The Recent Progress of Natural Sources and Manufacturing Process of Biodiesel: A Review

Abstract

1. Introduction

2. Methods of Screening Paper

3. Biodiesel Sources

3.1. Plant Oils

3.1.1. Palm

3.1.2. Soybean

3.1.3. Corn

3.1.4. Canola

3.1.5. Jatropha

3.1.6. Jojoba

3.1.7. Sunflower

3.1.8. Peanut

3.1.9. Flax

3.1.10. Safflower

3.1.11. Castor Seed

3.1.12. Cotton

3.1.13. Avocado

3.1.14. Mahua

3.1.15. Pongamia pinnata

3.1.16. Mustard

3.1.17. Coconut

3.1.18. Cannabis sativa

3.1.19. Camelina

3.1.20. Algae

3.2. Waste Cooking Oils

3.2.1. Grease

3.2.2. Waste Cooking Oil

3.3. Animal Fats

3.3.1. Beef

3.3.2. Sheep

3.3.3. Pork

3.3.4. Fish

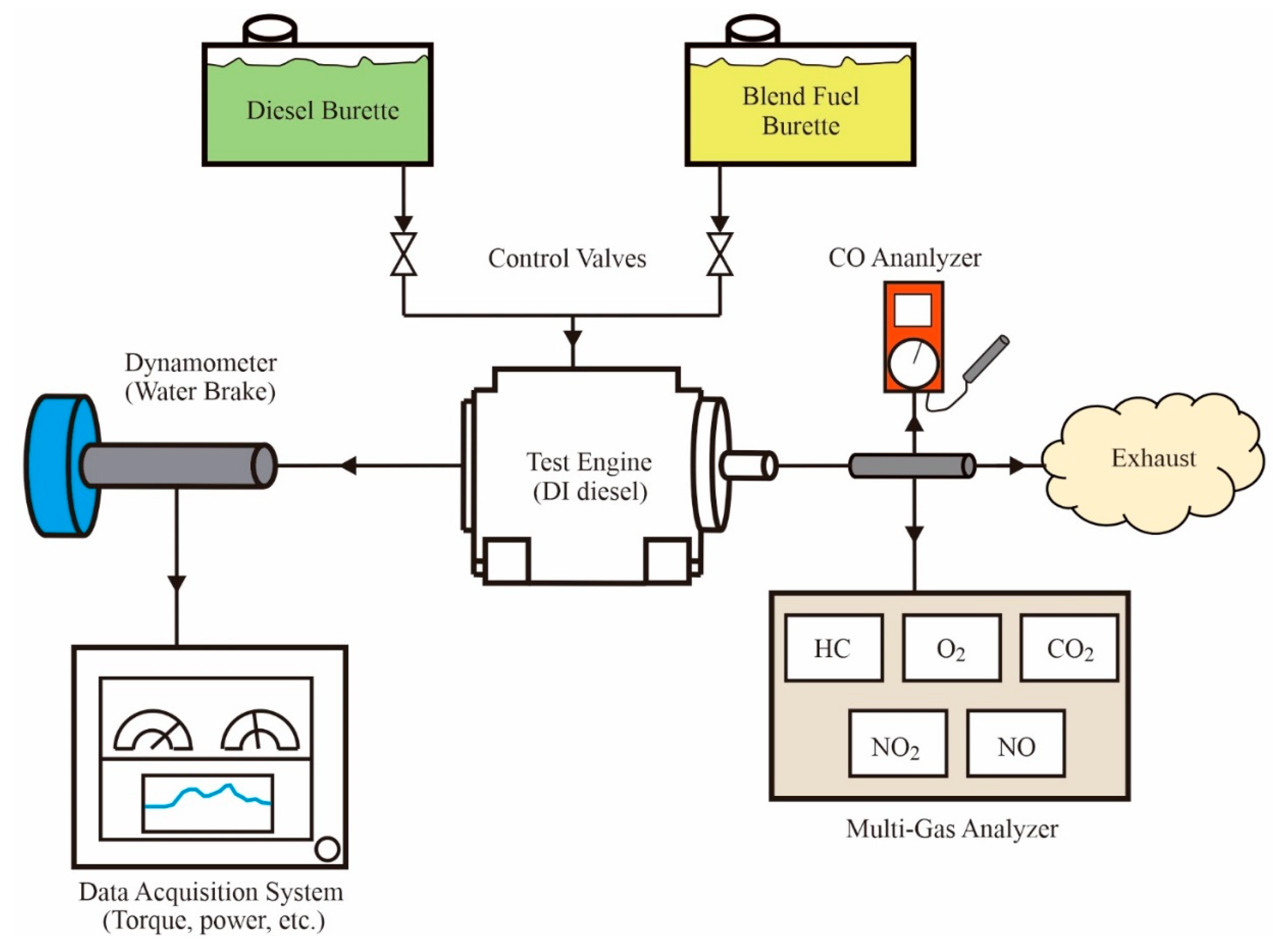

4. Manufacturing Process of Biodiesel

4.1. Direct Use and Blending

4.2. Microemulsion

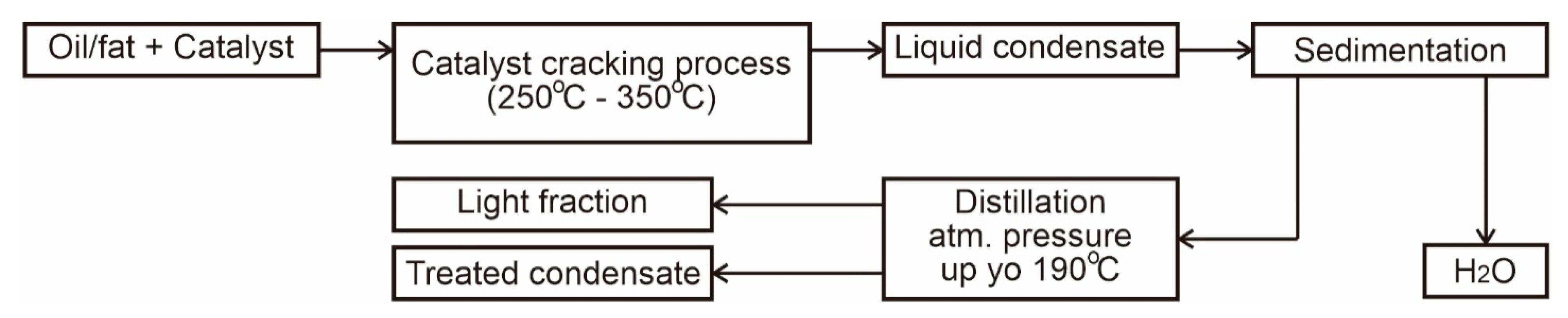

4.3. Pyrolysis

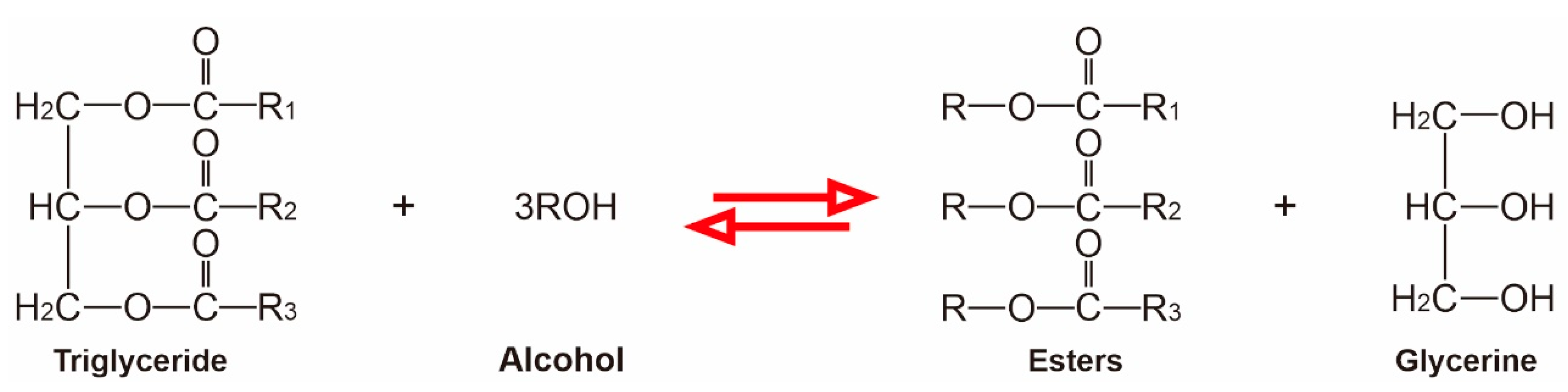

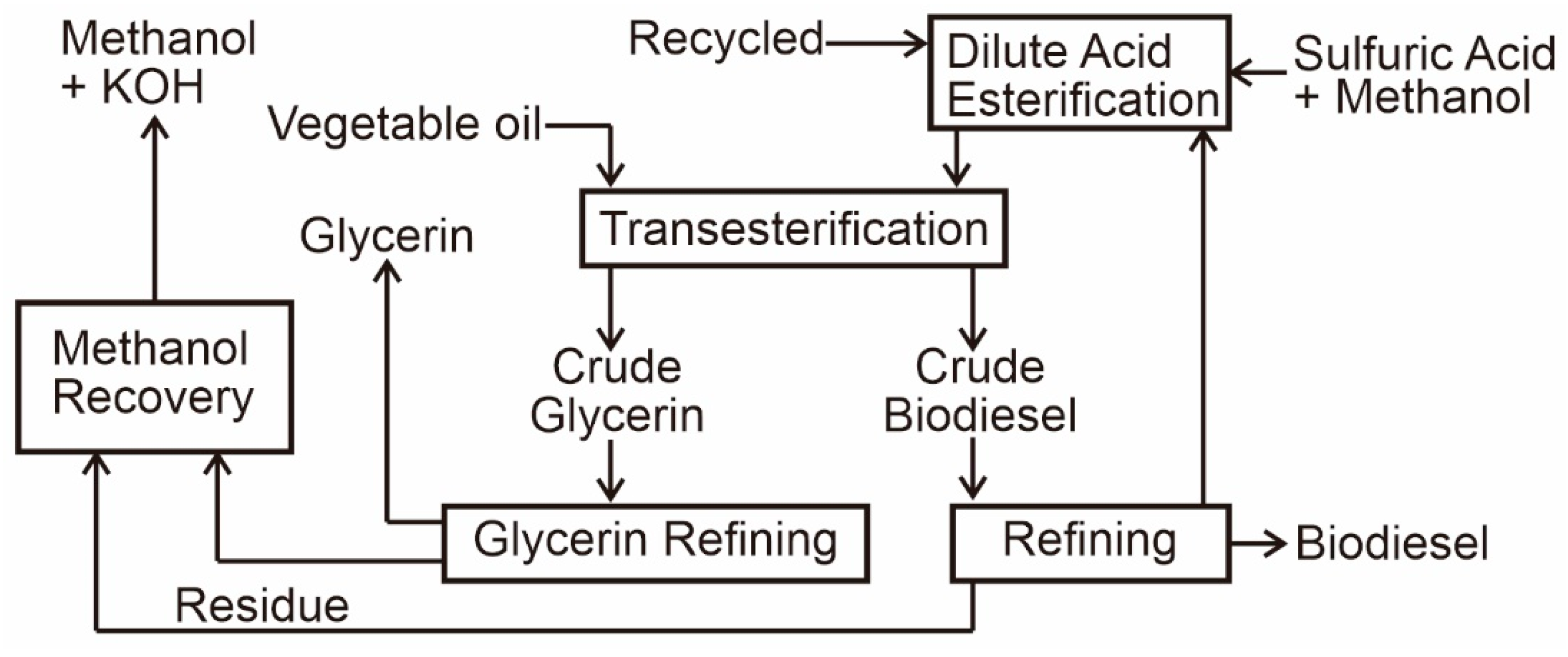

4.4. Transesterification

5. Future Trends

6. Conclusions

- With increasing concerns about global warming partly caused by greenhouse gas (GHG) emissions from fossil-fuel combustion and the limited availability of fossil-fuels, sustainable, environmentally friendly, and renewable fuels such as biodiesel are important to be developed and applied immediately on a daily basis.

- The cost of raw material takes up most of the biodiesel production cost. Economic, agricultural, and technical evaluations are needed to choose the most feasible natural sources in biodiesel production without having to sacrifice the quality.

- The use of biodiesel is very beneficial from the environmental perspective since they generally reduce the amount of HC, CO, and smoke emissions. However, running biodiesel fuel in diesel engines usually causes an increase in NOx emission compared to straight diesel.

- Biodiesel has some poor properties such as higher viscosity, higher density, and lower calorific value that cause a reduction in engine performance parameters when they are used as fuel on a diesel engine.

- Performance and emission characteristics of biodiesel fuel and blends vary, depending on their natural sources, physicochemical properties, and engine operating conditions.

- Of the various biodiesel production methods available, transesterification is currently the most superior method since it can efficiently yield biodiesel products that have superior characteristics compared to other biodiesel produced with other methods.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| AC | air-cooled |

| ASTM | American society for testing and materials |

| B0 | diesel fuel |

| B10 | blended diesel fuel (90%) and biodiesel (10%) |

| B20 | blended diesel fuel (80%) and biodiesel (20%) |

| B50 | blended diesel fuel (50%) and biodiesel (50%) |

| B100 | pure biodiesel fuel |

| BDM | bio-oil-in-diesel microemulsion |

| BSFC | brake specific fuel consumption |

| BTE | brake thermal efficiency |

| CI | compression ignition |

| CO | carbon monoxide |

| CO2 | carbon dioxide |

| CR | compression ratio |

| CRDI | common rail direct injection |

| DEE | diethyl ether |

| DI | direct injection |

| EFBs | empty fruit bunches |

| EGR | exhaust gas recirculation |

| EMA | engine manufacturers association |

| FOME | fish oil methyl ester |

| FTIR | Fourier transform infrared spectroscopy |

| GC | gas chromatography |

| GC-MS | gas chromatography-mass spectrometry |

| GHG | greenhouse gas |

| HC | hydrocarbons |

| JME | jatropha methyl ester |

| LGO | lemongrass oil |

| NA | naturally aspirated |

| NOx | nitrogen oxides |

| PDWO | palm-derived waste oil |

| PM | particulate matters |

| rpm | rotation per minute (unit) |

| RSO | rapeseed oil |

| TCLP | toxicity characteristic leaching procedure |

| WC | water-cooled |

| WCO | waste cooking oil |

| WPO | wood pyrolysis oil |

References

- Administration, U.S.E.I. Energy Information Administration. Choice Rev. Online 2007, 44, 44–3624. [Google Scholar] [CrossRef]

- Li, L.; Sun, W.; Hu, W.; Sun, Y. Impact of natural and social environmental factors on building energy consumption: Based on bibliometrics. J. Build. Eng. 2021, 37, 102136. [Google Scholar] [CrossRef]

- Chong, C.T.; Loe, T.Y.; Wong, K.Y.; Ashokkumar, V.; Lam, S.S.; Chong, W.T.; Borrion, A.; Tian, B.; Ng, J.-H. Biodiesel sustainability: The global impact of potential biodiesel production on the energy–water–food (EWF) nexus. Environ. Technol. Innov. 2021, 22, 101408. [Google Scholar] [CrossRef]

- Soliman, M.N.; Guen, F.Z.; Ahmed, S.A.; Saleem, H.; Khalil, M.J.; Zaidi, S.J. Energy consumption and environmental impact assessment of desalination plants and brine disposal strategies. Process Saf. Environ. Prot. 2021, 147, 589–608. [Google Scholar] [CrossRef]

- Bourdeau, M.; Zhai, X.Q.; Nefzaoui, E.; Guo, X.; Chatellier, P. Modeling and forecasting building energy consumption: A review of data-driven techniques. Sustain. Cities Soc. 2019, 48, 101533. [Google Scholar] [CrossRef]

- OPEC. OPEC 2020 World Oil Outlook 2045; OPEC: Vienna, Austria, 2020; Volume 14, ISBN 9783950489002. [Google Scholar]

- Luque, R.; Lin, C.S.K.; Wilson, K.; Clark, J. Handbook of Biofuels Production: Processes and Technologies, 2nd ed.; Woodhead Publishing: Cambridge, UK, 2016; ISBN 9780081004562. [Google Scholar]

- Schmidt, J.; De Rosa, M. Certified palm oil reduces greenhouse gas emissions compared to non-certified. J. Clean. Prod. 2020, 277, 124045. [Google Scholar] [CrossRef]

- Lee, S.; Shah, Y.T. Biofuels and Bioenergy Processes and Technologies; CRC Press: Florida, FL, USA, 2013; ISBN 9781420089561. [Google Scholar]

- Mohiddin, M.N.B.; Tan, Y.H.; Seow, Y.X.; Kansedo, J.; Mubarak, N.; Abdullah, M.O.; Chan, Y.S.; Khalid, M. Evaluation on feedstock, technologies, catalyst and reactor for sustainable biodiesel production: A review Mohd. Build. Environ. 2020, 184, 107229. [Google Scholar] [CrossRef]

- Raheem, I.; Mohiddin, M.N.B.; Tan, Y.H.; Kansedo, J.; Mubarak, N.M.; Abdullah, M.O.; Ibrahim, M.L. A review on influence of reactor technologies and kinetic studies for biodiesel application. J. Ind. Eng. Chem. 2020, 91, 54–68. [Google Scholar] [CrossRef]

- Aydın, S. Comprehensive analysis of combustion, performance and emissions of power generator diesel engine fueled with different source of biodiesel blends. Energy 2020, 205. [Google Scholar] [CrossRef]

- Bibin, C.; Gopinath, S.; Aravindraj, R.; Devaraj, A.; Gokula Krishnan, S.; Jeevaananthan, J.K.S. The production of biodiesel from castor oil as a potential feedstock and its usage in compression ignition Engine: A comprehensive review. Mater. Today Proc. 2019, 33, 84–92. [Google Scholar] [CrossRef]

- Jayakumar, M.; Karmegam, N.; Gundupalli, M.P.; Gebeyehu, K.B.; Asfaw, B.T.; Chang, S.W.; Balasubramani, R.; Awasthi, M.K. Heterogeneous base catalysts: Synthesis and application for biodiesel production—A review. Bioresour. Technol. 2021, 125054. [Google Scholar] [CrossRef] [PubMed]

- Alagumalai, A.; Mahian, O.; Hollmann, F.; Zhang, W. Environmentally benign solid catalysts for sustainable biodiesel production: A critical review. Sci. Total Environ. 2021, 768, 144856. [Google Scholar] [CrossRef]

- Vignesh, P.; Kumar, A.R.P.; Ganesh, N.S.; Jayaseelan, V.; Sudhakar, K. A review of conventional and renewable biodiesel production. Chin. J. Chem. Eng. 2020. [Google Scholar] [CrossRef]

- Chozhavendhan, S.; Singh, M.V.P.; Fransila, B.; Kumar, R.P.; Devi, G.K. A review on influencing parameters of biodiesel production and purification processes. Curr. Res. Green Sustain. Chem. 2020, 1, 1–6. [Google Scholar] [CrossRef]

- Syafiuddin, A.; Chong, J.H.; Yuniarto, A.; Hadibarata, T. The current scenario and challenges of biodiesel production in Asian countries: A review. Bioresour. Technol. Rep. 2020, 12, 100608. [Google Scholar] [CrossRef]

- Pullen, J.; Saeed, K. Factors affecting biodiesel engine performance and exhaust emissions—Part I: Review. Energy 2014, 72, 1–16. [Google Scholar] [CrossRef]

- Macor, A.; Pavanello, P. Performance and emissions of biodiesel in a boiler for residential heating. Energy 2009, 34, 2025–2032. [Google Scholar] [CrossRef]

- Bazooyar, B.; Ghorbani, A.; Shariati, A. Combustion performance and emissions of petrodiesel and biodiesels based on various vegetable oils in a semi industrial boiler. Fuel 2011, 90, 3078–3092. [Google Scholar] [CrossRef]

- Ghorbani, A.; Bazooyar, B.; Shariati, A.; Jokar, S.M.; Ajami, H.; Naderi, A. A comparative study of combustion performance and emission of biodiesel blends and diesel in an experimental boiler. Appl. Energy 2011, 88, 4725–4732. [Google Scholar] [CrossRef]

- Alonso, J.S.J.; Sastre, J.A.L.; Romero-Ávila, C.; López, E. A note on the combustion of blends of diesel and soya, sunflower and rapeseed vegetable oils in a light boiler. Biomass Bioenergy 2008, 32, 880–886. [Google Scholar] [CrossRef][Green Version]

- Suthisripok, T.; Semsamran, P. The impact of biodiesel B100 on a small agricultural diesel engine. Tribol. Int. 2018, 128, 397–409. [Google Scholar] [CrossRef]

- Shahir, V.K.; Jawahar, C.P.; Suresh, P.R.; Vinod, V. Experimental Investigation on Performance and Emission Characteristics of a Common Rail Direct InjectionEngine Using Animal Fat Biodiesel Blends. Energy Procedia 2017, 117, 283–290. [Google Scholar] [CrossRef]

- Ishola, F.; Adelekan, D.; Mamudu, A.; Abodunrin, T.; Aworinde, A.; Olatunji, O.; Akinlabi, S. Biodiesel production from palm olein: A sustainable bioresource for Nigeria. Heliyon 2020, 6, e03725. [Google Scholar] [CrossRef] [PubMed]

- Bazooyar, B.; Shariati, A.; Hashemabadi, S.H. Economy of a utility boiler power plant fueled with vegetable oil, biodiesel, petrodiesel and their prevalent blends. Sustain. Prod. Consum. 2015, 3, 1–7. [Google Scholar] [CrossRef]

- Aghbashlo, M.; Peng, W.; Tabatabaei, M.; Kalogirou, S.A.; Soltanian, S.; Hosseinzadeh-Bandbafha, H.; Mahian, O.; Lam, S.S. Machine learning technology in biodiesel research: A review. Prog. Energy Combust. Sci. 2021, 85, 100904. [Google Scholar] [CrossRef]

- Gebremariam, S.N.; Marchetti, J.M. Economics of biodiesel production: Review. Energy Convers. Manag. 2018, 168, 74–84. [Google Scholar] [CrossRef]

- Rochelle, D.; Najafi, H. A review of the effect of biodiesel on gas turbine emissions and performance. Renew. Sustain. Energy Rev. 2019, 105, 129–137. [Google Scholar] [CrossRef]

- Sharma, A.; Maurya, N.K.; Singh, Y.; Singh, N.K.; Gupta, S.K. Effect of design parameters on performance and emissions of DI diesel engine running on biodiesel-diesel blends: Taguchi and utility theory. Fuel 2020, 281. [Google Scholar] [CrossRef]

- Abu-Hamdeh, N.H.; Bantan, R.A.R.; Alimoradi, A.; Pourhoseini, S.H. The effect of injection pressure on the thermal performance and emission characteristics of an oil burner operating on B20 palm oil biodiesel-diesel blend fuel. Fuel 2020, 278, 118174. [Google Scholar] [CrossRef]

- Roy, M.M.; Wang, W.; Bujold, J. Biodiesel production and comparison of emissions of a DI diesel engine fueled by biodiesel-diesel and canola oil-diesel blends at high idling operations. Appl. Energy 2013, 106, 198–208. [Google Scholar] [CrossRef]

- Yasin, M.H.M.; Paruka, P.; Mamat, R.; Yusop, A.F.; Najafi, G.; Alias, A. Effect of Low Proportion Palm Biodiesel Blend on Performance, Combustion and Emission Characteristics of a Diesel Engine. Energy Procedia 2015, 75, 92–98. [Google Scholar] [CrossRef]

- Al-Dawody, M.F.; Bhatti, S.K. Experimental and computational investigations for combustion, performance and emission parameters of a diesel engine fueled with soybean biodiesel-diesel blends. Energy Procedia 2014, 52, 421–430. [Google Scholar] [CrossRef]

- Balaji, D.; Pillai, T.M.; Gnanasekaran, K.; Balachandar, M.; Ravikumar, T.S.; Sathish, S.; Sathyamurthy, R. Dataset for compression ignition engine fuelled with corn oil methyl ester biodiesel. Data Br. 2019, 27, 104683. [Google Scholar] [CrossRef] [PubMed]

- Öztürk, E.; Can, Ö.; Usta, N.; Yücesu, H.S. Effects of retarded fuel injection timing on combustion and emissions of a diesel engine fueled with canola biodiesel. Eng. Sci. Technol. Int. J. 2020, 23, 1466–1475. [Google Scholar] [CrossRef]

- Paul, G.; Datta, A.; Mandal, B.K. An experimental and numerical investigation of the performance, combustion and emission characteristics of a diesel engine fueled with jatropha biodiesel. Energy Procedia 2014, 54, 455–467. [Google Scholar] [CrossRef]

- Hariram, V.; Solomon, G.R.; Raj, D.S.; Dev, M.J.; Kumar, U.N.; Gokulakesavan, M.; Premkumar, T.M.; Seralathan, S. Impact of compression ratio in the emission and performance phenomenon of a CI engine fuelled with jojoba biodiesel blends. Mater. Today Proc. 2020. [Google Scholar] [CrossRef]

- Hemanandh, J.; Narayanan, K.V. Emission and Performance analysis of hydrotreated refined sunflower oil as alternate fuel. Alex. Eng. J. 2015, 54, 389–393. [Google Scholar] [CrossRef]

- Santos, B.S.; Capareda, S.C.; Capunitan, J.A. Engine Performance and Exhaust Emissions of Peanut Oil Biodiesel. J. Sustain. Bioenergy Syst. 2013, 03, 272–286. [Google Scholar] [CrossRef]

- Rashedul, H.K.; Masjuki, H.H.; Kalam, M.A.; Ashraful, A.M.; Rashed, M.M.; Sanchita, I.; Shaon, T. Performance and emission characteristics of a compression ignition engine running with linseed biodiesel. RSC Adv. 2014, 4, 64791–64797. [Google Scholar] [CrossRef]

- Balasubramanian, K.; Purushothaman, K. Performance, emission and combustion characteristics of safflower, neem and corn biodiesels fuelled in a CI engine. Nat. Environ. Pollut. Technol. 2019, 18, 1265–1273. [Google Scholar]

- Islam, S.; Ahmed, A.S.; Islam, A.; Aziz, S.A.; Xian, L.C.; Mridha, M. Castor Biodiesel. J. Chem. 2014, 2014, 1–8. [Google Scholar] [CrossRef]

- Sundar, K.; Udayakumar, R. Comparative evaluation of the performance of rice bran and cotton seed biodiesel blends in VCR diesel engine. Energy Rep. 2020, 6, 795–801. [Google Scholar] [CrossRef]

- Anawe, P.A.L.; Folayan, J.A. Data on physico-chemical, performance, combustion and emission characteristics of Persea Americana Biodiesel and its blends on direct-injection, compression-ignition engines. Data Br. 2018, 21, 1533–1540. [Google Scholar] [CrossRef] [PubMed]

- Raman, R.; Kumar, N. Performance and emission characteristics of twin cylinder diesel engine fueled with mahua biodiesel and DEE. Transp. Eng. 2020, 2, 100024. [Google Scholar] [CrossRef]

- Sureshkumar, K. Performance and Characteristics Study of the Use of Environment Friendly Pongamia Pinnata Methyl Ester in CI Engines. J. Energy Environ. 2007, 5, 60–71. [Google Scholar]

- Sanjid, A.; Masjuki, H.H.; Kalam, M.A.; Abedin, M.J.; Rahman, S.M.A. Experimental Investigation of Mustard Biodiesel Blend Properties, Performance, Exhaust Emission and Noise in an Unmodified Diesel Engine. APCBEE Procedia 2014, 10, 149–153. [Google Scholar] [CrossRef]

- Liaquat, A.M.; Masjuki, H.H.; Kalam, M.A.; Fattah, I.M.R.; Hazrat, M.A.; Varman, M.; Mofijur, M.; Shahabuddin, M. Effect of coconut biodiesel blended fuels on engine performance and emission characteristics. Procedia Eng. 2013, 56, 583–590. [Google Scholar] [CrossRef]

- Afif, M.K.; Biradar, C.H. Production of Biodiesel from Cannabis sativa (Hemp) Seed oil and its Performance and Emission Characteristics on DI Engine Fueled with Biodiesel Blends. Int. Res. J. Eng. Technol. 2019, 6, 246–253. [Google Scholar]

- Akar, M.A. Performance and emission characteristics of compression ignition engine operating with false flax biodiesel and butanol blends. Adv. Mech. Eng. 2016, 8, 1–7. [Google Scholar] [CrossRef]

- Chaichan, M.T.; Sabah, P.; Ahmed, T. Evaluation of Performance and Emissions Characteristics for Compression Ignition Engine Operated with Disposal Yellow Grease. Int. J. Eng. Sci. 2013, 2, 111–122. [Google Scholar]

- Avase, S.A.; Srivastava, S.; Vishal, K.; Ashok, H.V.; Varghese, G. Effect of Pyrogallol as an Antioxidant on the Performance and Emission Characteristics of Biodiesel Derived from Waste Cooking Oil. Procedia Earth Planet. Sci. 2015, 11, 437–444. [Google Scholar] [CrossRef]

- Erdoğan, S.; Balki, M.K.; Aydın, S.; Sayın, C. Performance, emission and combustion characteristic assessment of biodiesels derived from beef bone marrow in a diesel generator. Energy 2020, 207. [Google Scholar] [CrossRef]

- Selvam, M.; Srinivasan, C. An investigation Performances, Emission and Combustion Characteristics on Sheep Fat oil as Biodiesel with help of Ultrasonic assisted Transesterification Process. Int. J. Eng. Appl. Sci. 2017, 4, 257385. [Google Scholar]

- John Panneer Selvam, D.; Vadivel, K. The effects of ethanol addition with waste pork lard methyl ester on performance, emission, and combustion characteristics of a diesel engine. Therm. Sci. 2014, 18, 217–228. [Google Scholar] [CrossRef][Green Version]

- Elkelawy, M.; Alm-Eldin Bastawissi, H.; El Shenawy, E.A.; Taha, M.; Panchal, H.; Sadasivuni, K.K. Study of performance, combustion, and emissions parameters of DI-diesel engine fueled with algae biodiesel/diesel/n-pentane blends. Energy Convers. Manag. X 2020, 100058. [Google Scholar] [CrossRef]

- Nautiyal, P.; Subramanian, K.A.; Dastidar, M.G.; Kumar, A. Experimental assessment of performance, combustion and emissions of a compression ignition engine fuelled with Spirulina platensis biodiesel. Energy 2020, 193. [Google Scholar] [CrossRef]

- Prakash, S.; Prabhahar, M.; Sendilvelan, S.; Venkatesh, R.; Singh, S.; Bhaskar, K. Experimental studies on the performance and emission characteristics of an automobile engine fueled with fish oil methyl ester to reduce environmental pollution. Energy Procedia 2019, 160, 412–419. [Google Scholar] [CrossRef]

- Labecki, L.; Cairns, A.; Xia, J.; Megaritis, A.; Zhao, H.; Ganippa, L.C. Combustion and emission of rapeseed oil blends in diesel engine. Appl. Energy 2012, 95, 139–146. [Google Scholar] [CrossRef]

- Altin, R.; Çetinkaya, S.; Yücesu, H.S. Potential of using vegetable oil fuels as fuel for diesel engines. Energy Convers. Manag. 2001, 42, 529–538. [Google Scholar] [CrossRef]

- Chen, H.; Xie, B.; Ma, J.; Chen, Y. NOx emission of biodiesel compared to diesel: Higher or lower? Appl. Therm. Eng. 2018, 137, 584–593. [Google Scholar] [CrossRef]

- Reddy, E.R.K.; Subbalakshmi, Y.; Raju, V.D.; Rao, K.A.; Kumar, M.H.; Reddy, S.R.; Sai, P.T.; Subbalakshmi, Y.; Raju, V.D.; Rao, K.A.; et al. Assessment of performance, combustion and emission characteristics of the Assessment of performance, combustion and emission characteristics of the diesel engine powered with corn biodiesel blends. Int. J. Ambient Energy 2019, 1–9. [Google Scholar] [CrossRef]

- Shehu, B.G.; Clarke, M.L. Successful and sustainable crop based biodiesel programme in Nigeria through ecological optimisation and intersectoral policy realignment. Renew. Sustain. Energy Rev. 2020, 134. [Google Scholar] [CrossRef]

- Yin, C.Y.; Kadir, S.A.S.A.; Lim, Y.P.; Syed-Ariffin, S.N.; Zamzuri, Z. An investigation into physicochemical characteristics of ash produced from combustion of oil palm biomass wastein a boiler. Fuel Process. Technol. 2008, 89, 693–696. [Google Scholar] [CrossRef]

- Sukiran, M.A.; Abnisa, F.; Syafiie, S.; Daud, W.M.A.W.; Nasrin, A.B.; Aziz, A.A.; Loh, S.K. Experimental and modelling study of the torrefaction of empty fruit bunches as a potential fuel for palm oil mill boilers. Biomass Bioenergy 2020, 136, 105530. [Google Scholar] [CrossRef]

- Hanna, M.; Fangrui, M. Biodiesel production: A review. Bioresour. Technol. 1999, 70, 1–15. [Google Scholar]

- Abbaszaadeh, A.; Ghobadian, B.; Omidkhah, M.R.; Najafi, G. Current biodiesel production technologies: A comparative review. Energy Convers. Manag. 2012, 63, 138–148. [Google Scholar] [CrossRef]

- De Almeida, S.C.A.; Belchior, C.R.; Nascimento, M.V.G.; Vieira, L.D.S.R.; Fleury, G. Performance of a diesel generator fuelled with palm oil. Fuel 2002, 81, 2097–2102. [Google Scholar] [CrossRef]

- Agarwal, A.K.; Rajamanoharan, K. Experimental investigations of performance and emissions of Karanja oil and its blends in a single cylinder agricultural diesel engine. Appl. Energy 2009, 86, 106–112. [Google Scholar] [CrossRef]

- Sathiyamoorthi, R.; Sankaranarayan, G. Fuel injection timings of a direct injection diesel engine running on neat lemongrass oil-diesel blends. Int. J. Automot. Mech. Eng. 2015, 11, 2348. [Google Scholar] [CrossRef]

- Altun, Ş.; Bulut, H.; Öner, C. The comparison of engine performance and exhaust emission characteristics of sesame oil-diesel fuel mixture with diesel fuel in a direct injection diesel engine. Renew. Energy 2008, 33, 1791–1795. [Google Scholar] [CrossRef]

- Forson, F.K.; Oduro, E.K.; Hammond-Donkoh, E. Performance of jatropha oil blends in a diesel engine. Renew. Energy 2004, 29, 1135–1145. [Google Scholar] [CrossRef]

- Patidar, V.; Chandra, A.; Singh, M.; Kale, R.K. Phase behaviour and physicochemical study of Karanj oil-ethanol microemulsion as alternative renewable biofuel. J. Sci. Ind. Res. 2014, 73, 461–464. [Google Scholar]

- Liang, J.; Qian, Y.; Yuan, X.; Leng, L.; Zeng, G.; Jiang, L.; Shao, J.; Luo, Y.; Ding, X.; Yang, Z.; et al. Span80/Tween80 stabilized bio-oil-in-diesel microemulsion: Formation and combustion. Renew. Energy 2018, 126, 774–782. [Google Scholar] [CrossRef]

- Ziejewski, M.; Kaufman, K.R.; Schwab, A.W.; Pryde, E.H. Diesel engine evaluation of a nonionic sunflower oil-aqueous ethanol microemulsion. J. Am. Oil Chem. Soc. 1984, 61, 1620–1626. [Google Scholar] [CrossRef]

- Singh, P.J.; Khurma, J.; Singh, A. Preparation, characterisation, engine performance and emission characteristics of coconut oil based hybrid fuels. Renew. Energy 2010, 35, 2065–2070. [Google Scholar] [CrossRef]

- Charoensaeng, A.; Khaodhiar, S.; Sabatini, D.A.; Arpornpong, N. Exhaust emissions of a diesel engine using ethanol-in-palm oil/diesel microemulsion-based biofuels. Environ. Eng. Res. 2018, 23, 242–249. [Google Scholar] [CrossRef]

- Qi, D.H.; Yang, K.; Zhang, D.; Chen, B.; Wei, Q.; Zhang, C.H. Experimental investigation of a turbocharged CRDI diesel engine fueled with Tung oil-diesel-ethanol microemulsion fuel. Renew. Energy 2017, 113, 1201–1207. [Google Scholar] [CrossRef]

- Qi, D.H.; Chen, H.; Matthews, R.D.; Bian, Y.Z. Combustion and emission characteristics of ethanol-biodiesel-water micro-emulsions used in a direct injection compression ignition engine. Fuel 2010, 89, 958–964. [Google Scholar] [CrossRef]

- Neto, A.A.D.; Fernandes, M.R.; Neto, E.L.B.; Dantas, T.N.C.; Moura, M.C.P.A. Effect of Biodiesel/Diesel-Based Microemulsions on the Exhaust Emissions of a Diesel Engine. Braz. J. Pet. Gas 2014, 7, 141–153. [Google Scholar] [CrossRef][Green Version]

- Prasad, S.S.; Singh, A.; Prasad, S. Degummed Pongamia oil—Ethanol microemulsions as novel alternative CI engine fuels for remote Small Island Developing States: Preparation, characterization, engine performance and emissions characteristics. Renew. Energy 2020, 150, 401–411. [Google Scholar] [CrossRef]

- Imtenan, S.; Masjuki, H.H.; Varman, M.; Arbab, M.I.; Sajjad, H.; Fattah, I.M.R.; Abedin, M.J.; Abu, A.S. Emission and performance improvement analysis of biodiesel-diesel blends with additives. Procedia Eng. 2014, 90, 472–477. [Google Scholar] [CrossRef]

- Rajalingam, A.; Jani, S.P.; Kumar, A.S.; Khan, M.A. Production methods of biodiesel. J. Chem. Pharm. Res. 2016, 8, 170–173. [Google Scholar]

- Du, Z.; Li, Y.; Wang, X.; Wan, Y.; Chen, Q.; Wang, C.; Lin, X.; Liu, Y.; Chen, P.; Ruan, R. Microwave-assisted pyrolysis of microalgae for biofuel production. Bioresour. Technol. 2011, 102, 4890–4896. [Google Scholar] [CrossRef] [PubMed]

- Schwab, A.W.; Dykstra, G.J.; Selke, E.; Sorenson, S.C.; Pryde, E.H. Diesel fuel from thermal decomposition of soybean oil. J. Am. Oil Chem. Soc. 1988, 65, 1781–1786. [Google Scholar] [CrossRef]

- Lima, D.G.; Soares, V.C.D.; Ribeiro, E.B.; Carvalho, D.A.; Cardoso, É.C.V.; Rassi, F.C.; Mundim, K.C.; Rubim, J.C.; Suarez, P.A.Z. Diesel-like fuel obtained by pyrolysis of vegetable oils. J. Anal. Appl. Pyrolysis 2004, 71, 987–996. [Google Scholar] [CrossRef]

- Prakash, R.; Singh, R.K.; Murugan, S. Experimental Studies on a Diesel Engine Fueled withWood Pyrolysis Oil Diesel Emulsions. Int. J. Chem. Eng. Appl. 2011, 2, 395–399. [Google Scholar] [CrossRef]

- Prakash, R.; Singh, R.K.; Murugan, S. Experimental investigation on a diesel engine fueled with bio-oil derived from waste wood-biodiesel emulsions. Energy 2013, 55, 610–618. [Google Scholar] [CrossRef]

- Megahed, O.A.; Keera, S.T.; Abdallah, R.I.; Zaher, F.A. Thermally decomposed ricebran oil as a diesel fuel. Grasas Aceites 1998, 49, 165–169. [Google Scholar] [CrossRef]

- Da Mota, S.D.P.; Mancio, A.A.; Lhamas, D.E.L.; De Abreu, D.H.; Da Silva, M.S.; Dos Santos, W.G.; De Castro, D.A.R.; De Oliveira, R.M.; Araújo, M.E.; Borges, L.E.P.; et al. Production of green diesel by thermal catalytic cracking of crude palm oil (Elaeis guineensis Jacq) in a pilot plant. J. Anal. Appl. Pyrolysis 2014, 110, 1–11. [Google Scholar] [CrossRef]

- Barnwal, B.K.; Sharma, M.P. Prospects of biodiesel production from vegetable oils in India. Renew. Sustain. Energy Rev. 2005, 9, 363–378. [Google Scholar] [CrossRef]

- Marchetti, J.M.; Miguel, V.U.; Errazu, A.F. Possible methods for biodiesel production. Renew. Sustain. Energy Rev. 2007, 11, 1300–1311. [Google Scholar] [CrossRef]

- Fukuda, H.; Kondo, A.; Noda, H. Biodiesel fuel production by transesterification of oils. J. Biosci. Bioeng. 2001, 92, 405–416. [Google Scholar] [CrossRef]

- Sathish, A.; Smith, B.R.; Sims, R.C. Effect of moisture on in situ transesterification of microalgae for biodiesel production. J. Chem. Technol. Biotechnol. 2014, 89, 137–142. [Google Scholar] [CrossRef]

- Haas, M.J.; Scott, K.M. Moisture removal substantially improves the efficiency of in situ biodiesel production from soybeans. J. Am. Oil Chem. Soc. 2007, 84, 197–204. [Google Scholar] [CrossRef]

- Kusdiana, D.; Saka, S. Kinetics of transesterification in rapeseed oil to biodiesel fuel as treated in supercritical methanol. Fuel 2001, 80, 693–698. [Google Scholar] [CrossRef]

- Kapilakarn, K.; Peugtong, A. A comparison of costs of biodiesel production from transesterication. Int. Energy J. 2007, 8, 1–6. [Google Scholar]

- Pang, H.; Yang, G.; Li, L.; Yu, J. Efficient transesterification over two-dimensional zeolites for sustainable biodiesel production. Green Energy Environ. 2020. [Google Scholar] [CrossRef]

- Mansir, N.; Teo, S.H.; Mijan, N.A.; Taufiq-Yap, Y.H. Efficient reaction for biodiesel manufacturing using bi-functional oxide catalyst. Catal. Commun. 2021, 149, 106201. [Google Scholar] [CrossRef]

- Kongjan, P.; Jariyaboon, R.; Reungsang, A.; Sittijunda, S. Co-fermentation of 1,3-propanediol and 2,3-butanediol from crude glycerol derived from the biodiesel production process by newly isolated Enterobacter sp.: Optimization factors affecting. Bioresour. Technol. Rep. 2021, 13, 100616. [Google Scholar] [CrossRef]

- Bazooyar, B.; Hashemabadi, S.H.; Shariati, A. NOX formation of biodiesel in utility power plant boilers; Part B. Comparison of NO between biodiesel and petrodiesel. Fuel 2016, 182, 323–332. [Google Scholar] [CrossRef]

- Sun, C.; Liu, Y.; Qiao, X.; Ju, D.; Tang, Q.; Fang, X.; Zhou, F. Experimental study of effects of exhaust gas recirculation on combustion, performance, and emissions of DME-biodiesel fueled engine. Energy 2020, 197. [Google Scholar] [CrossRef]

- Sentanuhady, J.; Majid, A.I.; Prasidha, W.; Saputro, W.; Gunawan, N.P.; Raditya, T.Y.; Muflikhun, M.A. Analysis of the Effect of Biodiesel B20 and B100 on the Degradation of Viscosity and Total Base Number of Lubricating Oil in Diesel Engines with Long-Term Operation Using ASTM D2896 and ASTM D445-06 Methods. TEKNIK 2020, 41, 269–274. [Google Scholar] [CrossRef]

- Sentanuhady, J.; Saputro, W.; Muflikhun, M.A. Metals and chemical compounds contaminants in diesel engine lubricant with B20 and B100 biofuels for long term operation. Sustain. Energy Technol. Assess. 2021, 45, 101161. [Google Scholar] [CrossRef]

| Fuel Type | Blend Composition | Engine Type | Test Condition | BSFC | BTE | Exhaust Gas Temperature | Ref |

|---|---|---|---|---|---|---|---|

| Palm | B5 | Mitsubishi 4D68 SOHC DI 4-stroke, 4-cylinder engine with EGR | variable speeds from 1000 to 3000 rpm | ↑ 3.80% (1000 rpm) ↑ 4.22% (3000 rpm) | [34] | ||

| Soy | B20, B40, B100 | single cylinder, air cooled, vertical, DI diesel engine | variable loads at a constant speed of 1500 rpm | ↑ 4.2% B20, ↑ 8.7% B40, ↑ 14.65% B100 | ↓ 2.61% B20, ↓ 4.95% B40, ↓ 8.07% B100 | [35] | |

| Corn | B10, B20, B30 | single cylinder, 4-stroke, WC diesel engine | variable loads with maximum speed of 1500 rpm | ↑ 4.13% B10 and B20, ↑ 2.48% B30 | ↑ 3.39% for B10, ↑ 2.07% for B20, ↑ 2.88% for B30 | [36] | |

| Canola | B10 | DI, CI engine | variable loads at maximum speed of 2200 rpm | ↑ | ↓ | [37] | |

| Jatropha | B100 | double cylinder, DI, CI diesel engine | variable loads at constant speed of 1500 rpm | ↑ 56.55% at full load | ↓ 26.70% at full load | [38] | |

| Jojoba | B20, B40 | 4-stroke, single cylinder CI engine | variable compression ratio (17:1, 17.5:1, and 18:1), variable loads at a constant speed | ↑ (B40 > B20) at full load | ↓ (B20 > B40) at CR 17:1 and 17.5:1 ↑ (B40 > B20) at CR 18:1 | [39] | |

| Sun flower (hydrotreated, refined) | B25, B100 | 4-stroke, stationary DI diesel engine | variable loads at a constant speed of 1500 rpm | ↓ 25% B25, ↓ 12.5% B100 | ↑ 10% B25, ↑ 38% B100 | [40] | |

| Peanut | B5, B20, B50, B100 | 3-cylinder Yanmar 3009D diesel engine | variable engine speeds (rated power = 14.2 kW) | ↑ up to 9%, B100 (B100 > B50 > B20 > B5) | [41] | ||

| Flax | B10, B20, B30 | an inline 4-cylinder, WC Mitsubishi Pajero engine | variable loads at a constant speed of 2000 rpm | ↑ up to 13% at full load, B30 (B30 > B20 > B10) | ↓ up to 7.47% at full load, B20 (B20 < B30 < B10) | [42] | |

| Safflower | B100 | a single cylinder, 4- stroke, CI engine | variable loads at a constant speed of 1500 rpm | ↑ 16.87% (full load) | ↓ 15.09% (full load) | [43] | |

| Castor Seed | B10, B20, B30, B40 | Techno-mate, TNM-TDE-700 machine | fixed load and speed | ↑ 3.59% B10, ↑ 3.96% B20, ↑ 4.68% B30, ↑ 6.23% B40, | [44] | ||

| Cotton | B20 | Kirloskar, single cylinder, 4-stroke diesel engine (CR 18:1) | variable loads at a constant speed of 1500 rpm | ↑ 17.1% | ↓ 4.13% | [45] | |

| Avocado | B20, B40, B50, B60, B80, B100 | single cylinder, 4-stroke, air cooled, direct injection-compression ignition engine (CR 20:1) | variable loads at a constant speed of 3600 rpm | ↑ 6.06% B20, ↑ 12.12% B40, ↑ 15.15% B50, ↑ 18.18% B60, ↑ 27.27% B80, ↑ 33.33% B100 (at full load) | ↓ 2.41% B20, ↓ 4.83% B40, d6.02% B50, ↓ 7.24% B60, ↓ 9.38% B80, ↓ 11.36% B100 (at full load) | ↓ (B100 < B80 < B60 < B50 < B40 < B20) | [46] |

| Mahua | B5, B10, B15, B20 | Kirloskar, twin cylinder diesel engine | variable loads at a constant speed of 1500 rpm | ↓ 9.42% B5, ↑ 3.04% B10, ↑ 3.95% B15, ↑ 5.17% B20 (full load) | ↑ 1.48 B5, ↓ 1.11% B10, ↓ 2.59% B15, ↓ 3.70% B20 (full load) | [47] | |

| Pongamia pinnata | B20, B40, B60, B80, B100 | Kirloskar, single cylinder 4-stroke, WC, CI engine | variable loads at a constant speed of 1500 rpm | ↓ slightly for B20, almost same for B40, ↑ for B60, B80, and B100 (B100 > B80 > B60) | [48] | ||

| Mustard | B10, B20 | an inline 4-cylinder, WC, Mitsubishi Pajero engine (CR 21:1) | variable loads and speeds ranging from 1000 to 4000 rpm | ↑ 8.5% B10 ↑ 13.4% B20 | [49] | ||

| Coconut | B5, B15 | a 1-cylinder, 4-stroke, DI diesel engine | 100% load with variable speeds of 1500 to 2400 rpm (interval 100 rpm) | ↑ 0.53% for B5 and ↑ 2.11% for B15 | ↑ 2.22% for B5 and ↑ 3.33% for B15 (2200 rpm) | [50] | |

| Hemp | B10, B20, B30, B50, B100 | Kirloskar TV1, single cylinder, 4-stroke, DI engine | variable loads at a constant speed of 1500 rpm | ↓ 2.56% B10 & B20, ↑ 2.56% B30, ↑ 5.13% B50 & B100 | ↓ 0.35% B10, ↓ 1.06% B20, ↓ 10.28% B30, ↓ 14.54% B50, ↓ 16.31% B100 | ↑ (B30 > B20 > B50 > B10 > B100) | [51] |

| Camelina | B20, B100 | 4-cylinder, 4-stroke, DI diesel engine | variable speeds between 1200 and 2600 rpm (interval 200 rpm) at full load | ↑ 0.86% B20, ↑ 3.84% B100 | [52] | ||

| Grease | B20, B100 | 4-cylinder, 4-stroke, DI Fiat diesel engine | variable loads at a constant speed of 1500 rpm | ↑ significantly (B100 > B20) | ↑ slightly (B100 > B20) | [53] | |

| Waste cooking oil | B20 | single cylinder, 4-stroke, DI Kirloskar diesel engine | variable loads at a constant speed of 1500 rpm | ↑ 2.96% (at full load) | ↑ 10.79% (at full load) | [54] | |

| Beef (beef bone marrow) | B50, B100 | 4-stroke, 4-cylinder, direct-injection diesel generator engine | variable loads (3.6, 7.2, and 10.8 kW) | ↑ (B100 > B50) at all loads | ↓ (B100 > B50) at 3.6 and 10.8 kW ↓ (B50 > B100) at 7.2 kW | ↑ (B100 > B50) at all loads | [55] |

| Sheep (sheep fat) | B25, B50, B75, B100 | Kirloskar TV1, single cylinder, WC diesel engine | variable loads at a constant speed of 1500 rpm | ↓ from 1.8% to 2.3% (B100 < B75 < B50 < B25) | [56] | ||

| Pork (pork lard) | B100 | single cylinder, WC, DI diesel engine | variable loads at a constant speed of 1500 rpm | ↓ | [57] | ||

| Algae (Scenedesmus obliquus) | B50 | single cylinder, 4-stroke, WC diesel engine (CR 20:1) | variable loads at a constant speed of 1400 rpm | ↑ 14.55% | ↓ 4.75% | ↓ 5.21% | [58] |

| Algae (Spirulina platensis) | B10, B20, B100 | 1-cylinder, 4-stroke, compression ignition engine | variable loads at a constant speed of 1500 rpm | ↓ 1.48% B10, ↓ 4.49% B20, ↓ 2.50% B100 (full load) | [59] | ||

| Fish | B20, B40, B60, B80, B100 | single cylinder, 4-stroke, air-cooled diesel engine | variable loads and speeds | ↓ up to 12.68% (B100 < B80 < B60 < B40 < B20) | [60] | ||

| Rapeseed oil | B10, B20, B30, B50 | Four cylinder, 4-stroke, diesel engine | 2000 rpm | ↑ 30% (2000 rpm) compared to diesel fuel | [61] |

| Fuel Type | Blend Composition | Engine Type | Test Condition | HC | CO | CO2 | NOx | Smoke Opacity | Ref |

|---|---|---|---|---|---|---|---|---|---|

| Palm | B5 | Mitsubishi 4D68 SOHC DI, 4-stroke, 4-cylinder engine with EGR | variable speeds from 1000 to 3000 rpm | ↓ insignificantly | ↓ (↑ at 1500 rpm) | ↓ insignificantly (↓ significantly at 3000 rpm) | ↑ significantly | [34] | |

| Soy | B20, B40, B100 | single cylinder, air cooled, vertical, DI diesel engine | variable loads at a constant speed of 1500 rpm | ↓ 15% B20, ↓ 27%, B40, ↓ 38.4%, B100 | ↓ 11.36 B20, ↓ 29% B40, ↓ 41.7% B100 | ↑ 7.5%, B20 (B100 > B40 > B20) | ↓ 20.5% B20, ↓ 33.41% B40, ↓ 48.23% B100 | [35] | |

| Corn | B10, B20, B30 | single cylinder, 4-stroke, WC diesel engine | variable loads with maximum speed of 1500 rpm | ↓ 7.69% B10, ↑ 15.38% for B20, ↑ 30.77% for B30 | ↓ 1.48% B10, ↓ 2.79% B20, ↓ 4.07% B30 | [36] | |||

| Canola | B10 | DI, CI diesel engine | variable loads at maximum speed of 2200 rpm | ↓ | ↓ | ↑ | ↑ | ↓ | [37] |

| Jatropha | B100 | double cylinder, DI, CI diesel engine | variable loads at a constant speed of 1500 rpm | ↑ 37.70% at full load | [38] | ||||

| Jojoba | B20, B40 | 4-stroke, single cylinder, CI engine | variable compression ratios (17:1, 17.5:1, and 18:1), variable loads at a constant speed | B40 > diesel > B20l (CR 17:1) Diesel > B20 > B40 (CR 17,5:1) B20 > Diesel > B40 (CR 18) | Various for different CR and loads, but generally Diesel > B20 > B40 | - | B20 > diesel > B40 (CR 17,5:1 and 18:1) B20 > B40 > diesel (CR 17:1) | B40 > diesel > B20 at full loads | [39] |

| Sun flower (hydrotreated refined) | B25, B100 | 4-stroke, stationary DI diesel engine | variable loads at a constant speed of 1500 rpm | ↓ 42% for B25, ↓ 55% for B100 (at full load) | ↓ 9% for B25, ↓ 37% for B100 (at full load) | ↓ 10% B25, ↓ 18.18%. B100 | [40] | ||

| Peanut | B5, B20, B50, B100 | 3-cylinder Yanmar 3009D diesel engine | variable engine speeds (rated power = 14.2 kW) | ↑ for B20 and B100 (↑ 30%, B100), d for B5 and B50 | ↓ up to 29%, B50 (B50 < B100 < B5 < B20) | ↑ up to 18%, B100 (B100 > B50 > B5 > B20) | ↑ up to 30%, B100 (B100 > B50 > B20 > B5) | [41] | |

| Flax | B10, B20, B30 | an inline 4-cylinder, WC Mitsubishi Pajero engine | variable loads at a constant speed of 2000 rpm | ↑ up to 15.8% at full load, B30 (B30 > B20 > B10) | ↓ up to 27.7% at full load, B20 (B20 < B30 < B10) | ↑ up to 14.4% at full load, B30 (B30 > B20 > B10) | [42] | ||

| Safflower | B100 | a single cylinder, 4-stroke, CI engine | variable loads at a constant speed of 1500 rpm | ↓ 3.85% (full load) | ↓ 4.21% (full load) | ↑ 1.27% (full load) | ↓ 2.57% (full load) | [43] | |

| Castor Seed | B20, B40, B60, B80, B100 | Techno-mate, TNM-TDE-700 machine | fixed load and speed | ↓ 20% B20, ↓ 37% B40, ↓49% B60, ↓ 59% B80, ↓ 67% B100 | ↓ 13% B20, ↓ 24% B40, ↓ 33% B60, ↓ 40% B80, ↓ 48% B100 | ↑ 2% B20, ↑ 4% B40, ↑ 6% B60, ↑ 8% B80, ↑ 10% B100 | [44] | ||

| Cotton | B20 | Kirloskar, single cylinder, 4-stroke, diesel engine (CR 18:1) | variable loads at a constant speed of 1500 rpm | ↓ 3.86% | ↓ 18.4% | ↑ 14.0% | ↑ 8.0% | [45] | |

| Avocado | B20, B40, B50, B60, B80, B100 | single cylinder, 4-stroke, air cooled direct injection-compression ignition engine (CR 20:1) | variable loads at a constant speed of 3600 rpm | ↓ (B100 < B80 < B60 < B50 < B40 < B20) | ↓ (B100 < B80 < B60 < B50 < B40 < B20) | ↑ (B100 > B80 > B60 > B50 > B40 > B20) | ↓ (B100 < B80 < B60 < B50 < B40 < B20) | [46] | |

| Mahua | B5, B10, B15, B20 | Kirloskar, twin cylinder diesel engine | variable loads at a constant speed of 1500 rpm | ↓ 6.56% B5, ↓ 11.48% B10, ↓ 16.39% B15, ↓ 21.31% B20 (full load) | ↓ 21.05% B5, ↓ 31.58% B10, ↓ 36.84% B15, ↓ 42.11% B20 (full load) | ↑ 11.11% B5, ↑ 15.24% B10, ↑ 22.33% B15, ↑ 26.98% B20 (full load) | ↓ 12.5% B5, ↓ 22.92% B10, ↓ 37.5% B15, ↓ 50% B20 (full load) | [47] | |

| Pongamia pinnata | B20, B40, B60, B80, B100 | Kirloskar, single cylinder 4-stroke, WC, CI engine. | variable loads at a constant speed of 1500 rpm | ↓ B20, almost zero for B40, B60, B80, and B100 | ↓ B80 and B100, zero for B20, B40, B60 (75% load) | ↓ except for B20 (B60 < B40 < B100 < B80 < B20) | ↓ (B60 < B40 < B80 < B100 < B20) | [48] | |

| Mustard | B10, B20 | an inline 4-cylinder, WC, Mitsubishi Pajero engine (CR 21:1) | variable loads and speeds ranging from 1000 to 4000 rpm | ↓ 24% B10, 42% B20 | ↓ significantly (19-40% lower) (B20 < B10 < B0) | ↑ 9% B10, ↑ 12% B20 | [49] | ||

| Coconut | B5, B15 | a one-cylinder, 4-stroke, DI diesel engine | variable loads at a constant speed of 2200 rpm | ↓ 13.89% for B5 and ↓ 22.88% for B15 (full load) | ↓ 13.38% for B5 and ↓ 21.51% for B15 (full load) | ↑ 2.54% for B5 and ↑ 4.64% for B15 (full load) | ↑1.42% for B5 and ↑ 3.19% for B15 (full load) | [50] | |

| Hemp | B10, B20, B30, B50, B100 | Kirloskar TV1, single cylinder, 4-stroke, DI engine | variable loads at a constant speed of 1500 rpm | ↓ 11.11% B10, ↓ 2.22% B20, ↑ 2.22% B30, ↓ 8.89% B50, ↓ 4.44% B100 | ↓ 0.13% B10, ↓ 0.14% B20, ↓ 0.17% B30, ↓ 0.18% B50 ↓ 0.21% B100 | ↑ 2.08% B10 and B50, unchanged for B20, ↓ 5.00% B30, ↑ 6.25% B100 | ↑ 4.17% B10, ↑ 10.42% B20, ↑ 19.79% B30 and B50, ↑ 20.83% B100 | ↓ 18.79% B10, ↓ 15.03% B20, ↓ 12.72% B30, ↓ 4.34% B50, ↑ 6.36% B100 | [51] |

| Camelina | B20, B100 | 4-cylinder, 4-stroke, DI diesel engine | variable speeds between 1200 and 2600 rpm (interval 200 rpm) at full load | ↓ 15.4% B100 (B100 < B20) | ↓ 13.8% B100 (B100 < B20) | ↑ 9.6% B100 (B100 > B20) | [52] | ||

| Grease | B20, B100 | 4-cylinder, 4-stroke, DI Fiat diesel engine | variable loads at a constant speed of 1500 rpm | ↓ slightly B20, ↓ significantly B100 | ↓ 11.26% B20 ↓ 43% B100 (full load) | ↑ 1.8% B20, ↑ 0.7% B100 (full load) | ↑ 12.28% B20 ↑ 20.52% B100 (full load) | [53] | |

| Waste cooking oil | B20 | single cylinder, 4-stroke, DI Kirloskar diesel engine | variable loads at a constant speed of 1500 rpm | ↓ 2.86% (at full load) | ↓ 29.07% (at full load) | ↑ 3.19% (at full load) | ↑ 5.33% (at full load) | [54] | |

| Beef (beef bone marrow) | B50, B100 | 4-stroke, 4-cylinder, direct-injection diesel generator engine | variable loads (3.6, 7.2, and 10.8 kW) | ↓ 24% B50 ↓ 12% B100 | Diesel > B100 > B50 at all loads | ↑ slightly for both B50 and B100 | ↓ slightly (B50 > B100) | - | [55] |

| Sheep (sheep fat) | B25, B50, B75, B100 | Kirloskar TV1, single cylinder, WC diesel engine | variable loads at a constant speed of 1500 rpm | ↑ slightly except for B100 (B100 > B75 > B50 > B25) | ↑ significantly (B100 > B75 > B50 > B25) | ↓ significantly at full load (B100 < B75 < B50 < B25) | ↑ (B100 > B75 > B50 > B25) | [56] | |

| Pork (pork lard) | B100 | single cylinder, WC, DI diesel engine | variable loads at a constant speed of 1500 rpm | ↓ slightly (less than 7.5%) | ↓ 12.32% | ↓ 3.74% (full load) | ↓ 7.69% | [57] | |

| Algae (Scenedesmus obliquus) | B50 | single cylinder, 4-stroke, WC diesel engine (CR 20:1) | variable loads at a constant speed of 1400 rpm | ↓ 2.84% | ↓ 4.63% | ↓ 4.46% | ↑ 4.63% | [58] | |

| Algae (Spirulina platensis) | B10, B20, B100 | 1-cyllinder, 4-stroke, compression ignition engine | variable loads at a constant speed of 1500 rpm | ↓ up to 33.33% (B100 < B20 < B10) | ↓ 17.42% B10, ↓ 24.84% B20, ↓ 61.29% B100 (at full load) | ↑ 1.75% B10, ↑ 6.25% B20, ↑ 23.31% B100 | ↓ (B100 < B20 < B10) | [59] | |

| Fish | B20, B40, B60, B80, B100 | single cylinder, 4-stroke, air-cooled diesel engine | variable loads and speeds | ↓ up to 20.45% (B100 < B80 < B60 < B40 < B20) | ↓ up to 43.94% (B100 < B80 < B60 < B40 < B20) | ↑ up to 55.03%, (B100) | [60] | ||

| Rapeseed oil | B100 | Single cylinder, 4-stroke, diesel engine | variable speeds from 900 to 1800 rpm | ↓ insignificantly | ↓ insignificantly | ↓ insignificantly | ↑ significantly | [62] |

| Emulsion | 80% B30 Tung Oil-Diesel—20% Ethanol | 80% Soybean Biodiesel—20% Ethanol | 81% B20 Soybean Biodiesel—15% NP5EO—4% Water | 52% Crude Pongamia Oil (CPO)—23% Ethanol—25% Buthanol | 95% B15 Palm Biodiesel—5% Ethanol |

|---|---|---|---|---|---|

| Reference | [80] | [81] | [82] | [83] | [84] |

| Density (g/mL) | 0.843 | 0.8552 | 0.871 | 0.864 | 0.833 |

| Kinematic viscosity (mm2/s) | 4.8 (at 40 °C) | 13.51 (at 21 °C) | 3.23 (at 40 °C) | ||

| Lower heating value (kJ/kg) | 37,990 | 31,283 | |||

| Flash point (°C) | 46.2 | 84.5 | |||

| Stoichiotric air-fuel ratio (AFR) (kg/kg) | 12.87 | 11.249 | |||

| Engine | 6-cylinder, 4-stroke, turbocharged, inter-cooled, CRDI diesel engine | single cylinder, 4-stroke, WC, CR 16.5:1, DI diesel engine | single-cylinder, 4-stroke, AC, DI diesel engine | single-cylinder, 4-stroke, DI diesel engine | single cylinder, 4-stroke, DI diesel engine |

| Performance | BSFC ↑, BTE ↑ slightly | BSFC ↑ slightly | BSFC ↑, BTE ↓ 2.75% | BSFC ↑, BTE ↓ |

| Percent by Weight | ||||

|---|---|---|---|---|

| High Oleic Safflower | Soy | |||

| N2 Sparge | Air | N2 Sparge | Air | |

| Alkanes | 37.5 | 40.9 | 31.3 | 29.9 |

| Alkenes | 22.2 | 22.0 | 28.3 | 24.9 |

| Alkadienes | 8.1 | 13.0 | 9.4 | 10.9 |

| Aromatics | 2.3 | 2.2 | 2.3 | 1.9 |

| Unresolved unsaturates | 9.7 | 10.1 | 5.5 | 5.1 |

| Carboxylic acids | 11.5 | 16.1 | 12.2 | 9.6 |

| Unidentified | 8.7 | 12.7 | 10.9 | 12.6 |

| Catalyst Load (kg/100 kg Oil) | |||||

|---|---|---|---|---|---|

| Diesel | 0.5 | 1.0 | 2.0 | 3.0 | |

| API gravity | 31–41 | 32.08 | 35.75 | 33.80 | 33.99 |

| Specific gravity | 0.82–0.87 | 0.865 | 0.846 | 0.856 | 0.855 |

| Pour point (°C) | +4.5–15 | +12 | +6 | 0.0 | +6 |

| Kinematic viscosity (m2S−1 × 106) | ≤7 | 8.61 | 7.19 | 9.42 | 9.39 |

| Calorific Value (MJ/kg) | 44.3 | 40.437 | 38.199 | 39.675 | 35.860 |

| Heating value compared to diesel | 1 | 0.91 | 0.86 | 0.89 | 0.81 |

| Flash point (°C) | ≥55 | 54 | 51 | 56 | 51 |

| Cetane number | ≥55 | 59.69 | 52.24 | 52.26 | 59.68 |

| Cetane index | - | 51 | 54 | 52 | 54 |

| Properties | Unit | Green Diesel | Diesel |

|---|---|---|---|

| Density | kg/m3 | 790 | 820–880 |

| Kinematic viscosity | mm2/s | 1.48 | 2–5 |

| Flash point, min | °C | 10 | 38 |

| Copper strip corrosion, 3 h 50 °C, max | - | 1a | 1a |

| Carbon residue, max | wt% | 0.02 | 0.25 |

| Acid value | mg KOH/g | 1.68 | 0.5 |

| Saponification value | mg KOH/g | 7.93 | - |

| Refraction index | - | 1.44 | - |

| Ester value | mg KOH/g | 6.25 | - |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Supriyanto, E.; Sentanuhady, J.; Dwiputra, A.; Permana, A.; Muflikhun, M.A. The Recent Progress of Natural Sources and Manufacturing Process of Biodiesel: A Review. Sustainability 2021, 13, 5599. https://doi.org/10.3390/su13105599

Supriyanto E, Sentanuhady J, Dwiputra A, Permana A, Muflikhun MA. The Recent Progress of Natural Sources and Manufacturing Process of Biodiesel: A Review. Sustainability. 2021; 13(10):5599. https://doi.org/10.3390/su13105599

Chicago/Turabian StyleSupriyanto, Eko, Jayan Sentanuhady, Ariyana Dwiputra, Ari Permana, and Muhammad Akhsin Muflikhun. 2021. "The Recent Progress of Natural Sources and Manufacturing Process of Biodiesel: A Review" Sustainability 13, no. 10: 5599. https://doi.org/10.3390/su13105599

APA StyleSupriyanto, E., Sentanuhady, J., Dwiputra, A., Permana, A., & Muflikhun, M. A. (2021). The Recent Progress of Natural Sources and Manufacturing Process of Biodiesel: A Review. Sustainability, 13(10), 5599. https://doi.org/10.3390/su13105599