Abstract

In Saudi Arabia, the carbon footprint and energy use that results from using concrete in construction is a major negative contributor to the environmental effects of building materials. Likewise, the impact of annual cooling and heating energy demands has an equally prominent role to play. These demands need to be assessed and benchmarked in order that reduction targets can be set. Saudi Arabia presents its own unique context and local conditions, which creates a challenge when utilizing generic frameworks for assessing the environmental impact of domestic buildings. In meeting this aim, this paper presents a resilience and environmental sustainability assessment framework (RESAF) developed specifically for domestic buildings in Saudi Arabia. RESAF helps designers/builders to minimize the carbon footprint of the building fabric and reduce in-use energy demands of domestic buildings in Saudi Arabia. This paper shows how this framework can be used to reduce, by approximately 23%, the carbon impact from construction materials, primarily by substituting a portion of cement for pulverized fly ash (PFA) or ground granulated blast furnace slag (GGBS). A reduction of 19% in annual cooling and heating energy demand were additionally achieved throughout the building’s life, simply by increasing insulation and using triple-glazed windows. The importance of passing these alternative solutions through the resilience filter is highlighted, not least questioning whether they are really fit-for-purpose.

1. Introduction

Many authors have identified challenges or concerns with the current situation of Saudi Arabian domestic buildings with regard to their sustainability and resilience [1,2,3,4,5,6]. This may be because no homegrown/developed building rating system exists that considers the country’s unique factors [7]. That said, a sustainability code is currently being developed, which will likely soon be released by the National Committee for the Saudi Building Code [8]. In Saudi Arabia, the construction sector negatively impacts the environment, using higher amounts of energy and material resources than other sectors [9]. At the same time, the region experiences high temperatures [10], which can reach 50 °C between June and July [11]. In Saudi Arabia, cooling systems currently account for around 70% of household electrical demands during summer months [12]. Therefore, it is not surprising that domestic buildings consume approximately half of the country’s electricity production [1,5]. This is an area where considerable environmental improvements can be made. However, these improvements should not solely indicate an occupied building’s energy use. In other words, the materials used within a building and the allied construction processes used to create them (i.e., embodied and embedded impacts) must also be considered given they have a significant environmental impact [13]. A large part of society’s total carbon footprint is produced from the carbon emissions connected with built environments [14]. Sustainable strategies for construction are attracting increased attention among scholars/practitioners and society as a whole due to their concerns over environmental damage and the world-wide depletion of resources [15], not least of which is oil. It has been argued that civil engineers have engineered with society in mind and have thus always placed sustainability at the heart of their work [16]. Therefore, better consideration of the materials used therein cannot be ignored.

For sustainable building practices to be implemented in Saudi Arabian construction, a balance must be struck between environmental, social, and economic performance [17]. When assessing the environmental sustainability of a building, it is widely considered that energy performance is the most important of these criteria [18], especially considering the advent of climate change, which strongly impacts the other two pillars. Therefore, it is not surprising that this area receives the greatest attention.

At the same time, the sustainable long-game in Saudi Arabia has to be considered. The impact on future generations to provide for themselves is a key factor, as is the longevity or resilience of future societies. Resilience in this context means that under changing circumstances, the function (in this case that of a domestic building) can still be delivered no matter what transpires [19]. Future uncertainties are inevitable and ‘resilience proofing’ is a concept that addresses these uncertainties [20]. Certainties and uncertainties (perhaps better considered by asking a series of ‘what if?’ questions) include both expected and unexpected circumstances and outcomes, natural, or man-made [21].

In recent years, the number of natural disasters in Saudi Arabia, such as dust storms and floods, have increased [22]. Viewing these concerns and challenges from two perspectives—i.e., sustainability and resilience—is extremely beneficial to future-proofing domestic building designs [23]. However, for practitioners and scholars to successfully incorporate the concepts of sustainability and resilience, new frameworks and tools must be developed and utilized in the built environment [24]. Reassuringly, many published studies have concluded that it is technically possible to incorporate resilience indicators and metrics with those for sustainability; for the most part the two work in parallel to each other [25].

In an ideal world, construction systems would incorporate robust resilience standards and sustainable performance criteria [26] because buildings are likely to encounter changing circumstances as they emerge in the future. If they cannot adapt (by themselves or through minimal intervention) they will quickly reach their end-of life state and become obsolete [27]. In order to be resilient, individuals or entities must possess characteristics that enable them to maintain their identity when they are faced with stressful and unusual situations. Ambitiously, they may even emerge stronger from such situations [28]. Those working in construction design should, therefore, place a high priority on ensuring that new buildings are able to cope with potential loads and stresses, which future circumstances may impose on them and that they can withstand the damage they may sustain from current and future climatic events [29]. Buildings should also be constructed in line with local cultural and environmental conditions [30].

The selection of construction materials is important as it contributes significantly to environmental sustainability [31]. The building industry has several unique features, such as extremely long lifespans, the range of construction methods and a vast selection of materials [32]. Achieving high impact with sustainability in construction is influenced by design and decisions at the early stages [33]. Research by Alaidroos and Krarti [34] affirms the promotion of energy saving for buildings by motivating and investing. In a country such as Saudi Arabia, zero-carbon homes as a concept may become possible through the utilization of solar energy [2]. Sustainability concerns must be addressed in the early stages of building projects, when decisions are being made about building materials and techniques, following the life cycle concept [35]. Huge demands for energy should be minimized as much as possible before applying zero-energy home solutions [36]. As a potential example of consideration given to construction materials, a former study achieved a 20% reduction in carbon by using a design with a reused steel structure [37]. In Saudi Arabia, although efforts are being made to propose new regulations and government policies, and energy-efficient technologies are available, the energy consumption habits and lifestyle of Saudi citizens must be improved if these are to have an impact [38] in both the short and long term.

Whilst there are many tools available for measuring sustainability and resilience [3], questions exist about whether these tools meet the local conditions and context for Saudi Arabia. One of the difficulties is that there are reported contradictions between energy performance figures once the building is occupied (operation stage) as compared to the simulated long-term performance suggested in the design stage [39]. Furthermore, a study by Alshuwaikhat and Mohammed [40] asserted that a methodology suitable for one country cannot necessarily be transferred successfully to another, because of the different contexts existing in each. This may go some way towards explaining why such discrepancies exist. A number of factors in Saudi Arabia need to be taken into account [41]:

- Policies and regulations

- Culture and traditions

- Public opinion/behavior

- Environmental factors

- Climate

- Geographical characteristics

- Systems and materials used in construction

- How resources are consumed

- The prospect for integration of renewable energy

Saudi government organizations have also been paying greater attention to sustainability in recent years [4,42]. A tangible example of this is Saudi Vision 2030, which takes a huge positive step towards implementing sustainability [43]. In addition it is recommended that tools tailored for sustainable assessment of Saudi Arabian homes be developed from within [44,45]. Additionally, it is recommended that such innovative tools be employed by building owners so that they can manage construction decisions (including renovation projects) sustainably, especially when they own a large portfolio of buildings [46].

In meeting this aim this paper presents a resilience and environmental sustainability assessment framework (RESAF) for domestic buildings. RESAF helps designers/builders minimize the carbon footprint of the building fabric and thereby reduce in-use energy demand of domestic buildings in Saudi Arabia. The sections of the paper are outlined as follows: Section 2 explains the methodological design of the RESAF by pointing out the filters and steps. Section 3 outlines the results of applying a domestic building case study to the RESAF. Section 4 discusses the developed framework and the results. Finally, the conclusion is drawn in Section 5, which also outlines recommendations for future work in relation to this study.

2. RESAF: The Methodological Framework

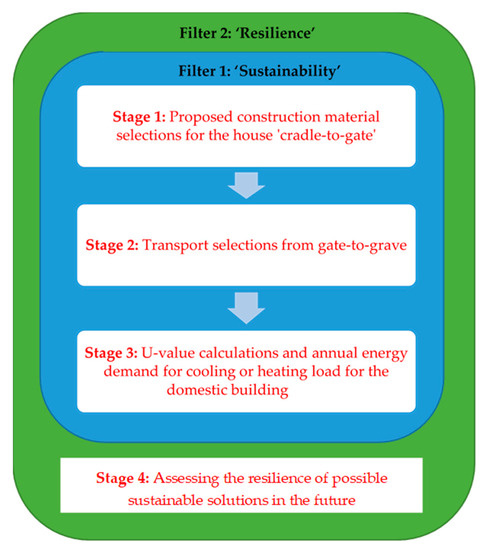

The RESAF has been developed to help practitioners (e.g., designers, engineers, contractors) in Saudi Arabia to select appropriate construction materials which meet sustainability (i.e., environmental) and resilience criteria. Although the developed framework is intended to be used for domestic buildings in Saudi Arabia, it could, with minor adjustments, be used for other types of buildings. Likewise, the generic aspects could allow application to other regions. Figure 1 shows the dual filter approach: the inner sustainability filter (Section 2.1) and the outer resilience filter (Section 2.2).

Figure 1.

Resilience and environmental sustainability assessment framework (RESAF) framework filters and steps.

The inner filter consists of three stages of assessment for materials used (i.e., cradle-to-gate, gate-to-grave (transport), and U-value calculations).

The units of measure used therein are: Embodied carbon (kgCO2e); embodied energy (MJ) where 1 MJ = 0.2778 kWh; and U-value (W/m2.K).

The following information is required in order to make an assessment of the domestic building:

- Domestic building plans and dimensions

- Location of the building

- Soil types at the location of the building (see: 2.1.3.3)

- Construction materials (types and quantities)

- Modes of transport and gate-to-grave (from the factory gate to the end of the use of the building) distances (where available)

- Detailing about wall and roof construction

- Glazing types (e.g., windows or skylights)

Utilizing the framework might be possible, even if some of the information listed above is not available. However, in such cases, appropriate assumptions should be made and suitable justification provided. The accuracy and efficiency of the outcomes (i.e., results) are very much dependent on the availability of the above-mentioned information as well as the choices made by the users while implementing the framework.

The excel-based tool, which accompanies the framework, was developed to allow ease of considering the impact of changing material choices within a domestic building design.

2.1. Part 1: Information and Details about Proposed House Building (Inputs)

2.1.1. Stage 1: Proposed Construction Material Selection for a House ‘Cradle-to-Gate’

At this stage, we consider the embodied carbon and energy from the cradle-to-gate assessment for construction materials. Cradle-to-gate is defined as the life cycle of the product from the moment the resources are extracted to the time the material is ready for transport to the factory gate [47,48]. Stage 1 is designed in line with the basic data extracted from the inventory of carbon and energy (ICE) version 2.0. [49]. The data from this (and previous) versions have been used in a number of studies. Therefore, no future validation is needed [50,51,52]. In addition to this, data have been organized based on (LCA), (ISO) 14040/44 principles, and associated framework developed by Hammond and Jones [53].

There are 14 categories of construction materials in the framework: aggregate and sand, aluminum, block, carpet, cement, ceramics, ready-mix concrete, precast concrete, glass, insulation, paint, plastics, steel, and timber. All these categories include a number of types, making 162 types in total, covering the most important materials which are likely to be used in a domestic property.

The data presented at this stage are based on embodied carbon coefficients (ECC; in kgCO2e/kg) and the embodied energy coefficients (EEC; in MJ/kg) for the construction materials. To calculate the embodied carbon (EC; in kgCO2e) and embodied Eeergy (EE; in MJ) for the construction materials, refer to Equation (1):

where Q denotes construction material quantities (kg).

EC = ECC × Q or EE = EEC × Q

The following is an example of Equation (1): if Q is 4 kg and the ECC is 0.07 kgCO2e/kg, then the EC for this material is 4 × 0.07= 0.28 kgCO2e.

2.1.2. Stage 2: Transport Selection from Gate-to-Grave

In order to improve the outcome of embodied carbon kgCO2e for the construction materials, Stage 2 is included in the framework. ‘Freighting goods (downstream)’ and ‘well-to-tank (WTT) (upstream)’ data have been taken from government emission conversion factors for greenhouse gas company reporting [54]. As per the same reference and the greenhouse gas protocol reported by Ranganathan et al. [55], freighting goods emissions data are associated with the fuel used during transport modes. However, the WTT reports emissions of fuel before the transport mode, such as those embodied from the extraction and refining of fossil fuel. Data for an average load of each transport mode has been included. Data are reported in kgCO2e/tonne.km and converted to kgCO2e for each mode of transport (i.e., heavy goods vehicle (HGV) diesel, diesel vans, petrol vans, rail, freight flights, and cargo ships)

2.1.3. Stage 3: U-Value Calculations for Domestic Buildings

U-value calculations have been considered in order to help select building materials that reduce the long term (in-use) energy demand for heating and cooling domestic buildings [56].

U-value (W/m2.K) calculations are undertaken for: walls and roof sections; windows and roof light glazing; and ground floors. U-values are converted to gain or loss coefficients (W K–1). Finally, an annual energy demand and embodied kgCO2e are calculated for both cooling and heating.

To calculate the U-value of a construction section, consisting of multiple layers of different material, a simple formulation is used as shown in Equation (2) [57].

where:

U = 1/(RSI + R1 + R2 + … + RSE)

U = U-value of individual element (walls and roofs) (W/m2.K)

RSI = Internal surface resistance (m²KW−1)

RSE = External surface resistance (m²KW−1)

R1 and R2 = Thermal resistance for components of walls and roofs (materials layers) (m²KW−1)

It is assumed that the internal thermal resistance is 0.13 and the external thermal resistance is 0.04 m²KW−1 [58]. A calculation for the thermal resistance of components like R1 is shown in Equation (3)

where:

R1 = (d1/λ1)

d1 = thickness of material (m)

λ1 = thermal conductivity (W m–1 K–1)

The glazing U-value for the building depends on several properties (i.e., types of frames, glazing, gap between panes, and conditions) and whether it is a window or roof light. The result for the U-value are based on the criteria tables sourced from CIBSE [57].

The ground floor U-value for a building depends on the ground floor area and perimeter as well as the soil type (clay/silt, sand/gravel, or homogeneous rock) and thermal insulation resistance (m²KW−1). The result for the U-value are once again based on the criteria tables sourced from CIBSE [57].

Equation (4) is used to calculate the annual energy demand (kWh) from a building’s cooling or heating load [58].

where:

Ht × CDD × 24/1000 or Ht × HDD × 24/1000

Ht = Total contribution to the heat gain or loss coefficient of a house from walls, roofs, grounds floors, windows, and ventilation) (W K−1)

CDD = Cooling degree-days (°C)

HDD = Heating degree-days (°C)

The data on degree days were extracted from the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) [59]. Degree days are the total of the differences between the outside temperature and a reference temperature measured over a determined period of time [60]. A base temperature of 18.3 degrees is used when calculating heating and cooling degree days, which adheres to the Saudi Building Code [61]. The multiplication by 24 is necessary to convert days into hours and kilowatt-hours (kWh) are obtained by dividing by 1000.

Ht is calculated from Equation (5):

where:

U × A

U = U-value of individual element (i.e., walls, roofs, grounds floors, windows) (W/m2.K)

A = area of element (m2).

Note that the contribution of ventilation to the heat gain or loss coefficient (W K–1) is calculated as in Equation (6):

where:

0.33 × V × n

V = volume of the house (m3)

n = rate of air changes per hour (ACH).

2.1.4. Stage 4: Assessing the Resilience of Possible Sustainable Solutions in the Future

Today, it is not unusual for building designs to incorporate considerations of sustainability and resilience (in addition to adaptability and livability) [62]. As reported by Rogers [62], civil engineers must be provided with support to improve how their interventions (in this case materials) are conceived, prepared, and implemented so they align with these concepts and are able to adapt to changing circumstances.

The assessment of the resilience in filter 2 uses an urban futures assessment. In other words, the future performance of materials selected in Stages 1, 2, and 3 are considered within the context of three very different future scenarios.

Scenario 1. Market forces (MF): a conventional scenario sometimes referred to as business-as-usual, where no major changes to current patterns of behavior are expected. In terms of material selection, this would likely mean that sustainability does not feature high up the agenda and the aesthetics (i.e., form) and function of a material waste is considered far more readily than sustainability credentials.

Scenario 2. Policy reform (PR): based on strict policy to achieve sustainability goals. In terms of material choice sustainability is likely to feature much higher on the agenda enforced by strict policies for improving material selection.

Scenario 3. New sustainability paradigm (NSP) is led by the widely accepted sustainable citizen values and behavior. For material selection, it is likely that citizens readily embrace sustainable material choice and the governance systems support such implementation.

In order to do this a number of necessary conditions (NCs), which are conditions necessary to allow selected materials to deliver their function in the long term, should be derived [19]. These are shown in Table 1.

Table 1.

Necessary conditions (NC) for materials used in domestic buildings.

The matrix in Table 2 is used to evaluate the necessary conditions for the sustainable solution (selected materials) regarding their performance in three future scenarios. This evaluation is to decide whether these solutions should be implemented, adapted, or replaced by other solutions that will go through the evaluation process again [19]. In each of these future scenarios, there are three grade levels to assess respecting necessary conditions. They are as follows:

Table 2.

An example of the resilience matrix for assessing materials [19].

- Green: condition highly likely to continue in the future;

- Amber: condition at risk in the future;

- Red: condition highly unlikely to continue in the future.

If green grades are allocated in all three scenarios, such as in condition (A), there is the possibility of a solution utilized with confidence. However, if amber or red grades are allocated to one of the three future scenarios, such as conditions (B) and (C), it simply means that the proposed solution is not resilient, requiring more research for the possibility of the adaptation or conceptualization of other alternative solutions.

2.2. Outline of the Case Study

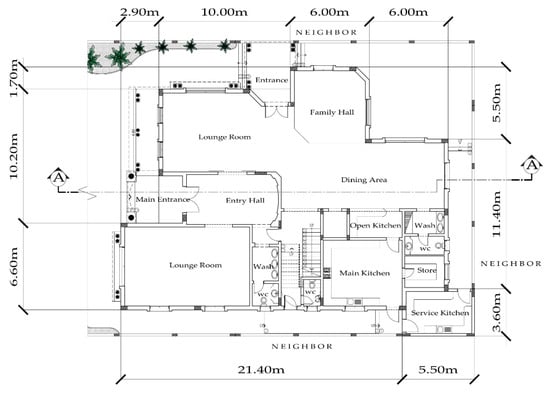

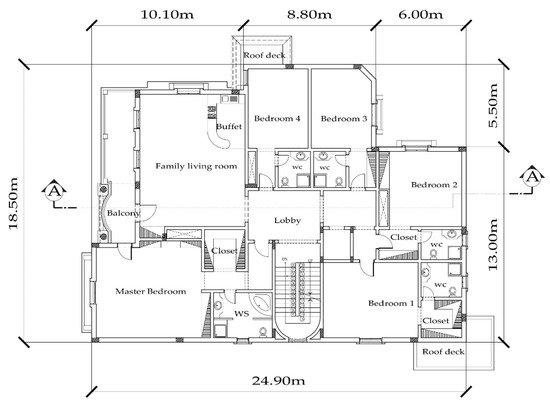

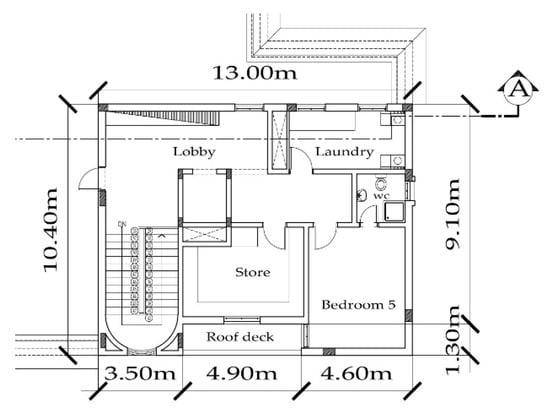

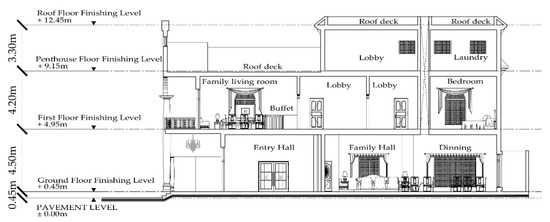

The house project is a proposed design to be built in Dammam, Saudi Arabia. The total floor space is 890 m2. The house is composed of ground, first, and penthouse floors (Figure 2, Figure 3, Figure 4 and Figure 5). The building is a concrete structure using a two-way ribbed slab system. The construction materials are specified in the proposed design and the usage of materials, quantities, and specifications are summarized in Table 3. The total weight of the materials amounts to approximately 3,319,162 Kg.

Figure 2.

Ground floor plans for the domestic building (built area is 381 m2).

Figure 3.

First floor plan (built area is 380 m2).

Figure 4.

Penthouse floor plan (built area is 129 m2).

Figure 5.

Vertical section (A-A) and floors level.

Table 3.

Proposed construction materials in the domestic building design.

3. Results

3.1. Cradle-to-Gate

The results from cradle-to-gate presented in Table 4 and Table 5 illustrate the embodied kgCO2e and MJ from the construction materials proposed by the case study designer. Overall, the influence of concrete materials on the outcome is clear for both the embodied carbon and energy. This was to be expected even though the resources needed to produce concrete are locally available [64], particularly in developing countries. The issue is that its manufacture involves a huge amount of energy, especially the cement. In this building it can be seen that steel has a remarkable impact with 11.51% of the total embodied carbon (kgCO2e) and 16.46% of the total embodied energy (MJ). Steel and reinforced concrete are used extensively by structural engineers and architects, and both materials make intensive use of energy [65]. Taken together, there is an indication that the types of materials adopted need enhancing or different materials need to be used in order to minimize the negative effects on the environment.

Table 4.

Embodied Carbon kgCO2e for cradle-to-gate.

Table 5.

Embodied energy (MJ) for cradle-to-gate.

With these negative impacts in mind, a number of suggested actions will be highlighted for the case study. Looking ahead, specifying materials that have less impact on the environment such as substitutes for cement [66], could be a substantive step towards solutions for currently unsustainable materials.

The first action is to partially substitute the cement with replacement materials when using ready-mix concrete, for example by using pulverized fly ash (PFA) or ground granulated blast furnace slag (GGBS). Table 6 demonstrates the extent of the savings that can be made in terms of embodied carbon and energy (i.e., 76,084 kg of ready-mix concrete (25–30 MPa) and 1,870,152 kg for ready-mix concrete (28–35 MPa). The savings could lead to a 41% reduction in embodied carbon and 27% reduction in energy consumption when substituting cement in this way. A further advantage of utilizing PFA or GGBS is that these ‘waste’ materials would not need to be disposed of in landfill, thus reducing the significant negative environmental impacts from a domestic building’s construction [67].

Table 6.

The influence of blast furnace slag or fly ash replacement on embodied carbon kgCO2e and embodied energy (MJ) of ready-mix concrete [(25–30 MPa) and (28–35 MPa)].

There are three types of blocks in the building: autoclaved aerated blocks, concrete blocks (8 MPa), and concrete blocks (12 MPa). They have been used as presented in Table 7. Concrete blocks (12 MPa) and (8 MPa) will still be proposed. However, the second action is to change the selection of autoclaved aerated blocks to concrete blocks (8 MPa). This will result in a significant reduction (>20%) of embodied carbon and energy. Table 7 shows the breakdown of these savings in detail. The reason for this reduction is that autoclaved aerated blocks embody 3.50 MJ/kg and 0.326 kgCO2e/kg, compared with 0.59 MJ/kg and 0.063 kgCO2e/kg, respectively, for concrete blocks (8 MPa).

Table 7.

Comparison of the two proposed options for blocks (concrete products) ready-mix concrete.

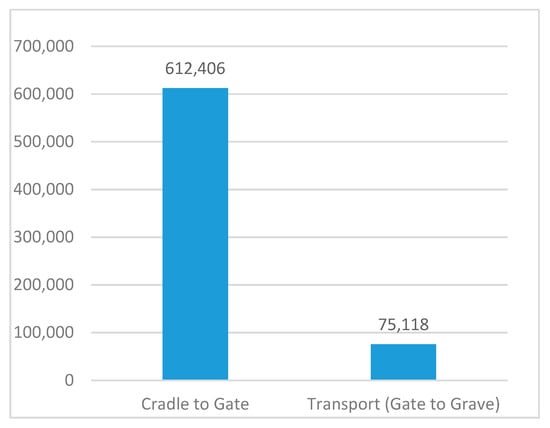

3.2. Gate-to-Grave

Transport (gate-to-grave) examines how these construction materials are delivered to the site and how they are disposed of at the end of the building’s operation. It has been presumed that most of the selected materials will be delivered locally from manufacturers in Saudi Arabia, except ceramic, granite, and marble (from Italy, for example). It is also assumed that all the materials will be disposed of, except steel. Figure 6 represents the result. The transport from just gate-to-grave consumes approximately 75,118 kgCO2e, while 612,406 kgCO2e is the consumption from cradle-to-gate for all activities (e.g., material processing and manufacturing, transport to the factory). Ignoring the transport from gate-to-grave is not a reasonable approach when calculating the embodied carbon as it equals 12% of cradle-to-gate embodied carbon, as shown in Figure 6. Return of transport to its base has not been included as this is not directly controlled by the framework users who select the materials and potential suppliers, otherwise the carbon emissions might increase twofold and be 150,236 kgCO2e.

Figure 6.

Comparison of cradle-to-gate and transport (gate-to-grave) in terms of embodied carbon kgCO2e for all materials (shown on vertical axis).

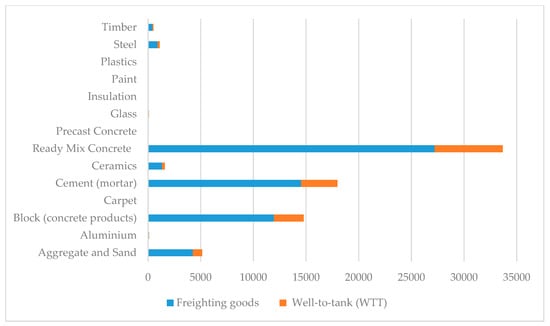

In Figure 7, ready-mix concrete, cement, and concrete blocks are the main contributors to embodied carbon from freighting goods and well-to-tank (WTT), even though they are locally sourced. Aggregate and sand (including marble and granite sourced from Italy, while gravel is locally sourced) still reach 5000 kgCO2e. Other materials (plastic, paint, insulation, glass, carpet, and aluminum) have no tangible effect on the embodied carbon. Freighted goods’ carbon emissions are dramatically higher, with 81% of the total carbon embodied transport from gate-to-grave, compared with WTT emissions. No direct solution can be proposed and whenever possible materials are sourced locally, which reduces carbon emissions. A number of studies have highlighted the necessity of reducing the carbon dioxide emissions which arise from the transportation of materials during the distribution of materials and the construction stage [68]. It is, therefore, suggested that companies should make an effort to select the nearest supplier and avoid deliveries of small amounts of goods. Bear in mind that the impact of transportation can still be high if low-energy materials are transported over long distances [69].

Figure 7.

Both freighting goods and WTT embodied carbon for Transport (gate-to-grave). Horizontal scale shows embodied kgCO2e.

3.3. In-Use Consumption of Energy

It is not sufficient to calculate the improvement to embodied energy alone due to material choices made. A holistic assessment should also look at the impact that these choices have on the yearly energy demand (consumption) for the heating or cooling load in the domestic property during the operation of the building. With the material properties proposed, the respective U-value properties for each of the building elements adopted are presented in Table 8. Contribution to heat gain or loss coefficient from ventilation is calculated as 431.39 (W K–1), the building volume is 3735 m3, and the rate of air changes per hour is 0.35 ACH [70].

Table 8.

Properties of elements used in the case study building.

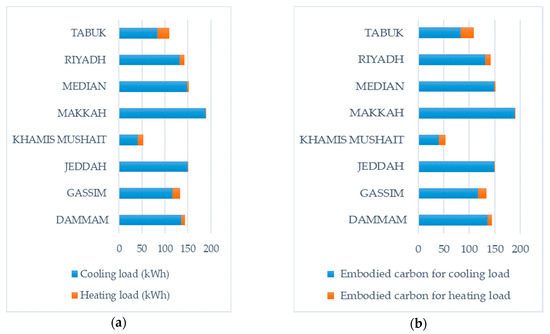

Based on these values, a building in Dammam would expect to consume on average a total energy of 176,295 kWh/year, (198 kWh/m2/year). Breaking this number down into detail, 94% (166,080 kWh/year) is for cooling and 6% (10,215 kWh/year) is for heating. Assuming that 0.726 kgCO2e/kWh is the factor for conversion from energy used to carbon emitted in Saudi Arabia (this has been adapted by adding 6% to the 0.685 kgCO2/kWh factor provided by Taleb and Sharples [44] based on a recommendation by Hammond and Jones [49]) it can be calculated that during its operation stage a building in Dammam embodies 127,990 kgCO2e year.

A study by Alaidroos and Krarti [34] reported the energy consumption in different cities for domestic buildings with the same properties, but the study did not include embodied carbon. Since the developed framework provides an option to select other cities, Figure 8 illustrates the energy consumption and embodied kgCO2e in different cities. These figures are dramatically high in comparison with other benchmarks and is nowhere near achieving a carbon neutral design. Carbon neutrality may be way off. However, it has been proposed that the domestic sector in Saudi Arabia should aim to achieve low-carbon energy consumption rates of approximately 77 kWh/m2 and 98 kWh/m2 yearly [71]. It is interesting to note that the yearly embodied figure for a city like Khamis Mushait is 73 kWh/m2 (53 kgCO2e/m2), which actually meets the low-carbon embodied benchmark recommended by Aldossary et al. [71], while a city like Makkah is 260 kWh/m2 (189 kgCO2e/m2), which is the highest. The figures for all of the cities are most significantly influenced by cooling load, with only a slight effect from the heating load.

Figure 8.

A comparison between different cities for the same case study (the domestic building): (a) the comparison in annual embodied energy (kWh/m2) and (b) the comparison in annual embodied carbon/m2.

A reduction in the rates of kWh or kgCO2e per meter square, as presented in Figure 8, can be achieved by using extra insulation for walls and roofs and changing the type of windows, especially since these materials do not have tangibly negative impacts on the environment in terms of overall embodied carbon and energy (refer to Table 4 and Table 5 for more information). Table 9 shows the annual energy and carbon savings of the three options according to the different changes to elements. For example, in option 2, by increasing the extruded polystyrene from 20 mm to 30 mm for the walls and roofs, changing the window type to triple glazing and retaining the other originally proposed elements (in Table 8), annual energy consumption and carbon emissions can be reduced by approximately 17%. This reduction can also increase to 19% if the window frames are replaced with plastic (PVC), as in Option 3.

Table 9.

Proposed changes to specific properties of elements.

Three alternatives are illustrated in Table 10 to outline the environmental impacts in both the construction material stage and the in-use building stage.

Table 10.

Different alternatives for use of the framework.

It is worthwhile to note that when in-use stage changes have not been performed (Alternative 1), there is no change to long-term energy consumption during operation of the building. The only benefits from the cradle-to-gate materials stage are further reductions in embedded carbon (22.16%) and energy (12.48%).

Alternative 2 showed a 17% reduction in yearly energy consumption and carbon production: 145,792 kWh and 103,285 kgCO2e (164 kWh/m2 and 119 kgCO2e/m2). In short, a slight increase of less than 1% in embodied energy and carbon from materials compared to Alternative 1 (which comes from glass and insulation) is well worth the tradeoff when a considerable amount more can be saved each year of use. Over a 50- to 100-year lifespan, this can be considerable (i.e., up to 100 times more).

However, Alternative 3 demonstrated a 19% savings in energy use as well as a slightly higher savings of less than 1% of embodied carbon and energy from materials compared to Alternatives 1 and 2. The reason for this slight improvement is that the PVC used as a frame for the windows has much lower carbon and energy coefficients (in MJ/kg and kgCO2e/kg) than aluminum (see Table 5).

It is assumed that these significantly reduced impacts will apply to other Saudi Arabian cities. During building life cycle, this will result in years of savings from both the point of view of the materials and also from the enhanced in-use performance of the building.

There is also another point to consider: many Saudi studies have previously ignored embodied carbon and energy from materials [1,34]. It seems they conducted this because the in-use stage is where the majority of the energy consumption for a building exists. This philosophy may not be accurate, especially when examining Table 10 and attempting to explain the numbers in the base case. The embodied energy of the materials is equal to approximately nine years of energy consumption from a building operation and the carbon equals approximately five years of yearly carbon emissions from a building operation. This shows that a philosophy of ignoring it may not be appropriate and justifies the research presented here.

The next section considers the resilience filter, which will determine the future resilience of these material choices (solutions) to reduce energy and carbon.

3.4. Future Resilience of Material Choices

This domestic building case study utilizes a number of proposed solutions, such as partially replacing cement for concrete mix, not using autoclaved aerated block, increasing insulation thickness, and using triple-glazed windows with PVC frames. Thus, the main question is: Are the solutions fit-for-purpose in the future? Table 11 offers an assessment of this by considering their resilience within three reported future scenario archetypes: the new sustainability paradigm, policy reform, and market forces [19,72]. This urban futures methodological approach helps evaluate whether the proposed solutions can be implemented and whether they will function and cope with changes in the future

Table 11.

Assessing the resilience of possible sustainable solutions in the future for the case study. PFA: pulverized fly ash; GGBS: ground granulated blast furnace slag.

PFA and GGBS have been proposed as alternatives to using a percentage of cement (up to 50%) as well as to reduce the carbon and energy footprint for concrete. The availability of materials is an important factor in the selection of materials in the construction industry. Availability is paramount because specific materials may be in irregular supply and regulations to enforce adoption may lead to an increase in demand by stakeholders in the market. Concrete producers should therefore be ready to make these cement substitutes readily available. High demands for specific materials leads to a shortage, which will be reflected in the price. The search for replacements for cement will provide more alternatives for the industry. Based on a study by Kupwade-Patil et al. [50], one example is pozzolans, which can be found in Saudi Arabia. This supports the proposal of reducing the environmental impacts of concrete production by a number of cement alternatives, not just PFA and GGBS.

The bounce back ability of the structure of the building is also a matter of concern. When selecting a concrete mix with replacement cement, such as PFA or GGBS, a designer must choose the same compressive strength so that the building can function as it was intended to. In this case study, for example, the concrete mixes are 25–30 MPa and 28–35 MPa. There are other solutions where the designer may reduce the compressive strength or concrete sections, especially when the structure building is overdesigned. This will reduce the negative environmental effects from concrete, but the designer must make sure that the building is safe and will function (carry the design loads) without any problems.

Another proposal is to replace aluminum frames with PVC. PVC frames reduce in-use energy, they also have smaller carbon and energy embodied coefficients than aluminum (i.e., aluminum uses 155 MJ/kg and 9.16 kgCO2e, respectively, whereas PVC uses 77.2 MJ/kg and 3.1 kgCO2e, respectively). However, PVC may be affected by the hot weather of Saudi Arabian summers. Referring again to Section 3.2, Alternative 2 with aluminum frames (with triple glazing) saves 17% of in-use energy and is better in terms of extreme heat resilience than Alternative 3 with PVC. What is important here is that decision-makers do not get too distracted by the targets in hand and chase these at the detriment of missing other environmental impacts. For example, around 10 years ago in the European Union, the push to meet carbon targets prompted (through policy changes and tax incentives) an uptake of diesel cars with more miles per gallon. However, other negative environmental effects (such as particulates) were not readily considered [73]. In essence, it was not a resilient solution. Selecting Alternative 3 with PVC frames is still a solution in cities such as Khamis Mushait, which have lower temperatures. The construction community may face difficulties in implementing this change as plastic is known to be environmentally unfriendly, but it could be promoted if regulations attach a condition that only recycled PVC were used. Stichnothe and Azapagic [74] concluded that the use of recycled PVC frames leads to a huge reduction in carbon emissions. The use of recycled PVC would therefore be an alternative, slightly modified, and environmentally friendly solution.

Maintaining the current environmental footprint for transport is an important necessary condition because it was assumed at the design stage that most materials would be from local manufacturers or suppliers (not least PFA). Regulating types of transport and enforcing the use of those with minimum carbon emissions is a solution, but unfortunately this is not within the control of the construction industry. If policy suggests that PFA and GGBS should be adopted as concrete replacements for cement, this may initially be supplied locally. Coal fired power stations reduce supplies and have to be imported further afield, which inadvertently increases carbon emissions. Another issue confronted by designers is that all materials except for steel are disposed of after the end of the building’s life. In the future, most materials, including concrete and blocks, should be recycled/reused when a building nears the end of its life in order to maximize sustainability benefits, hopefully there are not long term implications of having PFA and GGBS within concrete These Transportation and recycling requirements would need to be considered for all materials adopted.

When it comes to regulations, including building codes, certain U-values for building elements should be set, for example, a maximum embodied carbon of materials and so on. These measures will add positive value to utilize the RESAF framework itself, so that users will aim to achieve these requirements to meet (and exceed) minimum performance. If the levels of sustainability are to keep improving in the future, assessment and continuous improvement are essential [33]. It is fair to say that the engineering and construction community needs to work much harder to ensure the promotion of sustainability in work practices. A gradual enforcement of the regulations is a good approach to making the rules easy to follow, practical, and enduring.

The final issue is the ability of the public to accept these proposed solutions. It is sometimes difficult for people to change their behavior. People have built their houses using normal concrete or single- and double-glazing. Designers, however, might suggest alternatives. The role of designers is to highlight the short- and long-term benefits in figures. For example, they might translate the yearly savings in energy (kWh) into a percentage of a homeowner’s electricity bill. Increasing awareness of sustainability among the local community is also a major change that is required for the implementation of sustainable and resilient buildings. One way to increase public awareness is to use the media to introduce the Saudi public to the concept of sustainability [6]. In the present environment, stakeholders might promote sustainability and resilience through social networking applications.

The present study uses a specific case (domestic building) in Saudi Arabia to demonstrate the maximum benefits of an RESAF framework.

4. Discussion

The scope of this RESAF framework is wider than that of former studies that targeted domestic buildings in Saudi Arabia. The researchers developed this framework to addresses previous shortcomings of studies that used aspects in isolation rather than combination. For example, a cradle-to-gate assessment of embodied carbon and negative effects on the environment included the global warming potential (GWP) of the materials utilized for a housing project in Saudi Arabia [63]. An assessment of energy consumption (during operation) was used for a domestic building [1,34,44,75] in Saudi Arabia. The establishment of a standard definition for low energy demand in the form of kWh/m2 was accepted for domestic buildings in Saudi Arabia [71].

Looking into the results of applying the domestic case study, RESAF is able to provide a picture of how construction materials perform environmentally, as well as how this performance may be improved. Results showed overall improvement in terms of environmental impacts, which meets the reason behind the design of this framework. These improvements illustrate recognizable reductions in carbon emissions and energy consumption in both the materials (embodied impacts) and for the long-term cooling and heating of domestic buildings (see different alternatives for use of the framework in Table 10, Section 3). These reductions were achieved simply by implementing minor changes to construction materials. Furthermore, these changes have been assessed in the context of the necessary resilience conditions, such as availability of proposed materials. This is because it is important to understand how these selected materials (proposed solutions) fit-for-purpose in the future (see Table 11). In sum, the RESAF considers many key environmental concerns, such as the annual energy demand and related carbon for the cooling or heating load (the important part of energy consumption during building use) and the construction materials used to construct the building, with assessment of their embodied energy and carbon. It explains how different materials will contribute to the in-use energy of the building and the negative environmental effects of the materials themselves. Moreover, RESAF provides an insight into important considerations for the resilience of sustainable solutions proposed, specifically in terms of uncertainty in the future, and how these solutions will perform, which has not been broadly discussed in Saudi Arabia. Although resilience in Saudi Arabia has been studied [22,76,77] and a framework for community resilience to disaster has been proposed, it was not directed at buildings, which this RESAF framework focusses on.

5. Conclusions

It is hoped that, in Saudi Arabia, sustainability and resilience can be integrated to the maximum extent at earliest stages possible within the decision-making processes. The RESAF presented within the paper will help building construction and design projects create a more favorable long-term legacy at each stage of the material selection process [3]. This was done by illustrating how materials contribute to the two filters of sustainability and resilience. The application of the RESAF tool has shown that minor changes to building material selection (replacing cement with PFA or GGBS) can play a vital role in reducing embodied energy or carbon in the life cycle of materials (by >13%) and the operation of the building (over 22%). It is also worth noting transport practices such as gate-to-grave, which accounted for approximately 12% of the embodied kgCO2e through RESAF application, is more readily considered. Whilst some choices (i.e., introducing more insulation and adoption of triple-glazed PVC windows) increase the embodied carbon of the building itself (1%), this is far outweighed by the annual savings they bring (17%), which leads to a considerable multiplying effect (between 50 and 100 times) over the lifetime of the building. These are important findings for Saudi Arabia, as they showcase tangible reductions in the environmental effects when using a RESAF.

The research presented here shows how to holistically assess the choices we make when it comes to material selection for Saudi Arabian domestic homes. The added advantage of the RESAF is that once the iterative process of making environmental improvements has been made, the alternative materials solutions can be passed through the resilience filter. This allows the resilience of the solutions to be more readily considered in order for long term impacts of the choices to be highlighted, i.e., the availability of PFA and GGBS in the far future along with the durability of alternative materials to extreme heat. Moreover, the role of policy, market forces, and sustainability were considered in this study. In other words, conducting the selection of construction materials using the RESAF increases the ability of maintaining sustainable solutions (selected material) in the future.

In light of RESAF’s future, there are some further points to consider. One consideration is that it is important to gain feedback about the developed framework from Saudi Arabian experts in the domestic construction industry. Feedback may be collected by conducting interviews or a series of workshops with potential users. This is to ensure that such a framework can be smoothly implemented by potential industry users. In addition, transforming the RESAF to an online web or mobile application is also a possible solution for better implementation in the future. Such an idea may help to promote the RESAF across the construction industry, as well as enhance how the selection of construction materials is beneficial to sustainability and resilience. Finally, this framework is a pathway to establishing regulations and rules for sustainable and resilient domestic buildings in the country.

Author Contributions

Conceptualization, M.S.M.A.; methodology, M.S.M.A.; software, M.S.M.A.; validation, M.S.M.A., D.V.L.H., and C.D.F.R.; formal analysis, M.S.M.A.; investigation, M.S.M.A.; resources, M.S.M.A.; data curation, M.S.M.A.; writing—original draft preparation, M.S.M.A.; writing—review and editing, M.S.M.A., D.V.L.H. and C.D.F.R.; visualization, M.S.M.A.; supervision, D.V.L.H. and C.D.F.R.; project administration, D.V.L.H.; funding acquisition, M.S.M.A. All authors have read and agreed to the published version of the manuscript.

Funding

Mohammad Almulhim gratefully acknowledges the financial support of Imam Abdulrahman Bin Faisal University in Saudi Arabia given to him during his doctoral studies, Dexter Hunt and Chris Rogers also gratefully acknowledge the financial support given to them by the UK Engineering and Physical Sciences Research Council (EPSRC) under grant EP/J017698/1 (Transforming the Engineering of Cities to Deliver Societal and Planetary Wellbeing).

Conflicts of Interest

The authors declare no conflict of interest.

References

- Felimban, A.; Prieto, A.; Knaack, U.; Klein, T.; Qaffas, Y. Assessment of current energy consumption in residential buildings in Jeddah, Saudi Arabia. Buildings 2019, 9, 163. [Google Scholar] [CrossRef]

- Abd-ur-Rehman, H.M.; Al-Sulaiman, F.A.; Mehmood, A.; Shakir, S.; Umer, M. The potential of energy savings and the prospects of cleaner energy production by solar energy integration in the residential buildings of Saudi Arabia. J. Clean. Prod. 2018, 183, 1122–1130. [Google Scholar] [CrossRef]

- Almulhim, M.S.; Hunt, D.V.L.; Rogers, C.D.F. Framework for assessing the environmentally sustainable and resilience performance of domestic building materials in Saudi Arabia. In Proceedings of the 2nd International Conference on Sustainability, Human Geography and Environment, Kraków, Poland, 28 November–2 December 2018. [Google Scholar]

- Alrashed, F.; Asif, M. Saudi building industry’s views on sustainability in buildings: Questionnaire survey. Energy Proced. 2014, 62, 382–390. [Google Scholar] [CrossRef]

- Aldossary, N.A.; Rezgui, Y.; Kwan, A. Consensus-based low carbon domestic design framework for sustainable homes. Renew. Sustain. Energy Rev. 2015, 51, 417–432. [Google Scholar] [CrossRef]

- Susilawati, C.; Al Surf, M. Challenges facing sustainable housing in Saudi Arabia: A current study showing the level of public awareness. In Proceedings of the 17th Pacific Rim Real Estate Society Conference, Gold Coast, Australia, 16–19 January 2011. [Google Scholar]

- Shaawat, M.E.; Jamil, R. A guide to environmental building rating system for construction of new buildings in saudi arabia. Emir. J. Eng. Res. 2014, 19, 47–56. [Google Scholar]

- SBC. Saudi Building Code National Committee. Available online: https://www.sbc.gov.sa/en/NationalCommittee/Pages/PublicConsultation.aspx (accessed on 1 October 2019).

- El Mallakh, R. Saudi Arabia: Rush to Development (RLE Economy of Middle East): Profile of an Energy Economy and Investment; Routledge: London, UK, 2015. [Google Scholar]

- Al-Tamimi, N. A state-of-the-art review of the sustainability and energy efficiency of buildings in Saudi Arabia. Energy Effic. 2017, 10, 1129–1141. [Google Scholar] [CrossRef]

- Rahman, F.; Rehman, S.; Abdul-Majeed, M.A. Overview of energy storage systems for storing electricity from renewable energy sources in Saudi Arabia. Renew. Sustain. Energy Rev. 2012, 16, 274–283. [Google Scholar] [CrossRef]

- Alshahrani, J.; Boait, P. Reducing High Energy Demand Associated with Air-Conditioning Needs in Saudi Arabia. Energies 2019, 12, 87. [Google Scholar] [CrossRef]

- Ramírez-Villegas, R.; Eriksson, O.; Olofsson, T. Life Cycle Assessment of Building Renovation Measures–Trade-off between Building Materials and Energy. Energies 2019, 12, 344. [Google Scholar] [CrossRef]

- Fenner, A.E.; Kibert, C.J.; Woo, J.; Morque, S.; Razkenari, M.; Hakim, H.; Lu, X. The carbon footprint of buildings: A review of methodologies and applications. Renew. Sustain. Energy Rev. 2018, 94, 1142–1152. [Google Scholar] [CrossRef]

- Govindan, K.; Shankar, K.M.; Kannan, D. Sustainable material selection for construction industry–A hybrid multi criteria decision making approach. Renew. Sustain. Energy Rev. 2016, 55, 1274–1288. [Google Scholar] [CrossRef]

- Rogers, C.D.; Bouch, C.J.; Williams, S.; Barber, A.R.; Baker, C.J.; Bryson, J.R.; Chapman, D.N.; Chapman, L.; Coaffee, J.; Jefferson, I. Resistance and resilience–paradigms for critical local infrastructure. Proc. Inst. Civil Eng. Munic. Eng. 2012, 165, 73–83. [Google Scholar] [CrossRef]

- Akadiri, P.O.; Chinyio, E.A.; Olomolaiye, P.O. Design of a sustainable building: A conceptual framework for implementing sustainability in the building sector. Buildings 2012, 2, 126–152. [Google Scholar] [CrossRef]

- Berardi, U. Sustainability assessment in the construction sector: Rating systems and rated buildings. Sustain. Dev. 2012, 20, 411–424. [Google Scholar] [CrossRef]

- Lombardi, D.; Leach, J.; Rogers, C.; Aston, R.; Barber, A.R.G.; Boyko, C.; Brown, J.; Bryson, J.R.; Butler, D.; Caputo, S.; et al. Designing Resilient Cities; IHS BRE Press: Berkshire, UK, 2012. [Google Scholar]

- Sharifi, A. A critical review of selected tools for assessing community resilience. Ecol. Indic. 2016, 69, 629–647. [Google Scholar] [CrossRef]

- Rogers, C.D.; Hunt, D.V. Realising Visions for Future Cities: An Aspirational Futures Methodology. Proc. Inst. Civ. Eng. Urban Des. Plan. 2019, 172, 1–39. [Google Scholar] [CrossRef]

- Alshehri, S.A.; Rezgui, Y.; Li, H. Delphi-based consensus study into a framework of community resilience to disaster. Nat. Hazards 2015, 75, 2221–2245. [Google Scholar] [CrossRef]

- Marjaba, G.; Chidiac, S. Sustainability and resiliency metrics for buildings—Critical review. Build. Environ. 2016, 101, 116–125. [Google Scholar] [CrossRef]

- Lizarralde, G.; Chmutina, K.; Bosher, L.; Dainty, A. Sustainability and resilience in the built environment: The challenges of establishing a turquoise agenda in the UK. Sustain. Cit. Soc. 2015, 15, 96–104. [Google Scholar] [CrossRef]

- Roostaie, S.; Nawari, N.; Kibert, C. Sustainability and resilience: A review of definitions, relationships, and their integration into a combined building assessment framework. Build. Environ. 2019. [Google Scholar] [CrossRef]

- Burroughs, S. Development of a tool for assessing commercial building resilience. Proced. Eng. 2017, 180, 1034–1043. [Google Scholar] [CrossRef]

- Markelj, J.; Kitek Kuzman, M.; Grošelj, P.; Zbašnik-Senegačnik, M. A simplified method for evaluating building sustainability in the early design phase for architects. Sustainability 2014, 6, 8775–8795. [Google Scholar] [CrossRef]

- Böschen, S.; Binder, C.R.; Rathgeber, A. Resilience constructions: How to make the differences between theoretical concepts visible? In Resilience in Social, Cultural and Political Spheres; Springer: Wiesbaden, Germany, 2019; pp. 11–39. [Google Scholar]

- Champagne, C.L.; Aktas, C.B. Assessing the resilience of LEED certified green buildings. Proced. Eng. 2016, 145, 380–387. [Google Scholar] [CrossRef]

- Mortada, H. Sustainable desert traditional architecture of the central region of Saudi Arabia. Sustain. Dev. 2016, 24, 383–393. [Google Scholar] [CrossRef]

- Al-Gahtani, K.; Alsulaihi, I.; El-Hawary, M.; Marzouk, M. Investigating sustainability parameters of administrative buildings in Saudi Arabia. Technol. Forecast. Soc. Chang. 2016, 105, 41–48. [Google Scholar] [CrossRef]

- Rashid, A.F.A.; Yusoff, S. A review of life cycle assessment method for building industry. Renew. Sustain. Energy Rev. 2015, 45, 244–248. [Google Scholar] [CrossRef]

- Bakhoum, E.S.; Brown, D.C. Developed sustainable scoring system for structural materials evaluation. J. Constr. Eng. Manag. 2011, 138, 110–119. [Google Scholar] [CrossRef]

- Alaidroos, A.; Krarti, M. Optimal design of residential building envelope systems in the Kingdom of Saudi Arabia. Energy Build. 2015, 86, 104–117. [Google Scholar] [CrossRef]

- Zhong, Y.; Wu, P. Economic sustainability, environmental sustainability and constructability indicators related to concrete-and steel-projects. J. Clean. Prod. 2015, 108, 748–756. [Google Scholar] [CrossRef]

- Alrashed, F.; Asif, M.; Burek, S. The role of vernacular construction techniques and materials for developing zero-energy homes in various desert climates. Buildings 2017, 7, 17. [Google Scholar] [CrossRef]

- De Wolf, C.E.L.; Brütting, J.; Fivet, C. Embodied Carbon Benefits of Reusing Structural Components in the Built Environment: A Medium-rise Office Building Case Study. In Proceedings of the 34th PLEA Conference, Smart & Healthy within the 2 Degree Limit, Hong Kong, China, 10–12 December 2018. [Google Scholar]

- Asif, M. Growth and sustainability trends in the buildings sector in the GCC region with particular reference to the KSA and UAE. Renew. Sustain. Energy Rev. 2016, 55, 1267–1273. [Google Scholar] [CrossRef]

- Alyami, S.H.; Rezgui, Y.; Kwan, A. Developing sustainable building assessment scheme for Saudi Arabia: Delphi consultation approach. Renew. Sustain. Energy Rev. 2013, 27, 43–54. [Google Scholar] [CrossRef]

- Alshuwaikhat, H.; Mohammed, I. Sustainability matters in national development visions—Evidence from Saudi Arabia’s Vision for 2030. Sustainability 2017, 9, 408. [Google Scholar] [CrossRef]

- Attia, M.K.M. LEED as a tool for enhancing affordable housing sustainability in Saudi Arabia: The case of Al-Ghala project. Smart Sustain. Built Environ. 2013, 2, 224–250. [Google Scholar] [CrossRef]

- Alyami, S.H.; Rezgui, Y.; Kwan, A. The development of sustainable assessment method for Saudi Arabia built environment: Weighting system. Sustain. Sci. 2015, 10, 167–178. [Google Scholar] [CrossRef]

- Government of Saudi Arabia. Saudi Arabia’s Vision for 2030; Saudi Vision 2030:Saudi Arabia; 2016. Available online: https://vision2030.gov.sa/sites/default/files/report/Saudi_Vision2030_EN_2017.pdf (accessed on 3 April 2017).

- Taleb, H.M.; Sharples, S. Developing sustainable residential buildings in Saudi Arabia: A case study. Appl. Energy 2011, 88, 383–391. [Google Scholar] [CrossRef]

- Aldossary, N.A.; Rezgui, Y.; Kwan, A. An investigation into factors influencing domestic energy consumption in an energy subsidized developing economy. Habitat Int. 2015, 47, 41–51. [Google Scholar] [CrossRef]

- Nielsen, A.N.; Jensen, R.L.; Larsen, T.S.; Nissen, S.B. Early stage decision support for sustainable building renovation—A review. Build. Environ. 2016, 103, 165–181. [Google Scholar] [CrossRef]

- Moretti, L.; Mandrone, V.; D’Andrea, A.; Caro, S. Comparative “from cradle to gate” life cycle assessments of Hot Mix Asphalt (HMA) materials. Sustainability 2017, 9, 400. [Google Scholar] [CrossRef]

- Jacquemin, L.; Pontalier, P.-Y.; Sablayrolles, C. Life cycle assessment (LCA) applied to the process industry: A review. Int. J. Life Cycle Assess. 2012, 17, 1028–1041. [Google Scholar] [CrossRef]

- Hammond, G.; Jones, C. Inventory of Carbon & Energy (ICE) Version 2.0; University of Bath: Bath, UK, 2011. [Google Scholar]

- Kupwade-Patil, K.; De Wolf, C.; Chin, S.; Ochsendorf, J.; Hajiah, A.E.; Al-Mumin, A.; Büyüköztürk, O. Impact of Embodied Energy on materials/buildings with partial replacement of ordinary Portland Cement (OPC) by natural Pozzolanic Volcanic Ash. J. Clean. Prod. 2018, 177, 547–554. [Google Scholar] [CrossRef]

- Hashemi, A.; Cruickshank, H.; Cheshmehzangi, A. Environmental impacts and embodied energy of construction methods and materials in low-income tropical housing. Sustainability 2015, 7, 7866–7883. [Google Scholar] [CrossRef]

- Vilches, A.; Garcia-Martinez, A.; Sanchez-Montanes, B. Life cycle assessment (LCA) of building refurbishment: A literature review. Energy Build. 2017, 135, 286–301. [Google Scholar] [CrossRef]

- Hammond, G.; Jones, C. Embodied Carbon: The Inventory of Carbon and Energy (ICE); BSRIA: Bracknell, UK, 2011. [Google Scholar]

- Department for Business Energy & Industrial Strategy. Government Emission Conversion Factors for Greenhouse Gas Company Reporting: Conversion Factors 2018—Full Set (for Advanced Users); Department for Business Energy & Industrial Strategy: London, UK, 2018.

- Ranganathan, J.; Corbier, L.; Bhatia, P.; Schmitz, S.; Gage, P.; Oren, K. The Greenhouse Gas Protocol: A Corporate Accounting and Reporting Standard (Revised Edition); World Resources Institute and World Business Council for Sustainable Development: Washington, DC, USA, 2004. [Google Scholar]

- Reilly, A.; Kinnane, O. The impact of thermal mass on building energy consumption. Appl. Energy 2017, 198, 108–121. [Google Scholar] [CrossRef]

- Chartered Institute of Building Services Engineers (CIBSE). CIBSE Guide A, Environmental Design; CIBSE: London, UK, 2018. [Google Scholar]

- Everett, B. Energy in Buildings Course; The Open University: Milton Keynes, UK, 2018. [Google Scholar]

- ASHRAE. Handbook of Fundamentals. SI Edition; American Society of Heating, Refrigerating and Air-Conditioning Engineers: Atlanta, GA, USA, 2017. [Google Scholar]

- Ciulla, G.; Lo Brano, V.; Moreci, E. Degree days and building energy demand. In Proceedings of the 3rd Southern African Solar Energy Conference (SASEC), Kruger National Park, South Africa, 11–13 May 2015. [Google Scholar]

- Indraganti, M.; Boussaa, D. A method to estimate the heating and cooling degree-days for different climatic zones of Saudi Arabia. Build. Serv. Eng. Res. Technol. 2017, 38, 327–350. [Google Scholar] [CrossRef]

- Rogers, C.D. Engineering future liveable, resilient, sustainable cities using foresight. Proc. Inst. Civ. Eng. Civ. Eng. 2018, 171, 3–9. [Google Scholar] [CrossRef]

- Asif, M.; Dehwah, A.; Ashraf, F.; Khan, H.; Shaukat, M.; Hassan, M. Life cycle assessment of a three-bedroom house in Saudi Arabia. Environments 2017, 4, 52. [Google Scholar] [CrossRef]

- Kisku, N.; Joshi, H.; Ansari, M.; Panda, S.; Nayak, S.; Dutta, S.C. A critical review and assessment for usage of recycled aggregate as sustainable construction material. Constr. Build. Mater. 2017, 131, 721–740. [Google Scholar] [CrossRef]

- Yeo, D.; Gabbai, R.D. Sustainable design of reinforced concrete structures through embodied energy optimization. Energy Build. 2011, 43, 2028–2033. [Google Scholar] [CrossRef]

- Monahan, J.; Powell, J.C. An embodied carbon and energy analysis of modern methods of construction in housing: A case study using a lifecycle assessment framework. Energy Build. 2011, 43, 179–188. [Google Scholar] [CrossRef]

- Balaguera, A.; Carvajal, G.I.; Albertí, J.; Fullana-i-Palmer, P. Life cycle assessment of road construction alternative materials: A literature review. Resour. Conserv. Recycl. 2018, 132, 37–48. [Google Scholar] [CrossRef]

- Ng, S.T.; Wong, J.M.; Skitmore, S.; Veronika, A. Carbon dioxide reduction in the building life cycle: A critical review. Proc. Inst. Civ. Eng. Civ. Eng. Eng. Sustain. 2012, 165, 281–292. [Google Scholar] [CrossRef]

- Vukotic, L.; Fenner, R.; Symons, K. Assessing embodied energy of building structural elements. Proc. Inst. Civ. Eng. Civ. Eng. Eng. Sustain. 2010, 163, 147–158. [Google Scholar] [CrossRef]

- Çengel, Y.; Ghajar, A. Heat and Mass Transfer: Fundamentals and Applications, 5th ed.; McGraw-Hill Education: New York, NY, USA, 2015. [Google Scholar]

- Aldossary, N.A.; Rezgui, Y.; Kwan, A. Establishing domestic low energy consumption reference levels for Saudi Arabia and the Wider Middle Eastern Region. Sustain. Cit. Soc. 2017, 28, 265–276. [Google Scholar] [CrossRef]

- Hunt, D.V.; Lombardi, D.R.; Atkinson, S.; Barber, A.R.; Barnes, M.; Boyko, C.T.; Brown, J.; Bryson, J.; Butler, D.; Caputo, S.; et al. Scenario archetypes: Converging rather than diverging themes. Sustainability 2012, 4, 740–772. [Google Scholar] [CrossRef]

- Magueta, D.; Madaleno, M.; Dias, M.F.; Meireles, M. New cars and emissions: Effects of policies, macroeconomic impacts and cities characteristics in Portugal. J. Clean. Prod. 2018, 181, 178–191. [Google Scholar] [CrossRef]

- Stichnothe, H.; Azapagic, A. Life cycle assessment of recycling PVC window frames. Resour. Conserv. Recycl. 2013, 71, 40–47. [Google Scholar] [CrossRef]

- Alaidroos, A.; Krarti, M. Impact of passive cooling strategies on energy consumption reduction of residential buildings in the Kingdom of Saudi Arabia. In Proceedings of the ASME 2019 13th International Conference on Energy Sustainability (ES2019), San Diego, CA, USA, 28 June–2 July 2015. [Google Scholar]

- Alshehri, S.A.; Rezgui, Y.; Li, H. Public perception of the risk of disasters in a developing economy: The case of Saudi Arabia. Nat. Hazards 2013, 65, 1813–1830. [Google Scholar] [CrossRef]

- Alshehri, S.A.; Rezgui, Y.; Li, H. Disaster community resilience assessment method: A consensus-based Delphi and AHP approach. Nat. Hazards 2015, 78, 395–416. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).