Feeding Models to Optimize Dairy Feed Rations in View of Feed Availability, Feed Prices and Milk Production Scenarios

Abstract

1. Introduction

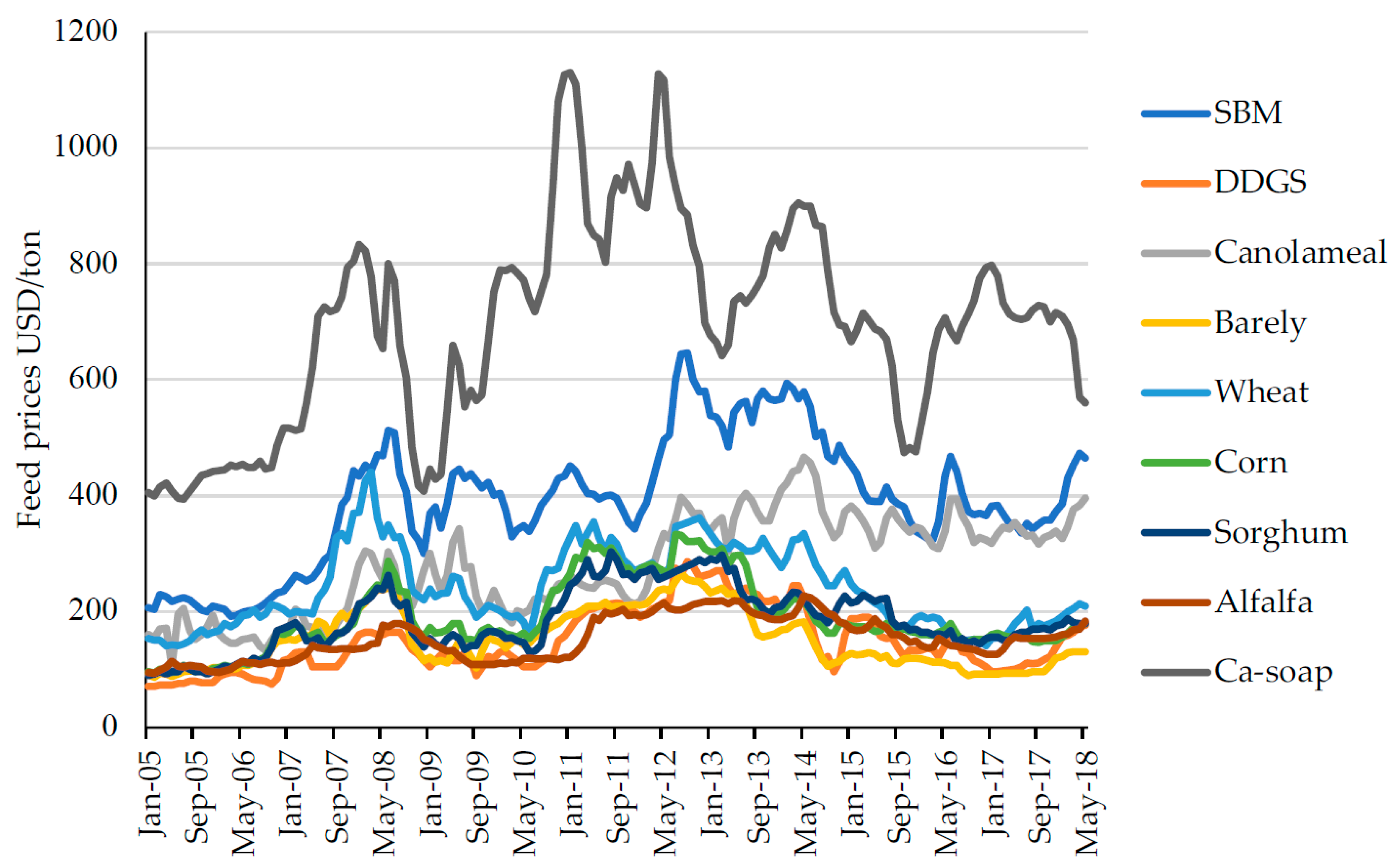

2. Materials and Methods

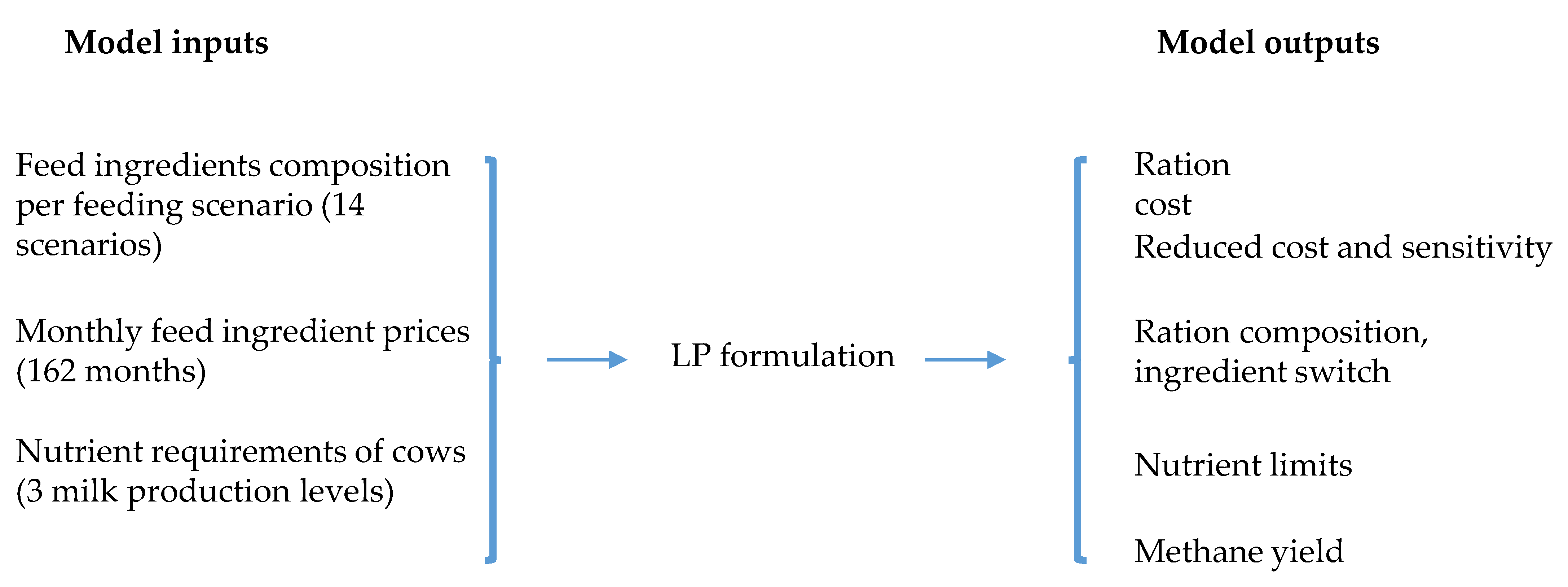

2.1. Multi-Period LP Model

2.2. Model Structure

2.3. Statistical Analysis

2.4. Modeled Scenarios

2.5. Scenario Definitions

3. Results and Discussion

3.1. Feed Rations Selection Across Scenarios and Dairy Production Levels

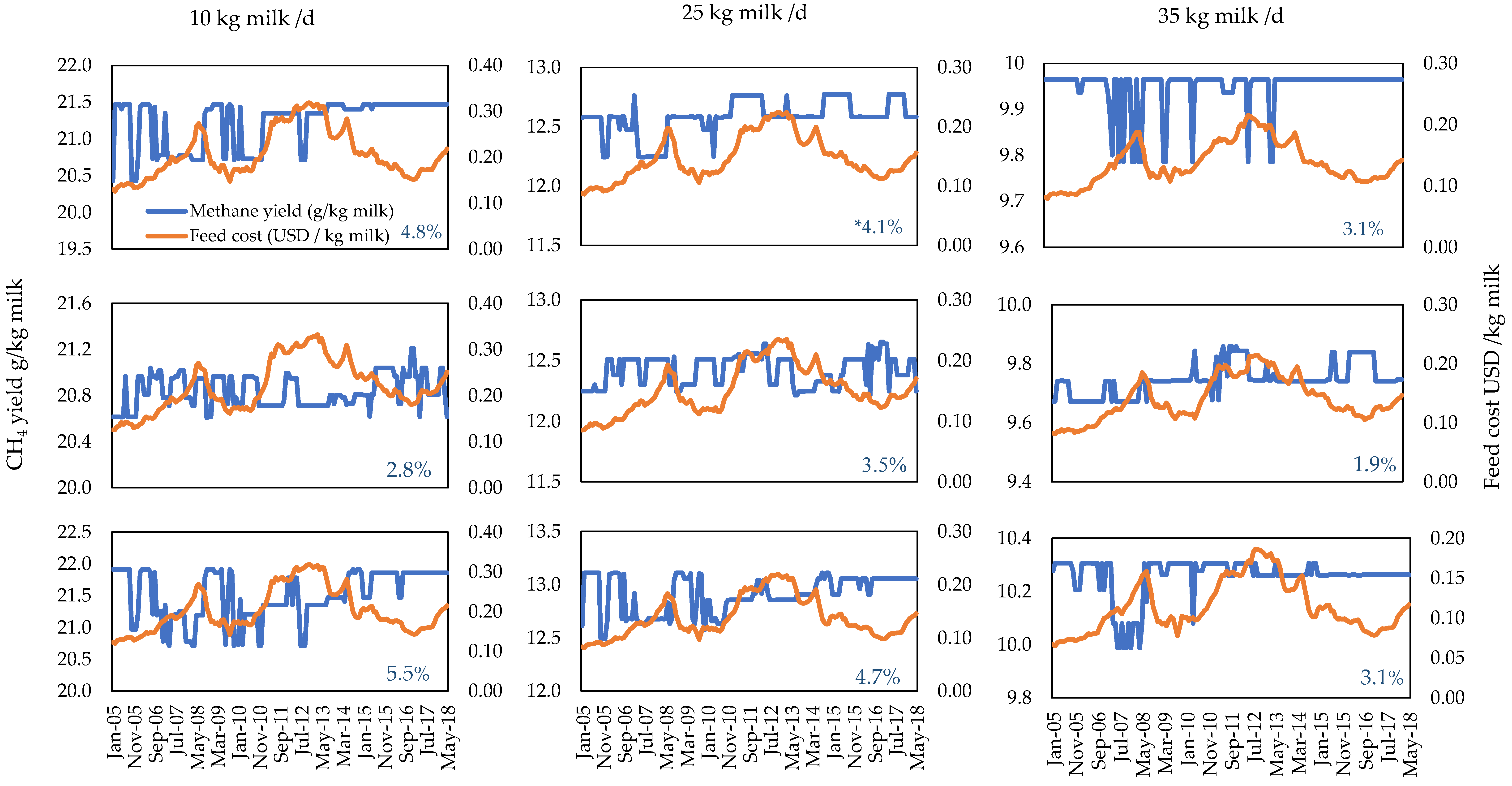

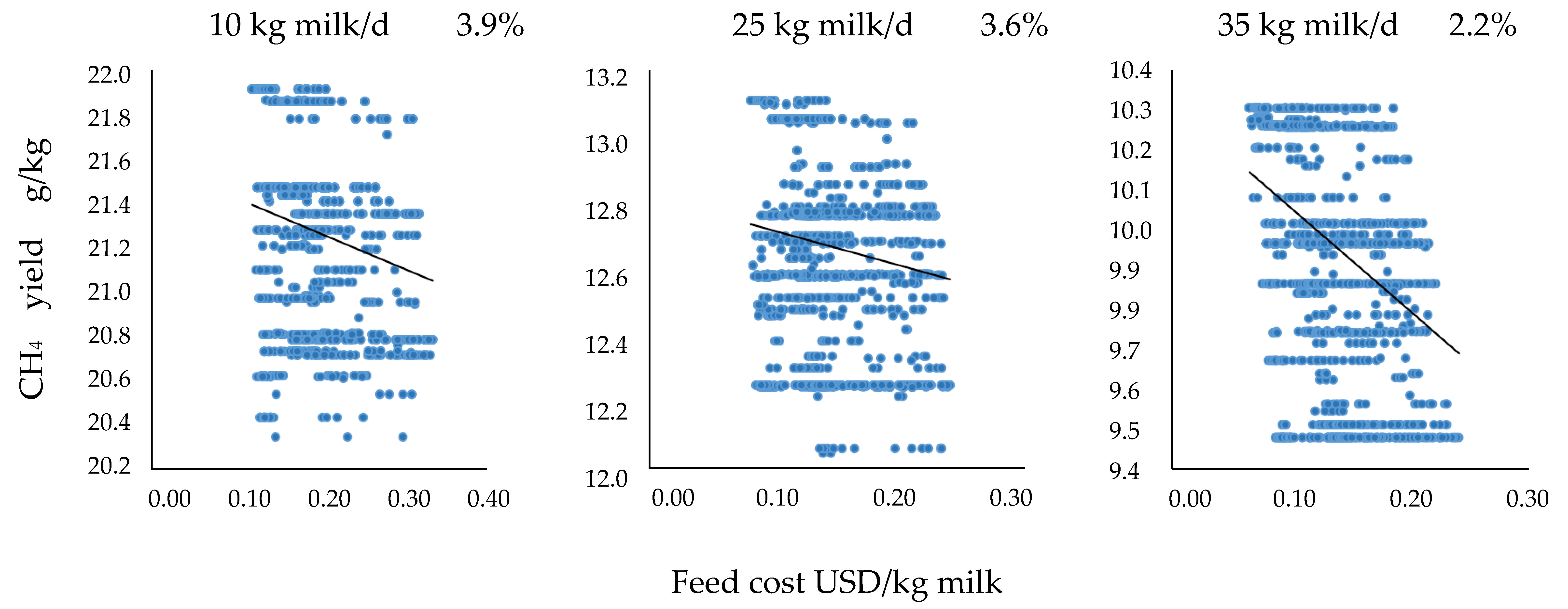

3.2. Predicted Methane Production in Relation to Feed Cost

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Hemme, T. IFCN Dairy Report; International Farm Comparison Network, IFCN Dairy Research Center: Kiel, Germany, 2019. [Google Scholar]

- Hemme, T.; Alqaisi, O.A.; Ndambi, O.A.; Boelling, D. IFCN Contribution to the IDF/FAO/IFCN Joint Project, World Mapping of Animal Feeding Systems in the Dairy Sector; International Dairy Federation: Rome, Italy, 2014. [Google Scholar]

- Hagemann, M.; Hemme, T.; Ndambi, O.A.; Alqaisi, O.; Sultana, M.N. Bechmarking of greenhouse gas emission of bovine milk production systems for 38 countries. Anim. Feed Sci. Technol. 2011, 166, 46–58. [Google Scholar] [CrossRef]

- Alqaisi, O.; Hemme, T.; Latacz-Lohmann, U.; Susenbeth, A. Evaluation of food industry by-products as feed in semi-arid dairy farming systems: The case of Jordan. Sustain. Sci. 2014, 9, 361–377. [Google Scholar] [CrossRef]

- Alqaisi, O.; Moares, L.; Ndambi, O.; Williams, R. Optimal dairy feed input selection under alternative feeds availability and relative prices. Inf. Process. Agric. 2019, 6, 438–453. [Google Scholar] [CrossRef]

- Alqaisi, O.; Ndambi, O.A.; Hemme, T. Global view on feed cost and feed efficiency on dairy farms. All Feed 2011, 2. Available online: http://www.allaboutfeed.net/Process-Management/Management/2011/7/Global-view-on-feed-costand-feed-efficiency-on-dairy-farms-AAF011993W/ (accessed on 17 October 2018).

- Wilkinson, J.M.; Garnsworthy, P.C. Dietary options to reduce the environmental impact of milk production. J. Agric. Sci. 2017, 155, 334–347. [Google Scholar] [CrossRef]

- Miglior, F.; Fleming, A.; Malchiodi, F.; Brito, L.F.; Martin, P.; Baes, C.F. A 100-Year Review: Identification and genetic selection of economically important traits in dairy cattle. J. Dairy Sci. 2017, 100, 10251–10271. [Google Scholar] [CrossRef] [PubMed]

- Knapp, J.R.; Laur, G.L.; Vadas, P.A.; Weiss, W.P.; Tricarico, J.M. Invited review: Enteric methane in dairy cattle production: Quantifying the opportunities and impact of reducing emissions. J. Dairy Sci. 2014, 97, 3231–3261. [Google Scholar] [CrossRef] [PubMed]

- R Core Team. R: A Language and Environment for Statistical Computing; R Foundation for Statistical Computing: Vienna, Austria, 2018; Available online: https://www.R-project.org/ (accessed on 25 November 2018).

- World Bank. World Bank Monthly Commodity Feed Prices 2018. Available online: http://www.worldbank.org/en/research/commodity-markets (accessed on 12 February 2019).

- Monthly US Hay Price. Available online: https://hayandforage.com (accessed on 12 February 2019).

- USDA. Biofuel Feedstock and Coproduct Market Data 2018. 2019. Available online: https://www.ers.usda.gov/webdocs/DataFiles/53657/table09.xls?v=43074 (accessed on 12 February 2019).

- National Research Council (NRC). Nutrient Requirements of Dairy Cattle: Seventh Revised Edition; The National Academies Press: Washington, DC, USA, 2001; pp. 266–289. [Google Scholar]

- Mertens, D.R. Creating a system for meeting the fiber requirements of dairy cows. J. Dairy Sci. 1997, 80, 1463–1481. [Google Scholar] [CrossRef]

- Ellis, J.L.; Kebreab, E.; Odongo, N.E.; McBride, B.W.; Okine, E.K.; France, J. Prediction of methane production from dairy and beef cattle. J. Dairy Sci. 2007, 90, 3456–3467. [Google Scholar] [CrossRef] [PubMed]

- Yates, C.M.; Cammell, S.B.; France, J.; Beever, D.E. Prediction of methane emissions from dairy cows using multiple regression analysis. In Proceedings of the British Society of Animal Science; British Society of Animal Science: Penicuik, UK, 2000; p. 94. [Google Scholar]

- Moraes, L.E.; Wilen, J.E.; Robinson, P.H.; Fadel, J.G. A linear programming model to optimize diets in environmental policy scenarios. J. Dairy Sci. 2012, 95, 1267–1282. [Google Scholar] [CrossRef] [PubMed]

- Cottle, D.J.; Nolan, J.V.; Wiedemann, S.G. Ruminant enteric methane mitigation: A review. Anim. Prod. Sci. 2011, 51, 491–514. [Google Scholar] [CrossRef]

- Moraes, L.E.; Fadel, J.G.; Castillo, A.R.; Casper, D.P.; Tricarico, J.M.; Kebreab, E. Modeling the trade-off between diet costs and methane emissions: A goal programming approach. J. Dairy Sci. 2015, 98, 5557–5571. [Google Scholar] [CrossRef]

- Richardson, C.M.; Baes, C.F.; Amer, P.R.; Quinton, C.; Martin, P.; Osborne, V.R.; Pryce, J.E.; Miglior, F. Determining the economic value of daily dry matter intake and associated methane emissions in dairy cattle. Animal 2020, 14, 171–179. [Google Scholar] [CrossRef]

- Buza, M.H.; Holden, L.A.; White, R.A.; Ishler, V.A. Evaluating the effect of ration composition on income over feed cost and milk yield. J. Dairy Sci. 2014, 97, 3073–3080. [Google Scholar] [CrossRef] [PubMed]

| Monthly Feed Prices | SBM | DDGS | Canola Meal | Barley | Wheat | Corn | Sorghum | Alfalfa Hay | Ca-Soap | Dicalcium Phosphate | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Objfn1 | Ob1P1 | Ob2P1 | Ob3P1 | Ob4P1 | Ob5P1 | Ob6P1 | Ob7P1 | Ob8P1 | Ob9P1 | Ob10P1 | ||||||

| Objfn2 | Ob1P2 | Ob2P2 | Ob3P2 | Ob4P2 | Ob5P2 | Ob6P2 | Ob7P2 | Ob8P2 | Ob9P2 | Ob10P2 | ||||||

| Objfn3 | … | … | … | … | … | … | … | … | … | … | ||||||

| Objfnn | Ob1Pn | Ob2Pn | Ob3Pn | Ob4Pn | Ob5Pn | Ob6Pn | Ob7Pn | Ob8Pn | Ob9Pn | Ob10Pn | ||||||

| RHS Constraints | ||||||||||||||||

| Constraints | Unit | SBM | DDGS | Canola meal | Barley | Wheat | Corn | Sorghum | Alfalfa hay | Ca-soap | Dicalcium phosphate | 10 kg milk | 25 kg milk | 35 kg milk | ||

| Constraint 1 | Weight | kg | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | “=“ | 1 | 1 | 1 |

| Constraint 2 | CP | g/kg DM | 499 | 297 | 378 | 124 | 142 | 94 | 116 | 192 | 0 | 0 | “≥“ | 119 | 147 | 152 |

| Constraint 3 | UCP | g/kg DM | 175 | 172 | 113 | 35 | 33 | 54 | 71 | 52 | 0 | 0 | “≥“ | 22 | 49 | 55 |

| Constraint 4 | NFC | % | 27 | 16 | 19 | 63 | 70 | 76 | 69 | 25 | 0 | 0 | “≤“ | 44 | 44 | 44 |

| Constraint 5 | Fat | % | 1.6 | 10 | 5.4 | 2.2 | 2.3 | 4.2 | 3.1 | 2.5 | 84.5 | 0 | “≤“ | 5 | 5 | 5 |

| Constraint 6 | ME | MJ/kg DM | 13.8 | 12.7 | 11.5 | 12.2 | 13 | 13.1 | 11.5 | 8.2 | 26.2 | 0 | “≥“ | 8 | 10 | 11 |

| Constraint 7 | NDF | % | 15 | 39 | 30 | 21 | 13 | 10 | 11 | 42 | 0 | 0 | “≥“, “≤“ | 27–35 | 27–33 | 27–33 |

| Constraint 8 | Ca | g/kg DM | 4 | 1 | 8 | 1 | 1 | 0 | 1 | 15 | 0 | 176 | “≥“ | 4.07 | 6.03 | 6.7 |

| Constraint 9 | P | g/kg DM | 7.1 | 6.6 | 11.6 | 3.8 | 4.3 | 3 | 2.8 | 2.4 | 0 | 205 | “≥“ | 2.64 | 3.8 | 3.6 |

| Constraint 10 | peNDF | % | 6 | 15.5 | 11.9 | 14.7 | 8 | 3.8 | 6.5 | 39.5 | 0 | 0 | “≥“ | 22 | 22 | 22 |

| Upper bound | % | inf | 20 | 15 | inf | inf | inf | inf | inf | inf | 2 | |||||

| Lower bound | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alqaisi, O.; Schlecht, E. Feeding Models to Optimize Dairy Feed Rations in View of Feed Availability, Feed Prices and Milk Production Scenarios. Sustainability 2021, 13, 215. https://doi.org/10.3390/su13010215

Alqaisi O, Schlecht E. Feeding Models to Optimize Dairy Feed Rations in View of Feed Availability, Feed Prices and Milk Production Scenarios. Sustainability. 2021; 13(1):215. https://doi.org/10.3390/su13010215

Chicago/Turabian StyleAlqaisi, Othman, and Eva Schlecht. 2021. "Feeding Models to Optimize Dairy Feed Rations in View of Feed Availability, Feed Prices and Milk Production Scenarios" Sustainability 13, no. 1: 215. https://doi.org/10.3390/su13010215

APA StyleAlqaisi, O., & Schlecht, E. (2021). Feeding Models to Optimize Dairy Feed Rations in View of Feed Availability, Feed Prices and Milk Production Scenarios. Sustainability, 13(1), 215. https://doi.org/10.3390/su13010215