1. Introduction

Prefabricated buildings can be traced back to 1940, which refers to buildings built with elements produced in the component production factory and then delivered and assembled at the construction site [

1]. Prefabricated buildings have advantages of high construction efficiency, being cost-saving, and environmentally friendly. Owing to the sustainable development strategy, the Chinese government has issued relevant policies to promote the reform of the construction industry, and local governments at all levels have shown active support. As a result, a large number of prefabricated building element suppliers have come into the market accordingly. Nowadays, making an optimal choice among the numerous suppliers to maintain a safe and stable construction, to save the cost to the greatest extent, and to cooperate with future construction projects for a long time has become an urgent issue in China’s construction industry.

Construction with prefabricated components is considered an efficient method to improve productivity and construction efficiency [

2]. However, without proper management and planning from the beginning of the construction element supplier selection, the investment risks are likely to occur, which is not conducive to the sustainable development of construction enterprises [

3]. The current research on the selection of prefabricated construction suppliers is still at an early stage [

4]. By investigating the relevant literature in recent years, most of the research on supplier selection focuses on manufacturing, logistics, and agricultural economy. The selection of building components suppliers is relatively rare [

5].

The comprehensive evaluation of assembly building suppliers can be analyzed jointly from the method and multi-dimensional factors. The use of multi-dimensional system indicators in the analysis method will make the results more scientific. There are many methods for the use of establishing a comprehensive evaluation system, including the sensitivity analysis method of grey system theory [

6], cluster analysis method [

7], analytic hierarchy process [

8,

9], fuzzy comprehensive evaluation method [

10], rough set analytic hierarchy process [

11], and factor analysis method [

12], etc. Although the above methods introduce the uncertainty of factors in the analysis, there is no random and objective evaluation of the influencing factors of supplier selection. To overcome the shortcomings, the structural equation model was used in this paper. The advantage of the structural equation model is that it combines the statistical results with the hypothetical relationship to verify and estimate the logical relationship between factors, which overcomes the shortcomings of the above methods. Chang [

13] used an SEM model to analyze the safety risk mechanism of prefabricated building construction, conducted analyses from the aspects of personnel, management, and mechanical technology, and quantified the index system to determine the biggest risk factor in a project. Li [

14] used SEM to quantitatively evaluate the impact of investment risk of prefabricated buildings and made suggestions on avoiding the most influential factors. Hong et al. [

15] have characterized and quantified the factors of construction equipment shutdown based on SEM and strengthened the management of key risks. Wei [

16] studied the management mode and supply chain of congregate apartments, analyzed the problems existing in the development of the supply chain ecosystem, and provided corresponding suggestions. Huang [

17] established a performance evaluation model in the supplier research of prefabricated building elements, which provided ideas for the sustainable development strategy of prefabricated buildings. Cheng studied the difference of concrete rates for prefabricated elements and reduced the subsequent cost of construction projects in terms of the economy [

18]. Zhao took the fabricated buildings constructed with the regular mode in Hefei as an example, analyzed the strategic objectives of traditional cast-in-place buildings, and found it has a serious pollution problem, which makes them unsuitable for sustainable development. In contrast, he expounded the comprehensive economic benefits of the prefabricated buildings and put forward a comprehensive benefit evaluation model, which theoretically supported the sustainability of prefabricated buildings [

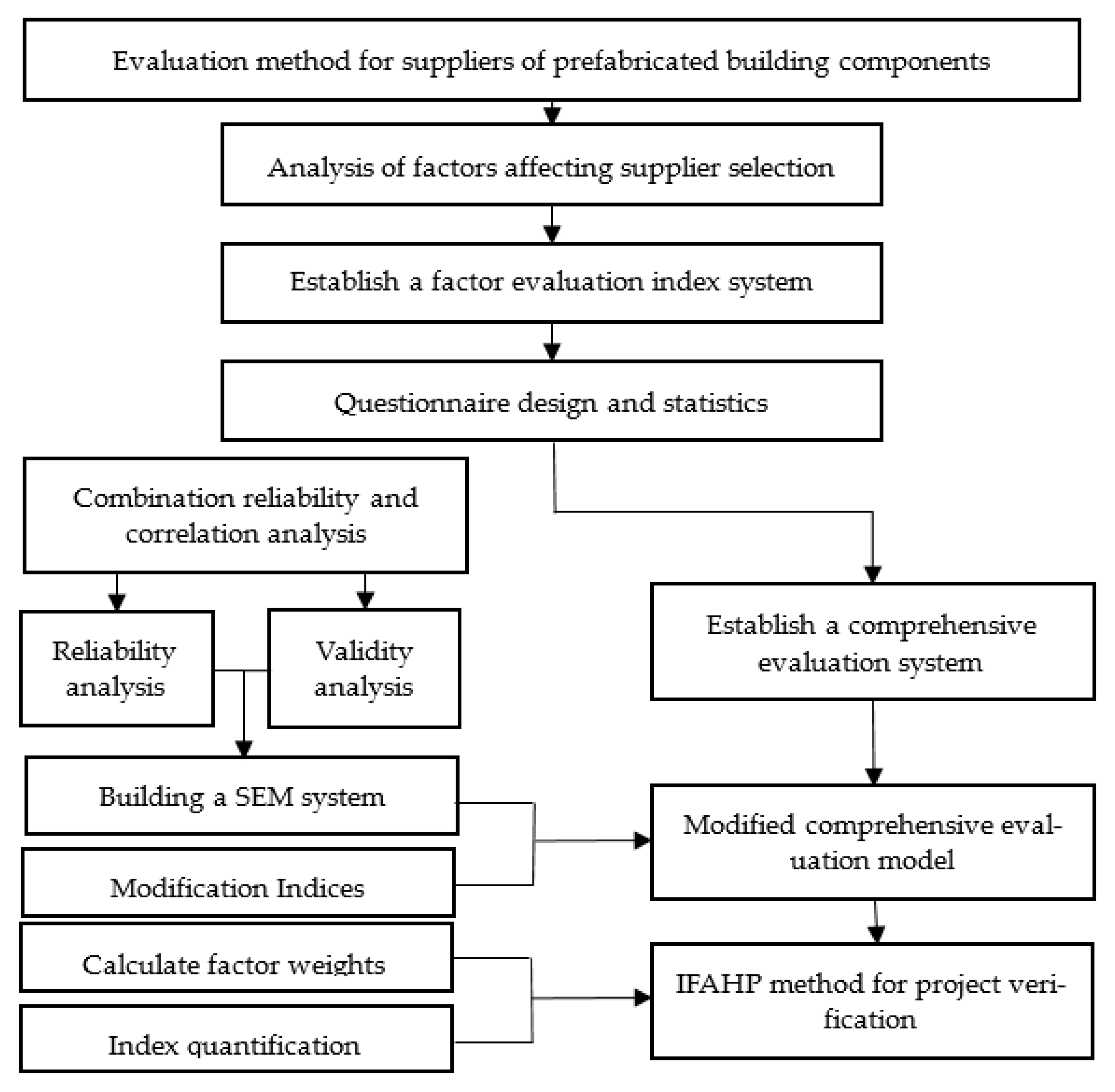

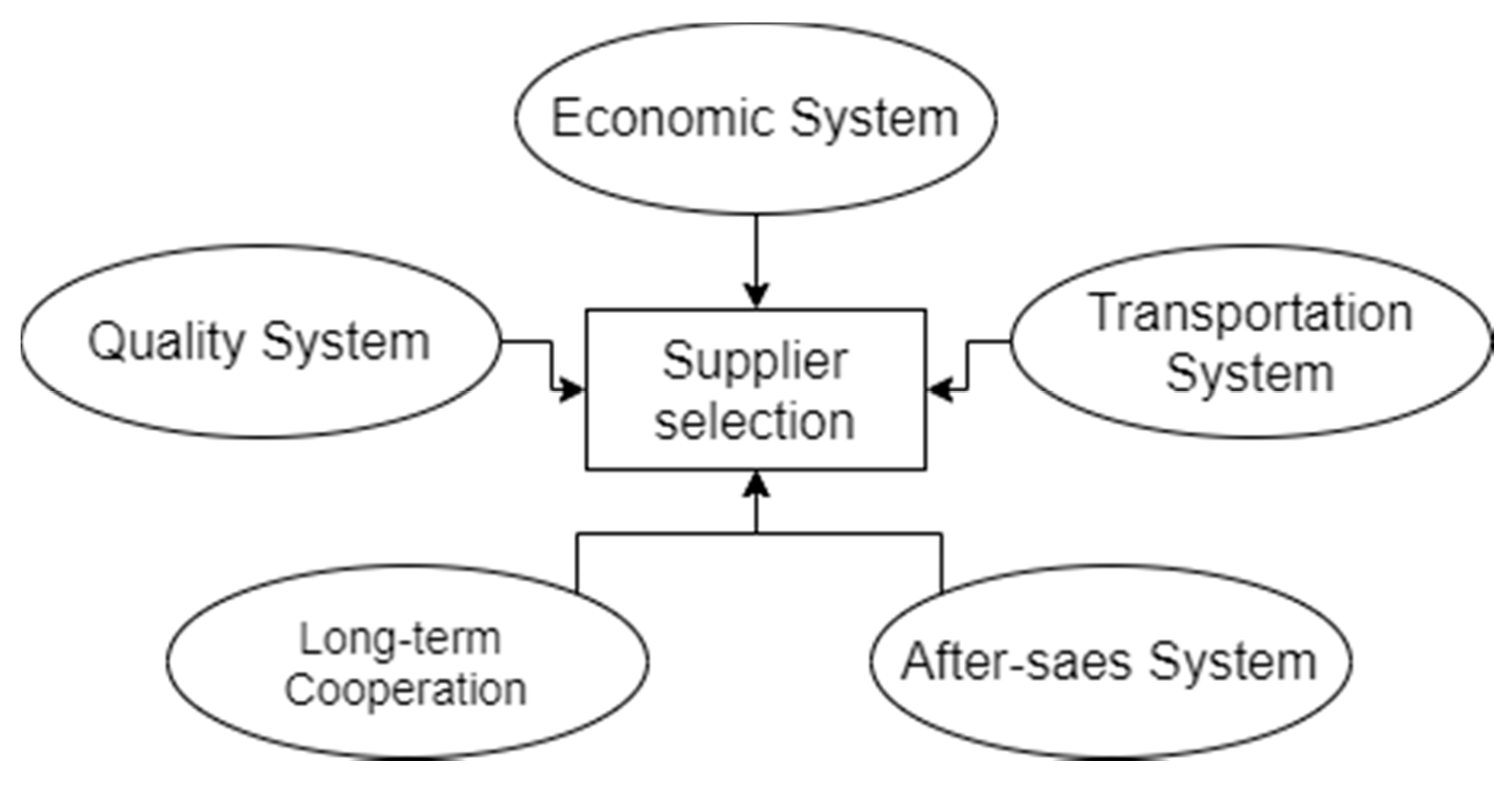

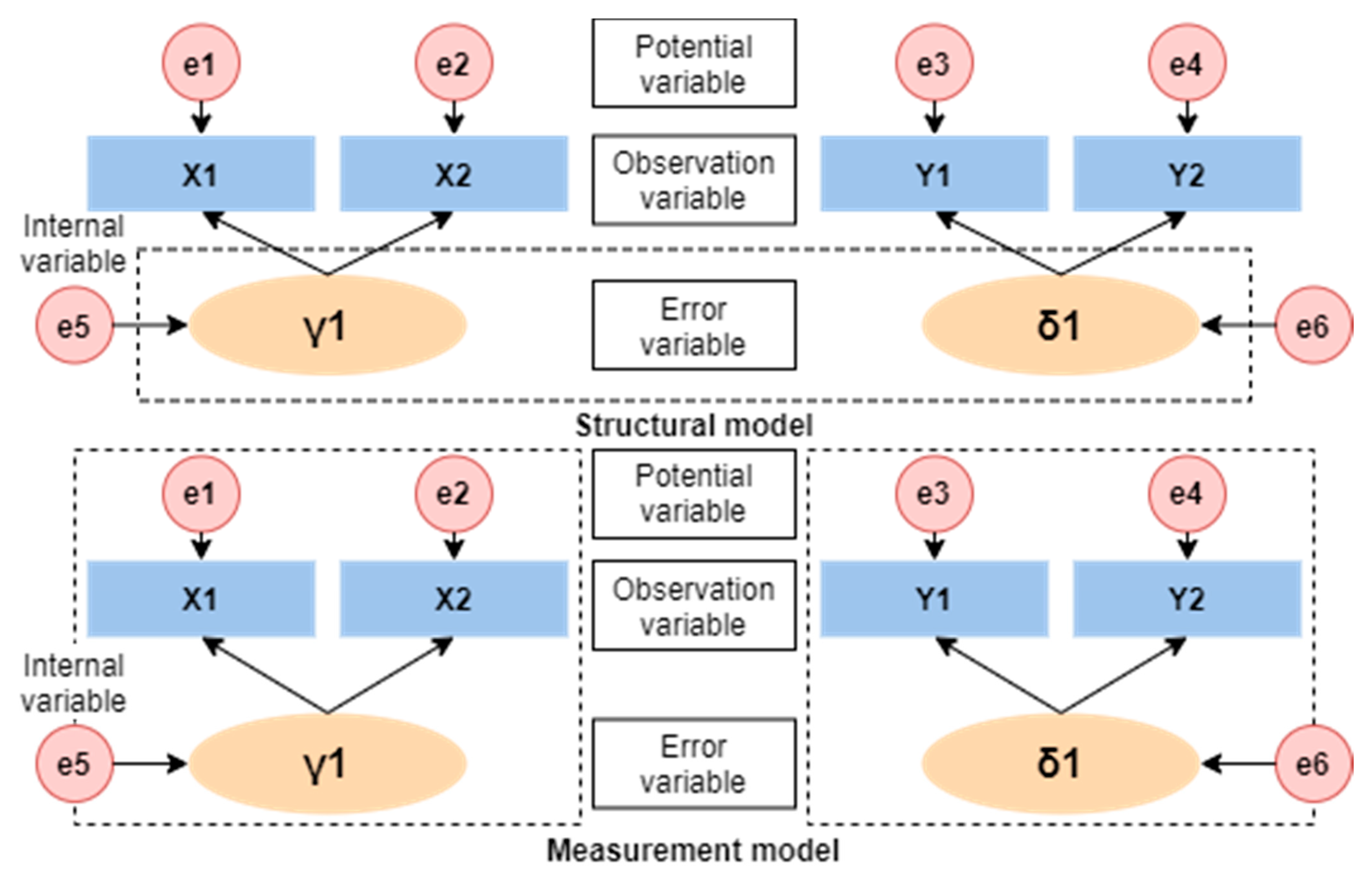

19]. According to the review of previous investigations, it is found that the research on the development of prefabricated buildings is mostly based on the existing political factors, economic factors, management factors, etc., and therefore can only take care of the existing problems. Different from previous studies, this work regards time as a factor of sustainable development and takes care of the problems in the follow-up long-term cooperation and building operation stage. On the analysis of selecting the prefabricated building element suppliers, the affecting factors covered the aspects from quality, technology, economy, and management to long-term cooperation.

In summary, when selecting a prefabricated building element supplier, various aspects need to be taken into consideration. First, a risk assessment (RIA) is needed, which helps to analyze the source of fabrication risks and economic risks in the construction process of prefabricated buildings, as well as the common mistakes in the long-term follow-up cooperation [

20]. Zhang et al. effectively combined the risk problem with the mathematical model [

21]. Nevertheless, many investigations focusing on supplier selection management are mainly based on decision theory combined with actual engineering experience and only give decision evaluations for the short term, which makes it hard for construction enterprises to find long-term cooperative suppliers. Therefore, for the selection of element suppliers, the key is to highlight the risk source for the whole process, starting from production and installation to the later operation stage, and establish a comprehensive evaluation index system for construction enterprises to comprehensively evaluate the suppliers. In the process of production, construction, and long-term operation of the prefabricated elements, this study explores the potential relationship between various indexes in the evaluation system of element supplier selection, establishes the relevance model, and constantly modifies it in the process of verification. The relevance degrees between different factors were highlighted, which fed back the evaluation system. In response to the problems found in the research process, this research will further discuss and put forward guiding suggestions.

The purposes of this study are as follows:

(1) To establish a comprehensive selection index system for sustainable cooperation between the construction company and prefabricated element supplier.

(2) To clarify the hidden correlations between latent variables and optimize the structural equation model.

(3) Use the SEM-IFAHP method to select sustainable prefabricated building element suppliers for Shuangyashan prefabricated construction companies to achieve maximum economic benefits.

4. Discussion

The purpose of this study is to find and verify the potential influencing factors of supplier selection of prefabricated building elements. The results show that there are relative independence and causality among the influencing factors. In order to make the research results more practical, here we do the following discussion

The factors that affect the economy of the prefabricated construction project come from the whole process of elements from production to operation and maintenance. Therefore, the best supplier should have the ability to properly handle any problems arising from the process.

When comparing the standardized values of the first level indicators, the maximum value is 0.892, the minimum value is 0.552, and the value of the standard distance is less than 0.5. Considering the relationship between SEM mediating effect and hypothesis in this study, we can conclude that economy, quality, transportation, after-sales service, long-term cooperation, and other factors are independent in the whole supplier selection process. This finding is consistent with the research of Yang (2001) [

20]. In the study of supplier selection, risk identification should be carried out for the whole life cycle of components.

In the calculation results of the first level indicators, it is found that the weight value of the quality system is the largest.

Therefore, in the process of supplier investigation, more attention should be paid to the quality of prefabricated elements. After calculating the weight of secondary indicators, it is found that the weight values of qualified rate and return rate are almost the same. In addition, 67.2% of the employees working in construction enterprises think that the impact of return rate is higher than that of qualified rate on the quality system. Based on the investigation and analysis of this special phenomenon, it is found that, under the policy requirements of the Chinese government, some suppliers may temporarily improve the production quality during quality inspections, but choose to save the material cost in daily production, thus reducing the quality. This causes some suppliers with the highest qualification rate to face return events in actual projects.

The recovery rate determines whether the project schedule is delayed, whether the transportation cost is wasted, and whether there will be disputes in the future contract documents.

Therefore, in the investigation and evaluation of supplier quality system, we should comprehensively consider the product qualification rate, return rate, quality management level, and other indicators [

25]. In case of any abnormality in the sample data, the supervision and analysis of the product delivery should be carried out.

In the second cost system, cost is the only principle throughout the supplier selection strategy, which is affected by various factors. The weights of the secondary indicators of the economic system are 0.068, 0.063, 0.079, and 0.062, respectively, and the average difference is not more than 0.01. Therefore, in the stage of cost control, the superimposed cost caused by other factors should be considered, which is also consistent with the research of Ilqbla [

22]. One proposed suggestion is to count the price fluctuation of suppliers’ products in recent years to avoid economic disputes during cooperation.

In the studied case of this paper, the weight of the relationship between enterprises and suppliers is relatively high. In the second level indicators of long-term cooperation system, the weight value of supplier enterprise management factor reaches 0.064, which is twice the weight value of enterprise financial level factor. When evaluating the long-term cooperation of suppliers, the management level of enterprises should be considered. A good enterprise organizational structure can ensure that suppliers can develop better even in the face of financial crisis [

54].

Supplier’s customer service can play an important role, but it is often ignored. Most companies only consider the cost and quality of products when choosing suppliers. Once there are various levels of risks, without the follow-up technical support from suppliers [

16], the construction is likely to be delayed. This study analyzes the after-sales service of suppliers and introduces relevant factors into the index system to reduce the possibility of conflict between construction enterprises and suppliers in terms of legal and economic risks. The weight values of secondary indicators in the after-sales service system are evenly distributed, and the average difference is not more than 0.01. The results show that, when the supplier has advantages in any aspect of the after-sales service system, the service quality of the other aspects will also be higher. In the investigation of after-sales service system of suppliers, a unified decision can be made (Russell, a, F, 2003) [

33].

In addition, according to the mediating effect found in this paper, transportation risk can also significantly induce project economic risk. According to the path coefficient of the SEM model, it can be found that the path coefficient of traffic violation rate and delivery reliability is 0.15, showing a positive correlation trend. When it comes to legal issues, transportation problems will not only lead to construction delay, but also face high government fines (Liao, Shu Hsien, 2021) [

55]. In addition, that delay depends on the efficiency of the local government. Therefore, when selecting a supplier, in terms of transportation, it is necessary to verify the violation rate of drivers in recent years. If there is transportation risk, the supplier should be able to quickly deliver another batch of goods. In the process of supplier selection, we should strengthen the review of supplier’s route planning and product flexible scheduling ability, so as to minimize the risk of construction delay.

5. Conclusions

5.1. Theoretical and Practical Contributions

Compared with the traditional building mode, the fabricated building mode has the advantages of less pollution, faster construction speed, saving labor work and being economical, and is consistent with China’s sustainable development strategy. The findings of this study have theoretical and practical contributions to academic research and engineering practice.

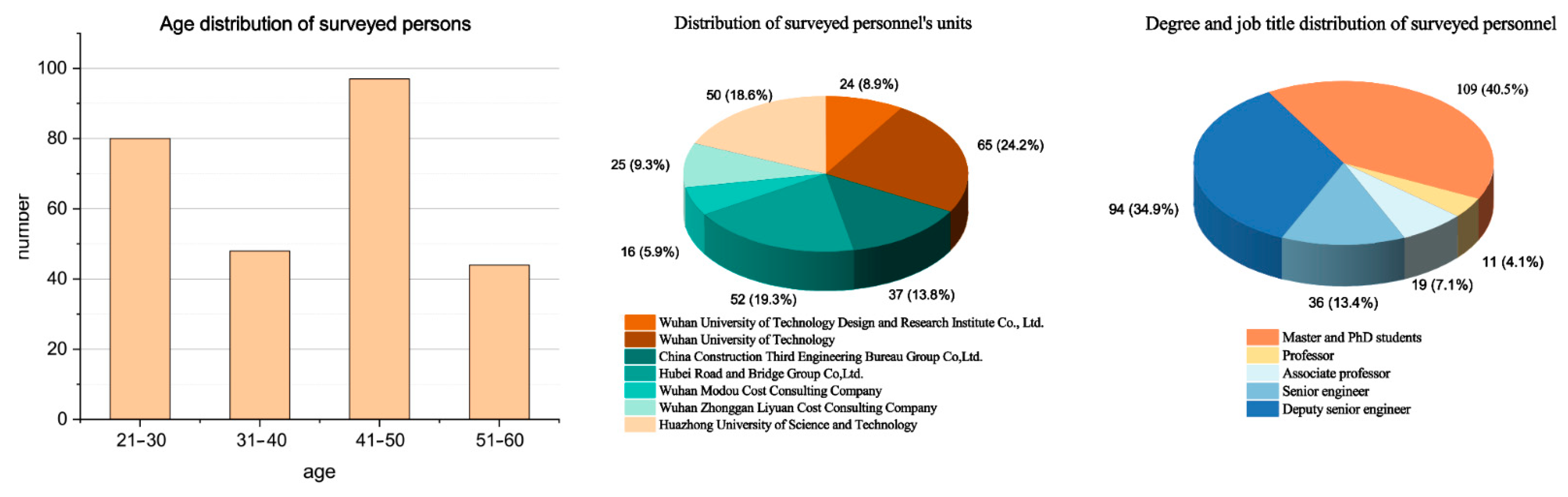

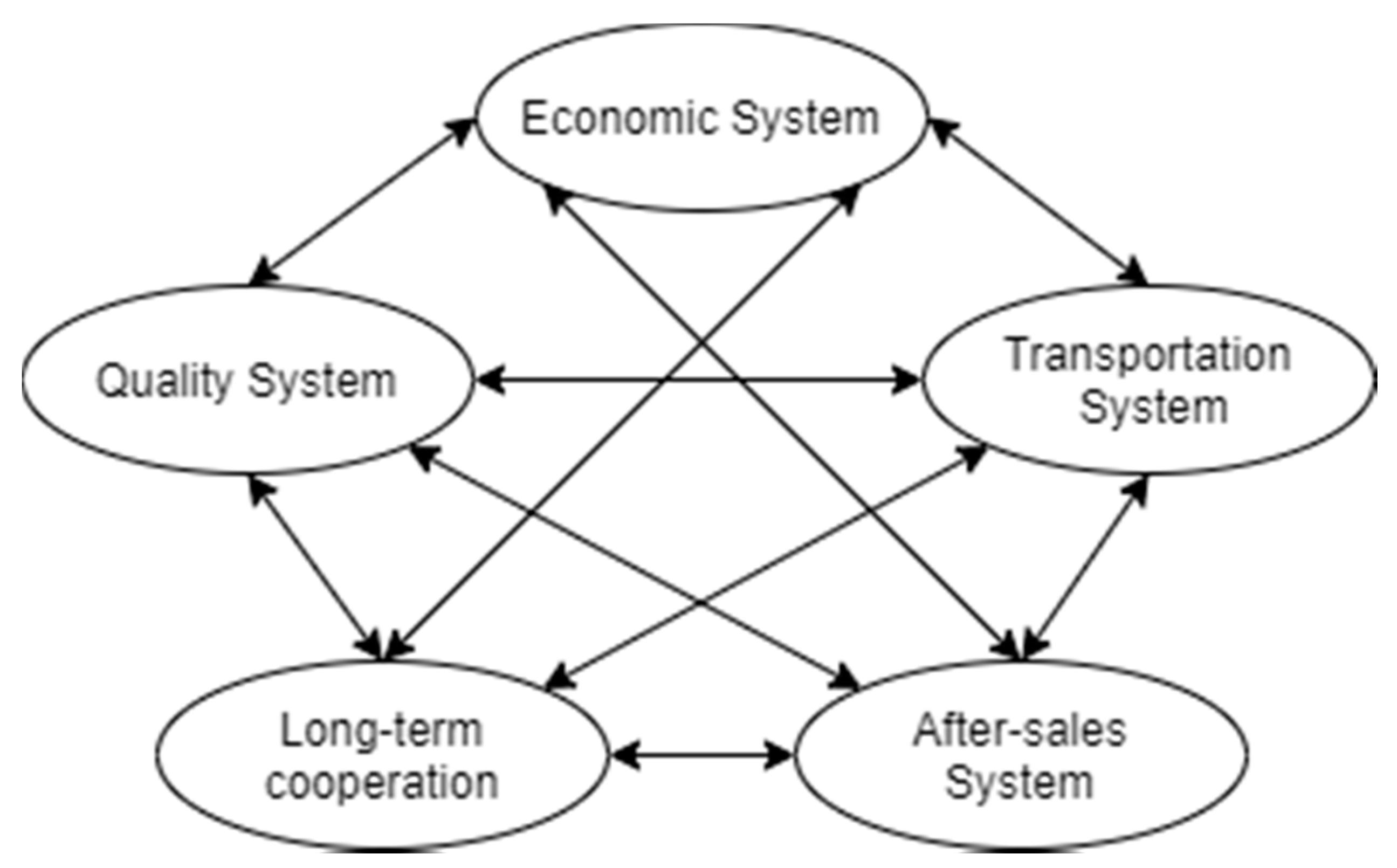

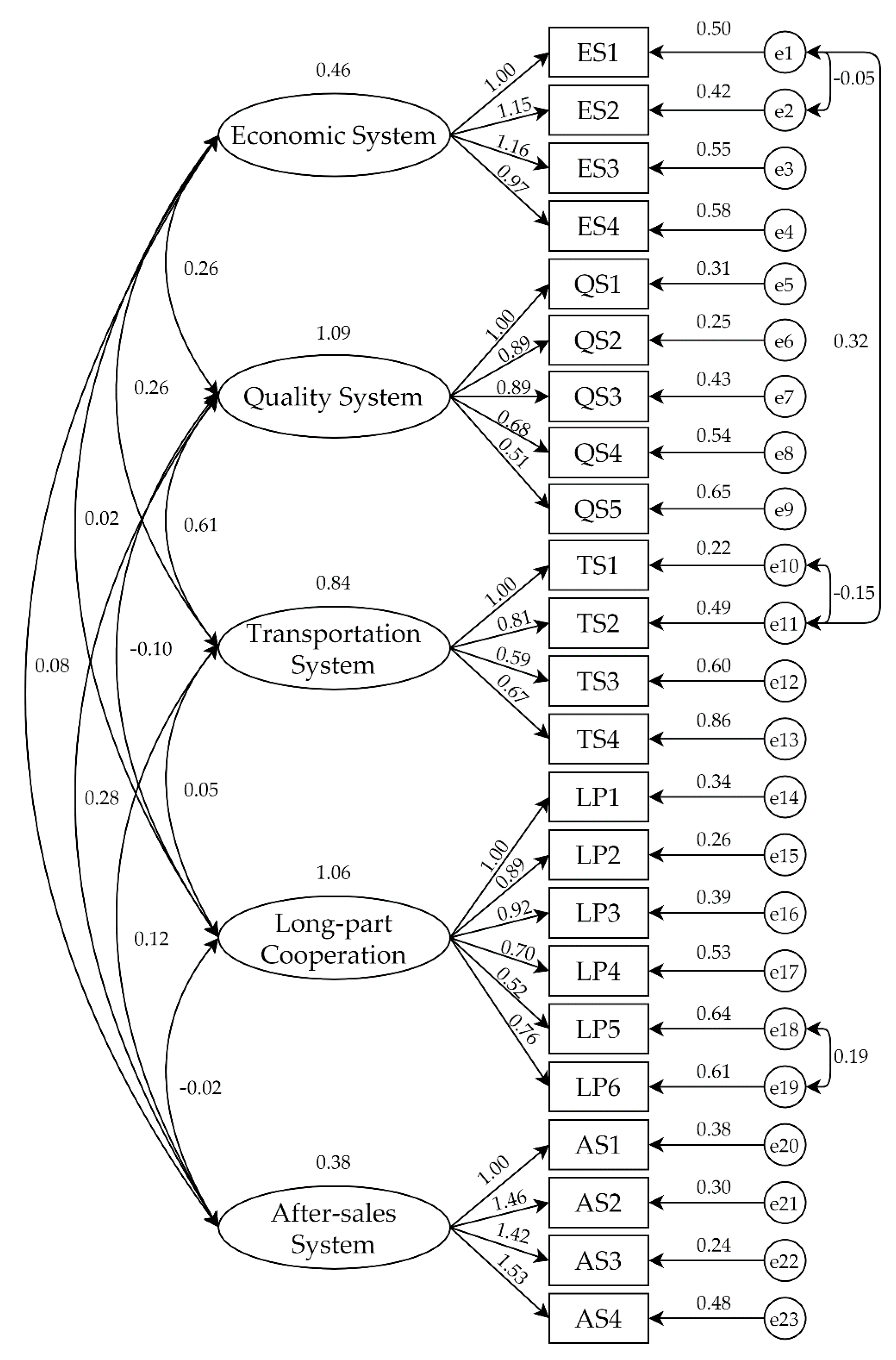

Theoretically speaking, this study introduces the concept of the whole life cycle of prefabricated elements, that is, from the production stage to the operation stage, all aspects of the possible risks of prefabricated elements in the whole life cycle are considered. As the main theoretical contribution, this study first identified five potential variables and 23 observed variables, which have a significant impact on the selection of component suppliers. Secondly, a comprehensive evaluation factor system suitable for Chinese construction enterprises to choose prefabricated building element suppliers is established, and the SEM model of prefabricated element supplier selection is constructed. Thirdly, through the analysis of the MI value and PC value, the SEM model of supplier selection is modified, and the capability of suppliers in all aspects is evaluated with IFAHP method. The evaluation rules are taken from the supplier evaluation index system of this study, which provides the optimal options and suggestions for the Shuangyashan prefabricated construction project to select the appropriate element suppliers. The research results also provide guidance for the selection of suppliers for similar projects in the future.

From the practical point of view, according to the calculation results of SEM and IFAHP, the research provides important practical significance. First, there are potential links between the factors in the index system, especially the quality system and the transportation system. For example, it is suggested that construction enterprises should not only pay attention to the qualified rate when investigating the quality of suppliers’ products, but also the return rate, so as to prevent some enterprises from using special methods to improve the qualified rate of their products. Second, problems in the transportation system can also affect the supplier’s economic system. When reviewing the supplier’s information, we should pay attention to the intermediary effect between factors and pay attention to the supplier’s financial report.

Finally, this study avoids the problem in which the overall decision-making results are easily affected by individuals and considers the economic problems of subsequent projects of the same enterprise, which will greatly save on the future economic and labor costs.

5.2. Limitations and Further Suggestions

Although the purpose of this study has been achieved, there are still some limitations.

(1) In the questionnaire survey, although the respondents are widely distributed, most of them are in Wuhan area, and their evaluations of enterprises in other areas may be too subjective.

(2) The Chinese government has incentives for prefabricated construction projects, making some results unsuitable for other countries.

Although there are the problems above, the combination method between SEM and IFAHP is proved to be scientific and reasonable through the case study, so the research in this paper is still valuable.

In order to make this research more practical and sustainable, it is necessary to classify policies and regulations in different regions so as to make the evaluation system more comprehensive and make the application of SEM-IFAHP wider.