Supply Chain Ambidexterity and Green SCM: Moderating Role of Network Capabilities

Abstract

1. Introduction

2. Theoretical Background and Hypotheses Development

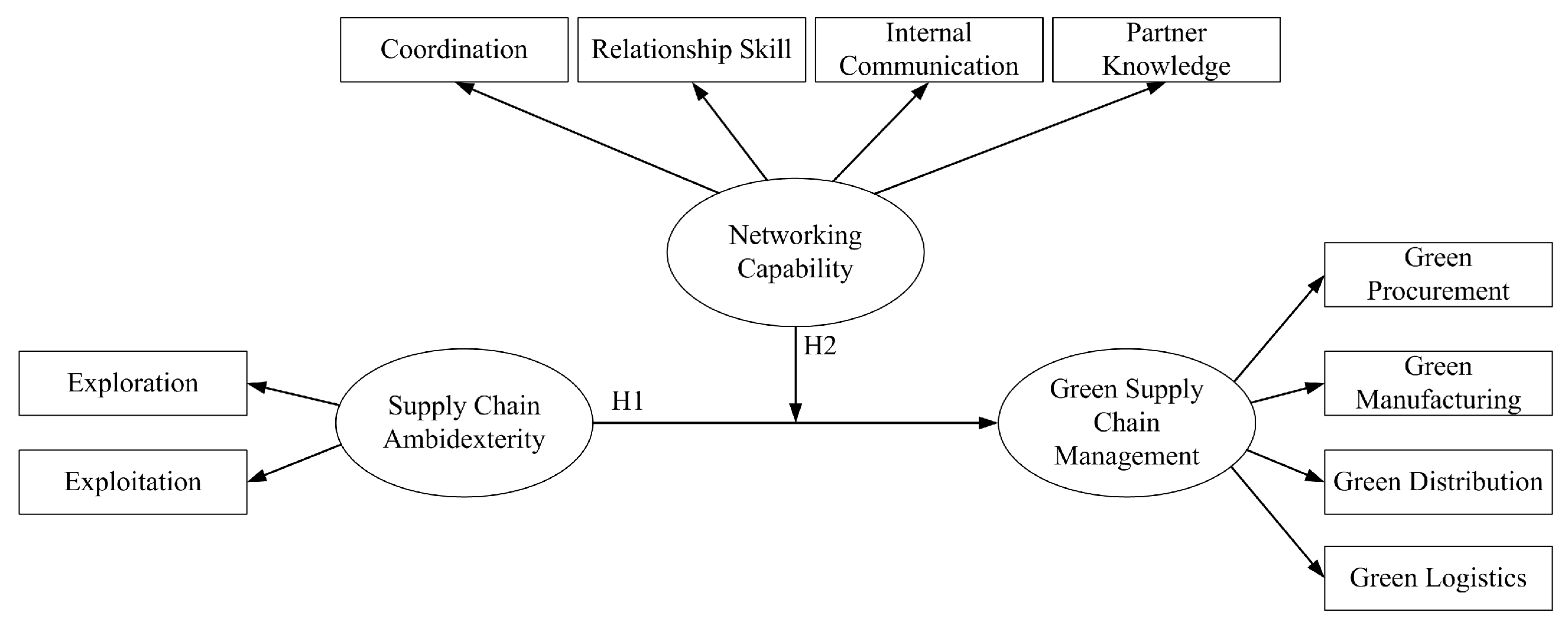

2.1. Supply Chain Ambidexterity and Green Supply Chain Management

2.2. The Moderating Role of Networking Capability

- (1)

- Risk-based strategy: This is the simplest type of GSCM strategy. Firms using this strategy will invest the lowest possible resources and will in turn demand from their suppliers to conform with the environmental rules;

- (2)

- Efficiency-based strategy: Firms engaged in these strategies focus on the optimization of cost and operational procedures. This strategy is comparatively complicated, and it benefits the firms not only economically but also toward the efficient management of their resources;

- (3)

- Innovation-based strategy: Firms engaged in this strategy follow a guideline to design green product life cycles, demand their suppliers to follow the environmental concerns and train them in adapting the innovative green initiatives. As a result, firms following this strategy invest more resources and develop up-to-date capabilities to manage the green supply chain;

- (4)

- Closed-loop strategy: In this strategy, the environmental performance is connected to all the links of the supply chain. This is comparatively the most complicated strategy. One of the examples related to this strategy is recycling materials from the manufacturing processes and end-of-life products. This strategy requires the firms to have efficient coordination with many parties to cultivate specialized information.

3. Research Method

4. Data Analysis

4.1. Outer Model and Validation

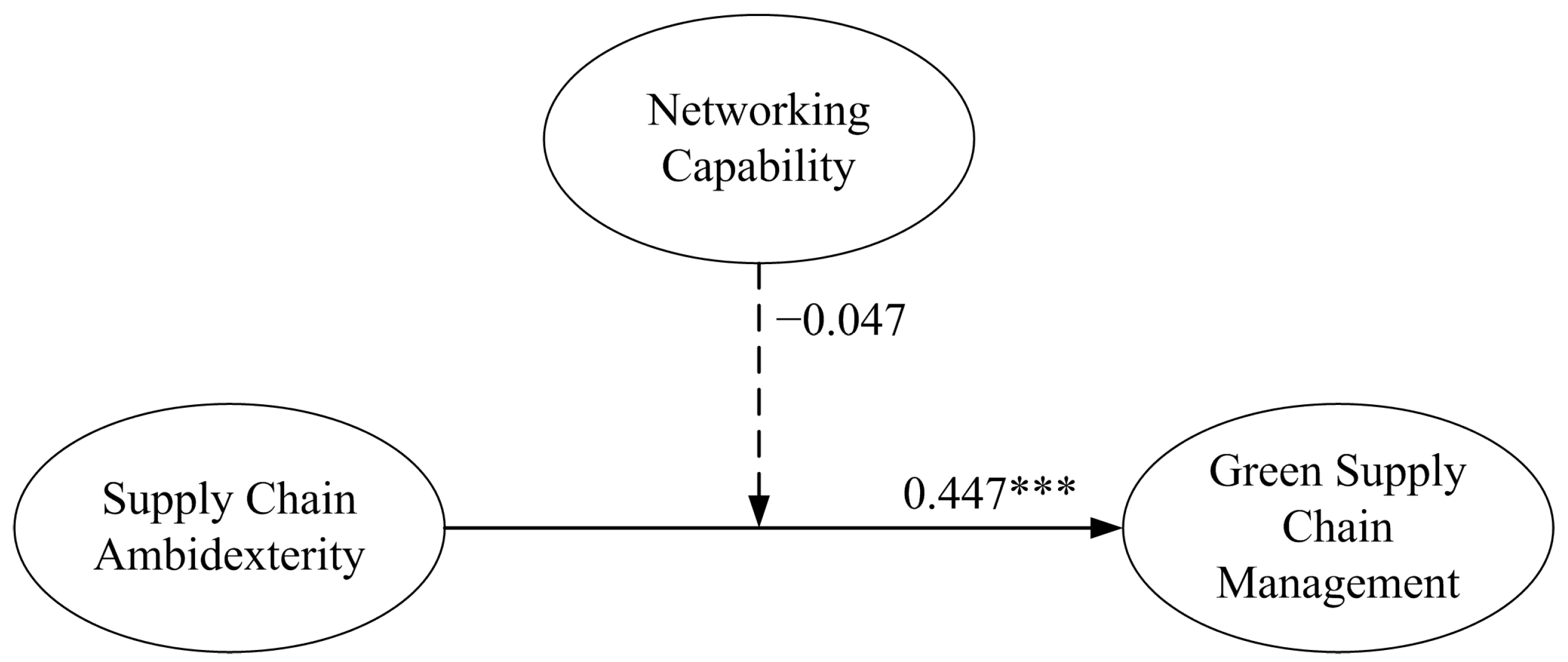

4.2. Inner Model Result and Hypotheses Testing

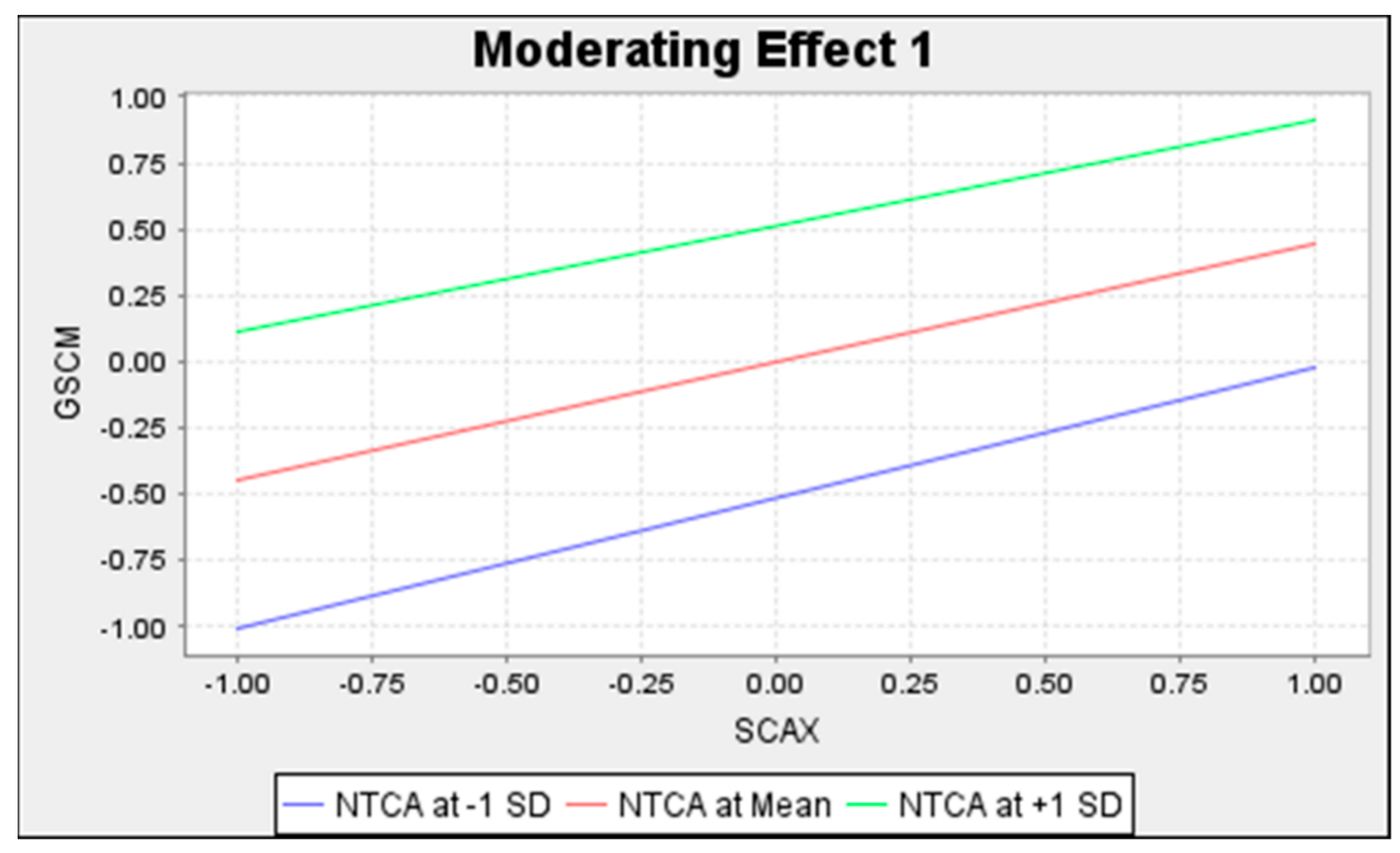

4.3. Moderation Test

5. Discussion and Implications

6. Research Limitations and Future Directions

Author Contributions

Funding

Informed Consent Statement

Conflicts of Interest

Appendix A

- In order to stay competitive, our supply chain managers focus on reducing operational redundancies in our existing processes;

- Leveraging our current supply chain technologies is important to our firm’s strategy;

- In order to stay competitive, our supply chain managers focus on improving our existing technologies;

- Our managers focus on developing stronger competencies in our existing supply chain processes.

- We proactively pursue new supply chain solutions;

- We continually experiment to find new solutions that will improve our supply chain;

- To improve our supply chain, we continually explore new opportunities;

- We are constantly seeking novel approaches to solve supply chain problems.

- We follow the principles of the 3Rs: reuse, recycle and reduce in the process of green procurement in terms of paper and parts container (plastic bag/box);

- We place purchase orders through email (paperless);

- We use eco-labeling on our products;

- We ensure our suppliers’ environmental compliance certifications;

- We conduct auditing for suppliers’ internal environmental management.

- We as a manufacturer, design products that facilitate the reuse, recycle and recovery of parts and material components;

- We avoid or reduce the use of hazardous products within the production process;

- We minimize the consumption of materials as well as energy.

- We use strategies to downsize packaging;

- We use “green” packaging materials;

- We promote recycling and reuse programs;

- We cooperate with vendors to standardize packaging;

- We encourage and adopt returnable packaging methods;

- We minimize material uses and time to unpack;

- We use a recyclable pallet system and lastly;

- We save energy in warehouses.

- We collect used products and packaging from customers for recycling;

- We return packaging and products to suppliers for reuse;

- We require suppliers to collect their packaging material.

- In our company, we have regular meetings for every project;

- In our company employees develop informal contacts among themselves;

- In our company managers and employees often give feedback to each other.

- In our company, we analyze what we would like and desire to achieve with which partner;

- In our company, we develop relations with each partner based on what they can contribute;

- In our company, we discuss regularly with our partners how we can support each other.

- In our company, we have the ability to build good personal relationships with our business partners;

- In our company, we can deal flexibly with our partners;

- In our company, we almost always solve problems constructively with our partners.

- In our company, we know our partners’ markets;

- In our company, we know our partners’ products/procedures/services;

- In our company, we know our partners’ strengths and weaknesses.

References

- Levinthal, D.A.; March, J.G. The myopia of learning. Strateg. Manag. J. 1993, 14, 95–112. [Google Scholar] [CrossRef]

- Kristal, M.M.; Huang, X.; Roth, A.V. The effect of an ambidextrous supply chain strategy on combinative competitive capabilities and business performance. J. Oper. Manag. 2010, 28, 415–429. [Google Scholar] [CrossRef]

- Borzillo, S.; Schmitt, A.; Antino, M. Communities of practice: Keeping the company agile. J. Bus. Strategy 2012, 33, 22–30. [Google Scholar] [CrossRef]

- Junni, P.; Sarala, R.; Taras, V.; Tarba, S. Organizational ambidexterity and performance: A meta-analysis. Acad. Manag. Perspect. 2013, 27, 299–312. [Google Scholar] [CrossRef]

- Zhang, X.; Yang, B.; Hui, J.; Liu, M.; Chi, Z.; Liu, S.; Xu, J.; Wei, Y. A novel method for preparing AIE dye based cross-linked fluorescent polymeric nanoparticles for cell imaging. Polym. Chem. 2014, 5, 683–688. [Google Scholar] [CrossRef]

- Parikh, M. Move over Mintzberg, let adhocracy give way to ambidexterity. Manag. Decis. 2016, 54, 1047–1058. [Google Scholar] [CrossRef]

- D’Souza, D.E.; Sigdyal, P.; Struckell, E. Relative ambidexterity: A measure and a versatile framework. Acad. Manag. Perspect. 2017, 31, 124–136. [Google Scholar] [CrossRef]

- Zhu, Q.; Sarkis, J.; Geng, Y. Green supply chain management in China: Pressures, practices and performance. Int. J. Oper. Prod. Manag. 2005, 25, 449–468. [Google Scholar] [CrossRef]

- Kumar, V.; Holt, D.; Ghobadian, A.; Garza-Reyes, J.A. Developing green supply chain management taxonomy-based decision support system. Int. J. Prod. Res. 2015, 53, 6372–6389. [Google Scholar] [CrossRef]

- Chin, T.A.; Tat, H.H.; Sulaiman, Z. Green supply chain management, environmental collaboration and sustainability performance. Procedia CIRP 2015, 26, 695–699. [Google Scholar] [CrossRef]

- Younis, H. The Impact of the Dimensions of Green Supply Chain Management Practices on Corporate Performance. Ph.D. Thesis, University of Wollongong in Dubai, Dubai, United Arab Emirates, 2016. [Google Scholar]

- Kumar, S.; Putnam, V. Cradle to cradle: Reverse logistics strategies and opportunities across three industry sectors. Int. J. Prod. Econ. 2008, 115, 305–315. [Google Scholar] [CrossRef]

- Golicic, S.L.; Smith, C.D. A meta-analysis of environmentally sustainable supply chain management practices and firm performance. J. Supply Chain Manag. 2013, 49, 78–95. [Google Scholar] [CrossRef]

- Partanen, J.; Kohtamäki, M.; Patel, P.C.; Parida, V. Supply chain ambidexterity and manufacturing SME performance: The moderating roles of network capability and strategic information flow. Int. J. Prod. Econ. 2020, 221, 107470. [Google Scholar] [CrossRef]

- Morrissey, W.J.; Pittaway, L. Buyer-supplier relationships in small firms: The use of social factors to manage relationships. Int. Small Bus. J. 2006, 24, 272–298. [Google Scholar] [CrossRef]

- Kauppila, O.-P. Alliance management capability and firm performance: Using resource-based theory to look inside the process black box. Long Range Plan. 2015, 48, 151–167. [Google Scholar] [CrossRef]

- Wynarczyk, P.; Watson, R. Firm growth and supply chain partnerships: An empirical analysis of UK SME subcontractors. Small Bus. Econ. 2005, 24, 39–51. [Google Scholar] [CrossRef]

- Im, G.; Rai, A. Knowledge sharing ambidexterity in long-term interorganizational relationships. Manag. Sci. 2008, 54, 1281–1296. [Google Scholar] [CrossRef]

- March, J.G. Exploration and exploitation in organizational learning. Organ. Sci. 1991, 2, 71–87. [Google Scholar] [CrossRef]

- Kortmann, S. The mediating role of strategic orientations on the relationship between ambidexterity-oriented decisions and innovative ambidexterity. J. Prod. Innov. Manag. 2015, 32, 666–684. [Google Scholar] [CrossRef]

- Raisch, S.; Birkinshaw, J. Organizational ambidexterity: Antecedents, outcomes, and moderators. J. Manag. 2008, 34, 375–409. [Google Scholar] [CrossRef]

- Lee, S.M.; Rha, J.S. Ambidextrous supply chain as a dynamic capability: Building a resilient supply chain. Manag. Decis. 2016, 54, 2–23. [Google Scholar] [CrossRef]

- Wong, C.W.; Wong, C.Y.; Boon-itt, S. The combined effects of internal and external supply chain integration on product innovation. Int. J. Prod. Econ. 2013, 146, 566–574. [Google Scholar] [CrossRef]

- Bui, T.-D.; Tsai, F.M.; Tseng, M.-L.; Tan, R.R.; Yu, K.D.S.; Lim, M.K. Sustainable supply chain management towards disruption and organizational ambidexterity: A data driven analysis. Sustain. Prod. Consum. 2020, 26, 373–410. [Google Scholar] [CrossRef] [PubMed]

- De Oliveira, U.R.; Espindola, L.S.; Da Silva, I.R.; Da Silva, I.N.; Rocha, H.M. A systematic literature review on green supply chain management: Research implications and future perspectives. J. Clean. Prod. 2018, 187, 537–561. [Google Scholar] [CrossRef]

- Rao, P.; Holt, D. Do green supply chains lead to competitiveness and economic performance? Int. J. Oper. Prod. Manag. 2005, 25, 898–916. [Google Scholar] [CrossRef]

- Younis, H.; Sundarakani, B.; O’Mahony, B. Green supply chain management and corporate performance: Developing a roadmap for future research using a mixed method approach. IIMB Manag. Rev. 2019, 32, 305–324. [Google Scholar] [CrossRef]

- Geng, R.; Mansouri, S.A.; Aktas, E. The relationship between green supply chain management and performance: A meta-analysis of empirical evidences in Asian emerging economies. Int. J. Prod. Econ. 2017, 183, 245–258. [Google Scholar] [CrossRef]

- Birkinshaw, J.; Gibson, C.B. Building an ambidextrous organisation. Adv. Inst. Manag. Res. Pap. 2004, 3, 1–19. [Google Scholar] [CrossRef]

- Semrau, T.; Sigmund, S. Networking ability and the financial performance of new ventures: A mediation analysis among younger and more mature firms. Strateg. Entrep. J. 2012, 6, 335–354. [Google Scholar] [CrossRef]

- Stam, W.; Arzlanian, S.; Elfring, T. Social capital of entrepreneurs and small firm performance: A meta-analysis of contextual and methodological moderators. J. Bus. Ventur. 2014, 29, 152–173. [Google Scholar] [CrossRef]

- Granovetter, M. The strength of weak ties: A network theory revisited. Sociol. Theory 1983, 1, 201–233. [Google Scholar] [CrossRef]

- Tiwana, A. Do bridging ties complement strong ties? An empirical examination of alliance ambidexterity. Strateg. Manag. J. 2008, 29, 251–272. [Google Scholar] [CrossRef]

- Hansen, M.T. The search-transfer problem: The role of weak ties in sharing knowledge across organization subunits. Adm. Sci. Q. 1999, 44, 82–111. [Google Scholar] [CrossRef]

- Lavie, D.; Rosenkopf, L. Balancing exploration and exploitation in alliance formation. Acad. Manag. J. 2006, 49, 797–818. [Google Scholar] [CrossRef]

- Simpson, D.; Samson, D. Developing strategies for green supply chain management. Decis. Line 2008, 39, 12–15. [Google Scholar]

- Mitrega, M.; Forkmann, S.; Ramos, C.; Henneberg, S.C. Networking capability in business relationships—Concept and scale development. Ind. Mark. Manag. 2012, 41, 739–751. [Google Scholar] [CrossRef]

- Andriopoulos, C.; Lewis, M.W. Exploitation-exploration tensions and organizational ambidexterity: Managing paradoxes of innovation. Organ. Sci. 2009, 20, 696–717. [Google Scholar] [CrossRef]

- Holmström, J.; Partanen, J.; Tuomi, J.; Walter, M. Rapid manufacturing in the spare parts supply chain. J. Manuf. Technol. Manag. 2010, 21, 687–697. [Google Scholar] [CrossRef]

- Song, M.; Di Benedetto, C.A. Supplier’s involvement and success of radical new product development in new ventures. J. Oper. Manag. 2008, 26, 1–22. [Google Scholar] [CrossRef]

- Schreiner, M.; Kale, P.; Corsten, D. What really is alliance management capability and how does it impact alliance outcomes and success? Strateg. Manag. J. 2009, 30, 1395–1419. [Google Scholar] [CrossRef]

- Dyer, J.H. Effective interim collaboration: How firms minimize transaction costs and maximise transaction value. Strateg. Manag. J. 1997, 18, 535–556. [Google Scholar] [CrossRef]

- Jansen, J.J.; Simsek, Z.; Cao, Q. Ambidexterity and performance in multiunit contexts: Cross-level moderating effects of structural and resource attributes. Strateg. Manag. J. 2012, 33, 1286–1303. [Google Scholar] [CrossRef]

- Fernhaber, S.A.; Patel, P.C. How do young firms manage product portfolio complexity? The role of absorptive capacity and ambidexterity. Strateg. Manag. J. 2012, 33, 1516–1539. [Google Scholar] [CrossRef]

- Lubatkin, M.H.; Simsek, Z.; Ling, Y.; Veiga, J.F. Ambidexterity and performance in small-to medium-sized firms: The pivotal role of top management team behavioral integration. J. Manag. 2006, 32, 646–672. [Google Scholar] [CrossRef]

- Adler, P.S.; Benner, M.; Brunner, D.J.; MacDuffie, J.P.; Osono, E.; Staats, B.R.; Takeuchi, H.; Tushman, M.L.; Winter, S.; Boyer, K.K.; et al. Perspectives on the productivity dilemma. J. Oper. Manag. 2009, 27, 99–113. [Google Scholar]

- Ojha, D.; Acharya, C.; Cooper, D. Transformational leadership and supply chain ambidexterity: Mediating role of supply chain organizational learning and moderating role of uncertainty. Int. J. Prod. Econ. 2018, 197, 215–231. [Google Scholar] [CrossRef]

- Walter, A.; Auer, M.; Ritter, T. The impact of network capabilities and entrepreneurial orientation on university spin-off performance. J. Bus. Ventur. 2006, 21, 541–567. [Google Scholar] [CrossRef]

- Anderson, J.C.; Gerbing, D.W. Structural equation modeling in practice: A review and recommended two-step approach. Psychol. Bull. 1988, 103, 411. [Google Scholar] [CrossRef]

- Hulland, J. Use of partial least squares (PLS) in strategic management research: A review of four recent studies. Strateg. Manag. J. 1999, 20, 195–204. [Google Scholar] [CrossRef]

- Petter, S.; Straub, D.; Rai, A. Specifying formative constructs in information systems research. MIS Q. 2007, 31, 623–656. [Google Scholar] [CrossRef]

- Chin, W.W.; Newsted, P.R. Structural equation modeling analysis with small samples using partial least squares. Stat. Strateg. Small Sample Res. 1999, 1, 307–341. [Google Scholar]

- Hair, J.F., Jr.; Babin, B.J.; Anderson, R.E. A Global Perspectivie; Pearson: London, UK, 2010. [Google Scholar]

- Chin, W.W. The partial least squares approach to structural equation modeling. Mod. Methods Bus. Res. 1998, 295, 295–336. [Google Scholar]

- Fornell, C.; Larcker, D.F. Structural Equation Models with Unobservable Variables and Measurement Error: Algebra and Statistics; Sage Publications: Los Angeles, CA, USA, 1981. [Google Scholar]

- Hair, J.F., Jr.; Hult, G.T.M.; Ringle, C.; Sarstedt, M. A Primer on Partial Least Squares Structural Equation Modeling (PLS-SEM); Sage Publications: Los Angeles, CA, USA, 2016. [Google Scholar]

- Tenenhaus, M.; Vinzi, V.E.; Chatelin, Y.-M.; Lauro, C. PLS path modeling. Comput. Stat. Data Anal. 2005, 48, 159–205. [Google Scholar] [CrossRef]

- Wetzels, M.; Odekerken-Schröder, G.; Van Oppen, C. Using PLS path modeling for assessing hierarchical construct models: Guidelines and empirical illustration. MIS Q. 2009, 33, 177–195. [Google Scholar] [CrossRef]

- Purvis, R.L.; Sambamurthy, V.; Zmud, R.W. The assimilation of knowledge platforms in organizations: An empirical investigation. Organ. Sci. 2001, 12, 117–135. [Google Scholar] [CrossRef]

- Chin, W.W.; Marcolin, B.L.; Newsted, P.R. A partial least squares latent variable modeling approach for measuring interaction effects: Results from a Monte Carlo simulation study and an electronic-mail emotion/adoption study. Inf. Syst. Res. 2003, 14, 189–217. [Google Scholar] [CrossRef]

- Henseler, J.; Fassott, G. Testing moderating effects in PLS path models: An illustration of available procedures. In Handbook of Partial Least Squares; Springer: Berlin/Heidelberg, Germany, 2010; pp. 713–735. [Google Scholar]

- Gupta, K.; Jabrail, F.H. Effects of degree of deacetylation and cross-linking on physical characteristics, swelling and release behavior of chitosan microspheres. Carbohydr. Polym. 2006, 66, 43–54. [Google Scholar] [CrossRef]

- Eisenhardt, K.M.; Brown, S.L. Time pacing: Competing in markets that won’t stand still. Harv. Bus. Rev. 1998, 76, 59–70. [Google Scholar]

- Rothaermel, F.T.; Alexandre, M.T. Ambidexterity in technology sourcing: The moderating role of absorptive capacity. Organ. Sci. 2009, 20, 759–780. [Google Scholar] [CrossRef]

- Gupta, A.K.; Smith, K.G.; Shalley, C.E. The interplay between exploration and exploitation. Acad. Manag. J. 2006, 49, 693–706. [Google Scholar] [CrossRef]

- O’Reilly, C.A., III; Tushman, M.L. Ambidexterity as a dynamic capability: Resolving the innovator’s dilemma. Res. Organ. Behav. 2008, 28, 185–206. [Google Scholar] [CrossRef]

| Construct | Cronbach’s Alpha | Composite Reliability | AVE |

|---|---|---|---|

| GSCM | 0.909 | 0.923 | 0.501 |

| NTCA | 0.882 | 0.905 | 0.517 |

| SCAX | 0.899 | 0.920 | 0.590 |

| COOR | GRDS | GRLG | GRMF | GRPC | INCM | RLSK | XPLR | XPLT | |

|---|---|---|---|---|---|---|---|---|---|

| COOR1 | 0.842 | 0.536 | 0.486 | 0.343 | 0.505 | 0.602 | 0.529 | 0.420 | 0.460 |

| COOR2 | 0.758 | 0.514 | 0.466 | 0.297 | 0.487 | 0.476 | 0.513 | 0.479 | 0.413 |

| COOR3 | 0.734 | 0.515 | 0.462 | 0.412 | 0.466 | 0.390 | 0.580 | 0.478 | 0.494 |

| GRDS3 | 0.504 | 0.776 | 0.453 | 0.495 | 0.563 | 0.489 | 0.482 | 0.498 | 0.498 |

| GRDS4 | 0.439 | 0.754 | 0.471 | 0.464 | 0.582 | 0.470 | 0.412 | 0.504 | 0.529 |

| GRDS5 | 0.362 | 0.663 | 0.418 | 0.390 | 0.524 | 0.384 | 0.349 | 0.470 | 0.436 |

| GRDS6 | 0.551 | 0.765 | 0.572 | 0.266 | 0.523 | 0.599 | 0.465 | 0.431 | 0.516 |

| GRDS7 | 0.508 | 0.659 | 0.525 | 0.407 | 0.482 | 0.561 | 0.474 | 0.417 | 0.524 |

| GRDS8 | 0.601 | 0.745 | 0.602 | 0.329 | 0.488 | 0.563 | 0.540 | 0.436 | 0.495 |

| GRLG1 | 0.555 | 0.639 | 0.904 | 0.495 | 0.553 | 0.573 | 0.523 | 0.592 | 0.633 |

| GRLG2 | 0.522 | 0.575 | 0.879 | 0.375 | 0.484 | 0.590 | 0.455 | 0.491 | 0.523 |

| GRMF3 | 0.448 | 0.522 | 0.491 | 1.000 | 0.527 | 0.512 | 0.537 | 0.525 | 0.513 |

| GRPC1 | 0.504 | 0.574 | 0.494 | 0.399 | 0.791 | 0.561 | 0.410 | 0.665 | 0.657 |

| GRPC2 | 0.458 | 0.628 | 0.498 | 0.440 | 0.837 | 0.513 | 0.495 | 0.617 | 0.618 |

| GRPC3 | 0.591 | 0.642 | 0.489 | 0.429 | 0.886 | 0.522 | 0.536 | 0.689 | 0.712 |

| GRPC4 | 0.485 | 0.506 | 0.425 | 0.463 | 0.750 | 0.429 | 0.502 | 0.632 | 0.641 |

| INCM1 | 0.470 | 0.548 | 0.471 | 0.394 | 0.560 | 0.844 | 0.330 | 0.568 | 0.561 |

| INCM2 | 0.535 | 0.574 | 0.495 | 0.420 | 0.503 | 0.833 | 0.430 | 0.491 | 0.556 |

| INCM3 | 0.621 | 0.633 | 0.694 | 0.502 | 0.545 | 0.908 | 0.539 | 0.517 | 0.533 |

| RLSK1 | 0.624 | 0.534 | 0.383 | 0.436 | 0.517 | 0.457 | 0.860 | 0.416 | 0.392 |

| RLSK2 | 0.521 | 0.486 | 0.490 | 0.510 | 0.467 | 0.398 | 0.880 | 0.494 | 0.482 |

| RLSK3 | 0.650 | 0.565 | 0.558 | 0.455 | 0.559 | 0.470 | 0.865 | 0.567 | 0.556 |

| XPLR1 | 0.436 | 0.455 | 0.407 | 0.361 | 0.560 | 0.411 | 0.434 | 0.786 | 0.586 |

| XPLR2 | 0.504 | 0.497 | 0.455 | 0.386 | 0.656 | 0.485 | 0.438 | 0.831 | 0.678 |

| XPLR3 | 0.448 | 0.521 | 0.549 | 0.481 | 0.600 | 0.540 | 0.532 | 0.776 | 0.677 |

| XPLR4 | 0.422 | 0.471 | 0.474 | 0.394 | 0.644 | 0.433 | 0.347 | 0.698 | 0.635 |

| XPLT1 | 0.370 | 0.450 | 0.407 | 0.431 | 0.595 | 0.442 | 0.388 | 0.628 | 0.749 |

| XPLT2 | 0.486 | 0.603 | 0.605 | 0.452 | 0.689 | 0.500 | 0.444 | 0.626 | 0.842 |

| XPLT3 | 0.531 | 0.621 | 0.599 | 0.392 | 0.667 | 0.624 | 0.491 | 0.670 | 0.858 |

| XPLT4 | 0.535 | 0.540 | 0.543 | 0.430 | 0.709 | 0.534 | 0.494 | 0.825 | 0.864 |

| Hypothesis | Path Coefficient | t-Value | Result |

|---|---|---|---|

| H1: SCAX → GSCM | 0.447 *** | 6.085 | Supported |

| H2: SCAX × NTCA → GSCM | −0.047 (0.600) | 0.524 | Not Supported |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Khan, A.; Chen, C.-C.; Lu, K.-H.; Wibowo, A.; Chen, S.-C.; Ruangkanjanases, A. Supply Chain Ambidexterity and Green SCM: Moderating Role of Network Capabilities. Sustainability 2021, 13, 5974. https://doi.org/10.3390/su13115974

Khan A, Chen C-C, Lu K-H, Wibowo A, Chen S-C, Ruangkanjanases A. Supply Chain Ambidexterity and Green SCM: Moderating Role of Network Capabilities. Sustainability. 2021; 13(11):5974. https://doi.org/10.3390/su13115974

Chicago/Turabian StyleKhan, Asif, Chih-Cheng Chen, Kuan-Hua Lu, Ardy Wibowo, Shih-Chih Chen, and Athapol Ruangkanjanases. 2021. "Supply Chain Ambidexterity and Green SCM: Moderating Role of Network Capabilities" Sustainability 13, no. 11: 5974. https://doi.org/10.3390/su13115974

APA StyleKhan, A., Chen, C.-C., Lu, K.-H., Wibowo, A., Chen, S.-C., & Ruangkanjanases, A. (2021). Supply Chain Ambidexterity and Green SCM: Moderating Role of Network Capabilities. Sustainability, 13(11), 5974. https://doi.org/10.3390/su13115974