Decomposition Characteristics, Nutrient Release, and Structural Changes of Maize Straw in Dryland Farming under Combined Application of Animal Manure

Abstract

:1. Introduction

2. Materials and Methods

2.1. Experimental Site

2.2. Field Experiment Design

2.3. Soil Sampling and Measurement

2.4. Statistical Analysis

3. Results

3.1. Decomposition Rate

3.2. Carbon Release Rate

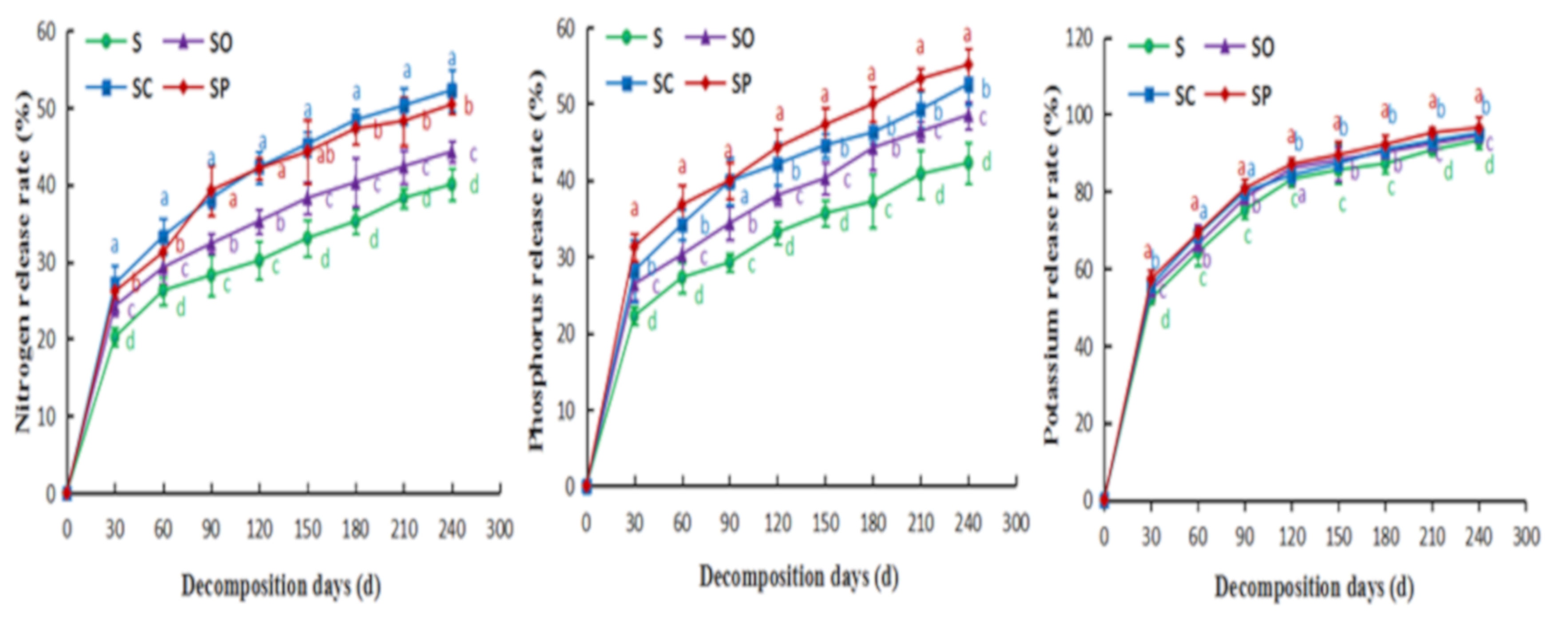

3.3. Nutrient Release Rate of Maize Straw

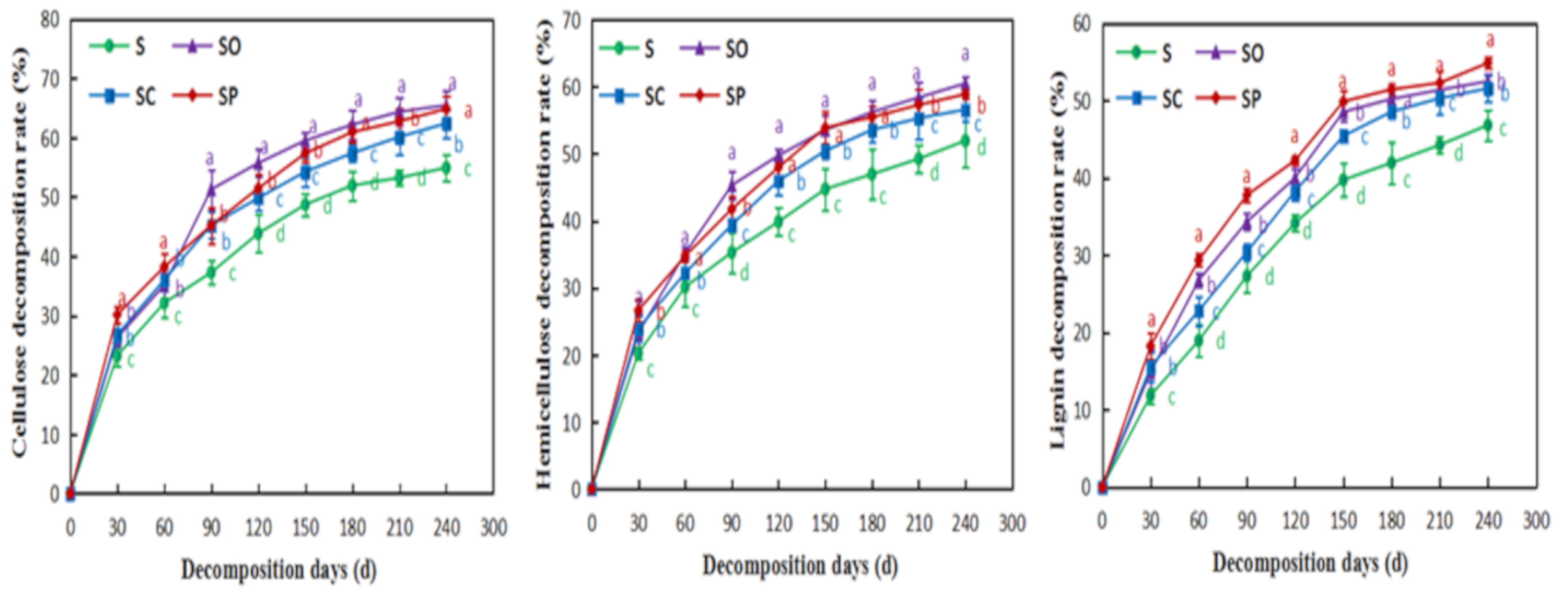

3.4. Decomposition Rates of Maize Straw Cellulose, Hemicellulose, and Lignin

3.5. SEM Images of Maize Straw Surface Structure

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Hansen, V.; Müller-Stöver, D.; Imparato, V.; Krogh, P.H.; Jensen, L.S.; Dolmer, A.; Hauggaard-Nielsen, H. The effects of straw or straw-derived gasification biochar applications on soil quality and crop productivity: A farm case study. Environ. Manag. 2017, 186, 88–95. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Wen, Y.; Li, X.; Li, Y.; Yang, X.; Lin, Z.; Song, Z.; Cooper, J.M.; Zhao, B. Soil labile organic carbon fractions and soil organic carbon stocks as affected by long-term organic and mineral fertilization regimes in the North China Plain. Soil Till. Res. 2018, 175, 281–290. [Google Scholar] [CrossRef] [Green Version]

- Nan, Q.; Wang, C.; Wang, H.; Yi, Q.; Liang, B.; Xu, J.; Wu, W. Biochar drives microbially-mediated rice production by increasing soil carbon. Hazard. Mater. 2020, 387, 121680. [Google Scholar] [CrossRef] [PubMed]

- Eagle, A.J.; Bird, J.A.; Horwath, W.R.; Linquist, B.A.; Brouder, S.M.; Hill, J.E.; Kessel, C. Rice Yield and Nitrogen Utilization Efficiency under Alternative Straw Management Practices. Agron. J. 2000, 92, 1096–1103. [Google Scholar] [CrossRef]

- Yanni, S.F.; Whalen, J.K.; Simpson, M.J.; Janzen, H.H. Plant lignin and nitrogen contents control carbon dioxide production and nitrogen mineralization in soils incubated with Bt and non-Bt corn residues. Soil Biol. Biochem. 2011, 43, 63–69. [Google Scholar] [CrossRef]

- Zhou, G.P.; Cao, W.D.; Bai, J.S.; Xu, C.X.; Zeng, N.H.; Gao, S.J.; Rees, R.M.; Dou, F.G. Co-incorporation of rice straw and leguminous green manure can increase soil available nitrogen (N) and reduce carbon and N losses: An incubation study. Pedosphere 2020, 30, 661–670. [Google Scholar] [CrossRef]

- Das, M.; Uppal, H.S.; Singh, R.; Beri, S.; Mohan, K.S.; Gupta, V.C.; Adholeya, A. Co-composting of physic nut (Jatropha curcas) deoiled cake with rice straw and different animal dung. Bioresour. Technol. 2011, 102, 6541–6546. [Google Scholar] [CrossRef] [PubMed]

- Mary, B.; Recous, S.; Darwis, D.; Robin, D. Interactions between decomposition of plant residues and nitrogen cycling in soil. Plant Soil 1996, 181, 71–82. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhang, X.; Xu, M.; Zhang, S.; Huang, S.; Liang, W. Responses of soil micro-food web to long-term fertilization in a wheat maize rotation system. Appl. Soil Ecol. 2016, 98, 56–64. [Google Scholar] [CrossRef]

- Guan, X.K.; Wei, L.; Turner, N.C.; Ma, S.C.; Yang, M.D.; Wang, T.C. Improved straw management practices promote in situ straw decomposition and nutrient release, and increase crop production. J. Clean. Prod. 2020, 250, 119514. [Google Scholar] [CrossRef]

- Zhao, S.C.; Qiu, S.J.; Xu, X.P.; Ciampitti, I.A.; Zhang, S.Q.; He, P. Change in straw decomposition rate and soil microbial community composition after straw addition in different long-term fertilization soils. Appl. Soil Ecol. 2019, 138, 123–133. [Google Scholar] [CrossRef]

- Latifmanesh, H.; Deng, A.; Li, L.; Chen, Z.; Zhang, W. How incorporation depth of corn straw affects straw decomposition rate and c&n release in the wheat-corn cropping system. Agric. Ecosyst. Environ. 2020, 300, 107000. [Google Scholar]

- Wang, F.T.; Zhang, X.; Yue, X.Y.; Song, M.Y.; Zhang, G.S.; Ming, J. Black Carbon: The Concentration and Sources Study at the Nam Co Lake, the Tibetan Plateau from 2015 to 2016. Atmosphere 2020, 11, 624. [Google Scholar] [CrossRef]

- Fan, J.; Xiao, J.; Liu, D.; Ye, G.; Luo, J.; Houlbrooke, D.; Laurenson, S.; Yan, J.; Chen, L.; Tian, J.; et al. Effect of application of dairy manure, effluent and inorganic fertilizer on nitrogen leaching in clayey fluvo-aquic soil: A lysimeter study. Sci. Total Environ. 2017, 592, 206–214. [Google Scholar] [CrossRef] [PubMed]

- Chung, C.E.; Kim, S.W.; Lee, M.; Yoon, S.C.; Lee, S. Carbonaceous aerosol AAE inferred from in-situ aerosol measurements at the Gosan ABC super site, and the implications for brown carbon aerosol. Atmos. Chem. Phys. 2012, 12, 6173–6184. [Google Scholar] [CrossRef] [Green Version]

- Walkley, A.; Black, L.A. An examination of the Degtjareff method of determining soil organic matter, and a proposed modification of the chromic acid titration method. Soil Sci. 1934, 37, 29–38. [Google Scholar] [CrossRef]

- Van-Soest, P.J. Use of detergents in the analysis of fibrous feeds II. A rapid method for the determination of fiber and lignin. Assoc. Off. Agr. Chem. Jour. 1963, 46, 829–835. [Google Scholar]

- Wang, F.; Pei, M.F.; Qiu, L.; Yao, Y.Q.; Zhang, C.G.; Qiang, H. Performance of Anaerobic Digestion of Chicken Manure Under Gradually Elevated Organic Loading Rates. Int. J. Environ. Res. Public Health 2019, 16, 2239. [Google Scholar] [CrossRef] [Green Version]

- Ferraro, A.; Massini, G.; Miritana, V.M.; Signorini, A.; Race, M.; Fabbricino, M. A simplified model to simulate bioaugmented anaerobic digestion of lignocellulosic biomass: Biogas production efficiency related to microbiological data. Sci. Total. Environ. 2019, 691, 885–895. [Google Scholar] [CrossRef]

- Huang, S.; Zeng, Y.; Wu, J.; Shi, Q.; Pan, X. Effect of crop residue retention on rice yield in China: A meta-analysis. Field Crop. Res. 2013, 154, 188–194. [Google Scholar] [CrossRef]

- Liao, P.; Huang, S.; van Gestel, N.C.; Zeng, Y.; Wu, Z.; van Groenigen, K.J. Liming and straw retention interact to increase nitrogen uptake and grain yield in a double rice-cropping system. Field Crop. Res. 2018, 216, 217–224. [Google Scholar] [CrossRef]

- Kumar, K.A.; Swain, D.K.; Bhadoria, P.B.S. Split application of organic nutrient improved productivity, nutritional quality and economics of rice-chickpea cropping system in lateritic soil. Field Crop. Res. 2018, 223, 125–136. [Google Scholar] [CrossRef]

- Marschner, P.; Hatam, Z.; Cavagnaro, T.R. Soil respiration, microbial biomass and nutrient availability after the second amendment are influenced by legacy effects of prior residue addition. Soil Biol. Biochem. 2015, 88, 169–177. [Google Scholar] [CrossRef]

- Kaewpradit, W.; Toomsan, B.; Cadisch, G.; Vityakon, P.; Limpinuntana, V.; Saenjan, P.; Jogloy, S.; Patanothai, A. Mixing groundnut residues and rice straw to improve rice yield and N use efficiency. Field Crop. Res. 2009, 110, 130–138. [Google Scholar] [CrossRef]

- Nair, A.; Ngouajio, M. Soil microbial biomass, functional microbial diversity, and nematode community structure as affected by cover crops and compost in an organic vegetable production system. Appl. Soil Ecol. 2012, 58, 45–55. [Google Scholar] [CrossRef]

- Sharma, P.; Laor, Y.; Raviv, M.; Medina, S.; Saadi, I.; Krasnovsky, A.; Vager, M.; Levy, G.J.; Bar-Tal, A.; Borisover, M. Green manure as part of organic management cycle: Effects on changes in organic matter characteristics across the soil profile. Geoderma 2017, 305, 197–207. [Google Scholar] [CrossRef]

- Qian, X.; Shen, G.; Wang, Z.; Guo, C.; Liu, Y.; Lei, Z.; Zhang, Z. Co-composting of livestock manure with rice straw: Characterization and establishment of maturity evaluation system. Waste Manag. 2014, 34, 530–535. [Google Scholar] [CrossRef] [Green Version]

- Baumann, K.; Marschner, P.; Smernik, R.J. Residue chemistry and microbial community structure during decomposition of eucalypt, wheat and vetch residues. Soil Biol. Biochem. 2009, 41, 1966–1975. [Google Scholar] [CrossRef]

- Preston, C.M.; Bhatti, J.S.; Flanagan, L.B. Stocks, chemistry, and sensitivity to climate change of dead organic matter along the Canadian boreal forest transect case study. Clim. Chang. 2006, 74, 223–251. [Google Scholar] [CrossRef]

- Yue, D.; Cai, L.Q.; Qi, P.; Zhang, R.Z.; Wu, J.; Gao, X.L. The decomposition characteristics and nutrient release of wheat and corn straw under different returning amount. J. Arid. Land Resour. Environ. 2016, 30, 80–85. [Google Scholar]

- Shen, F. Study on key technologies of biodegradation and anaerobic digestion of rice straw and pig manure. Jiangxi Agric. Univ. 2019, 12, 703–713. [Google Scholar]

- Zhang, W.M.; Yu, C.X.; Wang, X.J.; Hai, L. Increased abundance of nitrogen transforming bacteria by higher C/N ratio reduces the total losses of N and C in chicken manure and corn stover mix composting. Bioresour. Technol. 2020, 297, 122410. [Google Scholar] [CrossRef]

- Henriksen, T.M.; Breland, T.A. Carbon mineralization, fungal and bacterial growth, and enzyme activities as affected by contact between crop residues and soil. Biol. Fertil. Soils. 2002, 35, 41–48. [Google Scholar] [CrossRef]

- Geisseler, D.; Horwath, W.R.; Scow, K.M. Soil moisture and plant residue addition interact in their effect on extracellular enzyme activity. Pedobiologia 2011, 54, 71–78. [Google Scholar] [CrossRef]

- Hu, J. Decomposition characteristics of organic materials in semi-arid soil under plastic film mulching drip irrigation and its effect on organic carbon. Jilin Agric. Univ. 2018, 200, 313–321. [Google Scholar]

- Liu, C.; Lu, M.; Cui, J.; Li, B.; Fang, C. Effects of straw carbon input on carbon dynamics in agricultural soils: A meta-analysis. Glob. Chang. Biol. 2014, 20, 1366–1381. [Google Scholar] [CrossRef]

- Chen, X.F.; Liu, M.; Kuzyakov, Y.; Li, W.T.; Liu, J.; Jiang, C.Y.; Wu, M.; Li, Z.P. Incorporation of rice straw carbon into dissolved organic matter and microbial biomass along a 100-year paddy soil chronosequence. Appl. Soil Ecol. 2018, 130, 84–90. [Google Scholar] [CrossRef]

- Kamble, P.N.; Bååth, E. Comparison of fungal and bacterial growth after alleviating induced N-limitation in soil. Soil Biol. Biochem. 2016, 103, 97–105. [Google Scholar] [CrossRef]

- Qi, Y.F.; Tian, X.M.; Wei, M.; Wang, X.F. Effects of Crop Residues and Application Manners on Properties of Continuous Cropping Cucumber Soil in Solar Greenhouses. Hortic. Environ. Biotechnol. 2009, 50, 410–415. [Google Scholar]

- Yan, F.J.; Sun, Y.J.; Hui, X.; Jiang, M.J.; Xiang, K.H.; Wu, Y.X.; Zhang, Q.; Tang, Y.; Yang, Z.Y.; Sun, Y.Y.; et al. The effect of straw mulch on nitrogen, phosphorus and potassium uptake and use in hybrid rice. Paddy Water Environ. 2019, 17, 23–33. [Google Scholar] [CrossRef]

- Xia, L.; Lam, S.K.; Wolf, B.; Kiese, R.; Chen, D.; Butterbach-Bahl, K. Trade-offs between soil carbon sequestration and reactive nitrogen losses under straw return in global agroecosystems. Glob. Chang. Biol. 2018, 24, 5919–5932. [Google Scholar] [CrossRef]

- Wei, T.; Zhang, P.; Wang, K.; Ding, R.; Yang, B.; Nie, J.; Jia, Z.; Han, Q. Effects of wheat straw incorporation on the availability of soil nutrients and enzyme activities in semiarid areas. PLoS ONE 2015, 10, e0120994. [Google Scholar] [CrossRef] [Green Version]

- Yan, C.; Yan, S.S.; Jia, T.Y.; Dong, S.K.; Gong, Z.P. Decomposition characteristics of rice straw returned to the soil in northeast China. Nutr. Cycl. Agroecosyst. 2019, 114, 211–224. [Google Scholar] [CrossRef]

- Dai, Z.G.; Lu, J.W.; Li, X.K.; Lu, M.X.; Yang, W.B.; Gao, X.Z. Nutrient release characteristics of straw returned from different crops. Trans. CSAE 2010, 26, 272–276. [Google Scholar]

- Wu, J.; Guo, X.; Wang, Y.; Xu, Z.; Lu, J. Decomposition Characteristics of Rapeseed and Wheat Straws Under Different Rice Cultivations and Straw Mulching Models. Sci. Agric. Sin. 2011, 44, 3351–3360. [Google Scholar]

- Devêvre, O.C.; Horwáth, W.R. Decomposition of rice straw and microbial carbon use efficiency under different soil temperatures and moistures. Soil Biol. Biochem. 2000, 32, 1773–1785. [Google Scholar] [CrossRef]

- Deng, Y.Y.; Huang, Z.X.; Ruan, W.Q.; Zhao, M.X.; Miao, H.F.; Ren, H.Y. Co-inoculation of cellulolytic rumen bacteria with methanogenic sludge to enhance methanogenesis of rice straw. Int. Biodeterior. Biodegrad. 2017, 117, 224–235. [Google Scholar] [CrossRef]

- Zhou, C.; Liu, Z.; Huang, Z.L.; Dong, M.; Yu, X.L.; Ning, P. A new strategy for co-composting dairy manure with rice straw: Addition of different inocula at three stages of composting. Waste Manag. 2015, 40, 38–43. [Google Scholar] [CrossRef] [PubMed]

- Kuijk, S.J.A.; Sonnenberg, A.S.M.; Baars, J.J.P.; Hendriks, W.H.; Cone, J.W. The effect of adding urea, manganese and linoleic acid to wheat straw and wood chips on lignin degradation by fungi and subsequent in vitro rumen degradation. Anim. Feed. Sci. Technol. 2016, 213, 22–28. [Google Scholar] [CrossRef]

- Ilmen, M.; Saloheimo, A.; Onnela, M.; Penttila, M.E. Regulation of cellulase gene expression in the filamentous fungus Trichoderma reesei. Appl. Environ. Microbiol. J. 2007, 63, 1298–1306. [Google Scholar] [CrossRef] [Green Version]

- Wang, Z.J.; Wang, Z.Y.; Zhang, Z.; Lin, G.Y.; Liu, Z.; Cui, F. Effects of biochar on decomposition characteristics of straw returning with mixed application of bog fertilizer. Trans. Chin. Soc. Agric. Mach. 2018, 49, 279–285. [Google Scholar]

- Li, Y.H.; Bai, Y.X.; Pan, C.M.; Li, W.W.; Zheng, H.Q.; Zhang, J.N.; Fan, Y.T.; Hou, H.W. Effective conversion of maize straw wastes into bio-hydrogen by two-stage process integrating H2 fermentation and MECs. Environ. Sci. Pollut. Res. 2015, 22, 18394–18403. [Google Scholar] [CrossRef] [PubMed]

- Zeng, L.; Zhang, X.; Zhang, S.Q.; Wang, X.B.; Liang, G.Q.; Zhou, W.; Ai, C.; Zhang, Y.Q. Effects of nitrogen application rates on the decomposition of wheat straw and its nutrient release and structure in fluvial soil. Plant Nutr. Fertil. Sci. 2020, 26, 1565–1577. [Google Scholar]

| Property | Maize Straw | Ox Manure | Chicken Manure | Pig Manure |

|---|---|---|---|---|

| Organic C (g/kg) | 423.05 ± 1.93 a | 308.15 ± 2.10 c | 238.61 ± 3.09 d | 313.54 ± 2.19 b |

| Total N (g/kg) | 6.52 ± 0.46 d | 13.25 ± 0.64 c | 15.77 ± 0.58 b | 17.2 ± 1.01 a |

| C/N | 65.11 | 23.29 | 15.14 | 18.27 |

| Total P (g/kg) | 1.20 ± 0.06 d | 3.53 ± 0.09 c | 8.72 ± 0.07 a | 6.95 ± 0.1 b |

| Total K (g/kg) | 12.31± 0.09 b | 8.24 ± 0.11 c | 14.09 ± 0.13 a | 8.16 ± 0.02 c |

| Lignin (%) | 6.32 ± 0.2 b | 7.23 ± 0.11 a | 3.21 ± 0.24 d | 5.09 ± 0.31 c |

| Cellulose (%) | 32.28 ± 0.64 a | 23.53 ± 1.4 b | 7.04 ± 0.18 d | 14.41 ± 0.24 c |

| Hemicellulose (%) | 22.37 ± 1.1 a | 15.38 ± 0.46 b | 4.26 ± 0.12 d | 13.24 ± 0.3 c |

| Polyphenol (%) | 0.87 ± 0.02 a | 0.73 ± 0.1 b | 0.68 ± 0.06 b | 0.69 ± 0.07 b |

| Lignin/N | 9.71 ± 0.38 a | 5.47 ± 0.35 b | 2.04 ± 0.21 d | 2.97 ± 0.35 c |

| Soluble substance (%) | 32 ± 1.15 d | 42.24 ± 0.51 b | 40.24 ± 0.29 c | 47.56 ± 0.5 a |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, L.; Sun, Z.; Hu, J.; Yaa, O.-K.; Wu, J. Decomposition Characteristics, Nutrient Release, and Structural Changes of Maize Straw in Dryland Farming under Combined Application of Animal Manure. Sustainability 2021, 13, 7609. https://doi.org/10.3390/su13147609

Sun L, Sun Z, Hu J, Yaa O-K, Wu J. Decomposition Characteristics, Nutrient Release, and Structural Changes of Maize Straw in Dryland Farming under Combined Application of Animal Manure. Sustainability. 2021; 13(14):7609. https://doi.org/10.3390/su13147609

Chicago/Turabian StyleSun, Ling, Zhixu Sun, Juan Hu, Opoku-Kwanowaa Yaa, and Jinggui Wu. 2021. "Decomposition Characteristics, Nutrient Release, and Structural Changes of Maize Straw in Dryland Farming under Combined Application of Animal Manure" Sustainability 13, no. 14: 7609. https://doi.org/10.3390/su13147609

APA StyleSun, L., Sun, Z., Hu, J., Yaa, O.-K., & Wu, J. (2021). Decomposition Characteristics, Nutrient Release, and Structural Changes of Maize Straw in Dryland Farming under Combined Application of Animal Manure. Sustainability, 13(14), 7609. https://doi.org/10.3390/su13147609