Life Cycle Assessment of Bioplastics and Food Waste Disposal Methods

Abstract

1. Introduction

2. Materials and Methods

2.1. Description of End-of-Life Scenarios

2.2. Theory

2.2.1. Scenario 1: Anaerobic Digestion

2.2.2. Scenario 1a: Anaerobic Digestion of Bioplastics and Food Waste

2.2.3. Scenario 1b: Anaerobic Digestion of Pretreated Bioplastics and Food Waste

2.2.4. Scenario 2: Compost

2.2.5. Scenario 2a: Compost of Bioplastics and Food Waste

2.2.6. Scenario 2b: Compost of Pretreated Bioplastics and Food Waste

2.2.7. Scenario 3: Landfill of Bioplastics and Food Waste

2.3. Calculation—Life Cycle Inventory (LCI)

2.4. Life Cycle Impact Assessment (LCIA)

2.5. Credits and Offsets

2.6. Uncertainty Analysis

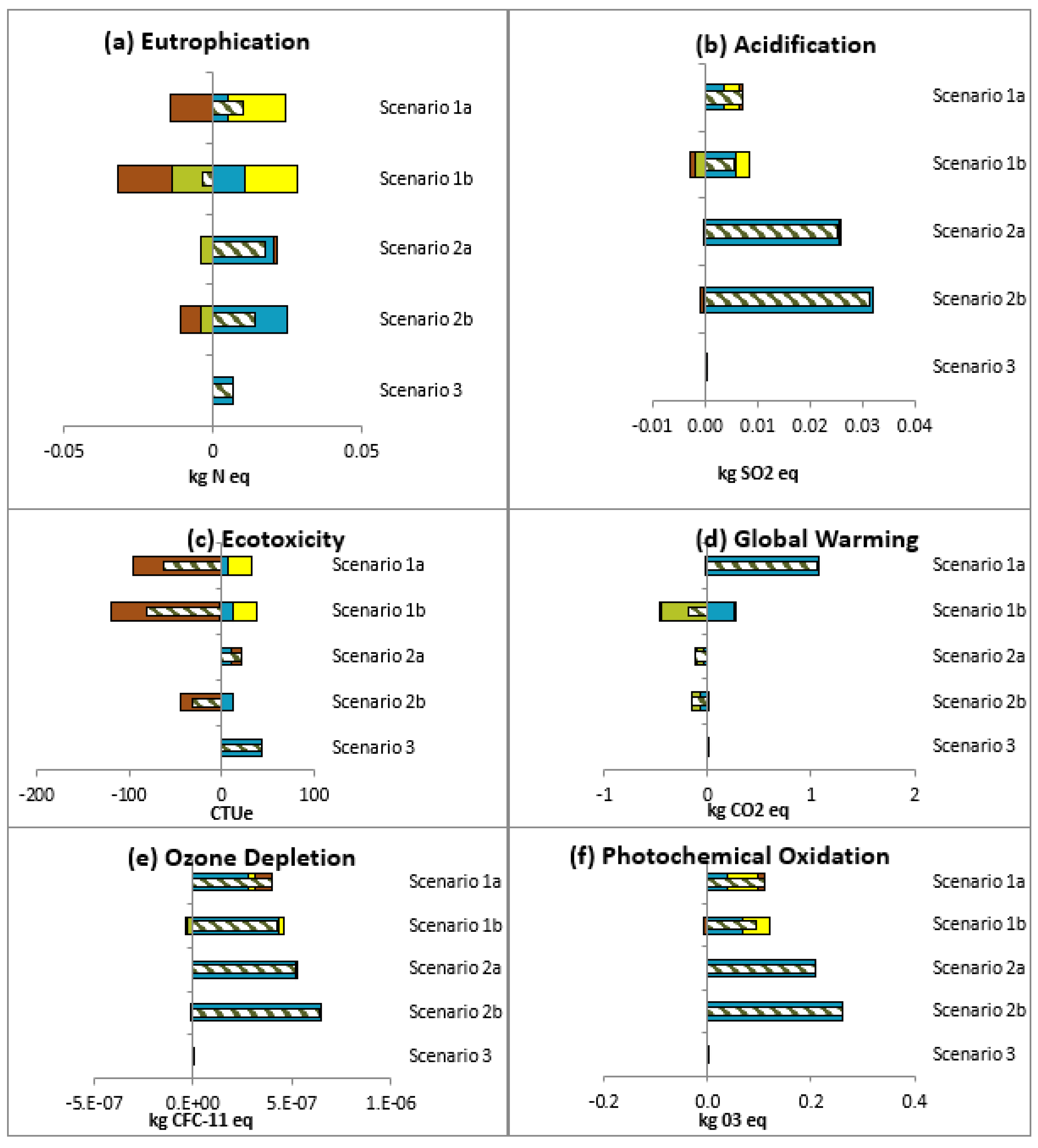

3. Results and Discussion

3.1. Compost (Scenarios 2a and 2b)

3.2. Anaerobic Digestion (Scenario 1a and 1b) and Landfill (Scenario 3) Environmental Impacts

3.3. Pedigree Matrix

3.4. Normalized Impact Assessment

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Hopewell, J.; Dvorak, R.; Kosior, E. Plastics recycling: Challenges and opportunities. Philos. Trans. R. Soc. Biol. Sci. 2009, 364, 2115–2126. [Google Scholar] [CrossRef] [PubMed]

- Calabrò, P.S.; Grosso, M. Bioplastics and waste management. Waste Manag. 2018, 78, 800–801. [Google Scholar] [CrossRef]

- Sudesh, K.; Iwata, T. Sustainability of Biobased and Biodegradable Plastics. CLEAN Soil Air Water 2008, 36, 433–442. [Google Scholar] [CrossRef]

- Meeks, D.; Hottle, T.; Bilec, M.M.; Landis, A.E. Compostable biopolymer use in the real world: Stakeholder interviews to better understand the motivations and realities of use and disposal in the US. Resour. Conserv. Recycl. 2015, 134–142. [Google Scholar] [CrossRef]

- EPA. Food Waste Management in the United States, 2014; EPA-Office of Resource Conservation and Recovery: Washington, DC, USA, 2016.

- SEPA. Biodegradable Municipal Waste Landfil Ban. In SEPA; S.E.P. Agency: Stirling, UK, 2018. [Google Scholar]

- Krause, M.J.; Townsend, T.G. Life-Cycle Assumptions of Landfilled Polylactic Acid Underpredict Methane Generation. Environ. Sci. Technol. Lett. 2016, 3, 166–169. [Google Scholar] [CrossRef]

- Martin, D.; Potts, L.; Reeves, A. Small-scale simulation of waste degradation in landfills. Biotechnol. Lett. 1997, 19, 683–685. [Google Scholar] [CrossRef]

- Lundie, S.; Peters, G.M. Life cycle assessment of food waste management options. J. Clean. Prod. 2005, 13, 275–286. [Google Scholar] [CrossRef]

- Siracusa, V.; Rocculi, P.; Romani, S.; Rosa, M.D. Biodegradable polymers for food packaging: A review. Trends Food Sci. Technol. 2008, 19, 634–643. [Google Scholar] [CrossRef]

- Hottle, T.A.; Agüero, L.M.; Bilec, M.M.; Landis, A.E. Alkaline Amendment for the Enhancement of Compost Degradation for Polylactic Acid Biopolymer Products. Compost. Sci. Util. 2016, 24, 159–173. [Google Scholar] [CrossRef]

- Pilarska, A.A.; Pilarski, K.; Ryniecki, A.; Tomaszyk, K.; Dach, J.; Wolna-Maruwka, A. Utilization of vegetable dumplings waste from industrial production by anaerobic digestion. Int. Agrophys. 2017, 31, 93–102. [Google Scholar] [CrossRef]

- Abraham, A.; Park, H.; Choi, O.; Sang, B.-I. Anaerobic co-digestion of bioplastics as a sustainable mode of waste management with improved energy production—A review. Bioresour. Technol. 2020, 124537. [Google Scholar] [CrossRef]

- UN. Sustainable Development Goals 17 Goals to Transform. Our World. Available online: https://www.un.org/sustainabledevelopment/blog/2015/12/sustainable-development-goals-kick-off-with-start-of-new-year/ (accessed on 4 February 2021).

- European Union. European Union Priorities for 2019–2024. Available online: https://europa.eu/european-union/about-eu/priorities_en (accessed on 4 February 2021).

- Benn, N.; Zitomer, D. Pretreatment and Anaerobic Co-digestion of Selected PHB and PLA Bioplastics [Original Research]. Front. Environ. Sci. 2018, 5. [Google Scholar] [CrossRef]

- Hobbs, S.R.; Devkota, J.; Parameswarn, P.; Landis, A. Environmental Implications of Food and PLA Waste Management Options 8th International Converence on Environmental Science and Technology; American Academy of Sciences: Houston, TX, USA, 2016. [Google Scholar]

- Hamad, K.; Kaseem, M.; Yang, H.; Deri, F.; Ko, Y. Properties and medical applications of polylactic acid: A review. Express Polym. Lett. 2015, 5, 9. [Google Scholar] [CrossRef]

- Bozano Gandolfi, P.; Nosiglia, V.; Vitali, G. Anaerobic Digestion Of Municipal Solid Waste, Biowaste & Commercial Wastes–Examples Of: 1) Successful Revamping Of Existing Plants 2) Co-Digestion Of Biowaste And Commercial Waste with Agricultural Residues. In Proceedings of the 20 EU BC&E. ETA-Florence Renewable Energies, Milan, Italy; 2012; pp. 1468–1472. Available online: https://www.semanticscholar.org/paper/Anaerobic-Digestion-Of-Municipal-Solid-Waste%2C-%26-Of%3A-Gandolfi-Nosiglia/6f49afdcee9e2c88a6c28cd8f60ba68b59f3a034 (accessed on 1 August 2020).

- Levis, J.W.; Barlaz, M.A.; Themelis, N.J.; Ulloa, P. Assessment of the state of food waste treatment in the United States and Canada. Waste Manag. 2010, 30, 1486–1494. [Google Scholar] [CrossRef] [PubMed]

- Hobbs, S.R.; Parameswarn, P.; Astmann, B.; Devkota, J.; Landis, A. Anaerobic Codigestion of Food Waste and Polylactic Acid: Effect of Pretreatment on Methane Yield and Solid Reduction. Adv. Mater. Sci. Eng. 2019, 2019, 6. [Google Scholar] [CrossRef]

- Klöpffer, W. Life cycle assessment. Environ. Sci. Pollut. Res. 1997, 4, 223–228. [Google Scholar] [CrossRef] [PubMed]

- Bernstad, A.; la Cour Jansen, J. A life cycle approach to the management of household food waste—A Swedish full-scale case study. Waste Manag. 2011, 31, 1879–1896. [Google Scholar] [CrossRef]

- Eriksson, M.; Strid, I.; Hansson, P.-A. Carbon footprint of food waste management options in the waste hierarchy—A Swedish case study. J. Clean. Prod. 2015, 93, 115–125. [Google Scholar] [CrossRef]

- Salemdeeb, R.; Bin Daina, M.; Reynolds, C.; Al-Tabbaa, A. An environmental evaluation of food waste downstream management options: A hybrid LCA approach. Int. J. Recycl. Org. Waste Agric. 2018, 7, 217–229. [Google Scholar] [CrossRef]

- Guinée, J.B. Handbook on life cycle assessment operational guide to the ISO standards. Int. J. Life Cycle Assess. 2002, 7, 311–313. [Google Scholar] [CrossRef]

- Dubanowitz, A.J. Design of a Materials Recovery Facility (MRF) for Processing the Recyclable Materials of New York City’s Municipal Solid Waste. Master’s Thesis, Columbia University, New York, NY, USA, May 2000. [Google Scholar]

- Vrancken, C.; Longhurst, P.J.; Wagland, S.T. Critical review of real-time methods for solid waste characterisation: Informing material recovery and fuel production. Waste Manag. 2017, 61, 40–57. [Google Scholar] [CrossRef] [PubMed]

- AlHumid, H.A.; Haider, H.; AlSaleem, S.S.; Alinizzi, M.; Shafiquzaman, M.; Sadiq, R. Performance Assessment Model for Municipal Solid Waste Management Systems: Development and Implementation. Environments 2019, 6, 19. [Google Scholar] [CrossRef]

- Lijó, L.; González-García, S.; Bacenetti, J.; Fiala, M.; Feijoo, G.; Lema, J.M.; Moreira, M.T. Life Cycle Assessment of electricity production in Italy from anaerobic co-digestion of pig slurry and energy crops. Renew. Energy 2014, 68, 625–635. [Google Scholar] [CrossRef]

- Tippayawong, N.; Thanompongchart, P. Biogas quality upgrade by simultaneous removal of CO2 and H2S in a packed column reactor. Energy 2010, 35, 4531–4535. [Google Scholar] [CrossRef]

- Stucki, M.; Jungbluth, N.; Leuenberger, M. Life Cycle Assessment of Biogas Production from Different Substrates; ESU-Services Ltd.: Schaffhausen, Switzerland, 2011. [Google Scholar]

- Power, G.; Gräfe, M.; Klauber, C. Bauxite residue issues: I. Current management, disposal and storage practices. Hydrometallurgy 2011, 108, 33–45. [Google Scholar] [CrossRef]

- EPA. Documentation for Greenhouse Gas Emission and Energy Factors Used in the Waste Reduction Model (WARM). In Background Chapters; U.S. Environmental Protection Agency Office of Resource Conservation and Recovery: Washington, DC, USA, 2016. [Google Scholar]

- Doka, G. Life Cycle Inventories of Waste Treatment Services; F.r.e.d. v2.0; Swiss Centre for LCI, Empa-TSL: Dübendorf, CH, USA, 2007. [Google Scholar]

- Bare, J.C. Traci: The tool for the reduction and assessment of chemical and other environmental impacts. J. Ind. Ecol. 2002, 6, 49–78. [Google Scholar] [CrossRef]

- Bösch, M.E.; Hellweg, S.; Huijbregts, M.A.J.; Frischknecht, R. Applying cumulative exergy demand (CExD) indicators to the ecoinvent database. Int. J. Life Cycle Assess. 2006, 12, 181. [Google Scholar] [CrossRef]

- Tambone, F.; Scaglia, B.; D’Imporzano, G.; Schievano, A.; Orzi, V.; Salati, S.; Adani, F. Assessing amendment and fertilizing properties of digestates from anaerobic digestion through a comparative study with digested sludge and compost. Chemosphere 2010, 81, 577–583. [Google Scholar] [CrossRef] [PubMed]

- EPA. Land Application of Sewage Sludge: A Guid for Land Appliers on the Requirements of the Federal Standards for the Use or Disposal of Sewage Sludge, 40 CFR Part 503; US Environmental Protection Agency: Washington, DC, USA, 1994.

- Pasqualino, J.C.; Meneses, M.; Abella, M.; Castells, F. LCA as a Decision Support Tool for the Environmental Improvement of the Operation of a Municipal Wastewater Treatment Plant. Environ. Sci. Technol. 2009, 43, 3300–3307. [Google Scholar] [CrossRef]

- Ciroth, A.; Fleischer, G.; Steinbach, J. Uncertainty calculation in life cycle assessments. Int. J. Life Cycle Assess. 2004, 9, 216. [Google Scholar] [CrossRef]

- Weidema, B.P. Multi-user test of the data quality matrix for product life cycle inventory data. Int. J. Life Cycle Assess. 1998, 3, 259–265. [Google Scholar] [CrossRef]

- European Commission. General guide for Life Cycle Assessment-Detailed guidance. In International Reference Life Cycle Data System (ILCD) Handbook; Institute for Environment and Sustainability: Luxembourg, 2010; Available online: https://eplca.jrc.ec.europa.eu/uploads/ILCD-Handbook-General-guide-for-LCA-DETAILED-GUIDANCE-12March2010-ISBN-fin-v1.0-EN.pdf (accessed on 12 August 2020).

- Edelmann, W.; Schleiss, K.; Joss, A. Ecological, energetic and economic comparison of anaerobic digestion with different competing technologies to treat biogenic wastes. Water Sci. Technol. 2000, 41, 263–273. [Google Scholar] [CrossRef] [PubMed]

- Hottle, T.A.; Bilec, M.M.; Landis, A.E. Biopolymer production and end of life comparisons using life cycle assessment. Resour. Conserv. Recycl. 2017, 122, 295–306. [Google Scholar] [CrossRef]

- Amlinger, F.; Peyr, S.; Cuhls, C. Green house gas emissions from composting and mechanical biological treatment. Waste Manag. Res. 2008, 26, 47–60. [Google Scholar] [CrossRef] [PubMed]

- Mezzullo, W.G.; McManus, M.C.; Hammond, G.P. Life cycle assessment of a small-scale anaerobic digestion plant from cattle waste. Appl. Energy 2013, 102, 657–664. [Google Scholar] [CrossRef]

- Güereca, L.P.; Gassó, S.; Baldasano, J.M.; Jiménez-Guerrero, P. Life cycle assessment of two biowaste management systems for Barcelona, Spain. Resour. Conserv. Recycl. 2006, 49, 32–48. [Google Scholar] [CrossRef]

| Scenarios | Reliability | Completeness | Temporal | Geographical | Technological | Average Pedigree Processes Score |

|---|---|---|---|---|---|---|

| Scenario 1a (AD) | ||||||

| Treatment of food waste and PLA | 2 | 5 | 5 | 5 | 5 | 4.4 |

| Treatment of sludge | 2 | 5 | 5 | 5 | 4 | 4.2 |

| Avoided production of fertilizer | 4 | 5 | 5 | 5 | 4 | 4.6 |

| Landfilled biosolids | 4 | 5 | 5 | 5 | 3 | 4.4 |

| Scenario 1b (AD with pretreatment) | ||||||

| Treatment of food waste and PLA | 2 | 4 | 5 | 5 | 3 | 3.8 |

| Treatment of sludge | 4 | 4 | 5 | 5 | 3 | 4.2 |

| Avoided production of fertilizer | 3 | 5 | 5 | 5 | 4 | 4.4 |

| Landfilled biosolids | 5 | 5 | 5 | 5 | 4 | 4.8 |

| Scenario 2a (Compost) | ||||||

| Treatment of food waste and PLA | 4 | 5 | 5 | 5 | 5 | 4.8 |

| Treatment of sludge | n/a | n/a | n/a | n/a | n/a | n/a |

| Avoided production of fertilizer | 4 | 5 | 5 | 5 | 4 | 4.6 |

| Landfilled biosolids | 4 | 5 | 5 | 5 | 4 | 4.6 |

| Scenario 2b (Compost with pretreatment) | ||||||

| Treatment of food waste and PLA | 4 | 5 | 5 | 5 | 4 | 4.6 |

| Treatment of sludge | n/a | n/a | n/a | n/a | n/a | n/a |

| Avoided production of fertilizer | 4 | 5 | 5 | 5 | 4 | 4.6 |

| Landfilled biosolids | 5 | 5 | 5 | 5 | 4 | 4.8 |

| Scenario 3 (Landfill) | ||||||

| Treatment of food waste and PLA | 5 | 5 | 5 | 5 | 5 | 5 |

| Treatment of sludge | n/a | n/a | n/a | n/a | n/a | n/a |

| Avoided production of fertilizer | n/a | n/a | n/a | n/a | n/a | n/a |

| Landfilled biosolids | n/a | n/a | n/a | n/a | n/a | n/a |

| Average Scenario Pedigree Score | 3.7 | 4.9 | 5.0 | 5.0 | 4.0 | 4.5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hobbs, S.R.; Harris, T.M.; Barr, W.J.; Landis, A.E. Life Cycle Assessment of Bioplastics and Food Waste Disposal Methods. Sustainability 2021, 13, 6894. https://doi.org/10.3390/su13126894

Hobbs SR, Harris TM, Barr WJ, Landis AE. Life Cycle Assessment of Bioplastics and Food Waste Disposal Methods. Sustainability. 2021; 13(12):6894. https://doi.org/10.3390/su13126894

Chicago/Turabian StyleHobbs, Shakira R., Tyler M. Harris, William J. Barr, and Amy E. Landis. 2021. "Life Cycle Assessment of Bioplastics and Food Waste Disposal Methods" Sustainability 13, no. 12: 6894. https://doi.org/10.3390/su13126894

APA StyleHobbs, S. R., Harris, T. M., Barr, W. J., & Landis, A. E. (2021). Life Cycle Assessment of Bioplastics and Food Waste Disposal Methods. Sustainability, 13(12), 6894. https://doi.org/10.3390/su13126894