Economic, Environmental and Social Gains of the Implementation of Artificial Intelligence at Dam Operations toward Industry 4.0 Principles

Abstract

1. Introduction

2. Systematic Literature Review on Economic and Environmental Advantages of Using Enabling Technologies on Dam Operations

3. Research Methodology

3.1. Problem Definition

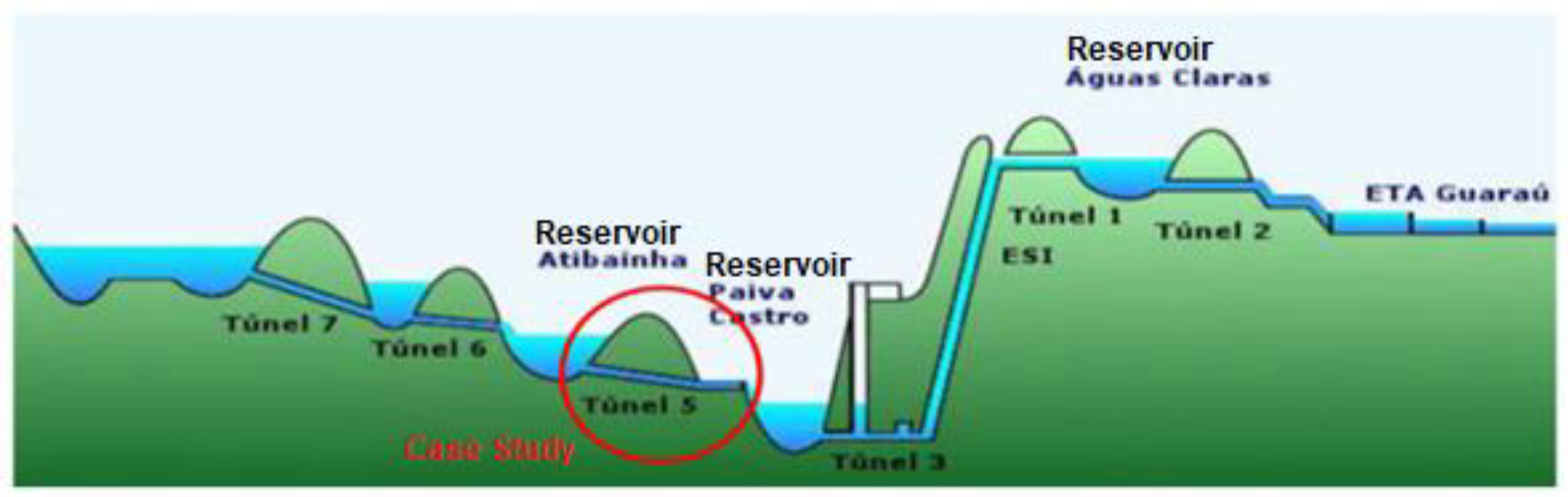

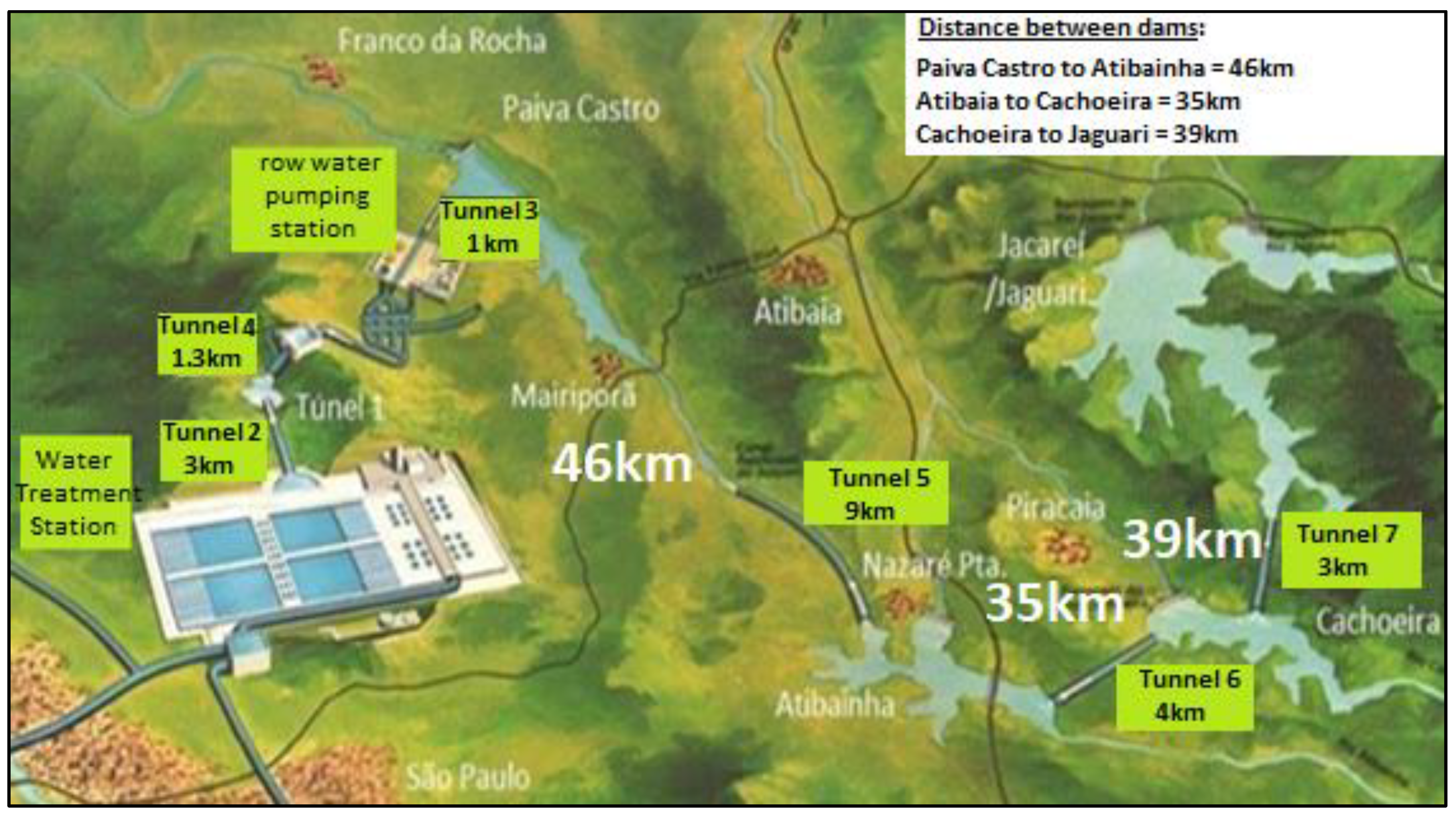

3.2. Research Delineation

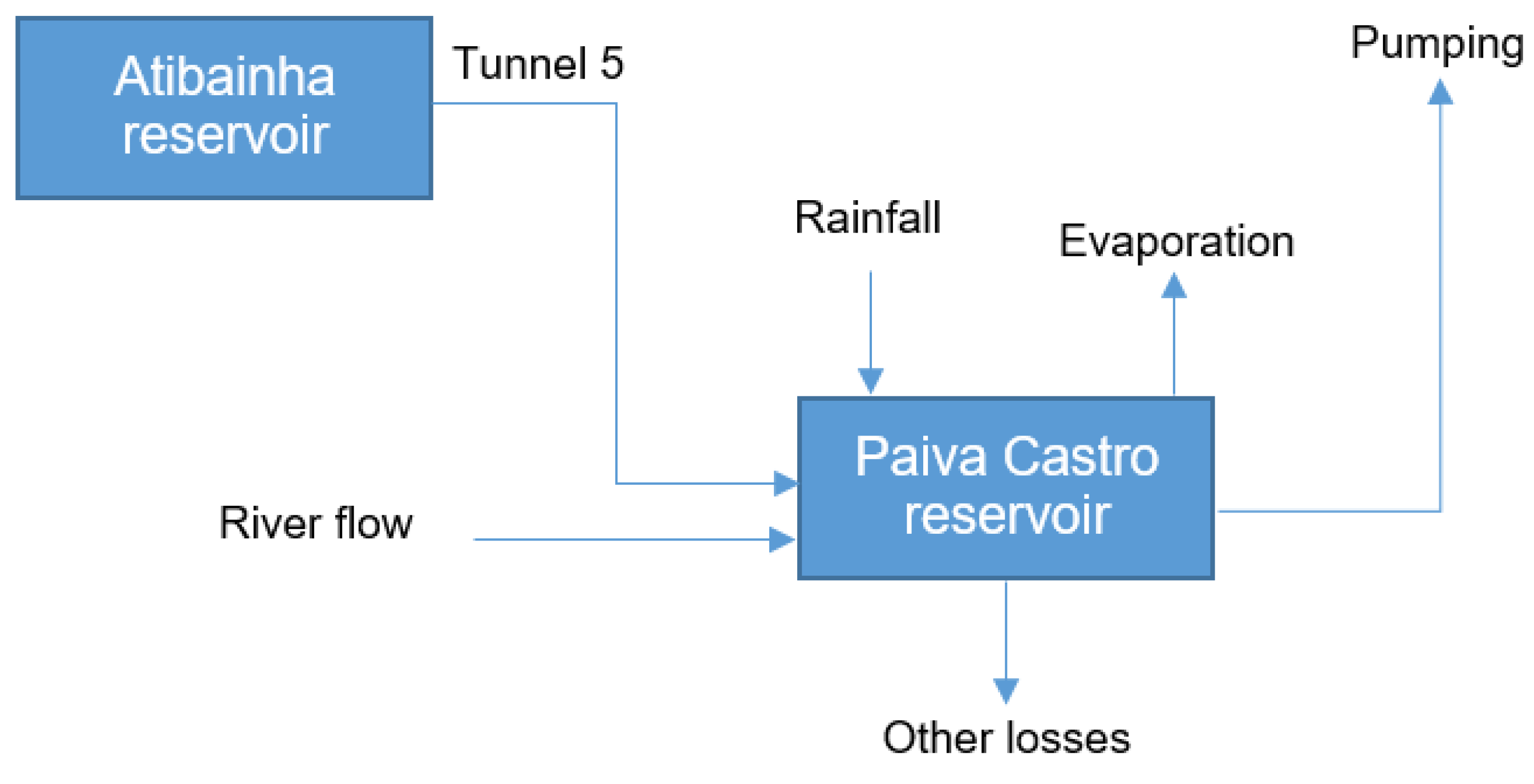

3.3. Data Collection

3.4. Data Analysis

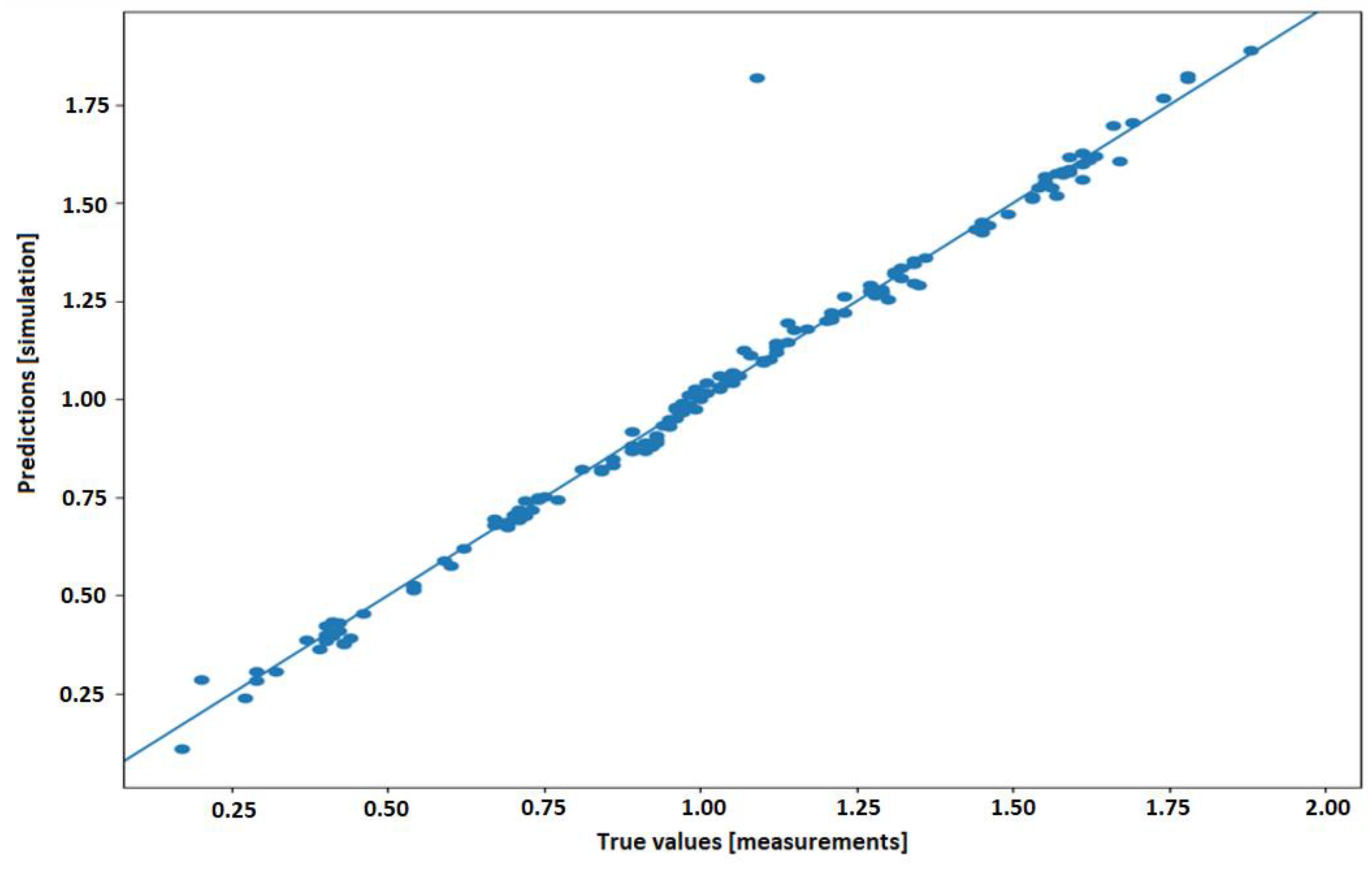

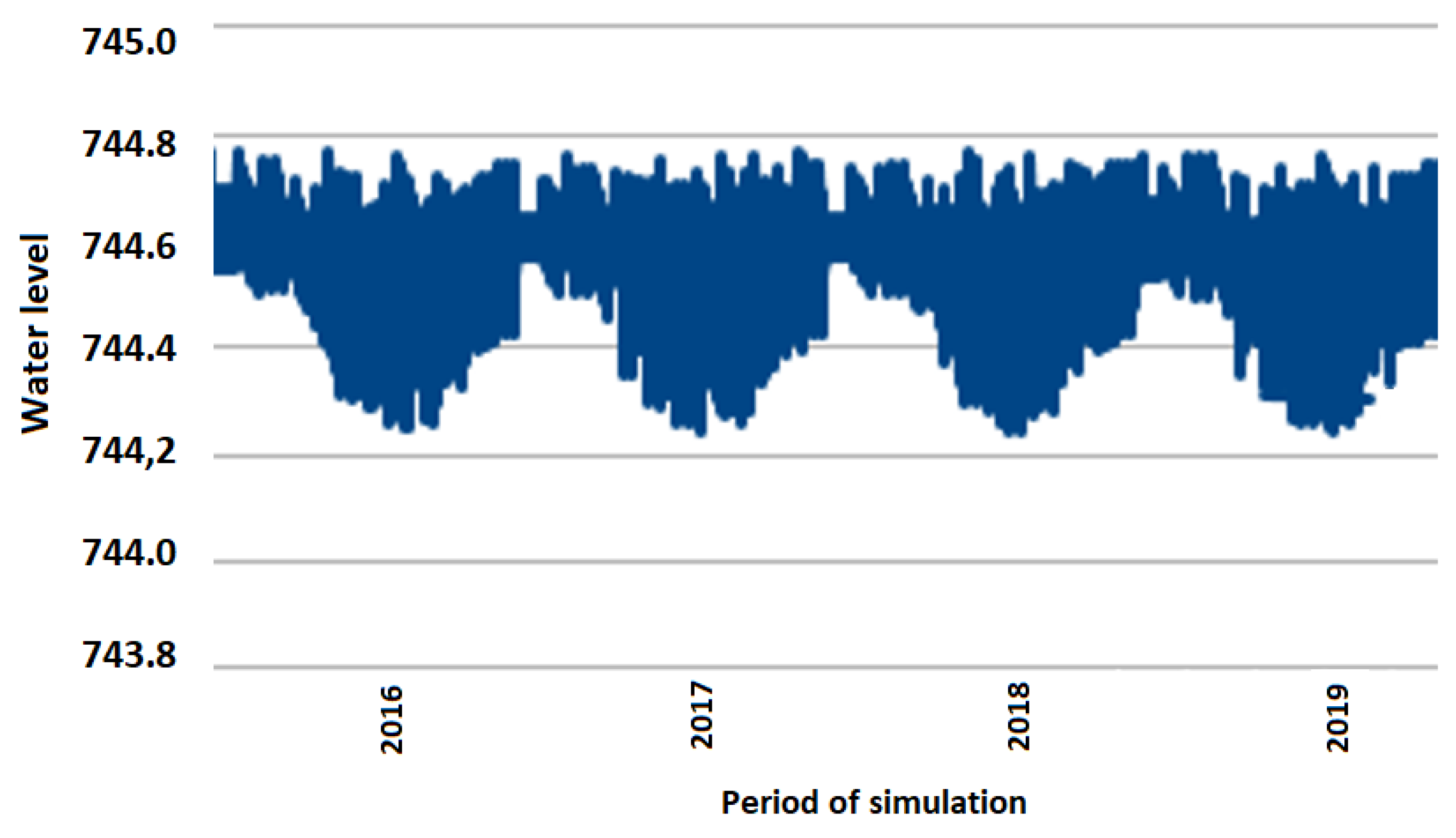

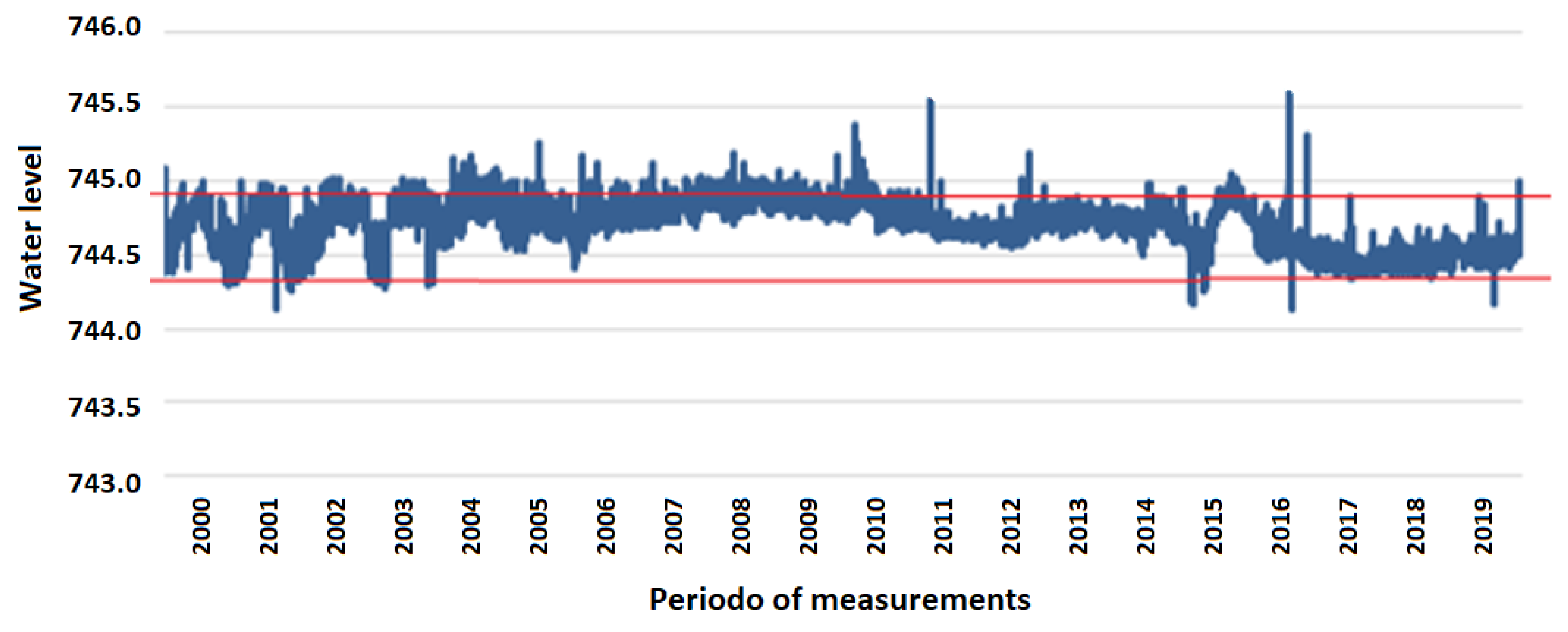

4. Results

4.1. System before Artificial Intelligence Implementation

4.2. Required System after Artificial Intelligence Implementation

4.3. Economic Evaluation

4.4. Environmental Evaluation

4.5. Social Evaluation

5. Discussion

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- SDG. Sustainable Development Goal 6: Synthesis Report on Water and Sanitation; SDG: New York, NY, USA, 2018. [Google Scholar]

- Haddock, J.; O’Keefe, R.M. Using Artificial Intelligence to Facilitate Manufacturing Systems Simulation. Comput. Ind. Eng. 1990, 18, 275–283. [Google Scholar] [CrossRef]

- Nilsson, N.J. Principles of Artificial Intelligence; Tioga Publishing Co.: Palo Alto, CA, USA, 1980. [Google Scholar]

- Davis, R.; Lenat, D.B. Knowledge-Based Systems in Artificial Intelligence; McGraw-Hill: New York, NY, USA, 1982. [Google Scholar]

- Joshi, S.; Chang, T.C.; Liu, C.R. Process planning formalization in an AI framework. Artif. Intell. Eng. 1986, 1, 45–53. [Google Scholar] [CrossRef]

- Jha, K.; Doshi, A.; Patel, P.; Shah, M. A comprehensive review on automation in agriculture using artificial intelligence. Artif. Intell. Agric. 2019, 2, 1–12. [Google Scholar] [CrossRef]

- Manghisi, V.M.; Uva, A.E.; Fiorentino, M.; Gattullo, M.; Boccaccio, A.; Evangelista, A. Automatic ergonomic postural risk monitoring on the factory shopfloor—The ergosentinel tool. Procedia Manuf. 2020, 42, 97–103. [Google Scholar] [CrossRef]

- Manghisi, V.M.; Uva, A.E.; Fiorentino, M.; Bevilacqua, V.; Trotta, G.F.; Monno, G. Real time RULA assessment using Kinect v2 sensor. Appl. Ergon. 2017, 65, 481–491. [Google Scholar] [CrossRef]

- Al Aani, S.; Bonny, T.; Hasan, S.W.; Hilal, N. Can machine language and artificial intelligence revolutionize process automation for water treatment and desalination? Desalination 2019, 458, 84–96. [Google Scholar] [CrossRef]

- Feng, Z.; Hou, Q.; Zheng, Y.; Ren, W.; Ge, J.; Li, T.; Cheng, C.; Lu, W.; Cao, S.; Zhang, J.; et al. Method of artificial intelligence algoritm to improve the automation level of Rietveld refinement. Comput. Mater. Sci. 2019, 156, 310–314. [Google Scholar] [CrossRef]

- Bezerra, M.A.; Lemos, V.A.; Oliveira, D.M.; Novaes, C.G.; Barreto, J.A.; Alves, J.P.S.; Cerqueira, U.M.F.M.; Santos, Q.O.; Araújo, S.A. Automation of continuos flow analysis systems. Microchem. J. 2020, 155, 1–17. [Google Scholar] [CrossRef]

- Magrini, L.C.; Kayano, P.S.D.; Crispino, F.; Carneiro, E.F.; Cappi, T.P.A.; Santos, A.L.C. Design of an Intelligent Sensor Network for Dam Monitoring Based on IoT Technology. In Proceedings of the 2018 IEEE 9th Power, Instrumentation and Measurement Meeting (EPIM), Salto, Uruguay, 14–16 November 2018; pp. 1–6. [Google Scholar]

- Jiang, H.; Lin, P.; Qiang, M.; Fan, Q. A labor consumption measurement system based on real-time tracking technology for dam construction site. Autom. Constr. 2015, 52, 1–15. [Google Scholar] [CrossRef]

- Di Sarno, C.; Garofalo, A.; Matteucci, I.; Vallini, M. A novel security information and event management system for enhancing cyber security in a hydroelectric dam. Int. J. Crit. Infrastruct. Prot. 2016, 13, 39–51. [Google Scholar] [CrossRef]

- Saha, G.; Pama, A.; Sushmitha, R.; Bhat, S. Automatic floodgates control using PLC with added focus on human safety. In Proceedings of the 2015 International Conference on Control Instrumentation Communication and Computational Technologies, ICCICCT 2015, Kumaracoil, India, 18–19 December 2015; pp. 417–422. [Google Scholar]

- Varghese, J.; Jolly, A.T.; Peter, A.; Rajeev, B.P.; Sajitha, K.S.; George, D.E. IoT based Disaster Monitoring and Management System for Dams (IDMMSD). In Proceedings of the 2019 1st International Conference on Innovations in Information and Communication Technology (ICIICT), CHENNAI, India, 25–26 April 2019. [Google Scholar]

- Jia, B.; Simonovic, S.P.; Zhong, P.; Yu, Z. A Multi-Objective Best Compromise Decision Model for Real-Time Flood Mitigation Operations of Multi-Reservoir System. Water Resour. Manag. 2016, 30, 3363–3387. [Google Scholar] [CrossRef]

- Uysal, G.; Şensoy, A.; Şorman, A.A.; Akgün, T.; Gezgin, T. Basin/Reservoir System Integration for Real Time Reservoir Operation. Water Resour. Manag. 2016, 30, 1653–1668. [Google Scholar] [CrossRef]

- Allawi, M.F.; Jaafar, O.; Mohamad Hamzah, F.; Koting, S.B.; Mohd, N.S.B.; El-Shafie, A. Forecasting hydrological parameters for reservoir system utilizing artificial intelligent models and exploring their influence on operation performance. Knowl.-Based Syst. 2019, 163, 907–926. [Google Scholar] [CrossRef]

- Tang, H.; Lei, Y.; Lin, B.; Zhou, Y.; Gu, Z. Artificial intelligence model for water resources management. Proc. Inst. Civ. Eng. Water Manag. 2010, 163, 175–187. [Google Scholar] [CrossRef]

- Russell, S.O.; Campbell, P.F. Reservoir operating rules with fuzzy programming. J. Water Resour. Plan. Manag. 1996, 122, 165–170. [Google Scholar] [CrossRef]

- Mao, Y.; Zhong, H.; Chen, H.; Li, X. Two-phase PT-Topk Query Processing Algorithm for Uncertain IOT Data in Dam Safety Monitoring. Intell. Autom. Soft Comput. 2017, 23, 581–588. [Google Scholar] [CrossRef]

- Sordo-Ward, A.; Garrote, L.; Martín-Carrasco, F.; Bejarano, M.D. Extreme flood abatement in large dams with fixed-crest spillways. J. Hydrol. 2012, 466, 60–72. [Google Scholar] [CrossRef]

- Sulis, M.; Marrocu, M.; Paniconi, C. Conjunctive use of a hydrological model and a multicriteria decision support system for a case study on the Caia catchment, Portugal. J. Hydrol. Eng. 2009, 14, 141–152. [Google Scholar] [CrossRef]

- Liao, D.; Wu, Y.; Wu, Z.; Zhu, Z.; Zhang, W.; Sun, G.; Chang, V. AI-based software-defined virtual network function scheduling with delay optimization. Clust. Comput. 2018, 22, 13897–13909. [Google Scholar] [CrossRef]

- Lin, W.; Peng, G.; Bian, X.; Xu, S.; Chang, V.; Li, Y. Scheduling Algorithms for Heterogeneous Cloud Environment: Main Resource Load Balancing Algorithm and Time Balancing Algorithm. J. Grid Comput. 2019, 17, 699–726. [Google Scholar] [CrossRef]

- Kalsi, S.; Kaur, H.; Chang, V. DNA Cryptography and Deep Learning using Genetic Algorithm with NW algorithm for Key Generation. J. Med. Syst. 2017, 42. [Google Scholar] [CrossRef] [PubMed]

- Sood, S.K.; Sandhu, R.; Singla, K.; Chang, V. IoT, big data and HPC based smart flood management framework. Sustain. Comput. Inform. Syst. 2018, 20, 102–117. [Google Scholar] [CrossRef]

- Siddiqa, A.; Karim, A.; Saba, T.; Chang, V. On the analysis of big data indexing execution strategies. J. Intell. Fuzzy Syst. 2017, 32, 3259–3271. [Google Scholar] [CrossRef]

- Coppolino, L.; D’Antonio, S.; Formicola, V.; Romano, L. Integration of a System for Critical Infrastructure Protection with the OSSIM SIEM Platform: A dam case study. In Computer Safety, Reliability, and Security; Flammini, F., Bologna, S., Vittorini, V., Eds.; Springer: Berlin/Heidelberg, Germany, 2011; pp. 199–212. [Google Scholar]

- Coppolino, L.; D’Antonio, S.; Formicola, V.; Romano, L. A framework for mastering heterogeneity in multi-layer security information and event correlation. J. Syst. Arch. 2016, 62, 78–88. [Google Scholar] [CrossRef]

- Dehghani, M.; Riahi-Madvar, H.; Hooshyaripor, F.; Mosavi, A.; Shamshirband, S.; Zavadskas, E.K.; Chau, K.W. Prediction of hydropower generation using Grey wolf optimization adaptive neuro-fuzzy inference system. Energies 2019, 12, 289. [Google Scholar] [CrossRef]

- Geressu, R.T.; Harou, J.J. Reservoir system expansion scheduling under conflicting interests. Environ. Model. Softw. 2019, 118, 201–210. [Google Scholar] [CrossRef]

- Liu, H.; He, X.; Qiu, L.; Chen, J.; Han, Y.; Li, Y. A Systematic Design Approach of a Float Type Sluice Gate for Flow Measurement Automation. IFAC-PapersOnLine 2018, 51, 304–308. [Google Scholar] [CrossRef]

- Siddula, S.S.; Babu, P.; Jain, P.C. Water Level Monitoring and Management of Dams using IoT. In Proceedings of the 2018 3rd International Conference on Internet of Things: Smart Innovation and Usages, IoT-SIU 2018, Bhimtal, India, 23–24 February 2018; pp. 1–5. [Google Scholar]

- Zhang, D.; Lin, J.; Peng, Q.; Wang, D.; Yang, T.; Sorooshian, S.; Liu, X.; Zhuang, J. Modeling and simulating of reservoir operation using the artificial neural network, support vector regression, deep learning algorithm. J. Hydrol. 2018, 565, 720–736. [Google Scholar] [CrossRef]

- Jaupi, O. Computer science: Application of technology/IoT in hydropower dams. In Proceedings of the UBT International Conference, Durres, Albania, 27 October 2017; pp. 49–53. [Google Scholar]

- Easwaramoorthy, N.S.V. Dam Gate Level Monitoring and Control over IoT. J. Adv. Res. Dyn. Control Syst. Spec. 2017, 12, 583–587. [Google Scholar]

- Feng, L.; Sun, X.; Zhu, X. Impact of floodgates operation on water environment using one-dimensional modelling system in river network of Wuxi city, China. Ecol. Eng. 2016, 91, 173–182. [Google Scholar] [CrossRef]

- Martac, R.; Milivojevic, N.; Milivojevic, V.; Cirovic, V.; Barac, D. Using internet of things in monitoring and management of dams in Serbia. Facta Univ. Ser. Electron. Energ. 2016, 29, 419–435. [Google Scholar] [CrossRef]

- Sousa, J.J.; Ruiz, A.M.; Bakon, M.; Lazecky, M.; Hlavácová, I.; Patricio, G.; Delgado, J.M.; Perissin, D. Potential of C-Band SAR Interferometry for Dam Monitoring. Procedia Comput. Sci. 2016, 100, 1103–1114. [Google Scholar] [CrossRef]

- Razavi, S.; Araghinejad, S. Reservoir inflow modeling using temporal neural networks with forgetting factor approach. Water Resour. Manag. 2008, 23, 39–55. [Google Scholar] [CrossRef]

- Anita, G.; Singh, R.; Choudhury, S.; Singh, B. Wireless disaster monitoring and management system for dams. Procedia Comput. Sci. 2015, 48, 381–386. [Google Scholar] [CrossRef]

- Okkan, U.; Inan, G. Statistical downscaling of monthly reservoir inflows for Kemer watershed in Turkey: Use of machine learning methods, multiple GCMs and emission scenarios. Int. J. Clim. 2014, 35, 3274–3295. [Google Scholar] [CrossRef]

- Yuan, D.; Zhang, Y.; Liu, J.; Gao, S.; Song, X. Water quantity and quality joint-operation modeling of dams and floodgates in Huai River Basin, China. J. Water Resour. Plan. Manag. 2015, 141, 04015005. [Google Scholar] [CrossRef]

- Chen, M.; Fang, H.; Zheng, Y.; He, G. Integrated flood management for beiyun river, China. J. Hydrol. Hydromech. 2013, 61, 177–187. [Google Scholar]

- Xue, L.Y.; Yang, J.H.; Li, S.B. Design of digital water-level monitoring system based on LM3S615. Appl. Mech. Mater. 2013, 333, 1605–1610. [Google Scholar] [CrossRef]

- Sun, E.; Zhang, X.; Li, Z. The internet of things (IOT) and cloud computing (CC) based tailings dam monitoring and pre-alarm system in mines. Saf. Sci. 2012, 50, 811–815. [Google Scholar] [CrossRef]

- Weihua, F.; Lanyu, X. Multi-Scale Model of Dam Safety Condition Monitoring Based On Dynamic Bayesian Networks. Intell. Autom. Soft Comput. 2012, 18, 909–921. [Google Scholar] [CrossRef]

- Andolfato, S.H.D.; Faggion, P.L. Proposta para um sistema de automação de níveis digitais. Rev. Agrogeoambient. 2011, 3, 53–62. [Google Scholar] [CrossRef][Green Version]

- Hu, J.; Liu, X. Design and implementation of tailings dam security monitoring system. Procedia Eng. 2011, 26, 1914–1921. [Google Scholar] [CrossRef]

- Yu, G.; Song, C.; Zou, J.; Wu, Y.; Pan, Y.; Li, L.; Li, R.; Wang, P.; Wang, Y. Applications of online monitoring technology for tailings dam on digital mine. Trans. Nonferrous Met. Soc. China 2011, 21, s604–s609. [Google Scholar] [CrossRef]

- Karaboga, D.; Bagis, A.; Haktanir, T. Controlling spillway gates of dams by using fuzzy logic controller with optimum rule number. Appl. Soft Comput. 2008, 8, 232–238. [Google Scholar] [CrossRef]

- Zhuan, X.; Zheng, G.; Xia, X. A modelling methodology for natural dam-river network systems. Control Eng. Pr. 2009, 17, 534–540. [Google Scholar] [CrossRef]

- Mediero, L.; Garrote, L.; Martín-Carrasco, F. A probabilistic model to support reservoir operation decisions during flash floods. Hydrol. Sci. J. 2007, 52, 523–537. [Google Scholar] [CrossRef]

- Johnson, B.M.; Saito, L.; Anderson, M.A.; Weiss, P.; Andre, M.; Fontane, D.G. Effects of climate and dam operations on reservoir thermal structure. J. Water Resour. Plan. Manag. 2004, 130, 112–122. [Google Scholar] [CrossRef]

- Yin, R. Case Study Research and Applications: Design and Methods, V.; SAGE: Newcastle, UK, 2015. [Google Scholar]

- Pearce, J.M. Return on investment for open source scientific hardware development. Sci. Public Policy 2016, 43, 192–195. [Google Scholar] [CrossRef]

- Ritthoff, M.; Rohn, H.; Liedtke, C. Calculating MIPS: Resource Productivity of Products and Services; Wuppertal Institute for Climate, Environment and Energy: Wuppertal, Germany, 2014. [Google Scholar]

- Oliveira Neto, G.C.; Tucci, H.N.P.; Pinto, L.F.R.; Costa, I.; Leite, R.R. Economic and Environmental Advantages of Rubber Recycling. In IFIP Advances in Information and Communication Technology; Springer: Cham, Switzerland, 2016; Volume 1, pp. 19–27. [Google Scholar]

- de Oliveira Neto, G.C.; de Sousa, W.C. Economic and Environmental Advantage Evaluation of the Reverse Logistic Implementation in the Supermarket Retail. IFIP—Adv. Inf. Commun. Technol. 2014, 439, 197–204. [Google Scholar]

- Oliveira Neto, G.C.; Chaves, L.E.C.; Pinto, L.F.R.; Santana, J.C.C.; Amorim, M.P.C.; Rodrigues, M.J.F. Economic, environmental and social benefits of adoption of pyrolysis process of tires: A feasible and ecofriendly mode to reduce the impacts of scrap tires in Brazil. Sustainability 2019, 11, 2076. [Google Scholar] [CrossRef]

- De Oliveira Neto, G.C.; Shibao, F.Y.; Filho, M.G.; Chaves, L.E.C. Cleaner Production: A study of the environmental and economic advantage in polymer recycling. Interciencia 2015, 40, 364–373. [Google Scholar]

- Neto, G.C.O.; Souza, M.T.S.; da Silva, D.; Silva, L.A. An assessment of the environmental and economic benefits of implementing reverse logistcs in the textured glass sector. Ambiente Sociedade 2014, 17, 199–220. [Google Scholar] [CrossRef]

- Odum, E.P. Ecology and Our Endangered Life-support Systems; Sinauer Associates: Sunderland, MA, USA, 1989. [Google Scholar]

| Intensity Factor | |||||

|---|---|---|---|---|---|

| Name | Unit | Abiotic | Biotic | Water | Air |

| Drinking water | (kg/kg) | 0.01 | - | 1.30 | - |

| Truck transport | (kg/tkm) | 0.22 | - | 1.91 | 0.21 |

| Rainy Season | Dry Season |

|---|---|

| November 1st to April 30th | May 1st to October 30th |

| Maximum level: 744.50 m | Maximum level: 744.65 m |

| Minimum level: 744.35 m | Minimum level: 744.50 m |

| Before AI Implementation | After AI Implementation | Reduction | Savings | |

|---|---|---|---|---|

| Travel distance | 38,400 km | 19,200 km | 50% | 19,200 km |

| Labor + 50% extra costs | US$ 117,000 | US$ 41,000 | 65% | US$ 76,000 |

| Vehicle rental costs | US$ 21,200 | US$ 10,600 | 50% | US$ 10,600 |

| Fuel | US$ 12,660 | US$ 6330 | 50% | US$ 6330 |

| Total | US$ 150,860 | US$ 57,930 | 61.6% | US$ 92,930 |

| Unit: US$ × (103) | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Year 0 | Y1 | Y2 | Y3 | Y4 | Y5 | Y6 | Y7 | Y8 | Y9 | Y10 | |

| Investment | (171.14) | ||||||||||

| Savings | 92.93 | 92.93 | 92.93 | 92.93 | 92.93 | 92.93 | 92.93 | 92.93 | 92.93 | 92.93 | |

| Operational expenses | (17.11) | (17.11) | (17.11) | (17.11) | (17.11) | (17.11) | (17.11) | (17.11) | (17.11) | (17.11) | |

| Gross balance | 75.81 | 75.81 | 75.81 | 75.81 | 75.81 | 75.81 | 75.81 | 75.81 | 75.81 | 75.81 | |

| Depreciation | (8.54) | (8.54) | (8.54) | (8.54) | (8.54) | (8.54) | (8.54) | (8.54) | (8.54) | (8.54) | |

| Profit before taxes | 67.28 | 67.28 | 67.28 | 67.28 | 67.28 | 67.28 | 67.28 | 67.28 | 67.28 | 67.28 | |

| Average taxes (24%) | (16.15) | (16.15) | (16.15) | (16.15) | (16.15) | (16.15) | (16.15) | (16.15) | (16.15) | (16.15) | |

| Profit after taxes | 51.13 | 51.13 | 51.13 | 51.13 | 51.13 | 51.13 | 51.13 | 51.13 | 51.13 | 51.13 | |

| Generated cash flow | 59.67 | 59.67 | 59.67 | 59.67 | 59.67 | 59.67 | 59.67 | 59.67 | 59.67 | 59.67 | |

| Discounted cash flow | 55.19 | 51.05 | 47.22 | 43.68 | 40.40 | 37.37 | 34.57 | 31.98 | 29.58 | 27.36 | |

| Accumulated cash flow | (171.14) | (115.95) | (64.90) | (17.68) | 26.00 | 66.40 | 103.78 | 138.34 | 170.32 | 199.90 | 227.25 |

| Economic Indicator | Value |

|---|---|

| Net Present Value (NPV) | US$ 227,250.00 |

| Internal Return Rate (IRR) | 32.80% |

| Discounted Payback Period | 3.5 years |

| Return on Investment (ROI)—single version | 248.65% |

| ROI—cash discounted flow | 132.79% |

| MIF | ||||||

|---|---|---|---|---|---|---|

| Substance | Qty | Abiotic (ton/year) | Biotic (ton/year) | Water (ton/year) | Air (ton/year) | MIT (ton/year) |

| Drinking water [ton/year] | 4,320,000 | 43,200 | - | 5,616,000 | - | |

| Truck transport [tkm/year] | 19.2 | 4 | - | 37 | 4 | |

| MIC | 43,204 | - | 5,616,037 | 4 | 5,659,245 | |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gomes, M.G.; da Silva, V.H.C.; Pinto, L.F.R.; Centoamore, P.; Digiesi, S.; Facchini, F.; Neto, G.C.d.O. Economic, Environmental and Social Gains of the Implementation of Artificial Intelligence at Dam Operations toward Industry 4.0 Principles. Sustainability 2020, 12, 3604. https://doi.org/10.3390/su12093604

Gomes MG, da Silva VHC, Pinto LFR, Centoamore P, Digiesi S, Facchini F, Neto GCdO. Economic, Environmental and Social Gains of the Implementation of Artificial Intelligence at Dam Operations toward Industry 4.0 Principles. Sustainability. 2020; 12(9):3604. https://doi.org/10.3390/su12093604

Chicago/Turabian StyleGomes, Marcos Geraldo, Victor Hugo Carlquist da Silva, Luiz Fernando Rodrigues Pinto, Plinio Centoamore, Salvatore Digiesi, Francesco Facchini, and Geraldo Cardoso de Oliveira Neto. 2020. "Economic, Environmental and Social Gains of the Implementation of Artificial Intelligence at Dam Operations toward Industry 4.0 Principles" Sustainability 12, no. 9: 3604. https://doi.org/10.3390/su12093604

APA StyleGomes, M. G., da Silva, V. H. C., Pinto, L. F. R., Centoamore, P., Digiesi, S., Facchini, F., & Neto, G. C. d. O. (2020). Economic, Environmental and Social Gains of the Implementation of Artificial Intelligence at Dam Operations toward Industry 4.0 Principles. Sustainability, 12(9), 3604. https://doi.org/10.3390/su12093604