Experimental and Informational Modeling Study on Flexural Strength of Eco-Friendly Concrete Incorporating Coal Waste

Abstract

:1. Introduction

2. Materials and Methods

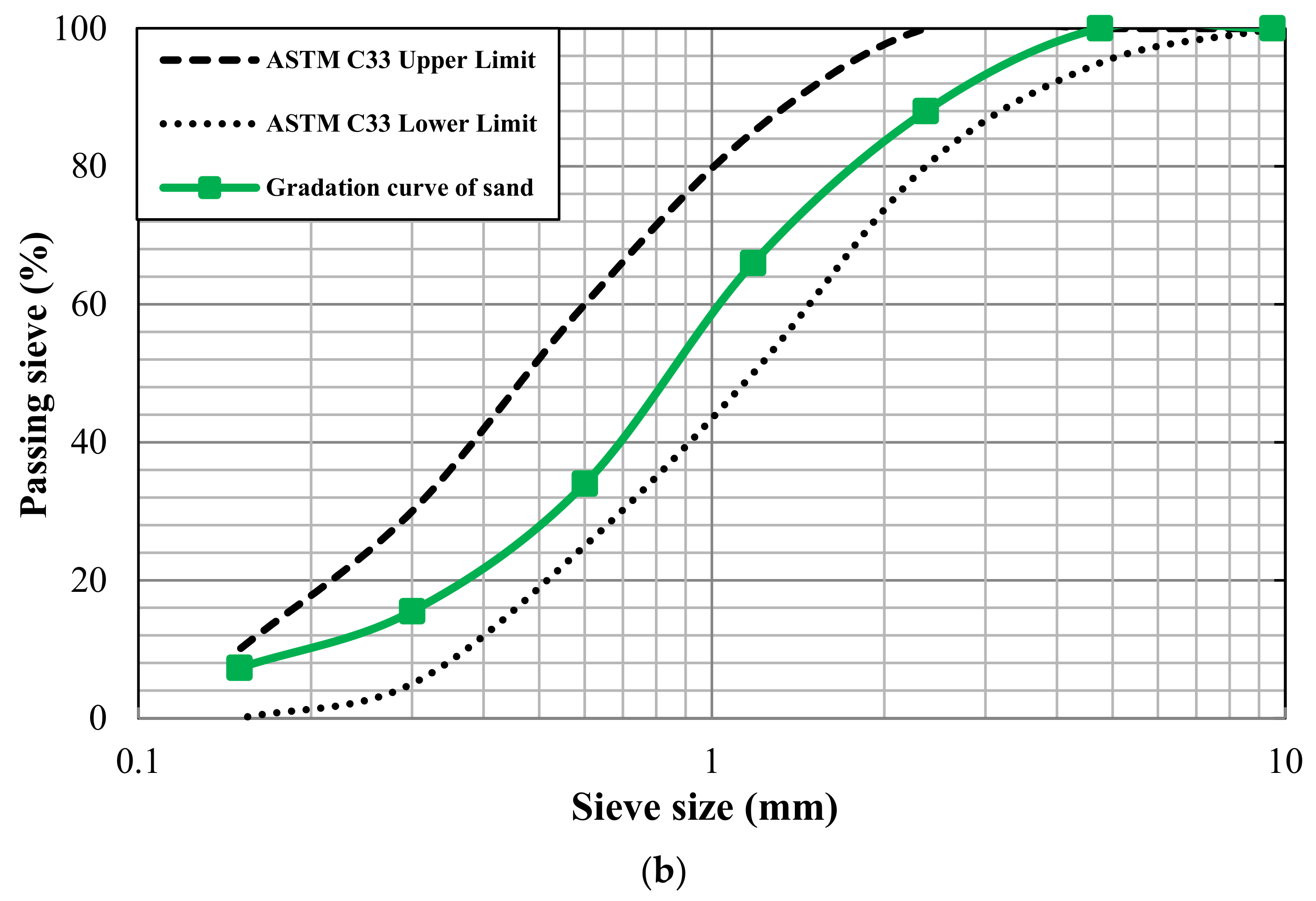

2.1. Materials

2.2. Concrete Mixtures and Experimental Procedures

3. Modeling Approach

4. Results and Discussion

4.1. Effect of Independent Parameters

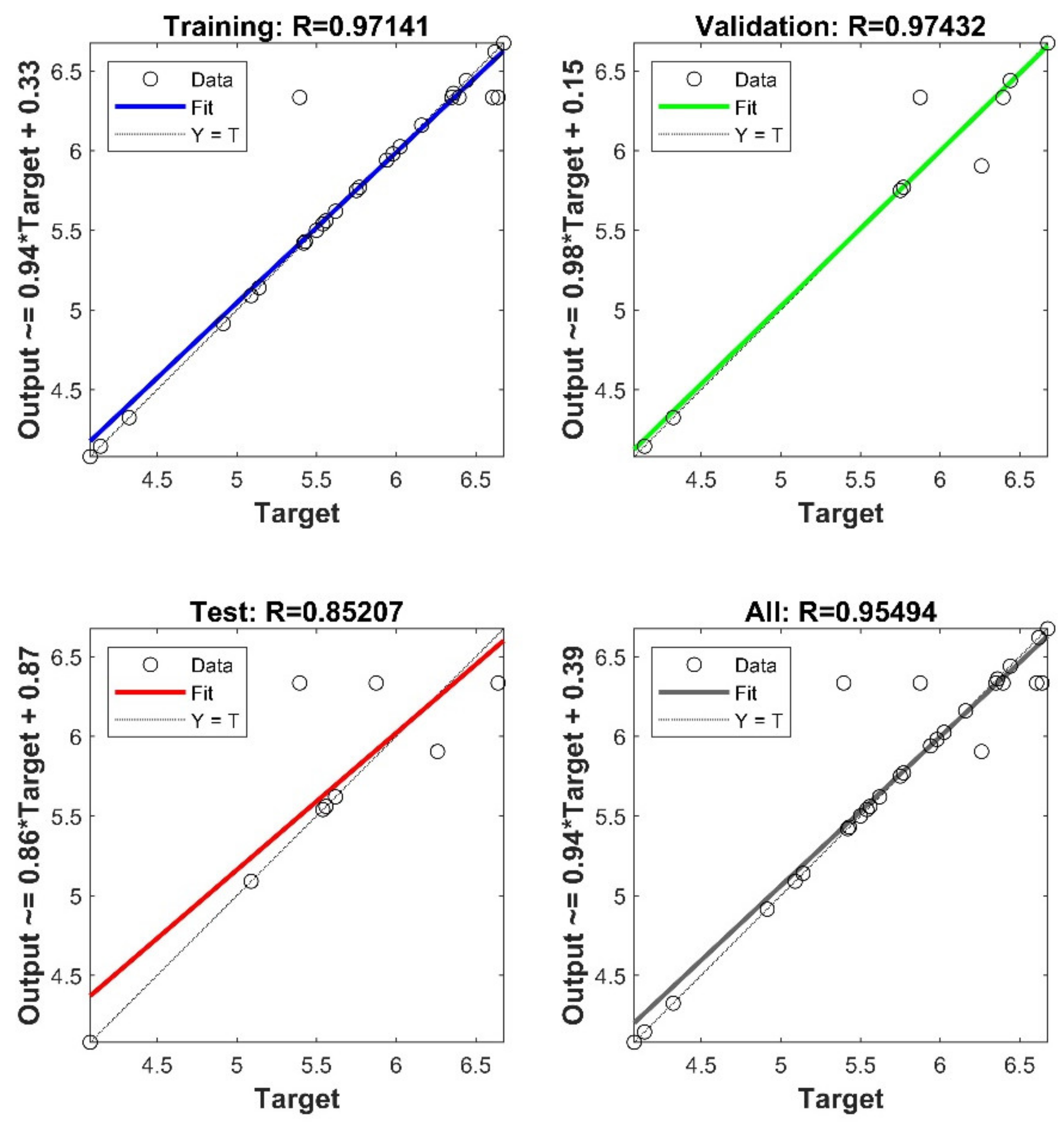

4.2. Predicting Flexural Strength Using ANN

4.3. Predicting Flexural Strength Using RSM-Modified Neural Network

4.4. Determining Most Suitable Network for Predicting Flexural Strength

5. Conclusions

- Experimental results demonstrate that coal waste powder can be used as an additive in concrete to mitigate the problem of landfilling this waste. Adequate control of the mixture design and dosage of coal waste allows beneficiating this byproduct in concrete while enhancing the flexural strength. Thus, using waste coal powder as a partial replacement for cement allows for reducing the cost of concrete production and carbon dioxide emission from cement production, while mitigating the environmental effects associated with waste coal disposal. A dosage of 3% coal waste was found to be optimal in enhancing the mechanical properties of waste coal-modified concrete.

- The response surface methodology (RSM) has proven to be an effective tool for mixture design optimization, allowing not only to quantify the effect of the coal waste parameter, but also the interactions of this parameter with other mixture design parameters. The RSM-modified artificial neural network (ANN) achieved less error compared to the traditional ANN, improving model accuracy and enhancing the reliability of predictions. Improving the accuracy of the model led to less output error of the neural network. The RMSE for the normal neural network and the RSM-modified neural networks was equal to 1.014 and 0.875, respectively.

- Errors typically arise when some effective parameters are disregarded in the modeling procedure. Accordingly, the RSM helped significantly in identifying the effective variables whose effects are not visible in the modeling. This approach, which increases the number of independent variables, increased the modeling accuracy and decreased the error between the actual data and the corresponding model-predicted ones.

- It is recommended that the effects of waste coal powder addition on the rheological and durability properties of concrete be explored in future work. One of the attractive features is to study the effects of ultrafine ground coal waste and explore whether it can play a more effective microfiller effect and better enhance the properties of concrete than the coarser powder investigated in this study.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Karimaei, M.; Dabbaghi, F.; Dehestani, M.; Rashidi, M. Estimating Compressive Strength of Concrete Containing Untreated Coal Waste Aggregates Using Ultrasonic Pulse Velocity. Materials 2021, 14, 647. [Google Scholar] [CrossRef]

- Rashidi, M.; Joshaghani, A.; Ghodrat, M. Towards Eco-Flowable Concrete Production. Sustainability 2020, 12, 1208. [Google Scholar] [CrossRef] [Green Version]

- Karimaei, M.; Dabbaghi, F.; Sadeghi-Nik, A.; Dehestani, M. Mechanical performance of green concrete produced with untreated coal waste aggregates. Constr. Build. Mater. 2020, 233, 117264. [Google Scholar] [CrossRef]

- Khotbehsara, M.M.; Manalo, A.; Aravinthan, T.; Ferdous, W.; Benmokrane, B.; Nguyen, K.T. Synergistic effects of hygrothermal conditions and solar ultraviolet radiation on the properties of structural particulate-filled epoxy polymer coatings. Constr. Build. Mater. 2021, 277, 122336. [Google Scholar] [CrossRef]

- Abousnina, R.; Manalo, A.; Ferdous, W.; Lokuge, W.; Benabed, B.; Al-Jabri, K.S. Characteristics, strength development and microstructure of cement mortar containing oil-contaminated sand. Constr. Build. Mater. 2020, 252, 119155. [Google Scholar] [CrossRef]

- Hooton, R.; Nehdi, M.; Khan, A. Cementitious Composites Containing Recycled Tire Rubber: An Overview of Engineering Properties and Potential Applications. Cem. Concr. Aggregates 2001, 23, 3. [Google Scholar] [CrossRef] [Green Version]

- Alfayez, S.; Suleiman, A.; Nehdi, M. Recycling Tire Rubber in Asphalt Pavements: State of the Art. Sustainability 2020, 12, 9076. [Google Scholar] [CrossRef]

- Aiello, M.; Leuzzi, F. Waste tyre rubberized concrete: Properties at fresh and hardened state. Waste Manag. 2010, 30, 1696–1704. [Google Scholar] [CrossRef]

- Ferdous, W.; Manalo, A.; AlAjarmeh, O.; Mohammed, A.A.; Salih, C.; Yu, P.; Khotbehsara, M.M.; Schubel, P. Static behaviour of glass fibre reinforced novel composite sleepers for mainline railway track. Eng. Struct. 2021, 229, 111627. [Google Scholar] [CrossRef]

- Rahmani, E.; Dehestani, M.; Beygi, M.H.A.; Allahyari, H.; Nikbin, I.M. On the mechanical properties of concrete containing waste PET particles. Constr. Build. Mater. 2013, 47, 1302–1308. [Google Scholar] [CrossRef]

- Tariq, A.; Nehdi, M. Developing durable paste backfill from sulphidic tailings. Proc. Inst. Civ. Eng. Waste Resour. Manag. 2007, 160, 155–166. [Google Scholar] [CrossRef]

- Kazmi, S.M.S.; Abbas, S.; Nehdi, M.L.; Saleem, M.A.; Munir, M.J. Feasibility of Using Waste Glass Sludge in Production of Ecofriendly Clay Bricks. J. Mater. Civ. Eng. 2017, 29, 04017056. [Google Scholar] [CrossRef]

- Abbas, S.; Arshad, U.; Abbass, W.; Nehdi, M.; Ahmed, A. Recycling Untreated Coal Bottom Ash with Added Value for Mitigating Alkali–Silica Reaction in Concrete: A Sustainable Approach. Sustainability 2020, 12, 10631. [Google Scholar] [CrossRef]

- Mohammed, A.; Nehdi, M.; Adawi, A. Recycling waste latex paint in concrete with added value. ACI Mater. J. 2008, 105, 367–374. [Google Scholar]

- Abbas, S.; Ahmed, A.; Nehdi, M.L.; Saeed, D.; Abbass, W.; Amin, F. Eco-Friendly Mitigation of Alkali-Silica Reaction in Concrete Using Waste-Marble Powder. J. Mater. Civ. Eng. 2020, 32, 04020270. [Google Scholar] [CrossRef]

- Andreão, P.V.; Suleiman, A.R.; Cordeiro, G.C.; Nehdi, M.L. Beneficiation of Sugarcane Bagasse Ash: Pozzolanic Activity and Leaching Behavior. Waste Biomass Valorization 2019, 11, 1–10. [Google Scholar] [CrossRef]

- Nehdi, M.L.; Yassine, A. Mitigating Portland Cement CO2 Emissions Using Alkali-Activated Materials: System Dynamics Model. Materials 2020, 13, 4685. [Google Scholar] [CrossRef]

- Dabbaghi, F.; Nasrollahpour, S.; Dehestani, M.; Yousefpour, H. Optimization of Concrete Mixtures Containing Lightweight Expanded Clay Aggregates Based on Mechanical, Economical, Fire-Resistance, and Environmental Considerations. ASCE J. Mater. Civ. Eng. 2021. [Google Scholar] [CrossRef]

- Dabbaghi, F.; Dehestani, M.; Yousefpour, H.; Rasekh, H.; Navaratnam, S. Residual compressive stress–strain relationship of lightweight aggregate concrete after exposure to elevated temperatures. Constr. Build. Mater. 2021, 298, 123890. [Google Scholar] [CrossRef]

- Zain, M.; Abd, S.M.; Hamid, R.; Jamil, M. Potential for Utilising Concrete Mix Properties to Predict Strength at Different Ages. J. Appl. Sci. 2010, 10, 2831–2838. [Google Scholar] [CrossRef]

- DeRousseau, M.; Kasprzyk, J.; Srubar, W. Computational design optimization of concrete mixtures: A review. Cem. Concr. Res. 2018, 109, 42–53. [Google Scholar] [CrossRef]

- Tsivilis, S.; Parissakis, G. A mathematical model for the prediction of cement strength. Cem. Concr. Res. 1995, 25, 9–14. [Google Scholar] [CrossRef]

- Nunez, I.; Marani, A.; Nehdi, M.L. Mixture Optimization of Recycled Aggregate Concrete Using Hybrid Machine Learning Model. Materials 2020, 13, 4331. [Google Scholar] [CrossRef]

- Nunez, I.; Nehdi, M.L. Machine learning prediction of carbonation depth in recycled aggregate concrete incorporating SCMs. Constr. Build. Mater. 2021, 287, 123027. [Google Scholar] [CrossRef]

- Keshtegar, B.; Nehdi, M.L.; Kolahchi, R.; Trung, N.-T.; Bagheri, M. Novel hybrid machine leaning model for predicting shear strength of reinforced concrete shear walls. Eng. Comput. 2021, 12, 1–12. [Google Scholar] [CrossRef]

- Marani, A.; Nehdi, M.L. Machine learning prediction of compressive strength for phase change materials integrated cementitious composites. Constr. Build. Mater. 2020, 265, 120286. [Google Scholar] [CrossRef]

- Ben Chaabene, W.; Nehdi, M.L. Novel soft computing hybrid model for predicting shear strength and failure mode of SFRC beams with superior accuracy. Compos. Part C Open Access 2020, 3, 100070. [Google Scholar] [CrossRef]

- Marani, A.; Jamali, A.; Nehdi, M.L. Predicting Ultra-High-Performance Concrete Compressive Strength Using Tabular Generative Adversarial Networks. Materials 2020, 13, 4757. [Google Scholar] [CrossRef]

- Almustafa, M.; Nehdi, M. Machine learning model for predicting structural response of RC slabs exposed to blast loading. Eng. Struct. 2020, 221, 111109. [Google Scholar] [CrossRef]

- Flah, M.; Nunez, I.; Ben Chaabene, W.; Nehdi, M.L. Machine Learning Algorithms in Civil Structural Health Monitoring: A Systematic Review. Arch. Comput. Methods Eng. 2021, 28, 2621–2643. [Google Scholar] [CrossRef]

- Ben Chaabene, W.; Flah, M.; Nehdi, M.L. Machine learning prediction of mechanical properties of concrete: Critical review. Constr. Build. Mater. 2020, 260, 119889. [Google Scholar] [CrossRef]

- ASTM C33/C33M-18, Standard Specification for Concrete Aggregates, Developed by Subcommittee: C09.20; ASTM International: West Conshohocken, PA, USA, 2018; Available online: www.astm.org (accessed on 15 April 2018).

- ASTM C192/C192M-19, Standard Practice for Making and Curing Concrete Test Specimens in the Laboratory; ASTM International: West Conshohocken, PA, USA, 2018; Available online: www.astm.org (accessed on 10 August 2000).

- ASTM C293/C293M-16, Standard Test Method for Flexural Strength of Concrete (Using Simple Beam with Center-Point Loading); ASTM International: West Conshohocken, PA, USA, 2018; Available online: www.astm.org (accessed on 15 April 2016).

- El-Chabib, H.; Nehdi, M. Neural network modelling of properties of cement-based materials demystified. Adv. Cem. Res. 2005, 17, 91–102. [Google Scholar] [CrossRef]

- Mukherjee, A.; Biswas, S.N. Artificial neural networks in prediction of mechanical behavior of concrete at high temperature. Nucl. Eng. Des. 1997, 178, 1–11. [Google Scholar] [CrossRef]

- Moghadam, M.T.; Qaderi, F. Modeling of petroleum wastewater treatment by Fe/Zn nanoparticles using the response surface methodology and enhancing the efficiency by scavenger. Results Phys. 2019, 15, 102566. [Google Scholar] [CrossRef]

- Qaderi, F.; Sayahzadeh, A.H.; Azizpour, F.; Vosughi, P. Efficiency modeling of serial stabilization ponds in treatment of phenolic wastewater by response surface methodology. Int. J. Environ. Sci. Technol. 2019, 16, 4193–4202. [Google Scholar] [CrossRef]

- Shi, L.; Wei, D.; Ngo, H.H.; Guo, W.; Du, B.; Wei, Q. Application of anaerobic granular sludge for competitive biosorption of methylene blue and Pb(II): Fluorescence and response surface methodology. Bioresour. Technol. 2015, 194, 297–304. [Google Scholar] [CrossRef]

- Yang, S.-S.; Guo, W.-Q.; Zhou, X.-J.; Meng, Z.-H.; Liu, B.; Ren, N.-Q. Optimization of operating parameters for sludge process reduction under alternating aerobic/oxygen-limited conditions by response surface methodology. Bioresour. Technol. 2011, 102, 9843–9851. [Google Scholar] [CrossRef]

- Design Expert Software; Version 13; Stat-Ease, Inc.: Minneapolis, MN, USA, 2016.

- Ergün, A. Effects of the usage of diatomite and waste marble powder as partial replacement of cement on the mechanical properties of concrete. Constr. Build. Mater. 2011, 25, 806–812. [Google Scholar] [CrossRef]

- Ganjian, E.; Khorami, M.; Maghsoudi, A.A. Scrap-tyre-rubber replacement for aggregate and filler in concrete. Constr. Build. Mater. 2009, 23, 1828–1836. [Google Scholar] [CrossRef]

| Chemical Properties (%) | Physical Properties | Compressive Strength (MPa) | |||

|---|---|---|---|---|---|

| SiO2 | 21.9 | Specific gravity | 3.15 | 3 days | 18.14 |

| Al2O3 | 4.86 | Specific surface (m2/gr) | 0.305 | 7 days | 28.93 |

| Fe2O3 | 3.3 | Initial setting time (min) | 140 | 28 days | 37.17 |

| CaO | 63.32 | Final setting time (min) | 190 | ||

| MgO | 1.15 | ||||

| SO3 | 2.1 | ||||

| Loss on ignition (L.O.I) | 2.4 | ||||

| Items | SiO2 | AL2O3 | Fe2O3 | MgO | CaO | P2O5–P2O3 | Na2O | K2O | MnO | TiO2 | L.O.I |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Untreated Coal waste | 37.8 | 13.14 | 2.85 | 0.73 | 0.76 | 0.27 | 0.28 | 2.02 | 0.02 | 1.17 | 40.96 |

| Mix | W/C | Coal Waste (%) | Cement (kg/m3) | Water (kg/m3) | Gravel (kg/m3) | Sand (kg/m3) | Coal Waste (kg/m3) | Flexural Strength (MPa) |

|---|---|---|---|---|---|---|---|---|

| R1 | 0.40 | 5.25 | 375 | 150 | 784 | 744.8 | 19.69 | 6.260 |

| R2 | 0.45 | 3.00 | 412 | 185.4 | 720 | 684.0 | 12.36 | 5.140 |

| R3 | 0.45 | 7.5 | 340 | 153.0 | 720 | 684.0 | 25.50 | 6.360 |

| R4 | 0.45 | 7.5 | 412 | 185.4 | 880 | 836.0 | 30.90 | 4.325 |

| R5 | 0.45 | 7.5 | 340 | 153.0 | 880 | 836.0 | 25.50 | 4.915 |

| R6 | 0.45 | 3.00 | 340 | 153.0 | 880 | 836.0 | 10.20 | 5.090 |

| R7 | 0.45 | 3.00 | 340 | 153.0 | 720 | 684.0 | 10.20 | 6.675 |

| R8 | 0.45 | 7.50 | 412 | 185.4 | 720 | 684.0 | 30.90 | 6.655 |

| R9 | 0.45 | 3.00 | 412 | 185.4 | 880 | 836.0 | 12.36 | 5.560 |

| R10 | 0.49 | 5.25 | 375 | 183.75 | 640 | 608.0 | 19.69 | 5.430 |

| R11 | 0.49 | 5.25 | 375 | 183.75 | 784 | 744.8 | 19.69 | 5.875 |

| R12 | 0.49 | 9.75 | 375 | 183.75 | 784 | 744.8 | 36.56 | 4.080 |

| R13 | 0.49 | 5.25 | 375 | 183.75 | 784 | 744.8 | 19.69 | 6.605 |

| R14 | 0.49 | 7.50 | 375 | 183.75 | 784 | 744.8 | 28.10 | 5.620 |

| R15 | 0.49 | 5.25 | 375 | 183.75 | 784 | 744.8 | 19.69 | 6.350 |

| R16 | 0.49 | 5.25 | 445 | 218.05 | 784 | 744.8 | 23.36 | 6.620 |

| R17 | 0.49 | 5.25 | 375 | 183.75 | 960 | 912.0 | 19.69 | 5.540 |

| R18 | 0.49 | 5.25 | 375 | 183.75 | 784 | 744.8 | 19.69 | 5.395 |

| R19 | 0.49 | 5.25 | 375 | 183.75 | 784 | 744.8 | 19.69 | 6.395 |

| R20 | 0.49 | 5.25 | 305 | 149.45 | 784 | 744.8 | 16.01 | 6.025 |

| R21 | 0.49 | 5.25 | 375 | 183.75 | 784 | 744.8 | 19.69 | 6.640 |

| R22 | 0.55 | 7.50 | 412 | 226.6 | 880 | 836.0 | 30.90 | 6.160 |

| R23 | 0.55 | 7.50 | 340 | 187.0 | 880 | 836.0 | 25.50 | 5.940 |

| R24 | 0.55 | 3.00 | 412 | 226.6 | 880 | 836.0 | 12.36 | 5.500 |

| R25 | 0.55 | 7.50 | 340 | 187.0 | 720 | 684.0 | 25.50 | 5.420 |

| R26 | 0.55 | 3.00 | 340 | 187.0 | 720 | 684.0 | 10.20 | 5.770 |

| R27 | 0.55 | 3.00 | 412 | 226.6 | 720 | 684.0 | 12.36 | 5.980 |

| R28 | 0.55 | 3.00 | 340 | 187.0 | 880 | 836.0 | 10.20 | 5.750 |

| R29 | 0.55 | 7.50 | 412 | 226.6 | 720 | 684.0 | 30.90 | 6.440 |

| R30 | 0.60 | 5.25 | 375 | 225.0 | 784 | 744.8 | 19.69 | 4.145 |

| Criteria for the Used Models | Equation |

|---|---|

| Root Mean Square: Random Error (R2) | |

| Mean Squared Error (MSE) | |

| Mean Absolute Error (MAE) | |

| Root Mean Square Error (RMSE) |

| Independent Variables | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| W/C | Cement | Gravel | Coal Waste | BIAS | ||||||||

| Layer 1 | N 1-1 | 1.4255 | −1.6036 | 0.65367 | 1.0762 | −2.5832 | ||||||

| N 1-2 | 0.75982 | 1.1982 | −1.3435 | −1.2943 | −2.1712 | |||||||

| N 1-3 | −0.95069 | 1.6273 | 1.3359 | −0.45526 | 1.8651 | |||||||

| N 1-4 | 2.5719 | −0.18724 | 0.77472 | −1.5824 | −1.1693 | |||||||

| N 1-5 | 0.16151 | 0.1784 | 0.202 | −3.04 | −0.74634 | |||||||

| N 1-6 | −1.2883 | −0.00035 | 1.177 | 1.932 | −0.17828 | |||||||

| N 1-7 | −1.5654 | −0.9002 | 1.1944 | 2.314 | −1.277 | |||||||

| N 1-8 | 0.5984 | 2.3704 | −0.91183 | −0.51606 | 1.5529 | |||||||

| N 1-9 | 1.3918 | 0.56141 | −0.10028 | 1.2735 | 2.8188 | |||||||

| N 1-10 | 0.80132 | 0.95138 | −0.28147 | −2.1724 | 2.4328 | |||||||

| Layer 1 | ||||||||||||

| N1-1 | N1-2 | N1-3 | N1-4 | N1-5 | N1-6 | N 1-7 | N 1-8 | N 1-9 | N1-10 | BIAS | ||

| Layer 2 | N 2-1 | −0.16 | 0.58 | −0.18 | 0.98 | 0.83 | −0.90 | −0.41 | 0.43 | −0.14 | −0.38 | 1.84 |

| N 2-2 | −0.31 | 0.66 | 0.003 | 1.29 | −0.91 | 0.22 | 0.06 | −0.34 | 0.15 | 0.88 | 1.28 | |

| N 2-3 | 0.54 | −0.30 | 0.14 | −0.05 | 0.79 | 0.22 | −0.71 | −0.87 | −0.48 | −0.70 | −0.83 | |

| N 2-4 | 0.32 | −0.03 | 0.06 | −1.25 | 0.75 | −0.20 | −1.75 | −0.97 | 0.09 | 0.71 | −0.22 | |

| N 2-5 | −0.77 | −0.24 | 1.11 | −0.43 | −0.25 | 1.32 | 0.69 | −0.62 | 0.21 | 0.07 | −0.23 | |

| N 2-6 | −0.07 | −0.77 | −0.42 | −0.37 | −0.84 | −0.40 | 0.62 | 0.46 | 0.39 | 0.94 | −0.70 | |

| N 2-7 | −0.30 | −0.95 | −0.025 | −0.15 | −0.33 | 0.61 | 0.96 | −0.10 | 0.10 | −0.69 | −1.06 | |

| N 2-8 | 0.39 | −0.21 | 0.42 | −0.57 | −0.48 | 0.67 | −0.94 | 0.22 | −0.85 | −0.10 | 1.77 | |

| Layer 2 | ||||||||||||

| N 2-1 | N 2-2 | N 2-3 | N 2-4 | N 2-5 | N 2-6 | N 2-7 | N 2-8 | BIAS | ||||

| Output | −0.228 | 0.85987 | −0.32309 | 1.1469 | 0.47257 | −0.027428 | −0.063393 | −0.44329 | −1.0208 | |||

| Response | Flexural Strength | ||||

|---|---|---|---|---|---|

| Analysis of Variance Table [Partial Sum of Squares—Type III] | |||||

| Source | Sum of Squares | * df | Mean Square | F Value | p-Value Prob > F |

| Model | 12.74 | 18 | 0.71 | 2.7 | 0.0479 |

| A-W/C | 1.85 | 1 | 1.85 | 7.08 | 0.0222 |

| B-Cement Content | 0.047 | 1 | 0.047 | 0.18 | 0.6792 |

| C-Gravel volume | 0.046 | 1 | 0.046 | 0.18 | 0.6832 |

| D-Coal waste | 0.31 | 1 | 0.31 | 1.18 | 0.3008 |

| AC | 1.35 | 1 | 1.35 | 5.15 | 0.0444 |

| AD | 0.083 | 1 | 0.083 | 0.32 | 0.5854 |

| BC | 6.97 × 10−3 | 1 | 6.97 × 10−3 | 0.027 | 0.8734 |

| BD | 0.27 | 1 | 0.27 | 1.02 | 0.3335 |

| CD | 0.22 | 1 | 0.22 | 0.85 | 0.3755 |

| A2 | 0.89 | 1 | 0.89 | 3.41 | 0.0917 |

| B2 | 9.62 × 10−6 | 1 | 9.62 × 10−6 | 3.68 × 10−5 | 0.9953 |

| C2 | 1.51 × 10−3 | 1 | 1.51 × 10−3 | 5.77E × 10−3 | 0.9408 |

| D2 | 2.39 | 1 | 2.39 | 9.13 | 0.0116 |

| ACD | 0.71 | 1 | 0.71 | 2.71 | 0.1278 |

| BCD | 0.66 | 1 | 0.66 | 2.52 | 0.1405 |

| AC2 | 2.15 | 1 | 2.15 | 8.22 | 0.0153 |

| B2C | 0.79 | 1 | 0.79 | 3 | 0.111 |

| A3 | 0 | 0 | |||

| D3 | 1.03 | 1 | 1.03 | 3.95 | 0.0724 |

| Residual | 2.88 | 11 | 0.26 | ||

| Lack of Fit | 1.71 | 6 | 0.28 | 1.22 | 0.4246 |

| Pure Error | 1.17 | 5 | 0.23 | ||

| Cor. Total | 15.62 | 29 | |||

| Independent Variables | |||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| W/C (A) | Cement (B) | Gravel (C) | Coal Waste (D) | AC | AD | BC | BD | CD | A2 | B2 | C2 | D2 | ACD | BCD | AC2 | B2C | A3 | D3 | BIAS | ||

| Layer 1 | N 1-1 | 0.12 | −0.25 | 0.07 | −0.05 | −0.32 | −0.24 | 0.13 | −0.35 | 0.47 | 0.48 | −0.07 | 0.35 | 0.49 | −0.25 | −0.56 | 0.33 | −0.51 | −0.41 | 0.5 | −1.57 |

| N 1-2 | 0.04 | 0.19 | −0.95 | 0.1 | −0.61 | −0.62 | −0.49 | −0.53 | 0.32 | 0.42 | 0.22 | −0.5 | 0.51 | 0.07 | −0.74 | −0.17 | −0.39 | −0.23 | 0.07 | 0.62 | |

| N 1-3 | −0.31 | 0.06 | 0.18 | 0.46 | 0.04 | 0.11 | 0.25 | −0.12 | 0.1 | −0.3 | −0.04 | 0.4 | 0.36 | −0.54 | 0.71 | 0.71 | −0.68 | −0.23 | −0.35 | 0.36 | |

| N 1-4 | −0.36 | −0.33 | 0.37 | 0.35 | 0.21 | −0.2 | 0.05 | 0.41 | −0.05 | 0.22 | −0.29 | 0.59 | 0.16 | 0.65 | −0.48 | −0.26 | −0.35 | 0.03 | −0.47 | 0.22 | |

| N 1-5 | 0.2 | 0.47 | 0.19 | −0.39 | −0.75 | −0.03 | −0.35 | 0.36 | 0.19 | −0.04 | −0.54 | 0.08 | 0.6 | −0.28 | −0.03 | −0.31 | −0.22 | −0.61 | 0.65 | 0.39 | |

| N 1-6 | 0.09 | 0.29 | 0.14 | 0.3 | 0.75 | 0.5 | 0.09 | 0.14 | −0.31 | 0.7 | −0.52 | 0.09 | −0.14 | 0.1 | 0.02 | −0.18 | −0.48 | 0.74 | 0.39 | −0.71 | |

| N 1-7 | −0.46 | 0.08 | −0.58 | −0.06 | −0.22 | 0.37 | 0.5 | −0.58 | −0.46 | −0.45 | −0.5 | −0.31 | −0.4 | −0.3 | −0.43 | 0.17 | 0.31 | 0.16 | −0.03 | −1.06 | |

| N 1-8 | 0.47 | 0.24 | 0.17 | −0.52 | −0.24 | −0.47 | 0.03 | −0.58 | 0.36 | 0.05 | −0.36 | 0.21 | 0.09 | 0.17 | −0.08 | −0.56 | −0.05 | −0.52 | −0.58 | 1.52 | |

| Layer 1 | |||||||||||||||||||||

| N1-1 | N1-2 | N1-3 | N1-4 | N1-5 | N1-6 | N 1-7 | N 1-8 | BIAS | |||||||||||||

| Layer 2 | N 2-1 | −0.370 | −0.877 | 0.97058 | 0.027 | −0.545 | −0.414 | −0.926 | 0.323 | 1.83 | |||||||||||

| N 2-2 | −0.067 | −0.644 | 0.24806 | 1.29 | −0.204 | −0.351 | 1.005 | −0.179 | 1.259 | ||||||||||||

| N 2-3 | −1.051 | 0.277 | −0.88341 | 0.34 | −0.868 | 0.407 | 0.207 | 0.841 | 0.726 | ||||||||||||

| N 2-4 | 0.087 | −0.189 | 0.97207 | 0.412 | −0.092 | −1.137 | −1.143 | −0.584 | −0.156 | ||||||||||||

| N 2-5 | −0.495 | −0.733 | −0.33314 | 0.217 | 0.638 | −0.969 | 0.107 | 1.086 | −0.321 | ||||||||||||

| N 2-6 | −0.0495 | 1.325 | −0.78808 | −0.183 | 0.28 | −1.067 | 0.41 | −0.578 | −0.903 | ||||||||||||

| N 2-7 | 0.125 | 0.568 | 0.83299 | 0.733 | −0.215 | −0.720 | −0.742 | 0.796 | 1.31 | ||||||||||||

| N 2-8 | −0.799 | 0.08 | −0.70271 | −0.223 | 0.711 | 0.759 | 0.909 | −0.488 | −1.823 | ||||||||||||

| Layer 2 | |||||||||||||||||||||

| N 2-1 | N 2-2 | N 2-3 | N 2-4 | N 2-5 | N 2-6 | N 2-7 | N 2-8 | BIAS | |||||||||||||

| Layer 3 | N 3-1 | 1.168 | −0.6722 | 1.1144 | −0.4385 | −0.5610 | −0.7026 | 0.2466 | −0.5264 | −1.4806 | |||||||||||

| N 3-2 | −0.0168 | −0.8588 | −0.2154 | −0.2713 | 0.7424 | 0.676 | −0.9124 | 0.613 | −1.0882 | ||||||||||||

| N 3-3 | −0.0259 | 0.7562 | 0.121 | −0.5339 | 0.3314 | 1.0392 | 0.4327 | −0.8359 | −0.5162 | ||||||||||||

| N 3-4 | 1.0796 | −0.0166 | −0.9398 | −0.6319 | 0.532 | −0.6619 | −0.1677 | 0.5409 | 0.3183 | ||||||||||||

| N 3-5 | 0.7894 | 0.148 | −0.2405 | 0.6315 | 1.2459 | −0.3098 | −0.3563 | 0.7113 | 1.2089 | ||||||||||||

| N 3-6 | −0.4737 | 0.0196 | −0.9185 | 0.7985 | 0.177 | 0.9209 | −0.4222 | −0.5776 | −1.7361 | ||||||||||||

| Layer 3 | |||||||||||||||||||||

| N 3-1 | N 3-2 | N 3-3 | N 3-4 | N 3-5 | N 3-6 | BIAS | |||||||||||||||

| output | 0.6294 | −0.19791 | 0.49824 | −1.0218 | 0.73563 | 0.50878 | −0.49803 | ||||||||||||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dabbaghi, F.; Rashidi, M.; Nehdi, M.L.; Sadeghi, H.; Karimaei, M.; Rasekh, H.; Qaderi, F. Experimental and Informational Modeling Study on Flexural Strength of Eco-Friendly Concrete Incorporating Coal Waste. Sustainability 2021, 13, 7506. https://doi.org/10.3390/su13137506

Dabbaghi F, Rashidi M, Nehdi ML, Sadeghi H, Karimaei M, Rasekh H, Qaderi F. Experimental and Informational Modeling Study on Flexural Strength of Eco-Friendly Concrete Incorporating Coal Waste. Sustainability. 2021; 13(13):7506. https://doi.org/10.3390/su13137506

Chicago/Turabian StyleDabbaghi, Farshad, Maria Rashidi, Moncef L. Nehdi, Hamzeh Sadeghi, Mahmood Karimaei, Haleh Rasekh, and Farhad Qaderi. 2021. "Experimental and Informational Modeling Study on Flexural Strength of Eco-Friendly Concrete Incorporating Coal Waste" Sustainability 13, no. 13: 7506. https://doi.org/10.3390/su13137506

APA StyleDabbaghi, F., Rashidi, M., Nehdi, M. L., Sadeghi, H., Karimaei, M., Rasekh, H., & Qaderi, F. (2021). Experimental and Informational Modeling Study on Flexural Strength of Eco-Friendly Concrete Incorporating Coal Waste. Sustainability, 13(13), 7506. https://doi.org/10.3390/su13137506