3.1. Surface Deflection and Modulus

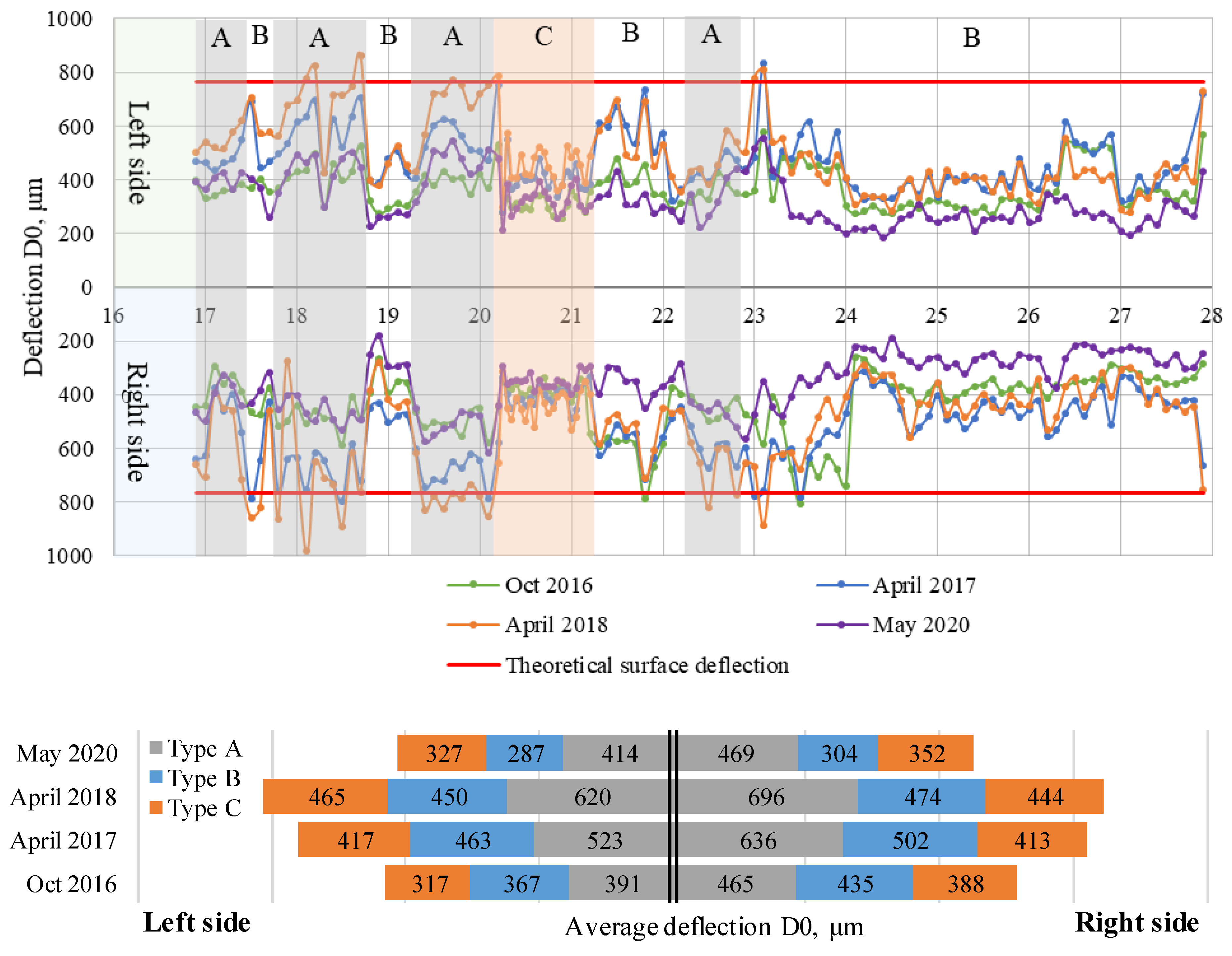

The normalized surface deflections (

d0) measured with a FWD on each side are represented in

Figure 6. The statistical analysis for this parameter is presented in

Table 4. The directly correlating parameter with deflections is the surface modulus

E0, which is represented in

Figure 7. The statistical analysis for this parameter is presented in

Table 5.

As seen from

Figure 6, deflection varied from 183 to 983 μm irrespective of the measurement time, while the surface moduli varied from 189 to 1025 MPa. The highest average deflection was determined on the pavement structure of Type A (with a bound base course on top of the existing sub-base) in April 2018 on the right side of the road—696 μm, while Type B (with a bound base with a frost-resistant layer) and Type C (with an unbound base layer) performed quite similarly—474 μm and 444 μm, respectively. The surface moduli were 287, 420 and 430 MPa, respectively, for Type A, Type B and Type C. Thus, the pavement structure of Type A performed 31.7% and 33.3% worse than Types B and C, respectively, during these conditions. In fact, during each measurement on each side of the road, the pavement structure of Type B and C always outperformed Type A, with an improvement varying from 8.6% to 38.0%. One possible reason for this is that the FWD measurement point across the road could have been right above the edge of the existing sub-base, on top of which the rest of the pavement structure Type A was installed and that the existing sub-base could have been weak, which influenced the new pavement performance; thus, specific attention has to be paid to the construction in those places to ensure the desirable bearing capacity. This type of pavement structure (Type A) is unreliable in comparison with the other two structures and, as a result, it is omitted from further discussion about the results.

The lowest average deflection was measured on pavement structure Type B in May 2020—287 and 304 μm (left and right side, respectively), with resulting surface moduli of 682 and 646 MPa, respectively. At that period, the average deflection on pavement structure Type C was 327 and 352 μm (left and right side, respectively), and the surface moduli—587 and 526 MPa, respectively. This resulted in the average surface modulus for pavement structure Type B to be 16.3–22.8% higher than Type C, depending on the side of the road at that measurement period. When compared to the measurement period right after reconstruction (October 2016), the average surface modulus on pavement structure Type B improved by 28.3–39.3% (for the left and right side of the road, respectively) over the first 4.5 years, while on pavement structure Type C on the right side of the road, it increased by only 8.1%, and on the left side of the road, it actually decreased by 2.9%.

The theoretical deflection calculated for standard asphalt pavement with unbound base layers is 764 μm. During all four measurement periods, the measured deflection on pavement Type C exceeded the theoretical deflection only at one point: the thaw period in April 2018 on the left side of the road at 20.2 km. This station is the first station on the border with pavement Type A, which is most likely the reason for the high deflections. The average deflection on this pavement type was 1.64–2.41 times lower than the theoretical deflection. During all four measurement periods, the deflection on pavement Type B exceeded the theoretical deflection only on several measurement points during thaw periods in 2017 and 2018 (up to three stations per measurement period per road side, which is up to 4.3% of all measurements). Most of the stations are also on a border with pavement structure Type A, which is the probable reason for the high deflections at those stations. The average deflection on this pavement type was 1.52–2.66 times lower than the theoretical deflection, which is similar to pavement structure Type C. The resulting numbers show a reserve for both pavement structures when comparing the measured deflections to the theoretical deflection of a standard pavement even during thaw periods. Based on an average deflection, the reserve ranges from 34.3% to 62.4% of the theoretical deflection.

In general, the average surface modulus on pavement structure Type B was 16.3–20.5% higher right after reconstruction in October 2016 when compared to the thaw period next year (April 2017) and 35.0–35.7% higher during the latest measurement period, May 2020, when compared to the thaw period in April 2018. For pavement structure Type C, the respective numbers are 5.9–23.3% (comparing 2016 to 2017) and 18.3–29.1% (comparing 2020 to 2018). The decrease in performance during thaw seasons is more substantial for pavement structure Type B than Type C, which could indicate that a pavement structure with a CCPR base course is more susceptible to hydrothermal conditions than the pavement structure with an unbound base course.

The surface modulus for the left side of the road was higher irrespective of different pavement structures and measurement time (period) than the right side of the road. For example, in October 2016, the average moduli of the left side for pavement structures Type B and Type C were, respectively, 14.6% and 24.1% higher than on the right side. The difference gradually decreased, and, in May 2020, the average moduli of the left side for pavement structures Type B and Type C were, respectively, only 5.6% and 11.5% higher than on the right side.

3.2. Deflection Basin Parameters (SCI, BDI, BCI)

The surface curvature indices (SCI) calculated for each side are represented in

Figure 8. The statistical analysis for this parameter is presented in

Table 6. The SCI varied from 31 to 251 μm irrespective of the measurement time. The lowest average SCI was calculated on pavement structure Type C immediately after reconstruction in October 2016—41 and 51 μm (left and right side of the road, respectively). The SCI on pavement structure Type B was two times higher than on Type C—83 and 108 μm, respectively. In May 2020, the average SCI increased to 51 and 57 μm for Type C and decreased to 60 and 71 μm for Type B. Thus, from 2016 to 2020, CCPR-based pavement structures’ disadvantage decreased from 100.4–109.7% to 18.3–25.2% compared to regular pavement regarding top layer performance. What is noticeable is that the average SCI on pavement structure Type B improved by 26.8–34.2% (depending on the road side) over the first 4.5 years, while on pavement structure Type C, the performance actually decreased by 10.2–24.0%.

The average SCI on pavement structure Type B was 37.6–57.8% higher during the thaw period in April 2017 when compared to the measurement period right after reconstruction in October 2016. The average SCI was 81.4–85.5% higher during the thaw period in April 2018 when compared to the latest measurement period, May 2020. For pavement structure Type C, the respective numbers are 40.9–76.4% (comparing 2017 to 2016) and 36.8–59.3% (comparing 2018 to 2020). This indicates that the top bound layer is almost equally susceptible to hydrothermal conditions irrespective of the pavement structure type.

As with the surface moduli, the condition on the left side of the road in regard of SCI was better than on the right side of the road. The average SCI for the left side of the road was lower than for the right side of the road irrespective of pavement structures and measurement time. For example, in October 2016, the average left side SCIs of the left sides of pavement structures Type B and Type C were, respectively, 23.4% and 19.9% lower than on the right side. The difference gradually decreased and, in May 2020, when the average SCIs of the left side of pavement structures Type B and Type C were, respectively, only 14.9% and 9.9% lower than on the right side. Although it is noticeable that, during thaw seasons, the SCI on the left side of the road was higher for pavement structure Type C (0.3% and 4.9%), while, for Type B, the left side condition was still better, lower by 12.2% and 13.0%, respectively.

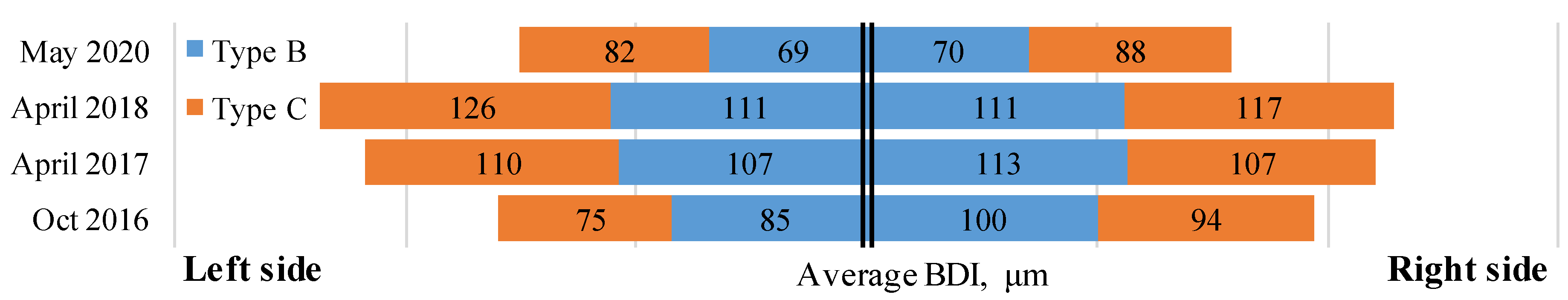

The base damage index is presented in

Figure 9. The statistical analysis for this parameter is presented in

Table 7. The BDI varied from 32 to 236 μm irrespective of the measurement time. The lowest average BDI was determined to be on pavement structure Type B during the latest filed test, on May 2020—69 and 70 μm (left and right side of the road, respectively). In October 2016, the average BDIs were 85 and 100 μm. This means that, over 4.5 years on average, the base condition improved by 18.4–30.2% for Type B, depending on the side of the road. At the same time, the base condition on pavement structure Type C improved only on the right side of the road (by 5.6%) and decreased by 8.4% on the left side of the road. During the latest measurement period in May 2020, the average BDI for pavement structure Type B was 15.1–20.9% lower than for Type C, depending on the side of the road.

The average BDI on pavement structure Type B was 13.1–26.9% higher during the thaw period in April 2017 when compared to the measurement period right after reconstruction in October 2016. The average BDI was 59.0–60.3% higher during the thaw period in April 2018 when compared to the latest measurement period, in May 2020. For pavement structure Type C, the respective numbers are 14.5–46.8% (comparing 2017 to 2016) and 32.1–54.9% (comparing 2018 to 2020). The results are inconsistent, as the first comparison shows a more substantial decrease in base performance for pavement structure Type C, while the second comparison shows a more substantial decrease in base performance for pavement structure Type B. This could be the result of an ongoing decrease of the average BDI for pavement structure Type B.

The average BDI for the left side of the road was lower than for the right side, irrespective of the measurement period, for pavement structure Type B, ranging from 0.2% to 15.4%. For pavement structure Type C, on the other hand, the left side of the road performed better than the right side only during the measurement periods October 2016 and May 2020 (by 7.8–19.8%), while, during the thaw seasons, the condition on the left side was worse than the right side (by 2.8–3.1%).

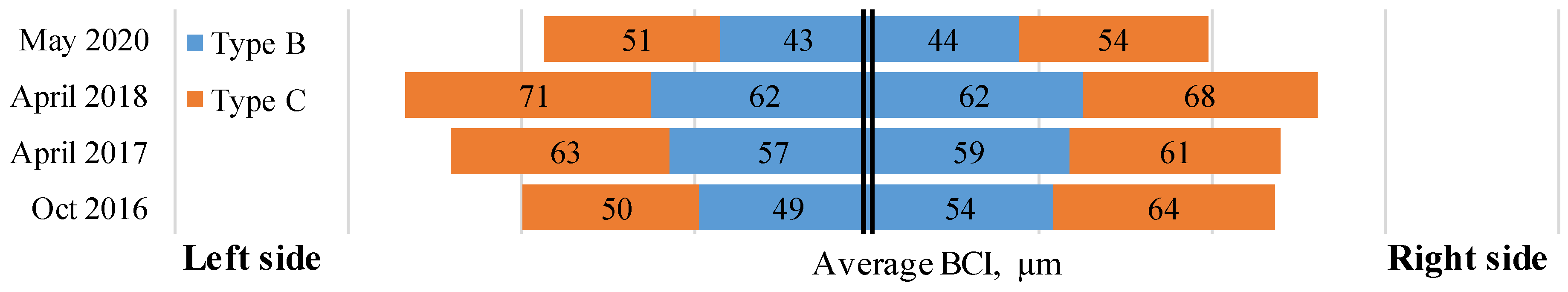

The base curvature index is presented in

Figure 10. The statistical analysis for this parameter is presented in

Table 8. The BCI varied from 25 to 134 μm irrespective of the measurement time. The lowest average BCI was determined on pavement structure Type B during the latest filed test, in May 2020—43 and 44 μm (left and right side of the road, respectively). In October 2016, the average BCI was 49 and 54 μm. This means that, over 4.5 years on average, the subgrade condition improved by 12.5–18.3% for Type B, depending on the side of the road. At the same time, the subgrade condition on pavement structure Type C improved only on the right side of the road (by 14.7%) and decreased by 0.5% on the left side of the road. During the latest measurement period of May 2020, the average BCI for pavement structure Type B was 15.9–19.0% lower than Type C depending on the side of the road.

The average BCI on pavement structure Type B was 9.1–17.5% higher during the thaw period in April 2017 when compared to the measurement period right after reconstruction in October 2016. The average BCI was 41.0–45.8% higher during the thaw period in April 2018 when compared to the latest measurement period, May 2020. For pavement structure Type C, an anomaly was detected, as the average BCI on the right side of the road was lower during the thaw period in April 2017 when compared to October 2016. While, on the right side during the thaw period, the subgrade performed 24.2% worse than right after reconstruction. The average BCI on pavement structure Type C was 26.0–39.9% higher during the thaw period in April 2018 when compared to the latest measurement period, May 2020.

The average BCI for the left side of the road was lower right after reconstruction for both pavement structures—Type B and Type C during the measurement period of October 2016 by 9.4% and 20.7%, respectively. During both thaw measurement periods, the difference was not significant, ranging from 3.7% lower performance on the left side to 2.4% higher performance on the left side when compared to the right side, irrespective of the pavement structure. The average BCI again improved for the left side for both pavement structures—Type B and Type C during the latest measurement period, May 2020, by 2.9% and 6.6% respectively.

3.3. Backcalculation E Modulus and Remaining Pavement Life

The back-calculated E moduli with ELMOD software for pavement structures of Type B and Type C are represented in

Table 9. During the measurement period October 2016, the average E modulus of the bound layer of pavement structure Type B was 1.88 times greater on the left side of the road (1.32 times greater on the right side of the road) than in the thaw season in April 2018. The average E modulus of the frost-resistant layer in October 2016 was 1.57 times greater on the left side of the road (1.29 times greater on the right side of the road) than in the thaw season in April 2018. The average E modulus of the subgrade in October 2016 was 1.23 times greater on the left side of the road (1.18 times greater on the right side of the road) than in the thaw season in April 2018.

The average back-calculated E modulus of the bound layer of pavement structures of Type C during the measurement period October 2016 was 1.91 times greater on the left side of the road (2.42 times greater on the right side of the road) than during the thaw season in April 2018. The average E modulus of the unbound layer in October 2016 was 1.37 times greater on the left side of the road (1.75 times greater on the right side of the road) than in the thaw season in April 2018. The average E modulus of the frost-resistant layer in October 2016 was 1.10 times greater on the left side of the road (1.45 times greater on the right side of the road) than in the thaw season in April 2018. The average E modulus of the subgrade in October 2016 was 1.08 times greater on the left side of the road (1.29 times greater on the right side of the road) than in the thaw season in April 2018.

The average back-calculated E modulus of the bound layer during the measurement period October 2016 of pavement structures Type C was 3.48 times greater on the left side of the road (5.07 times greater on the right side of the road) than pavement structure Type B. The average E modulus of the frost-resistant layer of pavement structure Type B was 1.75 times greater on the left side of the road (0.90 times smaller on the right side of the road) than pavement structure Type C. The average E modulus of the subgrade of pavement structure Type B was 1.35 times greater on the left side of the road (1.08 times greater on the right side of the road) than pavement structure Type C.

The average back-calculated E modulus of the bound layer during the measurement period of April 2018 of pavement structures Type C was 3.44 times greater on the left side of the road (2.76 times greater on the right side of the road) than pavement structure Type B. The average E modulus of the frost-resistant layer of pavement structure Type B was 1.02 times greater on the left side of the road (1.01 times greater on the right side of the road) than pavement structure Type C. The average E modulus of the subgrade of pavement structure Type B was 1.19 times greater on the left side of the road (1.18 times greater on the right side of the road) than pavement structure Type C.

Calculated pavement surface deflection, E

0 and the predicted number of ESALs are represented in

Table 10. Calculated pavement surface deflection of October 2016 for pavement structure Type B is 0.90 times smaller than the thaw season in April 2018 and, for pavement structure Type C—0.60 times smaller than the thaw season in 2018. E

0 modulus calculated for October 2016 for pavement structure Type B is 1.11 times greater than in the thaw season in April 2018 and, for pavement structure Type C, it is 1.65 times greater than the thaw season of April 2018. The predicted number of ESALs calculated of October 2016 for pavement structures B is 3 times greater than the thaw season of April 2018, for pavement structures C—45.43 times greater than the thaw season of April 2018.

Calculated pavement surface deflection of October 2016 for pavement structure Type B is 1.75 times greater than for pavement structure Type C, for the thaw season in April 2018 is 1.17 times greater. E0-modulus-calculated pavement surface deflection in October 2016 for pavement structure Type B is 0.57 times smaller than pavement structure Type C, for the thaw season of April 2018—0.86 times smaller. The predicted number of ESALs in October 2016 on pavement structure Type C is 106 times greater than pavement structure Type B and, for the thaw season of April 2018, 7 times greater.