Abstract

To facilitate transition to a sustainable food system, it is necessary to address food losses. A large proportion of waste occurs during primary production, with large quantities of edible crop parts left in the field at harvest. One such product is broccoli, where normally only around one-third of the edible parts of the plant are harvested in Sweden. Much of the broccoli plant consists of edible leaves and this side stream represents an unused resource with great potential. This study assessed the potential environmental savings that can be achieved by utilising broccoli side streams as a powder in soups and bread. Consequential and attributional life cycle assessments were conducted, based on scenarios relevant for growers in southern Sweden. The results showed that the scenario with the largest saving potential was to process the broccoli side streams into a powder for use in broccoli soup. The main saving was due to substitution of imported broccoli powder, which was assumed to be produced from broccoli florets using a more fossil-based energy mix. The second best scenario was to use the side-stream broccoli powder as a wheat substitute in bread but, since wheat flour is less resource-demanding than imported broccoli powder, the emission savings were lower in this case. However, replacing wheat flour with a vegetable-based product could provide additional health benefits that are important in achieving a healthy, locally available, and environmentally friendly diet suitable for a sustainable food system.

1. Introduction

Population growth drives demand for sustained food supply, which leads to increasing pressure on natural resources [1]. In each year until 2050, farmers will have to feed an additional 40–86 million people [2]. To meet this increasing food demand, solutions must be found to secure food for everyone, in both the current and future population. This will require changes in the way that food is produced, stored, processed, distributed and consumed, since the current system relies on nonrenewable resources. The authors of [3] suggest five major strategies to meet these challenges, i.e., closing the yield gap, increasing production limits by genetic modification, expanding aquaculture, dietary changes and reducing waste. These all involve utilising the full potential of production systems so that more food can be supplied without a parallel increase in resource inputs. One of the main challenges related to environmental impact and food security include human diet and food waste management [4,5,6]. As suggested by [7], multidisciplinary solutions for food waste valorisation, increased circularity in the currently linear food supply system and a transition towards a more plant-based diet is necessary to meet the 17 Sustainable Development Goals. Waste reduction and food waste valorisation is unique in this context, since it focuses on food that is already produced, but not consumed for various reasons. Since reduced waste of edible food is also one of the least controversial ways to make the food supply chain more productive, it has the potential to be used immediately to decrease competition for natural resources, allowing these resources to be saved for future production to avoid a future food crisis [8].

Food waste and losses occur in the whole food supply and consumption chain, with losses at household level often being regarded as a particular problem. However, studies suggest that food waste and losses in primary production pose a problem of equal magnitude to household losses (e.g., [9,10,11,12]), although it is less well researched. It is therefore critical to utilise all resources and prevent food losses and waste in the agricultural sector. It is common practice in the modern food supply chain to use only a fraction of the edible parts of certain crops. For example, in the case of some brassica vegetables, such as cauliflower and broccoli, only the florets and adjacent parts are used. According to the Swedish Food Agency and the Nordic Nutrition Recommendations, brassica vegetables are a foodstuff that should be prioritised in a healthy diet [13,14]. Fruit and vegetables are among the food groups known to have high waste and losses along the food supply chain [9], with e.g., carrots, cabbage and Brussel sprouts reported to have high losses in primary production [15,16]. These wastes have potential for use as side streams.

Utilising available by-products and side streams from the food supply chain could provide an opportunity for producers and food processing industries to maintain a stable supply of high-quality ingredients. Research suggests that there are multiple benefits associated with vegetable-based side stream recovery, e.g., fruit and vegetable residues can be used to produce flour, juice or chutney, for direct consumption or as a functional ingredient within the food supply chain to increase the nutritional value of other types of food [17,18,19]. Other studies suggest extracting valuable bioactive compounds such as vitamins and fibre from fruit and vegetable side streams, for use as additives in food production and pharmaceutical applications [20,21,22]. A common aim in many studies on side stream valorisation is to use existing resources in an efficient and circular manner, and thereby reduce the burden on the environment. Improved resource efficiency by reducing food losses is considered essential to maintain future food security, reduce the environmental impact related to the food system and support a circular economy, which are all important factors in achieving sustainable development [23]. Prevention of food waste and valorisation of surplus food for human consumption is also considered the most beneficial option for side stream recovery in the waste hierarchy [24].

Broccoli is a product where only a small fraction of what could be eaten is harvested, since primarily only the florets (head) and some of the adjacent stem are utilised. In Sweden, fresh broccoli is normally sold in 250 g packs, due to market requirements, and broccoli crops are harvested several times, at intervals, to obtain the required size. However, other parts of the broccoli plant, such as the leaves and additional parts of the stem, are also edible and could be used as food, along with florets rejected in the fields for being too small or too large. Ultimately, more than 75% of the aboveground parts of broccoli are left in the field [20], and the majority of these are edible. The leaves are rich in vitamin C, vitamin K and carotenoids, including provitamin A, while brassica vegetables also contain glucosinolates [25], which are attracting interest for their health promoting properties, e.g., anti-inflammatory and anticancer activity [26].

A study by [19] concluded that broccoli leaves and stems are highly nutritious and therefore could be utilised as a functional ingredient within the food supply chain. However, even if it is possible and beneficial to eat other parts of the broccoli plant than standard-size heads, the environmental benefits of avoiding wasting these parts are unknown. The aim of this study was therefore to assess the environmental impact of different products produced from what are currently unharvested broccoli parts, especially broccoli leaves, and the potential environmental benefits of shifting from the current production system to a multi-output production system. The goal was to assess if increased utilisation of broccoli side streams can contribute to a more sustainable food system.

2. Materials and Methods

The method used was life cycle assessment [27,28], covering Swedish production of broccoli and the potential in upgrading the currently unused side streams from broccoli production. This side stream consists mainly of leaves, but also heads that are too small or too large to be sold under current market quality criteria. All these parts are edible and could be used as food, instead of the current practice of leaving them in the field. The functional unit in the analysis was set to 1 kg of collected broccoli parts. To assess the system, both attributional life cycle assessment (ALCA) and consequential life cycle assessment (CLCA) were conducted. The reason for using both methodologies was to capture the product-oriented nature of the case study through ALCA and the system transformation perspective through CLCA. For modelling the system, the software OpenLCA, including the database Ecoinvent 3, was used. The impact assessment method used was the ILCD 1.0.8 2016 midpoint and system expansion was applied to evaluate the impacts of all products through the virgin products they substituted.

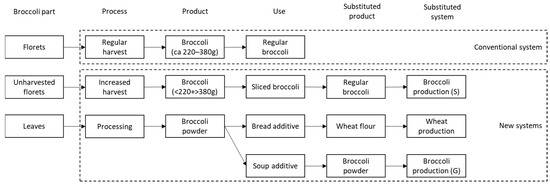

The system comprised the main stages of harvesting the broccoli leaves, transport and processing these materials into a powder. Thereafter, the broccoli powder was assumed to be used as an additive to replace wheat flour in bread (‘bread additive’ scenario 1) or to replace imported broccoli powder made from broccoli florets used in soups (‘soup additive’ scenario). For comparison, in a fictive third scenario broccoli floret products not fulfilling the size criteria were assumed to be sliced and sold as a salad component, replacing standard size broccoli (‘sliced broccoli’ scenario). Since a small-scale production system with limited influence on the whole market was considered, the potential market effect was excluded in the CLCA. Therefore, the only difference between the ALCA and CLCA (beside use of average and marginal data, respectively) was the perspective, where the ALCA compared the three new products (scenarios 1–3) and the CLCA assessed the potential in changing from the conventional production system to a new system with multiple outputs (Figure 1).

Figure 1.

General outline of the system assessed, with different broccoli parts as input and output in the form of products that can be used to substitute other products and associated production systems.

The system was based on an actual case in which different production steps were tested in a research project (EIP Agri, Swedish Board of Agriculture, project No. 2017–4500). However, this system is not yet fully established, so the assessment was not based on an existing operation, but rather on an operation that could be possible in a well-established business structure. This operation was centred on a vegetable wholesaler located in Helsingborg in southern Sweden and the broccoli was assumed to be produced by its contracted farmers currently growing broccoli. The processed broccoli powder was assumed to be used by a bakery in Lidköping and by a food producer in Fjälkinge. Only added processes and benefits to the conventional system were included in the assessment, which covered the processes from harvest to factory/wholesaler gate, where the product is ready for market. The potential loss of soil carbon due to greater outtake of crop biomass from the fields was not included in the assessment. Nether was the removal of other nutrients that potentially need to be supplemented by increased use of mineral fertilisers. This is motivated by the fact that the majority of the broccoli plant biomass would be left on the field even if the side streams were harvested.

2.1. Life Cycle Inventory for ALCA

In the ALCA, only the three different products in the new system were compared (Figure 1). The broccoli leaves and rejected heads were considered a free resource from an environmental perspective, since they do not require any extra input to be produced, so agricultural production was not included in the analysis. Included in the analysis were: harvest of leaves and substandard broccoli heads; transportation from fields to processing plant; processing of broccoli leaves to a powder; transport from processing plant to bakery or soup factory; substitution of regular broccoli, wheat flour or broccoli powder. The assessment considered the three products ‘bread additive’, ‘soup additive’ and ‘sliced broccoli’ (Figure 1).

2.1.1. Harvest

For the products ‘bread additive’ and ‘soup additive’, the broccoli leaves were assumed to be harvested and collected at the same time as commercial broccoli heads. However, this prolongs the harvesting procedure and the handling of trays extends the harvesting time. The heads outside the quality norms were assumed to be harvested after the last commercial harvest, thereby creating an extra work step. Harvesting was done by hand and therefore assumed to generate a negligible environmental impact. However, additional tractor transportation in the field was needed to collect any side stream parts. The same tractor transported the heads back to the farm, and it was assumed that the total distance driven was 3 km, including field operations on each farm.

Harvest of broccoli was assumed to take place on two farms in Båstad and Grevie, southern Sweden, that are currently producing broccoli for the vegetable wholesaler [29]. It was assumed that these farms contributed equally to the supply of broccoli products.

2.1.2. Transportation from Farm to Processing

Transportation was modelled based on the actual distances from the two farms to Norup, Sweden, for processing. The distances were calculated by letting Google maps [30] suggest the fastest (but not necessarily the shortest) route, as this is the most likely route for a truck to drive. Emissions were calculated based on the Ecoinvent [31] transport process with a lorry of 7.5–16 metric tons and a EURO6 engine. The transport distance was set to 110 and 1.03 km for the farm in Båstad and Grevie, respectively.

2.1.3. Processing

Processing took place in Norup and included washing, blanching, slicing, drying and milling to a powder with approximately 7% water content. From a harvested batch of approximately 300 kg of fresh leaves, 20 kg of broccoli powder was produced. It was assumed that one-third of the mass loss was due to the washing process and the rest evaporated during drying. The environmental impact was calculated using the model for processing and drying of bread grain, seed and legumes from Ecoinvent [31]. However, since this process is energy-demanding and was originally based on German electricity, it was not sufficient for the conditions in southern Sweden. Therefore, the electricity input was changed to include 50% Danish electricity mix and 50% Swedish electricity mix, due to energy trade between these nations and the proximity of southern Sweden to Denmark. This reduced the emissions due to the much larger proportion of renewables, especially in the Swedish energy mix.

2.1.4. Transportation from Wholesale to Industry Application

After processing, the powder was assumed to be transported from Norup to a bakery in Lidköping, Sweden (322 km) for the ‘bread additive’ scenario, and to a food producer in Fjälkinge, Sweden (23.8 km) for the ‘soup additive’ scenario. For the ‘sliced broccoli’ scenario, the broccoli was assumed to be transported to the vegetable wholesaler in Helsingborg. In transportation, only 67 g of broccoli powder needed to be transported for every kg of broccoli initially harvested, due to the large mass loss during processing. Transport was calculated as described previously, using the fastest way in Google maps [30] together with the Ecoinvent [31] transport process with a lorry of 7.5–16 metric tons and EURO6 engine.

2.1.5. Industry Application and Substitution

In two of the scenarios, broccoli powder was produced for industrial applications, while in the third scenario sliced broccoli was produced. In all three scenarios, other products made from virgin materials were substituted, giving an emission credit to each broccoli-based product.

In the ‘bread additive’ scenario, the broccoli powder replaced wheat flour in a 1:1 mass relationship. However, broccoli powder changes the flavour of bread and only about 1% of wheat flour could be replaced in a neutral-tasting bread event, although it would be technically possible to replace up to 30% of the wheat flour. The wheat flour replaced was assumed to follow the Ecoinvent [31] process for wheat production, which included yield of 7567 kg/ha to produce wheat grain with a moisture content at storage of 14.5%. This wheat was assumed to be further dried using the process for drying bread grain, seed, and legumes from Ecoinvent [31], but with adjustment to include Danish and Swedish electricity mix as specified above (Section 2.1.3). Transportation and milling impact were both assumed to be negligible due to the close proximity of the bakery to arable land and the low emissions generated in a milling process powered by a Swedish/Danish electricity mix.

In the broccoli ‘soup additive’ scenario, the broccoli powder was assumed to be transported to the food producer in Fjälkinge, which produces ingredients for ready meals like soups and sauces. Here the broccoli powder was assumed to replace other broccoli powder produced from broccoli florets grown and processed in Germany. The German broccoli powder was assumed to include the processes for broccoli production and for drying bread grain, seed, and legumes in Ecoinvent [31]. However, these processes were not adjusted to include any other electricity mix than the German mix. In addition to production, it was also assumed that this powder was transported by a large (>32 t) lorry with a EURO5 engine [31] over a transportation distance of 620 km, corresponding to the fastest route from the city of Hanover, located in central Germany, to the food producer in Fjälkinge.

In the ‘sliced broccoli’ scenario, it was assumed that sliced broccoli was harvested and sold, allowing both smaller (<220 g) and larger broccoli heads (>380 g) to be used. There are of course practical limitations on how small and large broccoli heads would actually be harvested, but since this scenario was not tested in practice, it was assumed that all broccoli parts could be included. To our knowledge, there is no interest among food supply chain actors in changing the current practice, but as this scenario was a very simple alternative, it was included for comparison. Since more broccoli was produced in this scenario, it was assumed that these sliced products replaced broccoli from the same producers, since it is likely that the producers can decrease production if they can harvest more from the same field. Through this scenario, 1 kg of sliced broccoli therefore replaced 1 kg of regular broccoli. This regular broccoli was modelled using the Ecoinvent [31] process for broccoli production.

2.2. Life Cycle Inventory for CLCA

In the CLCA, the same processes as in the ALCA were included, but here the focus was shifted from a single output system to a multiple output system where by-products were also used to produce food. Only the two products based on broccoli powder from leaves were included, in two scenarios that were compared with the ‘old system’. In the first scenario (‘new system’), it was assumed that the broccoli side stream was used to produce broccoli powder distributed equally as bread additive and soup base. The second scenario (‘optimised new system’) only included production of soup base, as this was the product with the best environmental performance.

Since the CLCA evaluated the shift from ‘the old system’ to two versions of a ‘new system’, primary production of broccoli was included in the assessment, unlike in the ALCA. The processes included were: agricultural production of broccoli; additional harvest of broccoli heads and leaves; transportation from field to processing plant; processing of broccoli leaves to a powder; transport from processing plant to bakery or soup factory; substitution of wheat flower or broccoli powder. The Ecoinvent processes used for the CLCA were the consequential processes, which use marginal energy sources and handle all by-products through system expansion, and not by the cut-off method used in the ALCA processes

2.2.1. Cultivation and Harvest

In the ‘old system’, cultivation of broccoli was modelled from the Ecoinvent [31] process for broccoli production. The extra harvesting relating to collection of broccoli leaves and associated transport were assumed to be with a tractor and trailer, modelled after the Ecoinvent [31] process for agricultural transport with tractor and trailer. It was assumed to be driven a total distance of 3 km, including field operations and transportation back to the farm.

2.2.2. Transportation and Processing

Transportation and processing were both based on the same data and assumptions as in the ALCA. The only difference was that the processes used from Ecoinvent [31] included system expansion to handle by-products.

2.2.3. Industry Application and Substitution

The industry applications for the two scenarios were broccoli powder produced as bread additive and as a soup base. In both scenarios, other products produced from virgin materials were substituted, giving an emissions credit to each product. For the bread scenario, the broccoli powder replaced wheat flour in a 1:1 mass relationship. The wheat flour replaced was assumed to involve the Ecoinvent [31] process for wheat production and was further dried using the process for drying bread grain, seed and legumes from Ecoinvent [31].

For the soup base scenario, the broccoli powder was assumed to be transported to the food producer, which produces ingredients for ready meals like soups and sauces. The broccoli powder was assumed to replace other broccoli powder produced from broccoli florets grown and processed in Germany. The German broccoli powder was assumed to involve the processes for broccoli production and for drying bread grain, seed and legumes [31]. These processes were not adjusted to include any other electricity mix than the German mix. In addition to the production step, it was assumed that this powder was transported by a large (>32 t) lorry with a EURO5 engine [31]. The transportation distance was assumed to be 620 km, which corresponds to the fastest route from the city of Hanover in central Germany to the food producer in Fjälkinge, Sweden.

Two scenarios were assessed based on the two products. A ‘new production’ scenario included production of broccoli together with production of the broccoli powder used as both a soup base and bread additive, equally distributed. An ‘optimised new production’ scenario included only the product that generated the lowest impact for the largest number of impact categories.

3. Results

For clarity, the results are structured into three sections. Section 3.1 presents the results from the ALCA comparing the impact of three products produced from broccoli side streams, while Section 3.2 presents the results of the CLCA describing the impact of a shift from conventional broccoli harvesting to a new system with multiple outputs. Section 3.3 presents the results of sensitivity analyses on all LCA results.

3.1. Comparing the Impact from Broccoli Side-Stream Products

The ALCA results in are displayed in Table 1. The ‘sliced broccoli’ scenario generated the lowest environmental impact in 13 of the 16 impact categories considered and the ‘soup additive’ scenario had the lowest impact in three categories, although the difference was very small for many categories. Of the environmental impact categories investigated, all indicated the ‘bread additive’ scenario to be that generating the highest environmental impact relative to the other products.

Table 1.

Attributional life cycle assessment (ALCA) results on the environmental impact in 16 different categories for the three scenarios investigated (bread additive, soup additive, sliced broccoli).

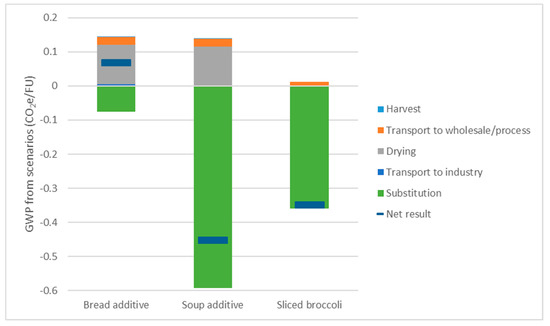

Global warming potential was selected as an environmental impact category to investigate in greater depth. In these results, the substitution process dominated the impact for the ‘soup additive’ scenario and the ‘sliced broccoli’ scenario (Figure 2). The impact was greatest for the ‘soup additive’ scenario, where broccoli powder produced in Germany was replaced, so this was the product with the lowest impact or the largest savings in terms of greenhouse gas emissions. The ‘bread additive’ scenario showed equal positive impacts from processing and transportation as the ‘soup additive’ scenario, but a much lower negative impact from the substitution process. This was due to the wheat flour replaced in the ‘bread additive’ scenario being much less resource-demanding in terms of production than the German broccoli powder it replaced. The net impact from the ‘sliced broccoli’ scenario lay between that of the other scenarios, even though only product substitution made a major contribution to the net result in that scenario.

Figure 2.

Global warming potential impact from each process included in the ‘bread additive’, ‘soup additive’ and ‘sliced broccoli’ scenarios.

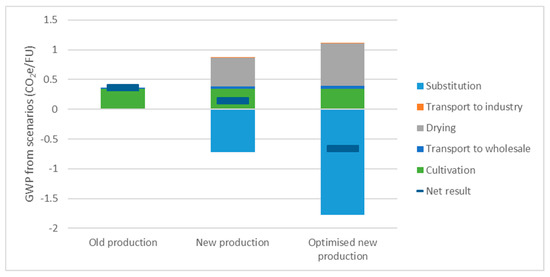

3.2. Consequences of a Shift in Production System

The CLCA results showed a slightly shifted perspective, indicating the change in impact imposed by the shift (Table 2) and not the impact from each scenario. A shift from the ‘old production’ system, where only broccoli heads of a certain size were harvested, to the ‘new production’ system, where the leaves were harvested and processed into broccoli powder, reduced the environmental impact for nine of the 16 impact categories studied. A shift from ‘old production’ to the ‘optimised new production’ system, where the broccoli powder was only used as a soup base to replace German broccoli production, reduced the environmental impact in all 16 categories assessed (Table 2).

Table 2.

Consequential life cycle assessment (CLCA) results on the environmental impact in 16 different categories for the ‘new production’ and ‘optimised new production’ scenarios compared with the ‘old production’ system. Negative values indicate a reduction in emissions following the shift and positive indicate an increase in emissions.

Once again, global warming potential was selected as an environmental impact category to investigate in greater depth. These results showed that the substitution process dominated the impact from the ‘new production’ system (Figure 3). This impact was largest for the soup base scenario, where broccoli powder produced in Germany was replaced, so the shift from ‘old production’ to ‘optimised new production’ gave the largest saving of greenhouse gas emissions. In the ‘new production’ scenario, the broccoli powder was used in equal amounts to replace wheat flour in bread and broccoli powder in soups and sauces. However, processing of the broccoli was quite resource-demanding in relation to the resources saved when replacing wheat production, so this scenario only slightly reduced the impact in relation to ‘old production’.

Figure 3.

Global warming potential impact from each process included in the ‘old production’, ‘new production’ and ‘optimised new production’ scenarios.

Both the ‘new production’ and ‘optimised new production’ scenarios reduced the environmental impact in relation to the ‘old production system’. This indicates that there is potential in collecting broccoli side streams, even though these will require additional processing to make products available to the market.

3.3. Sensitivity Analysis

A sensitivity analysis was carried out on both the ALCA and CLCA scenarios, to identify the parameters that had the greatest impact on the results. The parameters tested were selected due to their expected high influence on the results. Global warming potential was selected to represent the results and several of the assumptions were tested by changing the values in percentage terms (see Table 3). The results for both the ALCA and the CLCA scenarios showed that parameters affecting the energy consumption needed for drying the broccoli to produce broccoli powder, especially the type of energy used, were sensitive to variations. For the ALCA scenario, assumptions regarding the ratio of substitution between broccoli powder and the substituted product were sensitive to variation. The results for the CLCA showed that the type of energy used had the largest impact on the results. None of these findings were unexpected, as the substitution process and drying of broccoli were the processes with the largest impact on global warming potential in most of the scenarios analysed.

Table 3.

Results of sensitivity analysis on the attributional (ALCA) and consequential (CLCA) life cycle assessment scenarios with changes in input parameters. Positive values indicate an increase in global warming potential following changes in a specific parameter.

4. Discussion

This analysis clearly indicated that there are potential environmental savings in recovery of side streams from broccoli production. The current practice involves leaving much of the edible biomass from the broccoli plants in the field, since only heads of a certain size and visual appearance are considered sellable on the Swedish market. For all recovery scenarios investigated, there was an environmental cost in harvesting and processing the broccoli side stream, but that was balanced out by the (sometimes) larger environmental savings in replacing other products with a higher environmental impact. In the ALCA, all products assessed except the bread additive gave a negative value in all environmental impact categories, indicating that it would be an emission saving to produce any of these products using what is currently a free resource within broccoli production. Producing soup (or sauce) base from broccoli powder had the largest saving potential (in terms of global warming potential), mainly because it replaced other broccoli powder produced with large inputs from the German energy mix. The emissions reduction was also due to leaves (currently not harvested) being the side flow utilised in the ‘soup additive’ scenario, and to the energy source for drying the broccoli being shifted to energy sources generating much less greenhouse gas emissions.

In the CLCA, all results were slightly more extreme, most likely due to the shift from using average data to marginal data. However, the results were in line with those from the ALCA, e.g., the scenario with the largest saving potential was again that in which substandard broccoli heads were harvested together with leaves and processed into broccoli powder that replaced German broccoli powder made from florets only. When both LCA methods give the same results, this indicates that the results are more reliable. However, the sensitivity analysis indicated that all scenarios were still sensitive to variations in the major processes, including the substitution and the type of energy used for drying, so the results should be interpreted with these limitations in mind.

Other limitations to this study are of course uncertainties and representability in data, which is a common problem in LCA studies using inputs from databases. However, there are more fundamental limitations to this type of study. First, all scenarios were based on the assumption of market demand for the broccoli products assessed. If there is no demand for broccoli soup base or bread additive made using broccoli powder, there will be no gain in harvesting and processing the broccoli side stream. Another consideration is that German broccoli powder is fairly cheap and therefore will be difficult to outcompete (in a strict price perspective) by Swedish broccoli producers. As shown in [32], the environmental effect from substituting current production can be significant, especially if it is associated with direct and indirect land use change, but if the substituted product is cheaper than the new product there is a risk that the shift will never occur. However, the growing consumer interest in locally produced food [7,33] can add value to ingredients produced in a local area or country. In addition, consumers have been found to view country of origin and transport distance as important indicators of climate impact and sustainability for vegetables [34], so domestically produced products could be perceived as having added value. For commercial companies, green branding and environmental issues are becoming increasingly important [35,36].

In addition to market-based uncertainties, there will be a potential loss of soil carbon due to the higher outtake of biomass when broccoli leaves are harvested. However, since a substantial amount of biomass from stems, roots and the lowest leaves close to or in contact with the ground will still be left in the field, contributing to soil carbon, it seems unlikely that the soil carbon pool would be affected by harvesting of broccoli leaves to an extent that significantly alters the environmental impact results.

Despite the limitations described, the results obtained in this study are in line with previous findings. Several studies have shown that there are clear environmental gains from recovery of food waste, especially if it can be used to feed humans, either directly or following conversion (e.g., [18,23,24,37]). Previous assessments of vegetable surplus foods have found environmental savings when secondary use of by-products is included. For example, the authors of [38] found that 50% food loss prevention at farm level resulted in about 2% reduction in global warming potential, while including secondary use of peach by-products for energy production decreased global warming potential by 11% in comparison with not accounting for the food loss. Use of available biomass to replace food ingredients was also assessed by [39], who found that using food surplus materials with high nutritional value, such as animal blood or brewer spent grains, as a food ingredient or as animal feed gave greater global warming savings than reusing these materials for energy production or dumping them in landfill. In [40], the authors estimated that a 50% reduction in peach and nectarine loss would result in a 4% reduction in global warming potential, while utilising surplus food waste as animal feed could lower the global warming impact by more than 50% in comparison with landfilling. Thus, the environmental impact, especially with respect to global warming, decreases when food waste is utilised according to the higher priority levels of the waste hierarchy [6,18]. The results from the present study should therefore be considered consistent with previous findings.

There is always a risk of advanced solutions being developed for small problems that could be solved using a simpler solution. In the present case, it would be possible to eat broccoli leaves and substandard sizes of broccoli heads without any processing. As the results for the ‘sliced broccoli’ scenario indicated, it would be equally beneficial to harvest substandard sizes of broccoli heads and sell them as broccoli products in the supermarket, without any energy-demanding processing. However, the policy of selling broccoli in standard sizes was introduced partly to reduce food waste in supermarkets, since some irregular sizes are rejected by consumers. This ‘outsourcing’ of food waste from retail to upstream actors in the food supply chain is well known (e.g., [18,41,42,43,44]) and it was therefore not surprising to find it in the broccoli supply system. However, it is better to leave food in the field, rather than to transport and pack it, if it is going to be wasted, so it would be inadvisable to re-introduce irregular sizes of broccoli heads in supermarkets without changing consumer preferences to ensure that these products are acceptable.

Improved food security, improved nutrition and increased environmental sustainability are fundamental objectives motivating strong actions to reduce food losses and waste [1]. However, to fully utilise the potential of broccoli side streams, a production shift might need to be supported by policy interventions to increase broccoli consumption by Swedish consumers. Such policy interventions can be justified by the health benefits but can be difficult to implement within the legal boundaries of the European Union internal market. It will also be difficult to force people to eat more broccoli if their preferences dictate otherwise, but new products where broccoli side streams are included could be an easy way of adding health and environmental benefits to existing products. Since broccoli side streams are an available resource, using them as a functional ingredient within the food supply chain would likely also increase the nutritional value of other types of food [17,19,45]. There is currently a trend for increased awareness among modern consumers of the specific health properties of food products [6], so use of locally produced broccoli by-products in baked goods and soups could be a profitable business opportunity. Such products could also support the trend of eating less animal-based food, thereby supporting transition to a more sustainable diet. Implementing a plant-based diet on a regular basis has also been emphasised by [4,7] as a necessity action to mitigate environmental burdens related to the food system, especially considering climate impact.

Increased nutrient recovery and avoided food waste are essential components of a circular economy and could also help to achieve a more sustainable food supply chain. However, the economic aspect of upgrading horticultural side streams is important to consider, since new production processes often require economic initiatives. By opting for recovery solutions that require few refining steps and where preferably all available material can be reused, and not only certain nutrients, a more cost-efficient side-stream valorisation process could be achieved. In terms of sustainable development, it is important that policy makers and industry do not allow short-term economic aspects to overshadow the potential environmental benefits of food waste resource recovery [46,47]. On the contrary, food waste valorisation and integrated biorefining systems are predicted to pose as key components of a circular economy and sustainable food supply chain in the 21st century [6,7]. Producing value-added products from food waste that lower the environmental burden could justify a higher production and investment cost, especially as it also enables the transition towards more circular bioeconomy and efficient use of resources [46]. Ultimately, an efficient utilisation of agro-industrial residues and horticultural side streams could reduce both the economic and environmental impact of the food supply chain [47,48], provided that sustainable solutions are adapted and supported by policy makers, industry and consumers.

5. Conclusions

This study revealed potential environmental savings in recovery of side streams from broccoli production. In comparisons of products made from side streams, a sliced broccoli scenario generated the lowest environmental impact in 13 of 16 impact categories assessed. A soup additive scenario had the lowest impact in three categories, although the difference was very small for many categories. In assessments of a shift in production, a scenario where broccoli side streams (substandard heads and leaves) were harvested and used in broccoli soup gave the greatest potential to reduce the environmental impact. However, that system proved sensitive to parameters relating to the substitution and to energy input, which was of major importance for the processes with the highest impact on the results. Despite possible uncertainties in the data, the results clearly indicate that recovery of broccoli side streams confers important environmental benefits. If economic barriers can be overcome, this free resource can be used to replace other more resource-demanding products and more products can be recovered per unit production area.

Author Contributions

Conceptualisation, M.E.; data curation, M.E., K.L.; formal analysis, M.E., L.B., K.L., C.M., M.E.O.; writing—original draft, M.E., L.B., K.L.; writing—review and editing, L.B., K.L., C.M., M.E.O., project administration: K.L., M.E.O. All authors have read and agreed to the published version of the manuscript.

Funding

This study was part of the project ‘Utveckling av vegetariska inblandningsprodukter av sidoströmmar från broccoli-och grönkålsproduktion’ funded by EIP Agri; Swedish Board of Agriculture, project No. 2017–4500.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript, or in the decision to publish the results.

References

- FAO. The State of Food and Agriculture 2019: Moving Forward on Food Loss and Waste Reduction; Food and Agricultural Organization of the United Nations: Rome, Italy, 2019. [Google Scholar]

- Fyles, H.; Madramootoo, C. Emerging Technologies for Promoting Food Security; Elsevier: Amsterdam, The Netherlands, 2016; ISBN 978-1-78242-335-5. [Google Scholar]

- Godfray, H.C.J.; Beddington, J.R.; Crute, I.R.; Haddad, L.; Lawrence, D.; Muir, J.F.; Pretty, J.; Robinson, S.; Thomas, S.M.; Toulmin, C. Food Security: The Challenge of Feeding 9 Billion People. Science 2010, 327, 812–818. [Google Scholar] [CrossRef] [PubMed]

- Chai, B.C.; van der Voort, J.R.; Grofelnik, K.; Eliasdottir, H.G.; Klöss, I.; Perez-Cueto, F.J.A. Which Diet Has the Least Environmental Impact on Our Planet? A Systematic Review of Vegan, Vegetarian and Omnivorous Diets. Sustainability 2019, 11, 4110. [Google Scholar] [CrossRef]

- Scherer, L.; Svenning, J.-C.; Huang, J.; Seymour, C.L.; Sandel, B.; Mueller, N.; Kummu, M.; Bekunda, M.; Bruelheide, H.; Hochman, Z.; et al. Global Priorities of Environmental Issues to Combat Food Insecurity and Biodiversity Loss. Sci. Total Environ. 2020, 730, 139096. [Google Scholar] [CrossRef] [PubMed]

- Ahmed, I.; Zia, M.A.; Afzal, H.; Ahmed, S.; Ahmad, M.; Akram, Z.; Sher, F.; Iqbal, H.M.N. Socio-Economic and Environmental Impacts of Biomass Valorisation: A Strategic Drive for Sustainable Bioeconomy. Sustainability 2021, 13, 4200. [Google Scholar] [CrossRef]

- Sadhukhan, J.; Dugmore, T.I.J.; Matharu, A.; Martinez-Hernandez, E.; Aburto, J.; Rahman, P.K.S.M.; Lynch, J. Perspectives on “Game Changer” Global Challenges for Sustainable 21st Century: Plant-Based Diet, Unavoidable Food Waste Biorefining, and Circular Economy. Sustainability 2020, 12, 1976. [Google Scholar] [CrossRef]

- Nellemann, C.; MacDevette, M.; Manders, T.; Eickhout, B.; Svihus, B.; Prins, A.G.; Kaltenborn, B.P. The Environmental Food Crisis: The Environment’s Role in Averting Future Food Crises: A UNEP Rapid Response Assessment; United Nations Environment Programme, GRID—Arendal, Ed.; UNEP: Arendal, Norway, 2009; ISBN 978-82-7701-054-0. [Google Scholar]

- Gustavsson, J.; Cederberg, C.; Sonesson, U. Global Food Losses and Food Waste: Extent, Causes and Prevention; Food and Agriculture Organization of the United Nations: Rome, Italy, 2011; ISBN 978-92-5-107205-9. [Google Scholar]

- Strid, I.; Eriksson, M.; Andersson, S.; Olsson, M. Svinn Av Isbergssallat i Primärproduktionen Och Grossistledet i Sverige; The Swedish Board of Agriculture: Jönköping, Sweden, 2014. [Google Scholar]

- Hartikainen, H.; Svanes, E.; Franke, U.; Mogensen, L.; Andersson, S.; Bond, R.; Burman, C.; Einarsson, E.; Eklöf, P.; Joensuu, K.; et al. Food Losses and Waste in Primary Production; TemaNord; 2016:557.; Nordic Council of Ministers: Copenhagen, Denmark, 2017; ISBN 978-92-893-4767-9. [Google Scholar]

- Johnson, L.K.; Dunning, R.D.; Bloom, J.D.; Gunter, C.C.; Boyette, M.D.; Creamer, N.G. Estimating On-Farm Food Loss at the Field Level: A Methodology and Applied Case Study on a North Carolina Farm. Resour. Conserv. Recycl. 2018, 137, 243–250. [Google Scholar] [CrossRef]

- Nordic Council of Ministers, N.C. of M. Nordic Nutrition Recommendations 2012. Integr. Nutr. Phys. Act. 2008, 5, 1–3. [Google Scholar] [CrossRef]

- Konde, Å.B.; Bjerselius, R.; Haglund, L.; Jansson, A.; Pearson, M.; Färnstrand, J.S.; Johansson, A.-K. Swedish Dietary Guidelines-Risk and Benefit Management Report; Swedish National Food Agency: Uppsala, Sweden, 2015. [Google Scholar]

- Beausang, C.; Hall, C.; Toma, L. Food Waste and Losses in Primary Production: Qualitative Insights from Horticulture. Resour. Conserv. Recycl. 2017, 126, 177–185. [Google Scholar] [CrossRef]

- Johnson, L.K.; Dunning, R.D.; Gunter, C.C.; Dara Bloom, J.; Boyette, M.D.; Creamer, N.G. Field Measurement in Vegetable Crops Indicates Need for Reevaluation of On-Farm Food Loss Estimates in North America. Agric. Syst. 2018, 167, 136–142. [Google Scholar] [CrossRef]

- Ferreira, M.S.L.; Santos, M.C.P.; Moro, T.M.A.; Basto, G.J.; Andrade, R.M.S.; Gonçalves, É.C.B.A. Formulation and Characterization of Functional Foods Based on Fruit and Vegetable Residue Flour. J. Food Sci. Technol. 2015, 52, 822–830. [Google Scholar] [CrossRef]

- Eriksson, M.; Spångberg, J. Carbon Footprint and Energy Use of Food Waste Management Options for Fresh Fruit and Vegetables from Supermarkets. Waste Manag. 2017, 60, 786–799. [Google Scholar] [CrossRef]

- Berndtsson, E.; Andersson, R.; Johansson, E.; Olsson, M.E. Side Streams of Broccoli Leaves: A Climate Smart and Healthy Food Ingredient. IJERPH 2020, 17, 2406. [Google Scholar] [CrossRef] [PubMed]

- Domínguez-Perles, R.; Martínez-Ballesta, M.C.; Carvajal, M.; García-Viguera, C.; Moreno, D.A. Broccoli-Derived By-Products-A Promising Source of Bioactive Ingredients. J. Food Sci. 2010, 75, C383–C392. [Google Scholar] [CrossRef] [PubMed]

- Mirabella, N.; Castellani, V.; Sala, S. Current Options for the Valorization of Food Manufacturing Waste: A Review. J. Clean. Prod. 2014, 65, 28–41. [Google Scholar] [CrossRef]

- Maina, S.; Kachrimanidou, V.; Koutinas, A. A Roadmap towards a Circular and Sustainable Bioeconomy through Waste Valorization. Curr. Opin. Green Sustain. Chem. 2017, 8, 18–23. [Google Scholar] [CrossRef]

- Bergström, P.; Malefors, C.; Strid, I.; Hanssen, O.J.; Eriksson, M. Sustainability Assessment of Food Redistribution Initiatives in Sweden. Resources 2020, 9, 27. [Google Scholar] [CrossRef]

- Eriksson, M.; Strid, I.; Hansson, P.-A. Carbon Footprint of Food Waste Management Options in the Waste Hierarchy–a Swedish Case Study. J. Clean. Prod. 2015, 93, 115–125. [Google Scholar] [CrossRef]

- Liu, M.; Zhang, L.; Ser, S.; Cumming, J.; Ku, K.-M. Comparative Phytonutrient Analysis of Broccoli By-Products: The Potentials for Broccoli By-Product Utilization. Molecules 2018, 23, 900. [Google Scholar] [CrossRef]

- Maina, S.; Misinzo, G.; Bakari, G.; Kim, H.-Y. Human, Animal and Plant Health Benefits of Glucosinolates and Strategies for Enhanced Bioactivity: A Systematic Review. Molecules 2020, 25, 3682. [Google Scholar] [CrossRef]

- International Organization for Standardization. Environmental Management-Life Cycle Assessment-Principles and Framework; ISO 14040:2006; International Organization for Standardization: Geneva, Switzerland, 2006. [Google Scholar]

- International Organization for Standardization. Environmental Management-Life Cycle Assessment-Requirements and Guidelines; ISO 14044:2006; International Organization for Standardization: Geneva, Switzerland, 2006. [Google Scholar]

- Grönsaksmästarna. 2020. Available online: https://www.gronsaksmastarna.se/en/ (accessed on 10 May 2021).

- Google. Google Maps; Google: Mountain View, CA, USA, 2020. [Google Scholar]

- Ecoinvent. Ecoinvent; Ecoinvent: Zurich, Switzerland, 2020. [Google Scholar]

- Eriksson, M.; Ghosh, R.; Hansson, E.; Basnet, S.; Lagerkvist, C.-J. Environmental Consequences of Introducing Genetically Modified Soy Feed in Sweden. J. Clean. Prod. 2018, 176, 46–53. [Google Scholar] [CrossRef]

- Potter, H.K.; Röös, E. Multi-criteria evaluation of plant-based foods –use of environmental footprint and LCA data for consumer guidance. J. Clean. Prod. 2021, 280. [Google Scholar] [CrossRef]

- Shi, J.; Visschers, V.H.M.; Bumann, N.; Siegrist, M. Consumers’ Climate-Impact Estimations of Different Food Products. J. Clean. Prod. 2018, 172, 1646–1653. [Google Scholar] [CrossRef]

- Krizanova, A.; Masarova, G.; Štefanikova, U.; Rypakova, M. Building a Brand in the Context of Sustainable Development. In Proceedings of the 2015 International Conference on Management Engineering and Management Innovation (icmemi-15), Changsha, China, 10–11 January 2015. [Google Scholar]

- López-Pérez, M.E.; Melero, I.; Javier Sese, F. Management for Sustainable Development and Its Impact on Firm Value in the SME Context: Does Size Matter?: Management for Sustainable Development: Doses Size Matter? Bus. Strat. Environ. 2017, 26, 985–999. [Google Scholar] [CrossRef]

- Porter, S.D.; Reay, D.S.; Bomberg, E.; Higgins, P. Avoidable Food Losses and Associated Production-Phase Greenhouse Gas Emissions Arising from Application of Cosmetic Standards to Fresh Fruit and Vegetables in Europe and the UK. J. Clean. Prod. 2018, 201, 869–878. [Google Scholar] [CrossRef]

- Winans, K.; Marvinney, E.; Gillman, A.; Spang, E. An Evaluation of On-Farm Food Loss Accounting in Life-Cycle Assessment (LCA) of Four California Specialty Crops. Front. Sustain. Food Syst. 2020, 4, 10. [Google Scholar] [CrossRef]

- Scherhaufer, S.; Davis, J.; Metcalfe, P.; Gollnow, S.; Colin, F.; De Menna, F.; Vittuari, M.; Östergren, K. Environmental Assessment of the Valorisation and Recycling of Selected Food Production Side Flows. Resour. Conserv. Recycl. 2020, 161, 104921. [Google Scholar] [CrossRef]

- De Menna, F.; Davis, J.; Bowman, M.; Brenes Peralta, L.; Bygrave, K.; Garcia Herrero, L.; Luyckx, K.; McManus, W.; Vittuari, M.; van Zanten, H.; et al. LCA & LCC of food waste case studies: Assessment of food side flow prevention and valorisation routes in selected supply chains. REFRESH 2019. [Google Scholar] [CrossRef][Green Version]

- Eriksson, M.; Strid, I.; Hansson, P.-A. Food Losses in Six Swedish Retail Stores: Wastage of Fruit and Vegetables in Relation to Quantities Delivered. Resour. Conserv. Recycl. 2012, 68, 14–20. [Google Scholar] [CrossRef]

- Ghosh, R.; Eriksson, M. Food Waste Due to Retail Power in Supply Chains: Evidence from Sweden. Glob. Food Secur. 2019, 20, 1–8. [Google Scholar] [CrossRef]

- Brancoli, P.; Lundin, M.; Bolton, K.; Eriksson, M. Bread Loss Rates at the Supplier-Retailer Interface–Analysis of Risk Factors to Support Waste Prevention Measures. Resour. Conserv. Recycl. 2019, 147, 128–136. [Google Scholar] [CrossRef]

- Brancoli, P.; Bolton, K.; Eriksson, M. Environmental Impacts of Waste Management and Valorisation Pathways for Surplus Bread in Sweden. Waste Manag. 2020, 117, 136–145. [Google Scholar] [CrossRef]

- Melini, V.; Melini, F.; Luziatelli, F.; Ruzzi, M. Functional Ingredients from Agri-Food Waste: Effect of Inclusion Thereof on Phenolic Compound Content and Bioaccessibility in Bakery Products. Antioxidants 2020, 9, 1216. [Google Scholar] [CrossRef]

- Bartek, L.; Strid, I.; Henryson, K.; Junne, S.; Rasi, S.; Eriksson, M. Life cycle assessment of fish oil substitute produced by microalgae using food waste. Sustain. Prod. Consum. 2021. [Google Scholar] [CrossRef]

- Tassoni, A.; Tedeschi, T.; Zurlini, C.; Cigognini, I.M.; Petrusan, J.-I.; Rodríguez, Ó.; Neri, S.; Celli, A.; Sisti, L.; Cinelli, P.; et al. State-of-the-Art Production Chains for Peas, Beans and Chickpeas—Valorization of Agro-Industrial Residues and Applications of Derived Extracts. Molecules 2020, 25, 1383. [Google Scholar] [CrossRef] [PubMed]

- Messner, R.; Johnson, H.; Richards, C. From surplus-to-waste: A study of systemic overproduction, surplusand food waste in horticultural supply chains. J. Clean. Prod. 2021, 278, 123952. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).