Optical-Sensor-Based Nitrogen Management in Oat for Yield Enhancement

Abstract

:1. Introduction

2. Materials and Methods

2.1. Experimental Site

2.2. Experimental Material

2.3. Data Collection and Methodology

2.4. Standard Setting Condition for CID-340 Portable Photosynthesis System

2.5. Economic Analysis

2.6. Statistical Analysis

3. Results and Discussion

3.1. Days to Tillering

3.2. Tiller Plant−1

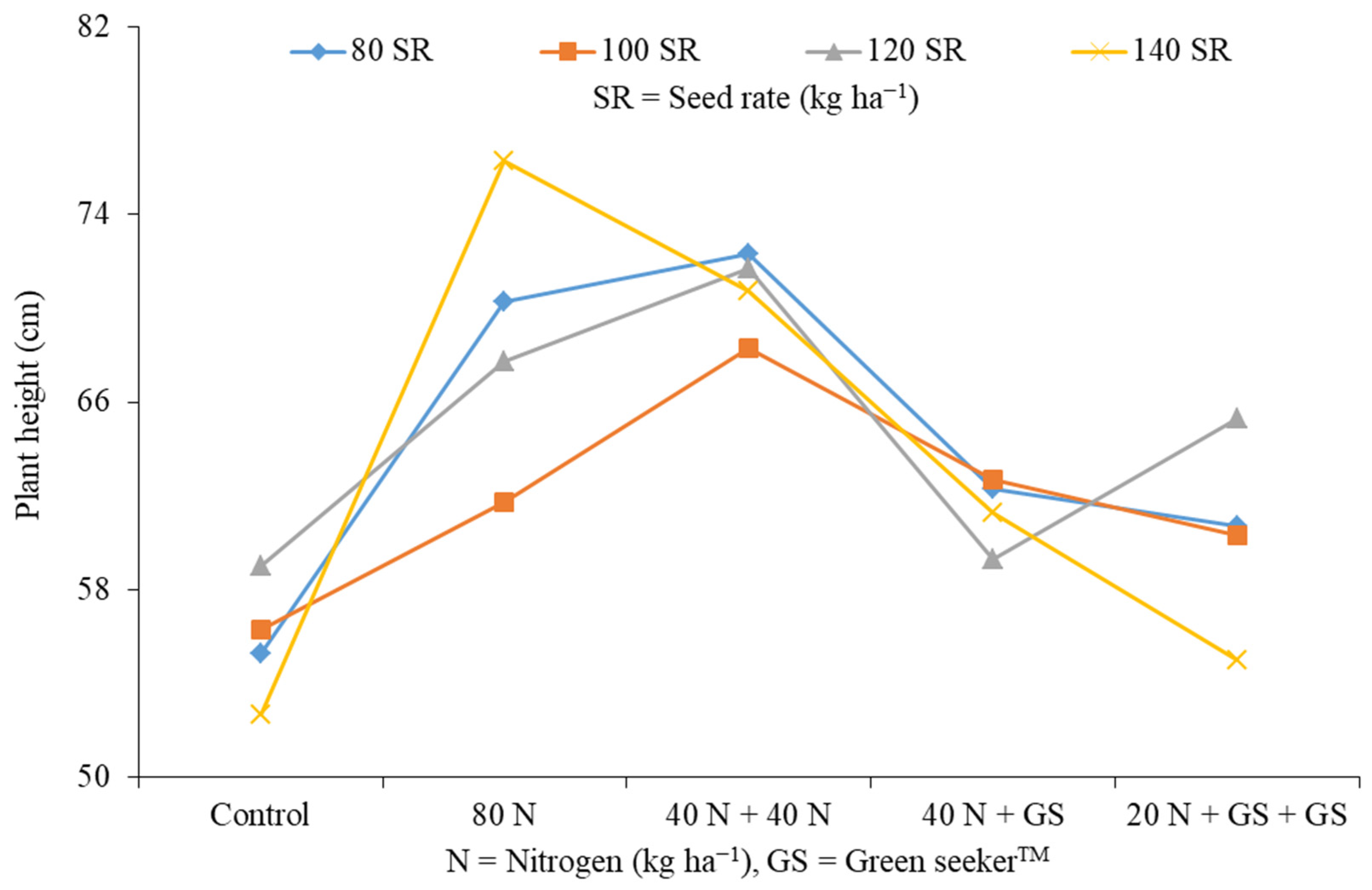

3.3. Plant Height (cm)

3.4. Leaf Area (cm2)

3.5. Plant Population (ha−1)

3.6. Days to Boot Stage

3.7. Green Fodder Yield (kg ha−1)

3.8. Photosynthetic Rate (µmol m−2 s−1)

3.9. Stomatal Conductance (mmol m−2 s−1)

3.10. Economic Analysis

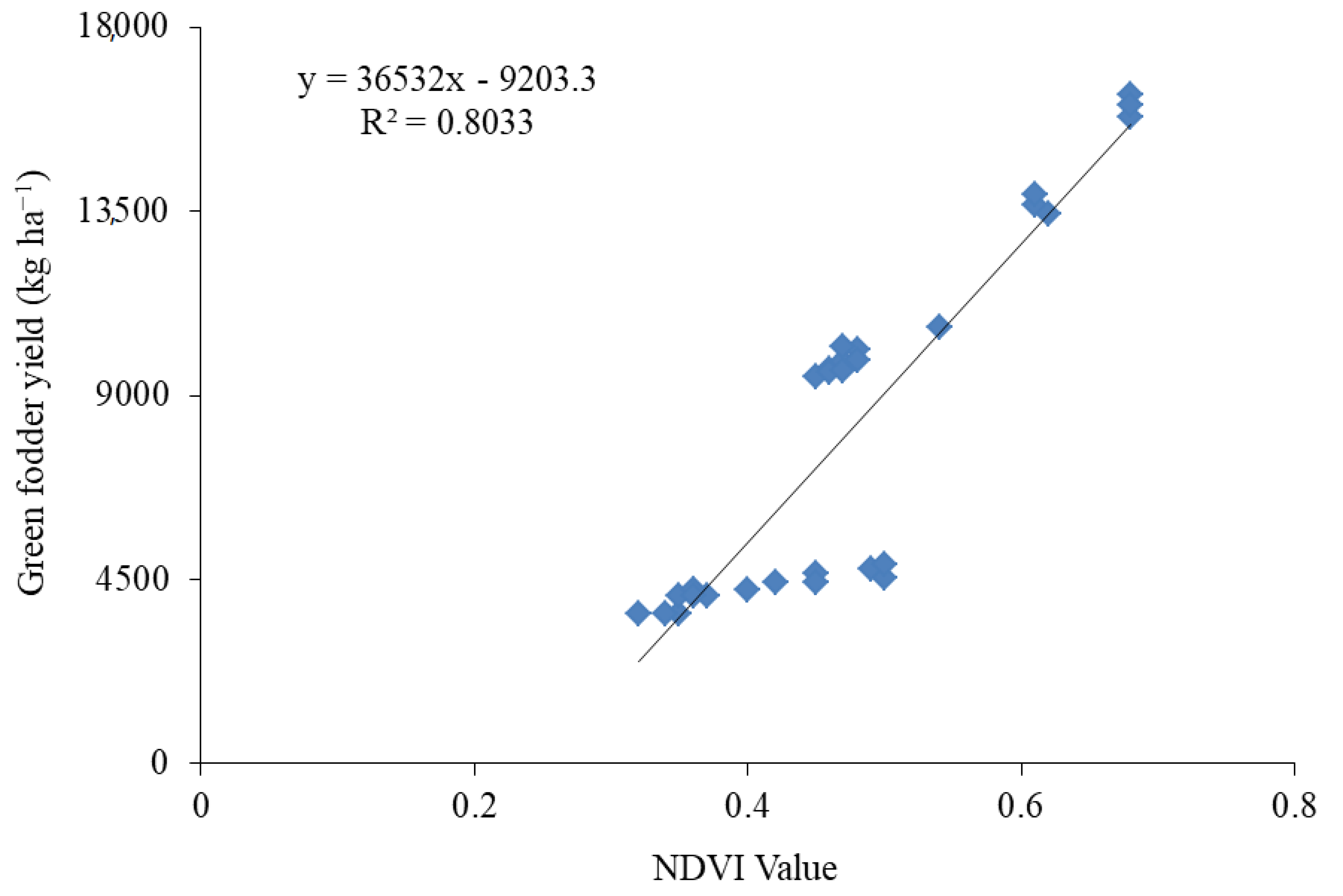

3.11. Normalized Difference Vegetative Index (NDVI)

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Mohr, R.; Grant, C.; May, W. Nitrogen, phosphorus and KCl management for oat. In Proceedings of the 4th Annual Manitoba Agronomists Conference, Winnipeg, MB, Canada, 9–10 December 2003; p. 254. [Google Scholar]

- Fageria, N.K.; Moreira, A. The role of mineral nutrition on root growth of crop plants. Adv. Agron. 2011, 110, 251–331. [Google Scholar]

- Delevatti, L.M.; Cardoso, A.S.; Barbero, R.P.; Leite, R.G.; Romanzini, E.P.; Ruggieri, A.C.; Reis, R.A. Effect of nitrogen application rate on yield, forage quality, and animal performance in a tropical pasture. Sci. Rep. 2019, 9, 7596. [Google Scholar] [CrossRef] [PubMed]

- Khosla, R.; Alley, M.M. Soil-specific nitrogen management on mid-Atlantic coastal plain soils. Better Crop. 1999, 83, 6–7. [Google Scholar]

- Lindblom, J.; Lundström, C.; Ljung, M.; Jonsson, A. Promoting sustainable intensification in precision agriculture: Review of decision support systems development and strategies. Precis. Agric. 2017, 18, 309–331. [Google Scholar] [CrossRef] [Green Version]

- Brisco, B.; Brown, R.J.; Hirose, T.; McNairn, H.; Staenz, K. Precision agriculture and the role of remote sensing: A review. Can. J. Remote Sens. 2014, 24, 315–327. [Google Scholar] [CrossRef]

- Robertson, M.J.; Llewellyn, R.S.; Mandel, R.; Lawes, R.; Bramley, R.G.V.; Swift, L.; Metz, N.; O’Callaghan, C. Adoption of variable rate fertilizer application in the Australian grains industry: Status, issues and prospects. Precis. Agric. 2012, 13, 181–199. [Google Scholar] [CrossRef]

- Padilla, F.M.; Gallardo, M.; Peña-Fleitas, M.T.; de Souza, R.; Thompson, R.B. Proximal optical sensors for nitrogen management of vegetable crops: A review. Sensors 2018, 18, 2083. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Marino, S.; Alvino, A. Proximal sensing and vegetation indices for site-specific evaluation on an irrigated crop tomato. Eur. J. Remote Sens. 2014, 47, 271–283. [Google Scholar] [CrossRef]

- De Souza, R.; Peña-Fleitas, M.T.; Thompson, R.B.; Gallardo, M.; Padilla, F.M. Assessing performance of vegetation indices to estimate nitrogen nutrition index in pepper. Remote Sens. 2020, 12, 763. [Google Scholar] [CrossRef] [Green Version]

- Naser, M.A.; Khosla, R.; Longchamps, L.; Dahal, S. Using NDVI to differentiate wheat genotypes productivity under dryland and irrigated conditions. Remote Sens. 2020, 12, 824. [Google Scholar] [CrossRef] [Green Version]

- Randelovic, P.; Ðordevic, V.; Milic, S.; Baleševic-Tubic, S.; Petrovic, K.; Miladinovic, J.; Ðukic, V. Prediction of soybean plant density using a machine learning model and vegetation indices extracted from RGB images taken with a UAV. Agronomy 2020, 10, 1108. [Google Scholar] [CrossRef]

- Guo, A.; Huang, W.; Ye, H.; Dong, Y.; Ma, H.; Ren, Y.; Ruan, C. Identification of wheat yellow rust using spectral and texture features of hyperspectral images. Remote Sens. 2020, 12, 1419. [Google Scholar] [CrossRef]

- Sandino, J.; Pegg, G.; Gonzalez, F.; Smith, G. Aerial mapping of forests affected by pathogens using UAVs, hyperspectral sensors, and artificial intelligence. Sensors 2018, 18, 944. [Google Scholar] [CrossRef] [Green Version]

- Siqueira, R.; Longchamps, L.; Dahal, S.; Khosla, R. Use of fluorescence sensing to detect nitrogen and potassium variability in maize. Remote Sens. 2020, 12, 1752. [Google Scholar] [CrossRef]

- Holland, K.H.; Schepers, J.S. Derivation of a variable rate nitrogen application model for in-season fertilization of corn. Agron. J. 2010, 102, 1415–1424. [Google Scholar] [CrossRef]

- Zhang, X.; Davidson, E.A.; Mauzerall, D.L.; Searchinger, T.D.; Dumas, P.; Shen, Y. Managing nitrogen for sustainable development. Nature 2015, 528, 51–59. [Google Scholar] [CrossRef] [Green Version]

- Lancashire, P.D.; Bleiholder, H.; Boom, T.V.D.; Langelüddeke, P.; Stauss, R.; Weber, E.; Witzenberger, A. A uniform decimal code for growth stages of crops and weeds. Ann. Appl. Biol. 1991, 119, 561–601. [Google Scholar] [CrossRef]

- Gutiérez-Soto, M.V.; Cadet-Piedra, E.; Rodríguez-Montero, W.; Araya-Alfaro, J.M. GreenSeeker and the diagnosis of crop health. Agron. Mesoam. 2011, 22, 397–403. [Google Scholar]

- Cornell, J.A.; Berger, R.D. Factors that influence the value of the coefficient of determination in simple linear and nonlinear regression models. Phytopathology 1987, 77, 63–70. [Google Scholar] [CrossRef]

- Ghilani, C.D. Adjustment Computations: Spatial Data Analysis; John Wiley & Sons: Hoboken, NJ, USA, 2017. [Google Scholar]

- Belsley, D.A.; Edwin, K.; Welsch, R.E. Regression Diagnostics: Identifying Influential Data and Sources of Collinearity; John Wiley & Sons: Hoboken, NJ, USA, 2005; Volume 571. [Google Scholar]

- CIMMYT. From Agronomic Data to Farmer Recommendations: An Economics Training Manual; Completely revised edition; CIMMYT: Mexico City, Mexico, 1988; pp. 31–33. [Google Scholar]

- Statistix 8.1. User’s Manual; Analytical Software: Tallahassee, FL, USA, 2003.

- Steel, R.G.D.; Torrie, J.H.; Dicky, D.A. Principles and Procedures of Statistics: A Biometrical Approach, 3rd ed.; McGraw Hill, Inc.: New York, NY, USA, 1997; pp. 352–358. [Google Scholar]

- Patel, T.U.; Arvadia, M.K.; Malik, P.K.; Patel, D.D.; Patel, P.S. Productivity of oat (Avena sativa) under different cutting management and split application of nitrogen. Indian J. Agron. 2011, 56, 164–167. [Google Scholar]

- Malik, P.R.E.E.T.I.; Duhan, B.S.; Midha, L.K. Effect of fertilizer application and cutting schedule on growth and yield parameters in oat (Avena sativa L.). Forage Res. 2015, 40, 264–267. [Google Scholar]

- Luikham, E.; Kamei, S.; Mariam, A.P.S. Yield, quality and economics of oat fodder (Avena sativa L.) as influenced by nitrogen and varieties. Forage Res. 2012, 38, 112–114. [Google Scholar]

- Nawaz, M.Q. Effect of different sowing methods and nitrogen levels on fodder yield of oat in salt affected soil. Pak. J. Agric. Res. 2017, 30, 323–328. [Google Scholar] [CrossRef]

- Pathan, S.H.; Bhilare, R.L.; Nawale, K.B.; Jadhav, V.T. Response of multicut oat varieties to nitrogen levels. Forage Res. 2007, 32, 269–270. [Google Scholar]

- Labra, M.H.; Struik, P.C.; Calderini, D.F.; Evers, J.B. Leaf nitrogen traits in response to plant density and nitrogen supply in oilseed rape. Agronomy 2020, 10, 1780. [Google Scholar] [CrossRef]

- Devi, U.; Panghaal, D.; Kumar, P.; Sewhag, M.; Kumar, P. Effect of nitrogen fertilizers on yield and quality of oats: A review. Int. J. Chem. Stud. 2019, 7, 1999–2005. [Google Scholar]

- Khattak, S.I.; Nadim, M.A.; Baloch, M.S.; Waseem, K.; Sohail, M. Impact of variable seeding dates on cereals’ performance under agro-ecological conditions of Dera Ismail Khan. Pak. J. Agric. Res. 2016, 29, 236–243. [Google Scholar]

- Kumar, B.S.; Singh, R.V.; Gupta, A.K.; Ravinder, J. Effect of nitrogen levels and cutting management on green forage yield of fodder oat (Avena sativa L.). J. Pharmacogn. Phytochem. 2017, 6, 635–637. [Google Scholar]

- Joshi, R.V.; Patel, B.J.; Patel, K.M. Effect of nitrogen levels and time of application on growth, yield, quality, nitrogen, phosphorus content and uptake for seed production of oat (Avena sativa L.). Forage Res. 2015, 41, 104–108. [Google Scholar]

- Song, X.; Zhou, G.; Ma, B.L.; Wu, W.; Ahmad, I.; Zhu, G.; Yan, W.; Jiao, X. Nitrogen application improved photosynthetic productivity, chlorophyll fluorescence, yield and yield components of two oat genotypes under saline conditions. Agronomy 2019, 9, 115. [Google Scholar] [CrossRef] [Green Version]

- Ranjan, R.D.; Gontia, A.S.; Pal, A.K.; Kumar, S.; Kumar, B.; Bhamini, K.; Kumari, N. Morphological and physiological responses of dual purpose wheat (Triticum aestivum L.) to nitrogen and seed rates: A review. Agric. Rev. 2016, 37, 279–289. [Google Scholar]

- Iqbal, A.; Iqbal, M.A.; Nabeel, F.; Khan, H.Z.; Akbar, N.; Abbas, R.N. Economic and sustainable forage oat (Avena sativa L.) production as influenced by different sowing techniques and sources of nitrogen. Agric. Environ. Sci. 2014, 14, 1035–1040. [Google Scholar]

- Wang, X.; Wang, G.; Guo, T.; Xing, Y.; Mo, F.; Wang, H.; Fan, J.; Zhang, F. Effects of plastic mulch and nitrogen fertilizer on the soil microbial community, enzymatic activity and yield performance in a dryland maize cropping system. Eur. J. Soil Sci. 2021, 72, 400–412. [Google Scholar] [CrossRef]

- Sultana, S.R.; Ali, A.; Ahmad, A.; Mubeen, M.; Zia-Ul-Haq, M.; Ahmad, S.; Ercisli, S.; Jaafar, H.Z.E. Normalized difference vegetation index as a tool for wheat yield estimation: A case study from Faisalabad, Pakistan. Sci. World J. 2014, 1–8. [Google Scholar] [CrossRef] [Green Version]

- Fu, Z.; Jiang, J.; Gao, Y.; Krienke, B.; Wang, M.; Zhong, K.; Cao, Q.; Tian, Y.; Zhu, Y.; Cao, W.; et al. Wheat growth monitoring and yield estimation based on multi-rotor unmanned aerial vehicle. Remote Sens. 2020, 12, 508. [Google Scholar] [CrossRef] [Green Version]

| Nitrogen Dose (kg ha−1) | Seed Rate (kg ha−1) | Mean | |||

|---|---|---|---|---|---|

| 80 | 100 | 120 | 140 | ||

| Control | 43.0 | 40.7 | 42.0 | 41.7 | 41.9 NS |

| 80 (one dose) | 41.7 | 43.3 | 40.0 | 42.0 | 41.8 NS |

| 80 (two split doses) | 42.0 | 42.3 | 34.3 | 40.0 | 39.7 NS |

| 40 + GS | 40.0 | 42.0 | 40.7 | 34.3 | 39.3 NS |

| 20 + GS + GS | 34.3 | 40.3 | 43.3 | 34.3 | 38.1 NS |

| Mean | 40.3 ab | 41.7 a | 40.1 ab | 38.5 b | |

| Control | 41.9 | ||||

| Rest | 39.7 | ||||

| Nitrogen Dose (kg ha−1) | Seed Rate (kg ha−1) | Mean | |||

|---|---|---|---|---|---|

| 80 | 100 | 120 | 140 | ||

| Control | 4.7 | 4.7 | 5.3 | 4.7 | 5 b |

| 80 (one dose) | 6.3 | 5.3 | 5.7 | 5.7 | 6 a |

| 80 (two split doses) | 5.0 | 5.3 | 5.3 | 5.0 | 5 b |

| 40 + GS | 5.3 | 5.7 | 5.7 | 5.3 | 6 a |

| 20 + GS + GS | 6.0 | 5.7 | 6.0 | 5.3 | 6 a |

| Mean | 5 b | 5 b | 6 a | 5 b | |

| Control | 5 b | ||||

| Rest | 6 a | ||||

| Nitrogen Dose (kg ha−1) | Seed Rate (kg ha−1) | Mean | |||

|---|---|---|---|---|---|

| 80 | 100 | 120 | 140 | ||

| Control | 55.3 | 56.3 | 59 | 52.7 | 55.8 b |

| 80 (one dose) | 70.3 | 61.7 | 67.7 | 76.3 | 69 a |

| 80 (two split doses) | 72.3 | 68.3 | 71.7 | 70.7 | 70.8 a |

| 40 + GS | 62.3 | 62.7 | 59.3 | 61.3 | 61.4 b |

| 20 + GS + GS | 60.7 | 60.3 | 65.3 | 55 | 60.3 b |

| Mean | 64.2 NS | 61.9 NS | 64.6 NS | 63.2 NS | |

| Control | 55.8 | ||||

| Rest | 65.17 | ||||

| Nitrogen Dose (kg ha−1) | Seed Rate (kg ha−1) | Mean | |||

|---|---|---|---|---|---|

| 80 | 100 | 120 | 140 | ||

| Control | 55.2 abcd | 50.93 cd | 56.95 abcd | 56.43 abcd | 54.88 b |

| 80 (one dose) | 54.43 bcd | 54.05 bcd | 64.10 abc | 53.37 bcd | 56.49 b |

| 80 (two split doses) | 62.37 abc | 69.74 a | 60.61 abcd | 63.86 abc | 64.14 a |

| 40 + GS | 46.19 d | 62.71 abc | 63.68 abc | 54.76 bcd | 56.84 b |

| 20 + GS + GS | 66.69 ab | 60.80 abcd | 60.11 abcd | 46.81 d | 58.60 ab |

| Mean | 56.97 NS | 59.65 NS | 61.09 NS | 55.05 NS | |

| Control | 54.88 | ||||

| Rest | 59.02 | ||||

| Nitrogen Dose (kg ha−1) | Seed Rate (kg ha−1) | Mean | |||

|---|---|---|---|---|---|

| 80 | 100 | 120 | 140 | ||

| Control | 91,333 | 91,000 | 91,333 | 92,333 | 91,500 bc |

| 80 (one dose) | 106,333 | 84,333 | 106,333 | 105,333 | 100,583 a |

| 80 (two split doses) | 84,333 | 92,333 | 84,333 | 91,000 | 88,000 c |

| 40 + GS | 92,333 | 105,333 | 92,333 | 84,333 | 93,583 b |

| 20 + GS + GS | 105,333 | 91,000 | 84,333 | 92,333 | 93,250 bc |

| Mean | 95,933 NS | 92,800 NS | 91,733 NS | 93,067 NS | |

| Control | 91,500 | ||||

| Rest | 93,854 | ||||

| Nitrogen Dose (kg ha−1) | Seed Rate (kg ha−1) | Mean | |||

|---|---|---|---|---|---|

| 80 | 100 | 120 | 140 | ||

| Control | 130 NS | 130 NS | 131 NS | 132 NS | 131 a |

| 80 (one dose) | 130 NS | 129 NS | 128 NS | 129 NS | 129 c |

| 80 (two split doses) | 128 NS | 129 NS | 129 NS | 129 NS | 129 c |

| 40 + GS | 129 NS | 129 NS | 130 NS | 130 NS | 130 b |

| 20 + GS + GS | 129 NS | 131 NS | 129 NS | 130 NS | 130 bc |

| Mean | 129 NS | 130 NS | 129 NS | 130 NS | |

| Control | 131 | ||||

| Rest | 129.5 | ||||

| Nitrogen Dose (kg ha−1) | Seed Rate (kg ha−1) | Mean | |||

|---|---|---|---|---|---|

| 80 | 100 | 120 | 140 | ||

| Control | 12,037 cde | 12,869 cde | 13,013 cd | 11,728 e | 12,411.64 e |

| 80 (one dose) | 13,611 cd | 13,343 cd | 12,963 d | 12,967 d | 13,221.07 d |

| 80 (two split doses) | 13,909 cd | 14,815 bcd | 14,824 bcd | 13,907 bcd | 14,363.88 c |

| 40 + GS | 14,337 bcd | 15,732 dc | 14,986 bcd | 17,189 a | 15,560.93 b |

| 20 + GS + GS | 15,801 bc | 16,366 b | 16,744 ab | 17,380 a | 16,572.85 a |

| Mean | 13,939.09 NS | 14,624.78 NS | 14,506.13 NS | 14,634.29 NS | |

| Control | 12,411.6 | ||||

| Rest | 14,929.69 | ||||

| Nitrogen Dose (kg ha−1) | Seed Rate (kg ha−1) | Mean | |||

|---|---|---|---|---|---|

| 80 | 100 | 120 | 140 | ||

| Control | 11.31 NS | 9.89 NS | 11.84 NS | 11.43 NS | 11.12 a |

| 80 (one dose) | 9.60 NS | 9.56 NS | 9.28 NS | 8.57 NS | 9.26 b |

| 80 (two split doses) | 13.53 NS | 12.01 NS | 9.81 NS | 10.87 NS | 11.55 a |

| 40 + GS | 10.46 NS | 9.48 NS | 10.93 NS | 12.06 NS | 10.73 ab |

| 20 + GS + GS | 12.97 NS | 9.97 NS | 11.54 NS | 12.09 NS | 11.64 a |

| Mean | 11.58 NS | 10.18 NS | 10.68 NS | 11.00 NS | |

| Control | 11.12 | ||||

| Rest | 10.78 | ||||

| Nitrogen Dose (kg ha−1) | Seed Rate (kg ha−1) | Mean | |||

|---|---|---|---|---|---|

| 80 | 100 | 120 | 140 | ||

| Control | 201.62 NS | 172.62 NS | 147.56 NS | 220.81 NS | 185.65 NS |

| 80 (one dose) | 158.54 NS | 197.98 NS | 166.06 NS | 218.97 NS | 185.39 NS |

| 80 (two split doses) | 191.45 NS | 233.76 NS | 202.82 NS | 183.41 NS | 202.86 NS |

| 40 + GS | 214.42 NS | 218.03 NS | 245.30 NS | 165.76 NS | 210.88 NS |

| 20 + GS + GS | 204.66 NS | 207.93 NS | 198.65 NS | 205.09 NS | 204.08 NS |

| Mean | 194.14 NS | 206.07 NS | 192.08 NS | 198.81 NS | |

| Control | 185.65 | ||||

| Rest | 200.80 | ||||

| Nitrogen Dose (kg ha−1) | N (kg ha−1) Actual Applied | Input Cost (ha−1) | Income (ha−1) | Net Income |

|---|---|---|---|---|

| N0 = Control | 0 | 320.78 | 895.81 | 575.03 |

| N1 = 100 % (80 kg ha−1) N in single dose | 80 | 372.10 | 954.24 | 582.13 |

| N2 = 80 kg ha−1 N in two split doses (40 kg ha−1 each) | 80 | 372.10 | 1036.71 | 664.61 |

| N3 = 40 kg N by broad cast + GS (28 kg) | 68 | 364.41 | 1123.11 | 758.71 |

| N4 = 20 kg N by broad cast + GS (20 kg N) + GS (18 kg N) | 58 | 357.99 | 1196.15 | 838.16 |

| Nitrogen Doses (kg ha−1) | Tillering Stage | Booting Stage |

|---|---|---|

| N0 = Control | 0.33 d | 0.45 c |

| N1 = 100 % (80 kg ha−1) N in single dose | 0.36 d | 0.47 c |

| N2 = 80 kg ha−1 N in two split doses (40 kg ha−1 each) | 0.37 d | 0.50 c |

| N3 = 40 kg N by broad cast + GS (28 kg) | 0.45 c | 0.61 b |

| N4 = 20 kg N by broad cast + GS (20 kg N ) + GS (18 kg N) | 0.48 c | 0.68 a |

| Mean | 0.40 b | 0.54 a |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shah, J.; Wang, X.; Khan, S.U.; Khan, S.; Gurmani, Z.A.; Fiaz, S.; Qayyum, A. Optical-Sensor-Based Nitrogen Management in Oat for Yield Enhancement. Sustainability 2021, 13, 6955. https://doi.org/10.3390/su13126955

Shah J, Wang X, Khan SU, Khan S, Gurmani ZA, Fiaz S, Qayyum A. Optical-Sensor-Based Nitrogen Management in Oat for Yield Enhancement. Sustainability. 2021; 13(12):6955. https://doi.org/10.3390/su13126955

Chicago/Turabian StyleShah, Junaid, Xiukang Wang, Sami Ullah Khan, Sajjad Khan, Zulfiqar Ali Gurmani, Sajid Fiaz, and Abdul Qayyum. 2021. "Optical-Sensor-Based Nitrogen Management in Oat for Yield Enhancement" Sustainability 13, no. 12: 6955. https://doi.org/10.3390/su13126955

APA StyleShah, J., Wang, X., Khan, S. U., Khan, S., Gurmani, Z. A., Fiaz, S., & Qayyum, A. (2021). Optical-Sensor-Based Nitrogen Management in Oat for Yield Enhancement. Sustainability, 13(12), 6955. https://doi.org/10.3390/su13126955