4. Discussion and Conclusions

This section summarizes the key findings regarding the calculation with an emphasis on (i) the limitations and potentials, and (ii) the results and impacts of a lithium ion battery and its life cycle stages. Later, it concludes with a look at (iii) the future research agenda.

- (i)

Calculation of impact: limitations and potentials

Challenges of resource scarcity can be met by using products, components and materials in multiple life cycles instead of a single life cycle if EoL scenarios and life cycle extensions are environmentally and economically valuable. In order to estimate the environmental impact of a product, such as a lithium ion battery, an LCA can be conducted.

Within this paper, three limitations of LCA regarding multiple life cycles were identified. First, an LCA is valid for rigid system boundaries and for a single use case. In general, it accounts for a single life cycle of the product, neglecting the multiple uses, especially in different applications. Second, for the consideration of the overall environmental impact, it may be disadvantageous that a sensitivity analysis cannot simply be performed, due to the rigid system boundaries. Therefore, the analysis needs to be recalculated for the changed parameters. Especially, the variation in the use phase can strongly influence the overall result. In reality, however, products are used differently to satisfy the requirements of various customers. Third, concerning multiple life cycles, both the impact of the process as well as the location, where it is performed, should be possible to interpret: 2nd life loops are characterized by uncertainties about the amount, the location and the demand for products. Therefore, more cases, such as the type of 2nd life application, its market share or the locations for reprocessing and distribution, are possible compared to the forward oriented production and distribution. The results of the LCA are stated in units as the CO2 eq., which combine the impact of both processes and location. On the one hand, it simplifies the interpretation of the impact for the calculated case. On the other hand, it limits the ability of the interpretation of the impact of processes and location to identify the main influence factors.

Resulting from the limitations of an LCA, three requirements have to be met: (A) in contrast to an LCA, the functional unit of the approach has to enable the comparison of multiple applications, as the function of a 1st and 2nd life application may differ; (B) the approach has to be easily adapted to different use cases to reflect reality as best as possible; (C) the results have to be location-independent in order to enable an impact analysis of the processes.

Based on the requirements from (A) to (C), a meta study is designed to demonstrate an LCA-complementing approach for 2nd life applications. A mathematical algorithm presents the calculation of energy demand for a case considering a product in multiple life cycles. It uses values from previous LCA studies, simplifying the effort of use and allows the estimation of the magnitude of the individual processes and to identify the main influencing factors.

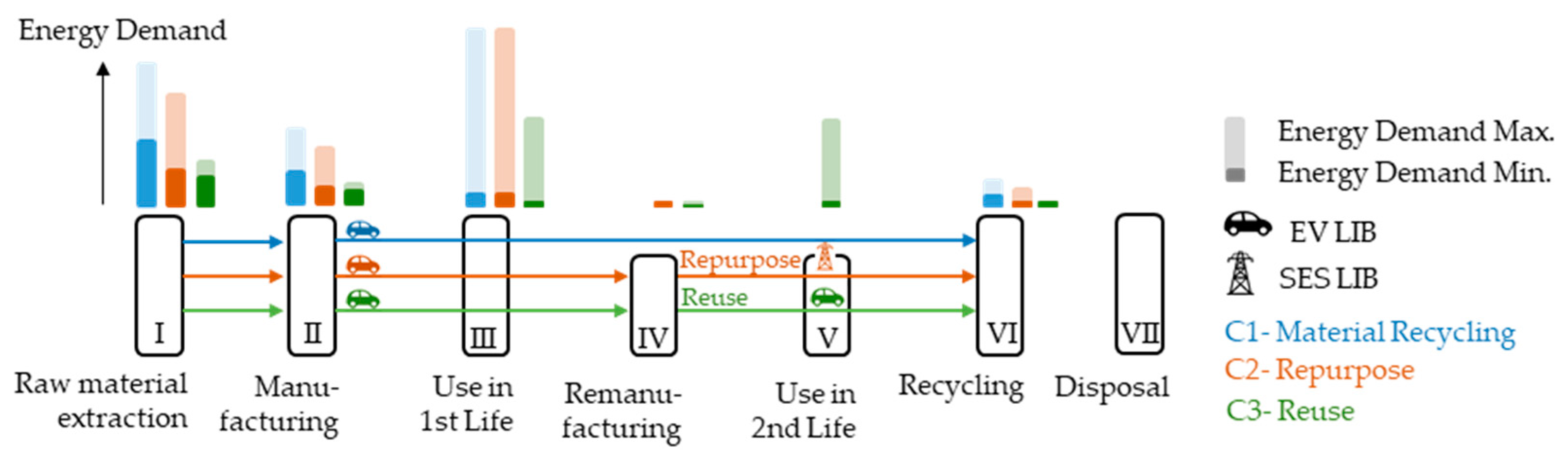

The algorithm is based on LCA-values as inputs. However, LCA studies are not available yet for all life cycle stages of a lithium ion battery. LCA studies with primary data exist only for the stages (I) raw material extraction, (II) manufacturing or (VI) recycling. Each study uses unique assumptions, different process boundaries and a specific way to present values and results. Existing values are converted into comparable units and areas of application. For the stage (IV) remanufacturing, no quantitative data could be found. The value for remanufacturing is estimated based on the general definition of the remanufacturing process and the energy demand for the comparable subprocesses stated in the LCA studies on manufacturing processes. It accounts for approximately 26% of the energy demand for the manufacturing process, saving accordingly 74% of the energy. This value gives a first estimation of the energy demand for the remanufacturing process as no calculation, experimental or experience value, and an exact definition of the process for a lithium ion battery exists. Further research on the technical feasibility of the processes combined with statistics on the expected state of health and longevity of a used battery will enable the validation of the proposed algorithm.

The state of health is particularly important for the determination of the use stage. The maximum life time or range of a battery determines the demand on units over a time period for a defined use intensity. This demand determines the amount of batteries to be produced and the energy demand in the considered time period.

- (ii)

Impact of a lithium ion battery and its life cycle stages

The impact of a lithium ion battery was calculated based on three cases: C1—production and recycling on LIBs; C2—production of new batteries for electric vehicles (EV LIB) and repurposing them into stationary energy storages (SES LIB); C3—remanufacturing the EV LIB and reuse again in electric vehicles.

Case C1—recycling discusses the ratio between the (III) use stage and stages (I) raw material extraction, (II) manufacturing and (VI) recycling. The results show that, dependent on the use intensity, this ratio accounts from 20% to 90%. As there exist different car users in real life, both the product, influencing stage (III), as well as process efficiency, influencing stages (I, II and VI), should be improved and researched in more detail.

Case C2—repurpose estimates the energy savings for the case, where the EV LIBs are remanufactured and repurposed to SES LIBs. This case requires the least amount of energy, saving up to 40% compared to C1—recycling.

Case C3—reuse highlights the influence on the expected life time of a battery. In the calculation, the assumption for the calendrical lifetime of a remanufactured battery for the reuse in electric vehicles is approximately six years. In the considered time span of 20 years, this means that for rarely used vehicles three (one new and two remanufactured) instead of two (new) batteries are needed. This higher demand for batteries implies no savings in energy demand. Further, the calculation assumes the maximum range of a remanufactured battery to be 120,000 km. This value is considered to be constant, regardless of the intensity of use. However, as explained in

Section 2, the use intensity has a significant influence on the ageing behavior of a battery. Nevertheless, this assumption simplifies the calculation. Adapting and specifying them for different areas of use intensity can provide new insights into whether and when reuse is appropriate. However, the aging behavior of 2nd life batteries remains insufficiently understood.

With the new method, the question of which treatment after the 1st life should be preferred, can be considered in more detail due to new findings. For example, in a certain case, the results of an LCA can indicate that the use of reprocessed products for the same application, meaning with the same function, is not reasonable. Then, the new method can be used to check to what extent the use in other applications, considering other functions, is reasonable. Further, by taking calendar aging into account, the results can be more closely adapted to real-life situations. This means that the method presented can additionally be used to check whether the frequency of the function assumed in the LCA can also be realized by the product. One example described in the paper is the use of a car for a long period of time for very low ranges. The influence of calendric aging is higher than the influence of functionality. This relationship is not considered in an LCA and is complemented by the method presented here. The presented method adds new perspectives to the results of an LCA. It does not claim to replace them.

- (iii)

Future research agenda

The aging behavior and the corresponding state of health of a 2nd life battery can be determined by practical tests and theoretical considerations such as energy intensive tests, including multiple charging and discharging, or post mortem analysis. A continuous condition monitoring for batteries with a capacity lower than 80% of their original capacity, or for remanufactured batteries, which have a higher capacity due to the exchange of single cells, is not possible yet. Further, sufficient data for this case are missing.

Theoretical considerations may lessen the practical test intensity. One possible solution is the evaluation of the exact history of the battery, for example by means of a battery log or passport. However, due to the large number of stakeholders involved during the life cycle of the battery, data storage becomes a challenging task for 2nd life applications. Further, due to possible conflicts of interest, the free use of these data will hardly be possible in the near future. A battery passport or data storage with new technologies, such as the blockchain, offer possible solutions. Nevertheless, these data should be applicable down to the module or cell level in order to enable the continuation of the data in further life cycles.

However, if it is assumed that the exact history of the battery will not be freely available, further approaches can be considered. Service providers of overall equipment manufacturers (OEMs) such as remanufacturing companies or contracted logistics companies have, on the one hand, experience data on the state of health of their take-back products and, on the other hand, some information on the previous owners. These data do not refer to the specific characteristics of a single battery, but to the characteristics of the delivery from a particular customer. For example, the location, with its climatic parameters, can affect the condition of the battery. In order to determine a probability for the expected condition of the battery batch, for example based on its origin, methods of artificial intelligence such as machine learning can be used. This assessment can help to carry out the required practical tests in a more targeted manner and thus reduce the energy requirement for them. This would further lessen the impact of remanufactured batteries and increase the potential for a 2nd life.

As shown in the case C3—reuse, the expected life time and range of a battery have a significant influence on the total energy demand over a time period. In this context, it was considered that a battery is used until a specific state of health, which does not allow further use in this application. Neither the technical feasibility, nor the market characteristics, such as the availability of comparable battery types, was considered. These aspects must be investigated separately.

The availability of comparable battery types for their remanufacturing may be a challenging task as the technical progress of batteries is very fast. The exchange of new batteries, available in the market in large quantities, may reduce this problem. Nowadays, the majority of users lease electric vehicles from the OEMs or their third parties, and the batteries remain the property of the distributor. This ownership enables new business models, such as battery pooling. These can be implemented, among other things, thanks to a network of battery exchange stations, where an empty battery is exchanged against a fully charged one. The empty battery can be checked for its condition and, if necessary, remanufactured at an early stage. This application would combine the stages (IV) remanufacturing and (V) use in 2nd life in a new manner. On the one hand, the lifetime of a battery could be extended. However, it remains unclear whether the lifetime would be as durable as the conventional one. On the other hand, the remanufacturing would occur more often, increasing the energy demand. The interaction of these two factors should be investigated in more detail.

The results of the case studies demonstrate the high potential of energy savings by implementing multiple life cycles of batteries. It has been shown that both the repurposing of EV LIBs into SES LIBs, as well as the reuse of EV LIB in electric vehicles, can reduce the total energy demand. The calculation, however, is based on assumptions that have to be verified by real cases. Especially the characteristics of used or remanufactured batteries and their handling is insufficiently known.

Future research should verify and/or revise these conclusions. The research field on multiple life cycles of EV LIBs is untapped from various perspectives. There exist many topics to investigate in the future that range from required processes over the demand or availability of the batteries to real-life applications with their benefits and disadvantages. To fully explore the potential of multiple life cycles in a battery, a broader consideration of these research fields is needed, in parallel to investigations on optimization of single processes and life cycle stages.