categories of analysis? In answer, this work highlights key factors that should be analyzed by GSCM models. Secondary purposes are to (i) review green management models and practices published from 2003 to 2019; (ii) propose a conceptual framework for managing green practices in GSCM, and (iii) propose directions for future research to amplify the application of the framework. These are the key issues of the study.

Green practices are operations that seek to reduce or eliminate negative impacts on the environment [23]. Greening is typically associated with the implementation of green practices in SCs [24,25], which requires multidimensional models and approaches [26]. This study approaches GSCM as a multidimensional problem. The model framework relies on dimensions supported by analytical categories [27], evolves from other models, and covers a larger set of dimensions and categories when compared to other models already proposed. Our framework details 64 green practices. These are the key factors addressed by this study. This number allows for more extensive analysis when compared with the models existing in the literature [23,28,29]. The models retrieved from the literature do not support more than 25 green practices, and this is the main novelty of our study.

Moreover, the framework provides support to identify environmental weaknesses and to assess and prioritize corrective actions in SCs. Green practices are considered at the level of the SC, covering internal practices and upstream and downstream relationships [5,30] as well as creating room for systemic possibilities [31] and systemic methods [32]. The key motivation of the study is the construction of a consistent tree-like structure or framework organizing key green practices that could facilitate many kinds of stakeholders (practitioners, managers, and scholars) who need to handle environmental concerns in managing supply chains.

The remainder of the article is organized as follows: Section 2 details the research methodology. Section 3 presents the results of the systematic review of the literature. Section 4 presents the conceptual framework and details of the dimensions, categories, and green practices. Section 5 discusses the research findings and conclusions.

2. Methodology and the Sample of Articles

Kassarjian [33] provides the following definition for a systematic literature review: “Systematic reviews aim to address problems by identifying, critically evaluating, and integrating the findings of all relevant, high-quality individual studies addressing one or more research questions.” Bearing such a definition in mind, our review pursues two objectives: Summarize recent research retrieving and interpreting similarities, themes, and issues on GSCM and contribute to the conceptual development of the theme and the future formation of a theory [34]. From a methodological perspective, the systematic literature review includes qualitative and quantitative aspects combined to evaluate structural and content standards. Therefore, the methodology used in this study follows the steps below [34]:

- −

- definition of the unit of research (models for structuring GSCM issues);

- −

- delimitation of the search: (i) only articles in English in peer-reviewed scientific journals published between 2010 and 2020; (ii) the use of Science Direct (www.sciencedirect.com accessed on 16 June 2021) and Emerald (www.emeraldinsight.com accessed on 16 June 2021) databases; and (iii) four journals outside databases (Chemical Engineering Transactions, International Journal of Applied Science and Engineering Research, Journal of Sustainable Development, and Journal of Operations and Supply Chain Management);

- −

- collection of articles according to the keyword green supply chain management, combined with green operation, green practices, and green performance;

- −

- reading and selection of articles: the rough sample was entirely reviewed and a final, refined sample was identified;

- −

- complete review of the final sample and description of the structural elements of the articles: bibliometric description of authors, journals, and studies;

- −

- content analysis of the retrieved GSCM models for the identification of dimensions and categories of analysis;

- −

- evaluation of the content of the articles of the final sample; and

- −

- identification of similarities of dimensions and construction of the structure for the conceptual framework.

In the content analysis, we assessed models and classified green practices in GSCM according to dimensions and categories of analysis. Three external experts, two scholars from research institutes with experience in supply chain management and one scholar with previous experience in supply chains as a practitioner in the industry, participated in the analysis. The participation of specialists minimizes interpretation risks and subjectivities [34]. Finally, we constructed and proposed a conceptual framework for the management of green practices in SC.

3. Descriptive Analysis

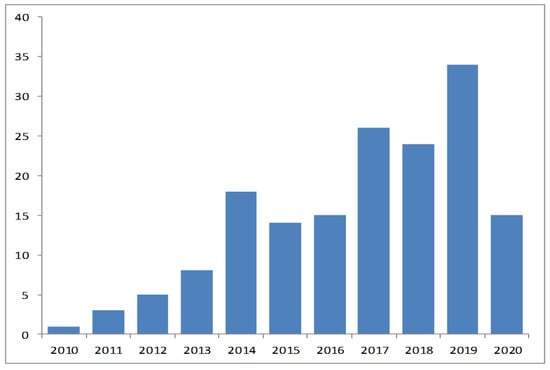

Seuring and Müller [34] state that the first publications related to GSCM date from 1994. However, the main publications appear at the beginning of the 21st century and become significant from 2010 [35], the year of the beginning of the analysis. Table 1 shows the keywords employed in the search and the number of the roughly selected articles. Figure 1 represents the time distribution of the roughly selected articles.

Table 1.

Keywords and selected articles.

Figure 1.

Time distribution of the first selection of articles.

By the title and the abstracts, we selected a refined, focused sample of 43 articles with the greatest adherence to the purpose of the research. We read in full the entire sample prior to proceeding with the descriptive analysis. The descriptive analysis contributes to the identification of the models, the dimensions, and the categories of analysis of green practices [36]. The descriptive analysis of the sample considered the following issues: Who are the main authors? What are the main journals? What are the main existing models for managing green practices in SC? What are the dimensions and categories identified in the sample? How often are the categories referenced?

3.1. Authors and Journals

Table 2 shows the three authors with the highest concentration of articles (individually or jointly) on GSCM and the main authors of the theme. The authors are also among the top 10 authors in the bibliometric review on GSCM published by Fahimnia et al. [35].

Table 2.

Main authors of selected articles.

Table 3 shows the journals. Five journals contribute 46% of the sample: Journal of Cleaner Production, International Journal of Operations and Production Management, Transportation Research Part E: Logistics and Transportation Review, Procedia—Social and Behavioral Sciences, and Resources, Conservation, and Recycling.

Table 3.

Journals that published the articles of the sample.

3.2. Models in GSCM

We identified six articles that consider complete and structured models for the evaluation of green practices in SC. We considered models that resemble a tree-like structure [37], that is, a top term supported by constructs that can be appraised by manifest variables or indicators [38].

3.2.1. Srivastava (2007)

The author reviews the literature on GSCM (approximately 1500 volumes, totaling 227 references). The author employed a tree-like structure, namely a top term (GSCM), 3 dimensions, and 14 categories, related to a set of green practices. As an early model, it has a certain amount of imbalance, as only two practices support the first dimension, the green design. Therefore, the author distributes the scope of GSCM into three main categories of analysis: environmental importance, eco-design, and green operations. Table 4 shows the organization of the dimensions and categories proposed by the author.

Table 4.

Green supply chain management (GSCM) dimensions and criteria.

3.2.2. Seuring and Muller (2008)

The authors review 191 articles published between 1994 and 2007, which supported the proposition of a sustainable theoretical framework and a set of green practices for GSCM [34]. According to the authors, focal companies are responsible for the environmental and social performance of suppliers and distributors, encouraging extension in the adoption of environmentally friendly practices. The authors also mention that the discussion of GSCM goes beyond environmental management and should include economic and social aspects. However, in their sample of articles, environmental concern is the most referenced category, as shown in Table 5.

Table 5.

Dimensions discussed in articles on sustainable development.

The authors identified three main dimensions for GSCM: pressures, incentives, and barriers; green supplier management; and green product management. Table 6 summarizes the main points that support pressures, barriers, and incentives.

Table 6.

Pressures, barriers, and incentives.

Table 7 considers the main points that support green supplier management.

Table 7.

Green supplier factors.

Regarding green product management, the authors include a discussion of firms’ ability to make products environmentally friendlier, which includes eco-design and lifecycle analysis, aiming mainly at the reduction of waste and agility in disassembly and disposal.

3.2.3. Zhu, Sarkis, Cordeiro, and Lai (2008)

The authors propose a model that structures green practices into five blocks: internal environmental management, green purchasing, cooperation with clients, eco-design, and investment recovery [29]. The authors identify that the variables have significant correlations with GSCM. Table 8 shows the model that the authors propose with a measurement scale to evaluate the implementation of GSCM practices. The model was tested for its validity and reliability in the Chinese industry.

Table 8.

Structure of the green practice measurement model for GSCM.

3.2.4. Testa and Iraldo (2010)

The authors analyze the determinants and motivators of green practice adoption and environmental and organizational performance. The study applied to 4000 organizations from different sectors in seven countries and tested whether GSCM positively influences environmental performance and the reputation of firms. The study classified the determinants into external and internal factors, related respectively to the pressures of the stakeholders and the company’s business strategies [40].

Regarding external factors, the authors verify that three institutional mechanisms influence environmental decisions: normative, coercive, and mimetic. Normative pressures occur when clients ask to align firm strategy with customer demands and regulatory pressure. Coercive pressure occurs when stakeholders influence the dissemination of environmental reports. Mimetic pressure results when the development of environmental practices in specific sectors or competitive arenas becomes so significant that it induces their adoption by followers. Regarding internal factors, the three most observed motivations for the adoption of GSCM practices are reputation, which involves environmental performance, lifecycle analysis, green logistics practices, and cooperation with partners; efficiency, which involves the reduction of raw materials and energy; and innovation, typically led by a focal company.

3.2.5. Azevedo, Carvalho, and Cruz Machado (2011)

The authors identify the relations between green practices and SC performance. The study applied to five Portuguese automotive supply chains. The authors retrieve from the literature a set of green practices analyzed at three levels: upstream of the focal company, developed by and depending exclusively on the focal company, and downstream of the focal company [23]. Table 9 transcends the evaluation of practices at the focal company level but also considers suppliers and consumers.

Table 9.

The theoretical framework of the influence of green practices on the performance of the supply chain (SC).

3.2.6. Sellitto (2018)

Sellitto [37] unified previous research. Sellitto et al. [8] propose a green practice management model applied to the Brazilian automotive chain. The study tested and refined a model to evaluate the effectiveness of GSCM implementation. Sellitto and Hermann [28] improved the model by adding a fuzzy-based decision method and implemented it in the agro-food industry. Based on those studies, the application was extended to other industries [37]. The model adopts a tree-like structure, formed by an overall concept (GSCM), supported by three constructs (Strategy, Innovation, Operation), that are also supported by 16 green practices. Table 10 shows the model.

Table 10.

The theoretical framework of green practices in SC.

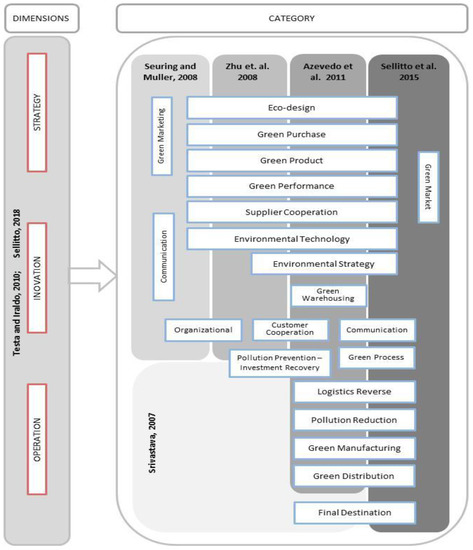

3.3. Summary of GSCM Models

To synthesize the analysis, it is necessary to integrate the retrieved categories and concepts into a single model as simply as possible. To do so, it is important to summarize the main results retrieved from the studies and to propose a model. From a paired analysis of the dimensions and categories exposed by the models, we found similarities in the category levels and dimensions. Table 11 summarizes the objectives and main results identified in the models. Figure 2 summarizes the dimensions and categories observed in the retrieved models.

Table 11.

Selected studies related to GSCM.

Figure 2.

Dimensions and categories observed in reviewed models.

A considerable part of the categories is related to one or more authors. For example, eco-design is discussed by [23,29,34,37], Refs. [37,40] present three dimensions, while [39] introduces the operations dimension. The other authors did not introduce dimensions.

3.4. Identification of the Key GSCM Categories

The dimensions and categories mapped from the revised conceptual models helped to identify 21 categories and 3 dimensions. Table 12 relates articles to categories, analyzing the frequency of appearance. Eco-design, green purchase, and customer cooperation appear, respectively, in 84%, 56%, and 49% of the articles.

Table 12.

Dimensions and categories in GSCM.

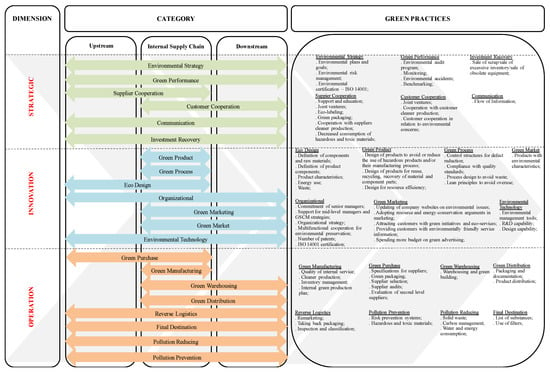

4. Conceptual Framework and Green Practices

The information provided by the articles helped to define the framework categories. Subsequently, invited specialists reviewed the main concepts underlying the categories and aggregated similar ones (e.g., green design and eco-innovation were jointly framed as eco-design). The systematic review of the literature provided information and data, but the specialists’ review guided and grounded the construction of the conceptual framework. Categories were organized considering their relationship with the dimensions and their relations and interactions within the SC (upstream, internal activities in the focal company, and upstream level). The specialists, together with the researchers, also classified 64 green practices retrieved from the literature in accordance with the categories.

Some of the categories can influence more than one sector of a typical SC. To deal with and illustrate this characteristic, the SC structure was separated into upstream (incoming materials and services), internal supply chain (the focal company and some small companies whose strategy is controlled by the focal company), and downstream (distribution and delivery materials and services) [23]. For example, the environmental strategy involves the three phases of the SC, supplier cooperation involves the first two, while customer cooperation involves the last two. Figure 3 shows the final conceptual framework, formed by 21 categories, 3 dimensions, and 64 green practices.

Figure 3.

A conceptual framework for green practices in GSCM.

4.1. Green Practices within the Categories of the Strategic Dimension

The strategic dimension includes 6 categories and 18 documented practices. Table 13 shows the practices allocated in the categories of the dimension and suitable references that provide empirical evidence of the application.

Table 13.

Green practices in the categories of the strategic dimension.

4.2. Green Practices within the Categories of the Innovation Dimension

Green innovation supports environmental sustainability by promoting changes to processes with less environmental impact [40,52]. Product and process innovations are involved in energy saving, pollution prevention, waste recycling, green or corporate product design, and environmental management [20]. Table 14 shows the practices allocated in the categories of the dimension and suitable references that provide empirical evidence of the application.

Table 14.

Green practices in the categories of the innovation dimension.

4.3. Green Practices within the Categories of the Operations Dimension

Environmental costs, production, logistics, processes, purchasing, and the reverse logistics process characterize SC green operations. Table 15 shows the practices allocated to the categories of this dimension and suitable references that provide empirical evidence of the application.

Table 15.

Green practices in the categories of the operations dimension.

5. Final Remarks, Implications, and Directions for Future Research

This study proposes a comprehensive conceptual framework that bridges the gap related to the need for effective models for GSCM. The conceptual framework considers dimensions, categories, and green practices identified in the literature. The proposed model can contribute to the literature given that empirical studies mostly select a limited number of dimensions to evaluate supply chain green practices.

The study has practical implications, mainly for service and industrial practitioners, managers, scholars, and government policymakers. Practitioners can use the results to implement management programs based on GSCM principles. Each category of analysis may provide guidelines for future implementation of green practices in SC. Practitioners can also use the prescribed model to assess the status of their SC regarding eco-efficiency, energy management, and other emergent issues regarding how manufacturing and service supply chains handle environmental issues. In handling our model of analysis, and supported by multicriteria techniques, managers can prioritize dimensions, constructs, and indicators according to the importance they demonstrate concerning SC strategic objectives. Scholars can use the proposed model for further in-depth studies, such as surveys in regional energy-intensive industries, waste producers, and various generators of carbon footprints. Finally, governmental policymakers of regional development policies can use the model to stimulate the development of regional initiatives aimed at innovative industries. Public policies developed on the basis of our model may promote equality and development regarding environmental issues, mainly concerning service and manufacturing SC.

Although the article analyzes green practices in SC retrieved from the systematic review of the literature, the study did not consider other elements such as pressure and incentives that influence green practices and their results. Predominantly, green practices in SC will be more or less effective according to the presence or absence of enablers or moderators such as pressure and incentives.

The sample size of articles, 43 articles, is the main limitation of this study. A secondary limitation is the number of dimensions, practices, and categories identified. This number can increase with the social dimension, which will imply using other keywords besides the current “green supply chain management.”

From the study, we derive future research directions. As quantitative models to GSCM analysis use a limited number of dimensions, further research should introduce new dimensions. Examples of new dimensions are corporate social responsibility and networking operations. The proposed conceptual framework requires empirical studies on the dimensions and categories in GSCM through the implementation of case studies. Another area in which studies are needed is more surveys in entire industries. An example is the agro-food SC, since such an industry has a significant impact on the international economic and environmental scenario [74]. Over time, there have been a limited number of studies evaluating the adoption of green practices in agro-food SC [28,38,74], mainly regarding production [75], warehousing, and transportation [76]. Similar studies could be applied to research on emerging markets [18], e-business [77], e-commerce [78], and renewable energy industries [79].

Author Contributions

Conceptualization, F.F.H. and A.P.B.-P.; methodology: A.P.B.-P.; validation and formal analysis: M.A.B. and S.M.; writing—original draft: F.F.H. and A.P.B.-P., writing—review and editing, M.A.B., S.M., and M.A.S.; supervision, M.A.S.; project administration, M.A.S.; funding acquisition, A.P.B.-P. and M.A.S. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

No new data were created or analyzed in this study. Data sharing is not applicable to this article.

Acknowledgments

CNPq: the Brazilian Agency for Scientific Research partially supported this study under the grant numbers [464140/2014-5; 303574/2016-0; 302570/2019-5]. Unisinos partially supported this study by grants provided by the Doctoral College Tordesillas.

Conflicts of Interest

The authors declare no conflict of interest.

References

- de Sousa Jabbour, A.B.L.; Jabbour, C.J.C.; Latan, H.; Teixeira, A.A.; De Oliveira, J.H.C. Quality management, environmental management maturity, green supply chain practices and green performance of Brazilian companies with ISO 14001 certification: Direct and indirect effects. Transp. Res. Part E Logist. Transp. Rev. 2014, 67, 39–51, reprinted in Transp. Res. Part E Logist. Transp. Rev. 2015, 74, 139–151. [Google Scholar] [CrossRef]

- de Sousa Jabbour, A.B.L. Understanding the genesis of green supply chain management: Lessons from leading Brazilian companies. J. Clean. Prod. 2015, 87, 385–390. [Google Scholar] [CrossRef]

- Ala-Harja, H.; Helo, P. Green supply chain decisions—Case-based performance analysis from the food industry. Transp. Res. Part E Logist. Transp. Rev. 2014, 69, 97–107, reprinted in Transp. Res. Part E Logist. Transp. Rev. 2015, 74, 11–21. [Google Scholar] [CrossRef]

- Garlet, T.B.; Ribeiro, J.L.D.; Savian, F.D.S.; Siluk, J.C.M. Paths and barriers to the diffusion of distributed generation of photovoltaic energy in southern Brazil. Renew. Sustain. Energy Rev. 2019, 111, 157–169. [Google Scholar] [CrossRef]

- Zhu, Q.; Sarkis, J.; Lai, K.-H. Institutional-based antecedents and performance outcomes of internal and external green supply chain management practices. J. Purch. Supply Manag. 2013, 19, 106–117. [Google Scholar] [CrossRef]

- Sellitto, M.A.; Camfield, C.G.; Buzuku, S. Green innovation and competitive advantages in a furniture industrial cluster: A survey and structural model. Sustain. Prod. Consum. 2020, 23, 94–104. [Google Scholar] [CrossRef]

- Sellitto, M.A.; Murakami, F.K.; Butturi, M.A.; Marinelli, S.; Kadel, N.J.; Rimini, B. Barriers, drivers, and relationships in industrial symbiosis of a network of Brazilian manufacturing companies. Sustain. Prod. Consum. 2021, 26, 443–454. [Google Scholar] [CrossRef]

- Sellitto, M.A.; Bittencourt, S.A.; Reckziegel, B.I. Evaluating the implementation of GSCM in industrial supply chains: Two cases in the automotive industry. Chem. Eng. Trans. 2015, 43, 1315–1320. [Google Scholar] [CrossRef]

- Kusi-Sarpong, S.; Gupta, H.; Sarkis, J. A supply chain sustainability innovation framework and evaluation methodology. Int. J. Prod. Res. 2018, 57, 1990–2008. [Google Scholar] [CrossRef] [Green Version]

- Ahi, P.; Searcy, C. A comparative literature analysis of definitions for green and sustainable supply chain management. J. Clean. Prod. 2013, 52, 329–341. [Google Scholar] [CrossRef]

- Zimon, D.; Tyan, J.; Sroufe, R. Drivers of sustainable supply chain management: Practices to alignment with UN sustainable development goals. Int. J. Qual. Res. 2020, 14, 219–236. [Google Scholar] [CrossRef]

- Zimon, D.; Tyan, J.; Sroufe, R. Implementing Sustainable Supply Chain Management: Reactive, Cooperative, and Dynamic Models. Sustainability 2019, 11, 7227. [Google Scholar] [CrossRef] [Green Version]

- Bowen, F.E.; Cousins, P.D.; Lamming, R.C.; Farukt, A.C. THE role of supply management capabilities in green supply. Prod. Oper. Manag. 2009, 10, 174–189. [Google Scholar] [CrossRef]

- Sarkis, J. A strategic decision framework for green supply chain management. J. Clean. Prod. 2003, 11, 397–409. [Google Scholar] [CrossRef]

- Sarkis, J.; Zhu, Q.; Lai, K.-H. An organizational theoretic review of green supply chain management literature. Int. J. Prod. Econ. 2011, 130, 1–15. [Google Scholar] [CrossRef]

- Zhu, Q.; Sarkis, J. An inter-sectoral comparison of green supply chain management in China: Drivers and practices. J. Clean. Prod. 2006, 14, 472–486. [Google Scholar] [CrossRef]

- Large, R.O.; Thomsen, C.G. Drivers of green supply management performance: Evidence from Germany. J. Purch. Supply Manag. 2011, 17, 176–184. [Google Scholar] [CrossRef]

- Gunasekaran, A.; Subramanian, N.; Rahman, S. Green supply chain collaboration and incentives: Current trends and future directions. Transp. Res. Part E Logist. Transp. Rev. 2015, 74, 1–10. [Google Scholar] [CrossRef]

- Gong, R.; Xue, J.; Zhao, L.; Zolotova, O.; Ji, X.; Xu, Y. A bibliometric analysis of green supply chain management based on the Web of Science (WOS) platform. Sustainability 2019, 11, 3459. [Google Scholar] [CrossRef] [Green Version]

- Bose, I.; Pal, R. Do green supply chain management initiatives impact stock prices of firms? Decis. Support Syst. 2012, 52, 624–634. [Google Scholar] [CrossRef]

- Igarashi, M.; De Boer, L.; Fet, A.M. What is required for greener supplier selection? A literature review and conceptual model development. J. Purch. Supply Manag. 2013, 19, 247–263. [Google Scholar] [CrossRef]

- Kushwaha, G.S.; Sharma, N.K. Green initiatives: A step towards sustainable development and firm’s performance in the automobile industry. J. Clean. Prod. 2016, 121, 116–129. [Google Scholar] [CrossRef]

- Azevedo, S.G.; Carvalho, H.; Machado, V.C. The influence of green practices on supply chain performance: A case study approach. Transp. Res. Part E Logist. Transp. Rev. 2011, 47, 850–871. [Google Scholar] [CrossRef]

- Holt, D.; Ghobadian, A. An empirical study of green supply chain management practices amongst UK manufacturers. J. Manuf. Technol. Manag. 2009, 20, 933–956. [Google Scholar] [CrossRef]

- Laosirihongthong, T.; Adebanjo, D.; Tan, C.K. Green supply chain management practices and performance. Ind. Manag. Data Syst. 2013, 113, 696–710. [Google Scholar] [CrossRef] [Green Version]

- Uygun, Ö.; Dede, A. Performance evaluation of green supply chain management using integrated fuzzy multi-criteria decision making techniques. Comput. Ind. Eng. 2016, 102, 502–511. [Google Scholar] [CrossRef]

- Beske, P.; Land, A.; Seuring, S. Sustainable supply chain management practices and dynamic capabilities in the food industry: A critical analysis of the literature. Int. J. Prod. Econ. 2014, 152, 131–143. [Google Scholar] [CrossRef]

- Sellitto, M.A.; Hermann, F.F. Prioritization of green practices in GSCM: Case study with companies of the peach industry. Gest. Prod. 2016, 23, 871–886. [Google Scholar] [CrossRef] [Green Version]

- Zhu, Q.; Sarkis, J.; Cordeiro, J.J.; Lai, K.-H. Firm-level correlates of emergent green supply chain management practices in the Chinese context. Omega 2008, 36, 577–591. [Google Scholar] [CrossRef]

- Rao, P.; Holt, D. Do green supply chains lead to competitiveness and economic performance? Int. J. Oper. Prod. Manag. 2005, 25, 898–916. [Google Scholar] [CrossRef]

- Sellitto, M.A.; Luchese, J.; Bauer, J.M.; Saueressig, G.G.; Viegas, C.V. Ecodesign practices in a furniture industrial cluster of southern Brazil: From incipient practices to improvement. J. Environ. Assess. Policy Manag. 2017, 19, 1750001. [Google Scholar] [CrossRef]

- Storch, L.A.; Nara, E.O.B.; Kipper, L.M. The use of process management based on a systemic approach. Int. J. Prod. Perform. Manag. 2013, 62, 758–773. [Google Scholar] [CrossRef]

- Kassarjian, H.H. Content analysis in consumer research. J. Consum. Res. 1977, 4, 8–18. [Google Scholar] [CrossRef]

- Seuring, S.; Müller, M. From a literature review to a conceptual framework for sustainable supply chain management. J. Clean. Prod. 2008, 16, 1699–1710. [Google Scholar] [CrossRef]

- Fahimnia, B.; Sarkis, J.; Davarzani, H. Green supply chain management: A review and bibliometric analysis. Int. J. Prod. Econ. 2015, 162, 101–114. [Google Scholar] [CrossRef]

- Soni, G.; Kodali, R. A critical review of supply chain management frameworks: Proposed framework. Benchmarking Int. J. 2013, 20, 263–298. [Google Scholar] [CrossRef]

- Sellitto, M.A. Assessment of the effectiveness of green practices in the management of two supply chains. Bus. Process. Manag. J. 2018, 24, 23–48. [Google Scholar] [CrossRef]

- Nara, E.O.B.; Gelain, C.; Moraes, J.A.R.; Benitez, L.B.; Schaefer, J.L.; Baierle, I.C. Analysis of the sustainability reports from multinationals tobacco companies in southern Brazil. J. Clean. Prod. 2019, 232, 1093–1102. [Google Scholar] [CrossRef]

- Srivastava, S.K. Green supply-chain management: A state-of-the-art literature review. Int. J. Manag. Rev. 2007, 9, 53–80. [Google Scholar] [CrossRef]

- Testa, F.; Iraldo, F. Shadows and lights of GSCM (Green Supply Chain Management): Determinants and effects of these practices based on a multi-national study. J. Clean. Prod. 2010, 18, 953–962. [Google Scholar] [CrossRef] [Green Version]

- Klassen, R.D.; Johnson, P.F. The green supply chain. In Understanding Supply Chains: Concepts, Critiques & Futures; New, S., Westbrook, R., Eds.; Oxford University Press: Oxford, UK, 2004; pp. 229–252. [Google Scholar] [CrossRef]

- Zhu, Q.; Sarkis, J. Relationships between operational practices and performance among early adopters of green supply chain management practices in Chinese manufacturing enterprises. J. Oper. Manag. 2004, 22, 265–289. [Google Scholar] [CrossRef]

- Zhu, Q.; Sarkis, J.; Lai, K.-H. Green supply chain management: Pressures, practices and performance within the Chinese automobile industry. J. Clean. Prod. 2007, 15, 1041–1052. [Google Scholar] [CrossRef]

- Chien, M.K.; Shih, L.H. An empirical study of the implementation of green supply chain management practices in the electrical and electronic industry and their relation to organizational performances. Int. J. Environ. Sci. Technol. 2007, 4, 383–394. [Google Scholar]

- Zhu, Q.; Sarkis, J.; Lai, K.-H. Confirmation of a measurement model for green supply chain management practices implementation. Int. J. Prod. Econ. 2008, 111, 261–273. [Google Scholar] [CrossRef]

- Zhu, Q.; Sarkis, J.; Lai, K.-H. Green supply chain management implications for closing the loop. Transp. Res. Part E Logist. Transp. Rev. 2008, 44, 1–18. [Google Scholar] [CrossRef]

- Darnall, N.; Jolley, G.J.; Handfield, R. Environmental Management Systems and Green Supply Chain Management: Complements for Sustainability? Bus. Strategy Environ. 2008, 45, 30–45. [Google Scholar] [CrossRef]

- Zhu, Q.; Sarkis, J.; Geng, Y. Green supply chain management in China: Pressures, practices and performance. Int. J. Oper. Prod. Manag. 2005, 25, 449–468. [Google Scholar] [CrossRef]

- Eltayeb, T.K.; Zailani, S. Going Green through Green Supply Chain Initiatives Toward Environmental Sustainability. Oper. Supply Chain Manag. Int. J. 2014, 2, 93–110. [Google Scholar] [CrossRef] [Green Version]

- Shang, K.-C.; Lu, C.-S.; Li, S. A taxonomy of green supply chain management capability among electronics-related manufacturing firms in Taiwan. J. Environ. Manag. 2010, 91, 1218–1226. [Google Scholar] [CrossRef] [PubMed]

- Zhu, Q.; Geng, Y.; Fujita, T.; Hashimoto, S. Green supply chain management in leading manufacturers. Manag. Res. Rev. 2010, 33, 380–392. [Google Scholar] [CrossRef]

- Nunes, B.; Bennett, D. Green operations initiatives in the automotive industry. Benchmarking Int. J. 2010, 17, 396–420. [Google Scholar] [CrossRef]

- Borchardt, M.; Sellitto, M.A.; Pereira, G.M.; Gomes, L.P. Ecodesign case studies for furniture companies using the Analytic Hierarchy Process. Int. J. Ind. Eng. Theory 2012, 19, 330–340. [Google Scholar]

- Eltayeb, T.K.; Zailani, S.; Ramayah, T. Green supply chain initiatives among certified companies in Malaysia and environmental sustainability: Investigating the outcomes. Resour. Conserv. Recycl. 2011, 55, 495–506. [Google Scholar] [CrossRef]

- Wu, K.-J.; Tseng, M.-L.; Vy, T. Evaluation the drivers of green supply chain management practices in uncertainty. Procedia Soc. Behav. Sci. 2011, 25, 384–397. [Google Scholar] [CrossRef] [Green Version]

- Diabat, A.; Govindan, K. An analysis of the drivers affecting the implementation of green supply chain management. Resour. Conserv. Recycl. 2011, 55, 659–667. [Google Scholar] [CrossRef]

- Li, Y. Research on the Performance Measurement of Green Supply Chain Management in China. J. Sustain. Dev. 2011, 4, 101. [Google Scholar] [CrossRef] [Green Version]

- Wu, G.-C.; Ding, J.-H.; Chen, P.-S. The effects of GSCM drivers and institutional pressures on GSCM practices in Taiwan’s textile and apparel industry. Int. J. Prod. Econ. 2012, 135, 618–636. [Google Scholar] [CrossRef]

- Toke, L. An empirical study of green supply chain management in Indian perspective. Int. J. Appl. Sci. Eng. Res. 2012, 1, 372–383. [Google Scholar] [CrossRef]

- Amit, P.; Pratik, M. An empirical study of green supply chain management drivers, practices and performances: With reference to the pharmaceutical industry of Ankleshwar (Gujarat). Int. J. Eng. Manag. Sci. 2012, 3, 339–355. [Google Scholar]

- Perotti, S.; Zorzini, M.; Cagno, E.; Micheli, G.J. Green supply chain practices and company performance: The case of 3PLs in Italy. Int. J. Phys. Distrib. Logist. Manag. 2012, 42, 640–672. [Google Scholar] [CrossRef]

- Green, K.W.J.; Zelbst, P.J.; Meacham, J.; Bhadauria, V.S. Green supply chain management practices: Impact on performance. Supply Chain Manag. Int. J. 2012, 17, 290–305. [Google Scholar] [CrossRef]

- Zhu, Q.; Sarkis, J.; Lai, K.-H. Green supply chain management innovation diffusion and its relationship to organizational improvement: An ecological modernization perspective. J. Eng. Technol. Manag. 2012, 29, 168–185. [Google Scholar] [CrossRef]

- Hsu, C.; Tan, K.C.; Zailani, S.H.M.; Jayaraman, V. Supply chain drivers that foster the development of green initiatives in an emerging economy. Int. J. Oper. Prod. Manag. 2013, 33, 656–688. [Google Scholar] [CrossRef] [Green Version]

- Lee, S.M.; Kim, S.T.; Choi, D. Green supply chain management and organizational performance. Ind. Manag. Data Syst. 2012, 112, 1148–1180. [Google Scholar] [CrossRef]

- Tseng, M.-L.; Chiu, A.S. Evaluating firm’s green supply chain management in linguistic preferences. J. Clean. Prod. 2013, 40, 22–31. [Google Scholar] [CrossRef]

- Yang, C.-S.; Lu, C.-S.; Haider, J.J.; Marlow, P.B. The effect of green supply chain management on green performance and firm competitiveness in the context of container shipping in Taiwan. Transp. Res. Part E Logist. Transp. Rev. 2013, 55, 55–73. [Google Scholar] [CrossRef]

- Luthra, S.; Garg, D.; Haleem, A. Green supply chain management: Implementation and performance—A literature review. J. Adv. Manag. Res. 2014, 11, 20–46. [Google Scholar] [CrossRef]

- Govindan, K.; Khodaverdi, R.; Vafadarnikjoo, A. Intuitionistic fuzzy based DEMATEL method for developing green practices and performances in a green supply chain. Expert Syst. Appl. 2015, 42, 7207–7220. [Google Scholar] [CrossRef]

- Ajamieh, A.; Benitez, J.; Braojos, J.; Gelhard, C.V. IT infrastructure and competitive aggressiveness in explaining and predicting performance. J. Bus. Res. 2016, 69, 4667–4674. [Google Scholar] [CrossRef]

- Luthra, S.; Garg, D.; Haleem, A. The impacts of critical success factors for implementing green supply chain management towards sustainability: An empirical investigation of Indian automobile industry. J. Clean. Prod. 2016, 121, 142–158. [Google Scholar] [CrossRef]

- Younis, H.; Sundarakani, B.; Vel, P. The impact of implementing green supply chain management practices on corporate performance. Compet. Rev. 2016, 26, 216–245. [Google Scholar] [CrossRef]

- Sellitto, M.A.; Hermann, F.F.; Blezs, A.E.; Barbosa-Póvoa, A.P. Describing and organizing green practices in the context of Green Supply Chain Management: Case studies. Resour. Conserv. Recycl. 2019, 145, 1–10. [Google Scholar] [CrossRef]

- Govindan, K.; Kadziński, M.; Sivakumar, R. Application of a novel PROMETHEE-based method for construction of a group compromise ranking to prioritization of green suppliers in food supply chain. Omega 2017, 71, 129–145. [Google Scholar] [CrossRef]

- Barbosa, F.S.; Scavarda, A.J.; Sellitto, M.A.; Marques, D.I.L. Sustainability in the winemaking industry: An analysis of Southern Brazilian companies based on a literature review. J. Clean. Prod. 2018, 192, 80–87. [Google Scholar] [CrossRef]

- Sellitto, M.A.; Borchardt, M.; Pereira, G.M.; Gomes, L.P. Environmental performance assessment of a provider of logistical services in an industrial supply chain. Theor. Found. Chem. Eng. 2012, 46, 691–703. [Google Scholar] [CrossRef]

- Ijaz, M.F.; Rhee, J. Constituents and consequences of online-shopping in sustainable e-business: An experimental study of online-shopping malls. Sustainability 2018, 10, 3756. [Google Scholar] [CrossRef] [Green Version]

- Wagner, G.; Schramm-Klein, H.; Steinmann, S. Online retailing across e-channels and e-channel touchpoints: Empirical studies of consumer behavior in the multichannel e-commerce environment. J. Bus. Res. 2020, 107, 256–270. [Google Scholar] [CrossRef]

- Adami, V.S.; Junior, J.A.V.A.; Sellitto, M.A. Regional industrial policy in the wind energy sector: The case of the state of Rio Grande do Sul, Brazil. Energy Policy 2017, 111, 18–27. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).