Optimal Allocation of Multiple Types of Distributed Generations in Radial Distribution Systems Using a Hybrid Technique

Abstract

:1. Introduction

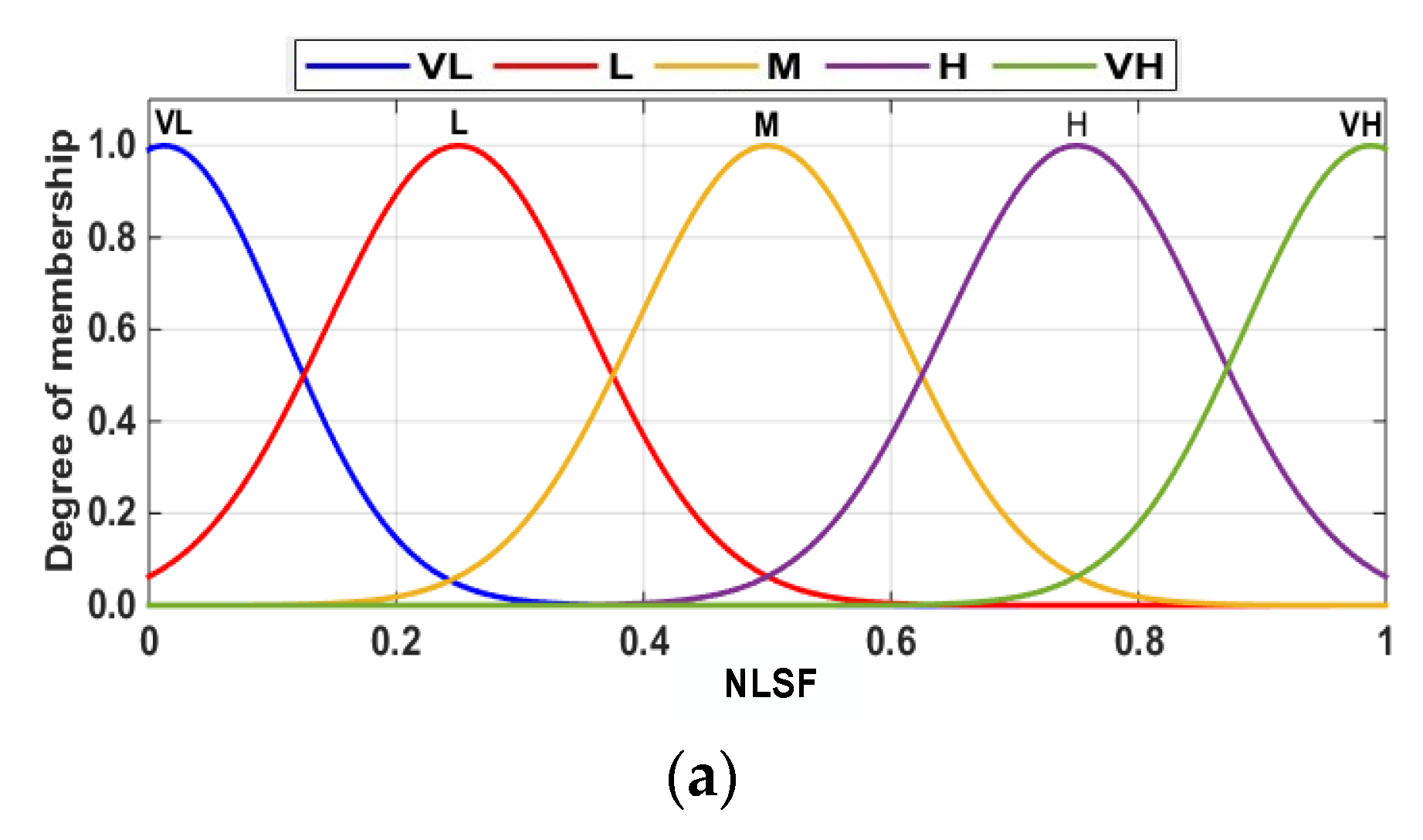

- Proposing candidate bus selection using loss sensitivity factor (LSF) with the fuzzy logic controller.

- Proposing a hybrid between the analytical technique and sine cosine algorithm (SCA).

- Applying the proposed hybrid technique to determine the optimal allocation of DG units in RDS to minimize the total losses.

- Checking the performance of the proposed hybrid technique compared to the conventional SCA and other well-known optimization methods using standard IEEE 33-bus and 69-bus RDS.

- Type I: Injects only active power.

- Type II: Injects only reactive power.

- Type III: Inject active and reactive power.

2. Problem Formulation

2.1. Power Flow Equations

2.2. Objective Function

2.3. Problem Constraints

2.3.1. Power Balance Equation

2.3.2. Inequality Constraints

3. Overview of the Optimization Methods

3.1. Candidate Buses Selection

3.2. Analytical Technique

- In the case of installing Type I of the DG ;

- In the case of installing Type, I Type II of the DG ;

- In the case of installing Type, I Type III of the DG .

3.3. Sine Cosine Algorithm (SCA)

- Step 1

- Specify the parameters of the sine cosine algorithm such as search agent number, number of the maximum iterations.

- Step 2

- Initialize the population of solutions randomly within the upper and lower borders of variables as follows:where i is the search agent number and j is the variables number (dimension).

- Step 3

- The situation for the population of solutions can be assigned as follows:

- Step 4

- Determine the objective function amount according to the search agent situation as follows:

- Step 5

- Calculate the purpose of fitness that is known as a preferable fitness and the purpose position that is known as a preferable position.

- Step 6

- Update the situation of the search agent as presented as follows:where is a variable that used to balance between the exploration and exploitation phases and can be expressed as follows:are random variables and expressed as follows:

- T is the current iteration.

- is the maximum iteration.

- is the objective global best solution.

- Step 7

- Iterate the steps from 3 to 5 until the standing criteria are ascertained.

- Step 8

- Acquire the optimal destination fitness and the optimal destination.

3.4. Proposed Hybrid Optimization Technique

- Step 1

- Enter line and load data, and bus voltage limits.

- Step 2

- Determine the power losses using forward/backward load flow sweep.

- Step 3

- Specify candidate buses using LSF and the sizes of the DGs using the analytical technique for Type I using (36) and Type II using (37).

- Step 4

- Initialize the population of solutions using the values obtained from step 3 within the limits in the search space and set = 0.

- Step 5

- If the voltage values of all buses are within the constraint, estimate the power losses using (1). Otherwise, that solution is infeasible.

- Step 6

- Select the solution associated with the best objective function and set the value of the objective function as the current fitness function.

- Step 7

- Update the situation of the search agent using (42) and (43).

- Step 8

- If , go to step 9; otherwise, go to step 6.

- Step 9

- Print the results and optimal purpose position including the locations and sizes of various types of multiple numbers of the DGs and the corresponding optimal destination fitness, which represents minimum power losses.

4. Result and Discussion

- Case 1: Base case (without DG).

- Case 2: Integrating one DG.

- Case 3: Integrating two DGs.

- Case 4: Integrating three DGs.

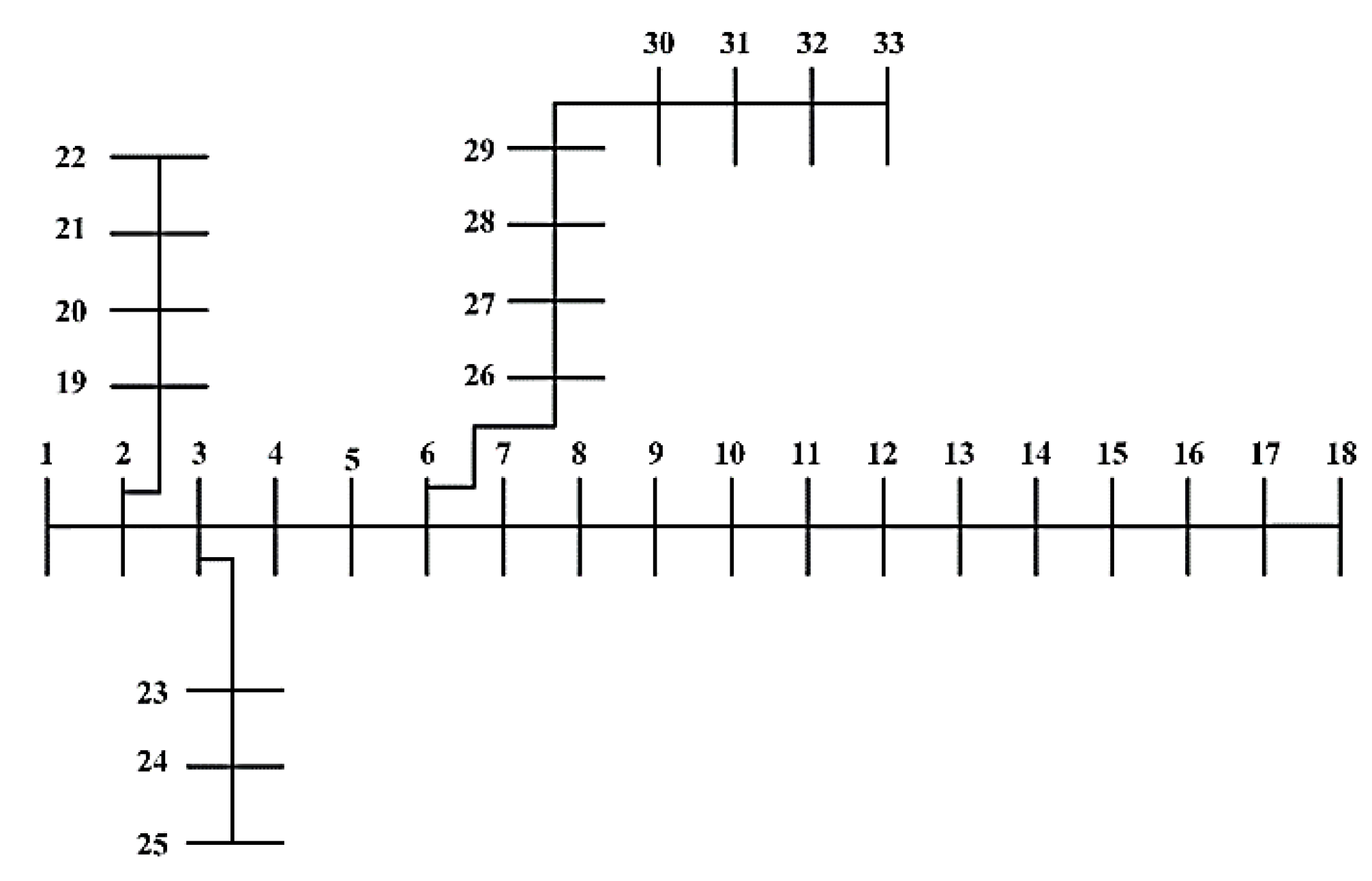

4.1. IEEE 33-Bus System

4.1.1. Case 1: Base Case

4.1.2. Case 2: Installing One DG

DG Type I

DG Type II

DG Type III

4.1.3. Case 3: Installing Two DGs

DG Type I

DG Type II

DG Type III

4.1.4. Case 4: Installing Three DGs

DG Type I

DG Type II

DG Type III

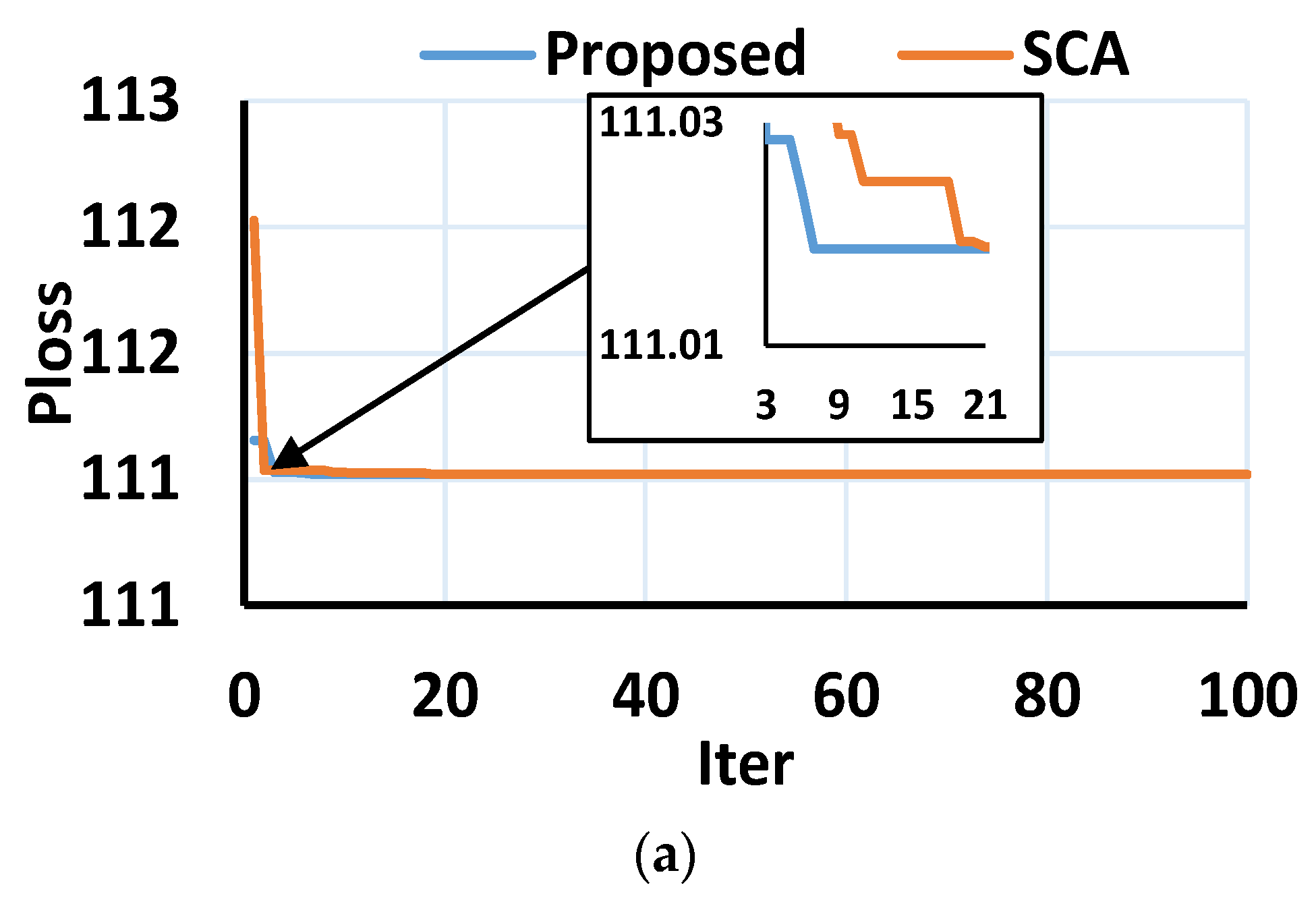

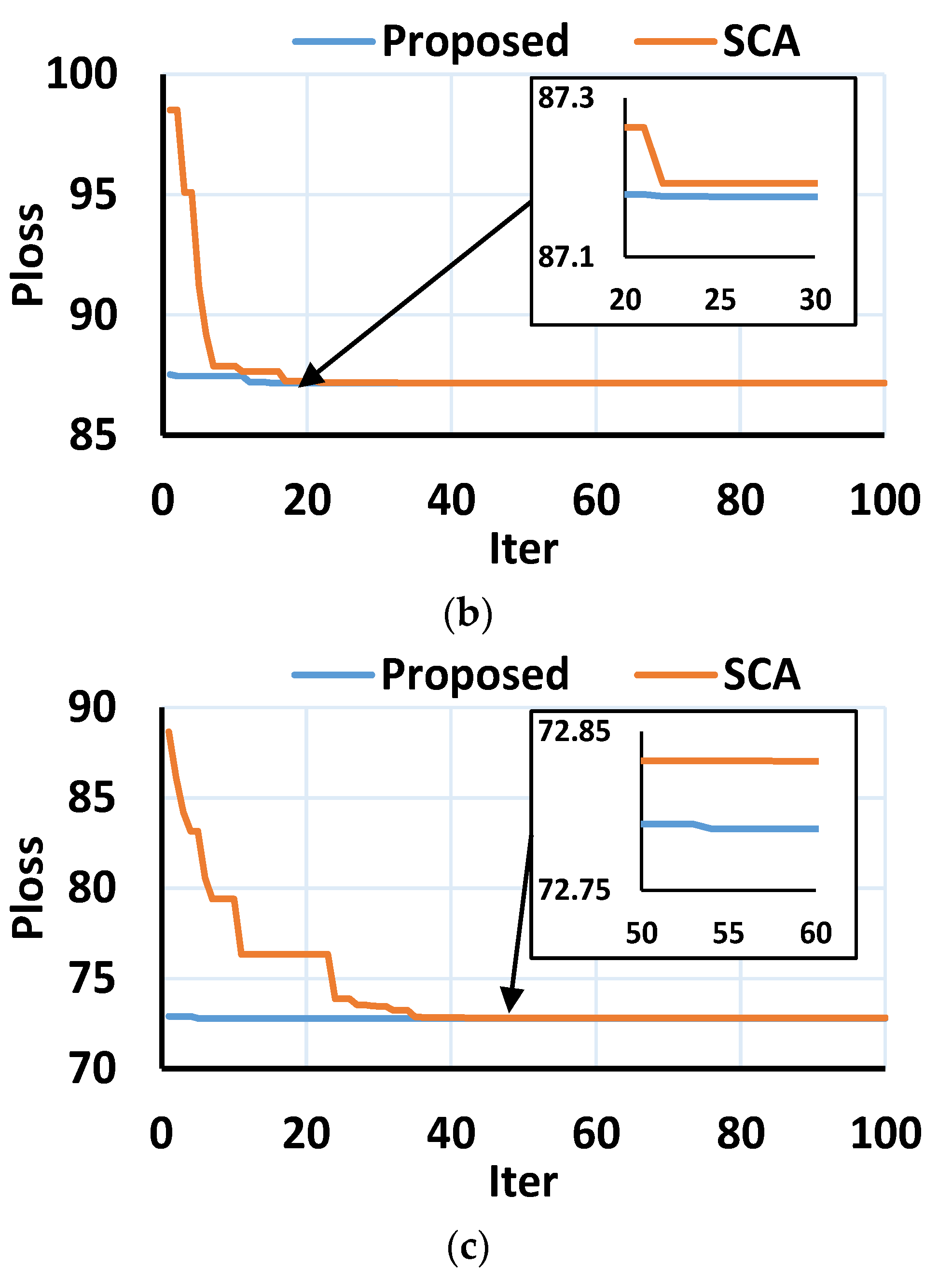

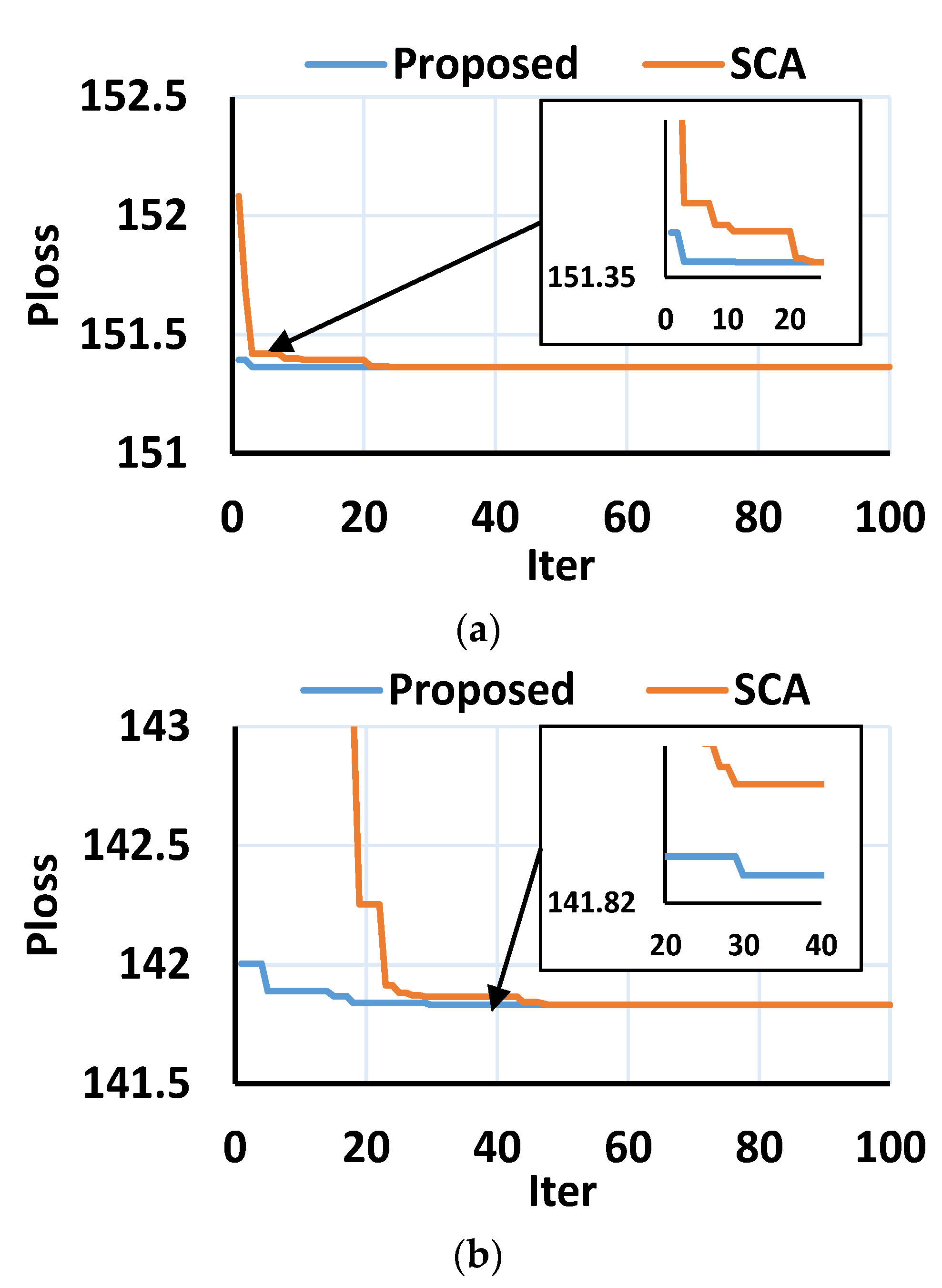

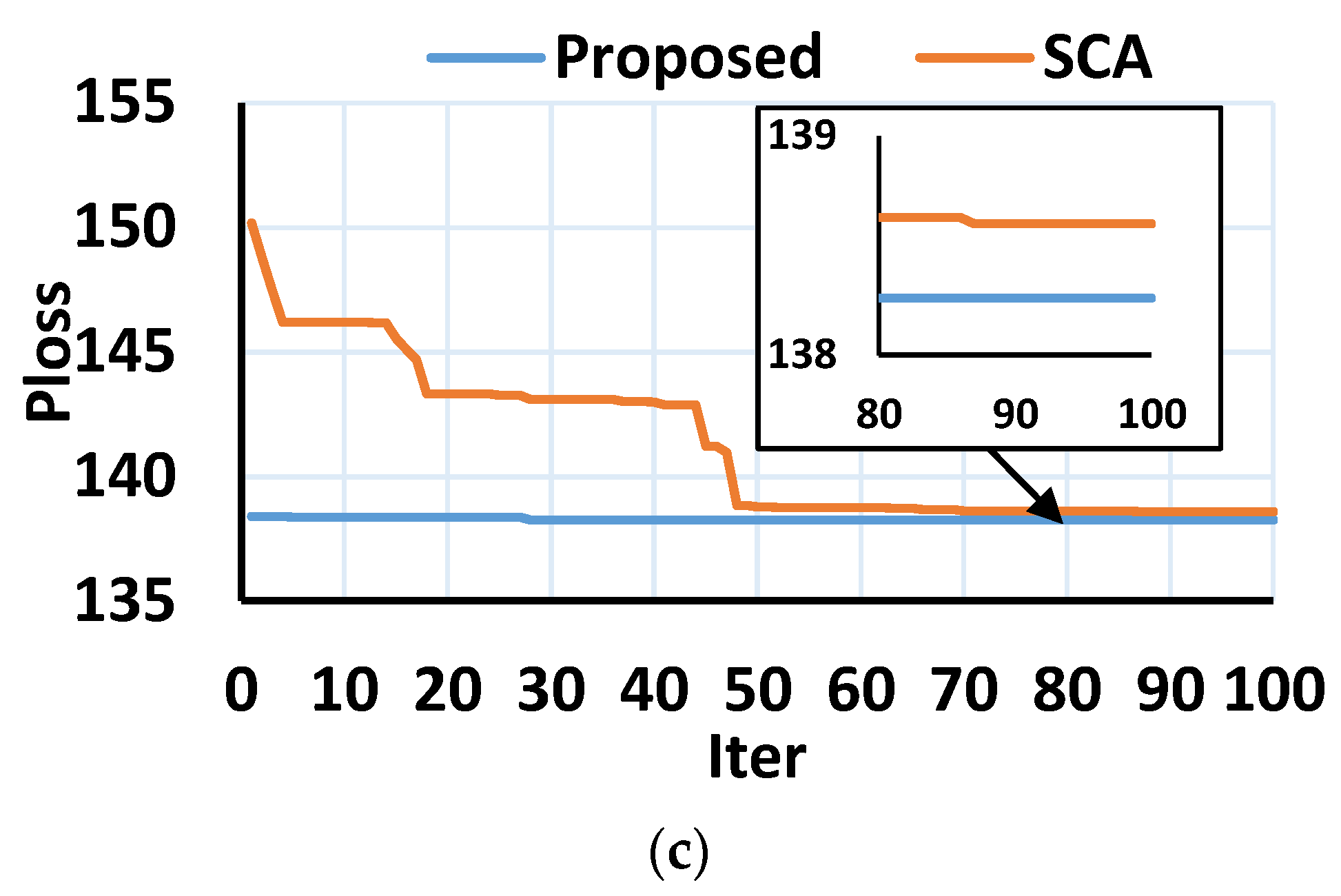

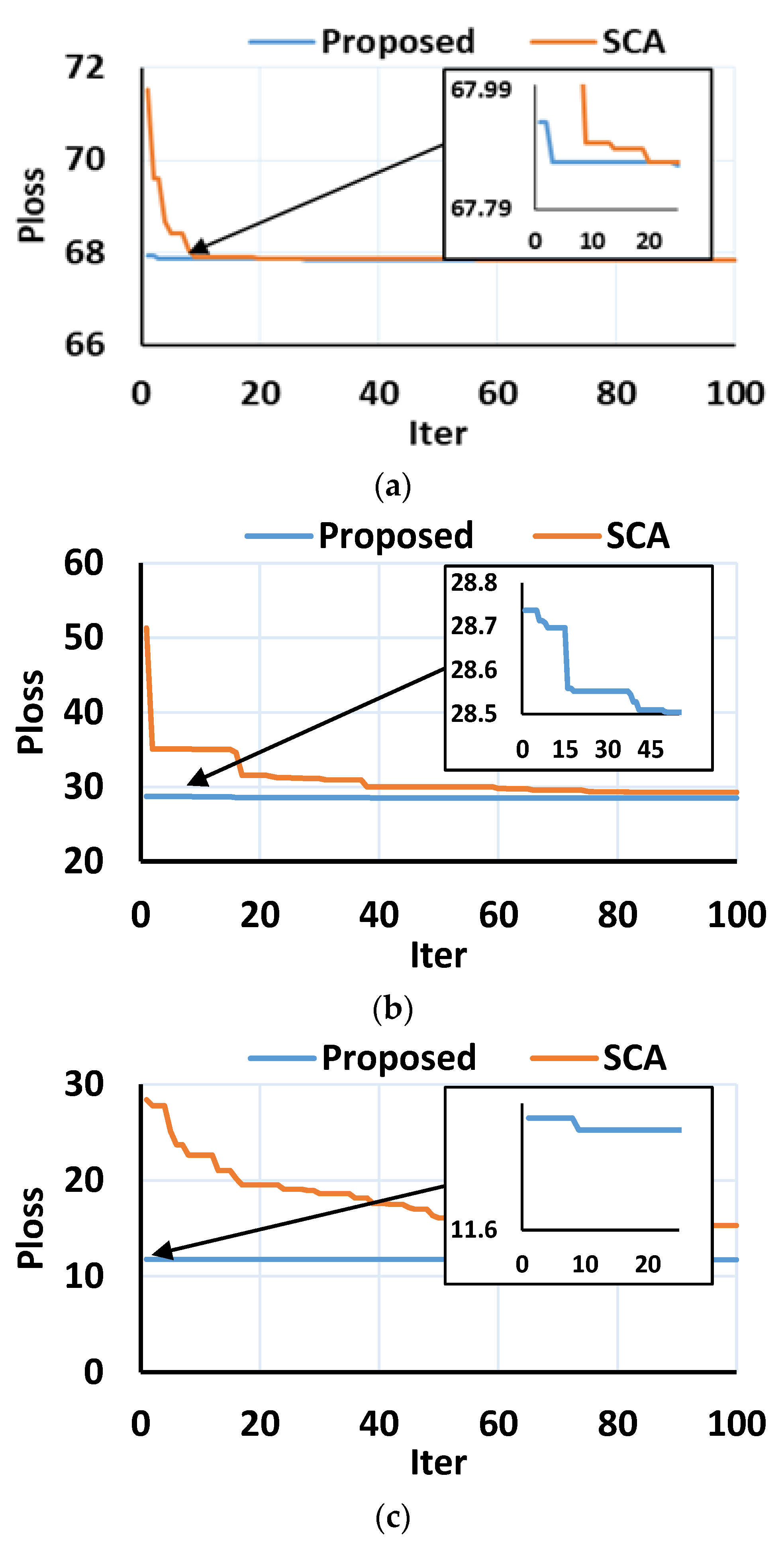

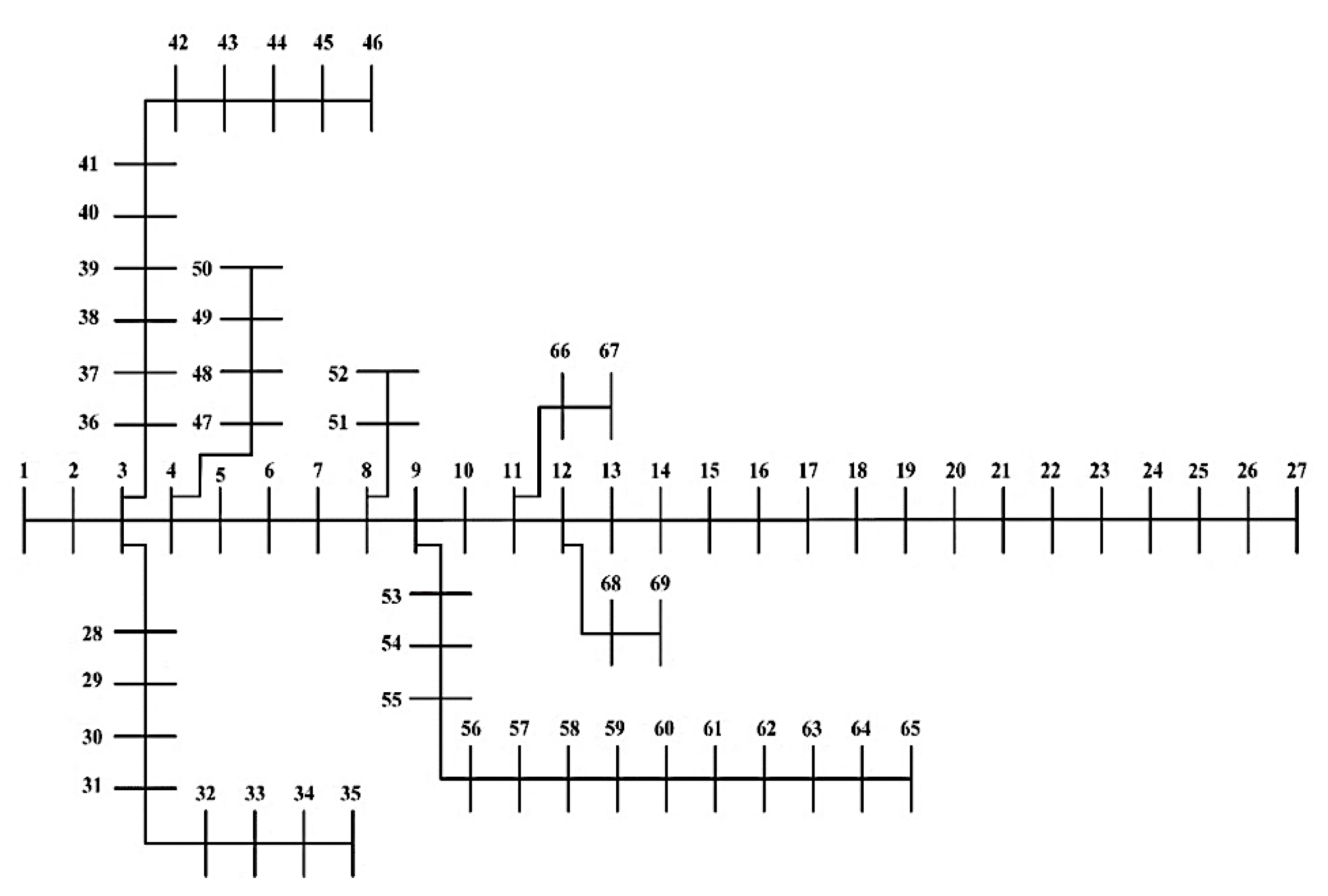

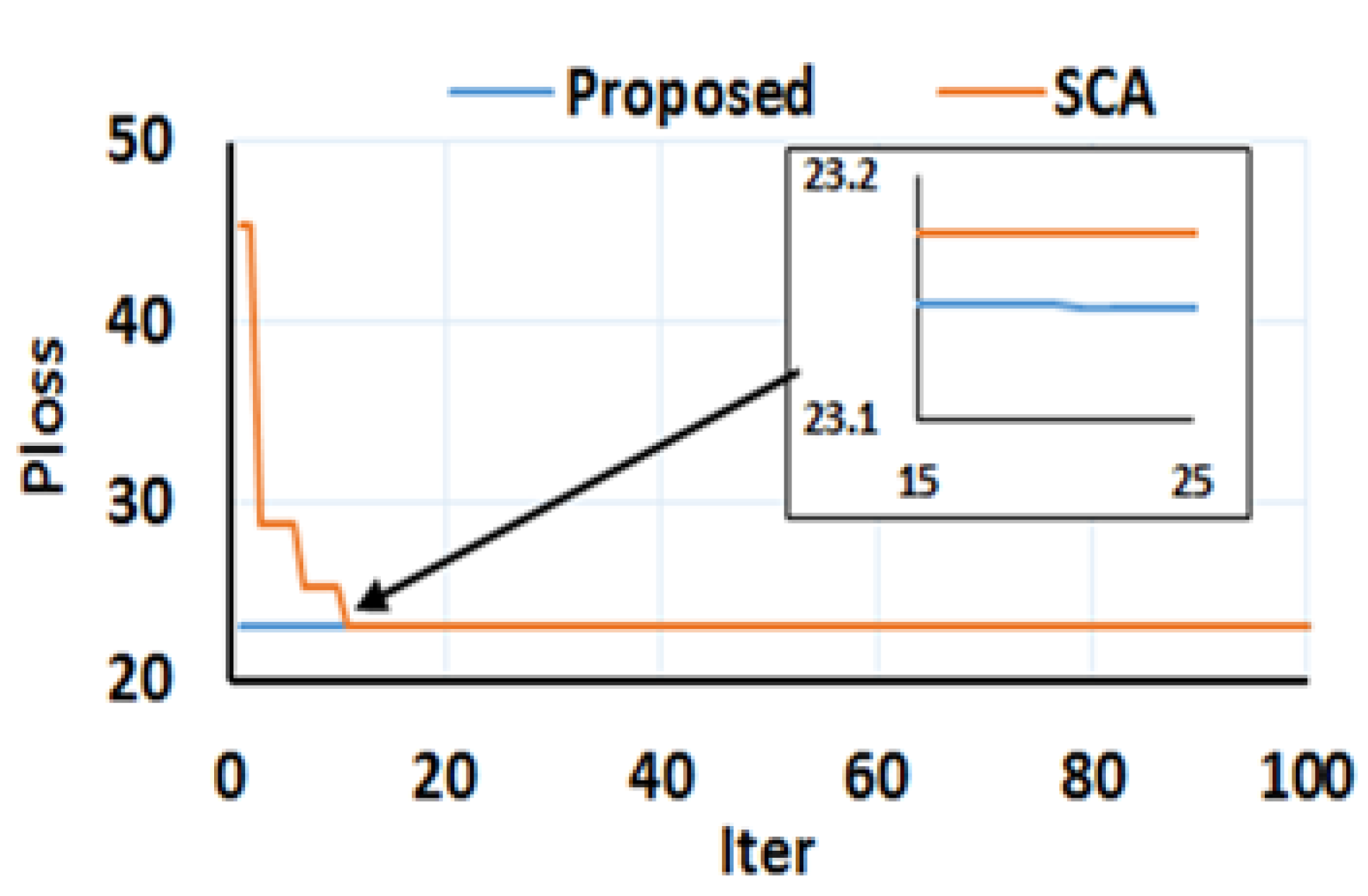

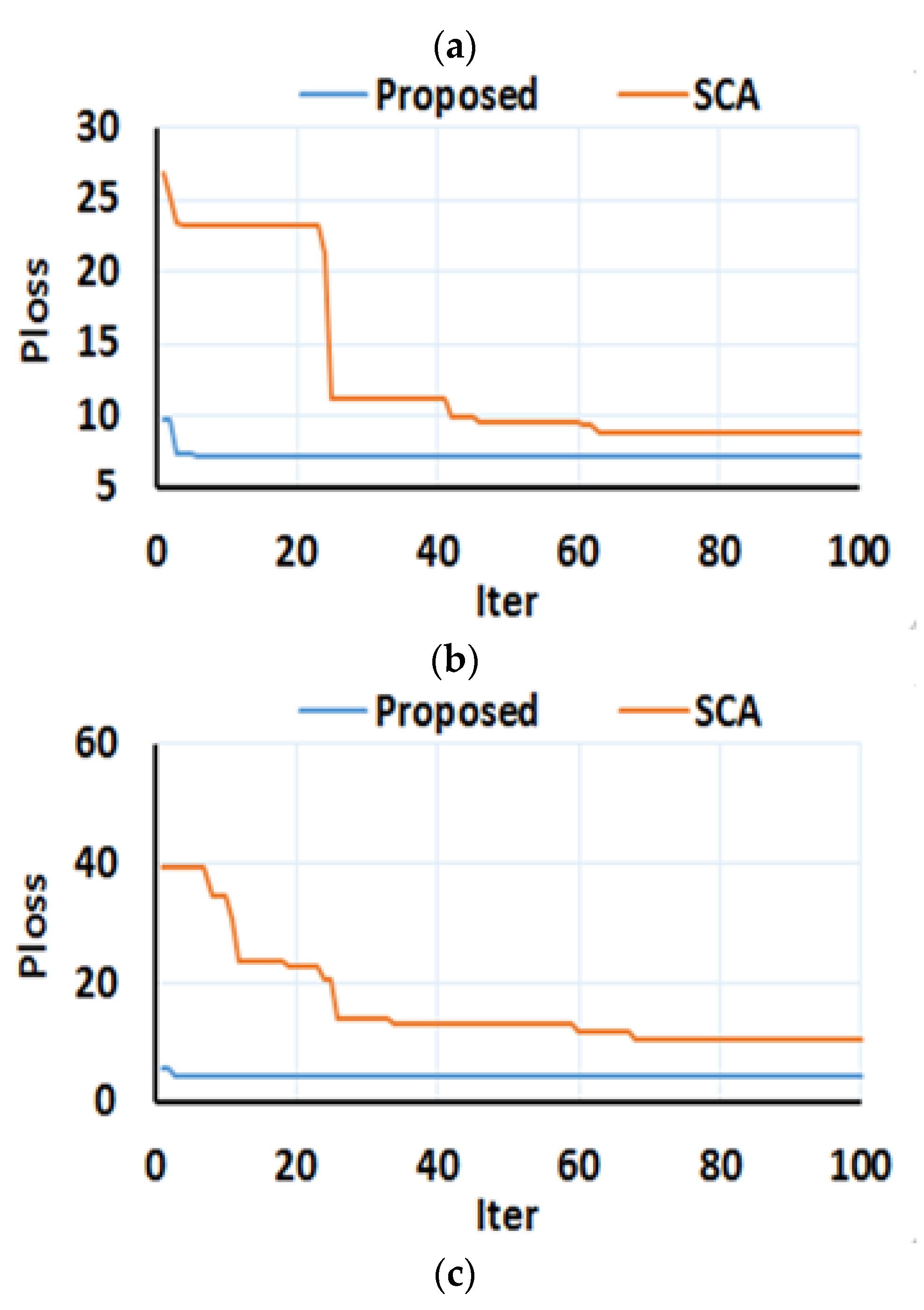

4.1.5. Performance Analysis for the Developed Technique

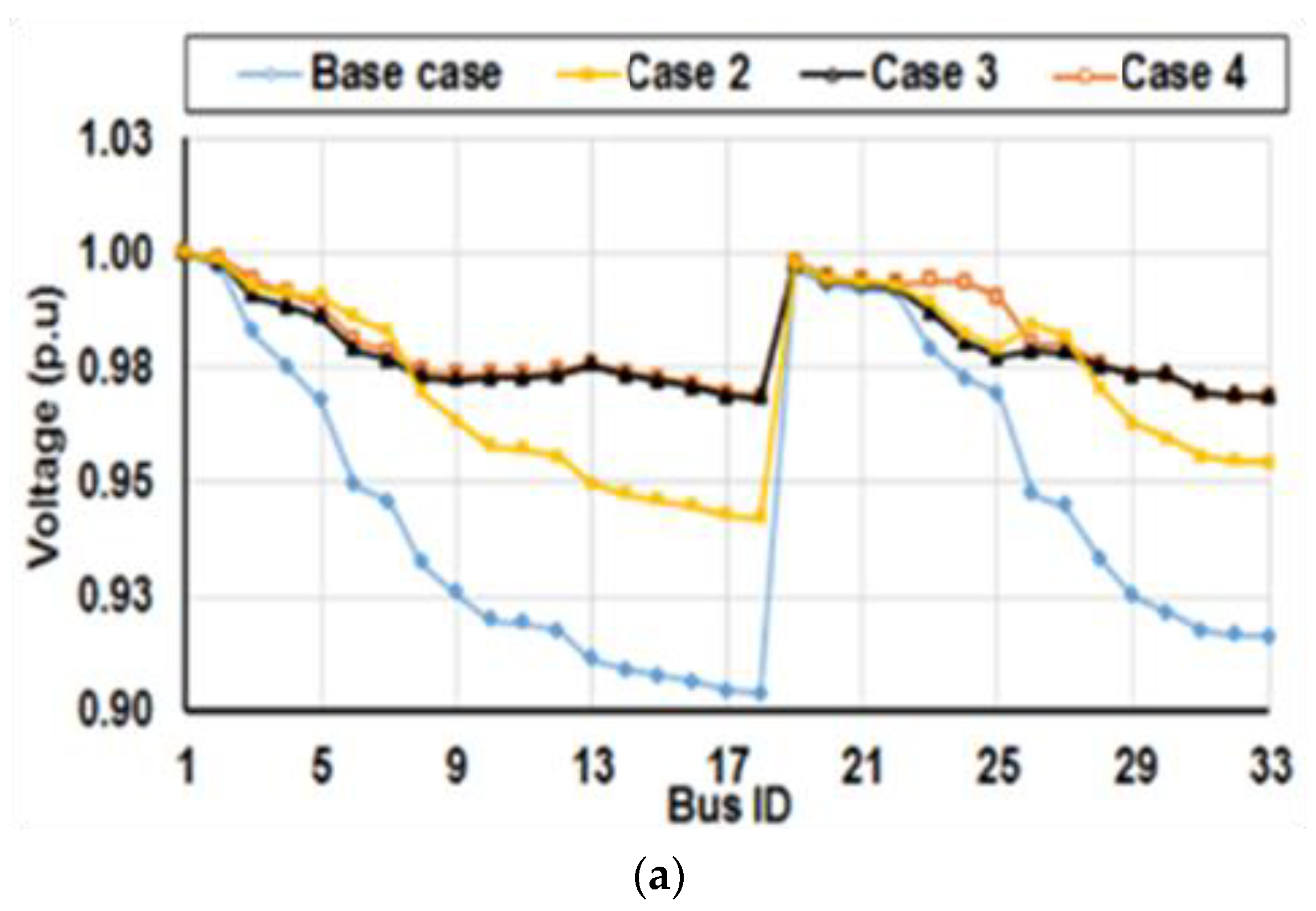

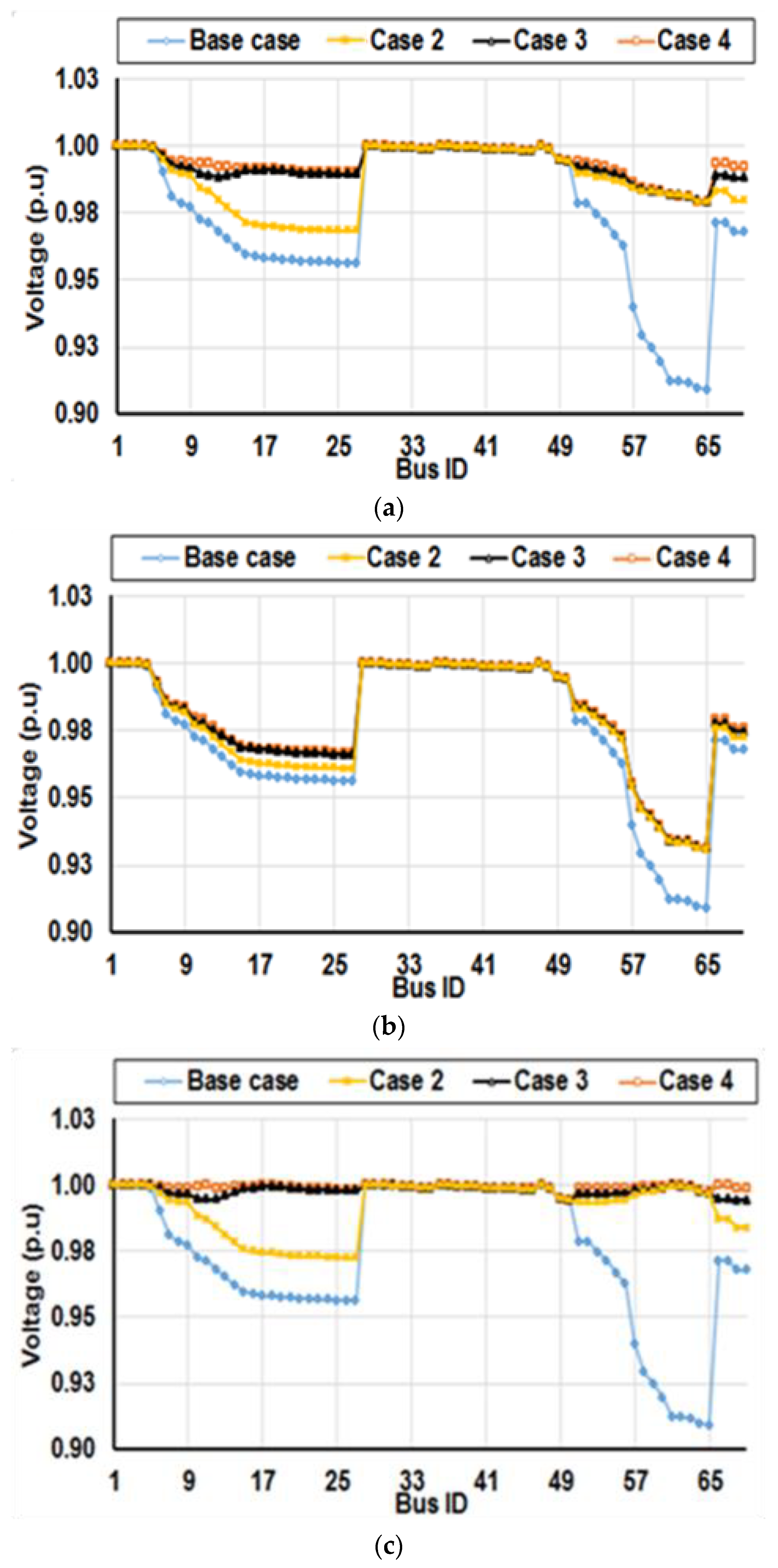

4.1.6. Voltage Profile

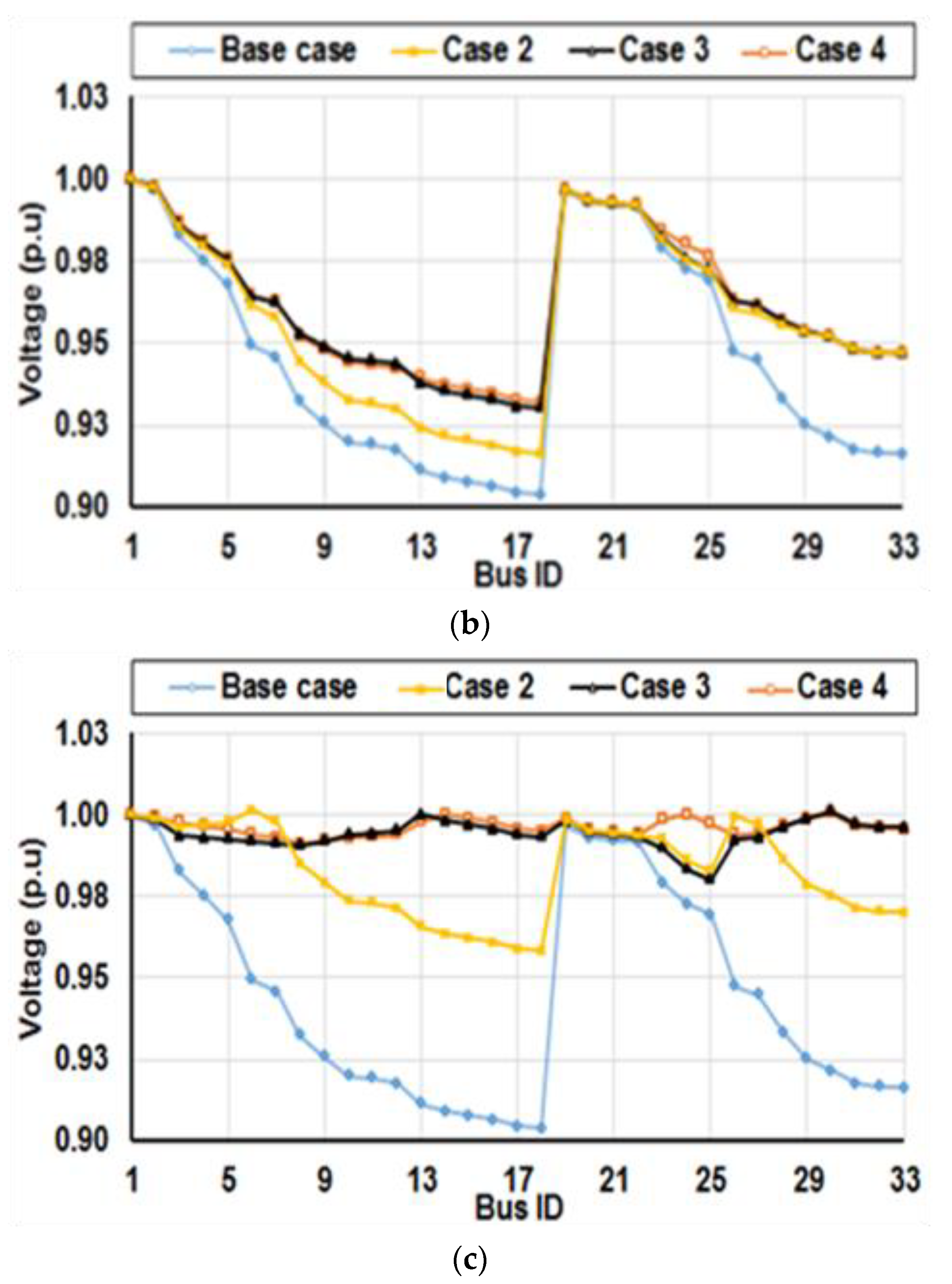

4.2. IEEE 69-Bus System

4.2.1. Case 1: Base Case

4.2.2. Case 2: Installing One DG

DG Type I

DG Type II

DG Type III

4.2.3. Case 3: Installing Two DGs

DG Type I

DG Type II

DG Type III

4.2.4. Case 4: Installing Three DGs

DG Type I

DG Type II

DG Type II

4.2.5. Performance Analysis for the Developed Technique

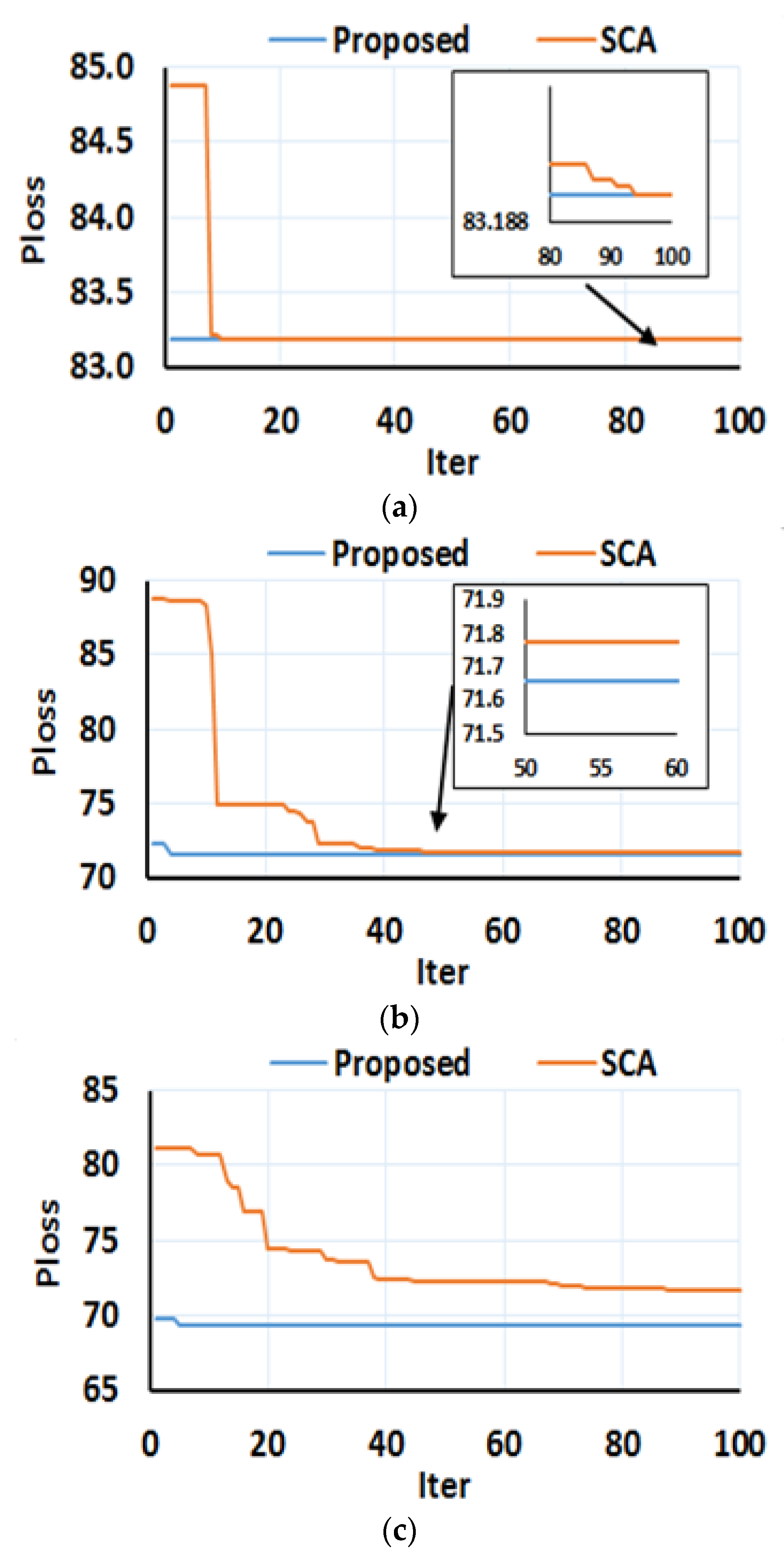

4.2.6. Voltage Profile

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Singh, D.; Misra, R.; Singh, D. Effect of load models in distributed generation planning. IEEE Trans. Power Syst. 2007, 22, 2204–2212. [Google Scholar] [CrossRef]

- El-Samahy, I.; El-Saadany, E. The effect of DG on power quality in a deregulated environment. In Proceedings of the IEEE Power Engineering Society General Meeting, San Francisco, CA, USA, 12–16 June 2005; IEEE: Piscataway, NJ, USA, 2005; pp. 2969–2976. [Google Scholar]

- Ackermann, T.; Andersson, G.; Söder, L. Distributed generation: A definition. Electr. Power Syst. Res. 2001, 57, 195–204. [Google Scholar] [CrossRef]

- Marwali, M.N.; Jung, J.-W.; Keyhani, A. Stability analysis of load sharing control for distributed generation systems. IEEE Trans. Energy Convers. 2007, 22, 737–745. [Google Scholar] [CrossRef]

- Prakash, P.; Khatod, D.K. Optimal sizing and siting techniques for distributed generation in distribution systems: A review. Renew. Sustain. Energy Rev. 2016, 57, 111–130. [Google Scholar] [CrossRef]

- HA, M.P.; Huy, P.D.; Ramachandaramurthy, V.K. A review of the optimal allocation of distributed generation: Objectives, constraints, methods, and algorithms. Renew. Sustain. Energy Rev. 2017, 75, 293–312. [Google Scholar]

- Mohamed, A.A.; Kamel, S.; Selim, A.; Khurshaid, T.; Rhee, S.-B. Developing a Hybrid Approach Based on Analytical and Metaheuristic Optimization Algorithms for the Optimization of Renewable DG Allocation Considering Various Types of Loads. Sustainability 2021, 13, 4447. [Google Scholar] [CrossRef]

- Hung, D.Q.; Mithulananthan, N. Multiple distributed generator placement in primary distribution networks for loss reduction. IEEE Trans. Ind. Electron. 2013, 60, 1700–1708. [Google Scholar] [CrossRef]

- Forooghi Nematollahi, A.; Dadkhah, A.; Asgari Gashteroodkhani, O.; Vahidi, B. Optimal sizing and siting of DGs for loss reduction using an iterative-analytical method. J. Renew. Sustain. Energy 2016, 8, 055301. [Google Scholar] [CrossRef]

- Naik, S.G.; Khatod, D.; Sharma, M. Optimal allocation of combined DG and capacitor for real power loss minimization in distribution networks. Int. J. Electr. Power Energy Syst. 2013, 53, 967–973. [Google Scholar] [CrossRef]

- Mahmoud, K.; Yorino, N.; Ahmed, A. Optimal distributed generation allocation in distribution systems for loss minimization. IEEE Trans. Power Syst. 2015, 31, 960–969. [Google Scholar] [CrossRef]

- Naik, S.N.G.; Khatod, D.K.; Sharma, M.P. Analytical approach for optimal siting and sizing of distributed generation in radial distribution networks. IET Gener. Transm. Distrib. 2014, 9, 209–220. [Google Scholar] [CrossRef]

- Selim, A.; Kamel, S.; Jurado, F. Optimal allocation of distribution static compensators using a developed multi-objective sine cosine approach. Comput. Electr. Eng. 2020, 85, 106671. [Google Scholar] [CrossRef]

- Ehsan, A.; Yang, Q. Optimal integration and planning of renewable distributed generation in the power distribution networks: A review of analytical techniques. Appl. Energy 2018, 210, 44–59. [Google Scholar] [CrossRef]

- El-Fergany, A. Optimal allocation of multi-type distributed generators using backtracking search optimization algorithm. Int. J. Electr. Power Energy Syst. 2015, 64, 1197–1205. [Google Scholar] [CrossRef]

- Ali, A.H.; Youssef, A.-R.; George, T.; Kamel, S. Optimal DG allocation in distribution systems using Ant lion optimizer. In Proceedings of the 2018 International Conference on Innovative Trends in Computer Engineering (ITCE), Aswan, Egypt, 19–21 February 2018; IEEE: Piscataway, NJ, USA, 2018; pp. 324–331. [Google Scholar]

- Sobieh, A.; Mandour, M.; Saied, E.M.; Salama, M. Optimal number size and location of distributed generation units in radial distribution systems using Grey Wolf optimizer. Int. Electr. Eng. J 2017, 7, 2367–2376. [Google Scholar]

- Saleh, A.A.; Mohamed, A.-A.A.; Hemeida, A. Optimal Allocation of Distributed Generations and Capacitor Using Multi-Objective Different Optimization Techniques. In Proceedings of the 2019 International Conference on Innovative Trends in Computer Engineering (ITCE), Aswan, Egypt, 2–4 February 2019; IEEE: Piscataway, NJ, USA, 2019; pp. 377–383. [Google Scholar]

- Saleh, A.A.; Mohamed, A.-A.A.; Hemeida, A.M.; Ibrahim, A.A. Comparison of different optimization techniques for optimal allocation of multiple distribution generation. In Proceedings of the 2018 International Conference on Innovative Trends in Computer Engineering (ITCE), Aswan, Egypt, 19–21 February; IEEE: Piscataway, NJ, USA, 2018; pp. 317–323. [Google Scholar]

- Yuvaraj, T.; Devabalaji, K.; Ravi, K. Optimal Allocation of DG in the Radial Distribution Network Using Bat Optimization Algorithm. In Advances in Power Systems and Energy Management; Springer: Berlin/Heidelberg, Germany, 2018; pp. 563–569. [Google Scholar]

- Sultana, S.; Roy, P.K. Krill herd algorithm for optimal location of distributed generator in radial distribution system. Appl. Soft Comput. 2016, 40, 391–404. [Google Scholar] [CrossRef]

- Sambaiah, K.S.; Jayabarathi, T. Optimal allocation of renewable distributed generation and capacitor banks in distribution systems using Salp Swarm algorithm. Int. J. Renew. Energy Res. 2019, 9, 96–107. [Google Scholar]

- Nowdeh, S.A.; Davoudkhani, I.F.; Moghaddam, M.H.; Najmi, E.S.; Abdelaziz, A.Y.; Ahmadi, A.; Razavi, S.; Gandoman, F.H. Fuzzy multi-objective placement of renewable energy sources in distribution system with objective of loss reduction and reliability improvement using a novel hybrid method. Appl. Soft Comput. 2019, 77, 761–779. [Google Scholar] [CrossRef]

- Rajendran, A.; Narayanan, K. Optimal multiple installation of DG and capacitor for energy loss reduction and loadability enhancement in the radial distribution network using the hybrid WIPSO–GSA algorithm. Int. J. Ambient Energy 2018, 41, 129–141. [Google Scholar] [CrossRef]

- Bala, R.; Ghosh, S. Applications, Optimal position and rating of DG in distribution networks by ABC–CS from load flow solutions illustrated by fuzzy-PSO. Neural Comput. 2019, 31, 489–507. [Google Scholar] [CrossRef]

- Kansal, S.; Kumar, V.; Tyagi, B. Hybrid approach for optimal placement of multiple DGs of multiple types in distribution networks. Int. J. Electr. Power Energy Syst. 2016, 75, 226–235. [Google Scholar] [CrossRef]

- Mirjalili, S. SCA: A sine cosine algorithm for solving optimization problems. Knowl.-Based Syst. 2016, 96, 120–133. [Google Scholar] [CrossRef]

- Baran, M.E.; Wu, F.F. Network reconfiguration in distribution systems for loss reduction and load balancing. IEEE Trans. Power Deliv. 1989, 4, 1401–1407. [Google Scholar] [CrossRef]

- Bayat, A.; Bagheri, A. Optimal active and reactive power allocation in distribution networks using a novel heuristic approach. Appl. Energy 2019, 233, 71–85. [Google Scholar] [CrossRef]

- Ali, E.; Elazim, S.A.; Abdelaziz, A. Ant Lion Optimization Algorithm for optimal location and sizing of renewable distributed generations. Renew. Energy 2017, 101, 1311–1324. [Google Scholar] [CrossRef]

- Kashyap, M.; Mittal, A.; Kansal, S. Optimal Placement of Distributed Generation Using Genetic Algorithm Approach. In Proceeding of the Second International Conference on Microelectronics, Computing & Communication Systems (MCCS 2017); Springer: Singapore, 2019; pp. 587–597. [Google Scholar]

- Kowsalya, M. Optimal size and siting of multiple distributed generators in distribution system using bacterial foraging optimization. Swarm Evol. Comput. 2014, 15, 58–65. [Google Scholar]

- Meera, P.; Hemamalini, S. Optimal siting of distributed generators in a distribution network using artificial immune system. Int. J. Electr. Comput. Eng. 2017, 7, 641. [Google Scholar]

- Baran, M.; Wu, F.F. Optimal sizing of capacitors placed on a radial distribution system. IEEE Trans. Power Deliv. 1989, 4, 735–743. [Google Scholar] [CrossRef]

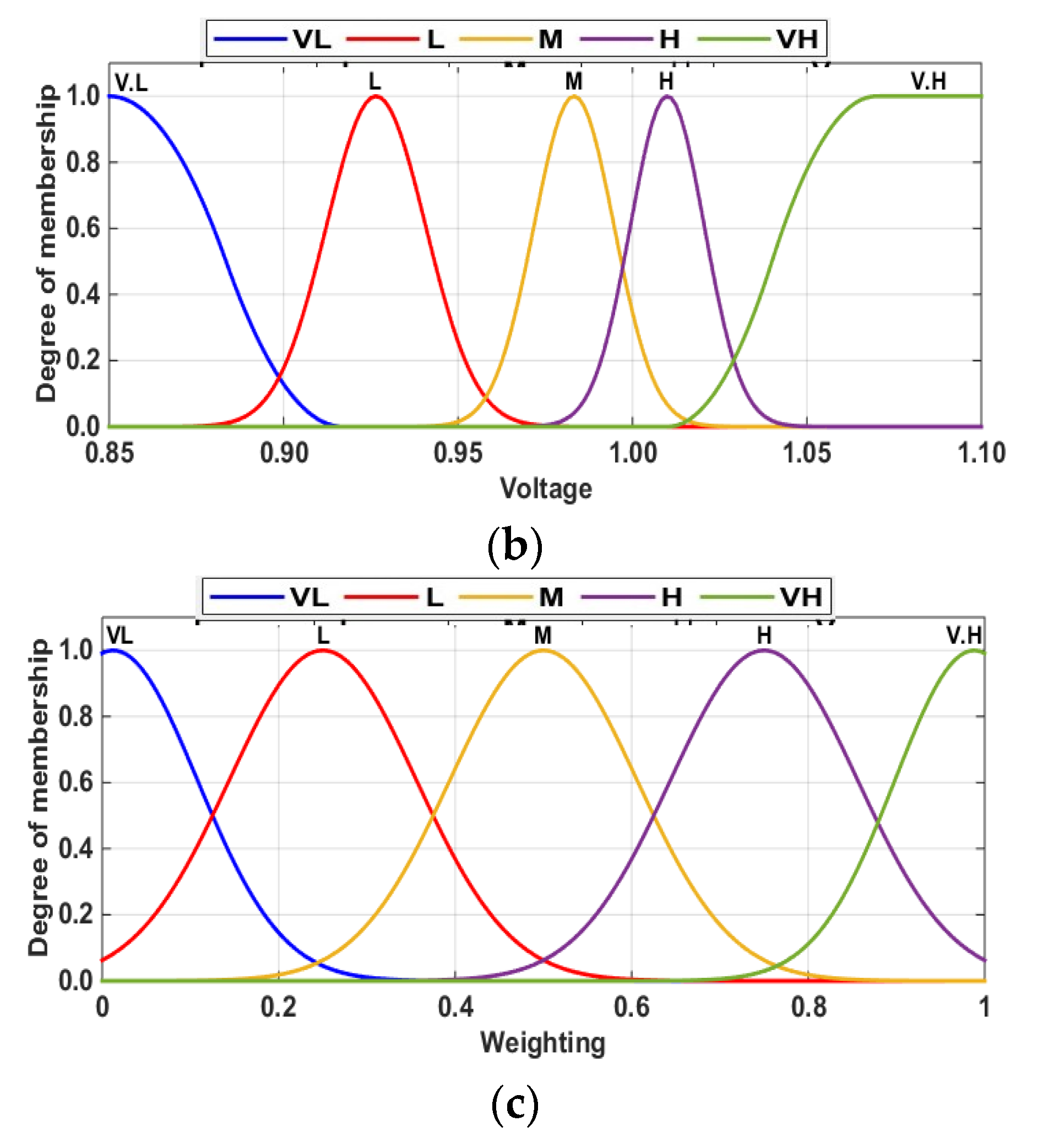

| Voltage | ||||||

|---|---|---|---|---|---|---|

| V.L | L | M | H | V.H | ||

| NLSF | V.L | L | L | V.L | V.L | V.L |

| L | L | L | V.L | V.L | V.L | |

| M | M | M | V.L | V.L | V.L | |

| H | H | H | V.L | V.L | V.L | |

| V.H | V.H | V.H | V.L | V.L | V.L | |

| Case | Technique | Location | Size (kW) | Total Capacity (kW) | Power Loss (kW) | V. min (p.u) (bus) | Reduction % |

|---|---|---|---|---|---|---|---|

| Case 1 | Base case | - | - | 210.9862 | 0.9038 (18) | 0 | |

| Case 2 | Proposed | 6 | 2590.213 | 2590.213 | 111.02 | 0.9424 (18) | 47.38 |

| SCA | 6 | 2590.159 | 2590.159 | 111.02 | 0.9424 (18) | 47.38 | |

| BSOA [15] | 8 | 1857.5 | 1857.5 | 118.12 | 0.9441 | NA | |

| Genetic algorithm (GA) [31] | 6 | 2600 | 2600 | 111.03 | 0.9425 | 47.38 | |

| ALO [16] | 6 | 2590.2 | 2590.2 | 111.03 | 0.9424 (18) | 47.38 | |

| TLBO–GWO [23] | 30 | 1000 | 1000 | 127.28 | 0.9285 | NA | |

| Case 3 | Proposed | 13 | 844.844 | 2011.008 | 87.17 | 0.9683 (18) | 58.69 |

| 30 | 1166.165 | ||||||

| SCA | 13 | 868.283 | 2004.532 | 87.19 | 0.9680 (18) | 58.68 | |

| 30 | 1136.249 | ||||||

| BSOA [15] | 13 | 880 | 1804 | 89.34 | 0.9665 | NA | |

| 31 | 924 | ||||||

| WIPSO–GSA [24] | 13 | 850 | 1990 | 87.18 | NA | 58.68 | |

| 30 | 1140 | ||||||

| GWO [24] | 13 | 903.04 | 2104.65 | 87.43 | 0.9706 (33) | NA | |

| 30 | 1201.61 | ||||||

| Case 4 | Proposed | 13 | 805.714 | 2954.26 | 72.79 | 0.9685 (33) | 65.50 |

| 24 | 1104.318 | ||||||

| 30 | 1044.227 | ||||||

| SCA | 13 | 827.295 | 2931.86 | 72.83 | 0.9680 (33) | 65.48 | |

| 24 | 1082.152 | ||||||

| 30 | 1022.406 | ||||||

| BFOA [32] | 14 | 652.1 | 1917.7 | 89.9 | 0.9705 (29) | 57.38 | |

| 18 | 198.4 | ||||||

| 32 | 1067.2 | ||||||

| KHA [21] | 13 | 810 | 2487 | 75.41 | 0.9676 (14) | 61.12 | |

| 25 | 836 | ||||||

| 30 | 841 | ||||||

| BA [20] | 13 | 720 | 2720 | 73.4 | 0.9628 | NA | |

| 24 | 1020 | ||||||

| 30 | 980 | ||||||

| WOA [18] | 31 | 748.15 | 2449.81 | 77.06 | 0.9686 (33) | NA | |

| 6 | 1051.1 | ||||||

| 14 | 650.56 | ||||||

| AIS [33] | 31 | 750 | 3000 | 73.62 | NA | NA | |

| 14 | 750 | ||||||

| 3 | 1500 |

| Cases | Technique | Location | /Size (kvar) | Total Capacity (kvar) | Power Loss (kW) | V. min (p.u) (Bus) | Reduction % |

|---|---|---|---|---|---|---|---|

| Case 1 | Base case | - | - | 210.9862 | 0.9038 (18) | 0 | |

| Case 2 | Proposed | 30 | 1258.01 | 1258.01 | 151.37 | 0.9165 (18) | 28.26 |

| SCA | 30 | 1258.01 | 1258.01 | 151.37 | 0.9165 (18) | 28.26 | |

| Heuristic approach [29] | 30 | 1190 | 1190 | 151.55 | NA | NA | |

| Hybrid [25] | 30 | 1230 | 1230 | 151.4 | NA | 28.24 | |

| Analytical [10] | 33 | 1000 | 1000 | 164.6 | 0.916 | NA | |

| Case 3 | Proposed | 12 | 464.11 | 1530.45 | 141.83 | 0.9303 (18) | 32.78 |

| 30 | 1066.33 | ||||||

| SCA | 12 | 463.39 | 1526.76 | 141.83 | 0.9303 (18) | 32.78 | |

| 30 | 1063.37 | ||||||

| WIPSO–GSA [24] | 10 | 570 | 1380 | 143.84 | NA | 31.83 | |

| 30 | 810 | ||||||

| Heuristic approach [29] | 13 | 405 | 1457 | 141.9 | NA | NA | |

| 30 | 1052 | ||||||

| Iterative–analytical method [9] | 12 | 433 | 1480 | 141.9 | 0.9292 (18) | 32.74 | |

| 30 | 1047 | ||||||

| Case 4 | Proposed | 13 | 396.10 | 1954.77 | 138.26 | 0.9321 (18) | 34.47 |

| 24 | 524.81 | ||||||

| 30 | 1044.23 | ||||||

| SCA | 12 | 427.40 | 1842.82 | 138.6 | 0.929 (18) | 34.31 | |

| 24/ | 468.83 | ||||||

| 30 | 946.59 | ||||||

| WIPSO–GSA [24] | 12 | 470.00 | 1107 | 141.84 | NA | 32.78 | |

| 29 | 530.00 | ||||||

| 30 | 530.00 | ||||||

| Heuristic approach [29] | 13 | 383.00 | 1769 | 138.65 | NA | NA | |

| 25 | 386.00 | ||||||

| 30 | 1000.00 | ||||||

| Hybrid [25] | 13 | 360.00 | 1890 | 138.37 | NA | 34.42 | |

| 24/ | 510.00 | ||||||

| 30 | 1020.00 |

| Cases | Technique | Location | Size (kVA) | PF | Total Capacity (kVA) | Power Loss (kW) | V. min (p.u) (Bus) | Reduction % |

|---|---|---|---|---|---|---|---|---|

| Case 1 | Base case | - | - | 210.98 | 0.9038 (18) | 0 | ||

| Case 2 | Proposed | 6 | 3105.75 | 0.82 | 3105.75 | 67.855 | 0.9584 (18) | 67.84 |

| SCA | 6 | 3105.86 | 0.82 | 3105.86 | 67.855 | 0.9584 (18) | 67.84 | |

| BSOA [15] | 8 | 1857.5 | 0.82 | 1857.5 | 82.78 | 0.9549 | NA | |

| TLBO–GWO [23] | 30 | 1000 | 0.80 | 1000.00 | 81.43 | 0.9360 | NA | |

| Case 3 | Proposed | 13 | 930 | 0.91 | 2761.11 | 28.51 | 0.9803 (25) | 86.49 |

| 30 | 1562.7 | 0.73 | ||||||

| SCA | 13 | 919.7 | 0.93 | 2967.86 | 29.28 | 0.9802 (25) | 86.12 | |

| 30 | 1600.9 | 0.66 | ||||||

| BSOA [15] | 13 | 777 | 0.89 | 1809.00 | 31.98 | 0.9796 | NA | |

| 29 | 1032 | 0.70 | ||||||

| WIPSO–GSA [24] | 13 | 930 | 0.88 | 2460.00 | 29.33 | NA | 86.1 | |

| 30 | 1530 | 0.8 | ||||||

| TLBO–GWO [23] | 10 | 861 | 0.87 | 1861.00 | 32.17 | 0.9796 | NA | |

| 30 | 1000 | 0.80 | ||||||

| Case 4 | Proposed | 14 | 839.78 | 0.91 | 3505.36 | 11.76 | 0.9912 (8) | 94.43 |

| 24 | 1206.73 | 0.90 | ||||||

| 30 | 1458.84 | 0.71 | ||||||

| SCA | 12 | 1056.53 | 0.80 | 3240.63 | 15.32 | 0.9904 (18) | 92.74 | |

| 25 | 823.02 | 0.82 | ||||||

| 30 | 1361.08 | 0.76 | ||||||

| WOA [18] | 3 | 1527 | 0.91 | 3270.38 | 19.91 | NA | NA | |

| 30 | 1135.1 | 0.80 | ||||||

| 14 | 608.28 | 0.79 | ||||||

| Moth Swarm Algorithm (MSA) [18] | 24 | 1029.2 | 0.90 | 2894.33 | 11.92 | NA | NA | |

| 14 | 715.23 | 0.90 | ||||||

| 30 | 1149.9 | 0.75 | ||||||

| TLBO–GWO [23] | 13 | 1000 | 0.81 | 2786 | 13.68 | 0.9892 | NA | |

| 24 | 789 | 0.87 | ||||||

| 30 | 997 | 0.87 | ||||||

| WIPSO–GSA [24] | 12 | 1020 | 0.85 | 3150 | 16.48 | NA | 92.19 | |

| 24 | 1030 | 0.84 | ||||||

| 30 | 1080 | 80 |

| DG Type | Case Study | SCA Time (s) | Proposed Time (s) |

|---|---|---|---|

| DG Type I | Case 2 | 75.12 | 69.17 |

| Case 3 | 69.68 | 64.72 | |

| Case 4 | 62.64 | 62.42 | |

| DG Type II | Case 2 | 73.30 | 61.91 |

| Case 3 | 70.91 | 62.62 | |

| Case 4 | 70.52 | 62.79 | |

| DG Type III | Case 2 | 69.84 | 63.24 |

| Case 3 | 72.46 | 63.70 | |

| Case 4 | 71.00 | 62.51 | |

| Average | 70.61 | 63.68 | |

| STD | 3.27 | 2.09 | |

| Case | Technique | Location | Size (kW) | Total Capacity (kW) | Power Loss (kW) | V. min (p.u) (bus) | Reduction % |

|---|---|---|---|---|---|---|---|

| Case 1 | Base case | 224.96 | 0.9092 (65) | - | |||

| Case 2 | Proposed | 61 | 1872.64 | 1872.64 | 83.19 | 0.9683 (27) | 63.04 |

| SCA | 61 | 1872.64 | 1872.64 | 83.19 | 0.9683 (27) | 63.04 | |

| ALO [16] | 61 | 1872.7 | 1872.7 | 83.22 | 0.968287 (27) | 63 | |

| TLBO–GWO [23] | 61 | 1000 | 1000 | 111.56 | 0.9478 | NA | |

| GWO [17] | 61 | 1928.67 | 1928.67 | 83.24 | 0.9687 (27) | NA | |

| fuzzy–PSO [26] | 61 | 1870 | 1870 | 83.21 | 0.9683 (27) | NA | |

| Case 3 | Proposed | 17 | 531.36 | 2312.84 | 71.66 | 0.9789 (65) | 68.16 |

| 61 | 1781.47 | ||||||

| SCA | 18 | 478.32 | 2283.60 | 71.77 | 0.9794 (65) | 68.11 | |

| 61 | 1805.28 | ||||||

| TLBO–GWO [23] | 61 | 1000 | 1863 | 83.34 | 0.9682 | NA | |

| 62 | 863 | ||||||

| GWO [17] | 17 | 566.08 | 2382.50 | 71.74 | 0.9803 (65) | NA | |

| 61 | 1816.42 | ||||||

| fuzzy–PSO [26] | 18 | 510 | 2310 | 71.7 | 0.9795 (65) | NA | |

| 61 | 1800 | ||||||

| Case 4 | Proposed | 11 | 522.22 | 2629.86 | 69.42 | 0.9788 (65) | 69.16 |

| 18 | 396.24 | ||||||

| 61 | 1711.4 | ||||||

| SCA | 15 | 567.6 | 2366 | 71.77 | 0.9783 (65) | 68.11 | |

| 27 | 49.08 | ||||||

| 61 | 1749.33 | ||||||

| PSO [19] | 61 | 1903 | 2700.3 | 74.77 | 0.9778 | 63.1 | |

| 16 | 636.5 | ||||||

| 65 | 160.8 | ||||||

| MFO [19] | 61 | 2000 | 2962.5 | 72.37 | 0.9939 | 64.29 | |

| 18 | 380.3 | ||||||

| 11 | 582.2 | ||||||

| WOA [18] | 49 | 840.46 | 3182.38 | 70.19 | NA | NA | |

| 18 | 533.52 | ||||||

| 61 | 1808.4 | ||||||

| DA [18] | 66 | 231.47 | 2524.6 | 71.1 | NA | NA | |

| 14/529.93 | |||||||

| 61/1763.2 |

| Case | Technique | Location | Size (kvar) | Total Capacity (kvar) | Power Loss (kW) | V. min (p.u) (Bus) | Reduction % |

|---|---|---|---|---|---|---|---|

| Case 1 | Base case | - | - | 224.96 | 0.9092 (65) | 0 | |

| Case 2 | Proposed | 61 | 1329.93 | 1329.93 | 152.00 | 0.9307 (65) | 32.45 |

| SCA | 61 | 1329.93 | 1329.93 | 152.00 | 0.9307 (65) | 32.45 | |

| Heuristic approach [29] | 61 | 1310 | 1310 | 152.1 | NA | NA | |

| Hybrid [25] | 61 | 1290 | 1290 | 152.10 | NA | 32.4 | |

| Case 3 | Proposed | 17 | 361.53 | 1636.64 | 146.41 | 0.9311 (65) | 34.92 |

| 61 | 1275.11 | ||||||

| SCA | 17 | 362.80 | 1631.35 | 146.42 | 0.9310 (65) | 34.91 | |

| 61 | 1268.54 | ||||||

| Heuristic approach [29] | 61 | 1224 | 1580 | 146.5 | NA | NA | |

| 17 | 356 | ||||||

| Iterative–analytical method [9] | 17 | 357 | 1592 | 146.43 | 0.9305 (65) | 34.88 | |

| 61 | 1235 | ||||||

| Hybrid [25] | 18 | 350 | 1.59 | 146.52 | NA | 34.88 | |

| 61 | 1240 | ||||||

| Case 4 | Proposed | 11 | 412.17 | 1872 | 145.09 | 0.9314 (65) | 35.5 |

| 21 | 229.24 | ||||||

| 61 | 1230.59 | ||||||

| SCA | 12 | 289.26 | 1858.46 | 145.48 | 0.9319 (65) | 35.33 | |

| 16 | 289.26 | ||||||

| 61 | 1279.94 | ||||||

| Heuristic approach [29] | 61 | 1210 | 1756 | 145.3 | NA | NA | |

| 21 | 226 | ||||||

| 12 | 320 | ||||||

| Iterative–analytical method [9] | 11 | 232 | 1825 | 145.29 | 0.9314 (65) | 35.34 | |

| 17 | 347 | ||||||

| 61 | 1246 | ||||||

| SSA [22] | 17 | 300 | 1800 | 145.26 | 0.9308 (65) | NA | |

| 60 | 1200 | ||||||

| 10 | 300 |

| Case | Technique | Location | Size (kVA) | PF | Total Capacity (kVA) | Power Loss (kW) | V. min (p.u) (Bus) | Reduction % |

|---|---|---|---|---|---|---|---|---|

| Case 1 | Base case | - | - | 224.96 | 0.9092 (65) | 0 | ||

| Case 2 | Proposed | 61 | 2243.50 | 0.81 | 2243.50 | 23.13 | 0.9725 (27) | 89.72 |

| SCA | 61 | 2244.03 | 0.81 | 2244.03 | 23.17 | 0.9725 (27) | 89.7 | |

| TLBO–GWO [23] | 61 | 1000 | 0.81 | 1000 | 58.80 | 0.9598 | NA | |

| ALO [30] | 61 | 2227.9 | 0.82 | 2227.9 | 23.16 | 0.9716 | 89.703 | |

| EA–optimal power flow (OPF) [11] | 61 | 1828 | 0.82 | 1828 | 23.17 | NA | NA | |

| EA [11] | 61 | 1878 | 0.82 | 1878 | 23.26 | NA | NA | |

| Case 3 | Proposed | 17 | 629.61 | 0.83 | 2759.66 | 7.20 | 0.9943 (50) | 96.8 |

| 61 | 2131.5 | 0.81 | ||||||

| SCA | 16 | 634.60 | 0.78 | 2967.85 | 8.80 | 0.9943 (69) | 96.09 | |

| 61 | 2333.25 | 0.81 | ||||||

| TLBO–GWO [23] | 61 | 1000 | 0/81 | 1820 | 23.28 | 0.9724 | NA | |

| 62 | 820 | 0.83 | ||||||

| Iterative–analytical method [9] | 17 | 629 | 0.82 | 2762 | 7.21 | 0.9943 (50) | 96.79 | |

| 61 | 2133 | 0.82 | ||||||

| ALO [30] | 17 | 726.627 | 0.83 | 2226.63 | 20.93 | 0.9742 (65) | 90.69 | |

| 61 | 1500 | 0.8 | ||||||

| Case 4 | Proposed | 11 | 595.93 | 0.82 | 3118.65 | 4.27 | 0.9943 (50) | 98.10 |

| 18 | 459.03 | 0.83 | ||||||

| 61 | 2063.68 | 0.81 | ||||||

| SCA | 17 | 668.17 | 0.79 | 4476.47 | 10.35 | 0.9939 (69) | 95.40 | |

| 49 | 1832.95 | 0.76 | ||||||

| 61 | 1975.35 | 0.89 | ||||||

| WOA [18] | 61 | 1807.6 | 0.85 | NA | 7.09 | 0.99433 (50) | NA | |

| 4 | 1988.7 | 0.85 | ||||||

| 17 | 534.72 | 0.85 | ||||||

| DA [18] | 11 | 496.3 | 0.85 | NA | 5.01 | 0.9943 (50) | NA | |

| 61 | 1748 | 0.85 | ||||||

| 17 | 395 | 0.85 | ||||||

| MFO [19] | 11 | 515.73 | 0.85 | NA | 5.00 | 0.9943 (50) | NA | |

| 61 | 1745.6 | 0.85 | ||||||

| 18 | 386.17 | 0.85 | ||||||

| TLBO–GWO [23] | 18 | 523 | 0.83 | 2246 | 7.27 | 0.9942 | NA | |

| 61 | 1000 | 0.82 | ||||||

| 62 | 723 | 0.8 |

| DG Type | Case Study | SCA Time (s) | Proposed Time (s) |

|---|---|---|---|

| DG Type I | Case 2 | 80.67 | 79.90 |

| Case 3 | 89.22 | 80.75 | |

| Case 4 | 83.74 | 81.17 | |

| DG Type II | Case 2 | 83.60 | 80.64 |

| Case 3 | 89.77 | 82.78 | |

| Case 4 | 87.22 | 82.49 | |

| DG Type III | Case 2 | 88.95 | 82.49 |

| Case 3 | 89.15 | 82.43 | |

| Case 4 | 90.42 | 83.07 | |

| Average | 86.97 | 81.75 | |

| STD | 3.25 | 1.07 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Selim, A.; Kamel, S.; Mohamed, A.A.; Elattar, E.E. Optimal Allocation of Multiple Types of Distributed Generations in Radial Distribution Systems Using a Hybrid Technique. Sustainability 2021, 13, 6644. https://doi.org/10.3390/su13126644

Selim A, Kamel S, Mohamed AA, Elattar EE. Optimal Allocation of Multiple Types of Distributed Generations in Radial Distribution Systems Using a Hybrid Technique. Sustainability. 2021; 13(12):6644. https://doi.org/10.3390/su13126644

Chicago/Turabian StyleSelim, Ali, Salah Kamel, Amal A. Mohamed, and Ehab E. Elattar. 2021. "Optimal Allocation of Multiple Types of Distributed Generations in Radial Distribution Systems Using a Hybrid Technique" Sustainability 13, no. 12: 6644. https://doi.org/10.3390/su13126644

APA StyleSelim, A., Kamel, S., Mohamed, A. A., & Elattar, E. E. (2021). Optimal Allocation of Multiple Types of Distributed Generations in Radial Distribution Systems Using a Hybrid Technique. Sustainability, 13(12), 6644. https://doi.org/10.3390/su13126644