An Optimization Scheme of Balancing GHG Emission and Income in Circular Agriculture System

Abstract

:1. Introduction

2. Materials and Methods

2.1. Study Area

2.2. Multi-Objective Linear Programming Model

2.3. GHG Emission Calculation

2.3.1. Agriculture GHG Emission Calculation

2.3.2. Agricultural Operation Inventory

2.3.3. Livestock GHG Emissions Calculation

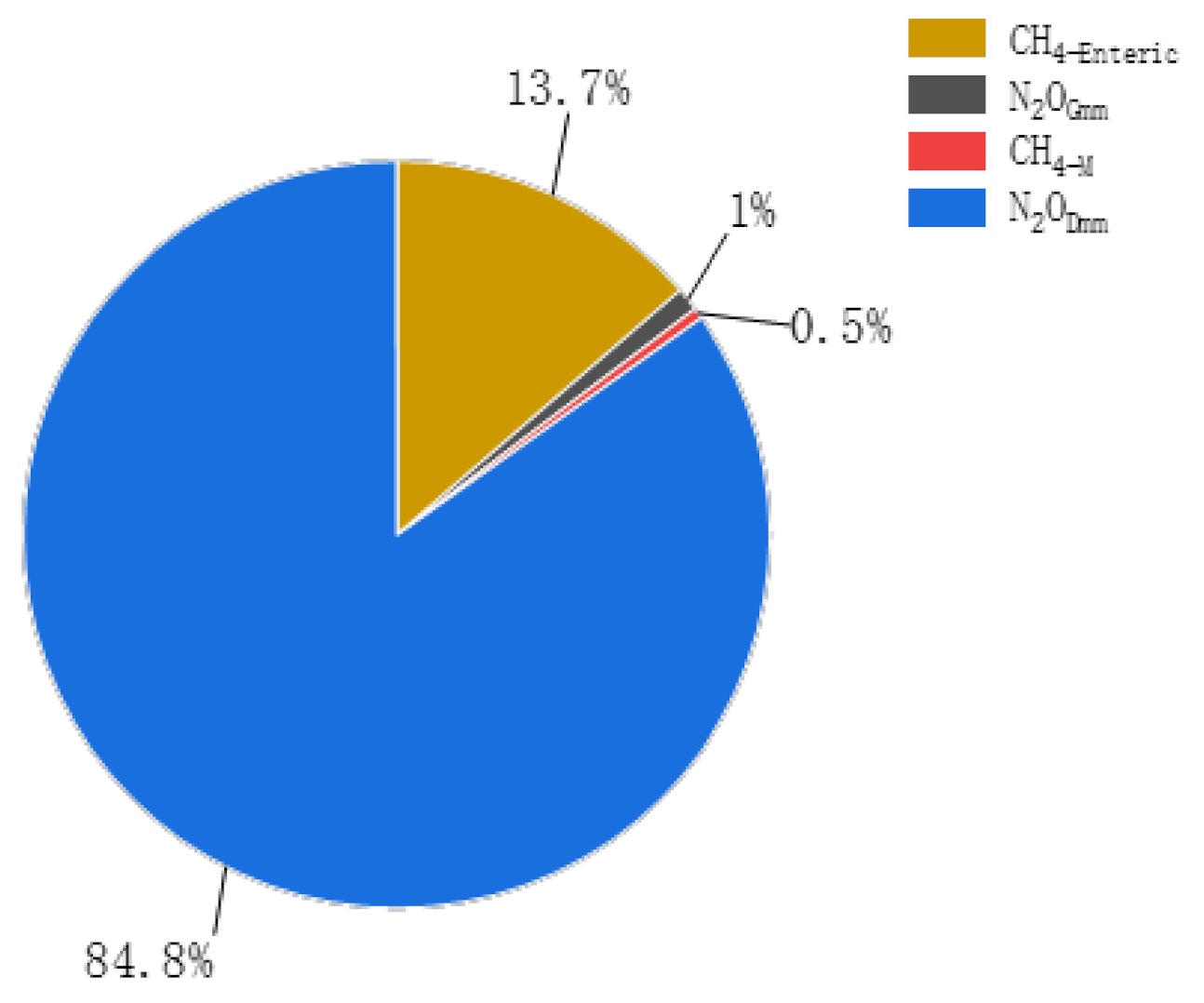

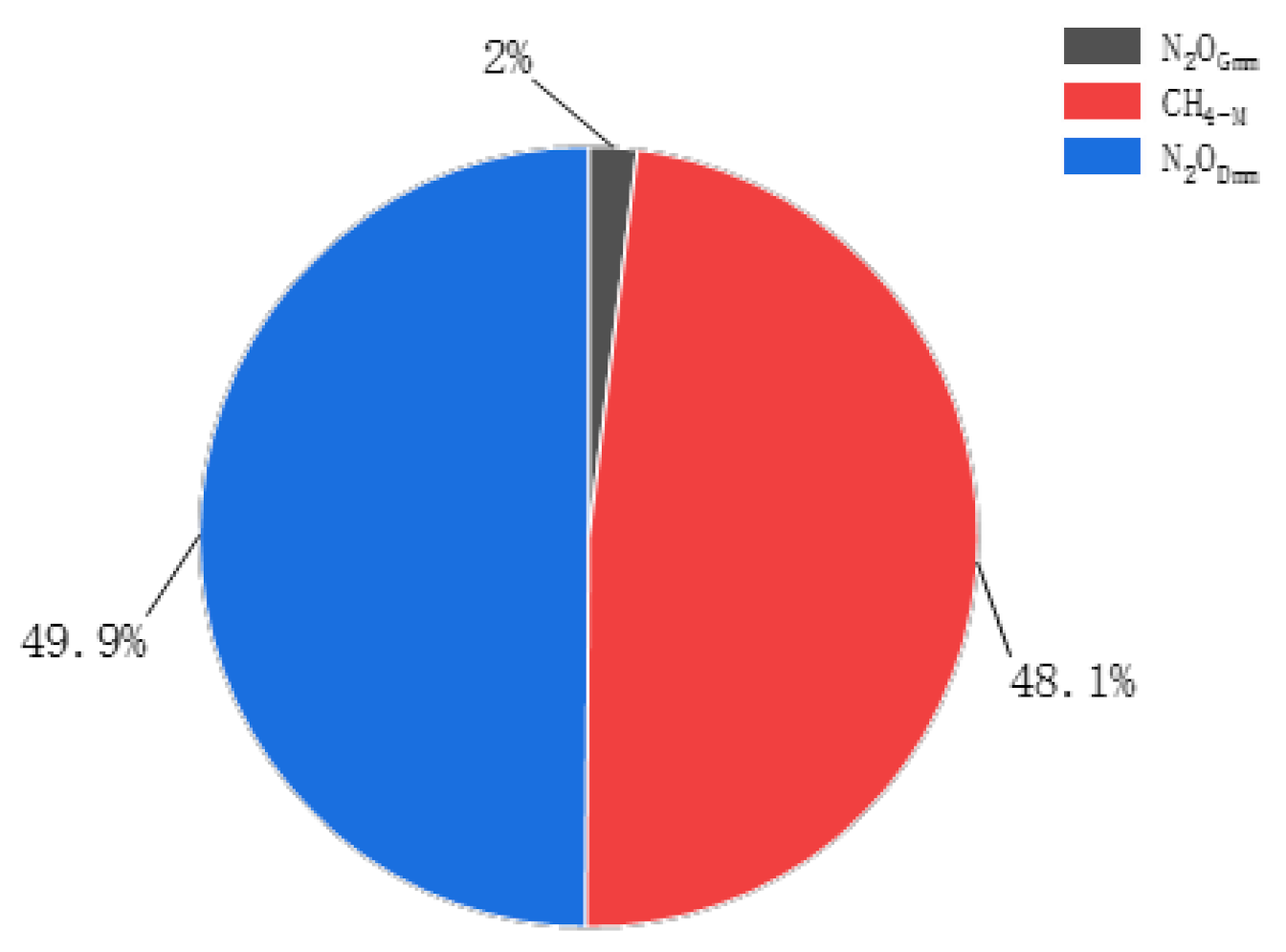

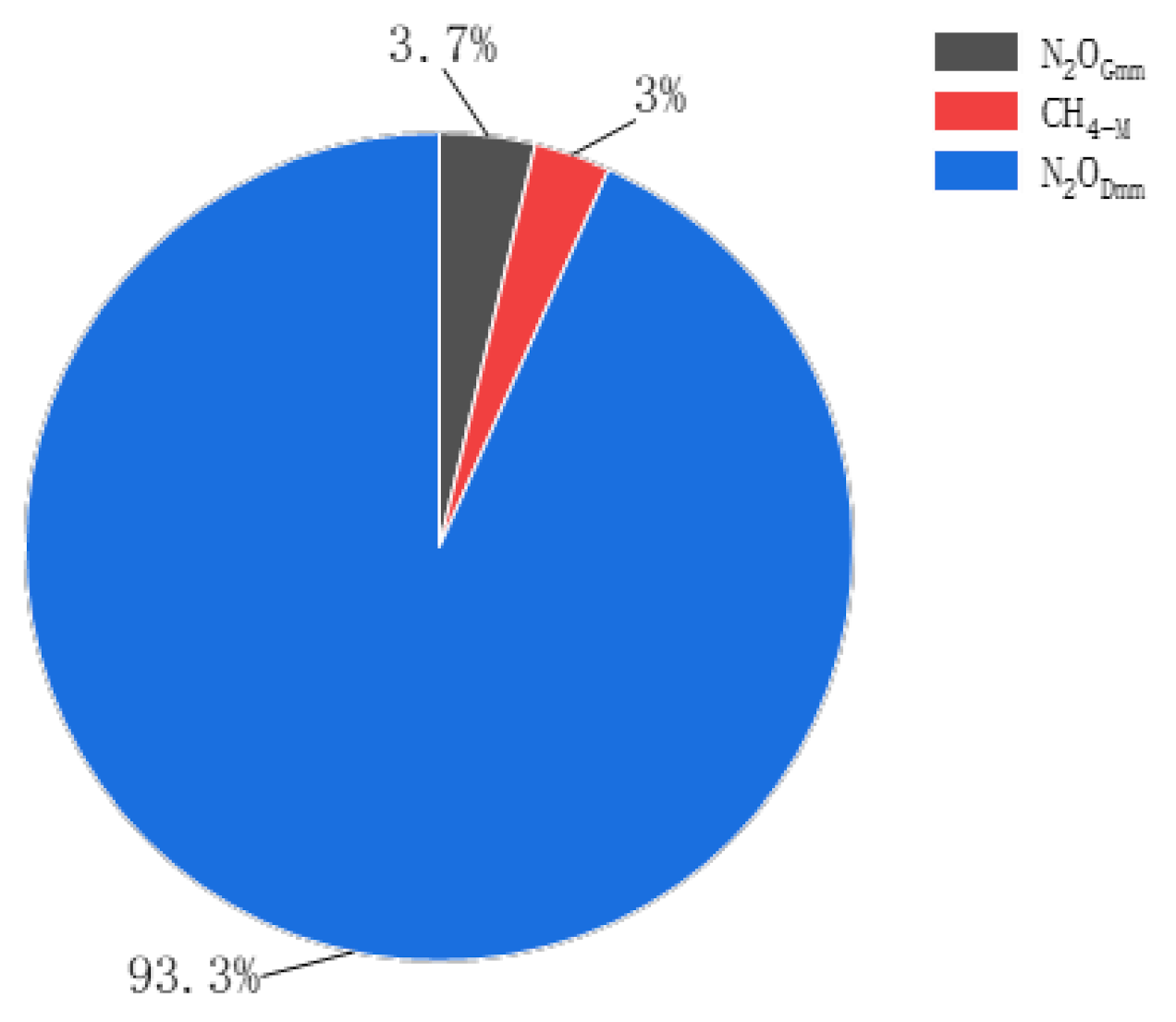

3. Model Building

- Corn feed: 6990 × x2 = 69.7 × x4 + 63.88 × x5 + 3.6 × x6 + 4.84 × x9 + 28.47 × x8;

- Wheat bran feed: 1050 × x1 = 19.92 × x5 + 1.8 × x7 + 0.74 × x9 + 4.38 × x8;

- Ensiling feed: 30,000 × x21 = 76.21 × x5 + 146 × x6 + 3.6 × x7;

4. Results and Discussions

4.1. Optimized Planting/Breeding Structure

4.2. Post-Optimization Benefits/Effects

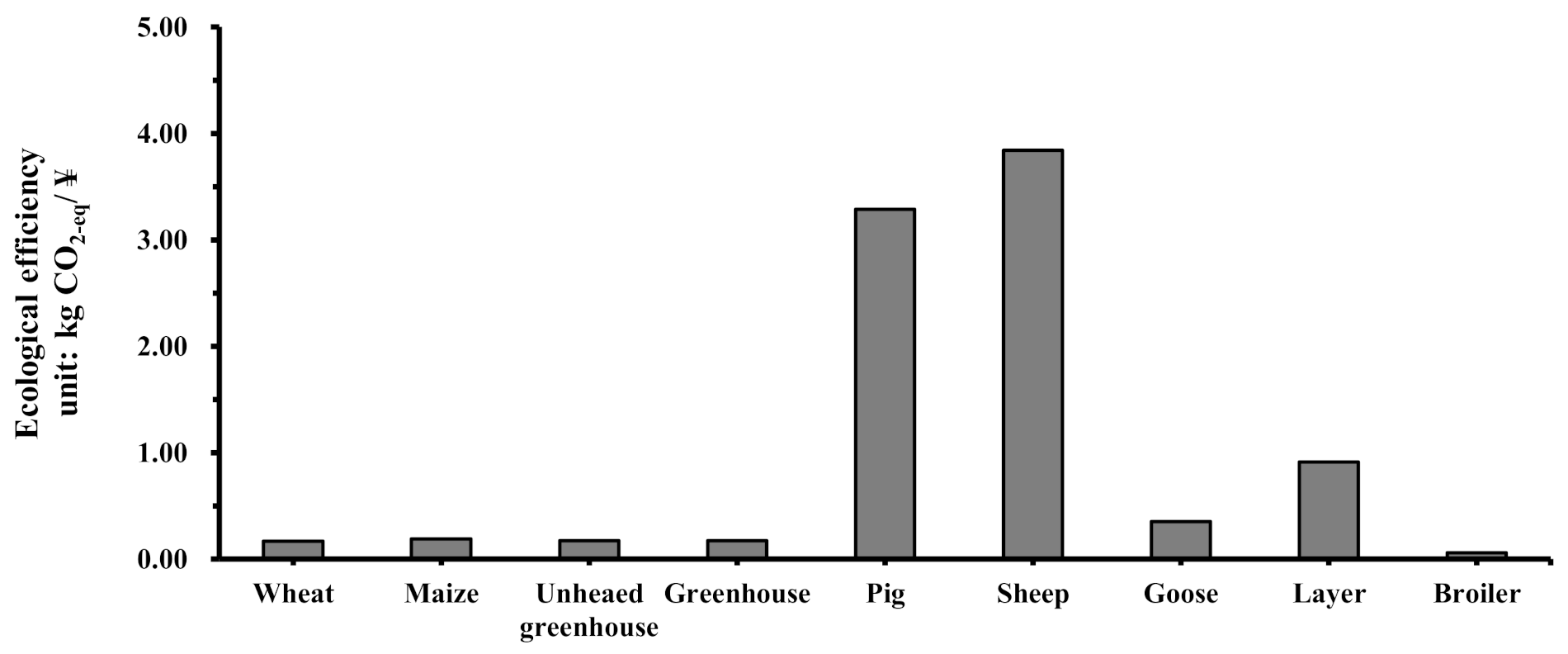

4.3. Balance in Economy and Environment

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wang, H.; Li, H.; Wu, X. Study on Information Needs for Promoting the Development of Circular Agriculture. In Environmental Technology and Resource Utilization II; Zhang, L., Ed.; Trans Tech Publications Ltd.: Stafa-Zurich, Switzerland, 2014; pp. 1028–1031. [Google Scholar]

- Ghisellini, P.; Cialani, C.; Ulgiati, S. A Review on Circular Economy: The Expected Transition to a Balanced Interplay of Environmental and Economic Systems. J. Clean. Prod. 2016, 114, 11–32. [Google Scholar] [CrossRef]

- Li, B.; Feng, Y.; Xia, X.; Feng, M. Evaluation of China’s Circular Agriculture Performance and Analysis of the Driving Factors. Sustainability 2021, 13, 1643. [Google Scholar] [CrossRef]

- Lalehzari, R.; Nasab, S.B.; Moazed, H.; Haghighi, A.; Yaghoobzadeh, M. Simulation–optimization modelling for water resources management using nsgaii-oip and modflow. Irrig. Drain. 2020, 69, 317–332. [Google Scholar] [CrossRef]

- Li, M.; Fu, Q.; Singh, V.P.; Ji, Y.; Liu, D.; Zhang, C.; Li, T. An optimal modelling approach for managing agricultural water-energy-food nexus under uncertainty. Sci. Total Environ. 2019, 651, 1416–1434. [Google Scholar] [CrossRef] [PubMed]

- Allam, M.M.; Eltahir, E.A.B. Water-Energy-Food Nexus Sustainability in the Upper Blue Nile (UBN) Basin. Front. Environ. Sci. 2019, 7, 7. [Google Scholar] [CrossRef] [Green Version]

- Groot, J.; Oomen, G.J.; Rossing, W.A. Multi-objective optimization and design of farming systems. Agric. Syst. 2012, 110, 63–77. [Google Scholar] [CrossRef]

- Klein, T.P.; Holzkämper, A.; Calanca, P.; Seppelt, R.; Fuhrer, J. Adapting agricultural land management to climate change: A regional multi-objective optimization approach. Landsc. Ecol. 2013, 28, 2029–2047. [Google Scholar] [CrossRef] [Green Version]

- Groot, J.C.J.; Rossing, W.A.H. Model-aided learning for adaptive management of natural resources: An evolutionary design perspective. Methods Ecol. Evol. 2011, 2, 643–650. [Google Scholar] [CrossRef]

- FAO. The State of Food and Agriculture: Climate Change, Agriculture and Food Security; FAO: Rome, Italy, 2016. [Google Scholar]

- Tilman, D.; Balzer, C.; Hill, J.; Befort, B.L. Global food demand and the sustainable intensification of agriculture. Proc. Natl. Acad. Sci. USA 2011, 108, 20260–20264. [Google Scholar] [CrossRef] [Green Version]

- Zhang, X.; Liu, H.; Lai, G. Relationship between fertilizer application and carbon emission reduction of large-scale farmers. Jiangsu Agric. Sci. 2018, 46, 279–284. [Google Scholar]

- Gan, Y.; Liang, C.; Campbell, C.A.; Zentner, R.P.; Lemke, R.L.; Wang, H.; Yang, C. Carbon footprint of spring wheat in response to fallow frequency and soil carbon changes over 25 years on the semiarid Canadian prairie. Eur. J. Agron. 2012, 43, 175–184. [Google Scholar] [CrossRef]

- She, W.; Wu, Y.; Huang, H.; Chen, Z.; Cui, G.; Zheng, H.; Guan, C.; Chen, F. Integrative analysis of carbon structure and carbon sink function for major crop production in China’s typical agriculture regions. J. Clean. Prod. 2017, 162, 702–708. [Google Scholar] [CrossRef]

- Liu, W.; Zhang, G.; Wang, X.; Lu, F.; Ouyang, Z. Carbon footprint of main crop production in China: Magnitude, spatial-temporal pattern and attribution. Sci. Total Environ. 2018, 645, 1296–1308. [Google Scholar] [CrossRef] [PubMed]

- Huang, J.; Chen, Y.; Pan, J.; Liu, W.; Yang, G.; Xiao, X.; Zheng, H.; Tang, W.; Tang, H.; Zhou, L. Carbon footprint of different agricultural systems in China estimated by different evaluation metrics. J. Clean. Prod. 2019, 225, 939–948. [Google Scholar] [CrossRef]

- Liu, C.; Lu, M.; Cui, J.; Li, B.; Fang, C. Effects of straw carbon input on carbon dynamics in agricultural soils: A meta-analysis. Glob. Chang. Biol. 2014, 20, 1366–1381. [Google Scholar] [CrossRef] [PubMed]

- Yan, M.; Cheng, K.; Luo, T.; Yan, Y.; Pan, G.; Rees, R.M. Carbon footprint of grain crop production in China—Based on farm survey data. J. Clean. Prod. 2015, 104, 130–138. [Google Scholar] [CrossRef]

- Yang, X.; Gao, W.; Zhang, M.; Chen, Y.; Sui, P. Reducing agricultural carbon footprint through diversified crop rotation systems in the North China Plain. J. Clean. Prod. 2014, 76, 131–139. [Google Scholar] [CrossRef]

- Ledgard, S.F.; Wei, S.; Wang, X.; Falconer, S.; Zhang, N.; Zhang, X.; Ma, L. Nitrogen and carbon footprints of dairy farm systems in China and New Zealand, as influenced by productivity, feed sources and mitigations. Agric. Water Manag. 2019, 213, 155–163. [Google Scholar] [CrossRef]

- West, T.O.; Marland, G. Net carbon flux from agriculture: Carbon emissions, carbon sequestration, crop yield, and land-use change. Biogeochemistry 2003, 63, 73–83. [Google Scholar] [CrossRef]

- Schmidhuber, J.; Tubiello, F.N. Global food security under climate change. Proc. Natl. Acad. Sci. USA 2007, 104, 19703–19708. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yu, J.; Wang, R.; Chang, H.; Gao, M.; Wang, Z.; Mo, J.; Gao, C. Optimization of crop and livestock industry in Daxinganling agricultural reclamation based on planting-breeding balance. J. China Agric. Resour. Reg. Plan. 2017, 38, 228–236. [Google Scholar]

- Ecoinvent Database [EB/OL] (2011-05-11). Available online: http://www.ecoinvent.ch (accessed on 20 June 2016).

- Liu, X.L.; Wang, H.T.; Chen, J.; He, Q.; Zhang, H.; Jiang, R.; Chen, X.X.; Hou, P. Method and basic model for development of Chinese reference life cycle database of fundamental industries. Acta Sci. Circumstantiate 2010, 30, 2136–2144. [Google Scholar]

- Li, J.; Wang, D.; Wang, L.; Wang, Y.; Li, H. Evaluation of nitrogen and water management on greenhouse gas mitigation in winter wheat-summer maize cropland system in North China. J. Plant. Nutr. Fertitizer 2016, 22, 921–929. [Google Scholar]

- National Development and Reform Commission on Climate Change. Low- Carbon Development and Provincial Greenhous Gas. Inventory Training Materials[R]; National Development and Reform Commission on Climate Change: Beijing, China, 2013. [Google Scholar]

- Niu, K. Studies of multi-objective linear programming model on Chinese agricultural structure adjustment. Acta Agric. Zhejiangensis 2011, 23, 840–846. [Google Scholar]

- Zhou, J.-M. The Effect of Different C/N Ratios on the Composting of Pig Manure and Edible Fungus Residue with Rice Bran. Compos. Sci. Util. 2017, 25, 120–129. [Google Scholar] [CrossRef]

- Pergola, M.; Persiani, A.; Palese, A.M.; Di Meo, V.; Pastore, V.; D’Adamo, C.; Celano, G. Composting: The way for a sustainable agriculture. Appl. Soil Ecol. 2018, 123, 744–750. [Google Scholar] [CrossRef]

- Todman, L.C.; Coleman, K.; Milne, A.E.; Gil, J.D.B.; Reidsma, P.; Schwoob, M.-H.; Treyer, S.; Whitmore, A.P. Multi-objective optimization as a tool to identify possibilities for future agricultural landscapes. Sci. Total Environ. 2019, 687, 535–545. [Google Scholar] [CrossRef] [PubMed]

- Gameiro, A.H.; Rocco, C.; Filho, J.V.C. Linear Programming in the economic estimate of livestock-crop integration: Application to a Brazilian dairy farm. Rev. Bras. Zootec. 2016, 45, 181–189. [Google Scholar] [CrossRef] [Green Version]

- Thornton, P.; Herrero, M. Integrated crop–livestock simulation models for scenario analysis and impact assessment. Agric. Syst. 2001, 70, 581–602. [Google Scholar] [CrossRef]

- Patra, A.K. Accounting methane and nitrous oxide emissions, and carbon footprints of livestock food products in different states of India. J. Clean. Prod. 2017, 162, 678–686. [Google Scholar] [CrossRef]

- Paul, B.K.; Groot, J.C.J.; Birnholz, C.A.; Nzogela, B.; Notenbaert, A.; Woyessa, K.; Sommer, R.; Nijbroek, R.; Tittonell, P. Reducing agro-environmental trade-offs through sustainable livestock intensification across smallholder systems in Northern Tanzania. Int. J. Agric. Sustain. 2019, 18, 35–54. [Google Scholar] [CrossRef] [Green Version]

- Bos, J.F.; Berge, H.F.T.; Verhagen, J.; Van Ittersum, M.K. Trade-offs in soil fertility management on arable farms. Agric. Syst. 2017, 157, 292–302. [Google Scholar] [CrossRef]

- Lyu, Y.; Li, J.; Hou, R.; Zhu, H.; Zhu, W.; Hang, S.; Ouyang, Z. Goats or pigs? Sustainable approach of different raising systems fed by maize silage. J. Clean. Prod. 2020, 254, 120151. [Google Scholar] [CrossRef]

- Accatino, F.; Tonda, A.; Dross, C.; Léger, F.; Tichit, M. Trade-offs and synergies between livestock production and other ecosystem services. Agric. Syst. 2019, 168, 58–72. [Google Scholar] [CrossRef]

- Shi, Z.L.; Jia, T.; Wang, Y.J.; Wang, J.C.; Sun, R.H.; Wang, F.; Li, X.; Bi, Y.Y. Comprehensive utilization status of crop straw and estimation of carbon from burning in China. J. China Agric. Resour. Reg. Plan. 2017, 38, 32–37. [Google Scholar]

- Song, D.; Hou, S.; Wang, X.; Liang, G.; Zhou, W. Nutrient resource quantity of animal manure and its utilization potential in China. J. Plant Nutr. Fertitizer 2018, 24, 1131–1148. [Google Scholar]

- Negi, S.; Mandpe, A.; Hussain, A.; Kumar, S. Collegial effect of maggots larvae and garbage enzyme in rapid composting of food waste with wheat straw or biomass waste. J. Clean. Prod. 2020, 258, 120854. [Google Scholar] [CrossRef]

- Sharma, D.; Yadav, K.D.; Kumar, S. Biotransformation of flower waste composting: Optimization of waste combinations using response surface methodology. Bioresour. Technol. 2018, 270, 198–207. [Google Scholar] [CrossRef]

- Afonso, S.; Arrobas, M.; Pereira, E.L.; Rodrigues, M. Ângelo Recycling nutrient-rich hop leaves by composting with wheat straw and farmyard manure in suitable mixtures. J. Environ. Manag. 2021, 284, 112105. [Google Scholar] [CrossRef] [PubMed]

- Mandryk, M.; Reidsma, P.; Kanellopoulos, A.; Groot, J.C.J.; Van Ittersum, M.K. The role of farmers’ objectives in current farm practices and adaptation preferences: A case study in Flevoland, the Netherlands. Reg. Environ. Chang. 2014, 14, 1463–1478. [Google Scholar] [CrossRef]

- Strauch, M.; Cord, A.F.; Pätzold, C.; Lautenbach, S.; Kaim, A.; Schweitzer, C.; Seppelt, R.; Volk, M. Constraints in multi-objective optimization of land use allocation—Repair or penalize? Environ. Model. Softw. 2019, 118, 241–251. [Google Scholar] [CrossRef]

- Sterk, B.; Van Ittersum, M.; Leeuwis, C.; Rossing, W.; Van Keulen, H.; Van De Ven, G.; Van Ittersum, M. Finding niches for whole-farm design models–contradictio in terminis? Agric. Syst. 2006, 87, 211–228. [Google Scholar] [CrossRef]

- Andrieu, N.; Nogueira, D.M. Modeling biomass flows at the farm level: A discussion support tool for farmers. Agron. Sustain. Dev. 2010, 30, 505–513. [Google Scholar] [CrossRef] [Green Version]

| Item | Unit | Wheat | Maize | Unit | Unheated Greenhouse | Greenhouse |

|---|---|---|---|---|---|---|

| Seeds | kg·ha−1 | 120 | 20 | Seedings/each | 3000 | 6000 |

| N | kg·ha−1 | 45 | 25 | kg/each | 225 | 345 |

| P2O5 | kg·ha−1 | 37.5 | 37.5 | kg/each | 225 | 345 |

| K2O | kg·ha−1 | 37.5 | 37.5 | kg/each | 225 | 345 |

| Manure Compost | N kg·ha−1 | 15 | 15 | N Kg/each | 90 | 90 |

| Herbicide | kg·ha−1 | 0.22 | 0.2 | ‒ | ‒ | ‒ |

| Diesel | L·ha−1 | 40 | 40 | ‒ | ‒ | ‒ |

| Electricity | Kwh·ha−1 | ‒ | ‒ | K·wh/each | 500 | 900 |

| GHG Emissions | CO2-eq kg·ha−1 | 323.583 | 292.78 | CO2-eq kg/each | 1138.75 | 1806.75 |

| Item | Emission Factor | Unit | Reference |

|---|---|---|---|

| Maize seed | 1.93 | kg CO2-eq/kg | Ecoinvent 2.2 [24] |

| Wheat seed | 0.58 | kg CO2-eq/kg | Ecoinvent 2.2 |

| Corn (fodder) | 0.79 | kg CO2-eq/kg | CLCD 0.7 [25] |

| Bean (fodder) | 0.84 | kg CO2-eq/kg | CLCD 0.7 |

| Bran (fodder) | 0.01 | kg CO2-eq/kg | CLCD 0.7 |

| Pesticide | 10.15 | kg CO2-eq/kg | Ecoinvent 2.2 |

| N from fertilizer | 1.53 | kg CO2-eq/kg | CLCD 0.7 |

| Manure Compost | 0.20 | kg CO2-eq/kg | (Li et al. 2016) [26] |

| P2O5 | 1.63 | kg CO2-eq/kg | CLCD 0.7 |

| K2O | 0.65 | kg CO2-eq/kg | CLCD 0.7 |

| Electricity | 0.527 | kg CO2-eq/K·wh | National Development & Reform Commission [27] |

| Diesel | 4.10 | kg CO2-eq/kg | CLCD 0.7 |

| Items | N from Fertilizer (kg N2O-N/kg N) | N from Manure Compost (kg N2O-N/kg N) |

|---|---|---|

| Managed soil | 60.00 | 30.00 |

| Direct emission | 1.41 | ‒ |

| Indirect emission | ‒ | 0.19 |

| Total | ‒ | 1.60 |

| Item | Wheat | Maize | Unheated Greenhouse | Greenhouse |

|---|---|---|---|---|

| Unit | CO2-eq kg·ha−1 | CO2-eq kg·ha−1 | CO2-eq kg/per | CO2-eq kg/per |

| Value | 907.91 | 706.19 | 2804.86 | 4090.00 |

| Species | CH4-Enetric | CH4-M | N2OD (mm) | N2OG (mm) | Bean | Total |

|---|---|---|---|---|---|---|

| Units | kg/head | kg/head | kg/head | kg/head | kg CO2-eq/head | kg CO2-eq/head |

| Pig | 0.33 | 1.50 | 3.10 | 7.75 × 10−2 | 6.51 × 10−2 | 985.00 |

| Sheep | 5.00 | 0.17 | 2.19 | 2.62 × 10−2 | 2.20 × 10−2 | 768.00 |

| Goose | ‒ | 0.02 | 0.04 | 1.77 × 10−3 | 1.48 × 10−3 | 14.10 |

| Layer | ‒ | 0.03 | 0.09 | 3.46 × 10−3 | 2.90 × 10−3 | 27.40 |

| Broiler | ‒ | 0.02 | 1.46 × 10−3 | 5.85 × 10−5 | 4.91 × 10−5 | 0.87 |

| Items | Variable | Unit | Profit/(¥·Unit−1) | Land/m2 | Fodder/(kg·Unit−1) | |||

|---|---|---|---|---|---|---|---|---|

| Corn | Bran | Ensiling | Bean | |||||

| Wheat | X1 | Ha | 5505 | 10000 | ‒ | 1050.00 | ‒ | ‒ |

| Maize | X2 | Ha | 3780 | 10000 | 6990 | ‒ | 30000 | ‒ |

| Unheated greenhouse | X3 | Each | 16,100 | 667.67 | ‒ | ‒ | ‒ | ‒ |

| Greenhouse | X4 | Each | 23,490 | 1335.34 | ‒ | ‒ | ‒ | ‒ |

| Pig | X5 | Head | 300 | 0.67 | −69.70 | −19.92 | −76.21 | −33.32 |

| Sheep | X6 | Head | 200 | 1.50 | −63.88 | ‒ | −146.00 | −41.96 |

| Goose | X7 | Head | 40 | 0.10 | −3.60 | −1.80 | −3.60 | −3.00 |

| Layer | X8 | Head | 30 | 0.25 | −28.47 | −4.38 | ‒ | −10.95 |

| Broiler | X9 | Head | 15 | 0.05 | −4.84 | −0.74 | ‒ | −1.86 |

| Species | Straw Demand | N from Manure Compost |

|---|---|---|

| kg/head | kg/head | |

| Pig | 398.59 | 25.68 |

| Sheep | 7.03 | 16.96 |

| Goose | 213.01 | 0.9 |

| Layer | 24.98 | 0.38 |

| Broiler | 0.98 | 0.02 |

| Item | Variable | Unit | Result | Actual Scale | Rate % |

|---|---|---|---|---|---|

| Wheat | X1 | ha | 5.67 | 7.33 | −22.73 |

| Maize | X2 | ha | 5.67 | 7.33 | −22.73 |

| Unheated greenhouse | X3 | each | 10 | 3 | 233.33 |

| Greenhouse | X4 | each | 9 | 2 | 350.00 |

| Pig | X5 | head | 0 | 55 | −100.00 |

| Sheep | X6 | head | 628 | 50 | 1156.00 |

| Goose | X7 | head | 183 | 1000 | −81.70 |

| Layer | X8 | head | 0 | 5500 | −100.00 |

| Broiler | X9 | head | 7635 | 1000 | 663.50 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hang, S.; Li, J.; Xu, X.; Lyu, Y.; Li, Y.; Gong, H.; Xu, Y.; Ouyang, Z. An Optimization Scheme of Balancing GHG Emission and Income in Circular Agriculture System. Sustainability 2021, 13, 7154. https://doi.org/10.3390/su13137154

Hang S, Li J, Xu X, Lyu Y, Li Y, Gong H, Xu Y, Ouyang Z. An Optimization Scheme of Balancing GHG Emission and Income in Circular Agriculture System. Sustainability. 2021; 13(13):7154. https://doi.org/10.3390/su13137154

Chicago/Turabian StyleHang, Sheng, Jing Li, Xiangbo Xu, Yun Lyu, Yang Li, Huarui Gong, Yan Xu, and Zhu Ouyang. 2021. "An Optimization Scheme of Balancing GHG Emission and Income in Circular Agriculture System" Sustainability 13, no. 13: 7154. https://doi.org/10.3390/su13137154

APA StyleHang, S., Li, J., Xu, X., Lyu, Y., Li, Y., Gong, H., Xu, Y., & Ouyang, Z. (2021). An Optimization Scheme of Balancing GHG Emission and Income in Circular Agriculture System. Sustainability, 13(13), 7154. https://doi.org/10.3390/su13137154