Key Barriers to the Adoption of Biomass Gasification in Burkina Faso

Abstract

:1. Introduction

1.1. Biomass as a Source of Energy for Agro-Industry in Developing Countries

1.2. Gasification and Pyrolysis Are Eco-Friendly and Efficient Routes for Lignocellulosic Biomass Conversion

1.3. Adoption Issue of Biomass Thermochemical Conversion Technologies

2. Materials and Methods

2.1. Case Studies of Gasification in Burkina Faso

2.2. Case Studies of Pyrolysis in Burkina Faso: Reference Benchmark

2.3. Data Collection

2.4. Analytic Hierarchy Process (AHP) Method

3. Results

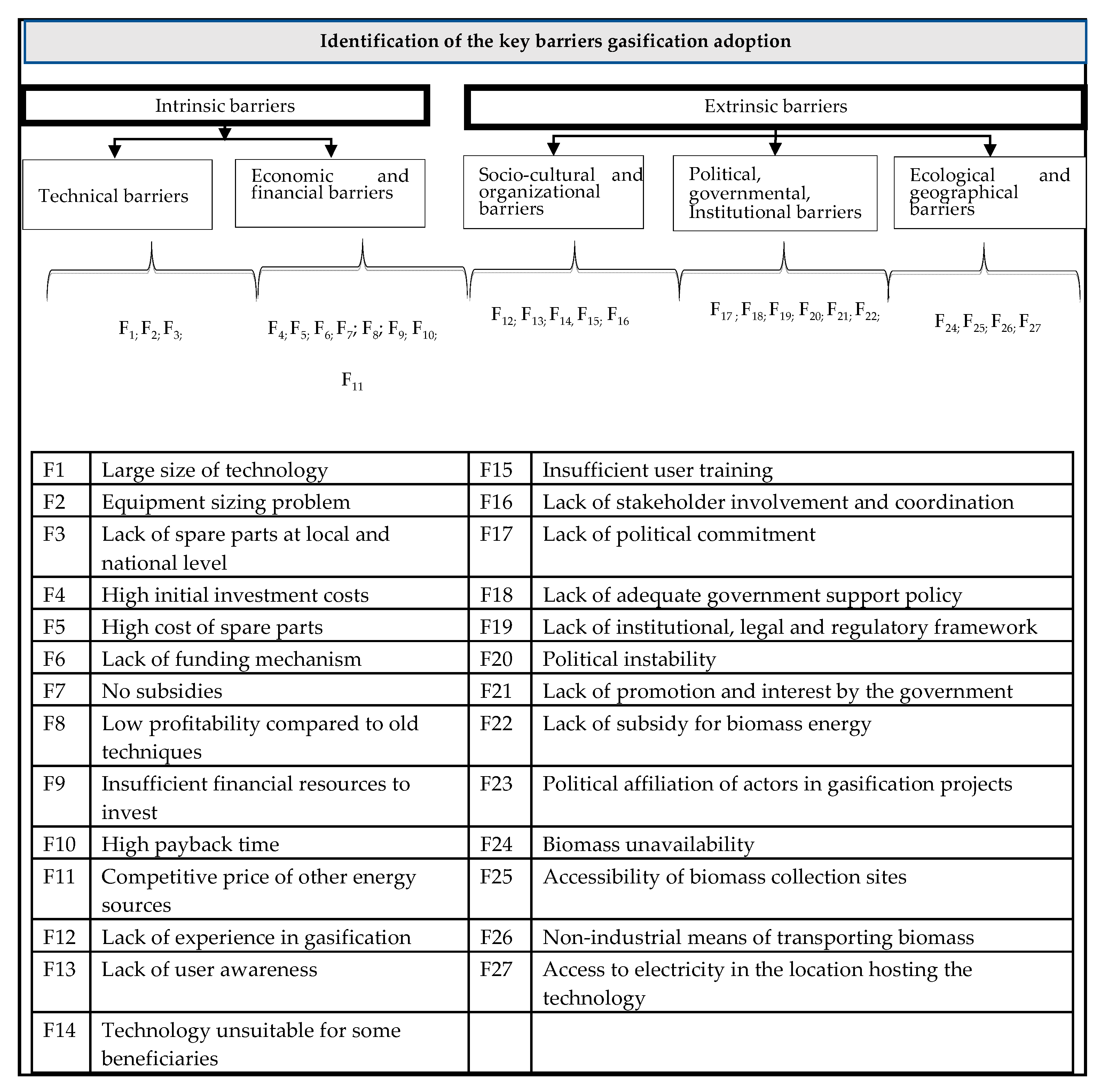

3.1. Typology of Barriers to the Adoption of Gasification

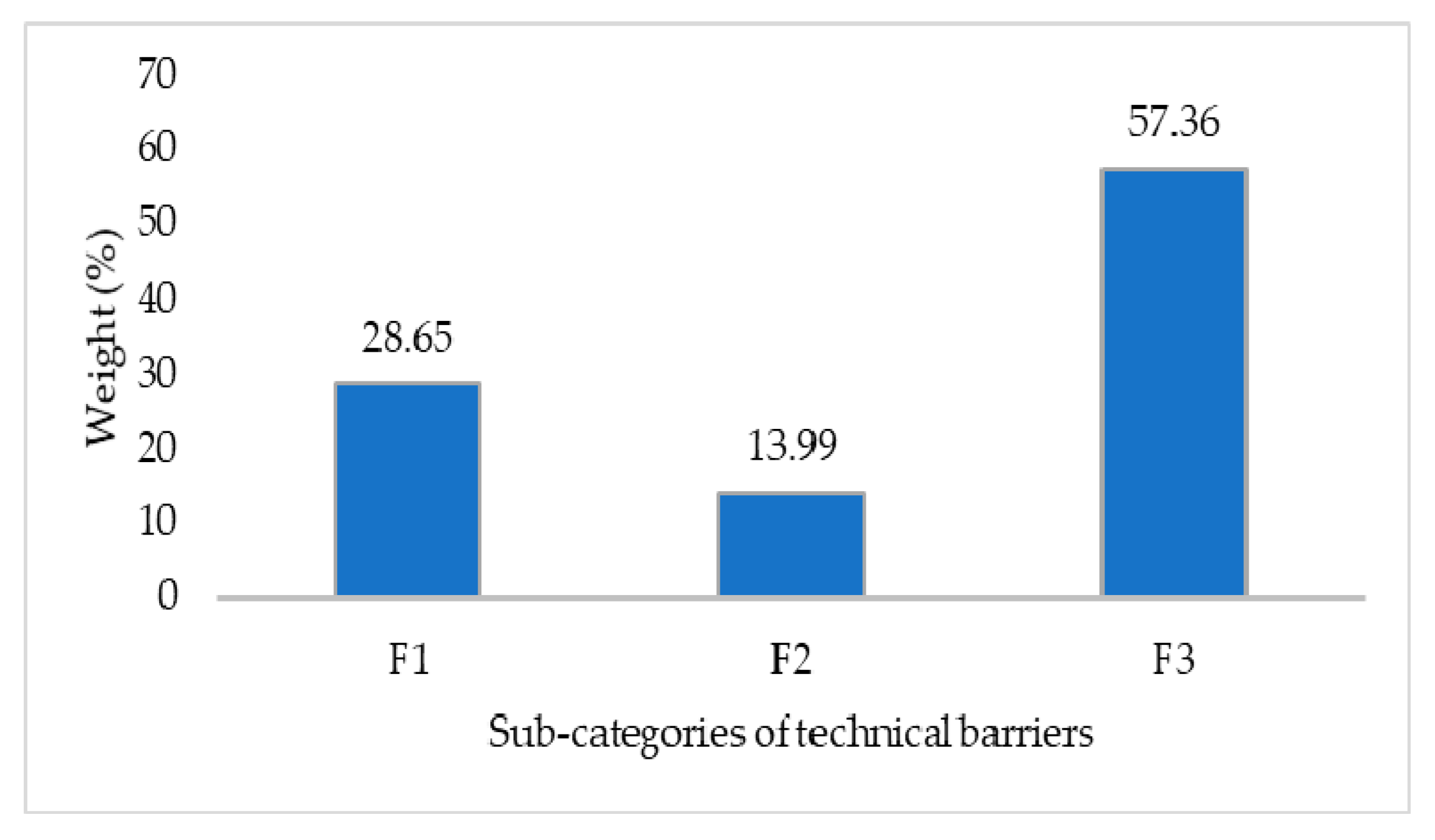

3.1.1. Technical Barriers

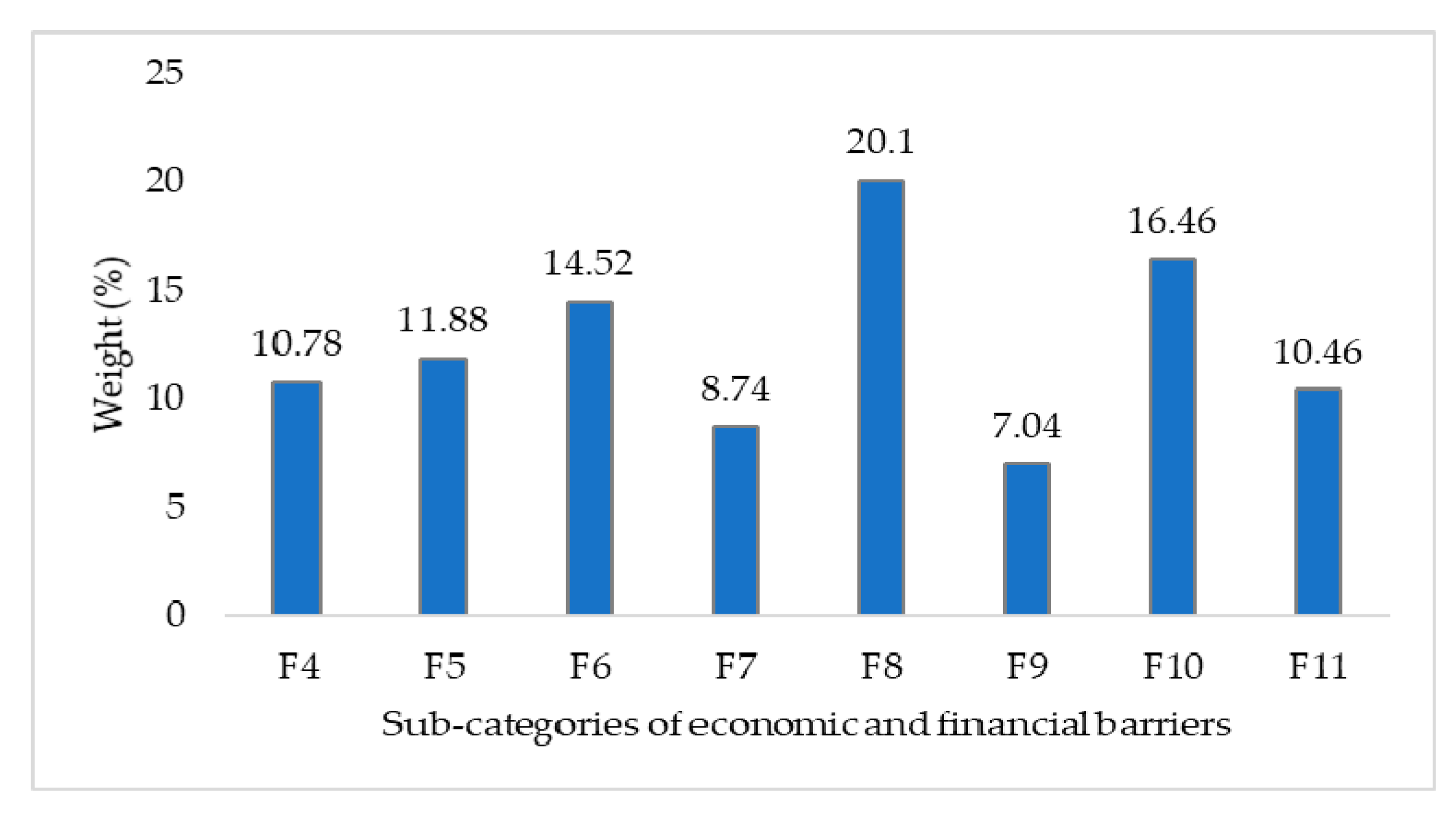

3.1.2. Economic and Financial Barriers

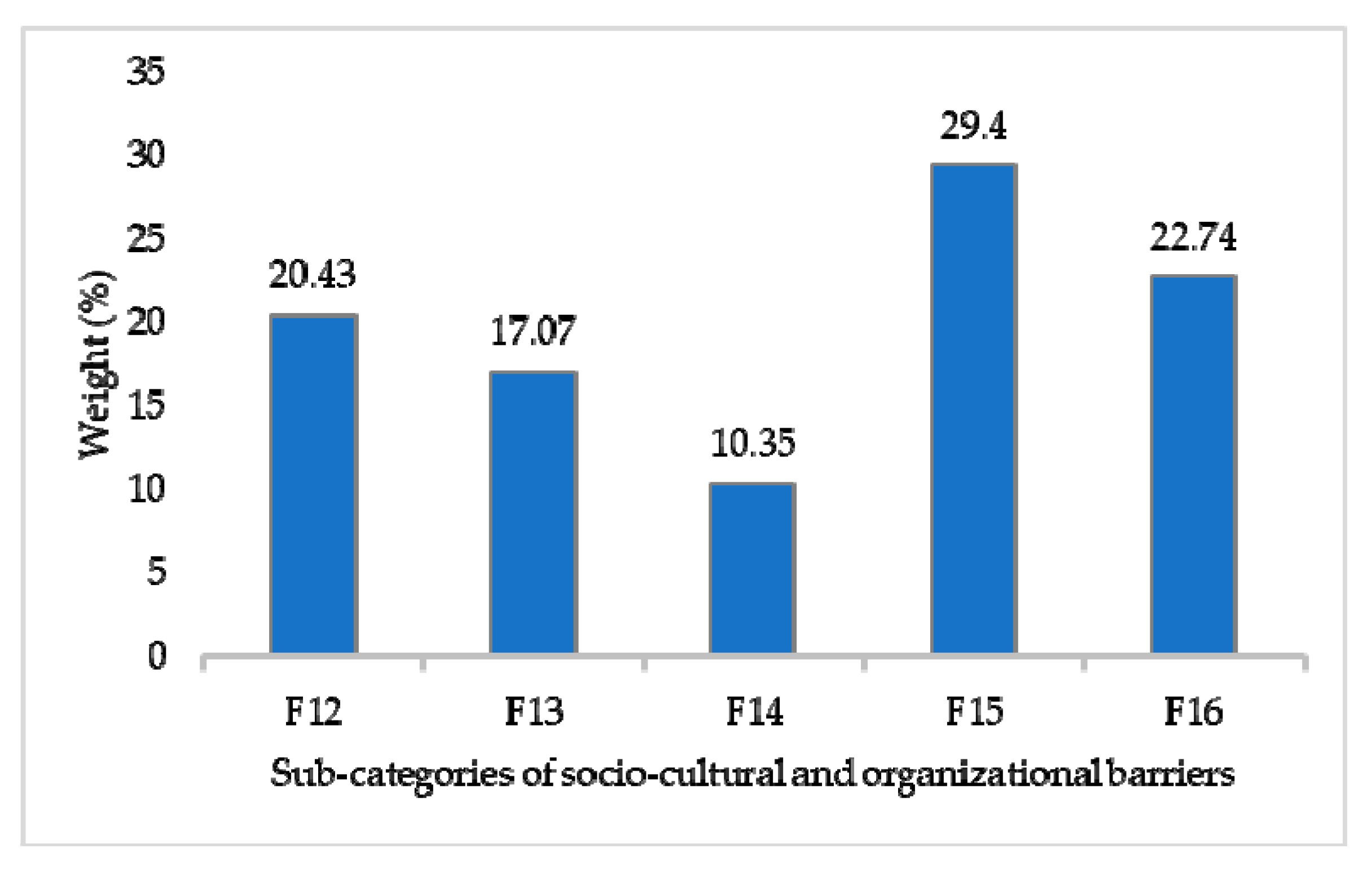

3.1.3. Socio-Cultural and Organizational Barriers

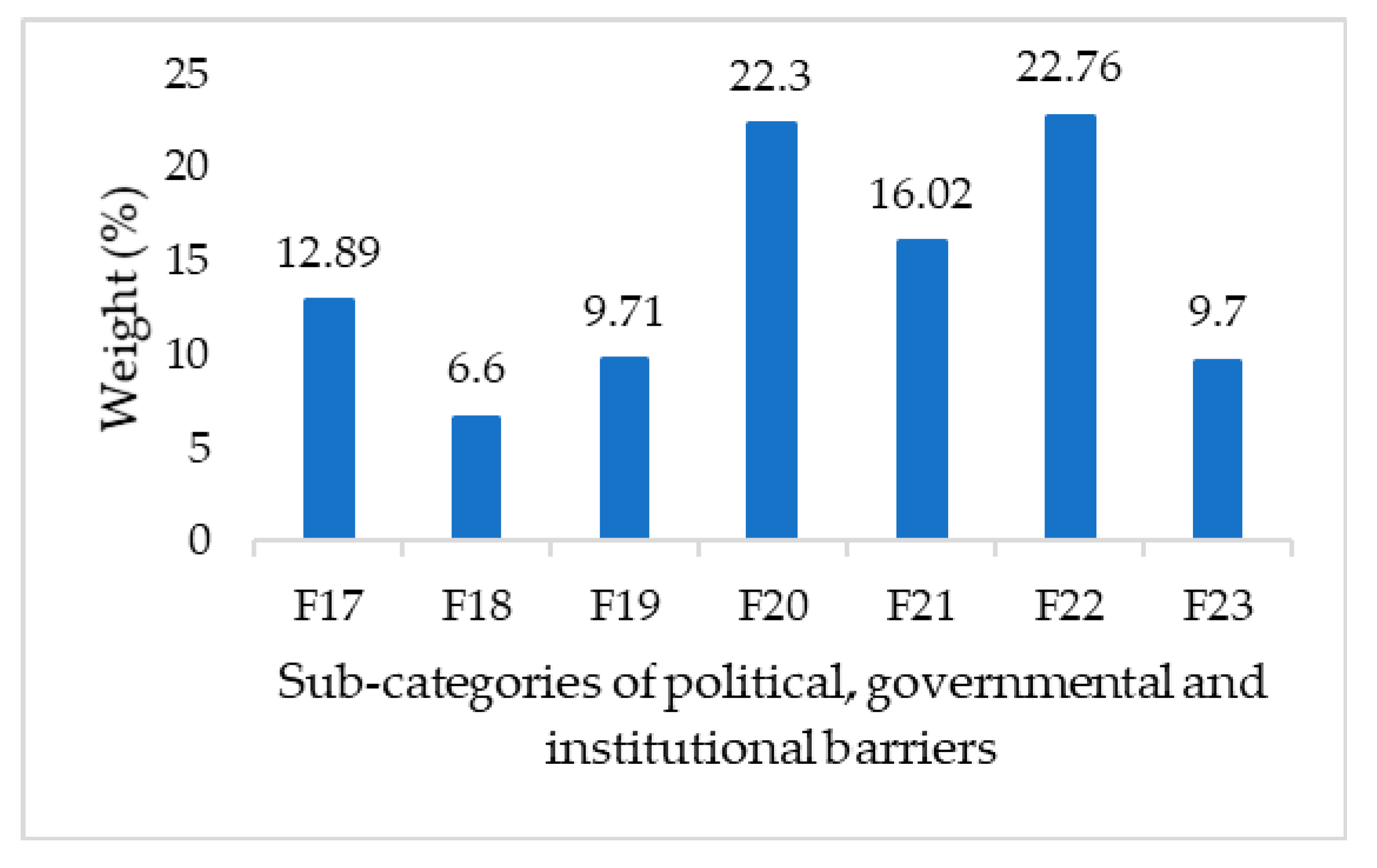

3.1.4. Political, Governmental, Institutional Barriers

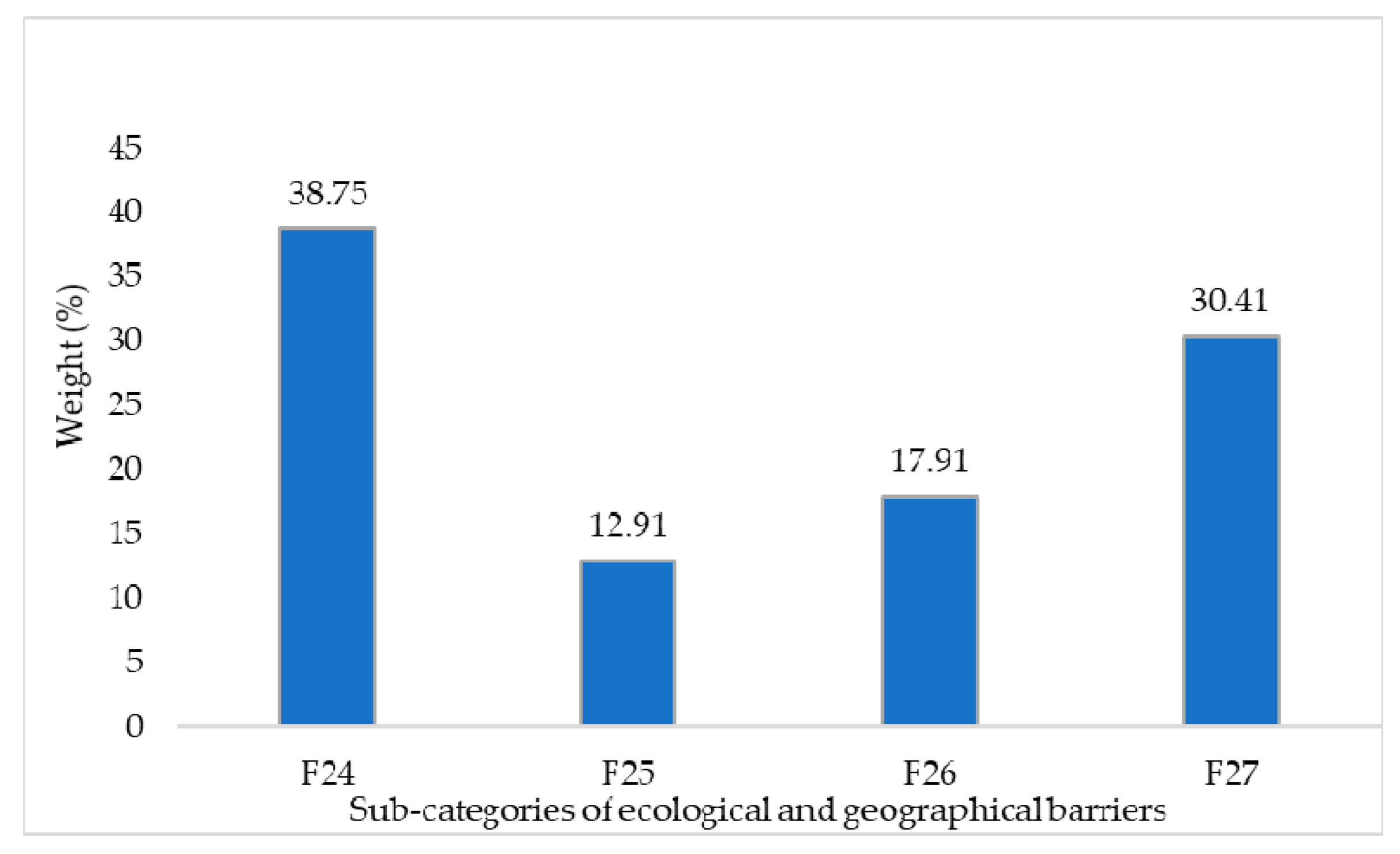

3.1.5. Ecological and Geographical Barriers

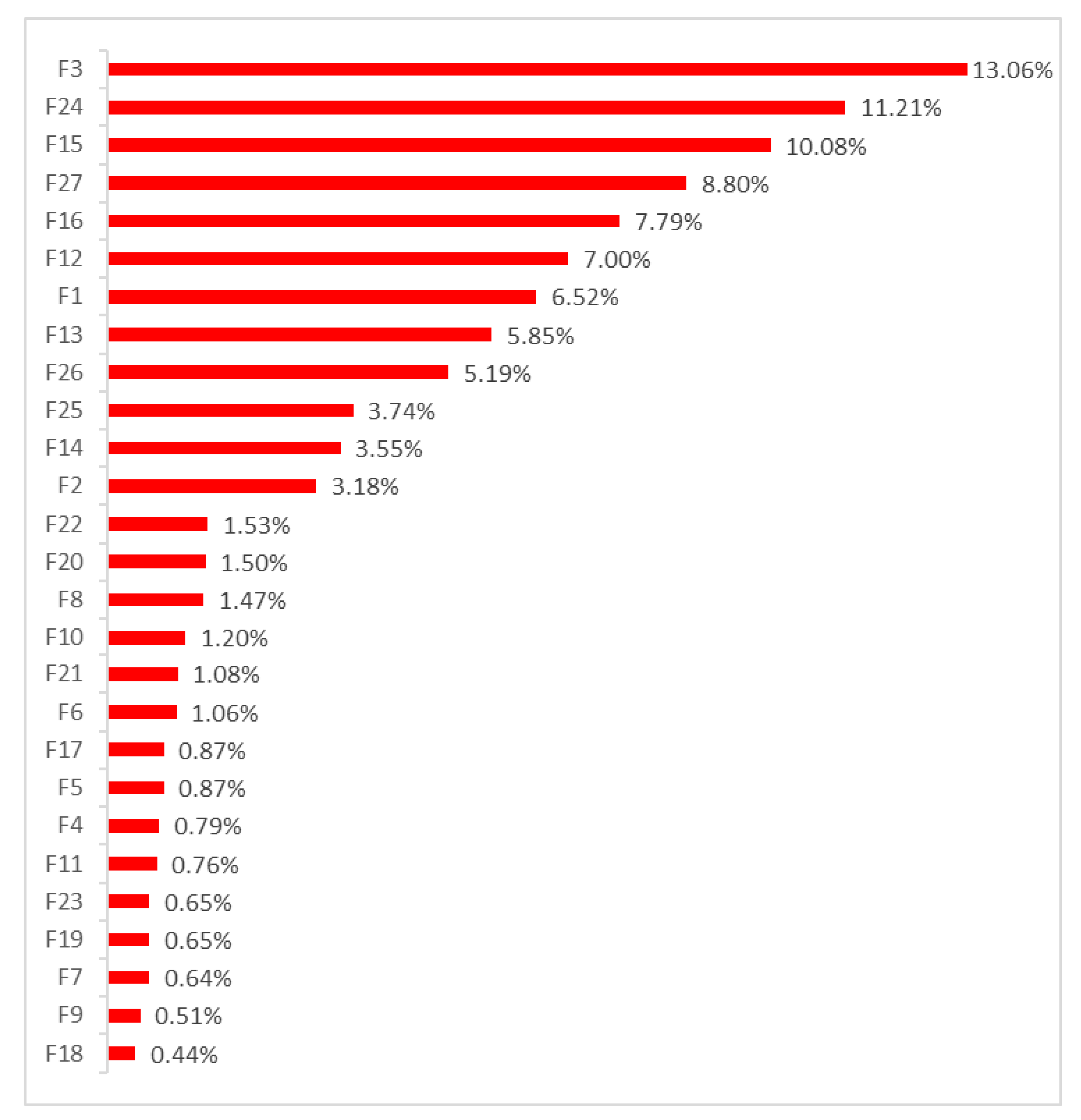

3.2. Hierarchy of Barriers Subcategories

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Beck, S.; Ribon, O.; Rieding, N. Chiffres clés de l’énergie Édition. Epsilon 2020, 2020, 1–80. [Google Scholar]

- Diedhiou, A.; Ndiaye, L.; Bensakhria, A.; Sock, O. Thermochemical conversion of cashew nut shells, palm nut shells and peanut shells char with CO2 and/or and/or steam to aliment a clay brick fi ring unit. Renew. Energy 2019, 142, 581–590. [Google Scholar] [CrossRef]

- Zulqarnain; Ayoub, M.; Yusoff, M.H.M.; Nazir, M.H.; Zahid, I.; Ameen, M.; Sher, F.; Floresyona, D.; Budi Nursanto, E. A comprehensive review on oil extraction and biodiesel production technologies. Sustainability 2021, 13, 788. [Google Scholar] [CrossRef]

- Yaqoob, H.; Teoh, Y.H.; Jamil, M.A.; Rasheed, T.; Sher, F. An experimental investigation on tribological behaviour of tire-derived pyrolysis oil blended with biodiesel fuel. Sustainability 2020, 12, 9975. [Google Scholar] [CrossRef]

- Bhattacharya, S.C. Commercialisation options for biomass energy technologies in ESCAP countries. Int. J. Energy Technol. Policy 2003, 1, 363–399. [Google Scholar] [CrossRef]

- Al-Juboori, O.; Sher, F.; Khalid, U.; Niazi, M.B.K.; Chen, G.Z. Electrochemical Production of Sustainable Hydrocarbon Fuels from CO2 Co-electrolysis in Eutectic Molten Melts. ACS Sustain. Chem. Eng. 2020, 8, 12877–12890. [Google Scholar] [CrossRef]

- Berahab, R. Energies Renouvelables en Afrique: Enjeux, défis et Opportunités. 2019, pp. 1–36. Available online: https://www.africaportal.org/publications/energies-renouvelables-en-afrique-enjeux-d%C3%A9fis-et-opportunit%C3%A9s-renewable-energy-africa-issues-challenges-and-opportunities/ (accessed on 2 May 2019).

- Secrétariat Permanent de la Coordination des Politiques Sectorielles Agricoles. Deuxième Programme National du Secteur Rural (PNSR) 2016–2020; Secrétariat Permanent de la Coordination des Politiques Sectorielles Agricoles: Ouagadougou, Burkina Faso, 2017. [Google Scholar]

- Louvel, R.; Gromard, C. De la biomasse à la bioéconomie, une stratégie énergétique pour l’Afrique? Afr. Contemp. 2017, 261–262, 223–240. [Google Scholar] [CrossRef]

- Kwofie, E.M.; Ngadi, M. A review of rice parboiling systems, energy supply, and consumption. Renew. Sustain. Energy Rev. 2017, 72, 465–472. [Google Scholar] [CrossRef]

- Patel, M.; Zhang, X.; Kumar, A. Techno-economic and life cycle assessment on lignocellulosic biomass thermochemical conversion technologies: A review. Renew. Sustain. Energy Rev. 2016, 53, 1486–1499. [Google Scholar] [CrossRef]

- Höök, M.; Tang, X. Depletion of fossil fuels and anthropogenic climate change—A review. Energy Policy 2013, 52, 797–809. [Google Scholar] [CrossRef] [Green Version]

- Sher, F.; Yaqoob, A.; Saeed, F.; Zhang, S.; Jahan, Z.; Klemeš, J.J. Torrefied biomass fuels as a renewable alternative to coal in co-firing for power generation. Energy 2020, 209, 13. [Google Scholar] [CrossRef]

- Basu, P. Biomass Gasification, Pyrolysis and Torrefaction. Practical Design and Theory; Academic Press: Cambridge, MA, USA, 2013. [Google Scholar]

- Makwana, J.P.; Pandey, J.; Mishra, G. Improving the properties of producer gas using high temperature gasification of rice husk in a pilot scale fluidized bed gasifier (FBG). Renew. Energy 2018. [Google Scholar] [CrossRef]

- Giuliano, A.; Freda, C.; Catizzone, E. Techno-economic assessment of bio-syngas production for methanol synthesis: A focus on the water–gas shift and carbon capture sections. Bioengineering 2020, 7, 70. [Google Scholar] [CrossRef] [PubMed]

- Alauddin, Z.A.B.Z.; Lahijani, P.; Mohammadi, M.; Mohamed, A.R. Gasification of lignocellulosic biomass in fluidized beds for renewable energy development: A review. Renew. Sustain. Energy Rev. 2010, 14, 2852–2862. [Google Scholar] [CrossRef]

- Tanger, P.; Field, J.L.; Jahn, C.E.; Defoort, M.W.; Leach, J.E.; Allison, G.G. Biomass for thermochemical conversion: Targets and challenges. Front. Plant Sci. 2013, 4, 1–20. [Google Scholar] [CrossRef] [Green Version]

- Chang, J.; Leung, D.Y.C.; Wu, C.Z.; Yuan, Z.H. A review on the energy production, consumption, and prospect of renewable energy in China. Renew. Sustain. Energy Rev. 2003, 7, 453–468. [Google Scholar] [CrossRef]

- Chang, Q.; Zhuo, S.; Meng, J.; Qin, S.; Yao, S. Clean coal technologies in China: Current status and future perspectives. Engineering 2016, 2, 447–459. [Google Scholar] [CrossRef]

- Brew-Hammond, A.; Kemausuor, F. Guidebook on Modern Bioenergy Conversion Technologies in Africa; UNIDO: Vienna, Austria, 2008. [Google Scholar]

- Zhang, Z.; Chen, B.; Chen, A.; Zhao, W. Barriers to commercialization development of crop straw gasification technology in China and promoting policy design. Energy Sources Part B Econ. Plan. Policy 2013, 8, 279–289. [Google Scholar] [CrossRef]

- Sansaniwal, S.K.; Rosen, M.A.; Tyagi, S.K. Global challenges in the sustainable development of biomass gasification: An overview. Renew. Sustain. Energy Rev. 2017, 80, 23–43. [Google Scholar] [CrossRef]

- Akbi, A. Les politiques de soutien aux biocarburants. CREDEN 2017, 33, 1–45. [Google Scholar]

- Dasappa, S.; Sridhar, H.V.; Sridhar, G.; Paul, P.J.; Mukunda, H.S. Biomass gasification—A substitute to fossil fuel for heat application. Biomass Bioenergy 2003, 25, 637–649. [Google Scholar] [CrossRef]

- Dai, J.; Cui, H.; Grace, J.R. Biomass feeding for thermochemical reactors. Prog. Energy Combust. Sci. 2012, 38, 716–736. [Google Scholar] [CrossRef]

- Buragohain, B.; Mahanta, P.; Moholkar, V.S. Biomass gasification for decentralized power generation: The Indian perspective. Renew. Sustain. Energy Rev. 2010, 14, 73–92. [Google Scholar] [CrossRef]

- Díaz González, C.A.; Pacheco Sandoval, L. Sustainability aspects of biomass gasification systems for small power generation. Renew. Sustain. Energy Rev. 2020, 134. [Google Scholar] [CrossRef]

- Saidou, A.L. Caractérisation des Performances d’une Unité Pilote de Gazéification de Biomasse: Analyse de Faisabilité Technique, Économique et Environnementale pour une Utilisation Chez un Artisan D’une Filière Agroalimentaire au Burkina; Institut International d’Ingénierie de l’Eau et de l’Environnement: Ouagadougou, Burkina Faso, 2013; p. 83. [Google Scholar]

- Chidikofan, G.F. Développement Méthodologique pour L’évaluation des Performances et de la Durabilité de Systèmes de Production D’électricité par Gazéification de Biomasse en Milieu Rural. Etude de cas au Burkina Faso; Institut International d’Ingénierie de l’Eau et de l’Environnement (2iE)/Energie, Ouagadougou en cotutelle avec École Nationale Supérieur d’Arts et Metiers/Génie Energétique: Paris, France, 2017. [Google Scholar]

- Ettorchi-Tardy, A.; Levif, M.; Michel, P. Le benchmarking: Une méthode d’amélioration continue de la qualité en santé. Prat. Organ. Soins 2011, 42, 35–46. [Google Scholar] [CrossRef] [Green Version]

- Abu-Taha, R.; Daim, T. Multi-criteria applications in renewable energy analysis, a literature review. Res. Technol. Manag. Electr. Ind. Green Energy Technol. 2013, 60, 17–31. [Google Scholar]

- Gunduz, M.; Almuajebh, M. Critical success factors for sustainable construction project management. Sustainability 2020, 12, 1990. [Google Scholar] [CrossRef] [Green Version]

- Hamurcu, M.; Eren, T. Strategic planning based on sustainability for urban transportation: An application to decision-making. Sustainability 2020, 12, 3589. [Google Scholar] [CrossRef]

- Bukari, D.; Kemausuor, F.; Quansah, D.A.; Adaramola, M.S. Towards accelerating the Deployment of decentralised renewable energy mini-grids in Ghana: Review and analysis of barriers. Renew. Sustain. Energy Rev. 2021, 135, 110408. [Google Scholar] [CrossRef]

- Numata, M.; Sugiyama, M.; Mogi, G. Barrier Analysis for the Deployment of Renewable-Based Mini-Grids in Myanmar Using the Analytic Hierarchy Process (AHP). Energies 2020, 13, 1400. [Google Scholar] [CrossRef] [Green Version]

- Karatayev, M.; Hall, S.; Kalyuzhnova, Y.; Clarke, M.L. Renewable energy technology uptake in Kazakhstan: Policy drivers and barriers in a transitional economy. Renew. Sustain. Energy Rev. 2016, 66, 120–136. [Google Scholar] [CrossRef]

- Ghimire, L.P.; Kim, Y. An analysis on barriers to renewable energy development in the context of Nepal using AHP. Renew. Energy 2018, 129, 446–456. [Google Scholar] [CrossRef]

- Luthra, S.; Kumar, S.; Garg, D.; Haleem, A. Barriers to renewable/sustainable energy technologies adoption: Indian perspective. Renew. Sustain. Energy Rev. 2015, 41, 762–776. [Google Scholar] [CrossRef]

- Saaty, T.L. Decision making with the analytic hierarchy process. Int. J. Serv. Sci. 2008, 1, 83–98. [Google Scholar] [CrossRef] [Green Version]

- Saaty, T.L. Fundamentals of the Analytic Hierarchy Process. In The Analytic Hierarchy Process in Natural Resource and Environmental Decision Making; Springer: Dordrecht, The Netherlands, 2001; pp. 15–35. [Google Scholar]

- Chang, C.W.; Wu, C.R.; Lin, C.T.; Chen, H.C. An application of AHP and sensitivity analysis for selecting the best slicing machine. Comput. Ind. Eng. 2007, 52, 296–307. [Google Scholar] [CrossRef]

- Saaty, T. Fundamentals of Decision Making and Priority Theory, 2nd ed.; RWS Publications: Pittsburgh, PA, USA, 2000. [Google Scholar]

- Saaty, T.L.; Kearns, K.P. Analytical Planning: The Organization of System; Pergamon Press: New York, NY, USA, 1985. [Google Scholar]

- Keeley, A.R.; Matsumoto, K. Relative significance of determinants of foreign direct investment in wind and solar energy in developing countries—AHP analysis. Energy Policy 2018, 123, 337–348. [Google Scholar] [CrossRef]

- Caupin, V.; Gravellini, J.-M.; Périou, C. L’action des bailleurs de fonds pour soutenir le développement financier en afrique: Le cas de l’agence française de développement. Rev. D’économie Financ. 2014, 4, 177–192. [Google Scholar] [CrossRef]

- Negro, S.O. Dynamics of Technological Innovation Systems: The Case of Biomass Energy; Copernicus Institute for Sustainable Development and Innovation: Utrecht, The Netherlands, 2007. [Google Scholar]

| Weight or Intensity of the Comparison | Verbal Judgment of Preference |

|---|---|

| 1 | Equal importance |

| 2 | Weak or slight |

| 3 | Moderate importance |

| 4 | Moderate plus |

| 5 | Strong importance |

| 6 | Strong plus |

| 7 | Very strong importance |

| 8 | Very, very strong |

| 9 | Extreme importance |

| Matrix size | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

|---|---|---|---|---|---|---|---|---|

| RI | 0.58 | 0.90 | 1.12 | 1.24 | 1.32 | 1.41 | 1.45 | 1.49 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Barry, F.; Sawadogo, M.; Bologo, M.; Ouédraogo, I.W.K.; Dogot, T. Key Barriers to the Adoption of Biomass Gasification in Burkina Faso. Sustainability 2021, 13, 7324. https://doi.org/10.3390/su13137324

Barry F, Sawadogo M, Bologo M, Ouédraogo IWK, Dogot T. Key Barriers to the Adoption of Biomass Gasification in Burkina Faso. Sustainability. 2021; 13(13):7324. https://doi.org/10.3390/su13137324

Chicago/Turabian StyleBarry, Fanta, Marie Sawadogo, Maïmouna Bologo (Traoré), Igor W. K. Ouédraogo, and Thomas Dogot. 2021. "Key Barriers to the Adoption of Biomass Gasification in Burkina Faso" Sustainability 13, no. 13: 7324. https://doi.org/10.3390/su13137324

APA StyleBarry, F., Sawadogo, M., Bologo, M., Ouédraogo, I. W. K., & Dogot, T. (2021). Key Barriers to the Adoption of Biomass Gasification in Burkina Faso. Sustainability, 13(13), 7324. https://doi.org/10.3390/su13137324