1. Introduction

Electric power distribution system planning is far more challenging than the power generation itself mainly because of several factors; initial investment cost, maintenance cost, line losses, power losses, and consumer services. Previously, a few reasons behind the energy crisis in Pakistan have been the shortage of electricity, the increasing number of consumers, and fluctuating fuel prices. However, currently, the crisis is mainly due to a low voltage power supply and a poor distribution system. On the other hand, Pakistan needs to move toward renewable resources due to environmental concerns. This creates the need for new types of environmentally friendly power plants and a reengineered distribution networks within the country. In this regard, the government is planning to install renewable plants, including solar and wind plants, to accommodate the energy needs of the country. Designing the new distribution network with new facilities at minimum cost is a challenge. On one hand, the expansion of the existing power distribution network and inclusion of new power plants, new grid stations, substations in the primary network, and transformers in secondary networks will make the network more complex. Also, the redesign and execution of the new distribution network will have an immense cost. This requires a careful and efficient plan which focuses on high efficiency as well as the minimum cost at the same time. Furthermore, the connection of the main grids with the different number of substations at different locations and the connection with other facilities in the network would be a critical decision due to the huge investment cost of the transmission lines.

Due to previous experiences with poor transmission lines and the cost of maintenance, the government is also concerned about the power losses and the probability of faults occurring in transmission lines. Such a level of complex planning makes it a network optimization problem where there is a dire need to identify the exact size, cost, and location of new power plants, substations, grids, routes, and transmission line branches to connect various facilities in the network. The objective of the network planning is to reduce the overall investment cost of the new facilities, the maintenance cost of the lines and facilities in the network and reduce power losses with maximum customer satisfaction. For example,

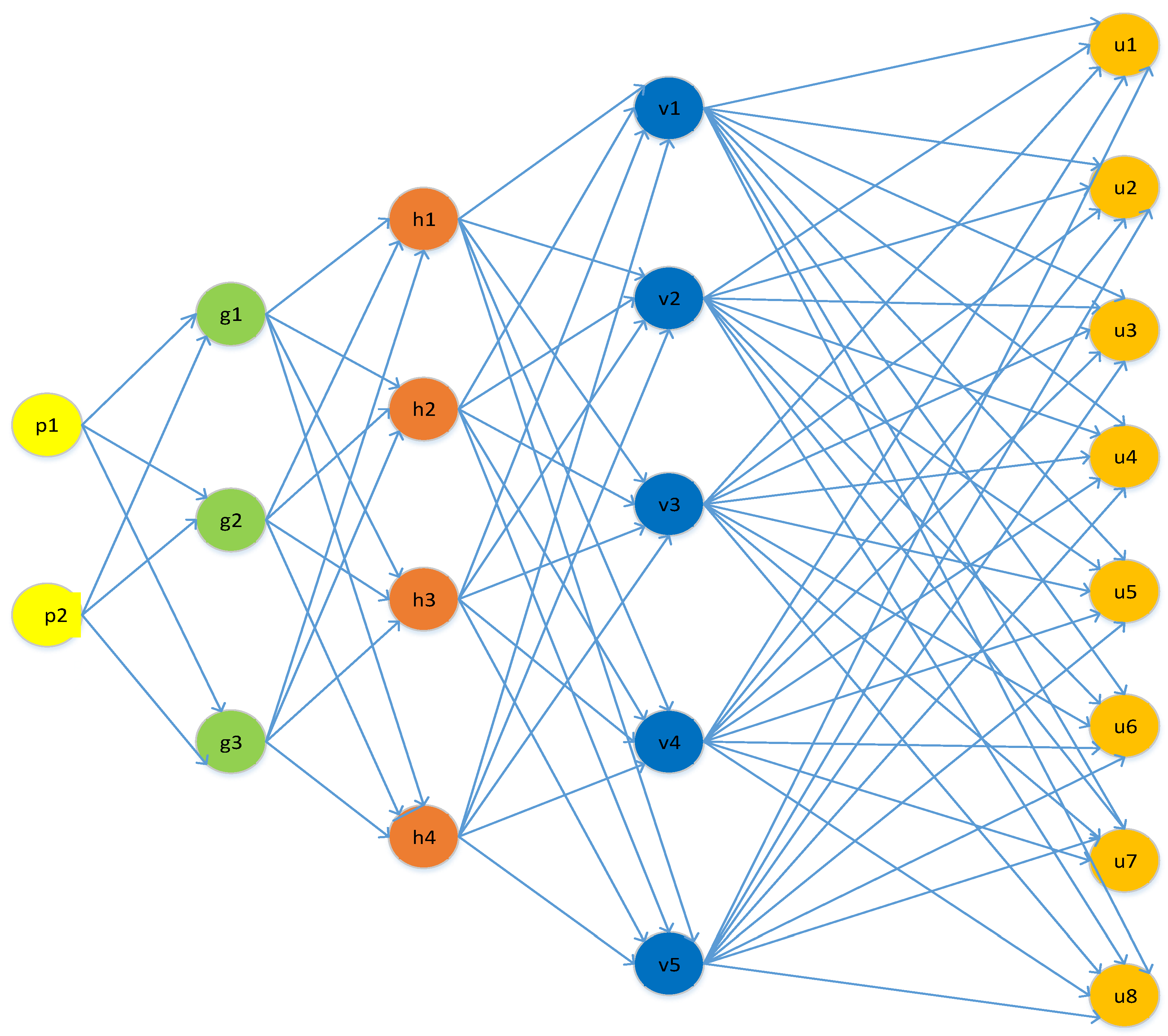

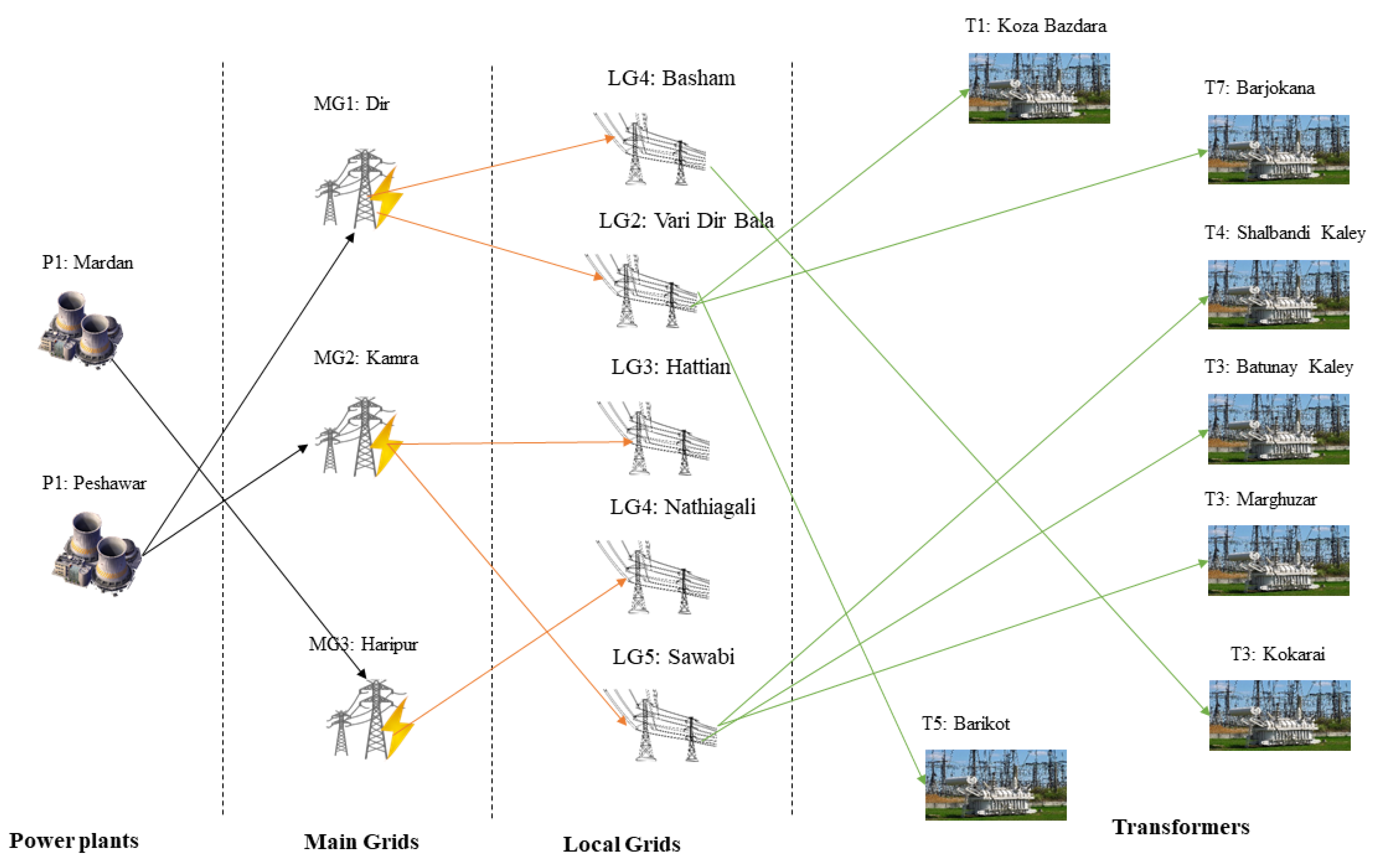

Figure 1 exhibits the complex nature of an electricity distribution supply chain network design that consists of power plants (p), main grids (g), local grids (h), and transformers (v), and customers (u). Power generation occurs at power plants, which are distributed to main grids, main grids distribute it to local grids, and finally, local grids are connected to transformers and users have connections with the transformers.

Based on the government’s concerns and the requirement of a new, expanded, and complex distribution network, this research proposes an optimization model that tends to select appropriate locations for plants, main grids, local grids, and transformers to reduce the total cost of installation and maintenance. Further, the model proposes that the decision to connect different power plants with main grids, main grids with local grids, and local grids with transformers is taken by minimizing the line losses as well as cost. This research focuses on the location-allocation of power plants, main grids, local grids, and transformers. In addition, it gives the optimal assignment of transformers to local grids, local grids to main grids, and main grids to the power plants. The objective includes minimizing the total cost, which is composed of fixed installation cost, maintenance cost, and energy costs, where energy cost is assumed to be uncertain during transmission and production. Our model addresses the shortcomings in the previously proposed models, for example, Gonela et al. [

1] designed an electricity generation network considering production strategies without taking into account the line losses, decisions for location selection, and assignment of power plants and main grids. Similarly, Bayatloo [

2] proposed a two-stage stochastic programming model for electricity supply chain network design by only considering location selection for power plants, main grids, and local grids to minimize the installation cost without considering the energy losses and maintenance in the supply chain network design. This model is an integration of the location-allocation and assignment model for the minimization of energy losses and maintenance cost that differentiate this model from previous literature Chen, Hsu, and Wu [

3].

This study proposes a four-phase approach; in the first phase, a mixed-integer linear programming model is formulated that minimizes the total supply chain cost considering uncertain energy losses. In the second phase, the energy loss is regarded as a fuzzy variable in this research as the electricity supply chain networks are too complex and involve large-scale optimization. To optimize the supply chain network design in the third phase, a fine-tuned and hybridized genetic algorithm (GA) is introduced that can solve large optimization in reduced computation time and improved cost value. In the last step, a real case study of the electricity network is proposed. In addition, a set of numerical examples were also solved using other methods such as GA and interior point. Gap analysis is used to assess the solution quality of the proposed algorithm compared to the existing methods.

2. Literature Review

Electric power transmission is the mass transmission of electrical energy from its source—for example, a power plant—to an electrical substation where it is consumed [

4]. The interconnected lines that carry this transmission are known as transmission lines [

5]. However, electric power distribution and transmission lines have always been challenging because of their complex nature, the costs involved in their erection, and the cost of maintenance, and have been the focus of many researchers [

6,

7,

8]. Mainly, literature on power distribution networks can be segregated into three dimensions; first, most of the researchers focused on the primary networks only [

9,

10,

11,

12,

13,

14,

15,

16], few focused on secondary [

17], and only a few researchers addressed both the primary and secondary networks [

18]. The second dimension is the selection of an objective function; for example, Paiva, Khodr, Dominguez-Navarro, Yusta, and Urdaneta [

18] selected the investment cost and the cost of energy loss as the objective functions. Whereas Zhao, Wang, Yu, and Chen [

15] considered optimal location and size of substations and feeders, and, Nahman and Peric [

14] considered the optimal location of feeders in the network with the objective to minimize investment cost and cost of energy loss.

Similarly, Navarro and Rudnick [

17] investigated the optimal location and size of substations and feeders with the objective to minimize the cost of investment as well as the cost of energy loss. Lavorato, Rider, Garcia, and Romero [

12] and Lotero and Contreras [

13] proposed a method to optimize the size and location of substations and feeders with the goal to minimize fixed and variable costs. Several other studies [

9,

10,

11,

13] considered the optimal location and size of substations, feeders, and distributed generation (DGs) to minimize the total cost. The literature shows that a lot of studies have been performed to address DGs for example, Ziari et al. [

19] Studied the optimal location and size of substations, feeders, and DGs with the objective to minimize fixed and variable costs. In most of the studies, only the cost is considered as an optimization objective and few studies have taken reliability into consideration while identifying optimal distribution network expansion. Similarly, [

20,

21] focused on optimizing the size of substations and feeders with the objective to minimize the cost of investment, cost of energy loss with the constraints of voltage drops, which is concerned with reliability.

The installation year of DG in the distribution system has also been considered along with the optimal size and location of DG [

22]. Another approach is presented by Gautam and Mithulananthan [

23] who worked on optimal placement, including size, to formulate two different objectives, namely, social welfare maximization and profit maximization. Consumer payment, evaluated as a product of location marginal price (LMP) and load at each load bus, is proposed as another ranking to identify candidate nodes for DG placement. Optimal placement and size are identified for social welfare as well as profit maximization problems. Another study was carried out regarding DG in which Celli and Pilo [

24] considered the optimal siting and sizing of DG units for a given network so that the cost of power losses during a prefixed period of study can be minimized and investments for grid upgrades can be deferred. The measures used in the literature for energy losses have the limitation that they do not take into consideration the future demand and robustness and flexibility of the network for future needs. The demand is variable and for the future demands of customers, the network is required to be reliable at handling uncertain power demands. For example, Ramírez-Rosado and Bernal-Agustín [

25] considered the optimal expansion of an existing distribution system, to meet its forecasted future power demands, determining the optimal sizing and location of future feeders (reserve feeders and operation feeders) and substations, and the optimal feeder reinforcements and/or substitution of the existing feeders, as well as the optimal size increase of the existing substations, with an objective function to reduce economic cost.

The third dimension of the literature reflects the methodology used for optimizing in general and network design in particular. For example, AlRashidi and AlHajri [

26] presented an improved particle swarm optimization algorithm (PSO) for the optimal planning of multiple DGs sources. Some studies used Pareto optimization concepts [

27,

28,

29,

30], especially, Carrano, Soares, Takahashi, Saldanha, and Neto [

27] presented a multi-objective approach to optimizing electric distribution networks using a multi-objective genetic algorithm (MO-GA) to get a Pareto solution for their proposed problem. Further, Mendoza, Bernal-Agustin, and Domínguez-Navarro [

29] used the Non-Dominated Sorting Genetic Algorithm (NSGA) and Strength Pareto Evolutionary Algorithm (SPEA) for multi-objective optimization and also proposed a fuzzy c-mean clustering algorithm for their considered problem. Moreover, Soroudi and Ehsan [

30] considered a multi-objective model for the distribution generation investment with the aim to optimize active losses, costs, and environmental emissions simultaneously to determine the optimal scheme of sizing and sitting of DGs. They obtained Pareto solutions using GA and a fuzzy satisfying method. Also, Cossi, Da Silva, Lazaro, and Mantovani [

28] formulated and presented a multi-objective simulated annealing algorithm to solve and get the Pareto results of the proposed problem. On the other hand, Khalesi et al. [

31] considered a multi-objective model for DGs to determine the optimal locations to place DGs in the distribution system with the aim to minimize power loss of the system and enhance reliability improvement and voltage profile.

García and Mena [

32] used a new evolutionary method called Teaching–Learning Based Optimization (TLBO) algorithm to find the best sites to connect DG systems in a distribution network, choosing among a large number of potential combinations to determine the optimal placement and size of Distributed Generation (DG) units in distribution systems. Fan and Jen [

33] introduced enhanced partial search approaches in the particle swarm algorithm to solve optimization problems in the supply chain. Furthermore, most of the literature focused on the existing power distribution models developed is focused on the conventional power generators including diesel units and turbines [

34]. However, due to environmental concerns and the shortage of conventional power plants, there is a need to develop models that can consider both types of power generators including conventional and renewable energy power generators, that is, solar power plants and wind turbines. Researchers like Gupta et al. [

35] discussed the integration of DGs into the present supply chain and Khatod et al. [

36] contributed to handling the uncertainties associated with load and renewable resources (wind and solar) to overcome issues in the continuous supply of power and discussed the optimal placement of photovoltaic arrays (PVAs) and wind turbine generators WTGs in a radial distribution system. Further, Mena et al. [

37] proposed a framework for the optimal size and location of the distributed renewable generation units (DG) and also considered the uncertainties in renewable resources availability, components failure and repair events, load and grid power supply. They aimed at simultaneous minimization of the energy not supplied and global cost. Atwa et al. [

38] presented a technique for the optimal allocation of different types of renewable distributed generation (DG) units, that is, wind-based DG, solar DG, and biomass DG in the distribution system with the aim to minimize annual energy loss. The global dependence on fossil fuels is dangerous to our environment in terms of their emissions unless specific policies and measures are put in place [

39]. Nevertheless, their research reveals that a reduction in the emissions of these gases is possible with the widespread adoption of distributed generation (DG) technologies that feed on renewable energy sources, in the generation of electric power. The main objective of their work is to reduce the harmful effect of the emission of greenhouse gases thus reducing the public concerns over human health risks caused by the conventional method of electricity generation.

In the literature, very little work has been carried out on allocation and assignment simultaneously. For example, García and Mena, Hosseini and Jenab [

40] worked on the expansion policy of power plant centers involving the choice of regions that must be allocated to power plant centers and power plant centers capacities over a specified planning horizon (years) were tackled. Nevertheless, in most of the studies, a single objective has been considered for the design of the optimal network. However, in real cases, more than one objective is desired to optimize the network design problems. Fan et al. [

41] proposed an algorithm that used the concept of Pareto dominance in multi-objective particle swarm algorithm with empirical-movement diversified-search. Most of the electricity distribution problems are nonlinear in nature and require special metaheuristics. However, the use of metaheuristics requires the management of parameters used in computations. Zahara and Fan [

42] introduced a real code genetic algorithm to solve stochastic optimization problems such as energy losses in electricity distribution networks.

In the literature, most of the studies have considered expansion planning in the primary network in terms of multi-objective optimization [

17,

18,

19,

20]. However, primary and secondary grids are both important in the distribution network expansion and planning to get a global solution. A few research studies have investigated the planning of primary and secondary networks together [

18,

20,

21]. However, they added the costs of primary and secondary grids to make a single objective optimization problem.

A few other studies in the literature [

16,

19,

43,

44,

45] considered both primary and secondary networks simultaneously. However, they also optimize the network with the single objective being minimizing the fixed and variable costs. The current research addresses an optimization model for the electricity distribution network. In the electricity distribution network, facilities such as power plants, main grids, local grids are connected with the help of transmission lines. The main objective of the research is to minimize the total cost of installation of new facilities, maintenance cost, and energy loss cost. Energy loss is the function of distance and temperature, so it is considered uncertain in this model. The uncertainty is modeled using fuzzy variables. To solve this integer linear programming issue, a fine-tuned genetic algorithm is used. The fine-tuning is carried out using the Taguchi design of experiments. The consideration of uncertain energy loss in the cost function and the use of Taguchi-based fine-tuned GA differentiate this research from the previous literature.