Mass Customisation for Zero-Energy Housing

Abstract

1. Introduction

2. Theoretical Background

2.1. Definition of Terms

2.1.1. Zero Energy

- Energy balance—the energy balance over a fixed period of time [41].

- Grid connection—position of the buildings’ energy connection to the grid [42,43]. The zero-energy balance implies a connection to an electrical grid; therefore, it really refers to ‘net’ energy. This article omits the word ‘net’ to avoid redundancy. Buildings not connected to the electricity grid, known as ‘off-grid’, offset all their energy consumption through their mediums [44].

- Metric—units used to measure energy content, with kWh being the most used in the operational domestic context [45];

- Balancing period—the period over which the energy balance is calculated or measured [28]. The energy calculations adjust to established time spans. Annual calculations are the most commonly used.

- Balance type—criteria used to verify the energy balance determined by the building boundary, energy generators, and energy consumers [46].

- Energy usage coverage—zero-energy standards usually omit gas in the energy equation as it is not possible to produce gas within the domestic realm to generate a balance and focus only on electricity.

- Generation type—the ways of generating energy. Carbon-free processes, or renewables balanced with carbon-based prime sources. Most energy standards contemplate all electricity imported from the grid as carbon-charged.

- Spatial boundary and generation location—the point where the building interacts with the electric grid usually matches where the meter locates.

2.1.2. Mass Customisation

- Solution space—pre-existing capability and degrees of freedom built into a given manufacturer’s production system framing the production extents of customisation. The solution space determines the universe of outcomes that a producer provides to their customers, and within that universe, specific product permutations are provided. Mass customisation does not mean to offer limitless choice but provides a choice restricted to options in the system’s capacities [74].

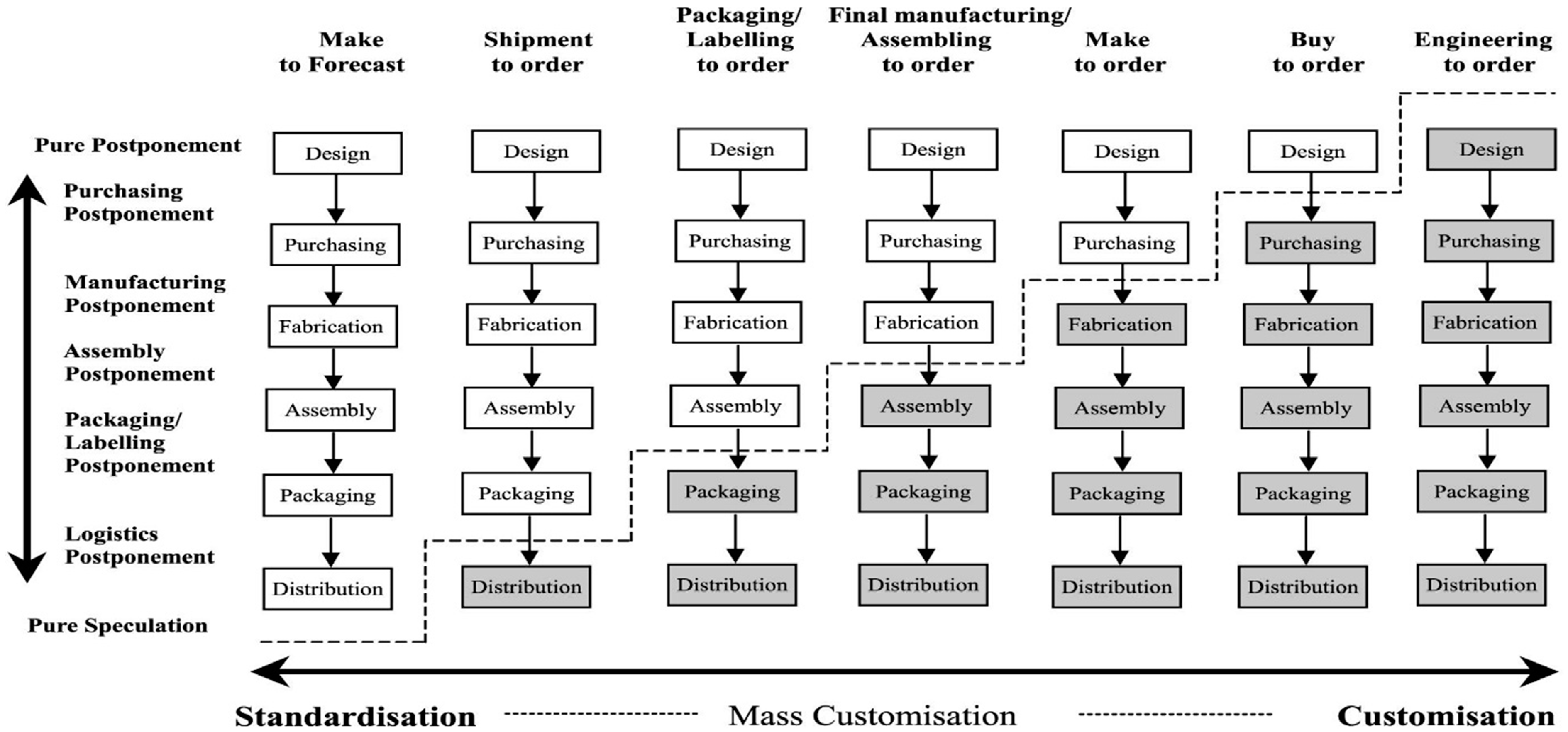

- Robust process—the capability to reuse, re-arrange, or re-combine existing organisational and value-chain resources to fulfil a system of differentiated customers’ needs [50,71,75]. A robust process can be achieved by having (1) flexible automation and modular processes which can be quickly and easily re-tasked depending on design change [76]; (2) adaptive human resources, where employees can deal with novel and ambiguous tasks to offset potential rigidities [77]; and (3) the supply chain separated into stages to postpone production and define product differentiation between fixed and flexible production stages. The point that separates decisions made under uncertainty (custom) from decisions made under certainty (standardised) is called ‘customer order decoupling point’ (CODP); its positioning in the supply chain sets the balance between productivity and flexibility [78,79,80]. The closer the CODP is from the supply perspective, the higher the customisability. Likewise, the closer to it is the demand perspective, the higher the production control, as shown in Figure 1 [55,81,82].

- Choice navigation—capabilities of a company to enable and support the customers to identify and customise their product by minimising the complexity and burden of choice. It refers to the interface where customers explore and decide on the producer offerings [83].

2.1.3. Agile and Lean Manufacturing

2.2. Mass Customisation Relation to Sustainable Housebuilding

3. The Japanese and UK Contexts

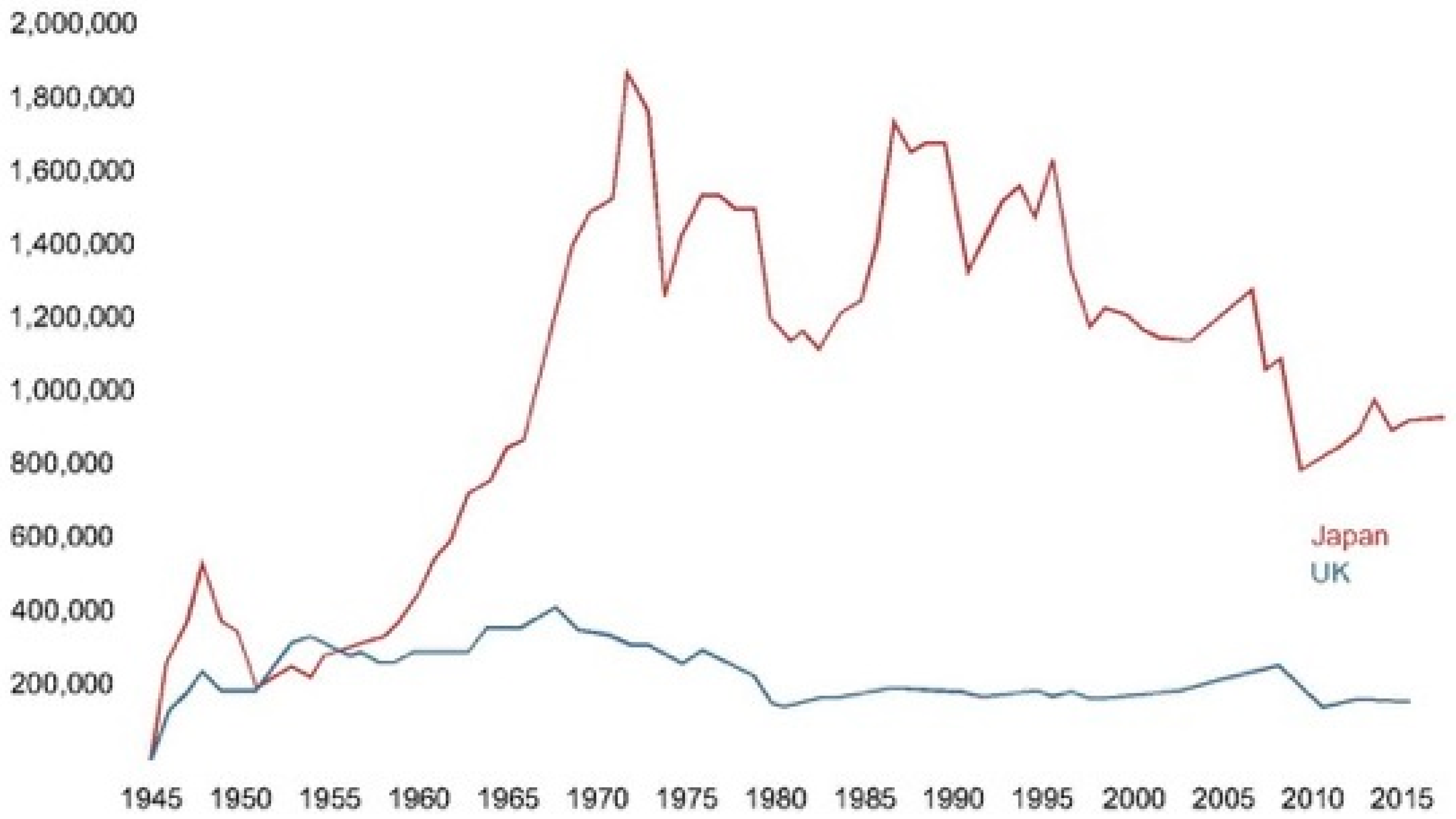

3.1. Historical Comparison of Housing from Postwar Times to the Present Day

3.2. Land Effect on Housing Processes

3.3. Planning Systems

3.4. Housing Need

3.5. Impact on Energy Efficiency

4. Materials and Methods

5. Results

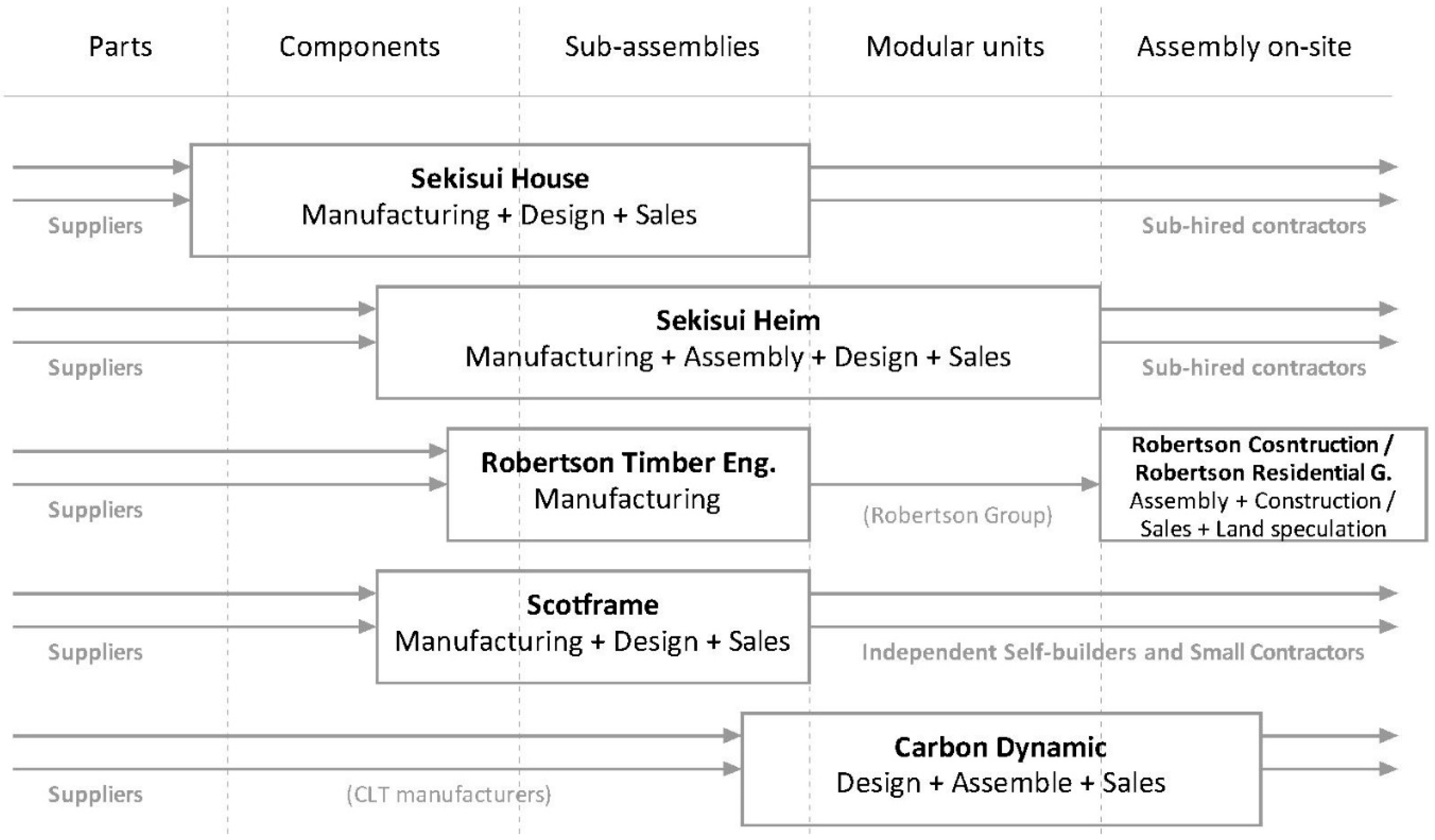

5.1. Manufacturing

5.2. Marketing, Co-Design, and Selling Processes

- Promotion—marketing strategies used to engage customers and promote the company’s values. This includes brochures, home portfolios, and visitor centres, also referred to as museums. The visitor centres consist of exhibition spaces open to the public, where companies display housing-related objects and information to reinforce their unique selling point in potential consumers. For example, Daiwa’s museum focuses on showing the company’s history, but also dedicates a whole floor to the exhibition of vernacular construction techniques around the world. Sekisui House focuses on informing customers about the importance of sustainable construction and energy efficiency (Figure 4).

- Show homes—facilities where customers can visit show homes and experience (see and touch) the offered house features. All Japanese companies possess various show homes around the country. Sekisui’s House main housing park has an area of 18,500 m2 with 21 buildings, including different show homes, prototypes, designed gardens (also on sale), screening rooms, and meeting areas. Sekisui Heim heavily populates the Japanese territory with individual show homes with design and selling agents, including show homes attached to factories (Figure 5).

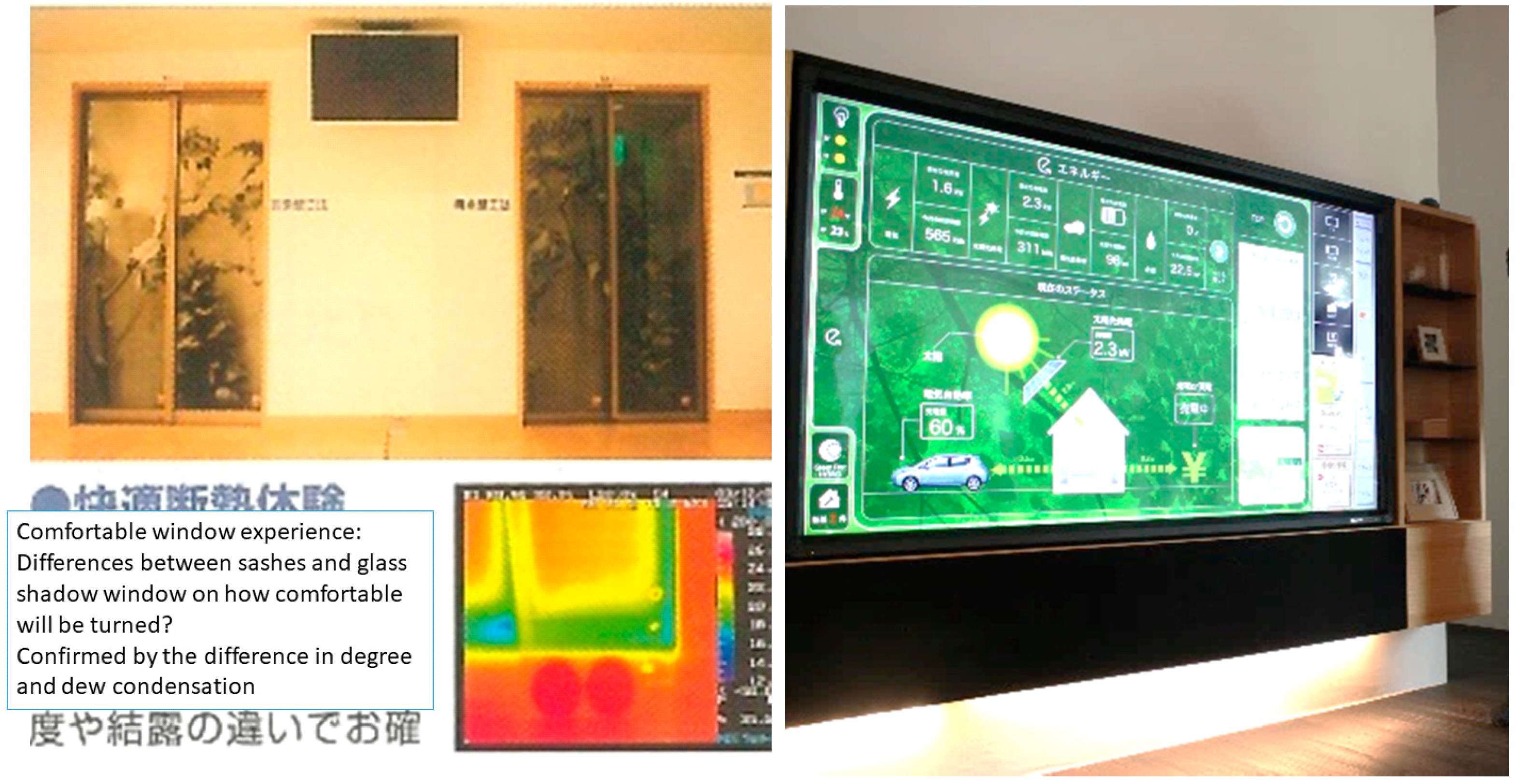

- Experience—strategies used to help customers make informed design decisions based on experiences. This consists of the accumulation of services provided to educate the customer on how the design decisions will affect the house performance, environmental impact, comfort, and maintenance cost. For example, Sekisui House has information centres with real-scale models of multiple house components for customers to understand their differences by interacting with them. It includes architectural features, such as lighting, staircases, and kitchen cabinets (Figure 6), as well as technical aspects related to energy efficiency and thermal performance, such as insulation, glazing, mechanical systems, and renewables (Figure 7).

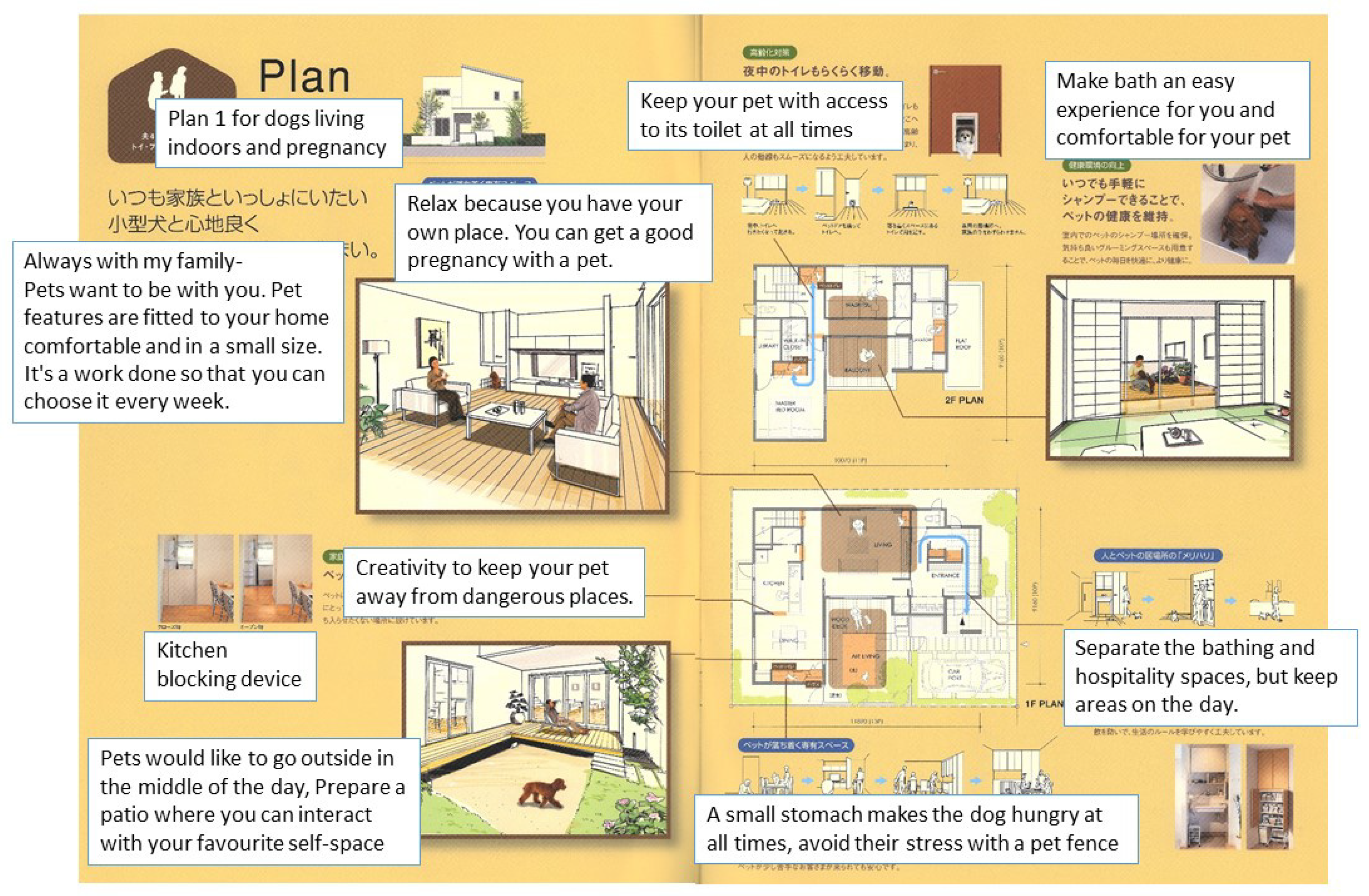

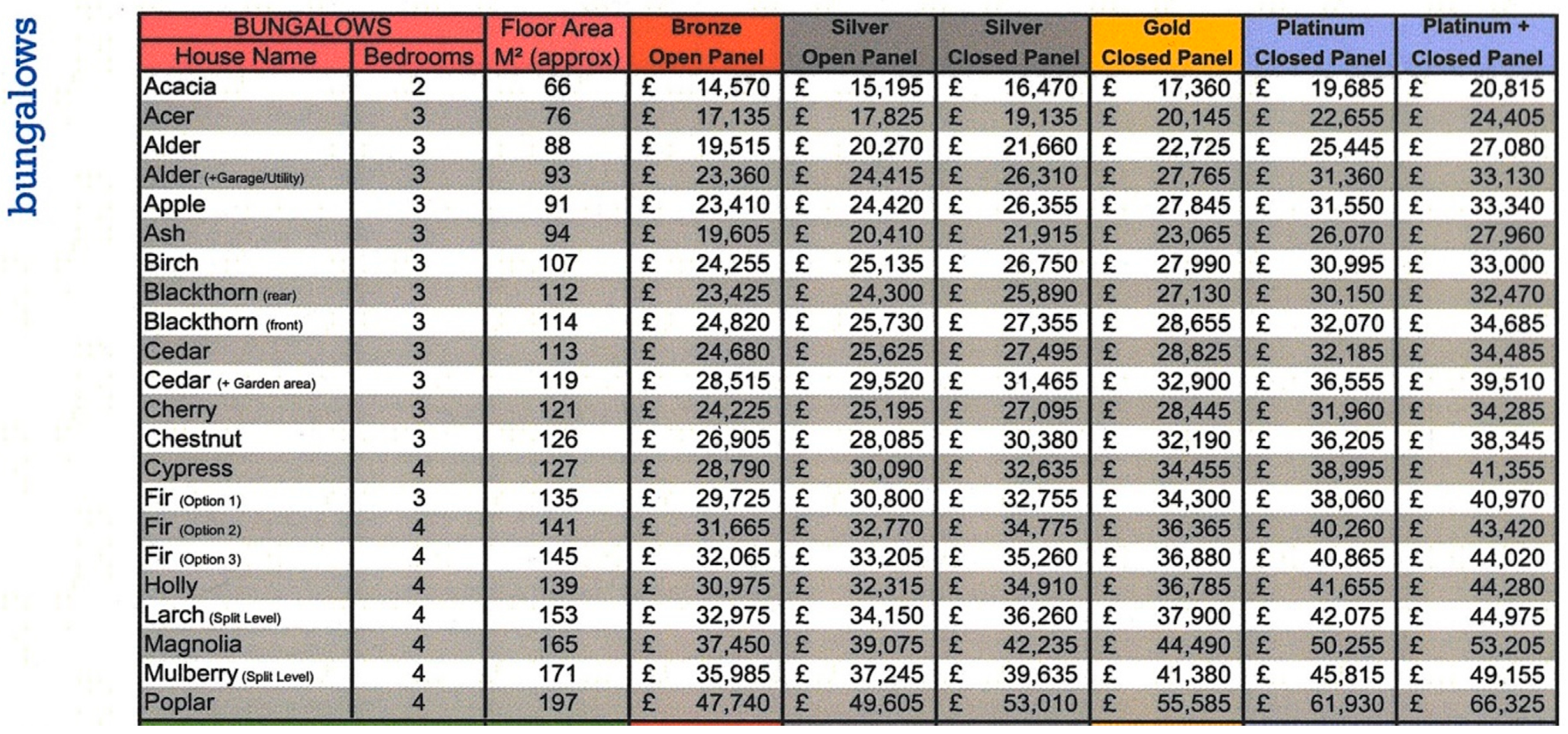

- Co-design—strategies used to extract information from the customers that represent design choices. A personal sales agent, usually an architect, is assigned to each customer for the whole designing and selling process. This process is highly linked to the ‘experience’ phase, as companies keep track of users’ preferences to imply design decisions. The agents use responsive virtual render visualisations to seamlessly show the appearance, cost, and energy and environmental performance of the expected dwellings. The co-design process takes place on several progressive meetings in which the customers decide some design aspects and take information home to decide on some more detailed decisions. Daiwa, for example, uses very informative brochures that include national data or testimonials from previous customers related to design-decisions, and how this could be adapted in future scenarios (Figure 8). They cover a wide range of potential design decisions with brochures for very particular living aspects, such as the selection of materials, appliances, and space arrangement depending on the customer’s pet breed and size (Figure 9).

5.3. Energy Efficiency Offer

‘Most clients don’t really want renewables. … They don’t also like the fact that they need to maintain them. … thermal heat pumps… it’s far too complicated for them. … Moreover, renewables are imported, so doesn’t help the economy’.

6. Discussion

6.1. Relation of Mass Customisation with Zero-Energy Housing

6.2. Adoption of Technology Is Not On

6.3. The Potential of Mass Customisation in the Context of Sustainable Housebuilding in the UK Relies on Improving the Housebuilders’ Solution Space and Navigation Tools

7. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Davis, S.M. Future Perfect, updated ed.; Addison-Wesley Publishing: Boston, MA, USA, 1987. [Google Scholar]

- Barlow, J. From Craft Production to Mass Customisation. Innovation Requirements for the UK Housebuilding Industry. Hous. Stud. 1999, 14, 23–42. [Google Scholar] [CrossRef]

- Naim, M.M.; Barlow, J. An innovative supply chain strategy for customized housing. Constr. Manag. Econ. 2003, 21, 593–602. [Google Scholar] [CrossRef]

- Lovell, H.; Smith, S.J. Agencement in housing markets: The case of the UK construction industry. Geoforum 2010, 41, 457–468. [Google Scholar] [CrossRef]

- Zero Carbon Hub. Zero Carbon Hub Compendium 2009; NHBC Foundation; Buildmark House: Amersham, UK, 2010. [Google Scholar]

- Hootman, T. Net Zero Energy Design: A Guide for Commercial Architecture; J. Wiley: Hoboken, NJ, USA, 2013. [Google Scholar]

- Guzowski, M. Towards Zero-Energy Architecture: New Solar Design; L. King: London, UK, 2010. [Google Scholar]

- Shafik, M.; Martin, P. The impact of procurement methods on the Scottish housebuilding industry. In Proceedings of the 22nd Annu ARCOM Conference, Birmingham, UK, 1 September 2006; Volume 1, pp. 81–90. Available online: http://www.arcom.ac.uk/publications/procs/ar2006-0081-0090_Shafik_and_Martin.pdf (accessed on 3 January 2018).

- Pitts, A. Passive House and Low Energy Buildings: Barriers and Opportunities for Future Development within UK Practice. Sustainability 2017, 9, 272. [Google Scholar] [CrossRef]

- Yashiro, T. Conceptual framework of the evolution and transformation of the idea of the industrialization of building in Japan. Constr. Manag. Econ. 2014, 32, 16–39. [Google Scholar] [CrossRef]

- Aitchison, M. Prefab Housing and the Future of Building: Product to Process; LH Professional: London, UK, 2018. [Google Scholar]

- Davies, C. The Prefabricated Home; Reaktion: London, UK, 2005. [Google Scholar]

- Noguchi, M.; Hirota, E.; Kim, J.-T.; Formoso, C.; Altan, H.; Bell, P.; Frattari, A.; Riscala, L. ZEMCH Business Operation in Japan. In ZEMCH: Toward the Delivery of Zero Energy Mass Custom Homes; Noguchi, M., Ed.; Springer International Publishing: Cham, Switzerland, 2016; pp. 339–360. [Google Scholar]

- Noguchi, M. Commercialisation principles for low-carbon mass customised housing delivery in Japan. In Mass Customisation and Personalisation in Architecture and Construction; Piroozfar, P.A.E., Piller, F.T., Eds.; Routledge: London, UK, 2013. [Google Scholar]

- Noguchi, M.; Hadjri, K.; Piller, F.T.; Tseng, M.M. Mass Custom Design for Sustainable Housing Development. In Handbook of Research in Mass Customization and Personalization; Piller, F., Tseng, M., Eds.; World Scientific: Singapore, 2010; pp. 892–910. [Google Scholar]

- Iwashita, S. Custom made housing in Japan and the growth of the super subcontractor. Constr. Manag. Econ. 2001, 19, 295–300. [Google Scholar] [CrossRef]

- Gropius, W. Scope of Total Architecture; no. v 2. F.; Allen & Unwin: London, UK, 1956. [Google Scholar]

- Habraken, N.J. Supports: An Alternative to Mass Housing; Architectural Press: London, UK, 1972. [Google Scholar]

- Stewart, D.E.; Corbusier, L. Towards a New Architecture. Art Educ. 1971, 24, 30. [Google Scholar] [CrossRef]

- Banham, R. The Architecture of the Well-Tempered Environment, 2nd ed.; Architectural Press: London, UK, 1984. [Google Scholar]

- Williams, J.J. Zero-Carbon Homes: A Road-Map; Routledge: Abingdon, UK, 2012. [Google Scholar]

- Kieran, S.; Timberlake, J. Refabricating Architecture: How Manufacturing Methodologies are Poised to Transform Building Construction; McGraw-Hill: New York, NY, USA, 2004. [Google Scholar]

- Farmer, M. Modernise or Die: Time to Decide the Industry’s Future|The Farmer Review of the UK Construction Labour Model. 2016. Available online: www.cast-consultancy.com (accessed on 21 August 2018).

- Reynolds, M.; Tate, S. How Modern Methods of Construction can Help Britain Build the Homes it Needs. 2018. Available online: https://www.macegroup.com/perspectives/180710-city-living-how-modern-methods (accessed on 16 November 2018).

- Pan, W.; Goodier, C.I. House-Building Business Models and Off-Site Construction Take-Up. J. Arch. Eng. 2012, 18, 84–93. [Google Scholar] [CrossRef]

- Heffernan, E.; Pan, W.; Liang, X.; De Wilde, P. Zero carbon homes: Perceptions from the UK construction industry. Energy Policy 2015, 79, 23–36. [Google Scholar] [CrossRef]

- Hu, M. Net Zero is not a Choice but an Ethical Practice—Evolution of Net Zero Building. 2018. Available online: https://www.acsa-arch.org/proceedings/Annual%20Meeting%20Proceedings/ACSA.AM.106/ACSA.AM.106.29.pdf (accessed on 5 May 2021).

- Marszal, A.; Heiselberg, P.; Bourrelle, J.; Musall, E.; Voss, K.; Sartori, I.; Napolitano, A. Zero Energy Building—A review of definitions and calculation methodologies. Energy Build. 2011, 43, 971–979. [Google Scholar] [CrossRef]

- Sartori, I.; Napolitano, A.; Voss, K. Net zero energy buildings: A consistent definition framework. Energy Build. 2012, 48, 220–232. [Google Scholar] [CrossRef]

- Stene, J.; Alonso, M.J.; Rønneseth, Ø.; Georges, L. State-of-the-art Analysis of Nearly Zero Energy Buildings. 2018. Available online: https://www.researchgate.net/publication/326684317 (accessed on 28 December 2018).

- Maclay, W. The New Net Zero: Leading-Edge Design and Construction of homes and Buildings for a Renewable energy Future; Chelsea Green Publishing: White River Junction, VT, USA, 2014. [Google Scholar]

- Srinivasan, R.; Moe, K. The Hierarchy of Energy in Architecture: Emergy Analysis; Routledge: London, UK, 2015. [Google Scholar]

- Noguchi, M.; (Melbourne University, Parkville, Australia); Jimenez-Moreno, P.; (University of Edinburgh, Edinburgh, Scotland). Personal communication, 2015.

- Voss, K.; Musall, E. Net Zero Energy Buildings: International Projects of Carbon Neutrality in Buildings, New Editio; EnOB: Munich, Germany, 2013. [Google Scholar]

- Li, D.H.; Yang, L.; Lam, J.C. Zero energy buildings and sustainable development implications—A review. Energy 2013, 54, 1–10. [Google Scholar] [CrossRef]

- Aelenei, L.; Aelenei, D.; Gonçalves, H.; Lollini, R.; Musall, E.; Scognamiglio, A.; Cubi, E.; Noguchi, M. Design Issues for Net Zero-Energy Buildings. Open House Int. 2013, 38, 7–14. [Google Scholar] [CrossRef]

- Torcellini, P.; Pless, S.; Deru, M.; Crawley, D. Zero Energy Buildings: A Critical Look at the Definition. 2006. Available online: http://www.osti.gov/bridge (accessed on 15 March 2019).

- Peterson, K.; Torcellini, P.; Grant, R. A Common Definition for Zero Energy Buildings. 2015. Available online: https://www.energy.gov/sites/default/files/2015/09/f26/bto_common_definition_zero_energy_buildings_093015.pdf (accessed on 21 March 2019).

- Athienitis, A.; Attia, S. Design, Optimization, and Modelling Issues of Net-Zero Energy Solar Buildings. 2010. Available online: https://orbi.uliege.be/bitstream/2268/167569/1/Design%20Optimization%20&%20Modeling%20of%20NZESBs%20FINAL.pdf (accessed on 22 April 2021).

- Jefferson, N.; Sellwood, P. Marketing Tomorrow’s New Homes: Raising Consumer Demand for Low & Zero Carbon Living|A Marketing Strategy for New Homes. 2010. Available online: www.zerocarbonhub.org (accessed on 4 April 2019).

- Ares, E.; Lester, P. Zero Carbon Homes. Design Building. No. 6678, House of Commons Library, London, UK, 2016. Available online: https://commonslibrary.parliament.uk/research-briefings/sn06678/ (accessed on 17 May 2021).

- Hernandez, P.; Kenny, P. From net energy to zero energy buildings: Defining life cycle zero energy buildings (LC-ZEB). Energy Build. 2010, 42, 815–821. [Google Scholar] [CrossRef]

- Marszal, A.J.; Heiselberg, P. A Literature Review of Zero Energy Buildings (ZEB) Definitions. Civ. Eng. 2009. Available online: http://vbn.aau.dk/en/publications/a-literature-review-of-zero-energy-buildings-zeb-definitions_da50db00-eaf6-11de-b63d-000ea68e967b.html (accessed on 4 May 2018).

- Laustsen, J. Energy Efficiency Requirements in Building Codes, Energy Efficiency Policies for New Buildings; IEA: Paris, France, 2008; pp. 1–85.

- Lund, H.; Marszal, A.; Heiselberg, P. Zero energy buildings and mismatch compensation factors. Energy Build. 2011, 43, 1646–1654. [Google Scholar] [CrossRef]

- Berry, S.; Davidson, K.; Saman, W. Defining zero carbon and zero energy homes from a performance-based regulatory perspective. Energy Effic. 2014, 7, 303–322. [Google Scholar] [CrossRef]

- Patterson, M.G. What Is Energy Efficiency? Concepts, Indicators and Methodological Issues. 1996. Available online: https://ac.els-cdn.com/0301421596000171/1-s2.0-0301421596000171-main.pdf?_tid=bfe7fcc3-a9d2-4bca-8052-072fd3fa3d13&acdnat=1553167145_82d4223246839fbf0fb66f1711faca31 (accessed on 21 March 2019).

- Greening, L.A.; Greene, D.L.; Difiglio, C. Energy e$ciency and Consumption * the Rebound e!ECT * a Survey. Energy Policy 2000, 28, 389–401. Available online: https://ac.els-cdn.com/S0301421500000215/1-s2.0-S0301421500000215-main.pdf?_tid=a93351bb-8075-475e-beb1-faa75370ae37&acdnat=1553167157_5093c139d63b41136aaf8fad19eae88f (accessed on 21 March 2019). [CrossRef]

- Nieboer, N.; Gruis, V.; Tsenkova, S.; van Hal, A. Introduction. In Energy Efficiency in Housing Management: Policies and Practice in Eleven Countries; Taylor and Francis Group: London, UK; New York, NY, USA, 2012. [Google Scholar]

- Hart, C.W. Mass customization: Conceptual underpinnings, opportunities and limits. Int. J. Serv. Ind. Manag. 1995, 6, 36–45. [Google Scholar] [CrossRef]

- Gilmore, J.H.; Pine, B.J., II. The Four Faces of Mass Customization. Harvard Business Review. 1997. Available online: https://hbr.org/1997/01/the-four-faces-of-mass-customization (accessed on 29 January 2019).

- Sandrin, E.; Trentin, A.; Forza, C. Organizing for Mass Customization: Literature Review and Research Agenda. Int. J. Ind. Eng. Manag. 2014, 5, 159–167. [Google Scholar]

- Da Silveira, G.; Borenstein, D.; Fogliatto, F.S. Mass customization: Literature review and research directions. Int. J. Prod. Econ. 2001, 72, 1–13. [Google Scholar] [CrossRef]

- Fogliatto, F.S.; da Silveira, G.J.; Borenstein, D. The mass customization decade: An updated review of the literature. Int. J. Prod. Econ. 2012, 138, 14–25. [Google Scholar] [CrossRef]

- Rudberg, M.; Wikner, J. Mass customization in terms of the customer order decoupling point. Prod. Plan. Control 2004, 15, 445–458. [Google Scholar] [CrossRef]

- Duray, R.; Ward, P.T.; Milligan, G.W.; Berry, W.L. Approaches to mass customization: Configurations and empirical validation. J. Oper. Manag. 2000, 18, 605–625. [Google Scholar] [CrossRef]

- Noguchi, M. Zero Energy Mass Custom Homes Research Paradigms EDITORIAL. Open House Int. 2013, 38, 3. [Google Scholar]

- Hounshell, D.A. From the American System to Mass Production, 1800–1932: The Development of Manufacturing Technology in the United States; Johns Hopkins University Press: Baltimore, MD, USA; London, UK, 1984. [Google Scholar]

- Noguchi, M.; Formoso, C.; Da Rocha, C.G.; Andújar-Montoya, M.D.; Bunster, V.; Cameron, R.; Imai, C. Mass Customisation. In ZEMCH: Toward the Delivery of Zero Energy Mass Custom Homes; Springer International Publishing: Cham, Switzerland, 2016. [Google Scholar]

- Kotha, S.; Pine, B.J. Mass Customization: The New Frontier in Business Competition. Acad. Manag. Rev. 1994, 19, 588. [Google Scholar] [CrossRef]

- Bock, T.; Linner, T. Robotic Industrialization: Automation and Robotic Technologies for Customized Component, Module, and Building Prefabrication; Cambridge University Press: New York, NY, USA, 2015. [Google Scholar]

- Piroozfar, P.; Piller, F. Mass Customisation and Personalisation in Architecture and Construction: An Introduction. In Mass Customisation and Personalisation in Architecture and Construction; Piroozfar, P., Piller, F., Eds.; Routledge: London, UK; New York, NY, USA, 2013. [Google Scholar]

- Toffler, A. The Third Wave: The corporate identity crisis. Manag. Rev. 1980, 69, 8–10. [Google Scholar]

- Kotler, P. From mass marketing to mass customization. Plan. Rev. 1989, 17, 10–47. [Google Scholar] [CrossRef]

- Duray, R. Mass customization origins: Mass or custom manufacturing? Int. J. Oper. Prod. Manag. 2002, 22, 314–328. [Google Scholar] [CrossRef]

- Barlow, J.; Jackson, R.; Meikle, J. Homes to DIY for: The UKs Self-Build Housing in the Twenty-First Century; Joseph Rowntree Foundation: New York, NY, USA, 2001. [Google Scholar]

- Kotha, S. From mass production to mass customization: The case of the National Industrial Bicycle Company of Japan. Eur. Manag. J. 1996, 14, 442–450. [Google Scholar] [CrossRef]

- Tseng, M.M.; Jiao, J.; Merchant, M.E. Design for Mass Customization. CIRP Ann. 1996, 45, 153–156. [Google Scholar] [CrossRef]

- Piller, F.T. Mass Customization: Reflections on the State of the Concept. Int. J. Flex. Manuf. Syst. 2004, 16, 313–334. [Google Scholar] [CrossRef]

- Thallmaier, S.R. Customer Co-Design: A Study in the Mass Customization Industry; Springer: Berlin/Heidelberg, Germany, 2015. [Google Scholar]

- Grafmüller, L.K.; Hankammer, S.; Hönigsberg, S.; Wache, H. Developing complex, mass-customized products in SME networks: Perspectives from co-creation, solution space development, and information system design. Int. J. Ind. Eng. Manag. 2018, 9, 215–227. [Google Scholar] [CrossRef]

- Piller, F.T.; Tseng, M. Introduction: Mass Customization Thinking: Moving from Pilot Stage to an Established Business Strategy. In Handbook of Research in Mass Customization and Personalization; Piller, F., Tseng, M., Eds.; World Scientific Publishing: Singapore, 2010. [Google Scholar]

- Zipkin, P. The Limits of Mass Customization. MIT Sloan Manag. Rev. 2001, 3, 81–87. [Google Scholar]

- Von Hippel, E. PERSPECTIVE: User toolkits for innovation. J. Prod. Innov. Manag. 2001, 18, 247–257. [Google Scholar] [CrossRef]

- Grize, Y.L. A review of robust process design approaches. J. Chemom. 1995, 9, 239–262. [Google Scholar] [CrossRef]

- Dickerson, S. What is Flexible Automation? CrossCo. Robotics & Machine Automation. 2014. Available online: https://www.crossco.com/blog/what-flexible-automation (accessed on 2 April 2019).

- Piller, F.; Salvador, F.; Walcher, D. Part 3: Solution Space Development: Understanding where Customers are Different|Innovation Management. Enabling Factors. 2012. Available online: http://www.innovationmanagement.se/2012/04/23/part-3-solution-space-development-understanding-where-customers-are-different/ (accessed on 2 April 2019).

- Mukherjee, K. Mass Customization. In Supplier Selection; Springer: India, India, 2017; pp. 59–66. [Google Scholar]

- Daaboul, J.; Da Cunha, C.; Le Duigou, J.; Novak, B.; Bernard, A. Differentiation and customer decoupling points: An integrated design approach for mass customization. Concurr. Eng. 2015, 23, 284–295. [Google Scholar] [CrossRef]

- Schoenwitz, M.; Potter, A.; Gosling, J.; Naim, M. Product, process and customer preference alignment in prefabricated house building. Int. J. Prod. Econ. 2017, 183, 79–90. [Google Scholar] [CrossRef]

- Yang, B.; Burns, N.D.; Backhouse, C.J. Postponement: A review and an integrated framework. Int. J. Oper. Prod. Manag. 2004, 24, 468–487. [Google Scholar] [CrossRef]

- Salvador, F.; de Holan, P.M.; Piller, F. Cracking the Code of Mass Customization. MIT Sloan Manag. Rev. 2009, 50, 71–78. [Google Scholar]

- Zhang, M. Three Essays on Mass Customization. Master’s Thesis, The Chinese University of Hong Kong, Hong Kong, China, 2010. [Google Scholar]

- Piller, F. Three Capabilities That Make Mass customisation Work. In Mass Customisation and Personalisation in Architecture and Construction; Piroozfar, P., Piller, F., Eds.; Routledge: London, UK; New York, NY, USA, 2013. [Google Scholar]

- Martinez, E.; Tommelein, I.D.; Alvear, A. Integration of Lean and Information Technology to Enable a Customization Strategy in Affordable Housing. In Proceedings of the 25th Annual Conference of the International Group for Lean Construction, Heraklion, Greece, 9–12 July 2017; Volume II, pp. 95–102. [Google Scholar] [CrossRef]

- Ben Naylor, J.; Naim, M.M.; Berry, D. Leagility: Integrating the lean and agile manufacturing paradigms in the total supply chain. Int. J. Prod. Econ. 1999, 62, 107–118. [Google Scholar] [CrossRef]

- Naim, M.M.; Gosling, J. On leanness, agility and leagile supply chains. Int. J. Prod. Econ. 2011, 131, 342–354. [Google Scholar] [CrossRef]

- Gunasekaran, A. Agile manufacturing: A framework for research and development. Int. J. Prod. Econ. 1999, 62, 87–105. [Google Scholar] [CrossRef]

- Stone, K.B. Four decades of lean: A systematic literature review. Int. J. Lean Six Sigma 2012, 3, 112–132. [Google Scholar] [CrossRef]

- Nahmens, I.; Mullens, M. The impact of product choice on lean homebuilding. Constr. Innov. 2009, 9, 84–100. [Google Scholar] [CrossRef]

- Wilson, L. How to Implement Lean Manufacturing, Online. 2015. Available online: https://freemindconsulting.files.wordpress.com/2009/12/lean-implementation-tools.pdf (accessed on 22 April 2021).

- Thwaites, T. The Toaster Project: Or the Heroic Attempt to Build a Simple Electric Appliance from Scratch; Princeton Architectural Press: New York, NY, USA, 2011. [Google Scholar]

- Barlow, J.; Ozaki, R. Building Mass Customised Housing through Innovation in the Production System: Lessons from Japan. Environ. Plan. A Econ. Space 2005, 37, 9–20. [Google Scholar] [CrossRef]

- Barlow, J.; Ozaki, R. Are You Being Served? Japanese Lessons on Customer Focused Housebuilding. 2001. Available online: https://www.researchgate.net/publication/259558218_Are_you_being_served_Japanese_lessons_on_customer_focused_housebuilding (accessed on 5 March 2018).

- Johnson, W. Lessons from Japan: A Comparative Study of the Market Drivers for Prefabrication in Japanese and UK Private Housing Development. 2007. Available online: http://eprints.ucl.ac.uk/5082/ (accessed on 4 March 2018).

- Zero Carbon Hub. Zero Carbon Compendium|Who’s Doing What in Housing Worldwide. 2009. Available online: http://www.zerocarbonhub.org/sites/default/files/resources/reports/Zero_Carbon_Compendium_Whos_Doing_What_in_Housing_Worldwide.pdf (accessed on 5 April 2019).

- Daniell, T. After the Crash: Architecture in Post-Bubble Japan; Princeton Architectural Press: New York, NY, USA, 2008. [Google Scholar]

- Bardakci, A.; Whitelock, J. Mass-customisation in marketing: The consumer perspective. J. Consum. Mark. 2003, 20, 463–479. [Google Scholar] [CrossRef]

- Knaack, U.; Chung-Klatte, S.; Hasselbach, R. Prefabricated Systems: Principles of Construction; Birkhauser: Basel, Switzerland, 2012. [Google Scholar]

- Linner, T.; Bock, T. Automation, robotics, services: Evolution of large-scale mass customisation in the Japanese building industry. In Mass Customisation and Personalisation in Architecture and Construction; Piroozfar, P., Piller, F., Eds.; Routledge: London, UK; New York, NY, USA, 2013. [Google Scholar]

- Pan, W.; Gibb, A.G.F.; Dainty, A.R.J. Leading UK housebuilders’ utilisation of o site modern methods of construction. Build. Res. Inf. 2008, 36, 56–67. [Google Scholar] [CrossRef]

- Winkelhake, C.; Pawley, M. Architecture versus Housing. J. Aesthetic Educ. 1973, 7, 111. [Google Scholar] [CrossRef]

- Buntrock, D. Prefabricated housing in Japan. In Offsite Architecture: Constructing the Future; Smith, R.E., Quale, J.D., Eds.; Routledge: London, UK, 2017; pp. 190–213. [Google Scholar]

- Koolhaas, R.; Obrist, H.U. Project Japan: Metabolism Talks; Taschen GmbH: Koln, Germany, 2011. [Google Scholar]

- Knoroz, T. Housing in Postwar Japan: Longing for a Better Life through State Policies and Theoretical Discourse in the Japan Architect Magazine. Bachelor’s Thesis, Politecnico di Milano, Milan, Italy, 2017. [Google Scholar]

- Waswo, A. Housing in Postwar Japan: A Social History; RoutledgeCurzon: London, UK, 2002. [Google Scholar]

- Blanchet, E.; Zhuravlyova, S. Prefabs: A Social and Architectural History; Historic England: Swindon, UK, 2018.

- Vale, B. Prefabs: A History of the UK Temporary Housing Programme; Spon: London, UK, 1995. [Google Scholar]

- Stevenson, G. Palaces for the People: Prefabs in Post-War Britain; Batsford: London, UK, 2003. [Google Scholar]

- Balchin, P. An Overview of Pre-Thatcherite Housing Policy. In Housing: The Essential Foundations; Balchin, P., Rhoden, M., Eds.; Routledge: London, UK, 1998; pp. 1–23. [Google Scholar]

- Kiprop, J. What Was the Japanese Economic Miracle?—WorldAtlas.com. WorldAtlas. 2018. Available online: https://www.worldatlas.com/articles/what-was-the-japanese-economic-miracle.html (accessed on 24 July 2019).

- Zhang, B. Housing Development in Post-war Japan: Historical Trajectory, Logic of Change, and the Vacancy Crisis. Master’s Thesis, University of Waterloo, Waterloo, ON, USA, 2017. [Google Scholar]

- Bergdoll, B.; Christensen, P.; Broadhurst, R.; Modern, A.M. Home Delivery: Fabricating the Modern Dwelling; Museum of Modern Art: New York, NY, USA, 2008. [Google Scholar]

- Gann, D.M. Construction as a manufacturing process? Similarities and differences between industrialized housing and car production in Japan. Constr. Manag. Econ. 1996, 14, 437–450. [Google Scholar] [CrossRef]

- Duncan, W.C. U.S.-Japan Automobile Diplomacy: A Study in Economic Confrontation; Ballinger: Cambridge, MA, USA, 1973. [Google Scholar]

- Barlow, J.; Childerhouse, P.; Gann, D.; Hong-Minh, S.; Naim, M.; Ozaki, R. Choice and delivery in housebuilding: Lessons from Japan for UK housebuilders. Build. Res. Inf. 2003, 31, 134–145. [Google Scholar] [CrossRef]

- Turner, C. Homes through the Decades. 2015. Available online: www.rcahms.gov.uk (accessed on 23 August 2018).

- Kobayashi, M. The Housing Market and Housing Policies in Japan. SSRN Electron. J. 2016, 18, 2019. [Google Scholar] [CrossRef]

- Hall, I. The Coalition and the UK Housing Market. Politics 2011, 31, 72–81. [Google Scholar] [CrossRef]

- HBF|Home Building Federation. 2017/18 Customer Satisfaction Survey. 2019. Available online: www.hbf.co.uk (accessed on 9 April 2019).

- Hairstans, R.; Sanna, F. A Scottish perspective on timber offsite construction. In Offsite Architecture: Constructing the Future; Smith, R.E., Quale, J.D., Eds.; Taylor and Francis: Abingdon, UK, 2017; pp. 224–251. [Google Scholar]

- Martini, R.; Kimura, S. Evaluation of Agricultural Policy Reforms in Japan. 2009. Available online: www.oecd.org/publishing/corrigenda (accessed on 25 July 2019).

- Ross, K. Non-Traditional Housing in the UK—A Brief Review. Build. Res. Establ. 2002, 5–13. Available online: http://www.cml.org.uk/documents/non-traditional-housing-in-the-uk-a-brief-overview-report/pdf_pub_misc_NontradhousingBR.pdf.pdf (accessed on 30 March 2018).

- Harding, R. Why Tokyo is the Land of Rising Home Construction but not Prices|Financial Times. House & Home|Financial Times. 2016. Available online: https://www.ft.com/content/023562e2-54a6-11e6-befd-2fc0c26b3c60 (accessed on 19 April 2019).

- Yamada, Y. Affordability Crises in Housing in Britain and Japan. Hous. Stud. 1999, 14, 99–110. [Google Scholar] [CrossRef]

- Griffith, M.; Jefferys, P. Solutions for the Housing Shortage How to Build the 250,000 Homes We Need Each Year. 2013. Available online: https://england.shelter.org.uk/__data/assets/pdf_file/0011/689447/Solutions_for_the_housing_shortage_-_FINAL.pdf (accessed on 30 April 2019).

- Jefferys, P.; Lloyd, T.; Argyle, A.; Sarling, J.; Crosby, J.; Bibby, J. Building the Homes We Need: A Programme for the 2015 Government. 2014. Available online: http://www.shelter.org.uk/__data/assets/pdf_file/0019/802270/Building_the_homes_we_need_-_a_programme_for_the_2015_government.pdf (accessed on 14 May 2019).

- Ball, M. Markets and the Structure of the Housebuilding Industry: An International Perspective. Urban Stud. 2003, 40, 897–916. [Google Scholar] [CrossRef]

- Parvin, A.; Saxby, D.; Cerulli, C.; Schneider, T. A Right to Build: The Next Mass-Housebuilding Industry; University of Sheffield: Sheffield, UK, 2011; Available online: https://issuu.com/alastairparvin/docs/2011_07_06_arighttobuild (accessed on 25 April 2021).

- Ball, M. Housing Supply and Planning Controls: The Impact of Development Control Processing Times on Housing Supply in England. 2010. Available online: http://www.communities.gov.uk/archived/general-content/nhpau/research/planningapproval/%255Cnhttp://centaur.reading.ac.uk/17234/ (accessed on 30 March 2018).

- Brown, S.; Cerulli, C.; Stevenson, F. Motivating Collective Custom Build. 2013. Available online: www.collectivecustombuild.org (accessed on 7 May 2019).

- Wallace, A.; Ford, J.; Quilgars, D. Build-It-Yourself? 2013. Available online: www.york.ac.uk/chp (accessed on 13 May 2019).

- Breach, A. Can Tokyo Show Us How to Solve Britain’s Housing Shortage? Centre for Cities. 2019. Available online: https://www.centreforcities.org/blog/can-tokyo-show-us-how-to-solve-britains-housing-shortage/ (accessed on 10 June 2019).

- Ministry of Land, Infrastructure and Transport City Planning Division. Urban Land Use Planning System in Japan. 2003. Available online: https://www.mlit.go.jp/common/001050453.pdf (accessed on 25 April 2021).

- Ozaki, R.; Lewis, J.R. Boundaries and the Meaning of Social Space: A Study of Japanese House Plans. Environ. Plan. D Soc. Space 2006, 24, 91–104. [Google Scholar] [CrossRef]

- Jimenez-Moreno, P.; Quinn, A.; Smith, N.; Kantute, C. Barriers to Innovative Housing in Scotland: NRGStyle’s ‘ZEMCH 109’ Case Study. In Proceedings of the ZEMCH 2018 International Conference, Melbourne, Australia, 29 January–1 February 2018. [Google Scholar]

- Butterworth, S.; Baker, J. Quietly Creating Vibrant High Streets: Proposals for New Permitted Development Rights. Planning Matters. 2018. Available online: https://lichfields.uk/blog/2018/november/23/quietly-creating-vibrant-high-streets-proposals-for-new-permitted-development-rights/ (accessed on 21 January 2019).

- Wetzl, G. Should Zoning be Introduced in England? Planning Matters. 2018. Available online: https://lichfields.uk/blog/2018/may/14/should-zoning-be-introduced-in-england/ (accessed on 21 January 2019).

- Storey, A. Living longer: How Our Population is Changing and Why It Matters. 2018. Available online: https://www.ons.gov.uk/releases/livinglongerhowourpopulationischangingandwhyitmatters (accessed on 27 July 2019).

- Yoneda, K.; Serweta, G. Society of Insatiable Consumption. Medium. 2019. Available online: https://medium.com/@kaz_yoneda/society-of-insatiable-consumption-b264cf5aacae (accessed on 29 April 2019).

- Kuma, K. Tragic Architectural History. In Small Architecture/Natural Architecture; Architectural Association Publications: London, UK, 2016; pp. 20–29. [Google Scholar]

- Noguchi, Y. Land Prices and House Prices in Japan. House Mark U.S. Japan. 1994. Available online: http://www.nber.org/chapters/c8820.pdf (accessed on 11 May 2018).

- Tsukamoto, Y.; Almazán, J. Scrap and Build Alternatives to the Corporate Redevelopment of Tokyo. MONU Mag. Urban 2006, 6–9. Available online: https://www.yumpu.com/en/document/read/10904632/scrap-and-build (accessed on 25 April 2021).

- Wilson, W.; Barton, C. Tackling the Under-Supply of Housing in England. 2018. Available online: www.parliament.uk/commons-library%7Cintranet.parliament.uk/commons-library%7Cpapers@parliament.uk%7C@commonslibrary (accessed on 19 June 2019).

- House of Lords. 1st Report of Session 2016–2017: Building More Homes. 2016. Available online: http://www.parliament.uk/mps-lords-and-offices/standards-and-interests/register-of-lords- (accessed on 7 January 2019).

- Martiskainen, M.; Kivimaa, P. Role of knowledge and policies as drivers for low-energy housing: Case studies from the United Kingdom. J. Clean. Prod. 2019, 215, 1402–1414. [Google Scholar] [CrossRef]

- Ofgem and Energy Saving Trust. A Review of the Energy Efficiency Standards of Performance 1994–2002. 2003. Available online: https://www.ofgem.gov.uk/ofgem-publications/58653/4211-eesopreportjuly03pdf (accessed on 30 July 2019).

- Murakoshi, C.; Nakagami, H.; Tsurusaki, T.; Nakamura, M. Japanese Energy Efficiency Policy and the 25% Greenhouse Gas Reduction Target: Prime Minister Takes on Mission Impossible? 2010. Available online: https://pdfs.semanticscholar.org/9cc8/e576921042a7510e0f5e34e13fc715035f30.pdf (accessed on 30 July 2019).

- Sunikka-Blank, M.; Iwafune, Y. Sustainable Building in Japan—Observations on a Market Transformation Policy. Environ. Policy Gov. 2011, 21, 351–363. [Google Scholar] [CrossRef]

- Ito, A. Policy and Programs for Energy Efficient Houses and Buildings. 2013. Available online: https://www.eu-japan.eu/sites/eu-japan.eu/files/ITO.pdf (accessed on 30 July 2019).

- Huang, B.; Mauerhofer, V.; Geng, Y. Analysis of existing building energy saving policies in Japan and China. J. Clean. Prod. 2016, 112, 1510–1518. [Google Scholar] [CrossRef]

- Wisker, G. The Postgraduate Research Handbook: Succeed with Your MA, MPhil, EdD and Ph.D., 2nd ed.; Palgrave Macmillan: New York, NY, USA, 2008. [Google Scholar]

- Walsh, I. Using quantitative data in mixed-design grounded theory studies: An enhanced path to formal grounded theory in information systems. Eur. J. Inf. Syst. 2015, 24, 531–557. [Google Scholar] [CrossRef]

- Moran-Ellis, J.; Alexander, V.D.; Cronin, A.; Dickinson, M.; Fielding, J.; Sleney, J.; Thomas, H. Triangulation and integration: Processes, claims and implications. Qual. Res. 2006, 6, 45–59. [Google Scholar] [CrossRef]

- Corbin, J.; Strauss, A. Basics of Qualitative Research: Techniques and Procedures for Developing Grounded Theory, 2nd ed.; Sage Publications, Inc.: Thousand Oaks, CA, USA, 2008. [Google Scholar]

- Vaivio, J.; Sirén, A. Insights into method triangulation and “paradigms” in interpretive management accounting research. Manag. Account. Res. 2010, 21, 130–141. [Google Scholar] [CrossRef]

- Rothbauer, P.M. Triangulation. In The SAGE Encyclopedia of Qualitative Research Methods; Given, L.M., Ed.; University of Alberta: Edmonton, Alberta, 2008; Volumes 1–2, pp. 892–894. [Google Scholar]

- Feilzer, M.Y. Doing Mixed Methods Research Pragmatically: Implications for the Rediscovery of Pragmatism as a Research Paradigm. J. Mix. Methods Res. 2009, 4, 6–16. [Google Scholar] [CrossRef]

- Drisko, J. Triangulation; Oxford University Press: Oxford, UK, 2011. [Google Scholar] [CrossRef]

- O’Cathain, A.; Murphy, E.; Nicholl, J. Three techniques for integrating data in mixed methods studies. BMJ 2010, 341, c4587. [Google Scholar] [CrossRef] [PubMed]

- Kolb, S.M. Grounded Theory and the Constant Comparative Method: Valid Research Strategies for Educators. J. Emerg. Trends Educ. Res. Policy Stud. 2012, 3, 83–86. [Google Scholar]

- Eaves, Y.D. A synthesis technique for grounded theory data analysis. J. Adv. Nurs. 2001, 35, 654–663. [Google Scholar] [CrossRef] [PubMed]

| Date | Company/Organisation | Location | Type of Facility | |

|---|---|---|---|---|

| Japan | May 2015 | Sekisui House | Kanto, Koga, Ibaraki | Building prototypes |

| Manufacturing facilities | ||||

| Housing park | ||||

| Manufacturing facilities | ||||

| Kizugawa, Kyoto | Information centre | |||

| Sekisui (Heim) Chemical | Toyohashi | Manufacturing facilities | ||

| Show home and selling centre | ||||

| Daiwa House | Nara | Museum | ||

| Information centre | ||||

| Research and development centre | ||||

| UK | March 2016 | Carbon Dynamic | Invergordon, Scotland | Manufacturing facilities |

| March 2017 | Scotframe | Cumbernauld, Scotland | Manufacturing facilities | |

| Design and engineering offices | ||||

| Showroom | ||||

| June 2017 | Robertson | Seaham, England | Manufacturing facilities |

| Company | Revenue (M) | Volume (Houses/Year)/No. Factories | Delay Supply Strategy | Manufacturing Organisation | Structural Material | Construction System | Off-Site/On Site | |

|---|---|---|---|---|---|---|---|---|

| Japan | Sekisui House | GBP 14,060 | 13,600/5 | Make to order | Flow line-like, group-like, production-line | Steel or timber | Panelised | 60/40% |

| Sekisui Heim | GBP 7388 | 10,500/8 | Assemble to order | Flow line-like, production-line | Steel or timber | Modular | 80/20% | |

| UK | Robertson | GBP 565 * | 1000/2 | Assemble to order ** | Flow line-like, workshop-like | Timber frame | Panelised | variable |

| Scotframe | GBP 30 | 1500/2 | Assemble to order | Flow line-like, workshop-like, production-line | Timber frame | Panelised | >50/-% | |

| Carbon Dynamic | GBP 3 | <100/1 | Assemble to order | Workbench-like | Cross-laminated timber (CLT) | Modular | 85/15% |

| Marketing Strategy | Japan | UK | |||||

|---|---|---|---|---|---|---|---|

| Sekisui House | Sekisui Heim | Daiwa House | Robertson | Scotframe | Carbon Dynamic | ||

| Promotion | Marketing brochures | X | X | X | - | X | X |

| Portfolio | X | X | X | X | X | X | |

| Factory visits | X | X | - | - | X | X | |

| Visitor centres ‘museums’ | X | - | X | - | - | - | |

| Show homes | Selling points | X | X | X | X | - | - |

| Show homes | X | X | X | X | - | - | |

| Show villas/house parks | X | X | X | - | - | - | |

| Product showroom | X | X | X | - | X | - | |

| Prototype show homes | X | - | - | - | - | - | |

| Experience | Information centres | X | - | X | - | - | - |

| Experience measurements | X | - | - | - | - | - | |

| Technology showrooms | X | X | X | - | - | - | |

| Co-design | Catalogue of houses | X | X | X | - | X | X |

| Catalogue of features | X | X | X | - | X | X | |

| Virtual interactive brochures | X | X | X | - | - | - | |

| Previous customers brochure | X | - | X | - | - | - | |

| Online configurator | - | - | - | - | - | X | |

| Assisted design | X | X | X | - | X | X | |

| Energy-Efficient/Zero Energy Equipment or Service | Japan | UK | |||||

|---|---|---|---|---|---|---|---|

| Sekisui House | Sekisui Heim | Daiwa House | Robertson | Scotframe | Carbon Dynamic | ||

| Fabric | Structural material | X | X | - | - | - | - |

| (steel or wood) | X | X | X | - | X | - | |

| Insulation level | X | X | X | - | X | - | |

| Window U-value | X | X | X | - | - | - | |

| Doors U-value | X | X | X | - | - | - | |

| Mechanical systems | Heating systems | X | X | X | - | - | - |

| Ventilation systems | X | X | X | - | - | - | |

| Monitoring systems | X | X | X | - | - | - | |

| Energy cells | X | X | - | - | - | - | |

| Heat pumps | X | X | X | - | - | - | |

| Electric car charger | X | X | X | - | - | - | |

| Renewables | Photovoltaics | X | X | X | - | - | - |

| Passive strategies | Green curtain | X | - | - | - | - | - |

| Water recycling systems | X | X | - | - | - | - | |

| Solar water heater | X | X | X | - | - | - | |

| Customer service | Warranty | X | X | X | * | * | * |

| Maintenance | X | X | X | - | - | - | |

| Rearrangement | X | X | - | - | - | - | |

| Re-customisation | - | X | - | - | - | - | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jimenez-Moreno, P. Mass Customisation for Zero-Energy Housing. Sustainability 2021, 13, 5616. https://doi.org/10.3390/su13105616

Jimenez-Moreno P. Mass Customisation for Zero-Energy Housing. Sustainability. 2021; 13(10):5616. https://doi.org/10.3390/su13105616

Chicago/Turabian StyleJimenez-Moreno, Pablo. 2021. "Mass Customisation for Zero-Energy Housing" Sustainability 13, no. 10: 5616. https://doi.org/10.3390/su13105616

APA StyleJimenez-Moreno, P. (2021). Mass Customisation for Zero-Energy Housing. Sustainability, 13(10), 5616. https://doi.org/10.3390/su13105616