Life Cycle Assessment of an Innovative Technology against Late Frosts in Vineyard

Abstract

1. Introduction

2. Materials and Methods

2.1. Goal and Scope Definition

2.2. Functional Unit

2.3. Boundaries

2.4. System Description

2.5. Life Cycle Inventory (LCI)

2.6. Data Acquisition

2.7. Life Cycle Assessment (LCA) Model

3. Results

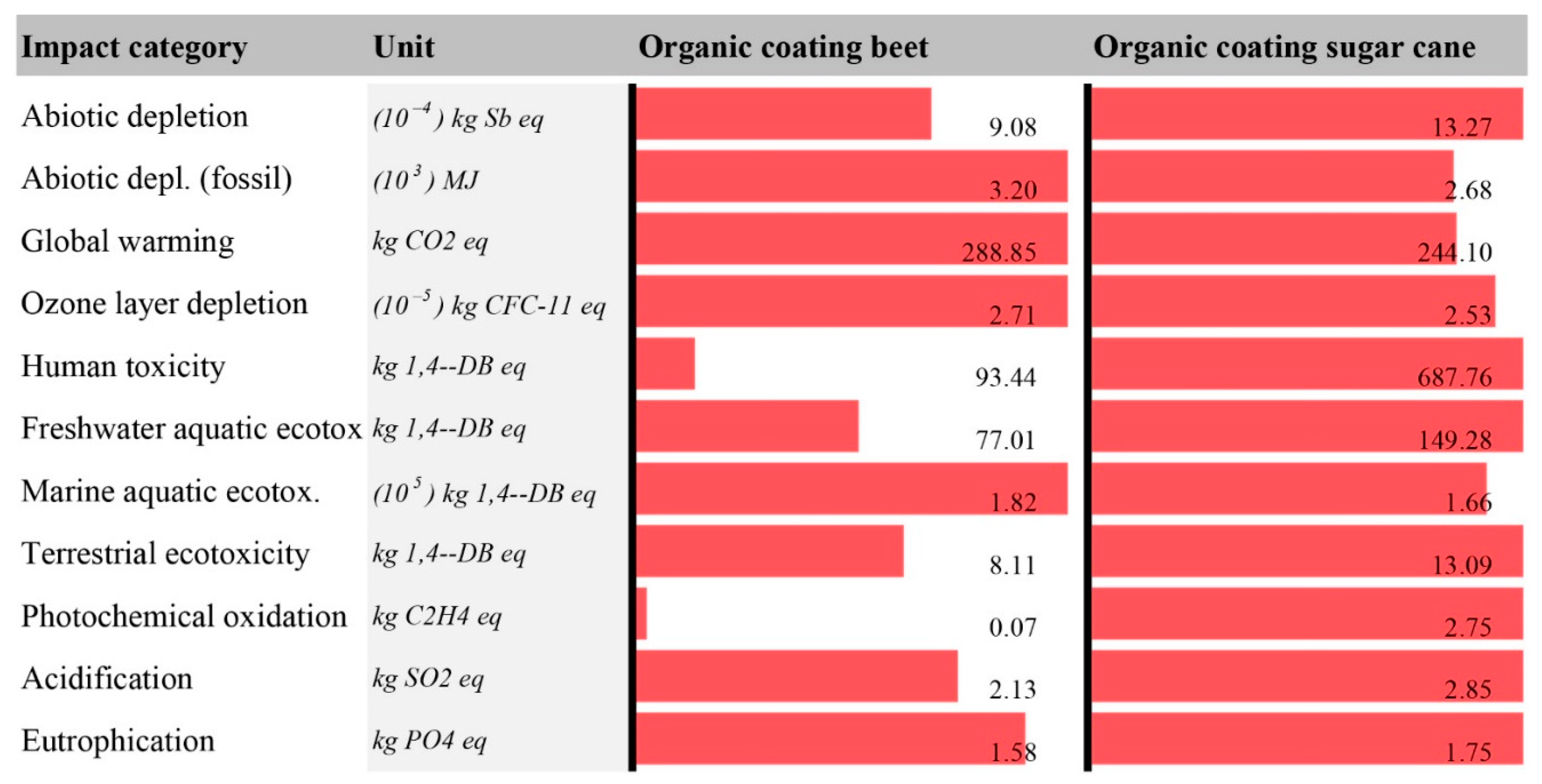

3.1. Organic Coating System Impact Assessment

3.2. Organic Coating System Comparison with Traditional Wood-Burning Technique

3.3. Sensitivity Analysis

3.4. Cost Analysis to Produce the Organic Frosting Protection

4. Discussion

4.1. Environmental Impact Aspects

4.2. Cost Aspects

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Coltivazioni: Uva, Vino, Olive, Olio. Available online: http://www.istat.it (accessed on 17 December 2020).

- Osservatori RRN. Indicatori Di Competitività-Agroalimentare-Produzione Agricola Per Settore a Valori Correnti. Osservatori RRN-Ismea. Available online: http://www.ismeamercati.it/osservatori-rrn/indicatori-competitivita/agroalimentare/produzione-agricola-per-settore-valori-correnti (accessed on 17 December 2020).

- Scheda Di Settore–Vino. Available online: http://www.ismeamercati.it/report-analisi-agroalimentare/schede-settore (accessed on 18 December 2020).

- Focus Uve da Tavola. Available online: www.ismeamercati.it (accessed on 18 December 2020).

- Vermeulen, S.J.; Campbell, B.M.; Ingram, J.S.I. Climate change and food systems. Annu. Rev. Environ. Resour. 2012, 37, 195–222. [Google Scholar] [CrossRef]

- Smith, P.; Martino, D.; Cai, Z. Agriculture. In Climate change 2007: Mitigation. Contribution of Workgroup III to the Fourth Assessment Report of the Intergovernamental Panel on Climate Change; Metz, B., Davidson, O.R., Bosch, P.R., Dave, R., Meyer, L.A., Eds.; Cambridge University Press: New York, NY, USA, 2007. [Google Scholar]

- UN Food and Agricultural Organization. Livestock’s Long Shadow: Environmental Issues and Options; UN Food and Agriculture Organization: Rome, Italy, 2006. [Google Scholar]

- Bock, A.; Sparks, T.; Estrella, N.; Menzel, A. Changes in the phenology and composition of wine from Franconia, Germany. Clim. Res. 2011, 50, 69–81. [Google Scholar] [CrossRef]

- IPPC. Summary for Policymakers. Climate Changes 2013. The Physical Science Basis. Contribution of Working Group I to the Fifth Assessment Report on the Intergovernmental Panel on Climate Change; Cambridge University Press: Cambridge, UK, 2013. [Google Scholar]

- Duchêne, E.; Huard, F.; Dumas, V.; Shneider, C.; Merdinoglu, D. The challenge of adapting grapevine varieties to climate change. Clim. Res. 2010, 41, 193–204. [Google Scholar] [CrossRef]

- Leolini, L.; Moriondo, M.; Fila, G.; Costafreda-Aumedes, S.; Ferrise, R.; Bindi, M. Late spring frost impacts on future grapevine distribution in Europe. Field Crops Res. 2018, 222, 197–208. [Google Scholar] [CrossRef]

- Cuccia, C.; Bois, B.; Richard, Y.; Parker, A.K.; de Cortazar-Atauri, I.G.; van Leeuwen, C.; Castel, T. Phenological model performance to warmer conditions: Application to Pinot Noir in Burgundy. J. Int. Sci. Vigne. Vin. 2014, 48, 169–178. [Google Scholar] [CrossRef]

- de Orduña, R.M. Climate change associated effects on grape and wine quality and production. Food Res. Int. 2010, 43, 1844–1855. [Google Scholar] [CrossRef]

- Jones, G.V.; White, M.A.; Cooper, O.R.; Storchmann, K. Climate change and global wine quality. Clim. Chang. 2005, 73, 319–343. [Google Scholar] [CrossRef]

- Marta, A.D.; Grifoni, D.; Mancini, M.; Storchi, P.; Zipoli, G.; Orlandini, S. Analysis of the relationships between climate variability and grapevine phenology in the Nobile di Montepulciano wine production area. J. Agric. Sci. 2010, 148, 657–666. [Google Scholar] [CrossRef]

- Molitor, D.; Caffarra, A.; Sinigoj, P.; Pertot, I.; Hoffmann, L.; Junk, J. Late frost damage risk for viticulture under future climate conditions: A case study for the Luxembourgish winegrowing region. Aust. J. Grape Wine Res. 2014, 20, 160–168. [Google Scholar] [CrossRef]

- Orlandini, S.; di Stefano, V.; Lucchesini, P.; Puglisi, A.; Bartololini, G. Current trends of agroclimatic indices applied to grapevine in Tuscany (Central Italy). Q. J. Hung. Metereol. Serv. 2009, 113, 69–78. [Google Scholar]

- di Giuseppe, A.; Gambelli, A.M.; Rossi, F.; Nicolini, A.; Ceccarelli, N.; Palliotti, A. Insulating Organic Material as a Protection System against Late Frost Damages on the Vine Shoots. Sustainability 2020, 12, 6279. [Google Scholar] [CrossRef]

- di Giuseppe, A.; Gambelli, A.M.; Rossi, F.; Nicolini, A.; Ceccarelli, N.; Palliotti, A. A natural organic coating to control and minimize late frost damages on wine shoots. Heat Transf. Res. 2020, 51, 1625–1635. [Google Scholar] [CrossRef]

- Evans, R.G. The Art of Protecting Grapevines from Low Temperature Injury. In Proceedings of the ASEV 50th Anniversary Meeting, Seattle, WA, USA, 19–23 June 2000; pp. 60–72. [Google Scholar]

- Miranda, C.; Bilavcik, A.; Chaloupka, R.; Dreisiebner, S. EIP-AGRI Focus Group Protecting fruit production from frost damage. EIP-AGRI Agric. Innov. 2019, 20, 809–912. [Google Scholar]

- Poling, E.B. Spring cold injury to winegrapes and protection strategies and methods. HortScience 2008, 43, 1652–1662. [Google Scholar] [CrossRef]

- Evans, R.G. The ABCs of frost management. In Proceedings of the 104th Annual Meeting of the Washington State Horticultural Association, Yakima, WA, USA, 1–3 December 2009; pp. 79–96. [Google Scholar]

- Bonciarelli, F.; Bonciarelli, U. Agronomia, 1st ed.; RCS Scuola S.p.A.: Milano, Italy, 2003; pp. 32–35. [Google Scholar]

- Giving Frost the Cold Shoulder. Available online: https://www.vineyardmagazine.co.uk/giving-frost-the-cold-shoulder/ (accessed on 2 February 2021).

- Zinoni, F.; Antolini, G.; Palara, U.; Rossi, F.; Reggidori, G. Aspetti fisici ed ecofisiologici nella previsione e difesa delle piante da frutto dalle gelate tardive. Italus Hortus 2005, 12, 63–78. [Google Scholar]

- Snyder, R.L.; de Melo-Abreu, J.P. Frost protection: Fundamentals, practice and economics. In Environment and Natural Resources Series 10; FAO: Rome, Italy, 2005. [Google Scholar]

- Nesbitt, A. Are You looking for an Alternative to Bougies? Available online: https://www.vinescapes.com/vineyard-establishment/are-you-looking-for-an-alternative-to-bougies/ (accessed on 2 February 2021).

- Napa County California Valuing Wind Machines. Available online: https://www.countyofnapa.org/1073/Valuing-Wind-Machines (accessed on 5 February 2021).

- Hannan, J. Frost Protection for High Density Orchards. Available online: https://www.extension.iastate.edu/smallfarms/frost-protection-high-density-orchards (accessed on 2 February 2021).

- Lockshin, L.; Corsi, A.M. Consumer behaviour for wine 2.0: A review since 2003 and future directions. Wine Econ. Policy 2012, 1, 2–23. [Google Scholar] [CrossRef]

- Bartocci, P.; Fantozzi, P.; Fantozzi, F. Environmental impact of Sagrantino and Grechetto grapes cultivation for wine and vinegar production in central Italy. J. Clean. Prod. 2017, 140, 569–580. [Google Scholar] [CrossRef]

- Neto, B.; Dias, A.C.; Machado, M. Life cycle assessment of the supply chain of a Portuguese wine: From viticulture to distribution. Int. J. Life Cycle Assess. 2013, 18, 590–602. [Google Scholar] [CrossRef]

- Bosco, S.; di Bene, C.; Galli, M.; Remorini, D.; Massai, R.; Bonari, E. Greenhouse Gas Emissions in the Agricultural Phase of Wine Production in the Maremma Rural District in Tuscany, Italy. Ital. J. Agron. 2011, 6, 93–100. [Google Scholar] [CrossRef]

- Barry, M.T. Life Cycle Assessment and the New Zealand Wine Industry: A Tool to Support Continuous Environmental Improvement. Master’s Thesis, Massey University, Wellington, New Zealand, 2011. [Google Scholar]

- European Commission. ILCD Handbook-General Guide on LCA-Detailed Guidance; European Commission, Publications Office of the European Union: Luxembourg, 2010; ISBN 9789279190926. [Google Scholar]

- International Organization for Standardization. ISO 14040:2006 Environmental Management—Life Cycle Assessment—Principles and Framework; ISO: Geneva, Switzerland, 2006. [Google Scholar]

- International Organization for Standardization. ISO 14040:2006 Environmental Management—Life Cycle Assessment—Requirements and Guidelines; ISO: Geneva, Switzerland, 2006. [Google Scholar]

- Zampori, L.; Saouter, E.; Castellani, V.; Schau, E.; Cristobal, J.; Sala, S. Guide for Interpreting Life Cycle Assessment Result; Publications Office of the European Union: Luxembourg, 2016. [Google Scholar] [CrossRef]

- Cavazza, D. Nuova Enciclopedia Agraria Italiana. Parte V; Viticoltura; UTET: Turin, Italy, 1914; pp. 473–475. [Google Scholar]

- ISTAT. Temperatura e Precipitazione nelle Principali Città. Anni 2002–2016. Available online: https://www.istat.it/it/files//2018/06/Report_Meteoclima.pdf (accessed on 18 December 2020).

- Werner, F.; Hischier, R. Aktualisierung der Modelle und Datensätze zu Holz und Holzprodukten in der Datenbank ecoinvent, Schlussbericht. Available online: https://www.bafu.admin.ch/bafu/de/home/themen/wald/fachinformationen/strategien-und-massnahmen-des-bundes/aktionsplan-holz/projektuebersicht-und-ergebnisse-des-aktionsplans-holz0/ergebnisse--datengrundlagen-.html (accessed on 20 December 2020).

- Wernet, G.; Bauer, C.; Steubing, B.; Reinhard, J.; Moreno-Ruiz, E.; Weidema, B. The ecoinvent database version 3 (part I): Overview and methodology. Int. J. Life Cycle Assess. 2016, 21, 1218–1230. [Google Scholar] [CrossRef]

- PRé Sustainability B.V. SimaPro 8.4.0.0. Available online: https://simapro.com/2017/new-in-simapro-8-4/ (accessed on 5 July 2017).

- Doka, G. Treatment of Waste Wood, Untreated, Municipal Incineration. Ecoinvent Database, GLO 2020. Available online: https://www.ecoinvent.org/files/change_report_v3_5_20180823.pdf (accessed on 1 May 2021).

- PRé Sustainability B.V. Simapro Database Manual. Available online: https://support.simapro.com/articles/Manual/SimaPro-Methods-manual (accessed on 1 May 2021).

- Huijbregts, M.A.J.; Steinmann, Z.J.N.; Elshout, P.M.F.; Stam, G.; Verones, F.; Vieira, M.; Zijp, M.; Hollander, A.; van Zelm, R. ReCiPe2016: A harmonised life cycle impact assessment method at midpoint and endpoint level. Int. J. Life Cycle Assess. 2017, 22, 138–147. [Google Scholar] [CrossRef]

- European Commission Joint Research Center. Environmental Factsheet: Sugar. Available online: https://ec.europa.eu/jrc/sites/jrcsh/files/QMS_H08_BISO_D.8_BISO-EnvSust-Food-and-feed-Sugar_150513.pdf (accessed on 5 January 2021).

| Sugar Organic Coating and Straw | ||

|---|---|---|

| Materials/assemblies | ||

| Sugar, from sugar beet {GLO}|market for|Alloc Def, U | 0.5 | ton |

| Straw {GLO}|market for|Alloc Def, U | 0.1 | ton |

| Polypropylene, granulate {GLO}|market for|Alloc Def, U | 1.5 | kg |

| Tap water {Europe without Switzerland}|market for|Alloc Def, U | 1 | kg |

| Processes | ||

| Application of plant protection product, by field sprayer {RoW}|processing|Alloc Def, U | 1 | ha |

| Transport, tractor and trailer, agricultural {GLO}| market for|Alloc Def, U | 1.5 | tkm |

| Transport, passenger car {RER}|market for|Alloc Def, U | 40 | km |

| Stretch blow moulding {GLO}|market for|Alloc Def, U | 1.5 | kg |

| Cotton Candy Machine (5 Years Lifespan) | ||

| Materials/assemblies | ||

| Steel, low-alloyed {GLO}|market for|Alloc Def, U | 13 | kg |

| Cable, three-conductor cable {GLO}|market for|Alloc Def, U | 5 | m |

| Corrugated board boxes, technology mix, prod. mix, 16.6% primary fibre, 83.4% recycled fibre EU-25 S | 3 | kg |

| Processes | ||

| Transport, freight, light commercial vehicle {GLO}|market for|Alloc Def, U | 0.015 × 1500 | tkm |

| Electricity, low voltage {IT}|market for|Alloc Def, U | 68.75 | kWh |

| Materials/Assemblies | ||

|---|---|---|

| Wood chips, wet, measured as dry mass {RoW}|hardwood forestry, oak, sustainable forest management|Alloc Def, U | 5000 | kg |

| Polypropylene, granulate {GLO}|market for|Alloc Def, S | 10 | kg |

| Processes | ||

| Transport, freight, lorry, unspecified {GLO}|market for|Alloc Def, U | 650 | tkm |

| Transport, passenger car {RER}| market for|Alloc Def, U | 40 | km |

| Transport, tractor and trailer, agricultural {GLO}|market for|Alloc Def, S | 10 | tkm |

| Extrusion, plastic film {GLO}| market for|Alloc Def, U | 10 | kg |

| Wood burning | 5000 | kg |

| Tests Carried out with Sucrose and Straw | ||||

|---|---|---|---|---|

| Sugar Used in 1 He [kg] | Cost of Raw Materials [€] | Thermal Energy [kWh] | Cost of Energy Consumption [€] | Overall Costs [€] |

| 250 | 237 | 4612.5 | 960 | 1200 |

| 500 | 474.75 | 3787.5 | 787.5 | 1260 |

| 749 | 711.75 | 3577.5 | 742.5 | 1455 |

| 999 | 948.75 | 3255 | 675 | 1627.5 |

| 1249 | 1186.5 | 2925 | 607.5 | 1792.5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Frota de Albuquerque Landi, F.; Di Giuseppe, A.; Gambelli, A.M.; Palliotti, A.; Nicolini, A.; Pisello, A.L.; Rossi, F. Life Cycle Assessment of an Innovative Technology against Late Frosts in Vineyard. Sustainability 2021, 13, 5562. https://doi.org/10.3390/su13105562

Frota de Albuquerque Landi F, Di Giuseppe A, Gambelli AM, Palliotti A, Nicolini A, Pisello AL, Rossi F. Life Cycle Assessment of an Innovative Technology against Late Frosts in Vineyard. Sustainability. 2021; 13(10):5562. https://doi.org/10.3390/su13105562

Chicago/Turabian StyleFrota de Albuquerque Landi, Fabiana, Alessia Di Giuseppe, Alberto Maria Gambelli, Alberto Palliotti, Andrea Nicolini, Anna Laura Pisello, and Federico Rossi. 2021. "Life Cycle Assessment of an Innovative Technology against Late Frosts in Vineyard" Sustainability 13, no. 10: 5562. https://doi.org/10.3390/su13105562

APA StyleFrota de Albuquerque Landi, F., Di Giuseppe, A., Gambelli, A. M., Palliotti, A., Nicolini, A., Pisello, A. L., & Rossi, F. (2021). Life Cycle Assessment of an Innovative Technology against Late Frosts in Vineyard. Sustainability, 13(10), 5562. https://doi.org/10.3390/su13105562