The Nature of the Technosols on the Waste from Nickel Production

Abstract

:1. Introduction

2. Materials and Methods

3. Results

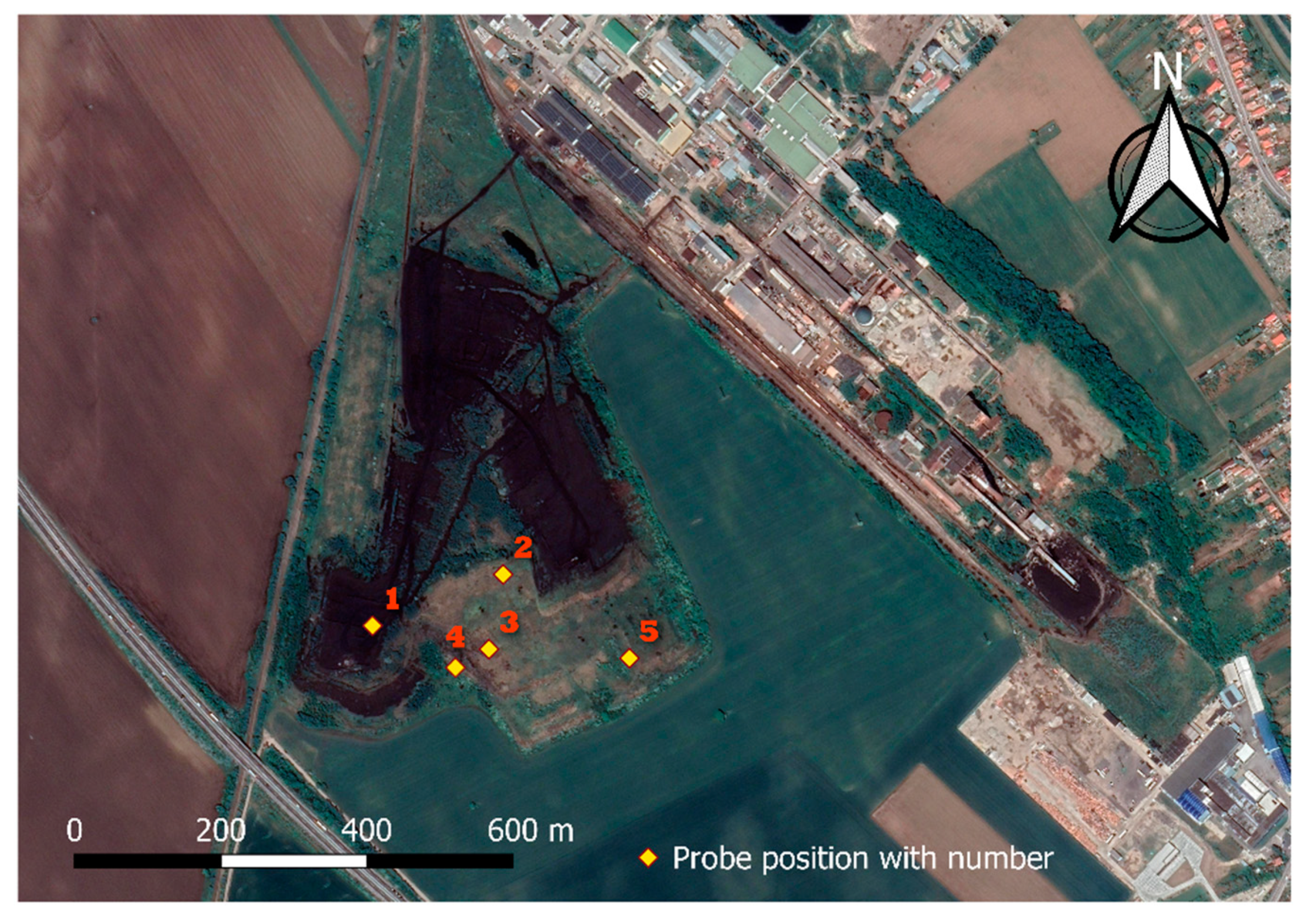

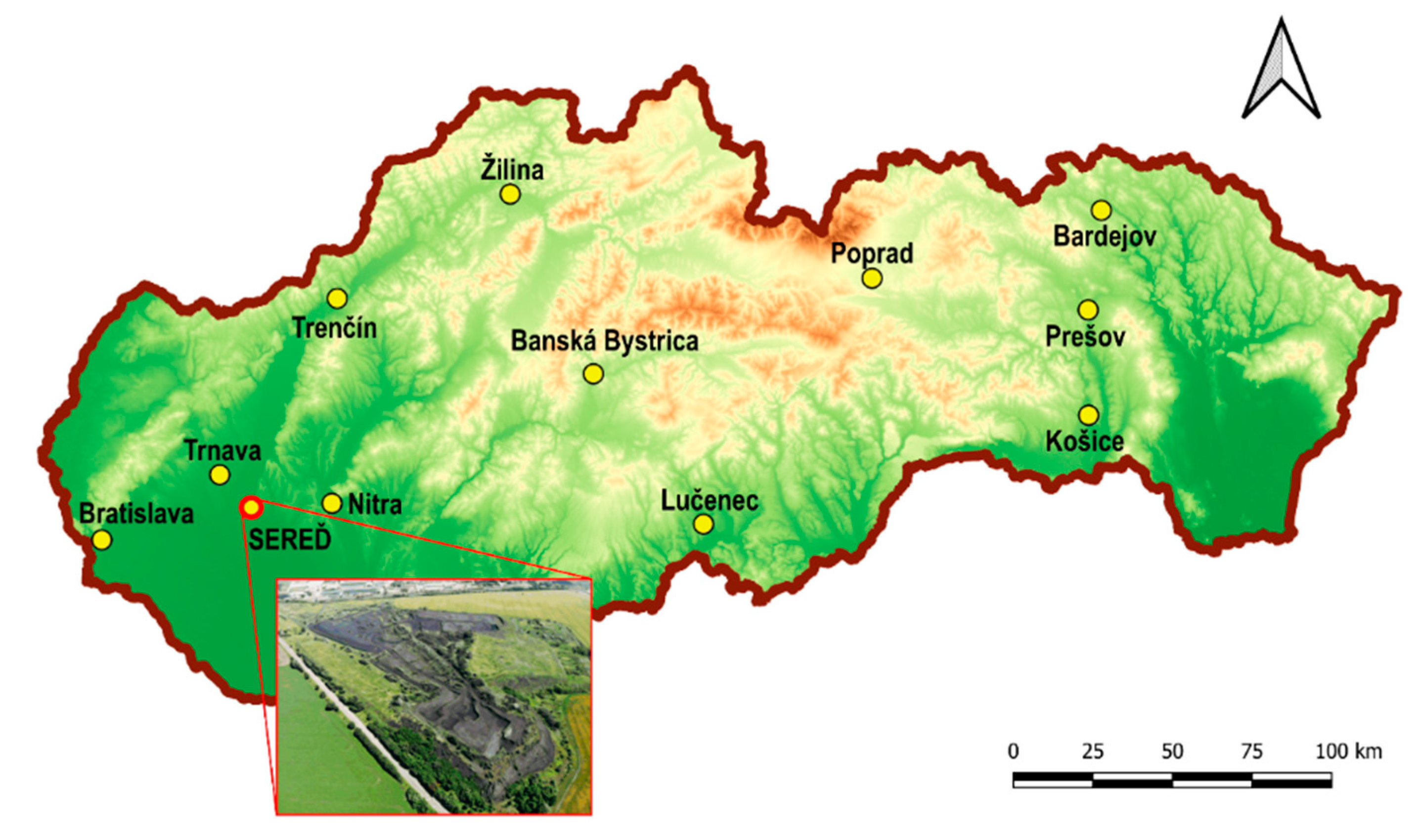

3.1. Study Area

3.2. External Natural and Anthropogenic Factors and Conditions of Study Area

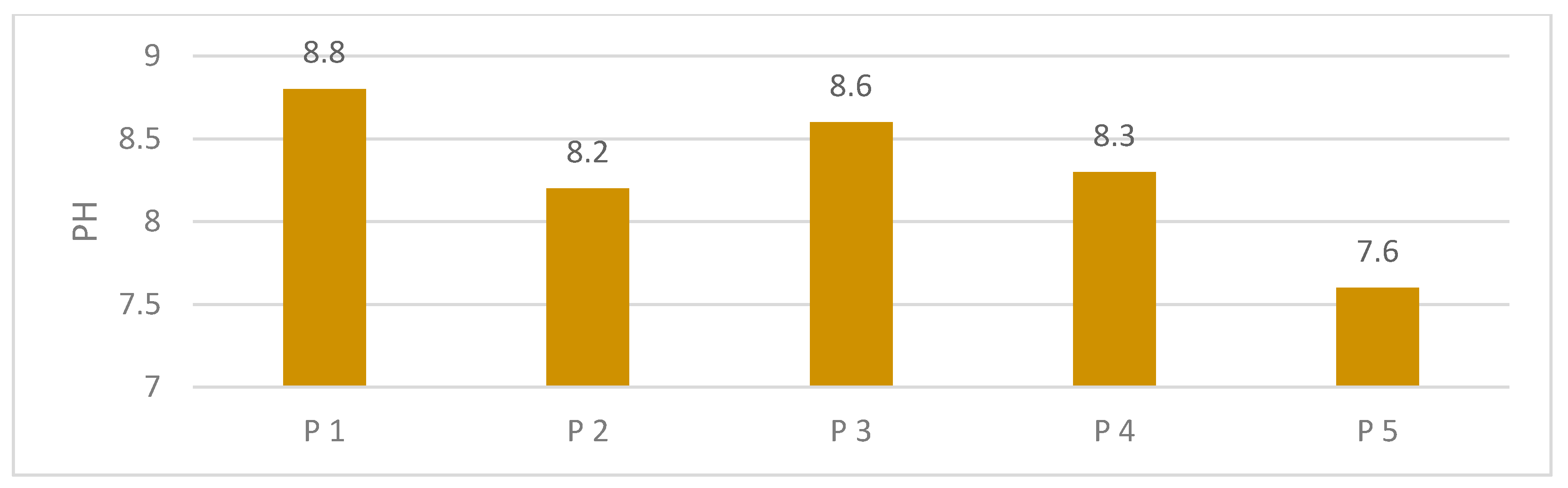

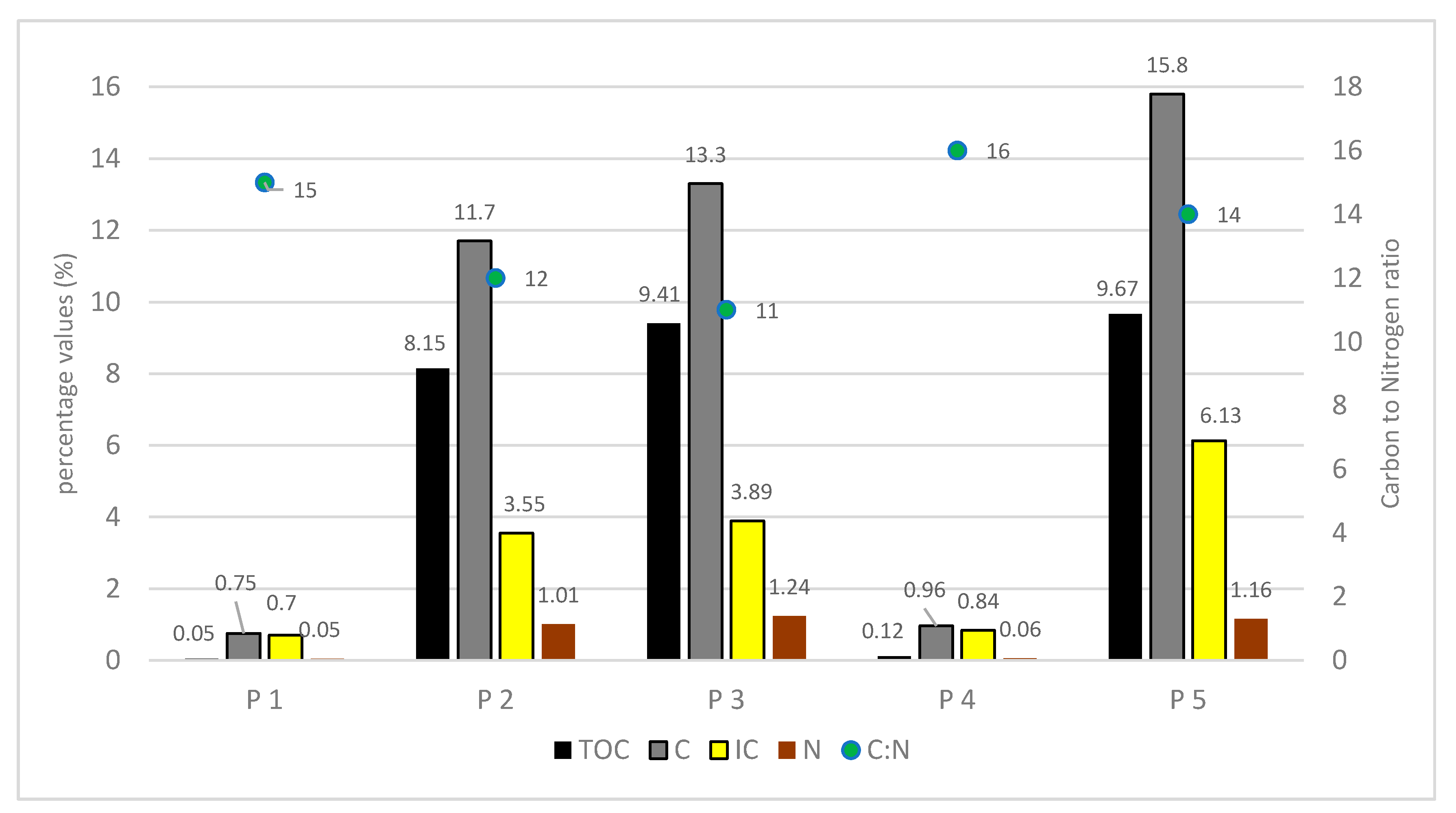

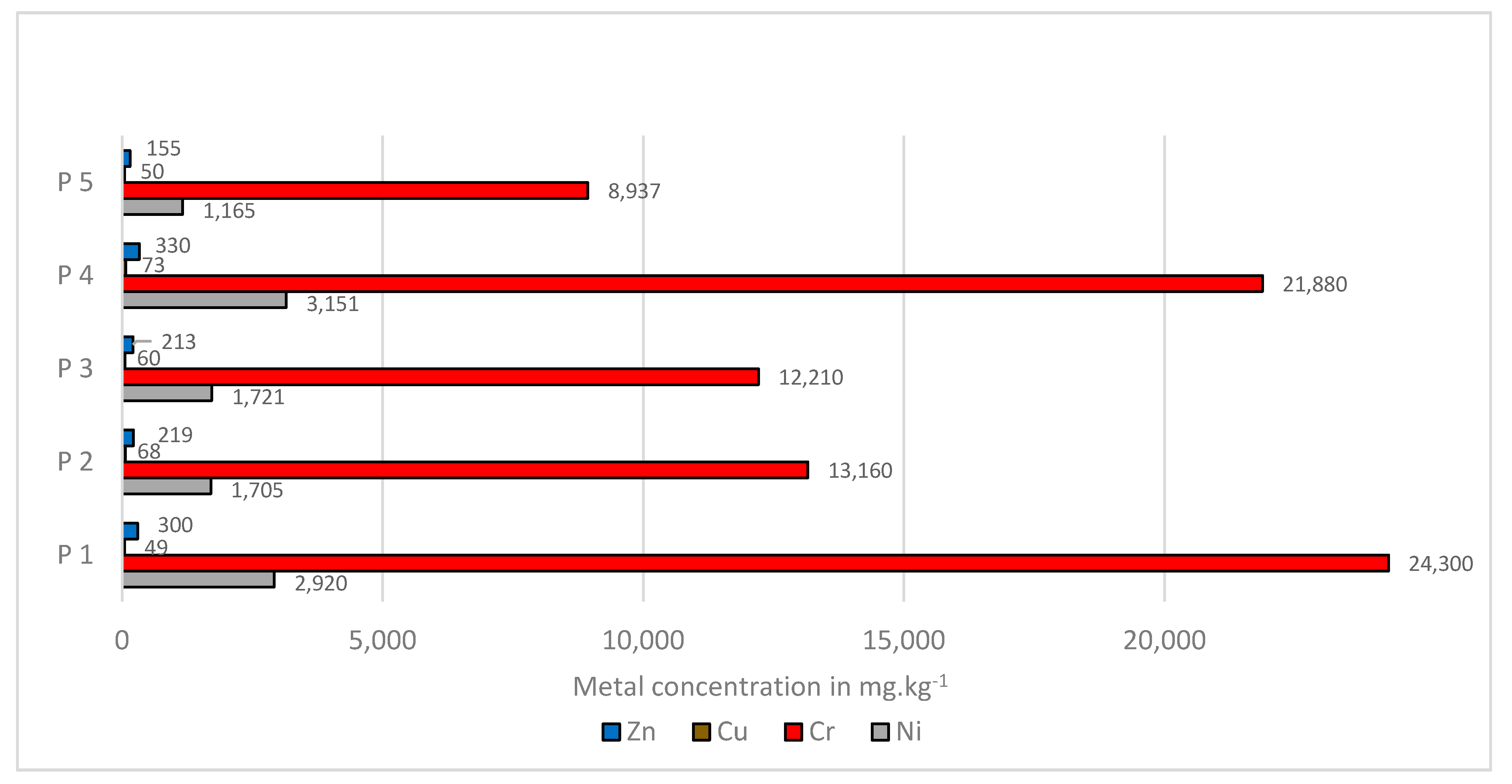

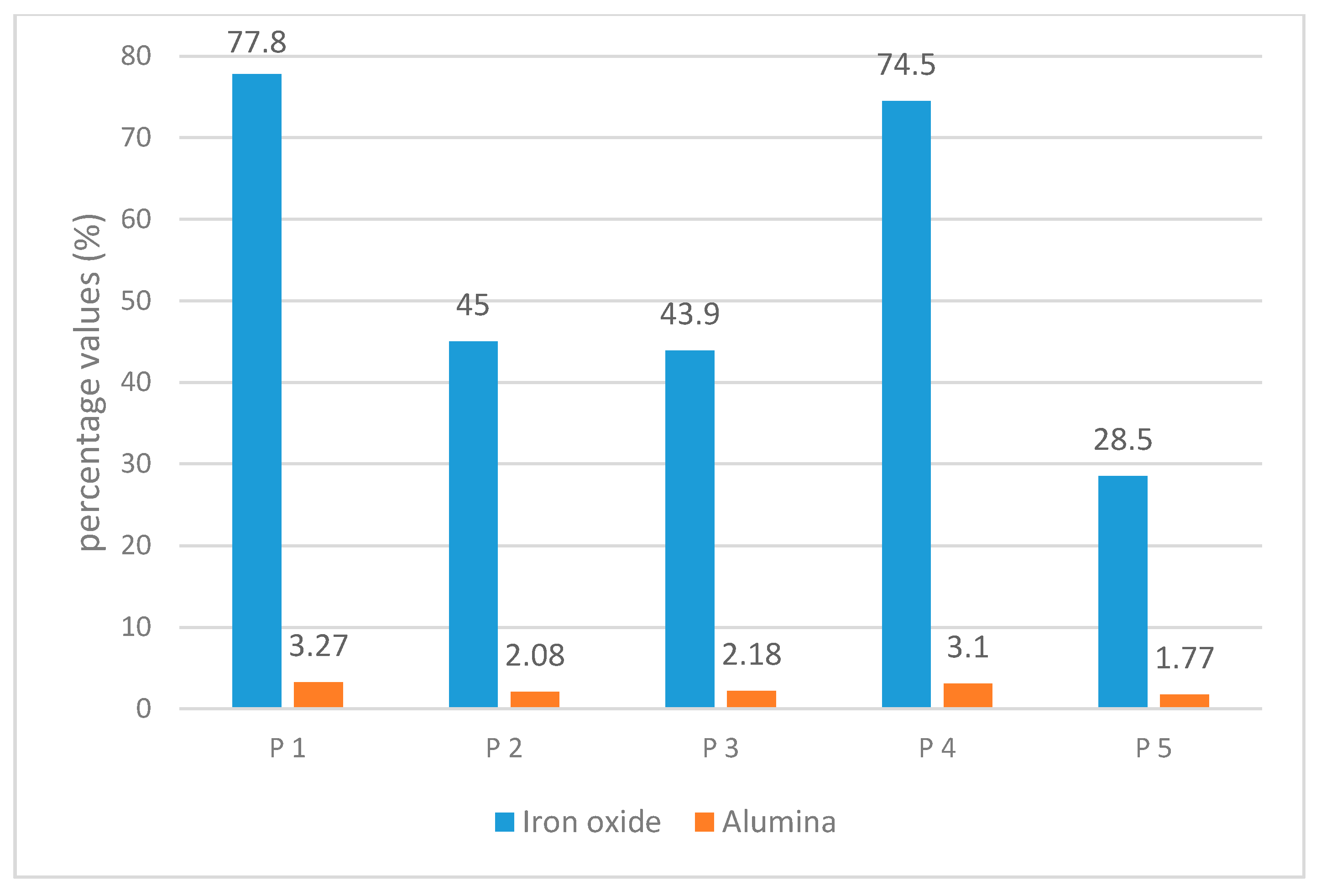

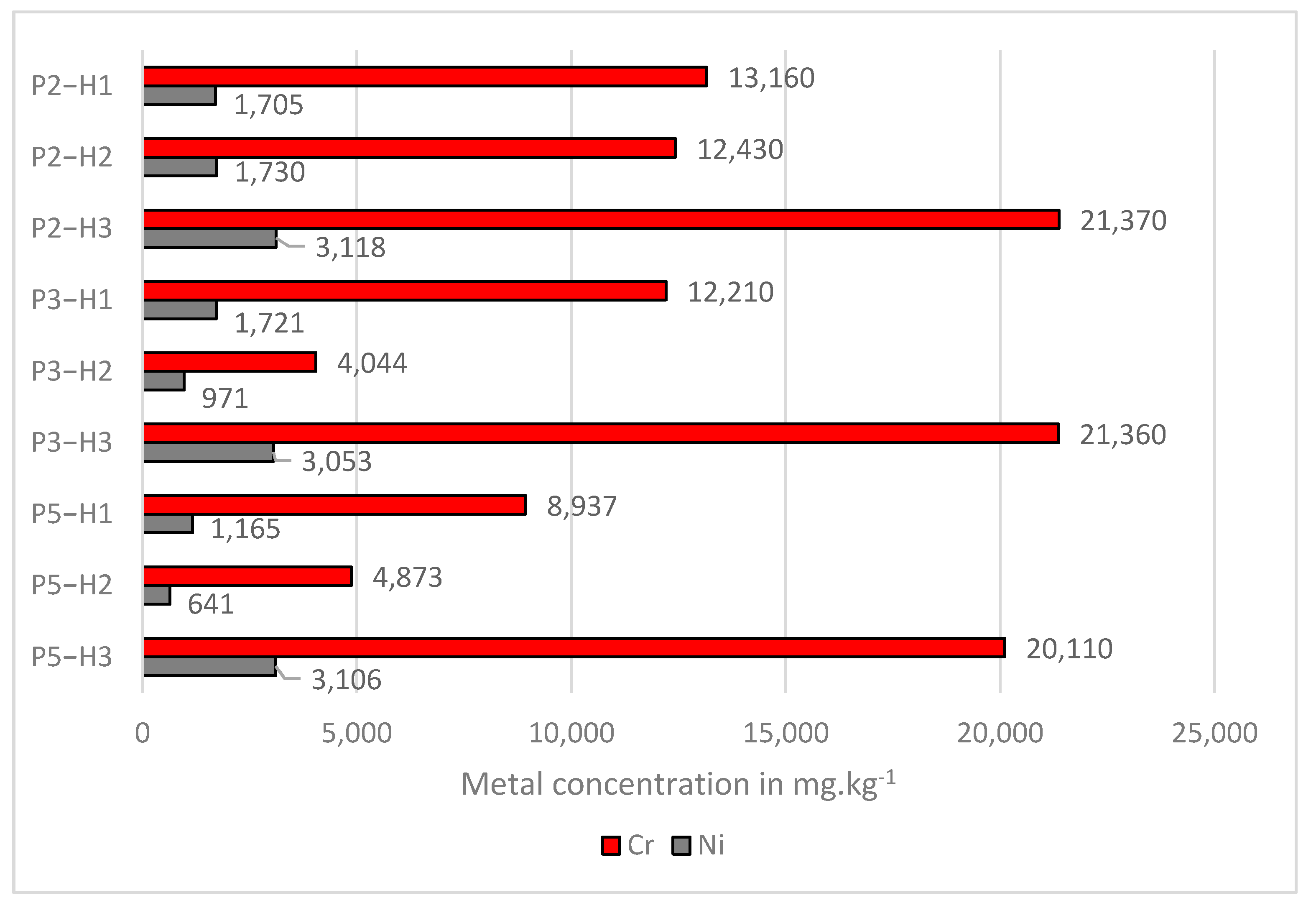

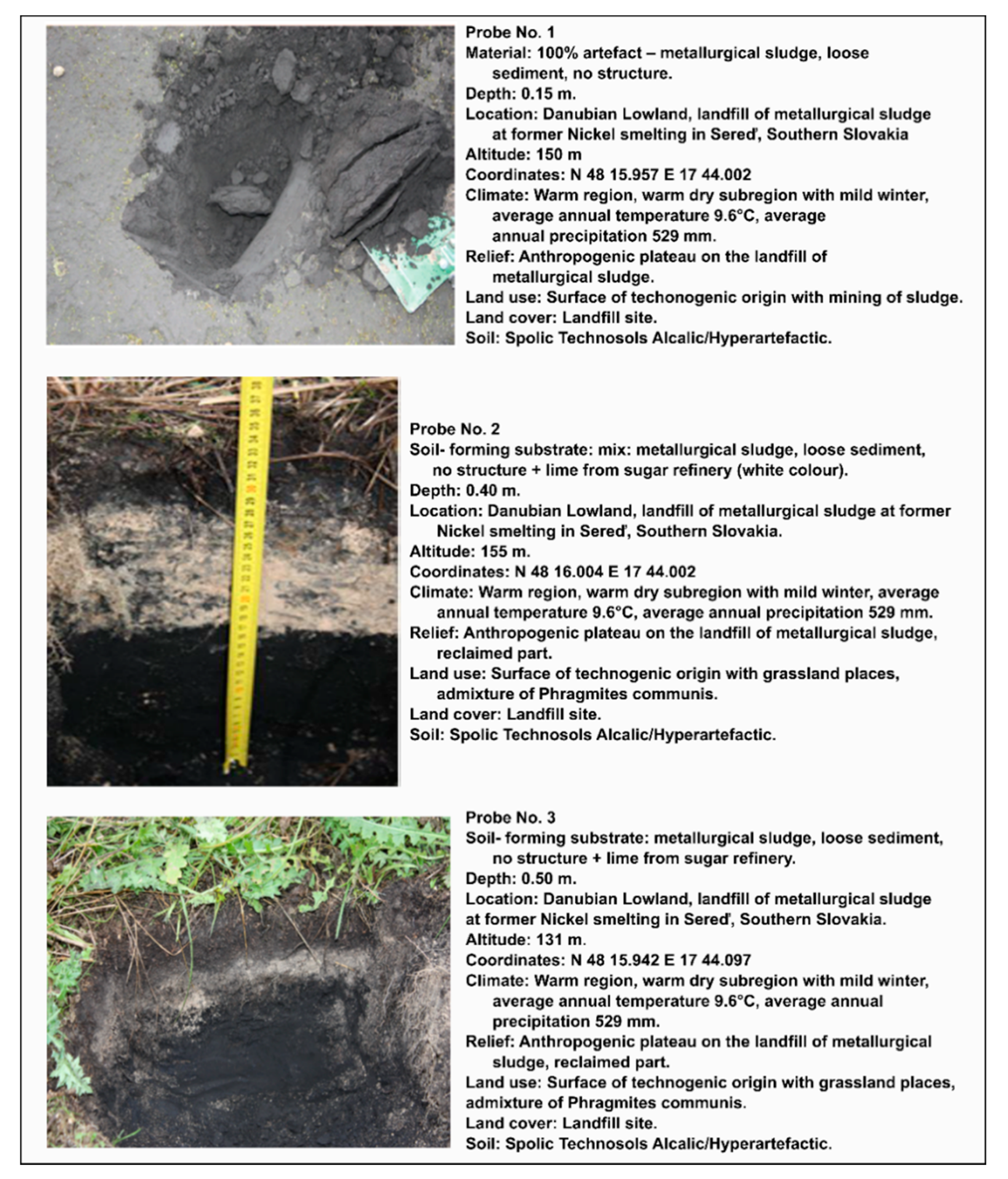

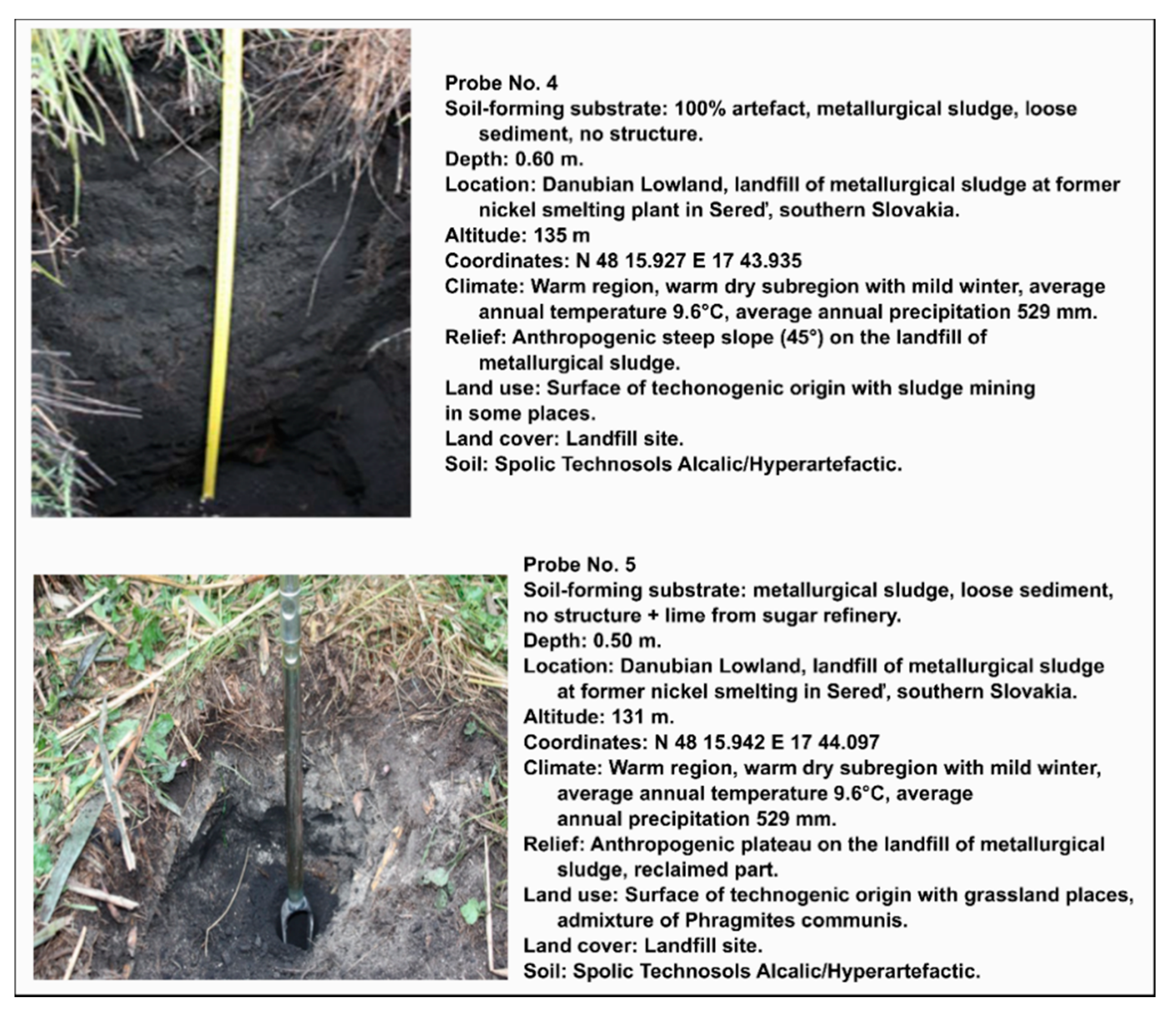

3.3. The Properties of the Metallurgical Sludge

4. Discussion

5. Conclusions

- -

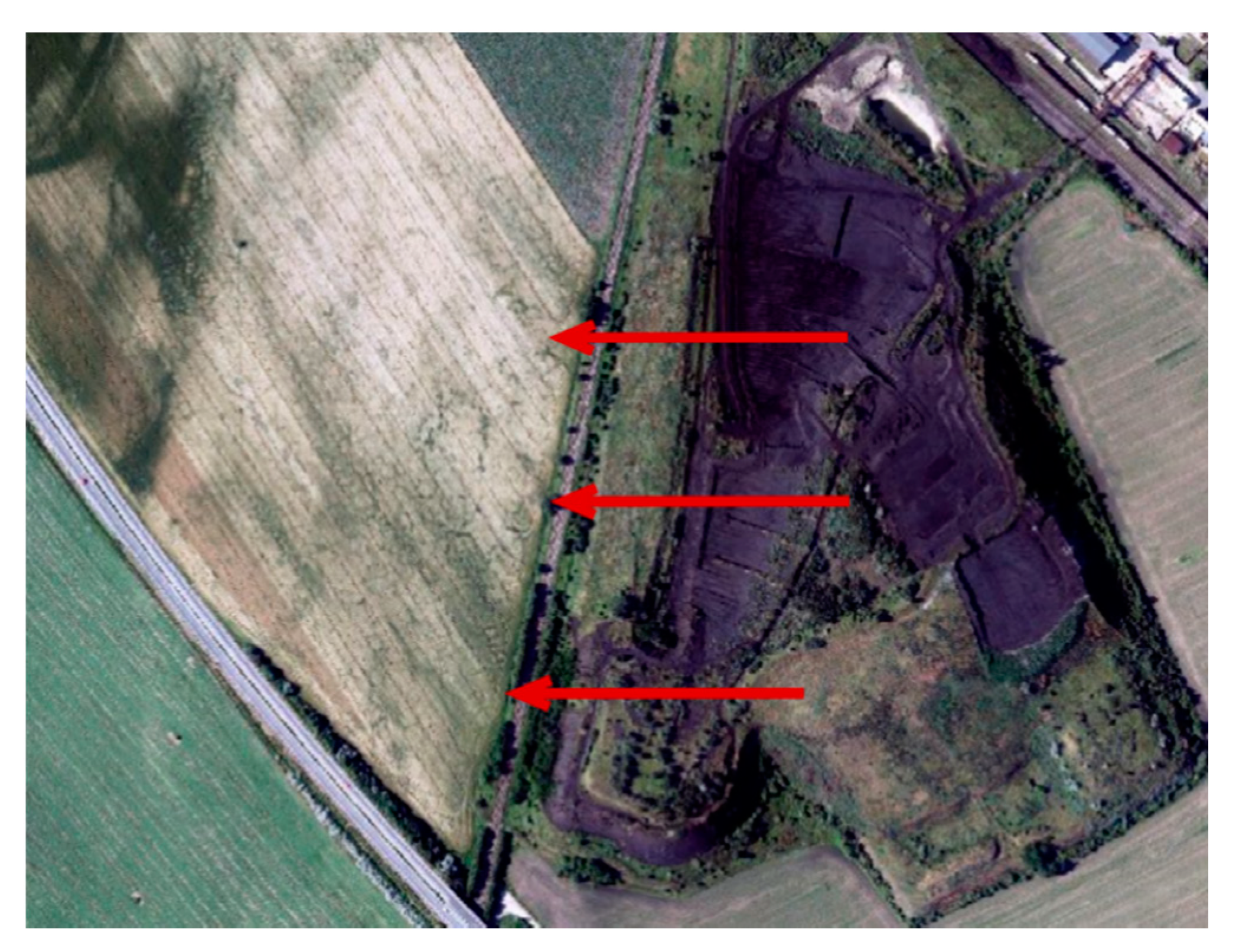

- With respect to the geographical location, the landfill lies in the agricultural landscape of the Danubian Lowland,

- -

- with respect to the relief, the surface of the landfill body is not stable, and it is subject to fluvial processes on the slopes and to the dangerous process of wind erosion as well as the anthropogenic erosion by the mining, which accelerates all of these processes,

- -

- with respect to the amount of sludge, its toxicity as well as the length of time (57 years) it has been present has induced an impact on the environment and the health of the population,

- -

- critically, the landfill is private property today and entry is only possible with the consent of the owners.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kalebáč, O.; Soušek, V.; Had, A. Výroba chrómového surového železa z loužencového aglomerátu. Hutnícke Listy 1987, 10, 705–711. [Google Scholar]

- Michaeli, E.; Boltižiar, M.; Ivanová, M. Geoecological structure of the dump of technological waste (Fe-concentrate) et Sereď. Acta Fac. Studiorum Humanit. Nat. Univ. Prešoviensis Folia Geographica. 2009, XLIX, 180–197. [Google Scholar]

- Mičian, Ľ. Vplyv geomorfologických pomerov na charakter pôdneho krytu. Acta Geol. Geogr. 1965, 5, 16–120. [Google Scholar]

- Maglay, J.; Pristaš, J.; Nagy, A. Vysvetlivky ku Geologickej Mape Podunajskej Nížiny-Trnavskej Pahorkatiny v Mierke: 1: 50 000; ŠGÚDŠ: Bratislava, Slovakia, 2005. [Google Scholar]

- Lewis, S.L.; Maslin, M.A. Defining the Anthropocene. Nature 2015, 519, 171–180. [Google Scholar] [CrossRef] [PubMed]

- Zapletal, L. Geneticko-morfologická klasifikace antropogenních forem reliéfu. Acta Univ. Palacki. Olomuc. Geogr. Geol. 1968, VIII, 239–427. [Google Scholar]

- Lacika, J. Antropogénna Transformácia Reliéfu Ako Indikátor Trvalej Udržateľnosti; FPV UMB: Banská Bystrica, Slovakia, 1999; ISBN 80-8055-471-4. [Google Scholar]

- Lapin, M.; Faško, P.; Melo, M.; Štasný, P.; Tomlain, J. Climatic regions. In Landscape atlas of the Slovak Republic, 1st ed.; Institute of Landscape Ecology of the Slovak Academy of Sciences Bratislava: Bratislava, Slovakia, 2002; p. 344. [Google Scholar]

- World Reference Base for Soil Resources. International Soil Classification System for Naming Soils and Creating Legends for Soil Maps; FAO: Rome, Italy, 2015. [Google Scholar]

- Jurko, A. Ekologické a Socioekonomické Hodnotenie Vegetácie; Vydavateľstvo Príroda: Bratislava, Slovakia, 1990; ISBN 80-07-00391-6. [Google Scholar]

- Sobocká, J.; Poltárska, K. Description of technogenic spoil bank and its influence on agricultural soils. (A case of nickel metallurgy refuse at Sereď). Ved. Práce VUPOP 2004, 103–112. [Google Scholar]

- Paulech, C.; Šály, A. Základný biologicko-ekologický prieskum v oblasti haldy lúženca v Niklovej hute v Seredi. In Záverečná Správa Ústav Experimentálnej Biológie a Ekológia SAV; Ústav experimentálnej biológie a ekológie SAV: Bratislava, Slovakia, 1983; pp. 8–24. [Google Scholar]

- Shishov, L.L.; Tonkonogov, V.D.; Lebedeva, I.I.; Gerasimova, M.I. Russian Soil Classification System; World Reference Base for Soil Resources 2015; Dokuchaev Soil Science Institute: Moscow, Russia, 2001. [Google Scholar]

- Schad, P. Technosols in the World Reference Base for Soil Resources-history and definitions. J. Soil Sci. Plant Nutr. 2018, 64, 138–144. [Google Scholar] [CrossRef]

| Metal Production | Quantity in [t] | Annual Waste Production | Waste Production over 30 Years Total [t] |

|---|---|---|---|

| Annual production of nickel and cobalt | 2510 | 2450 [t] nickel, 60 [t] cobalt | 75,300 |

| Annual production of waste | 300,000 | 120 [t] of waste per 1 [t] of metal | 9,000,000 |

| Annual consumption of chemicals | 5624 | 2.25 [t] chemicals per 1 [t] of metal | 168,720 |

| Annual deflation of sludge into the air | 20,000 | An average of 55 [t] per day | 600,000 [t]—30 years 1,140,000 [t]—57 years |

| Fractions in mm | PM10 < 0.01 mm | Dust 0.01–0.05 mm | Sand 0.05–2.0 mm |

|---|---|---|---|

| Share in % | 17.05 | 35.55 | 47.40 |

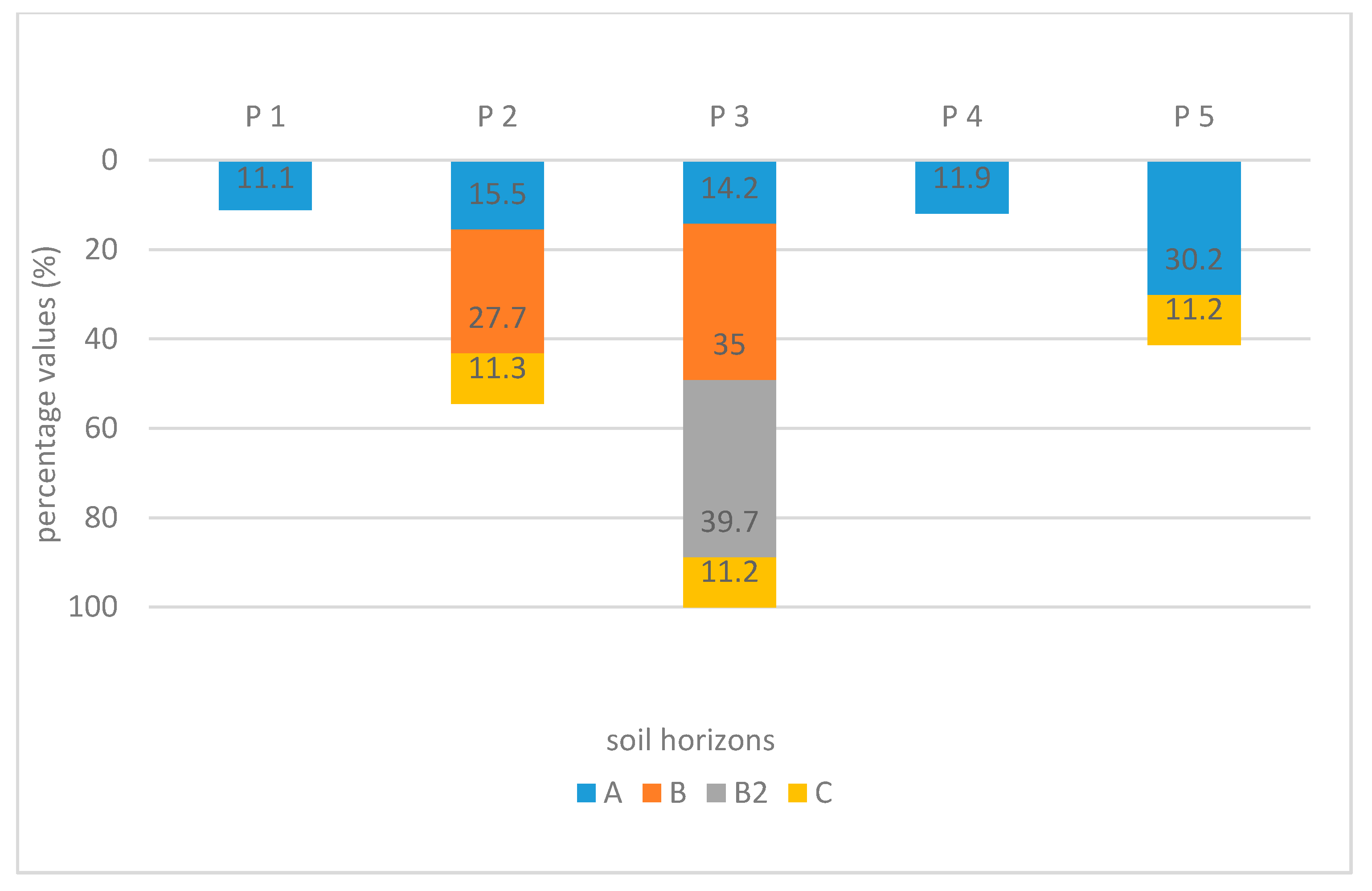

| Content of Dust Particles of Fraction >0.01 in Individual Horizon of Probes in % | Probe No. 1 | Probe No. 2 | Probe No. 3 | Probe No. 4 | Probe No. 5 | Average |

|---|---|---|---|---|---|---|

| Surface horizon | 11.1 | 15.5 | 14.2 | 11.9 | 30.2 | 16.0 |

| First subsurface horizon | - | 27.7 | 35.0 | - | 46.4 | 33.0 |

| Second subsurface horizon | - | 11.3 | 39.7 | - | 11.2 | 18.2 |

| Third subsurface horizom—only in probe No.3 | - | - | 11.2 | - | - | 11.2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Michaeli, E.; Solár, V.; Maxin, M.; Vilček, J.; Boltižiar, M. The Nature of the Technosols on the Waste from Nickel Production. Sustainability 2021, 13, 406. https://doi.org/10.3390/su13010406

Michaeli E, Solár V, Maxin M, Vilček J, Boltižiar M. The Nature of the Technosols on the Waste from Nickel Production. Sustainability. 2021; 13(1):406. https://doi.org/10.3390/su13010406

Chicago/Turabian StyleMichaeli, Eva, Vladimír Solár, Matúš Maxin, Jozef Vilček, and Martin Boltižiar. 2021. "The Nature of the Technosols on the Waste from Nickel Production" Sustainability 13, no. 1: 406. https://doi.org/10.3390/su13010406

APA StyleMichaeli, E., Solár, V., Maxin, M., Vilček, J., & Boltižiar, M. (2021). The Nature of the Technosols on the Waste from Nickel Production. Sustainability, 13(1), 406. https://doi.org/10.3390/su13010406