A Systematic Literature Review on Additive Manufacturing in the Context of Circular Economy

Abstract

1. Introduction

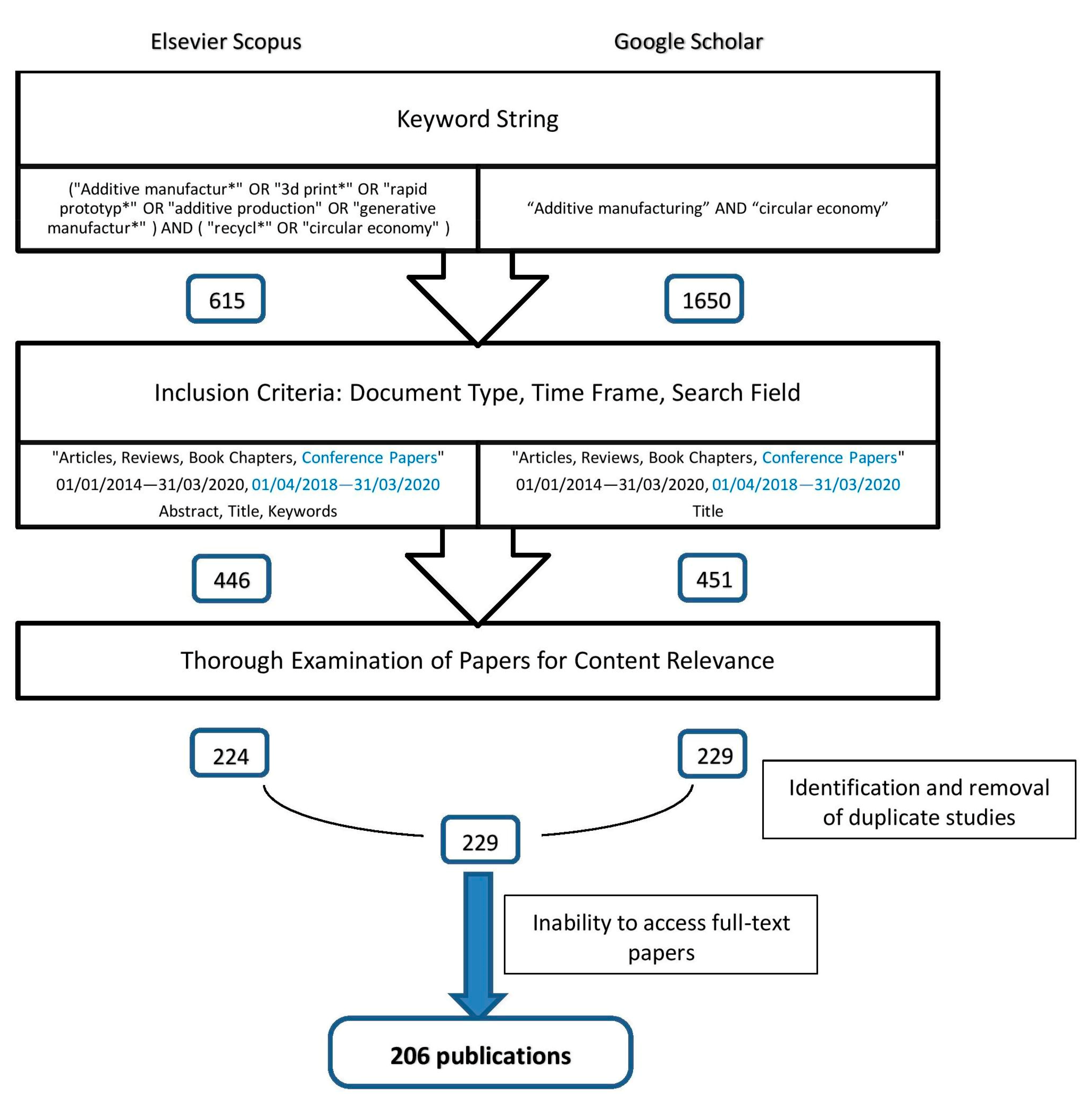

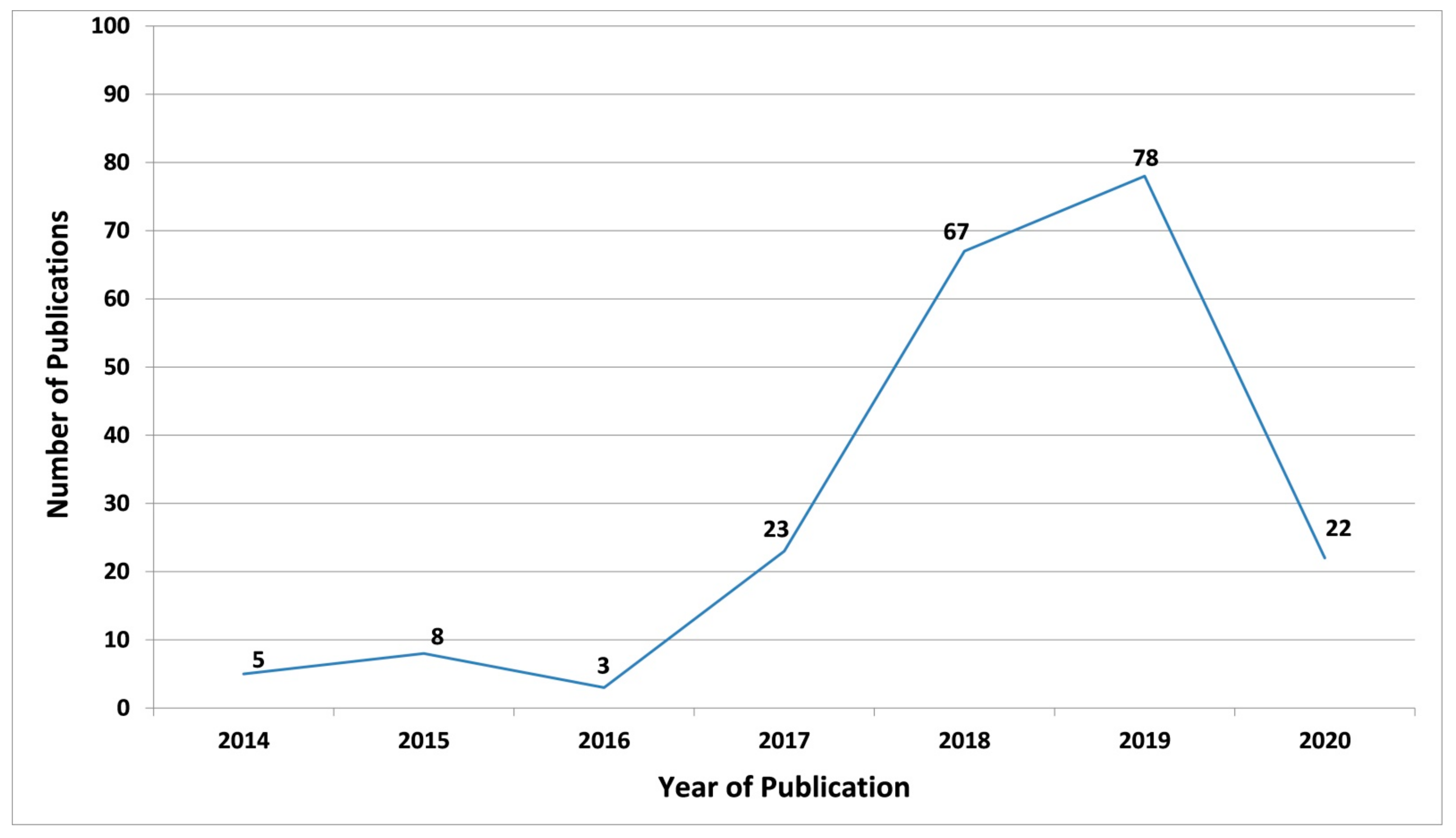

2. Methodology

3. Previous Review Efforts

3.1. The Review Collection Process

3.2. Review Classification

3.2.1. Review Subject

3.2.2. Review Type

4. Recycling, Reuse, Remanufacturing and Repair with the Help of AM

4.1. Recycling

4.1.1. Distributed Recycling

4.1.2. Closed-Loop Supply Chain

4.1.3. Recycling of Different Types of Waste

Plastic

Electronic Waste and Magnets

Glass, Sand and Concrete

Rubber Tires

4.2. Reuse

4.2.1. Reuse after Recycling

Metal

Plastic

Sand and Concrete

4.2.2. Reuse without Recycling

4.3. Remanufacturing & Repair

4.3.1. Remanufacturing

4.3.2. Repair

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Schwab, K. The Fourth Industrial Revolution: What It Means, How to Respond. Available online: https://www.weforum.org/agenda/2016/01/the-fourth-industrial-revolution-what-it-means-and-how-to-respond (accessed on 26 May 2021).

- Dalenogare, L.S.; Benitez, G.B.; Ayala, N.F.; Frank, A.G. The Expected Contribution of Industry 4.0 Technologies for Industrial Performance. Int. J. Prod. Econ. 2018, 204, 383–394. [Google Scholar] [CrossRef]

- Gibson, I.; Rosen, D.; Stucker, B.; Khorasani, M. Additive Manufacturing Technologies; Springer: Berlin/Heidelberg, Germany, 2014; Volume 17. [Google Scholar]

- Guo, N.; Leu, M.C. Additive Manufacturing: Technology, Applications and Research Needs. Front. Mech. Eng. 2013, 8, 215–243. [Google Scholar] [CrossRef]

- Tofail, S.A.; Koumoulos, E.P.; Bandyopadhyay, A.; Bose, S.; O’Donoghue, L.; Charitidis, C. Additive Manufacturing: Scientific and Technological Challenges, Market Uptake and Opportunities. Mater. Today 2018, 21, 22–37. [Google Scholar] [CrossRef]

- Ngo, T.D.; Kashani, A.; Imbalzano, G.; Nguyen, K.T.; Hui, D. Additive Manufacturing (3D Printing): A Review of Materials, Methods, Applications and Challenges. Compos. Part B Eng. 2018, 143, 172–196. [Google Scholar] [CrossRef]

- Ebenstein, A. The Consequences of Industrialization: Evidence from Water Pollution and Digestive Cancers in China. Rev. Econ. Stat. 2012, 94, 186–201. [Google Scholar] [CrossRef]

- Patnaik, R. Impact of Industrialization on Environment and Sustainable Solutions–Reflections from a South Indian Region. IOP Conf. Ser.: Earth Environ. Sci. 2018, 120, 012016. [Google Scholar] [CrossRef]

- Mishra, R.K.; Mohammad, N.; Roychoudhury, N. Soil Pollution: Causes, Effects and Control. Trop. For. Res. Inst. 2015, 3, 20–30. [Google Scholar]

- Mudakkar, S.R.; Zaman, K.; Khan, M.M.; Ahmad, M. Energy for Economic Growth, Industrialization, Environment and Natural Resources: Living with Just Enough. Renew. Sustain. Energy Rev. 2013, 25, 580–595. [Google Scholar] [CrossRef]

- Lu, Q.; Liang, F.; Bi, X.; Duffy, R.; Zhao, Z. Effects of Urbanization and Industrialization on Agricultural Land Use in Shandong Peninsula of China. Ecol. Indic. 2011, 11, 1710–1714. [Google Scholar] [CrossRef]

- European Cluster Collaboration Platform. European Cluster Collaboration Platform Difference between the Circular Economy and the Linear Economy. Available online: https://clustercollaboration.eu/community-news/difference-between-circular-economy-and-linear-economy (accessed on 17 February 2021).

- European Commission. Directorate General for Research and Innovation. Accelerating the Transition to the Circular Economy: Improving Access to Finance for Circular Economy Projects; European Commission Publications Office: Brussels, Belgium, 2019. [Google Scholar]

- Laila, N.; Ardianto; Das, P.K.; Singh, S. Plastic Waste Management in Indonesia: Review. Available online: /paper/Plastic-Waste-Management-in-Indonesia%3A-Review-Laila-Ardianto/aee4a2e8904d15624f7614c89075911dfdc50603 (accessed on 17 February 2021).

- Fangtao, R.; Jian, S.; Zhenzhen, X.; Jian, X. Research Progress in Recycling and Reuse of Carbon Fiber Reinforced Resin Composites. Fangzhi Xuebao 2019, 40, 152–157. [Google Scholar]

- Ahmed, S.; Bui, M.-P.N.; Abbas, A. Paper-Based Chemical and Biological Sensors: Engineering Aspects. Biosens. Bioelectron. 2016, 77, 249–263. [Google Scholar] [CrossRef]

- Trombettoni, V.; Lanari, D.; Prinsen, P.; Luque, R.; Marrocchi, A.; Vaccaro, L. Recent Advances in Sulfonated Resin Catalysts for Efficient Biodiesel and Bio-Derived Additives Production. Prog. Energy Combust. Sci. 2018, 65, 136–162. [Google Scholar] [CrossRef]

- Santecchia, E.; Spigarelli, S.; Cabibbo, M. Material Reuse in Laser Powder Bed Fusion: Side Effects of the Laser—Metal Powder Interaction. Metals 2020, 10, 341. [Google Scholar] [CrossRef]

- Wang, W.; Han, P.; Peng, P.; Zhang, T.; Liu, Q.; Yuan, S.-N.; Huang, L.-Y.; Yu, H.-L.; Qiao, K.; Wang, K.-S. Friction Stir Processing of Magnesium Alloys: A Review. Acta Metall. Sin. Engl. Lett. 2020, 33, 43–57. [Google Scholar] [CrossRef]

- Sibisi, P.N.; Popoola, A.P.I.; Arthur, N.K.; Pityana, S.L. Review on Direct Metal Laser Deposition Manufacturing Technology for the Ti-6Al-4V Alloy. Int. J. Adv. Manuf. Technol. 2020, 107, 1163–1178. [Google Scholar] [CrossRef]

- Kumar, R.; Singh, R.; Ahuja, I.P.S.; Hashmi, M.S.J. Processing Techniques of Polymeric Materials and Their Reinforced Composites. Adv. Mater. Process. Technol. 2020, 6, 591–607. [Google Scholar] [CrossRef]

- Wahab, D.A.; Azman, A.H. Additive Manufacturing for Repair and Restoration in Remanufacturing: An Overview from Object Design and Systems Perspectives. Processes 2019, 7, 802. [Google Scholar]

- Oros Daraban, A.E.; Negrea, C.S.; Artimon, F.G.; Angelescu, D.; Popan, G.; Gheorghe, S.I.; Gheorghe, M. A Deep Look at Metal Additive Manufacturing Recycling and Use Tools for Sustainability Performance. Sustainability 2019, 11, 5494. [Google Scholar] [CrossRef]

- Saboori, A.; Aversa, A.; Marchese, G.; Biamino, S.; Lombardi, M.; Fino, P. Application of Directed Energy Deposition-Based Additive Manufacturing in Repair. Appl. Sci. 2019, 9, 3316. [Google Scholar] [CrossRef]

- Nascimento, D.L.M.; Alencastro, V.; Quelhas, O.L.G.; Caiado, R.G.G.; Garza-Reyes, J.A.; Lona, L.R.; Tortorella, G. Exploring Industry 4.0 Technologies to Enable Circular Economy Practices in a Manufacturing Context: A Business Model Proposal. J. Manuf. Technol. Manag. 2019, 30, 607–627. [Google Scholar] [CrossRef]

- Navarro, J.C.; Centeno, M.A.; Laguna, O.H.; Odriozola, J.A. Policies and Motivations for the CO2 Valorization through the Sabatier Reaction Using Structured Catalysts. A Review of the Most Recent Advances. Catalysts 2018, 8, 578. [Google Scholar] [CrossRef]

- Gama, N.V.; Ferreira, A.; Barros-Timmons, A. Polyurethane Foams: Past, Present, and Future. Materials 2018, 11, 1841. [Google Scholar] [CrossRef] [PubMed]

- Walsh, F.C.; de Léon, C.P. Progress in Electrochemical Flow Reactors for Laboratory and Pilot Scale Processing. Electrochimica Acta 2018, 280, 121–148. [Google Scholar] [CrossRef]

- Peng, T.; Kellens, K.; Tang, R.; Chen, C.; Chen, G. Sustainability of Additive Manufacturing: An Overview on Its Energy Demand and Environmental Impact. Addit. Manuf. 2018, 21, 694–704. [Google Scholar] [CrossRef]

- Tan, J.H.; Wong, W.L.E.; Dalgarno, K.W. An Overview of Powder Granulometry on Feedstock and Part Performance in the Selective Laser Melting Process. Addit. Manuf. 2017, 18, 228–255. [Google Scholar] [CrossRef]

- Singh, S.; Ramakrishna, S.; Gupta, M.K. Towards Zero Waste Manufacturing: A Multidisciplinary Review. J. Clean. Prod. 2017, 168, 1230–1243. [Google Scholar] [CrossRef]

- Yang, W.G.; Lu, H.; Huang, W.M.; Qi, H.J.; Wu, X.L.; Sun, K.Y. Advanced Shape Memory Technology to Reshape Product Design, Manufacturing and Recycling. Polymers 2014, 6, 2287–2308. [Google Scholar] [CrossRef]

- Sanchez, F.A.C.; Boudaoud, H.; Camargo, M.; Pearce, J.M. Plastic Recycling in Additive Manufacturing: A Systematic Literature Review and Opportunities for the Circular Economy. J. Clean. Prod. 2020, 264, 121602. [Google Scholar] [CrossRef]

- Betim, D.V.; Heymann, M.C.; Quelhas, O.L.G.; Caiado, R.G.G.; Costa, H.G. Analysis of the Application of Additive Manufacturing in the Circular Economy: An Integrative Literature Review. In Proceedings of the International Conference on Production and Operations Management Society, Kandy, Sri Lanka, 14–16 December 2018; Springer: Berlin/Heidelberg, Germany, 2018; pp. 1075–1084. [Google Scholar]

- Mack, C.A. How to Write a Good Scientific Paper; SPIE: Bellingham, WA, USA, 2018. [Google Scholar]

- Grant, M.J.; Booth, A. A Typology of Reviews: An Analysis of 14 Review Types and Associated Methodologies. Health Inf. Libr. J. 2009, 26, 91–108. [Google Scholar] [CrossRef]

- Liberati, A.; Altman, D.G.; Tetzlaff, J.; Mulrow, C.; Gøtzsche, P.C.; Ioannidis, J.P.; Clarke, M.; Devereaux, P.J.; Kleijnen, J.; Moher, D. The PRISMA Statement for Reporting Systematic Reviews and Meta-Analyses of Studies That Evaluate Health Care Interventions: Explanation and Elaboration. J. Clin. Epidemiol. 2009, 62, e1–e34. [Google Scholar] [CrossRef]

- Juraschek, M.; Cerdas, F.; Posselt, G.; Herrmann, C. Experiencing Closed Loop Manufacturing in a Learning Environment. Procedia Manuf. 2017, 9, 57–64. [Google Scholar] [CrossRef]

- Wu, H.; Wu, R. The Role of Educational Action Research of Recycling Process to the Green Technologies, Environment Engineering, and Circular Economies. Int. J. Recent Technol. Eng. 2019, 8, 1639–1645. [Google Scholar] [CrossRef]

- Alkadi, F.; Lee, J.; Yeo, J.-S.; Hwang, S.-H.; Choi, J.-W. 3D Printing of Ground Tire Rubber Composites. Int. J. Precis. Eng. Manuf. Green Technol. 2019, 6, 211–222. [Google Scholar] [CrossRef]

- Giurco, D.; Littleboy, A.; Boyle, T.; Fyfe, J.; White, S. Circular Economy: Questions for Responsible Minerals, Additive Manufacturing and Recycling of Metals. Resources 2014, 3, 432–453. [Google Scholar] [CrossRef]

- Santander, P.; Cruz Sanchez, F.A.; Boudaoud, H.; Camargo, M. Closed Loop Supply Chain Network for Local and Distributed Plastic Recycling for 3D Printing: A MILP-Based Optimization Approach. Resour. Conserv. Recycl. 2020, 154. [Google Scholar] [CrossRef]

- Wu, H. Education for Environment Sustainability: 3D Printing’s Role in Transformation of Plastic Industry. Int. J. Adv. Res. Eng. Technol. 2019, 10, 128–134. [Google Scholar] [CrossRef]

- Cunico, M.W.M.; Kai, D.A.; Cavalheiro, P.M.; de Carvalho, J. Development and Characterisation of 3D Printing Finishing Process Applying Recycled Plastic Waste. Virtual Phys. Prototyp. 2019, 14, 37–52. [Google Scholar] [CrossRef]

- Dertinger, S.C.; Gallup, N.; Tanikella, N.G.; Grasso, M.; Vahid, S.; Foot, P.J.S.; Pearce, J.M. Technical Pathways for Distributed Recycling of Polymer Composites for Distributed Manufacturing: Windshield Wiper Blades. Resour. Conserv. Recycl. 2020, 157. [Google Scholar] [CrossRef]

- Pavlo, S.; Fabio, C.; Hakim, B.; Mauricio, C. 3D-Printing Based Distributed Plastic Recycling: A Conceptual Model for Closed-Loop Supply Chain Design. In Proceedings of the 2018 IEEE International Conference on Engineering, Technology and Innovation, Stuttgart, Germany, 17–20 June 2018. [Google Scholar]

- Zhong, S.; Pearce, J.M. Tightening the Loop on the Circular Economy: Coupled Distributed Recycling and Manufacturing with Recyclebot and RepRap 3-D Printing. Resour. Conserv. Recycl. 2018, 128, 48–58. [Google Scholar] [CrossRef]

- Sanchez, F.A.C.; Boudaoud, H.; Hoppe, S.; Camargo, M. Polymer Recycling in an Open-Source Additive Manufacturing Context: Mechanical Issues. Addit. Manuf. 2017, 17, 87–105. [Google Scholar] [CrossRef]

- Lanzotti, A.; Martorelli, M.; Maietta, S.; Gerbino, S.; Penta, F.; Gloria, A. A Comparison between Mechanical Properties of Specimens 3D Printed with Virgin and Recycled PLA. Procedia CIRP 2019, 79, 143–146. [Google Scholar] [CrossRef]

- Zander, N.E.; Gillan, M.; Burckhard, Z.; Gardea, F. Recycled Polypropylene Blends as Novel 3D Printing Materials. Addit. Manuf. 2019, 25, 122–130. [Google Scholar] [CrossRef]

- Anderson, I. Mechanical Properties of Specimens 3D Printed with Virgin and Recycled Polylactic Acid. 3D Print. Addit. Manuf. 2017, 4, 110–115. [Google Scholar] [CrossRef]

- Hart, K.R.; Frketic, J.B.; Brown, J.R. Recycling Meal-Ready-to-Eat (MRE) Pouches into Polymer Filament for Material Extrusion Additive Manufacturing. Addit. Manuf. 2018, 21, 536–543. [Google Scholar] [CrossRef]

- Kreiger, M.A.; Mulder, M.L.; Glover, A.G.; Pearce, J.M. Life Cycle Analysis of Distributed Recycling of Post-Consumer High Density Polyethylene for 3-D Printing Filament. J. Clean. Prod. 2014, 70, 90–96. [Google Scholar] [CrossRef]

- Reich, M.J.; Woern, A.L.; Tanikella, N.G.; Pearce, J.M. Mechanical Properties and Applications of Recycled Polycarbonate Particle Material Extrusion-Based Additive Manufacturing. Materials 2019, 12, 1642. [Google Scholar] [CrossRef] [PubMed]

- Woern, A.L.; Byard, D.J.; Oakley, R.B.; Fiedler, M.J.; Snabes, S.L.; Pearce, J.M. Fused Particle Fabrication 3-D Printing: Recycled Materials’ Optimization and Mechanical Properties. Materials 2018, 11, 1413. [Google Scholar] [CrossRef]

- Feeley, S.R.; Wijnen, B.; Pearce, J.M. Evaluation of Potential Fair Trade Standards for an Ethical 3-D Printing Filament. J. Sustain. Dev. 2014, 7. [Google Scholar] [CrossRef]

- Govindan, K.; Soleimani, H.; Kannan, D. Reverse Logistics and Closed-Loop Supply Chain: A Comprehensive Review to Explore the Future. Eur. J. Oper. Res. 2015, 240, 603–626. [Google Scholar] [CrossRef]

- Sauerwein, M.; Doubrovski, E.L. Local and Recyclable Materials for Additive Manufacturing: 3D Printing with Mussel Shells. Mater. Today Commun. 2018, 15, 214–217. [Google Scholar] [CrossRef]

- Mohammed, M.I.; Wilson, D.; Gomez-Kervin, E.; Tang, B.; Wang, J. Investigation of Closed-Loop Manufacturing with Acrylonitrile Butadiene Styrene over Multiple Generations Using Additive Manufacturing. ACS Sustain. Chem. Eng. 2019, 7, 13955–13969. [Google Scholar] [CrossRef]

- Zhao, P.; Rao, C.; Gu, F.; Sharmin, N.; Fu, J. Close-Looped Recycling of Polylactic Acid Used in 3D Printing: An Experimental Investigation and Life Cycle Assessment. J. Clean. Prod. 2018, 197, 1046–1055. [Google Scholar] [CrossRef]

- Domingues, J.; Marques, T.; Mateus, A.; Carreira, P.; Malça, C. An Additive Manufacturing Solution to Produce Big Green Parts from Tires and Recycled Plastics. Procedia Manuf. 2017, 12, 242–248. [Google Scholar] [CrossRef]

- Diaonescu, R. Status and Trends in the Global Manufacturing Sector; IIoT-Worldcom: Cleveland, OH, USA, 2018; Available online: http://iiot-world.com/industrial-iot/connected-industry/status-and-trends-in-the-global-manufacturing-sector/ (accessed on 26 May 2021).

- Beckman, E. The World’s Plastic Problem in Numbers. Available online: https://www.weforum.org/agenda/2018/08/the-world-of-plastics-in-numbers/ (accessed on 17 February 2021).

- Mortillaro, N. Humans Have Produced 8.3 Billion Tonnes of Plastic, Researchers Say. Available online: https://www.cbc.ca/amp/1.4210279 (accessed on 17 February 2021).

- Lee, D.; Lee, Y.; Lee, K.; Ko, Y.; Kim, N. Development and Evaluation of a Distributed Recycling System for Making Filaments Reused in Three-Dimensional Printers. J. Manuf. Sci. Eng. 2019, 141, 021007. [Google Scholar] [CrossRef]

- Charles, A.; Bassan, P.M.; Mueller, T.; Elkaseer, A.; Scholz, S.G. On the Assessment of Thermo-Mechanical Degradability of Multi-Recycled ABS Polymer for 3D Printing Applications. In Proceedings of the International Conference on Sustainable Design and Manufacturing, Budapest, Hungary, 4–5 July 2019; Springer: Berlin/Heidelberg, Germany, 2019; pp. 363–373. [Google Scholar]

- Romero-Alva, V.; Alvarado-Diaz, W.; Roman-Gonzalez, A. Design of a 3D Printer and Integrated Supply System. In Proceedings of the 2018 IEEE XXV International Conference on Electronics, Electrical Engineering and Computing (INTERCON), Lima, Peru, 8–10 August 2018; pp. 1–4. [Google Scholar]

- Chong, S.; Pan, G.-T.; Khalid, M.; Yang, T.C.-K.; Hung, S.-T.; Huang, C.-M. Physical Characterization and Pre-Assessment of Recycled High-Density Polyethylene as 3D Printing Material. J. Polym. Environ. 2017, 25, 136–145. [Google Scholar] [CrossRef]

- Singh, N.; Singh, R.; Ahuja, I.P.S. Recycling of Polymer Waste with SiC/Al2O3 Reinforcement for Rapid Tooling Applications. Mater. Today Commun. 2018, 15, 124–127. [Google Scholar] [CrossRef]

- Paciorek-Sadowska, J.; Borowicz, M.; Isbrandt, M. New Poly (Lactide-Urethane-Isocyanurate) Foams Based on Bio-Polylactide Waste. Polymers 2019, 11, 481. [Google Scholar] [CrossRef]

- Mosaddek, A.; Kommula, H.K.; Gonzalez, F. Design and Testing of a Recycled 3D Printed and Foldable Unmanned Aerial Vehicle for Remote Sensing. In Proceedings of the 2018 International Conference on Unmanned Aircraft Systems (ICUAS), Dallas, TX, USA, 12–15 June 2018; pp. 1207–1216. [Google Scholar]

- Exconde, M.K.J.E.; Co, J.A.A.; Manapat, J.Z.; Magdaluyo, E.R., Jr. Materials Selection of 3D Printing Filament and Utilization of Recycled Polyethylene Terephthalate (PET) in a Redesigned Breadboard. Procedia CIRP 2019, 84, 28–32. [Google Scholar] [CrossRef]

- Peeters, B.; Kiratli, N.; Semeijn, J. A Barrier Analysis for Distributed Recycling of 3D Printing Waste: Taking the Maker Movement Perspective. J. Clean. Prod. 2019, 241. [Google Scholar] [CrossRef]

- Singh, R.; Singh, J.; Singh, S. Investigation for Dimensional Accuracy of AMC Prepared by FDM Assisted Investment Casting Using Nylon-6 Waste Based Reinforced Filament. Measurement 2016, 78, 253–259. [Google Scholar] [CrossRef]

- Fateri, M.; Kaouk, A.; Cowley, A.; Siarov, S.; Palou, M.V.; González, F.G.; Marchant, R.; Cristoforetti, S.; Sperl, M. Feasibility Study on Additive Manufacturing of Recyclable Objects for Space Applications. Addit. Manuf. 2018, 24, 400–404. [Google Scholar] [CrossRef]

- Singh, R.; Singh, H.; Farina, I.; Colangelo, F.; Fraternali, F. On the Additive Manufacturing of an Energy Storage Device from Recycled Material. Compos. Part B Eng. 2019, 156, 259–265. [Google Scholar] [CrossRef]

- Turku, I.; Kasala, S.; Kärki, T. Characterization of Polystyrene Wastes as Potential Extruded Feedstock Filament for 3D Printing. Recycling 2018, 3, 57. [Google Scholar] [CrossRef]

- Popov, V.V., Jr.; Katz-Demyanetz, A.; Garkun, A.; Bamberger, M. The Effect of Powder Recycling on the Mechanical Properties and Microstructure of Electron Beam Melted Ti-6Al-4 V Specimens. Addit. Manuf. 2018, 22, 834–843. [Google Scholar] [CrossRef]

- Czyżewski, P.; Bieliński, M.; Sykutera, D.; Jurek, M.; Gronowski, M.; Ryl, Ł.; Hoppe, H. Secondary Use of ABS Co-Polymer Recyclates for the Manufacture of Structural Elements Using the FFF Technology. Rapid Prototyp. J. 2018, 24, 1447–1454. [Google Scholar] [CrossRef]

- Gaikwad, V.; Ghose, A.; Cholake, S.; Rawal, A.; Iwato, M.; Sahajwalla, V. Transformation of E-Waste Plastics into Sustainable Filaments for 3D Printing. ACS Sustain. Chem. Eng. 2018, 6, 14432–14440. [Google Scholar] [CrossRef]

- Gandha, K.; Ouyang, G.; Gupta, S.; Kunc, V.; Paranthaman, M.P.; Nlebedim, I.C. Recycling of Additively Printed Rare-Earth Bonded Magnets. Waste Manag. 2019, 90, 94–99. [Google Scholar] [CrossRef] [PubMed]

- Khazdozian, H.A.; Manzano, J.S.; Gandha, K.; Slowing, I.I.; Nlebedim, I.C. Recycled Sm-Co Bonded Magnet Filaments for 3D Printing of Magnets. AIP Adv. 2018, 8, 056722. [Google Scholar] [CrossRef]

- Stolz, B.; Mülhaupt, R. Cellular, Mineralized, and Programmable Cellulose Composites Fabricated by 3D Printing of Aqueous Pastes Derived from Paper Wastes and Microfibrillated Cellulose. Macromol. Mater. Eng. 2020, 305, 1900740. [Google Scholar] [CrossRef]

- Annapareddy, A.; Li, M.; Tan, M.J.; Ting, A.G.H.; Tay, D.Y.W.; Ting, A.G.H.; Tay, D.Y.W.; Annapareddy, A.; Li, M.; Tan, M.J. Effect of Recycled Glass Gradation in 3D Cementitious Material Printing. In Proceedings of the Conference on Progress in Additive Manufacturing (Pro-AM 2018), Singapore, 14–17 May 2018; Volume 50, p. 55. [Google Scholar]

- Ting, G.H.A.; Tay, Y.W.D.; Qian, Y.; Tan, M.J. Utilization of Recycled Glass for 3D Concrete Printing: Rheological and Mechanical Properties. J. Mater. Cycles Waste Manag. 2019, 21, 994–1003. [Google Scholar] [CrossRef]

- Annapareddy, A.; Panda, B.; Ting, A.G.H.; Li, M.; Tan, M.J. Flow and Mechanical Properties of 3D Printed Cementitious Material with Recycled Glass Aggregates. In Proceedings of the 3rd International Conference on Progress in Additive Manufacturing (Pro-AM 2018), Singapore, 14–17 May 2018; pp. 14–17. [Google Scholar]

- Baiani, S.; Altamura, P. Waste Materials Superuse and Upcycling in Architecture: Design and Experimentation. TECHNE 2018, 16, 142–151. [Google Scholar] [CrossRef]

- Rahimizadeh, A.; Kalman, J.; Fayazbakhsh, K.; Lessard, L. Recycling of Fiberglass Wind Turbine Blades into Reinforced Filaments for Use in Additive Manufacturing. Compos. Part B Eng. 2019, 175, 107101. [Google Scholar] [CrossRef]

- Quetzeri-Santiago, M.A.; Hedegaard, C.L.; Castrejón-Pita, J.R. Additive Manufacturing with Liquid Latex and Recycled End-of-Life Rubber. 3D Print. Addit. Manuf. 2019, 6, 149–157. [Google Scholar] [CrossRef]

- Melugiri-Shankaramurthy, B.; Sargam, Y.; Zhang, X.; Sun, W.; Wang, K.; Qin, H. Evaluation of Cement Paste Containing Recycled Stainless Steel Powder for Sustainable Additive Manufacturing. Constr. Build. Mater. 2019, 227, 116696. [Google Scholar] [CrossRef]

- Gorji, N.E.; Saxena, P.; Corfield, M.; Clare, A.; Rueff, J.P.; Bogan, J.; O’Connor, R. A New Method for Assessing the Utility of Powder Bed Fusion (PBF) Feedstock. Mater. Charact. 2020, 161, 110167. [Google Scholar] [CrossRef]

- Wang, L.; Kiziltas, A.; Mielewski, D.F.; Lee, E.C.; Gardner, D.J. Closed-Loop Recycling of Polyamide12 Powder from Selective Laser Sintering into Sustainable Composites. J. Clean. Prod. 2018, 195, 765–772. [Google Scholar] [CrossRef]

- Lutter-Günther, M.; Bröker, M.; Mayer, T.; Lizak, S.; Seidel, C.; Reinhart, G. Spatter Formation during Laser Beam Melting of AlSi10Mg and Effects on Powder Quality. Procedia CIRP 2018, 74, 33–38. [Google Scholar] [CrossRef]

- Gorji, N.E.; O’Connor, R.; Mussatto, A.; Snelgrove, M.; González, P.M.; Brabazon, D. Recyclability of Stainless Steel (316 L) Powder within the Additive Manufacturing Process. Materialia 2019, 8, 100489. [Google Scholar] [CrossRef]

- Turner, C.; Moreno, M.; Mondini, L.; Salonitis, K.; Charnley, F.; Tiwari, A.; Hutabarat, W. Sustainable Production in a Circular Economy: A Business Model for Re-Distributed Manufacturing. Sustain. Switz. 2019, 11, 4291. [Google Scholar] [CrossRef]

- Sutton, A.T.; Kriewall, C.S.; Karnati, S.; Leu, M.C.; Newkirk, J.W. Characterization of AISI 304L Stainless Steel Powder Recycled in the Laser Powder-Bed Fusion Process. Addit. Manuf. 2020, 32, 100981. [Google Scholar] [CrossRef]

- Idrees, M.; Jeelani, S.; Rangari, V. Three-Dimensional-Printed Sustainable Biochar-Recycled PET Composites. ACS Sustain. Chem. Eng. 2018, 6, 13940–13948. [Google Scholar] [CrossRef]

- Antonov, M.; Ivanov, R.; Holovenko, Y.; Goljandin, D.; Rahmaniahranjani, R.; Kollo, L.; Hussainova, I. 3D Printing of Plain and Gradient Cermets with Efficient Use of Raw Materials. Key Eng. Mater. 2019, 799, 239–245. [Google Scholar] [CrossRef]

- Sillani, F.; Kleijnen, R.G.; Vetterli, M.; Schmid, M.; Wegener, K. Selective Laser Sintering and Multi Jet Fusion: Process-Induced Modification of the Raw Materials and Analyses of Parts Performance. Addit. Manuf. 2019, 27, 32–41. [Google Scholar] [CrossRef]

- Kumar, S.; Czekanski, A. Development of Filaments Using Selective Laser Sintering Waste Powder. J. Clean. Prod. 2017, 165, 1188–1196. [Google Scholar] [CrossRef]

- Kozlovsky, K.; Schiltz, J.; Kreider, T.; Kumar, M.; Schmid, S. Mechanical Properties of Reused Nylon Feedstock for Powder-Bed Additive Manufacturing in Orthopedics. Procedia Manuf. 2018, 26, 826–833. [Google Scholar] [CrossRef]

- Quintana, O.A.; Alvarez, J.; Mcmillan, R.; Tong, W.; Tomonto, C. Effects of Reusing Ti-6Al-4V Powder in a Selective Laser Melting Additive System Operated in an Industrial Setting. JOM 2018, 70, 1863–1869. [Google Scholar] [CrossRef]

- Ahmed, F.; Ali, U.; Sarker, D.; Marzbanrad, E.; Choi, K.; Mahmoodkhani, Y.; Toyserkani, E. Study of Powder Recycling and Its Effect on Printed Parts during Laser Powder-Bed Fusion of 17-4 PH Stainless Steel. J. Mater. Process. Technol. 2020, 278, 116522. [Google Scholar] [CrossRef]

- Zapico, P.; Giganto, S.; Barreiro, J.; Martinez-Pellitero, S. Characterisation of 17-4PH Metallic Powder Recycling to Optimise the Performance of the Selective Laser Melting Process. J. Mater. Res. Technol. 2020, 9, 1273–1285. [Google Scholar] [CrossRef]

- Heiden, M.J.; Deibler, L.A.; Rodelas, J.M.; Koepke, J.R.; Tung, D.J.; Saiz, D.J.; Jared, B.H. Evolution of 316L Stainless Steel Feedstock Due to Laser Powder Bed Fusion Process. Addit. Manuf. 2019, 25, 84–103. [Google Scholar] [CrossRef]

- Cordova, L.; Campos, M.; Tinga, T. Revealing the Effects of Powder Reuse for Selective Laser Melting by Powder Characterization. JOM 2019, 71, 1062–1072. [Google Scholar] [CrossRef]

- Gong, H.; Xing, X.; Gu, H. Rheological Properties of Two Stainless Steel 316L Powders for Additive Manufacturing. IOP Conf. Ser. Earth Environ. Sci. 2019, 689, 012003. [Google Scholar] [CrossRef]

- Gruber, H.; Henriksson, M.; Hryha, E.; Nyborg, L. Effect of Powder Recycling in Electron Beam Melting on the Surface Chemistry of Alloy 718 Powder. Metall. Mater. Trans. A 2019, 50, 4410–4422. [Google Scholar] [CrossRef]

- Xu, C.; Wu, Q.; L’Espérance, G.; Lebel, L.L.; Therriault, D. Environment-Friendly and Reusable Ink for 3D Printing of Metallic Structures. Mater. Des. 2018, 160, 262–269. [Google Scholar] [CrossRef]

- Feng, L.; Wang, Y.; Wei, Q. PA12 Powder Recycled from SLS for FDM. Polymers 2019, 11, 727. [Google Scholar] [CrossRef]

- Kumar, S.; Czekanski, A. Roadmap to Sustainable Plastic Additive Manufacturing. Mater. Today Commun. 2018, 15, 109–113. [Google Scholar] [CrossRef]

- Gu, H.; Bashir, Z.; Yang, L. The Re-Usability of Heat-Exposed Poly (Ethylene Terephthalate) Powder for Laser Sintering. Addit. Manuf. 2019, 28, 194–204. [Google Scholar] [CrossRef]

- Zander, N.E.; Gillan, M.; Lambeth, R.H. Recycled Polyethylene Terephthalate as a New FFF Feedstock Material. Addit. Manuf. 2018, 21, 174–182. [Google Scholar] [CrossRef]

- Paris, H.; Mandil, G. The Development of a Strategy for Direct Part Reuse Using Additive and Subtractive Manufacturing Technologies. Addit. Manuf. 2018, 22, 687–699. [Google Scholar]

- Teixeira, G.; Bremm, L.; dos Santos Roque, A. Educational Robotics Insertion in High Schools to Promote Environmental Awareness about E-Waste. In Proceedings of the 2018 Latin American Robotic Symposium, 2018 Brazilian Symposium on Robotics (SBR) and 2018 Workshop on Robotics in Education (WRE), Joȧo Pessoa, Brazil, 6–10 November 2018; pp. 591–597. [Google Scholar]

- Sauerwein, M.; Doubrovski, E.; Balkenende, R.; Bakker, C. Exploring the Potential of Additive Manufacturing for Product Design in a Circular Economy. J. Clean. Prod. 2019, 226, 1138–1149. [Google Scholar] [CrossRef]

- Lahrour, Y.; Brissaud, D. A Technical Assessment of Product/Component Re-Manufacturability for Additive Remanufacturing. Procedia CIRP 2018, 69, 142–147. [Google Scholar] [CrossRef]

- Liu, J.; Zheng, Y.; Ma, Y.; Qureshi, A.; Ahmad, R. A Topology Optimization Method for Hybrid Subtractive–Additive Remanufacturing. Int. J. Precis. Eng. Manuf. Green Technol. 2020, 7, 939–953. [Google Scholar] [CrossRef]

- Guo, L.; Chen, X.; Zhang, H.; Zhou, J. Research on Additive Manufacturing Technology. In Proceedings of the Seventh Asia International Symposium on Mechatronics, Singapore, 19–22 September 2019; Springer: Berlin/Heidelberg, Germany, 2020; pp. 937–951. [Google Scholar]

- Leino, M.; Pekkarinen, J.; Soukka, R. The Role of Laser Additive Manufacturing Methods of Metals in Repair, Refurbishment and Remanufacturing—Enabling Circular Economy. Phys. Procedia 2016, 83, 752–760. [Google Scholar] [CrossRef]

- Van Thao, L.E.; Mandil, H.P.G. Extraction of features for combined additive manufacturing and machining processes in a remanufacturing context. In Advances on Mechanics, Design Engineering and Manufacturing; Springer: Berlin/Heidelberg, Germany, 2017; pp. 179–189. [Google Scholar]

- Tian, X.; Liu, T.; Wang, Q.; Dilmurat, A.; Li, D.; Ziegmann, G. Recycling and Remanufacturing of 3D Printed Continuous Carbon Fiber Reinforced PLA Composites. J. Clean. Prod. 2017, 142, 1609–1618. [Google Scholar] [CrossRef]

- Wilkinson, S.; Cope, N. 3D printing and sustainable product development. In Green Information Technology; Elsevier: Amsterdam, The Netherlands, 2015; pp. 161–183. [Google Scholar]

- Reames, L. Remanufacture vs. Repair: What Is the Difference? Available online: https://htscoatings.com/blogs/our-craft-our-culture/remanufacture-versus-repair (accessed on 17 February 2021).

- Liu, H.; Hu, Z.; Qin, X.; Wang, Y.; Zhang, J.; Huang, S. Parameter Optimization and Experimental Study of the Sprocket Repairing Using Laser Cladding. Int. J. Adv. Manuf. Technol. 2017, 91, 3967–3975. [Google Scholar] [CrossRef]

- Petrat, T.; Graf, B.; Gumenyuk, A.; Rethmeier, M. Laser Metal Deposition as Repair Technology for a Gas Turbine Burner Made of Inconel 718. Phys. Procedia 2016, 83, 761–768. [Google Scholar] [CrossRef]

- Zhang, B.; Kowsari, K.; Serjouei, A.; Dunn, M.L.; Ge, Q. Reprocessable Thermosets for Sustainable Three-Dimensional Printing. Nat. Commun. 2018, 9, 1831. [Google Scholar] [CrossRef]

- Walachowicz, F.; Bernsdorf, I.; Papenfuss, U.; Zeller, C.; Graichen, A.; Navrotsky, V.; Rajvanshi, N.; Kiener, C. Comparative Energy, Resource and Recycling Lifecycle Analysis of the Industrial Repair Process of Gas Turbine Burners Using Conventional Machining and Additive Manufacturing. J. Ind. Ecol. 2017, 21, S203–S215. [Google Scholar] [CrossRef]

- Tur, A.I.; Kokoulin, A.N.; Yuzhakov, A.A.; Polygalov, S.V.; Troegubov, A.S.; Korotaev, V.N. Beverage Container Collecting Machine Project. IOP Conf. Ser. Earth Environ. Sci. 2019, 317, 012006. [Google Scholar] [CrossRef]

| Journal | # * of Publications |

|---|---|

| Additive Manufacturing | 24 |

| Journal of Cleaner Production | 13 |

| IOP Conference Series: Materials Science and Engineering | 11 |

| Proceedings of the International Astronautical Congress, IAC | 10 |

| Composites Part B: Engineering | 8 |

| Procedia Manufacturing | 7 |

| ACS Applied Materials and Interfaces | 6 |

| Construction and Building Materials | 6 |

| JOM | 6 |

| Polymers | 6 |

| Procedia CIRP | 6 |

| 3D Printing and Additive Manufacturing | 5 |

| ACS Sustainable Chemistry and Engineering | 5 |

| Key Engineering Materials | 5 |

| Materials | 5 |

| Minerals, Metals and Materials Series | 5 |

| Powder Technology | 5 |

| Resources, Conservation and Recycling | 5 |

| References | The Study Deals with… | Acceptable? (Yes/No) |

|---|---|---|

| [14] | The identification of the most significant hurdles in recycling efforts in Indonesia. | N |

| [18] | The clarification of the interaction between laser and metal powder, with a strong focus on its side effects. | Y |

| [19] | Friction stir processing in the modification of the cast structure, superplastic deformation behavior, preparation of fine-grained Mg alloys and Mg-based surface composites, and AM. | Y |

| [20] | The classification of laser-based AM technologies, operational principles of direct laser metal deposition, feedstock quality requirements, material laser interaction mechanism, and metallurgy of Ti-6AL-4V alloy. | Y |

| [21] | Processing techniques used in recycling of thermoplastics polymers with different types of reinforcements, especially for AM applications. It bridges the gaps for use of primary (1°), secondary (2°), tertiary (3°) and quaternary (4°) routes as an industrial processing standard with low cost AM technology. | Y |

| [22] | The principles and capabilities offered by the existing metal AM technology for object repair and restoration namely, direct energy deposition, powder bed fusion, and cold spray technology. | Y |

| [23] | 3D metal AM from an interdisciplinary perspective, providing an overview on sustainability, basic principles, and a conceptual framework on environmental performance, implicit constraints regarding materials, recycling and use/reuse tools for extended life cycle. | Y |

| [24] | The Directed Energy Deposition (DED) process and its role in the repairing of metallic components. | Y |

| [15] | The recycling techniques and evolution of resin-based thermosetting and thermoplastic carbon fibers. | N |

| [25] | How rising technologies from Industry 4.0 can be integrated with CE practices to establish a business model that reuses and recycles wasted material such as scrap metal or e-waste. | Y |

| [26] | The main policies that have motivated the transition to a CE model and within this, to CO2 recycling. | Y |

| [27] | The fundamental aspects of the production of polyurethane foams (PUFs), the new challenges that the PUFs industry is expected to confront regarding process methodologies in the near future are outlined and some alternatives. | Y |

| [28] | Recent trends, such as fast prototyping of reactors via 3D printing of flow channels, miniaturisation and use of multi-physics modelling. | Y |

| [29] | The sustainability of AM, the context of which is introduced, with a focus on energy and environmental impacts. | Y |

| [17] | Cation-exchange resins, micro and mesoporous acidic resins, supported acidic ionic liquids, ionomeric membranes and the use of alternative organic polymer-based acidic catalysts (hybrid systems). | N |

| [30] | Τhe current progress of Metal AM feedstock and various powder characteristics related to the Selective Laser Melting process, with a focus on the influence of powder granulometry on feedstock and final part properties. | Y |

| [31] | Various recent sustainable manufacturing ideas applied in the prominent sectors with an aim to either recycle/reuse the discarded ones or to produce a fresh part in eco-friendly manners. | Y |

| [16] | The design, chemistry and engineering aspects of the development of paper-based chemosensors and biosensors. | N |

| [32] | The advanced shape memory technology with a focus on polymeric materials. | Y |

| Reference | The Study Deals with… | Acceptable? (Yes/No) |

|---|---|---|

| [33] | The current advances on thermoplastic recycling processes via AM technologies. | N |

| [34] | The guidelines and parameters that can guide the paths to the integration of AM with the concept of CE. | Y |

| References | Additive Manufacturing Methods | Sustainability | Additive Manufacturing Materials | Digitization-Industry 4.0 | Practical Applications |

|---|---|---|---|---|---|

| [21] | X | X | |||

| [18] | X | X | X | ||

| [20] | X | X | |||

| [19] | X | ||||

| [23] | X | X | X | ||

| [25] | X | X | |||

| [22] | X | ||||

| [24] | X | X | |||

| [34] | X | ||||

| [27] | X | ||||

| [26] | X | X | |||

| [29] | X | X | |||

| [28] | X | ||||

| [31] | X | ||||

| [30] | X | X | X | ||

| [32] | X | ||||

| # * of Publications | 4 | 10 | 6 | 3 | 4 |

| % | 25% | 62.5% | 37.5% | 18.75% | 25% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ponis, S.; Aretoulaki, E.; Maroutas, T.N.; Plakas, G.; Dimogiorgi, K. A Systematic Literature Review on Additive Manufacturing in the Context of Circular Economy. Sustainability 2021, 13, 6007. https://doi.org/10.3390/su13116007

Ponis S, Aretoulaki E, Maroutas TN, Plakas G, Dimogiorgi K. A Systematic Literature Review on Additive Manufacturing in the Context of Circular Economy. Sustainability. 2021; 13(11):6007. https://doi.org/10.3390/su13116007

Chicago/Turabian StylePonis, Stavros, Eleni Aretoulaki, Theodoros Nikolaos Maroutas, George Plakas, and Konstantina Dimogiorgi. 2021. "A Systematic Literature Review on Additive Manufacturing in the Context of Circular Economy" Sustainability 13, no. 11: 6007. https://doi.org/10.3390/su13116007

APA StylePonis, S., Aretoulaki, E., Maroutas, T. N., Plakas, G., & Dimogiorgi, K. (2021). A Systematic Literature Review on Additive Manufacturing in the Context of Circular Economy. Sustainability, 13(11), 6007. https://doi.org/10.3390/su13116007