Concrete Based on Clinker-Free Cement: Selecting the Functional Unit for Environmental Assessment

Abstract

1. Introduction

2. Materials and Methods

3. Approaches to Assessing the Impact of Clinker-Free Cements on the Environment

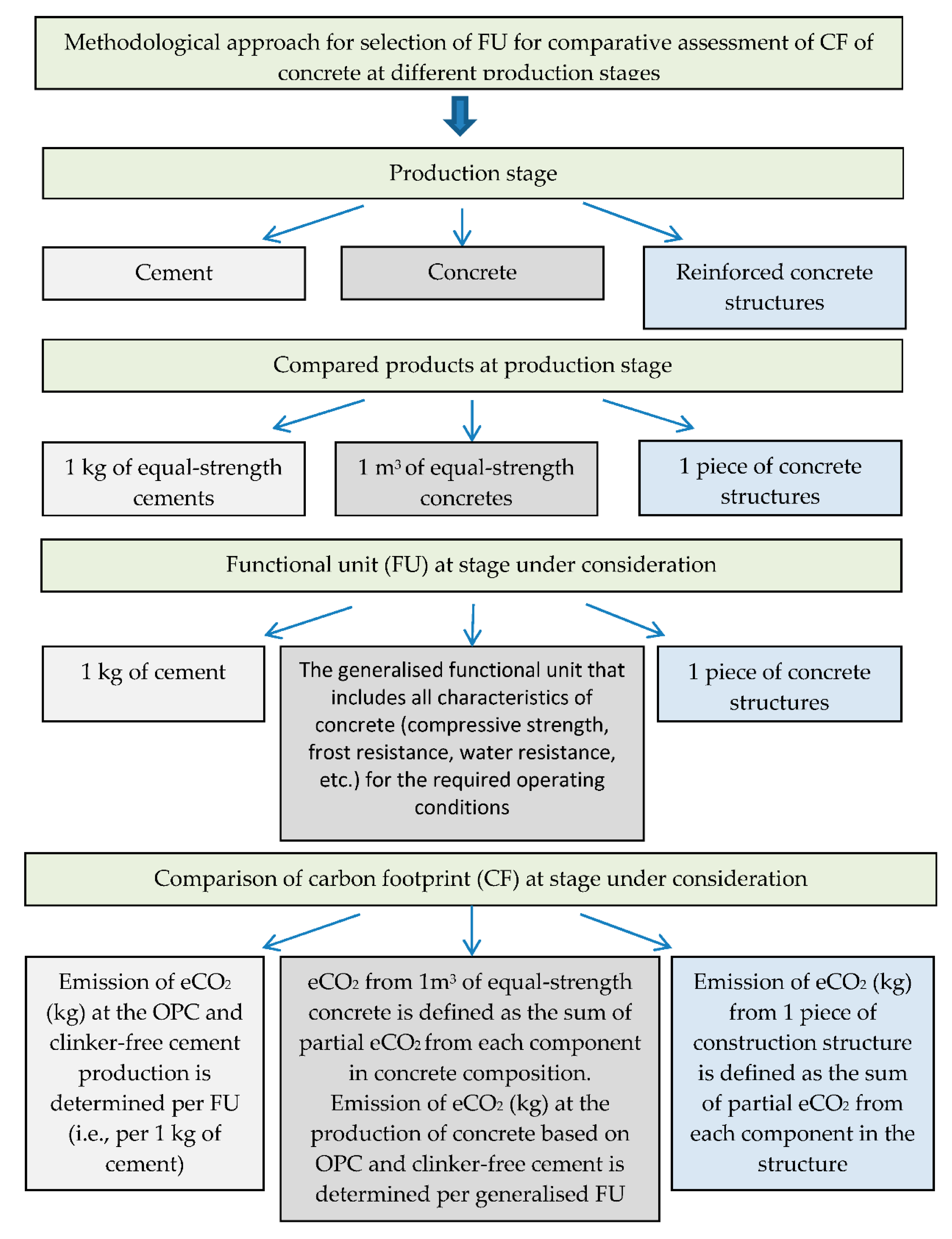

4. Selecting the Functional Unit for Assessing the Environmental Impact of Clinker-Free Cement

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Karapetian, K.; Dzhevaga, N. Modern technologies of complex processing of phosphates. ARPN J. Eng. Appl. Sci. 2017, 12, 4588–4594. [Google Scholar]

- Gorlanov, E.S.; Bazhin, V.Y.; Vlasov, A.A. Electrochemical borating of titanium-containing carbographite materials. Russ. Metall. 2017, 2017, 489–493. [Google Scholar] [CrossRef]

- Brichkin, V.N.; Kurtenkov, R.V.; Eldeeb, A.B.; Bormotov, I.S. State and development options for the raw material base of aluminum in non-bauxite regions. Obogashchenie Rud 2019, 4, 36–41. [Google Scholar] [CrossRef]

- Chen, L.; Wang, L.; Tsang, D.C.; Mechtcherine, V.; Poon, C.S. Efficacy of green alternatives and carbon dioxide curing in reactive magnesia cement-bonded particleboards. J. Clean. Prod. 2020, 258, 120997. [Google Scholar] [CrossRef]

- Beloglazov, I.I.; Bazhin, V.Y.; Zyryanova, O.V. Upgrading of the process of technological pulp separation in modern pressure filters. Non-Ferr. Met. 2016, 1, 38–40. [Google Scholar] [CrossRef]

- Litvinenko, V.S. Digital Economy as a Factor in the Technological Development of the Mineral Sector. Nat. Resour. Res. 2020, 29, 1521–1541. [Google Scholar] [CrossRef]

- Litvinenko, V.S.; Sergeev, I.B. Innovations as a Factor in the Development of the Natural Resources Sector. Stud. Russ. Econ. Dev. 2019, 30, 637–645. [Google Scholar] [CrossRef]

- Tcvetkov, P.; Cherepovitsyn, A.; Fedoseev, S. The changing role of CO2 in the transition to a circular economy: Review of carbon sequestration projects. Sustainability 2019, 11, 5834. [Google Scholar] [CrossRef]

- Pashkevich, M.A.; Bech, J.; Matveeva, V.A.; Alekseenko, A.V. Biogeochemical assessment of soils and plants in industrial, residential and recreational areas of Saint Petersburg. J. Min. Inst. 2020, 241, 125–130. [Google Scholar] [CrossRef]

- ElDeeb, A.B.; Brichkin, V.N.; Kurtenkov, R.V.; Bormotov, I.S. Extraction of alumina from kaolin by a combination of pyro-and hydro-metallurgical processes. Appl. Clay Sci. 2019, 172, 146–154. [Google Scholar] [CrossRef]

- Scrivener, K.L.; John, V.M.; Gartner, E.M. Eco-efficient cements: Potential economically viable solutions for a low-CO2 cement-based materials industry. Cem. Concr. Res. 2018, 114, 2–26. [Google Scholar] [CrossRef]

- Gartner, E.; Sui, T. Alternative cement clinkers. Cem. Concr. Res. 2018, 114, 27–39. [Google Scholar] [CrossRef]

- Juenger, M.C.G.; Snellings, R.; Bernal, S.A. Supplementary cementitious materials: New sources, characterization, and performance insights. Cem. Concr. Res. 2019, 122, 257–273. [Google Scholar] [CrossRef]

- Shi, C.; Qu, B.; Provis, J.L. Recent progress in low-carbon binders. Cem. Concr. Res. 2019, 122, 227–250. [Google Scholar] [CrossRef]

- Trindade, A.C.C.; Heravi, A.A.; Curosu, I.; Liebscher, M.; de Andrade Silva, F.; Mechtcherine, V. Tensile behavior of strain-hardening geopolymer composites (SHGC) under impact loading. Cem. Concr. Compos. 2020, 113, 103703. [Google Scholar] [CrossRef]

- Alekseev, A.V. Face deformation in tunneling in the zone of structural and mechanical heterogeneity. Min. Inf. Anal. Bull. 2018, 12, 48–56. [Google Scholar] [CrossRef]

- Palomo, A.; Monteiro, P.; Martauz, P.; Bílek, V.; Fernandez-Jimenez, A. Clinker-free binders: A journey from the past to a sustainable future (opus caementicium futurum). Cem. Concr. Res. 2019, 124, 105829. [Google Scholar] [CrossRef]

- García-Lodeiro, I.; Fernández-Jiménez, A.; Palomo, A. Variation in clinker-free cements over time. Alkaline activation of fly ash-portland cement blends. Cem. Concr. Res. 2013, 52, 112–122. [Google Scholar] [CrossRef]

- Fernández-Jiménez, A.; Garcia-Lodeiro, I.; Maltseva, O.; Palomo, A. Hydration mechanisms of clinker-free cements as a function of the way of addition of chemicals. J. Am. Ceram. Soc. 2019, 102, 427–436. [Google Scholar] [CrossRef]

- Al Makhadmeh, W.A.; Soliman, A. Effect of activator nature on property development of alkali-activated slag binders. J. Sustain. Cem. Based Mater. 2020, 1–17. [Google Scholar] [CrossRef]

- Klyuev, S.V.; Klyuev, A.V.; Vatin, N.I. Fiber concrete for the construction industry. Mag. Civ. Eng. 2018, 84, 41–47. [Google Scholar] [CrossRef]

- Namsone, E.; Korjakins, A.; Sahmenko, G.; Sinka, M. The environmental impacts of foamed concrete production and exploitation. IOP Conf. Ser. Mater. Sci. Eng. 2017, 251, 012029. [Google Scholar] [CrossRef]

- Sprince, A.; Pakrastins, L.; Gailitis, R. Long-Term Parameters of New Cement Composites. In 3rd International Conference on the Application of Superabsorbent Polymers (SAP) and Other New Admixtures towards Smart Concrete. SAP 2019; Boshoff, W., Combrinck, R., Mechtcherine, V., Wyrzykowski, M., Eds.; RILEM Bookseries; Springer: Cham, Switzerland, 2020; Volume 24, pp. 85–94. [Google Scholar]

- Erofeev, V.T.; Rodin, A.I.; Yakunin, V.V.; Tuvin, M.N. Structure, composition and properties of geopolymers from mineral wool waste. Mag. Civ. Eng. 2019, 90, 3–14. [Google Scholar] [CrossRef]

- Taskin, A.; Fediuk, R.; Grebenyuk, I.; Elkin, O.; Kholodov, A. Effective cement binders on fly and slag waste from heat power industry of the primorsky krai, Russian federation. Int. J. Sci. Technol. Res. 2020, 9, 3509–3512. [Google Scholar]

- Krivenko, P. Why alkaline activation–60 years of the theory and practice of alkali-activated materials. J. Ceram. Sci. Technol. 2017, 8, 323–333. [Google Scholar]

- Krivenko, P.V.; Petropavlovskyi, O.; Kovalchuk, O.; Cao, H.L.; Weng, L.Q. Efficiency of the Alkali-Activated Cement Concretes for Sea Construction. Mater. Sci. Forum 2019, 968, 3–12. [Google Scholar] [CrossRef]

- Qu, B.; Martin, A.; Pastor, J.Y.; Palomo, A.; Fernández-Jiménez, A. Characterisation of pre-industrial clinker-free cement and effect of pre-curing temperature. Cem. Concr. Compos. 2016, 73, 281–288. [Google Scholar] [CrossRef]

- Martauz, P.; Janotka, I.; Strigáč, J.; Bačuvčík, M. Fundamental properties of industrial clinker-free cement: Utilization in ready-mixed concretes and shrinkage-reducing applications. Mater. Constr. 2016, 66, 084. [Google Scholar]

- Luukkonen, T.; Abdollahnejad, Z.; Ohenoja, K.; Kinnunen, P.; Illikainen, M. Suitability of commercial superplasticizers for one-part alkali-activated blast-furnace slag mortar. J. Sustain. Cem. Based Mater. 2019, 8, 244–257. [Google Scholar] [CrossRef]

- Bazhenov, Y.; Kozlova, I.; Nechaev, K.; Kryuchkova, A. The use of finely ground slag in portland cement with mineral additives. In E3S Web of Conferences; EDP Sciences: Les Ulis, France, 2019; Volume 91, p. 02044. [Google Scholar]

- Yazdi, M.A.; Liebscher, M.; Hempel, S.; Yang, J.; Mechtcherine, V. Correlation of microstructural and mechanical properties of geopolymers produced from fly ash and slag at room temperature. Constr. Build. Mater. 2018, 191, 330–341. [Google Scholar] [CrossRef]

- Zhang, J.; He, X.; Yang, W.; Deng, X. Utilization of carbide slag-granulated blast furnace slag system by wet grinding as low carbon cementitious materials. Constr. Build. Mater. 2020, 249, 118763. [Google Scholar] [CrossRef]

- Bisikirske, D.; Blumberga, D.; Vasarevicius, S.; Skripkiunas, G. Multicriteria Analysis of Glass Waste Application. Environ. Clim. Technol. 2019, 23, 152–167. [Google Scholar] [CrossRef]

- Grengg, C.; Ukrainczyk, N.; Koraimann, G.; Mueller, B.; Dietzel, M.; Mittermayr, F. Long-term in situ performance of geopolymer, calcium aluminate and Portland cement-based materials exposed to microbially induced acid corrosion. Cem. Concr. Res. 2020, 131, 106034. [Google Scholar] [CrossRef]

- Petrova, T.M. Concrete for Transport Construction Based on Cement-Free Binders. Ph.D. Thesis, Petersburg State Transport University, Saint Petersburg, Russia, 1997; p. 511. [Google Scholar]

- Kazanskaya, L.F. Supersulphated Slag Binders and Concretes Based on Them (Based on Waste from the Chemical Industry of the South Ural Region). Ph.D. Thesis, Petersburg State Transport University, Saint Petersburg, Russia, 2000; p. 326. [Google Scholar]

- Kazanskaya, L.F.; Smirnova, O.M. Technological approaches to increase the quality of lightweight concrete based on clinker-free binders. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2019; Volume 666, p. 012038. [Google Scholar]

- Gartner, E.; Hirao, H. A review of alternative approaches to the reduction of CO2 emissions associated with the manufacture of binder phase in concrete. Cem. Concr. Res. 2015, 78, 126–142. [Google Scholar] [CrossRef]

- Lothenbach, B.; Scrivener, K.; Hooton, R.D. Supplementary cementitious materials. Cem. Concr. Res. 2011, 41, 1244–1256. [Google Scholar] [CrossRef]

- Sinka, M.; Van den Heede, P.; De Belie, N.; Bajare, D.; Sahmenko, G.; Korjakins, A. Comparative life cycle assessment of magnesium binders as an alternative for hemp concrete. Resources. Conserv. Recycl. 2018, 133, 288–299. [Google Scholar] [CrossRef]

- Rakhimova, N.R.; Rakhimov, R.Z. Literature review of advances in materials used in development of alkali-activated mortars, concretes, and composites. J. Mater. Civ. Eng. 2019, 31, 03119002. [Google Scholar] [CrossRef]

- Donatello, S.; Maltseva, O.; Fernandez-Jimenez, A.; Palomo, A. The early age hydration reactions of clinker-free cement containing a very high content of coal bottom ash. J. Am. Ceram. Soc. 2014, 97, 929–937. [Google Scholar] [CrossRef]

- El-Hassan, H.; Ismail, N. Effect of process parameters on the performance of fly ash/GGBS blended geopolymer composites. J. Sustain. Cem. Based Mater. 2018, 7, 122–140. [Google Scholar] [CrossRef]

- Krivenko, P.; Gelevera, O.; Kovalchuk, O.; Bumanis, G.; Korjakins, A. Alkali-aggregate reaction in alkali-activated cement concretes. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2019; Volume 660, p. 012002. [Google Scholar]

- Ochkurov, V.I.; Vilenskii, M.Y. Comparative evaluation of the saving of binder with fine ground slag. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2019; Volume 666, p. 012026. [Google Scholar]

- Kalina, L.; Bílek, V.; Kiripolský, T.; Novotný, R.; Másilko, J. Cement Kiln By-Pass Dust: An Effective Alkaline Activator for Pozzolanic Materials. Materials 2018, 11, 1770. [Google Scholar] [CrossRef]

- Habert, G.; Ouellet-Plamondon, C. Recent update on the environmental impact of geopolymers. Rilem Tech. Lett. 2016, 1, 17–23. [Google Scholar] [CrossRef]

- Teh, S.H.; Wiedmann, T.; Castel, A.; de Burgh, J. Clinker-free life cycle assessment of greenhouse gas emissions from cement, concrete and geopolymer concrete in Australia. J. Clean. Prod. 2017, 152, 312–320. [Google Scholar] [CrossRef]

- Li, C.; Cui, S.; Nie, Z.; Gong, X.; Wang, Z.; Itsubo, N. The LCA of Portland cement production in China. Int. J. Life Cycle Assess. 2015, 20, 117–127. [Google Scholar] [CrossRef]

- Damineli, B.L.; Kemeid, F.M.; Aguiar, P.S.; John, V.M. Measuring the eco-efficiency of cement use. Cem. Concr. Compos. 2010, 32, 555–562. [Google Scholar] [CrossRef]

- Gursel, A.P.; Masanet, E.; Horvath, A.; Stadel, A. Life-cycle inventory analysis of concrete production: A critical review. Cem. Concr. Compos. 2014, 51, 38–48. [Google Scholar] [CrossRef]

- Zimele, Z.; Sinka, M.; Korjakins, A.; Bajare, D.; Sahmenko, G. Life Cycle Assessment of Foam Concrete Production in Latvia. Environ. Clim. Technol. 2019, 23, 70–84. [Google Scholar] [CrossRef]

- Mohammadi, J.; South, W. Life cycle assessment (LCA) of benchmark concrete products in Australia. Int. J. Life Cycle Assess. 2017, 22, 1588–1608. [Google Scholar] [CrossRef]

- Salas, D.A.; Ramirez, A.D.; Ulloa, N.; Baykara, H.; Boero, A.J. Life cycle assessment of geopolymer concrete. Constr. Build. Mater. 2018, 190, 170–177. [Google Scholar] [CrossRef]

- Panesar, D.; Seto, K.; Churchill, C. Impact of the selection of functional unit on the life cycle assessment of green concrete. Int. J. Life Cycle Assess. 2017, 22, 1969–1986. [Google Scholar] [CrossRef]

- Robayo-Salazar, R.; Mejía-Arcila, J.; de Gutiérrez, R.M.; Martínez, E. Life cycle assessment (LCA) of an alkali-activated binary concrete based on natural volcanic pozzolan: A comparative analysis to OPC concrete. Constr. Build. Mater. 2018, 176, 103–111. [Google Scholar] [CrossRef]

- Purnell, P.; Black, L. Embodied carbon dioxide in concrete: Variation with common mix design parameters. Cem. Concr. Res. 2012, 42, 874–877. [Google Scholar] [CrossRef]

- Gutiérrez, A.S.; Eras, J.J.C.; Gaviria, C.A.; Van Caneghem, J.; Vandecasteele, C. Improved selection of the functional unit in environmental impact assessment of cement. J. Clean. Prod. 2017, 168, 463–473. [Google Scholar] [CrossRef]

- Messina, F.; Ferone, C.; Colangelo, F.; Roviello, G.C. Alkali activated waste fly ash as sustainable composite: Influence of curing and pozzolanic admixtures on the early-age physico-mechanical properties and residual strength after exposure at elevated temperature. Compos. Part B Eng. 2018, 132, 161–169. [Google Scholar] [CrossRef]

- Hassan, M.; Arif, M.; Shariq, M. Use of geopolymer concrete for a cleaner and sustainable environment–a review of mechanical properties and microstructure. J. Clean. Prod. 2019, 223, 704–728. [Google Scholar] [CrossRef]

- Pillai, R.G.; Gettu, R.; Santhanam, M.; Rengaraju, S.; Dhandapani, Y.; Rathnarajan, S.; Basavaraj, A.S. Service life and life cycle assessment of reinforced concrete systems with limestone calcined clay cement (LC3). Cem. Concr. Res. 2019, 118, 111–119. [Google Scholar] [CrossRef]

- Barboza-Chavez, A.C.; Gómez-Zamorano, L.Y.; Acevedo-Dávila, J.L. Synthesis and Characterization of a Clinker-free Cement Based on Fly Ash, Metakaolin and Portland Cement Clinker. Materials 2020, 13, 1084. [Google Scholar] [CrossRef] [PubMed]

- Khozin, V.; Khohryakov, O.; Baishev, D.; Makarenko, S. Low-water demand cements–a reliable way of CO2 emission reduction. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2019; Volume 667, p. 012040. [Google Scholar]

- Petrova, T.M.; Smirnova, O.M. Binder. Patent RU No. 2,556,563, 15 July 2014. [Google Scholar]

| Slags | SiO2 | А12О3 | СаО | MgO | SO3 | FeO | Fe2O3 | MnO |

|---|---|---|---|---|---|---|---|---|

| TiO2 | ||||||||

| Beloretsky slag (No.1) | 37.00 | 16.00 | 39.30 | 3.00 | 0.62 | 1.00 | - | 1.00 |

| Magnitogorsky (No.2) | 35.68 | 14.32 | 40.09 | 5.54 | 1.17 | - | 0.84 | 0.80 |

| Waste | SiO2 | СаО | MgO | К2О + Na2O | А12О3 | Fe2O3 | SO3 | (СаО + MgO)free | Сr |

|---|---|---|---|---|---|---|---|---|---|

| Solid residue of sodium carbonate production (SRS) | 5–12 | 40–50 | 1.8–2.6 | 0.2–1.0 | 2.8–4.7 | 1–3 | 1–5 | 5–12 | 3–12 |

| Waste of slaking the lime (WSL) | 2–4.5 | 58–62 | 1.0–2.5 | 0.15–0.25 | 2.0 | 1.3–4.0 | 2–3 | 22–35 | 0.3–0.5 |

| Cement kiln dust (CKD) | 13–15 | 42–45 | 2–3 | 1.0–1.5 | 3–6 | 2.5–4.0 | 0.7 | 6–7 | 0.3–0.5 |

| СаО | SO3 | Н2С | Р2О5 | R2O3 | R2O |

|---|---|---|---|---|---|

| 31.5 | 46.76 | 18.9 | 0.89 | 0.24 | 0.42 |

| No. | Binder | Compressive Strength, МPа | Frost Resistance, Cycles | Water Resistance, MPa |

|---|---|---|---|---|

| 1 | CEM 32.5 | 40 | 300 | 1.5 |

| 2 | CEM 52.5 | 60 | 600 | 2.1 |

| 3 | Slag Portland cement CEM III32.5 | 37 | 300 | 2.0 |

| 4 | Slag Portland cement CEM III42.5 | 41 | 400 | 2.0 |

| Slag No.1 (Мo = 0.8) | ||||

| 5 | Only slag | 2 | 25 | 0.5 |

| 6 | Slag + Na2CO3 * | 40 | 300 | 1.5 |

| 7 | Slag + NaOH * | 35 | 150 | 1.5 |

| 8 | Slag + Na2SiO3 * | 70 | 600 | 2.2 |

| 9 | Slag + K2CO3 * | 40 | 180 | 1.7 |

| Slag No.2 (Мo = 0.9) | ||||

| 10 | Only slag | 3 | 30 | 0.3 |

| 11 | Slag + Na2CO3 * | 50 | 400 | 2.0 |

| 12 | Slag + NaOH * | 40 | 200 | 1.0 |

| 13 | Slag + Na2SiO3 * | 78 | 700 | 2.5 |

| No. | Binder Composition | |||||||

|---|---|---|---|---|---|---|---|---|

| Slag | Sulfate Component | Activator | ||||||

| Type | Specific Surface Area, сm2/g | Mass, % | Type | Specific Surface Area, сm2/g | Mass, % | Type | Mass, % | |

| 6.1 | No.2 | 3200 | 80 | FG | 6000 | 20 | SKD | 10 |

| 6.2 | No.2 | 3200 | 80 | FG | 6000 | 20 | WSL | 5 |

| 6.3 | No.2 | 3200 | 80 | FG | 6000 | 20 | SRS | 10 |

| 6.4 | CEM I32.5 | |||||||

| 6.5 | CEM III22.5 | |||||||

| No. | Setting Time of Cement Paste, h–min | Water/Binder | Strength at 28 Days, МPа | Frost Resistance, Cycles | ||

|---|---|---|---|---|---|---|

| Begin | End | Tensile Strength in Bending | Compressive Strength | |||

| 6.1 | 2–40 | 7–00 | 0.48 | 5.1 | 36.2 | 70 |

| 6.2 | 2–20 | 6–10 | 0.47 | 4.8 | 35.0 | 65 |

| 6.3 | 3–30 | 9–10 | 0.47 | 4.4 | 28.0 | 60 |

| 6.4 | 2–20 | 5–20 | 0.38 | 5.6 | 42,0 | 150 |

| 6.5 | 2–40 | 6–10 | 0.41 | 4.6 | 31.7 | 110 |

| No. | Tensile Strength in Bending (MPa) after Storage: | |||||

|---|---|---|---|---|---|---|

| 105 Days | 150 days | |||||

| In Tap Water | In Aggressive Media | Resistance Coefficient Kr | In Tap Water | In Aggressive Media | RESISTANCE Coefficient Kr | |

| 6.1 | 7.2 | 6.8 | 0.94 | 8.4 | 7.5 | 0.90 |

| 6.2 | 6.8 | 6.1 | 0.90 | 7.7 | 6.7 | 0.87 |

| 6.3 | 6.1 | 5.1 | 0.83 | 7.0 | 5.6 | 0.80 |

| 6.4 | 8.8 | 5.8 | 0.66 | 9.7 | 5.1 | 0.53 |

| 6.5 | 6.9 | 5.4 | 0.78 | 7.6 | 5.7 | 0.75 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Smirnova, O.; Kazanskaya, L.; Koplík, J.; Tan, H.; Gu, X. Concrete Based on Clinker-Free Cement: Selecting the Functional Unit for Environmental Assessment. Sustainability 2021, 13, 135. https://doi.org/10.3390/su13010135

Smirnova O, Kazanskaya L, Koplík J, Tan H, Gu X. Concrete Based on Clinker-Free Cement: Selecting the Functional Unit for Environmental Assessment. Sustainability. 2021; 13(1):135. https://doi.org/10.3390/su13010135

Chicago/Turabian StyleSmirnova, Olga, Liliya Kazanskaya, Jan Koplík, Hongbo Tan, and Xianyue Gu. 2021. "Concrete Based on Clinker-Free Cement: Selecting the Functional Unit for Environmental Assessment" Sustainability 13, no. 1: 135. https://doi.org/10.3390/su13010135

APA StyleSmirnova, O., Kazanskaya, L., Koplík, J., Tan, H., & Gu, X. (2021). Concrete Based on Clinker-Free Cement: Selecting the Functional Unit for Environmental Assessment. Sustainability, 13(1), 135. https://doi.org/10.3390/su13010135