Abstract

This research aimed to investigate the mechanical and physical properties of Roller Compacted Concrete (RCC) used with Recycled Concrete Aggregate (RCA) as a replacement for natural coarse aggregate. The maximum dry density method was adopted to prepare RCC mixtures with 200 kg/m³ of cement content and coarse natural aggregates in the concrete mixture. Four RCC mixtures were produced from different RCA incorporation ratios (0%, 5%, 15%, and 30%). The compaction test, compressive strength, splitting tensile strength, flexural tensile strength, and modulus of elasticity, porosity, density, and water absorption tests were performed to analyze the mechanical and physical properties of the mixtures. One-way Analysis of Variance (ANOVA) was used to identify the influences of RCA on RCC’s mechanical properties. As RCA increased in mixtures, some mechanical properties were observed to decrease, such as modulus of elasticity, but the same was not observed in the splitting tensile strength. All RCCs displayed compressive strength greater than 15.0 MPa at 28 days, splitting tensile strength above 1.9 MPa, flexural tensile strength above 2.9 MPa, and modulus of elasticity above 19.0 GPa. According to Brazilian standards, the RCA added to RCC could be used for base layers.

1. Introduction

According to Balbo and Dornelas [1], Brazil has faced an annunciated transport crisis since the 1980s. There are two determining factors related to this crisis: Road network extension and pavement quality. There is around 1,720,700 km of roads in the country, but just 12.4% are paved, 78.5% are unpaved, and 9.1% are in the planning phase [2].

A considerable amount of materials is necessary to improve the Brazilian transport infrastructure, just like any other country investing in paving projects. Nowadays, the extraction of natural materials as aggregates requires several environmental permits because this procedure causes damage to the environment, and highway construction consumes a finite resource on our planet. Therefore, it would be interesting to verify the availability of utilizing solid waste as a material to mitigate the large-scale uses of Natural Aggregates (NA). Improving the infrastructure of highways without causing severe environmental damages, the use of Construction and Demolition Waste (CDW) could be an alternative to reduce the volume of NA and concomitantly reduce illegally dumped waste in urban areas improper for handling it, such as areas nearby creeks and roads [3,4].

Let us consider the case in Brazil: The production of CDW that represents 40% to 70% of all urban solid waste. Considering the country has a yearly production yield of CDW equal to 500 kg/year per capita and comprehending that Brazil has a population around of 210 million of inhabitants, the production of CDW is equal to 875,000,000 m³ (contemplating the specific mass of CDW = 1200 kg/m³). It represents a large-scale environmental problem, and one potential solution would be to use this waste as aggregate for producing building materials [3,5,6].

Research studies on CDW recommend using this material for use for pavements layers [1,4,7]. One type of CDW is Recycled Concrete Aggregate (RCA), which could be an excellent option to use as an aggregate for the pavement layer due to its physical properties. RCA was used in several types of concretes; in some researches studies, it was used as an aggregate for Roller Compacted Concrete (RCC) [8,9,10,11].

Using RCC mixed with Recycled Aggregate (RA) as RCA, for example, many countries can reduce NA extractions and reduce some environmental impacts from construction new roads or improving pavements, too. For example, Brazil can use RCC with RCA as a material for pavements or sub-base pavements to mitigate problems from infrastructure highways [1,2]. On the other hand, some recognized benefits of RCC in pavements are cost-effectiveness, faster construction, environmental friendliness, and high-level performance [12,13,14,15,16]. RCC is a zero-slump concrete used for hydraulic and paving construction sites in civil engineering. The main difference between conventional concrete and RCC is the consistency of the material. Moreover, the percentage of aggregates in mixtures is around 80%. It proves that aggregates are vital for producing this type of concrete [12,13,14,15,16,17,18].

The RCC can be designed to achieve high mechanical properties such as compressive strength due to compaction effort and aggregate interlock. To achieve a good compaction on the field, the RCC must be mix-stiff enough to support the roller compactor and wet enough to permit adequate distribution of material without segregation. The ingredients used for RCC are the same used for conventional concrete but has different mixture proportions [12,14,15]. RCC could be used in different pavement layers as a sub-base, base, and surface, modifying the cement content to achieve improved properties in different layers. The use of RCC as a base layer can improve the pavement bearing strength, especially the ability to withstand the tensile stress caused by bearing the traffic load [19,20].

Selecting materials is substantial in RCC to achieve excellent properties in pavement layer applications. There are several methods for mixture proportioning for producing RCC. The maximum dry density method is the most widely used mixture proportioning method for RCC pavements. This method basically consists of choosing well-graded aggregates, selecting a cement content, preparing a moisture–density relationship plot based on the Proctor test, and casting samples for measuring compressive strength and calculating mixture proportions [14,18].

According to Portland Cement Association (PCA), the compressive strength of RCC ranges from 28–41 MPa at 28 days, and the flexural strength ranges from 3.5–7 MPa at 28 days [14]. According to Boussetta et al. [21], RCC must display 20 MPa compressive strength at 28 days and 1.6 MPa splitting tensile strength at 28 days. In Brazil, RCC must achieve values lower than those mentioned above by varying the layer used as paving material. Table 1 displays these required RCC values to be employed based on the paving layer.

Table 1.

Roller Compacted Concrete (RCC) requirements in Brazil.

Considering that RCC consumes a considerable amount of NA for its production, the primary purpose of this research study has been to evaluate the physical and mechanical properties of RCC utilizing RCA and employing it as pavement base layer. The use of RCA as a coarse aggregate for RCC is based on other research studies conducted on RCC. It used different recycled aggregates in Brazil, such as CDW [25] or Reclaimed Asphalt Pavement (RAP) [26,27]. RCA was used as a coarse recycled aggregate in international research studies, and their results recommended the use of RCA added to RCC due to its availability as a material for pavements [8,9,10,11].

2. Materials and Methods

2.1. Materials

The maximum dry density method was used to select the cement content, fractional proportions of NA were chosen to achieve the suggested gradation range, and the Proctor test was carried out to identify the Optimum Moisture Content (OMC).

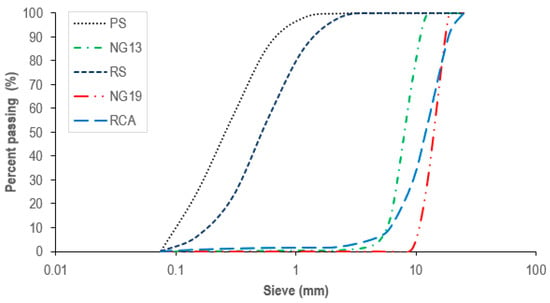

Portland cement type CP-V-ARI-RS (Brazilian Association of Portland Cement) was used. This type of cement provides high early strength and sulfate resistance. The chemical composition and physical properties of cement are shown in Table 2. Two types of natural sand were used: River sand (RS) with a maximum grain size of 2.4 mm and pit sand (PS) with a maximum grain size of 1.2 mm. Natural coarse-grain gneiss coarse was used with two maximum sizes of 13 mm (NG13) and 19 mm (NG19). The RCA was manufactured in a treatment plant company from Joinville (Brazil). The maximum size of the RCA was 25 mm; thus, screening was utilized on particles above 19.1 mm because the maximum size of Natural Gravel (NG) was 19 mm and intended to substitute fractional proportions of NG for RCA. The particle-size distribution is shown in Figure 1, and their properties are summarized in Table 3. The properties reported in Table 3 were defined by applying Brazilian standard test methods on materials for highway engineering [28,29,30]. The RCA used in this research displayed 92.37% in the volume composition of particles made up by mortar or particles of NG. The type of aggregate has been proven to be a RCA and not a Recycled Masonry Aggregate (RMA) [31,32].

Table 2.

Chemical composition and physical properties of CP-V-ARI-RS cement, according to Souza et al. [33].

Figure 1.

The particle size distribution of aggregates. Note: PS is the pit sand; NG13 is the natural gravel 13 mm; RS is the river sand; NG19 is the natural gravel 19mm; and RCA is the recycled concrete aggregate.

Table 3.

Properties of aggregates.

2.2. Dosage and Mixing Process

The maximum dry density method was chosen for dosing RCC. A cement content of 200 kg/m³ was adopted as the Brazilian standard recommending this minimum cement content for RCC for base and surface pavements [23]. The employed compaction energy was the intermediary Proctor energy required by another Brazilian standard, which recommends this energy when recycled aggregates are used in pavement layers [31]. RCA was chosen to replace NG, in the mass mixture, at three different proportions: 5%, 15%, and 30%, then the mixtures were named RCC-0 (without RCA), RCC-5, RCC-15, and RCC-30, corresponding to the replacement levels of the NG by RCA. The replacement percentage was defined at these percent levels because the replacement of more than 40% of coarse NA is not recommended in concrete as the mechanical properties could decrease when replacement is greater than 40% [18]. Furthermore, the observed percentage levels adopted by Borré [27] were replaced by 10% and 30% of NG basalt by RAP, and the 10% RAP mixture provided higher mechanical properties than the mixture with 30% RAP.

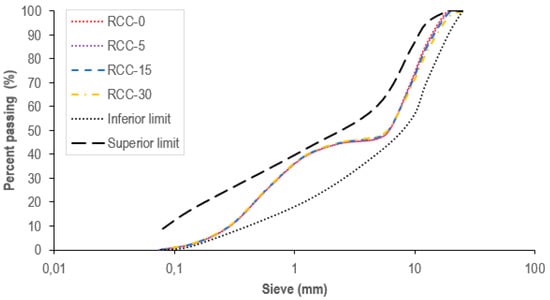

The adopted aggregate gradation range adopted in this research was proposed by Chhorn et al. [13] as an optimized gradation range suggested by PCA [14]. Figure 2 displays the aggregate gradation of RCC mixtures, and the similarity is evident among each aggregate gradation in each mixture.

Figure 2.

Aggregate gradation of Roller Compacted Concrete (RCC) mixtures.

According to Trichês [34], Equation (1) was used to calculate the proportion of necessary materials necessary to produce RCC, and the amounts of materials needed to produce 1 m³ of RCC are shown in Table 4. This equation was suggested in 1993 as part of the Brazilian method for designing RCC. This procedure is as also adopted in other Brazilian research studies on RCC [25,26,27]. The quantity of aggregate was calculated based on units of cement (m) by Equation (1), moisture was adopted as h = 6.5% because this value is common to OMC, and air void volume was Vv = 50 L [27,34].

C is the cement content, kg/m³; Vv is the air void volume, L; is the cement density, g/cm³; is the weighted average of the aggregate density, g/cm³; m is the total quantify of aggregates based on units of cement, dimensionless; h is the moisture, %.

Table 4.

Quantity of materials for producing 1 m³ of concrete.

The intermediary Proctor test was carried out to identify the OMC and the maximum dry density of each mixture. This test was performed according to the Brazilian standard [35]. The cylindrical specimens (150 × 300 mm) were cast at intermediary Proctor energy in a mechanical compactor.

2.3. Specimen Preparation

After the compaction test, cylindrical and prismatic specimens were molded to verify the properties of hardened RCC. The mixtures were prepared in an inclined axle concrete mixer according to the methodology adopted by Borré [27]. All specimens were molded using a manual compactor. The 68 cylindrical specimens (100 × 200 mm) were molded in three layers with 32 blows per layer. The eight prismatic specimens (100 × 100 × 550 mm) were molded in two layers with 163 blows per layer. Equation (2) was adopted to calculate the number of blows necessary for each type of specimen.

Ep is the potential energy, kg.cm/cm³; W is the compactor weight, kg; h is the falling height of the compactor, cm; is the number of blows per layer; is the number of layers, and V is the mold volume, cm³.

The values adopted in Equation (2) were Ep = 12.3 kg.cm/cm³ corresponding to intermediary Proctor energy, W = 4.536 kg and h = 45.7 cm, V and were dependent on the specimen type and was achieved [27]. The wet curing was done for 7 and 28 days in a water tank using Calcium hydroxide.

2.4. Experimental Tests

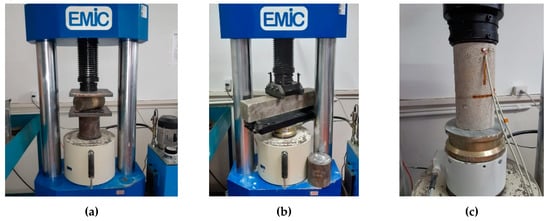

The following tests were carried out to verify the physical and mechanical properties of hardened RCC mixtures: Compressive strength [36], splitting tensile strength [37] (Figure 3a), flexural tensile strength [38] (Figure 3b), modulus of elasticity [39] (Figure 3c), and dry density, water absorption, and porosity [40].

Figure 3.

(a) Performing the splitting tensile test; (b) performing the flexural tensile test; (c) details of strain gage glued on specimens for modulus of elasticity test.

Then, 120 Ω strain gages were glued using cyanoacrylate glue in cylindrical specimens to obtain the modulus of elasticity. One strain gage was glued crosswise on the specimen, and another was glued longitudinally. A stress versus strain graph was plotted, and a secant line was added to start at origin of the graph until a point equal to 40% of rupture tension, according to Hooke’s law. Equation (3) was used to estimate the value of the modulus of elasticity [18].

E is the modulus of elasticity, GPa; is 40% of rupture stress, MPa; is the strain corresponding to 40% of rupture stress, m/m.

2.5. Statistical Analysis

The data obtained from physical and mechanical tests were statistically analyzed in the free RStudio open source software. Analysis of Variance (ANOVA) was performed (one-way) for each mechanical property to identify whether the percentage of RCA interferes in these RCC properties. Moreover, linear regression analysis between the physical and the mechanical properties of RCC were adjusted at 28 days. The correlation among RCC properties was performed to identify the relation between two variables. In this case, the correlation considers one predictor and one dependent variable. The correlation could indicate if any property was directly dependent on another property or not [41,42].

The ANOVA was used to identify differences among means observed in each hardened property of the RCC mixtures on the 7th and 28th day. A significance level of 0.05 was adopted for applying this statistical test. The one-way ANOVA analysis defined the equal averages, and the alternative hypothesis (H1) adopted was the null hypothesis (H0) where at least one mean was different from others, according to the common hypothesis tests [41,42].

Employing the one-way ANOVA analysis is vital to verify whether samples are independent, the residuals are distributed normally, and the variances are homogeneous. The RStudio software was used for performing the normality test of residuals was estimated by Shapiro test: Where the p-value was higher than 0.05, the assumption of normality was not violated. The Levene test was performed to verify the homoscedasticity, so if the p-value was higher than 0.05, the variances were equal, and if p-value was less than 0.05, the variances were different. These statistical tests were performed on all properties, and therefore, ANOVA assumptions were not violated.

3. Results and Discussion

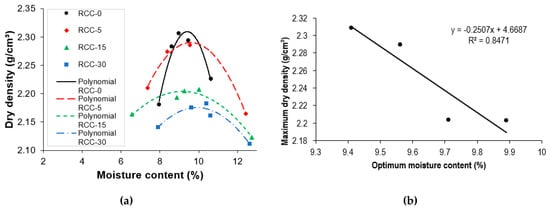

The values of Maximum Dry Density (MDD) and OMC in RCC mixtures are presented in Table 5. Figure 4a presents the relationship between the RCC moisture content and dry density. The OMC is above 9.0% in all moisture–density curves, which, according to Borré [27] and Trichês [34], is unusual for RCC because this value must vary around 6.5%. However, high moisture contents were adopted by other research studies, especially when recycled aggregates were included in the aggregate percentages.

Table 5.

Compaction test results for RCC mixtures with 200 kg/m³ of cement.

Figure 4.

(a) Compaction curves of RCC mixtures; (b) linear regression adjusted between maximum dry density and OMC of mixtures.

The OMC varied from 7.50% to 8.40% for RCC mixtures mixed with RAP [26], 8.40% and 10.00% for RCC mixed with CDW [25], and for RCC mixed with NA the OMC varied from 7.25% to 11.00% [43]. Our OMC values 9.41% and 9.89% abide by an acceptable limit of OMC as adopted in other research studies [25,43].

There was a good correlation between MDD and the obtained OMC (Table 6) as the correlation coefficient (R²) was 0.9202. When the percentage of RCA increases in a mixture, there were the MDD reduces, and OMC increases (Figure 4b). The RCA added to RCC and NA added to RCC did not display any significative difference among the mixtures of MDD. They varied 2.203–2.309 g/cm³. Lopez-Uceda et al. [8] observed the variation of MDD among mixture of NA added to RCC, and RCA ranged from 2.19–2.34 g/cm³ for RCC with a cement content equal to 110, 175, 250, and 350 kg/m³. Lopez-Uceda et al. [9] studied RCC with 150 and 250 kg/m³ of cement and 100% of RA, in comparison to the reference RCC mixture mixed with RA, which displayed decreases in the MDD values as well. Ricci and Balbo [25] observed MDD in RCC that showed decreasing CDW trends when the percent of CDW increased. Due to the particularity of bitumen in particles, the RAP also tends to decrease MDD in RCC and increases moisture content as its percentage in mixture increases [26,44]. Thus, these results confirm the hypothesis on the increasing percentage of RA in mixtures, as the MDD decreases, and then the moisture content increases.

Table 6.

Summary of correlation between Maximum Dry Density (MDD) and Optimum Moisture Content (OMC).

The mechanical property averages of RCC mixtures are displayed in Table 7. The results of one-way ANOVA are shown in Table 8. The modulus of elasticity, compressive strength at 7 days, and flexural tensile strength at 7 and 28 days were observed at significance level of 0.05, and these mechanical properties displayed differences among the averages. They tend to decrease as the percentage of RCA increases. The compressive strength at 28 days did not display a 0.05 significance level of interference as splitting tensile strength at any age.

Table 7.

Mechanical properties of RCC mixtures.

Table 8.

ANOVA tests for hardened RCC properties.

Some RCC mechanical properties did not show any statistical proof of interference as an RCA percentage in mixtures at a significance level of 0.05 in one-way ANOVA. These properties are compressive strength at 28 days and splitting tensile strength at 7 and 28 days. This was not expected because all mechanical RCC properties with added RCA from other research studies displayed a reduction when RCA percentages increased in the mixture [8,9,11]. It could be stated that the percentage of RCA had not interfered in the RCC mechanical properties when just analyzing these properties. Although, when the compressive strength was analyzed at 7 days, modulus of elasticity at 28 days, and flexural strength at 7 and 28 days, the interference of RCA percentage was evident in the mixture. In other words, when the percentage of RCA increased, the values of mechanical properties decreased in these properties. Lopez-Uceda et al. [8] also observed this behavior for their RCC mixtures, where the compressive strength at 7, 28, and 90 days, splitting tensile strength, flexural strength, and modulus of elasticity tended to decrease while RCA percentage increased in the mixture. The physical properties of RCA strongly influencing the mechanical behavior of RCC was able to be confirmed, and, it could be said that the RCA used in our research is inferior, in terms of particle composition or homogeneity, compared to those used by Lopez-Uceda et al. [8,9].

The type of cement is another factor that would interfere with the results of this research. CP-V-ARI-RS is very strong soon after casting, but this type of cement was used in different research studies on paving materials. There were two Brazilian research studies on RCC for this type of cement, and 200 kg/m³ cement content was adopted in the studies; modified Proctor energy was adopted a kind of adopted energy, and the mechanical properties were measured only at seven days. Fedrigo et al. [43] observed 12.37 MPa of compressive strength average with 2.007 MPa standard deviation and an average of 1.40 MPa of splitting tensile strength with 0.193 MPa of standard deviation. Less compaction energy and replacement of NA fractional proportions by RCA were observed in the mechanical properties at seven days when comparing these results to our research averages (compressive strength and splitting tensile strength) higher than the Fedrigo et al. [43] results.

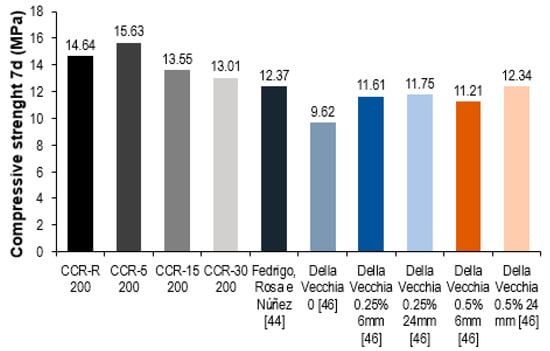

Della Vecchia [45] adopted the same methodology and mixture proportions studied by Fedrigo et al. [43] with added of 6 mm and 24 mm polypropylene fibers added at 0.25% and 0.50%. Figure 5 presents the comparison of average compressive strength averages at seven days obtained by mixtures of RCC studied in these three research projects. The mixtures analyzed in our research displayed higher average compressive strengths than the mixtures studied by Fedrigo et al. [43] with NA or the mixtures with the addition of polypropylene fibers studied by Della Vecchia [45].

Figure 5.

Comparison of compressive strength at seven days among RCC mixtures.

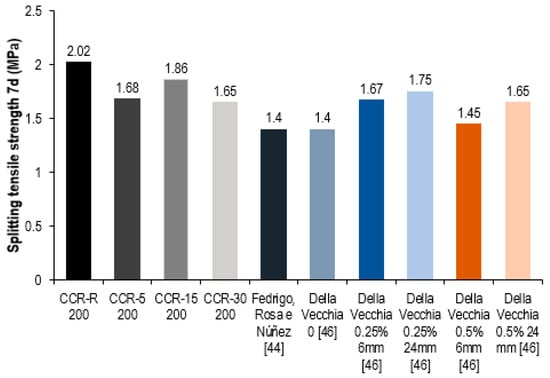

Comparing the studies by Fedrigo et al. [43] and Della Vecchia [45] using RCA proved to be a good option as an aggregate for RCC. However, when comparing splitting tensile strength at seven days (Figure 6), the averages are very close among mixtures, which makes their comparison difficult. However, the seven-day averages of splitting tensile strength for RCC with 100% of NA and without displayed polypropylene fibers 1.40 MPa. In contrast, RCC-0 showed 2.02 MPa, which means our average for RCC with NA is 144.29% of splitting tensile strength based on these research studies [43,45]. Therefore, when NA was replaced by RCA in our research, and Della Vecchia [45] added polypropylene fibers in RCC, the splitting tensile strength averages were closer at seven days. Replacing NA by RCA is not problematic as it is a contributing factor because some mechanical properties of RCC mixtures with RCA achieved better results than RCC with NA or very close results compared to RCC with polypropylene fibers.

Figure 6.

A comparison of splitting tensile strength means at seven days among RCC mixtures.

The evolution of compressive strength in this research study is very similar to other research studies based on their time frames. The compressive evolution ratio after seven days was 87.55%, 83.81%, 75.40%, and 82.81% for RCC-0, RCC-5, RCC-15, and RCC-30, respectively. Lopez-Uceda et al. [8] and Meddah et al. [46] obtained a mean ratio of 85% for control mixtures while Lopez-Uceda et al. [9] observed 78.3% for mixture with RCA as a coarse aggregate. It proves some similarities regarding improved resistance compared to other research studies on RCC.

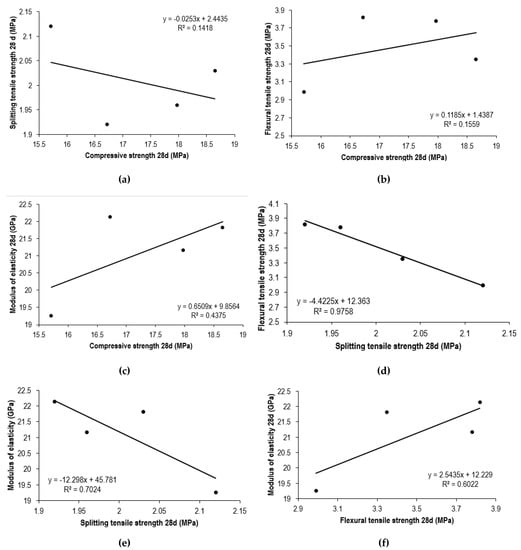

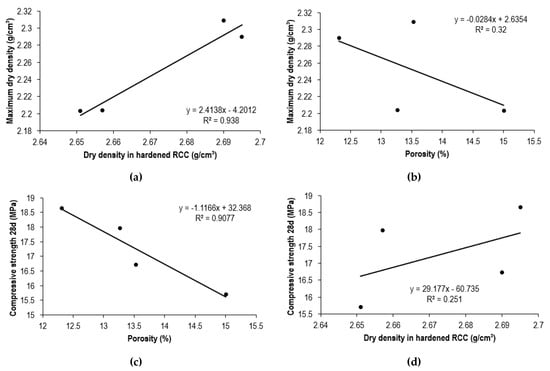

Furthermore, Table 9 displays the dry density results, porosity, and water absorption in hardened RCC. The correlations between mechanical properties at 28 days of RCC mixtures are shown in Figure 7. The correlations between physical properties and compressive strength at 28 days are plotted in Figure 8. The summaries of correlations are presented in Table 10.

Table 9.

Mean values of RCC hardened physical properties.

Figure 7.

(a) Linear regression between compressive strength and splitting tensile strength; (b) Linear regression between compressive strength and flexural tensile strength; (c) Linear regression between compressive strength and modulus of elasticity; (d) Linear regression between splitting tensile strength and flexural tensile strength; (e) Linear regression between splitting tensile strength and modulus of elasticity; (f) Linear regression between flexural tensile strength and modulus of elasticity.

Figure 8.

(a) Linear regression between dry density of hardened RCC and maximum dry density; (b) Linear regression between porosity and maximum dry density; (c) Linear regression between porosity and compressive strength; (d) Linear regression between dry density of hardened RCC and compressive strength.

Table 10.

Summary of correlations.

Figure 7a suggests the correlation between compressive strength at 28 days and splitting tensile strength at the same age, and it is weaker because correlation index is low (R² = 0.1418). The correlation index is low due to the higher scatter of these obtained property values. It is possible to observe a negative correlation between these mechanical properties, unlike Lopez-Uceda et al. [8,9] and Mardani-Aghabaglou and Ramyar [47] who studied RCC with a high volume of fly ash. Also, the averages of splitting tensile strength observed by Mardani-Aghabaglou and Ramyar [47] and Lopez-Uceda et al. [9] are around 10% compressive strength, which was not observed in our research study. Chhorn et al. [48] performed a regression analysis on the relationship between RCC compressive strength and splitting tensile strength, and the authors obtained a correlation with a correlation index equal to 0.62 with a positive relationship between these mechanical properties.

The correlation between flexural tensile strength and compressive strength at 28 days (Figure 7b) is weak; the correlation coefficient is low, too, at R² = 0.1550. This correlation is not as effective as the correlation between flexural tensile strength and splitting tensile strength as the values measured resulted in higher scattering for compressive strength. However, there is a positive correlation between these properties based on Lopez-Uceda et al. [8,9].

There is another weak correlation (R² = 0.4375) between modulus of elasticity and compressive strength as well (Figure 7c) due to the higher scattering of obtained compressive strength values. The positive correlation indicates that these properties tend to increase simultaneously. Lopez-Uceda et al. [8] observed the same linear correlation between compressive strength and modulus of elasticity, and the obtained correlation index obtained was equal to 0.5465, which was not as good in comparison with other mechanical property correlations.

The correlation between splitting tensile strength and flexural tensile strength (Figure 7d) displays a strong correlation index (R² = 0.9758). The same strong correlation was observed by Lopez-Uceda et al. [8] with R² = 0.9466 and Hashemi et al. [49] with R² = 0.9117 who observed a positive correlation between these properties in RCC with 9% and 12% cement content and NA. In addition, the adjusted correlation in this research study presented a negative trend, unlike the correlations adjusted by Lopez-Uceda et al. [8] and Hashemi et al. [49].

Figure 7e displays a good correlation between modulus of elasticity and splitting tensile strength with a correlation coefficient equal to 0.7024. In contrast, Figure 7f shows a medium correlation between flexural tensile strength and modulus of elasticity with a R² = 0.6022. The modulus of elasticity tends to decrease as splitting tensile increases and increases when flexural tensile strength increases. Furthermore, the correlation between modulus of elasticity and splitting tensile strength showed the same negative trend as the correlation between compressive strength and splitting tensile strength. The correlation between modulus of elasticity and flexural tensile strength showed the same positive trend as the correlation between compressive strength and flexural tensile strength.

A strong correlation was observed between MDD and dry density of hardened RCC (Figure 8a) with a correlation index equal to 0.9380, the same as Lopez-Uceda et al. [8]. It proves the high MDD values in dosage mixture steps tend to provide high dry density values in hardened RCC and, consequently, to reduce the porosity of concrete. That is because there is a minimum correlation (R² = 0.3200) between MDD and porosity of hardened RCC (Figure 8b), which was observed by Lopez-Uceda et al. [8] too.

It is possible to conclude that the porosity tends to affect the RCC negatively while the dry density tends to provide better values of compressive strength when it increases when comparing the correlations between compressive strength and porosity (Figure 8c). It proves the importance of material compaction for achieving better mechanical properties. These same relationships were also observed by Lopez-Uceda et al. [8] and Shafigh et al. [50].

All RCC mixtures comply with Brazilian standards (Table 1) using RCC mixtures as material for base or surface in the pavement, because they achieved compressive strength above 15 MPa at 28 days and tensile strength above 1.5 MPa at 28 days [24].

According to Harrington et al. [14], using RCC in the USA, the usual values of compressive strength at 28 days range from 28 to 41 MPa, and the compressive strength of RCC in France must be equal to or higher than 20 MPa at 28 days [21]. None of our RCC mixtures would meet these minimum values. The splitting tensile strength at 28 days must be equal or higher than 1.6 MPa in France, according to Boussetta et al. [21]; in this case, all RCC mixtures displayed averages higher than 1.6 MPa. The flexural tensile strength at 28 days in the USA usually ranges from 3.5 to 7 MPa [14]. In this case, just the RCC-0 and RCC-15 mixtures would adhere to the usual values of flexural tensile strength. In addition, this comparison is proven in Brazilian standards (Table 1) that require lower mechanical properties than other countries.

The Brazilian standards defined mechanical requirements for RCC lower than American or French standards, where the RCC usually displays compressive strengths ranging from 28 MPa to 41 MPa at 28 days; whereas the minimum limit is almost twice the value required by Brazilian standards using RCC as base pavement (15 MPa) [14,24].

These lower requirements for RCC mechanical properties indicate greater possibilities of using RA as a replacement of NA, and yet they still meet Brazilian standards. This research study demonstrated that replacing NA by up to 30% RCA can be employed in Brazilian paving layers. Perhaps higher percentages of replacement may still meet regulations. However, the use of RCA over 40% of RCA to replace NA is discouraged because the mechanical properties could be reduced [18]. Courard et al. [11] studied RCC with 250 kg/m³ of cement content and 100% of RCA. The compressive strength at 28 days was almost 40% compared to the compressive strength of RCC mixed with NA. Lopez-Uceda et al. [8] observed progressive reductions of all mechanical properties when RCA was increased in the mixture, for example RCC with 250 kg/m³ of cement content and the addition equal to 0%, 50%, and 100% of RCA. They observed a reduction in compressive strength at 28 days equal to 23.5% and 35.2% for RCC with 50% and 100% of RCA, respectively, compared to RCC with NA. The splitting tensile strength reduced by 8.3% and 26.0% for RCC with 50% and 100% of RCA compared to RCC with NA [8]. The flexural tensile strength reduced by 15.0% and 20.3% for RCC with 50% and 100% of RCA, compared to RCC with NA [8]. The modulus of elasticity reduced by 21.6% and 29% for RCC with 50% and 100% of RCA, compared to RCC with NA [8]. Those results from Courard et al. [11] and Lopez-Uceda et al. [8] proved that high percentages of RCA added in RCC mixtures tend to decrease the mechanical properties of RCC. The recommend parameter to follow is using a 40% ratio added to RCA in concrete when RCC dosage is desired.

Moreover, the use of RCA as an aggregate for RCC can mitigate some environmental trouble occurring in big cities, such as the reduction of CDW and, consequently, a decrease of NA extraction, as these are two benefits that would affect RCA when it is used as an aggregate for producing building materials.

4. Conclusions

This research study presents the results of an investigation on RCA added to RCC with an incorporation ratio of 0%, 5%, 15%, and 30%. The possible use was investigated to use these materials in Brazilian pavement layers. The following conclusions were drawn considering the observed results:

RCA can be used as a coarse aggregate in producing RCC because it displays a minimal content of fine particles, 2.19 g/cm³ specific gravity, 7.63% water absorption, and an LA coefficient equal to 32. However, a large ratio is not recommended for replacing RCC because this type of RA tends to reduce the mechanical properties of concrete. For example, the compressive strength is reduced by more than 30% when the ratio of RCA is 100% [8,11]. If the ratio of RCA is 30%, the compressive strength decreases just 6.0%, as observed in comparative results in RCC-0 and RCC-30.

The one-way ANOVA displayed some of the same properties as hardened RCC mixtures that are significantly influenced by the increased percentage of RCA in concrete at a significance level of 0.05. The compressive strength at 7 days, flexural strength at 7 and 28 days, and the modulus of elasticity displayed statistical proof of interference as an RCA percentage in the RCC mixtures. Other mechanical properties such as compressive strength at 28 days and splitting tensile strength at 7 and 28 days did not present any statistical significance influence on RCC properties due to RCA percentage in the RCC mixtures.

Compared with other Brazilian research studies on RCC, all RCC mixtures with RCA had displayed equal to or better properties related to compressive strength and splitting tensile strength of RCC mixtures mixed with NA [43] and RCC mixed with polypropylene fibers [45]. Furthermore, these research studies employed higher compaction energy (modified Proctor energy) than ours (intermediary Proctor energy). The RCC-30 presented the lowest average (13.01 MPa) of compressive strength at seven days. However, this average was higher than the best average of those research studies (12.37 MPa). The splitting tensile strength at seven days displayed closer averages because RCA was added to RCC reducing these mechanical properties, and fibers were added to RCC [45], increasing the values of splitting tensile strength.

Some correlations between mechanical properties at 28 days did not show a good correlation index (R²), indicating a weak correlation. The correlations between compressive strength and splitting tensile strength, the correlation between compressive strength and modulus of elasticity, and the correlation between compressive strength and flexural tensile strength obtained a low correlation index due to the higher scatter of measured compressive strength values. The correlation between splitting tensile strength and flexural tensile strength achieved a high correlation index as in other research studies [8,49].

All designed RCC mixtures met the minimum requirements of Brazilian standards such as the minimum cement content as 200 kg/m³ for pavement’s bases or surfaces [23], compressive strength at 28 days equal or greater than 15 MPa [23,24], and tensile strength equal to or greater than 1.5 MPa at 28 days [24]. All RCC mixtures did not meet the minimum values of 28 MPa [14] and 20 MPa [21] at 28 days for compressive strength compared to requirements from USA and France, but the RCC-0 and RCC-15 mixtures had displayed flexural tensile strength above the minimum value (3.5 MPa) [14] required for use RCC in American pavements while all mixtures achieved the minimum French amount required for splitting tensile strength (1.6 MPa) [21].

Author Contributions

Conceptualization, H.E.F.; methodology, H.E.F. and A.G.d.S.; software, H.E.F.; investigation, H.E.F.; data curation, H.E.F.; writing—original draft preparation, H.E.F.; writing—review and editing, A.G.d.S.; supervision, A.G.d.S. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Acknowledgments

The authors thank CAPES (Brazilian Higher Education Personnel Training Coordination) and FAPESC (Support to Research and Innovation Foundation of Santa Catarina State) for providing scholarships at a master’s degree level and for the Terraplenagem Medeiros company for donating the RCA.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Balbo, J.T.; Dornelas, R.C. Custos de reciclagem de pavimentos de concreto e seu potencial econômico na realidade brasileira. Transportes 2015, 23, 75–84. (In Portuguese) [Google Scholar] [CrossRef]

- Confederação Nacional de Transportes (CNT). Pesquisa CNT de Rodovias. Available online: https://pesquisarodovias.cnt.org.br/relatorio-gerencial (accessed on 3 January 2020). (In Portuguese).

- Conteras, M.; Teixeira, S.R.; Lucas, M.C.; Lima, L.C.N.; Cardoso, D.S.L.; Silva, G.A.C.; Gregório, G.C.; Souza, A.E.; Santos, A. Recycling of construction and demolition waste for producing new construction material (Brazil case-study). Constr. Build. Mater. 2016, 123, 594–600. [Google Scholar] [CrossRef]

- Leite, F.C.; Motta, R.S.; Vasconcelos, K.L.; Bernucci, L. Laboratory evaluation of recycled construction and demolition waste for pavements. Constr. Build. Mater. 2011, 25, 2972–2979. [Google Scholar] [CrossRef]

- Pinto, T.P. Metodologia Para a Gestão Diferenciada de Resíduos Sólidos da Construção Urbana. Ph.D. Thesis, University of São Paulo, São Paulo, Brazil, 1999. (In Portuguese). [Google Scholar]

- Intituto Brasileiro de Geografia e Estatística (IBGE). Available online: https://www.ibge.gov.br/apps/populacao/projecao/ (accessed on 10 December 2019).

- Cardoso, R.; Silva, R.V.; Brito, J.; Dhir, R. Use of recycled aggregates from construction and demolition waste in geotechnical applications: A literature review. Waste Manag. 2016, 49, 131–145. [Google Scholar] [CrossRef] [PubMed]

- Lopez-Uceda, A.; Agrela, F.; Cabrera, M.; Ayuso, J.; López, M. Mechanical performance of roller compacted concrete with recycled concrete aggregates. Road Mater. Pavement Des. 2018, 19, 36–55. [Google Scholar] [CrossRef]

- Lopez-Uceda, A.; Ayuso, J.; Jiménez, J.R.; Galvín, A.P.; Rey, I.D. Feasibility study of roller compacted concrete with recycled aggregates as base layer for light-traffic roads. Road Mater. Pavement Des. 2018, 21, 1–13. [Google Scholar] [CrossRef]

- Angelakopoulos, H.; Papastergiou, P.; Pilakoutas, K. Fibrous roller-compacted concrete with recycled materials—Feasibility study. Mag. Concr. Res. 2015, 67, 801–811. [Google Scholar] [CrossRef]

- Courard, L.; Michel, F.; Delhez, P. Use of concrete road recycled aggregates for Roller Compacted Concrete. Constr. Build. Mater. 2010, 24, 390–395. [Google Scholar] [CrossRef]

- Chhorn, C.; Lee, S.W. Influencing compressive strength of roller-compacted concrete. Constr. Mater. 2018, 171, 3–10. [Google Scholar] [CrossRef]

- Chhorn, C.; Hong, S.J.; Lee, S.W. A study on performance of roller-compacted concrete for pavement. Constr. Build. Mater. 2017, 153, 535–543. [Google Scholar] [CrossRef]

- Harrington, D.; Abdo, F.; Adaska, W.; Hazaree, C.V.; Ceylan, H. Guide for Roller-Compacted Concrete Pavements; Iowa State University: Ames, IA, USA, 2010. [Google Scholar]

- Valencia, L.E.S. Comentarios sobre el Concreto Compactado con Rodillo (CCR). Ciencia E Ingeniería Neogranadina 1999, 8, 9–23. (In Spanish) [Google Scholar] [CrossRef]

- Modarres, A.; Hosseini, Z. Mechanical properties of roller compacted concrete containing rice husk ash with original and recycled asphalt pavement material. Mater. Des. 2014, 64, 227–236. [Google Scholar] [CrossRef]

- Rao, M.; Yang, H.; Lin, Y.; Li, J.; Shi, Y. Influence of maximum aggregates sizes on the performance of RCC. Constr. Build. Mater. 2016, 115, 42–47. [Google Scholar] [CrossRef]

- Mehta, P.K.; Monteiro, P.J.M. Concrete: Microstructure, Properties and Materials, 4th ed.; McGraw-Hill Education: New York, NY, USA, 2014. [Google Scholar]

- Balbo, J.T. Pavimentação Asfáltica: Materiais, Projeto e Restauração; Oficina de Textos: São Paulo, Brazil, 2007. (In Portuguese) [Google Scholar]

- Bernucci, L.B.; Motta, L.M.; Ceratti, J.A.P.; Soares, J.B. Pavimentação Asfáltica: Formação Básica Para Engenheiros; Petrobrás, Abeda: Rio de Janeiro, Brazil, 2008. (In Potuguese) [Google Scholar]

- Boussetta, I.; Khay, S.E.E.; Neji, J. Experimental testing and modelling of roller compacted concrete incorporing RAP waste as aggregates. Eur. J. Environ. Civ. Eng. 2018, 1–15. [Google Scholar] [CrossRef]

- National Transport Infrastructure Department (DNIT). Norma DNIT 056/2013-ES; DNIT: Rio de Janeiro, Brazil, 2013. (In Portuguese)

- National Transport Infrastructure Department (DNIT). Norma DNIT 059/2004-ES; DNIT: Rio de Janeiro, Brazil, 2004. (In Portuguese)

- São Paulo City Hall (PMSP). Instrução de Projeto IP-07/2004; PMSP: São Paulo, Brazil, 2004. (In Portuguese)

- Ricci, G.; Balbo, J.T. Resistência e elasticidade de concretos compactados com agregados reciclados de construção e de demolição para aplicações em pavimentação. Transportes 2009, 17, 27–38. (In Portuguese) [Google Scholar] [CrossRef]

- Sachet, T. Estudo de Propriedades Mecânicas de Concretos Compactados com Incorporação de Fresados para Bases de Pavimentos. Ph.D. Thesis, University of São Paulo, São Paulo, Brazil, August 2012. (In Portuguese). [Google Scholar]

- Borré, G. Estudo de Resistência Mecânica do Concreto Compactado com Rolo com Emprego de Material Fresado Asfáltico Para Base de Pavimentos. Master’s Thesis, University of Santa Maria, Santa Maria, Brazil, August 2017. (In Portuguese). [Google Scholar]

- National Highways Department (DNER). ME 035: Agregados—Determinação de Abrasão “Los Angeles”; DNER: Rio de Janeiro, Brazil, 1998. (In Portuguese) [Google Scholar]

- National Highways Department (DNER). ME 194: Agregados—Determinação de Massa Específica de Agregados Miúdos por Meio de Frasco Chapman; DNER: Rio de Janeiro, Brazil, 1998. (In Portuguese) [Google Scholar]

- National Highways Department (DNER). ME 195: Agregados—Determinação da Absorção e da Massa Específica de Agregado Graúdo; DNER: Rio de Janeiro, Brazil, 1997. (In Portuguese) [Google Scholar]

- Brazilian Association of Technical Standards (ABNT). NBR 15115: Recycled Aggregates of Construction and Demolition Wastes—Construction of Pavement Layers—Procedures; ABNT: Rio de Janeiro, Brazil, 2004. (In Portuguese) [Google Scholar]

- Brazilian Association of Technical Standards (ABNT). NBR 15116: Recycled Aggregate of Solid Waste Residue of Building Constructions—Requirements and Methodologies; ABNT: Rio de Janeiro, Brazil, 2004. (In Portuguese) [Google Scholar]

- Souza, D.J.; Medeiros, M.H.F.; Hoppe Filho, J. Evaluation of the SR Portland cement against sodium and magnesium sulfate attack: A physical and comparative analysis of mortars. IBRACON Struct. Mater. J. 2018, 11, 1053–1075. Available online: http://www.scielo.br/pdf/riem/v11n5/pt_1983-4195-riem-11-05-01053.pdf (accessed on 19 February 2020). (In Portuguese). [CrossRef]

- Thichês, G. Concreto Compactado a Rolo Para Aplicação em Pavimentação: Estudo do Comportamento à Fadiga e Proposição de uma Metodologia de Dimensionamento. Ph.D. Thesis, Technology Institute of Aeronautics, São José dos Campos, Brazil, 1993. (In Portuguese). [Google Scholar]

- Brazilian Association of Technical Standards (ABNT). NBR 7182: Soil—Compaction Test; ABNT: Rio de Janeiro, 2016. (In Portuguese) [Google Scholar]

- Brazilian Association of Technical Standards (ABNT). NBR 5739: Concrete—Compression Test of Cylindrical Specimens; ABNT: Rio de Janeiro, Brazil, 2018. (In Portuguese) [Google Scholar]

- Brazilian Association of Technical Standards (ABNT). NBR 7222: Concrete and Mortar—Determination of the Tension Strength by Diametrical Compression of Cylindrical Test Specimens; ABNT: Rio de Janeiro, Brazil, 2011. (In Portuguese) [Google Scholar]

- Brazilian Association of Technical Standards (ABNT). NBR 12142: Concrete—Determination of Tension Strength in Flexure of Prismatic Specimens; ABNT: Rio de Janeiro, Brazil, 2010. (In Portuguese) [Google Scholar]

- Brazilian Association of Technical Standards (ABNT). NBR 8522: Concrete—Determination of Static Modulus of Elasticity and Deformation by Compression; ABNT: Rio de Janeiro, Braizl, 2017. (In Portuguese) [Google Scholar]

- Brazilian Association of Technical Standards (ABNT). NBR 9778: Hardened Mortar and Concrete—Determination of Absorption, Voids and Specific Gravity; ABNT: Rio de Janeiro, Brazil, 2009. (In Portuguese) [Google Scholar]

- Montgomery, D.C.; Runger, G.C. Applied Statistics and Probably for Engineers, 6th ed.; Wiley: Hoboken, NJ, USA, 2013. [Google Scholar]

- Morettin, P.A.; Bussab, W.O. Estatística Básica, 6th ed.; Saraiva: São Paulo, Brazil, 2010. (In Portuguese) [Google Scholar]

- Fedrigo, W.; Rosa, F.D.; Núñez, W.P. Dosagem de Concreto Compactado com Rolo visando sua aplicação em bases e sub-bases de pavimentos. In Proceedings of the Congresso Brasileiro de Mecânica dos Solos e Engenharia Geotécnica, Goiânia, Brazil, 9–13 September 2014. (In Portuguese). [Google Scholar]

- Settari, C.; Debieb, F.; Kadri, E.H.; Boukendakdji, O. Assessing the effects of recycled asphalt pavement materials on the performance of roller compacted concrete. Constr. Build. Mater. 2015, 101, 617–621. [Google Scholar] [CrossRef]

- Della Vecchia, A.F. Influência da Adição de Fibras de Polipropileno na Resistência e na Retração de um Concreto Compactado a Rolo. Master’s Thesis, University of Passo Fundo, Passo Fundo, Brazil, 2013. (In Portuguese). [Google Scholar]

- Meddah, A.; Beddar, M.; Bali, A. Use of shredded rubber tire aggregates for roller compacted concrete pavement. J. Clean. Product. 2014, 72, 187–192. [Google Scholar] [CrossRef]

- Mardani-Aghabaglou, A.; Ramyar, K. Mechanical properties of high-volume fly ash roller compacted concrete designed by maximum density method. Constr. Build. Mater. 2013, 38, 356–364. [Google Scholar] [CrossRef]

- Chhron, C.; Hong, S.J.; Lee, S.W. Relationship between compressive and tensile strengths of roller-compacted concrete. J. Traffic Trans. Eng. 2018, 5, 215–223. [Google Scholar] [CrossRef]

- Hashemi, M.; Shafigh, P.; Karim, M.R.B.; Atis, C.D. The effect of coarse to fine aggregate ratio on the fresh and hardened properties of roller-compacted pavement. Constr. Build. Mater. 2018, 169, 553–566. [Google Scholar] [CrossRef]

- Shafigh, P.; Hashemi, M.; Nam, B.H.; Koting, S. Optimum moisture content in roller-compacted concrete pavement. Int. J. Pavement Eng. 2019, 1–11. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).