An Examination of Last Mile Delivery Practices of Freight Carriers Servicing Business Receivers in Inner-City Areas

Abstract

1. Introduction

2. Literature Review

2.1. Overview of Last Mile Delivery Activities to Retailers and Businesses

2.2. Operational Challenges and Issues of Last Mile Delivery in the Inner City

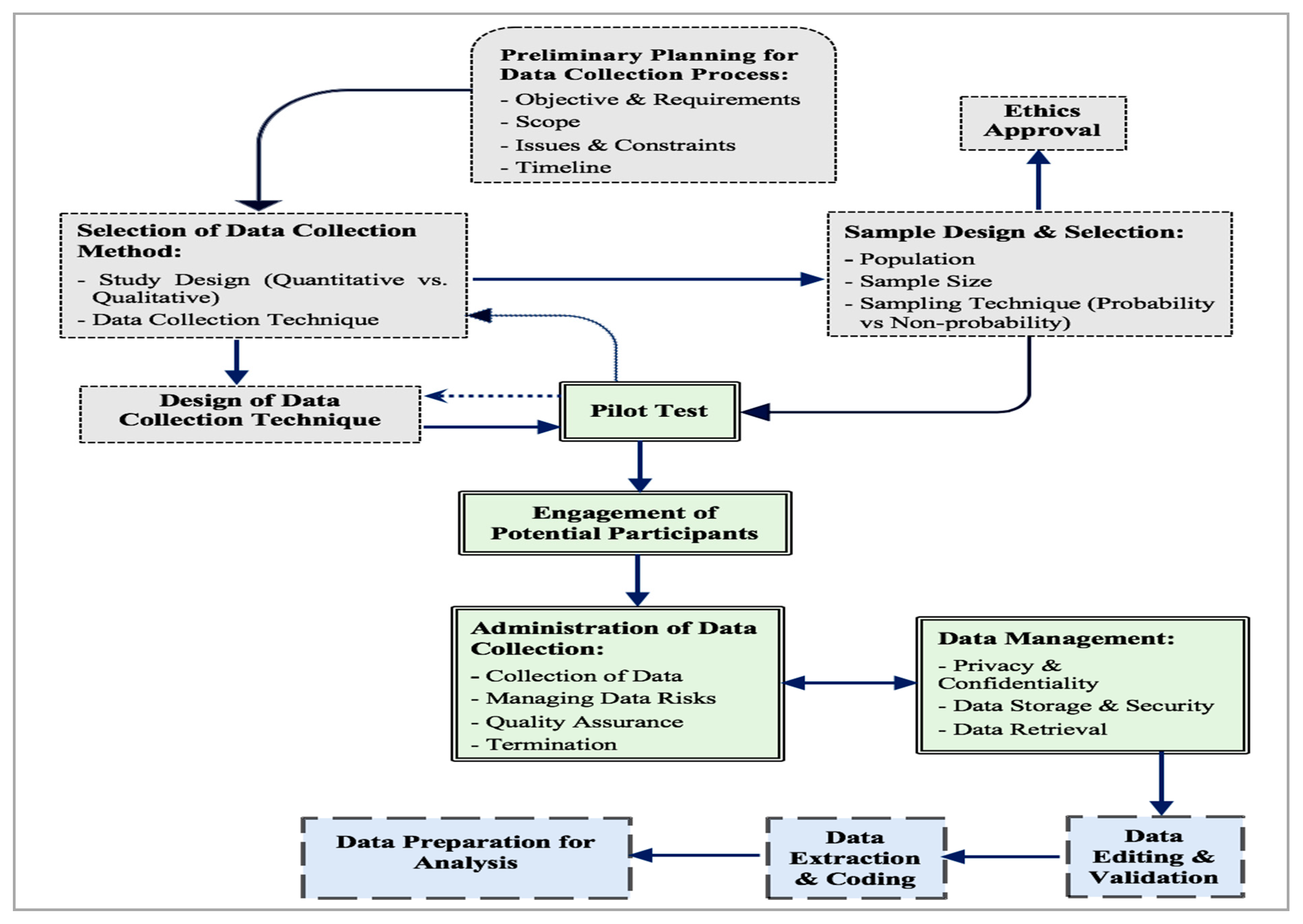

3. Methodology

3.1. Semistructured Interviews

3.2. Online Survey

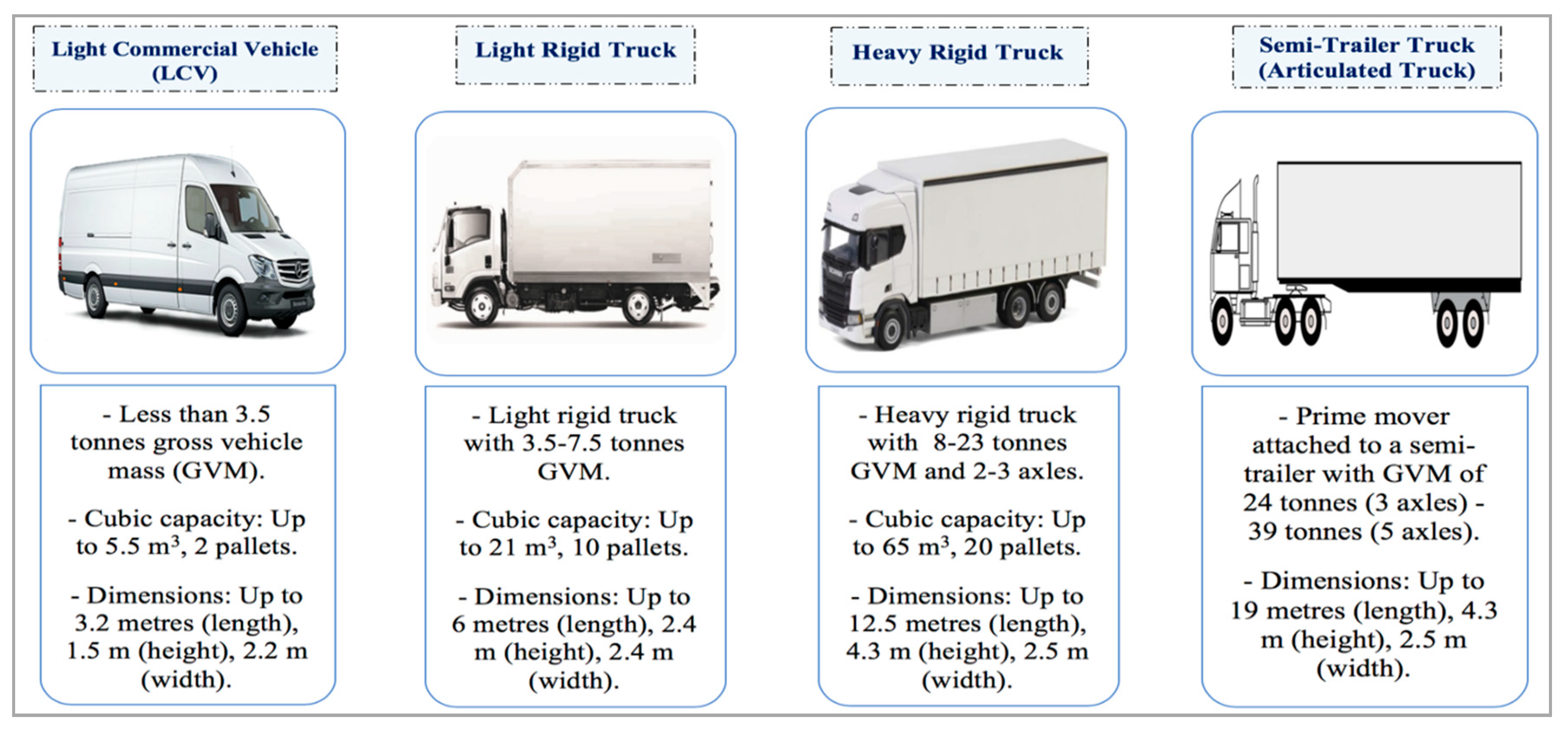

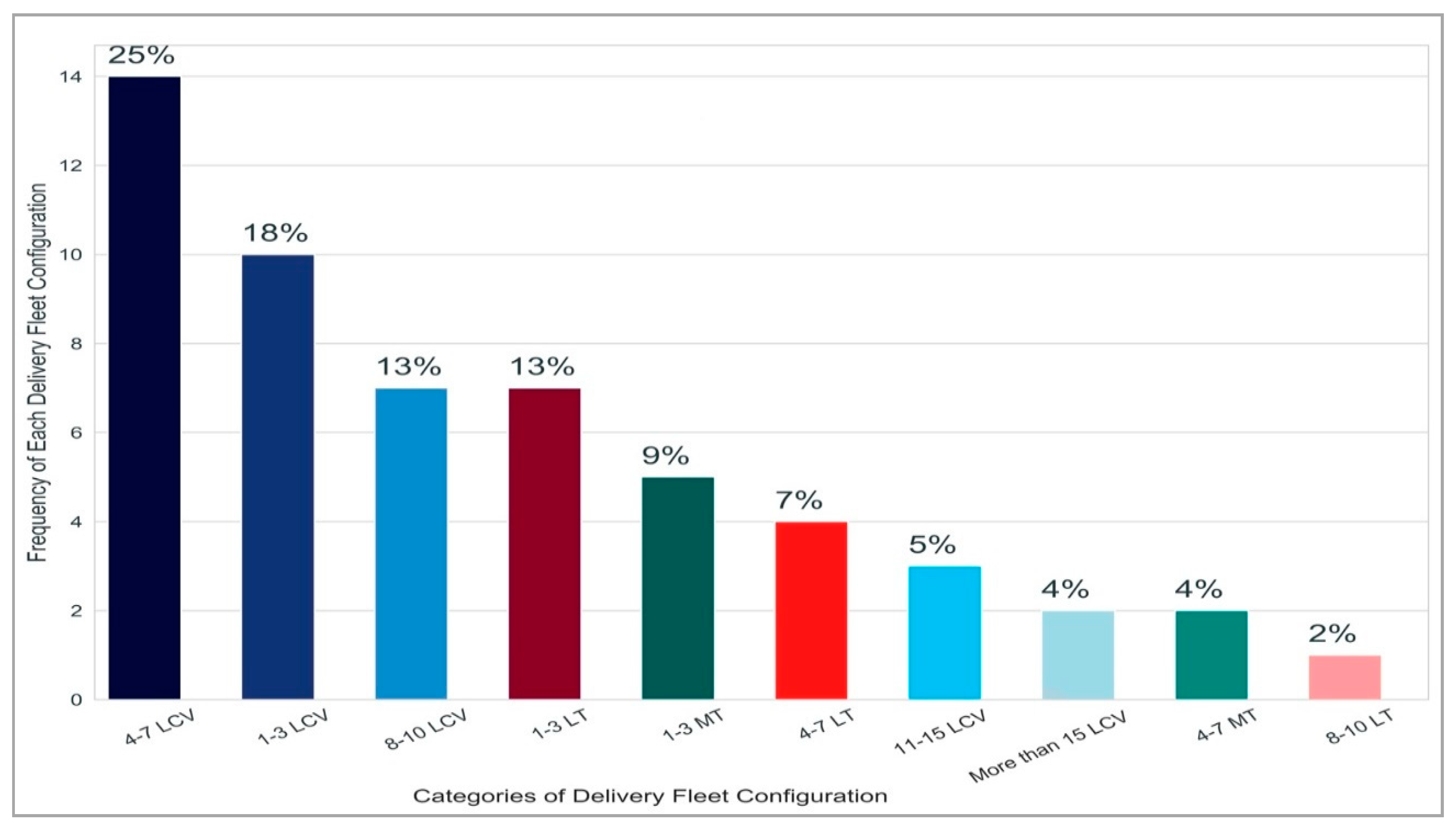

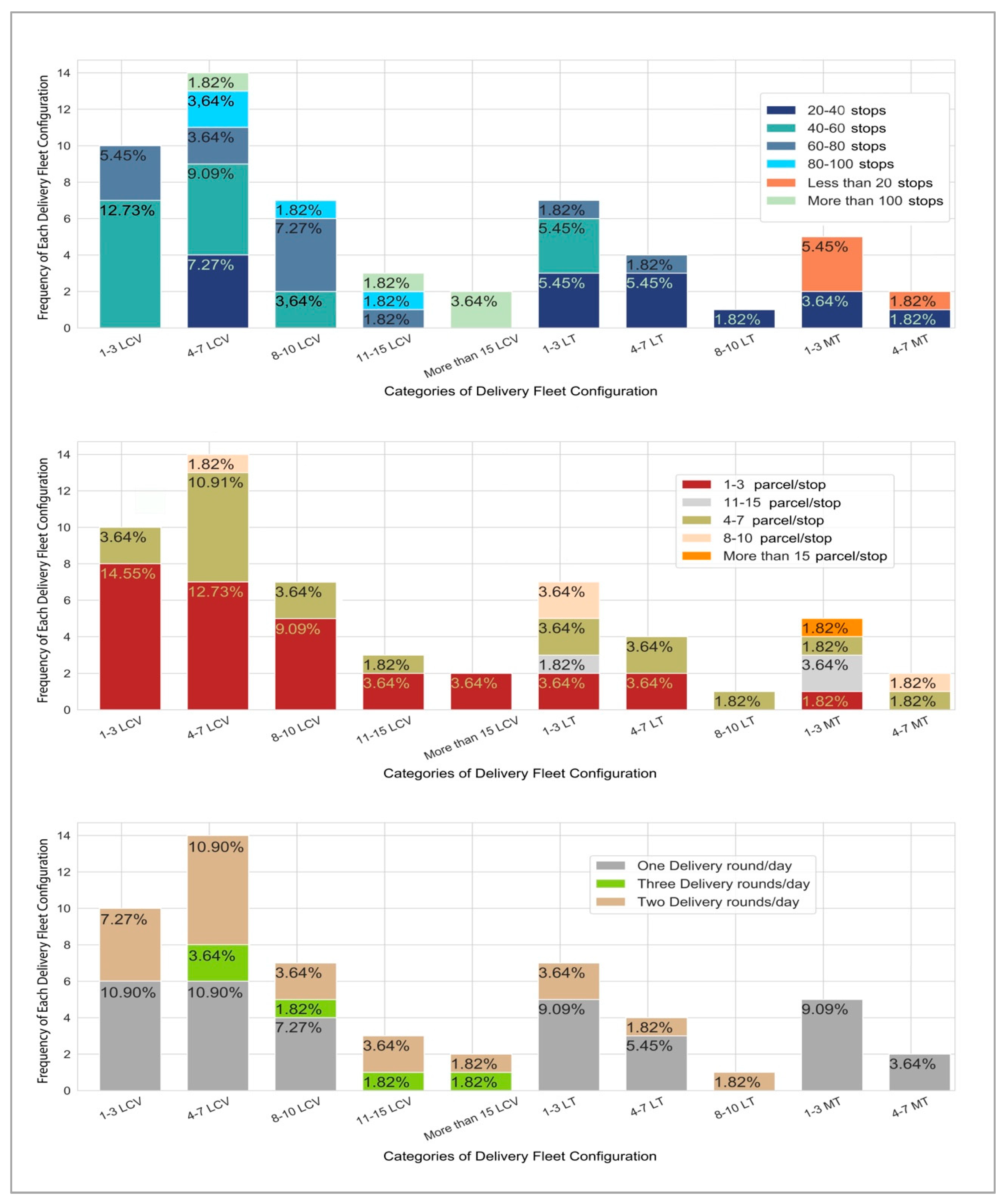

- the class and number of freight vehicles and the average vehicle fill rate

- decision-maker for the order of the stops

- number of daily delivery rounds

- number of daily delivery stops per vehicle

- average number of parcels delivered per stop

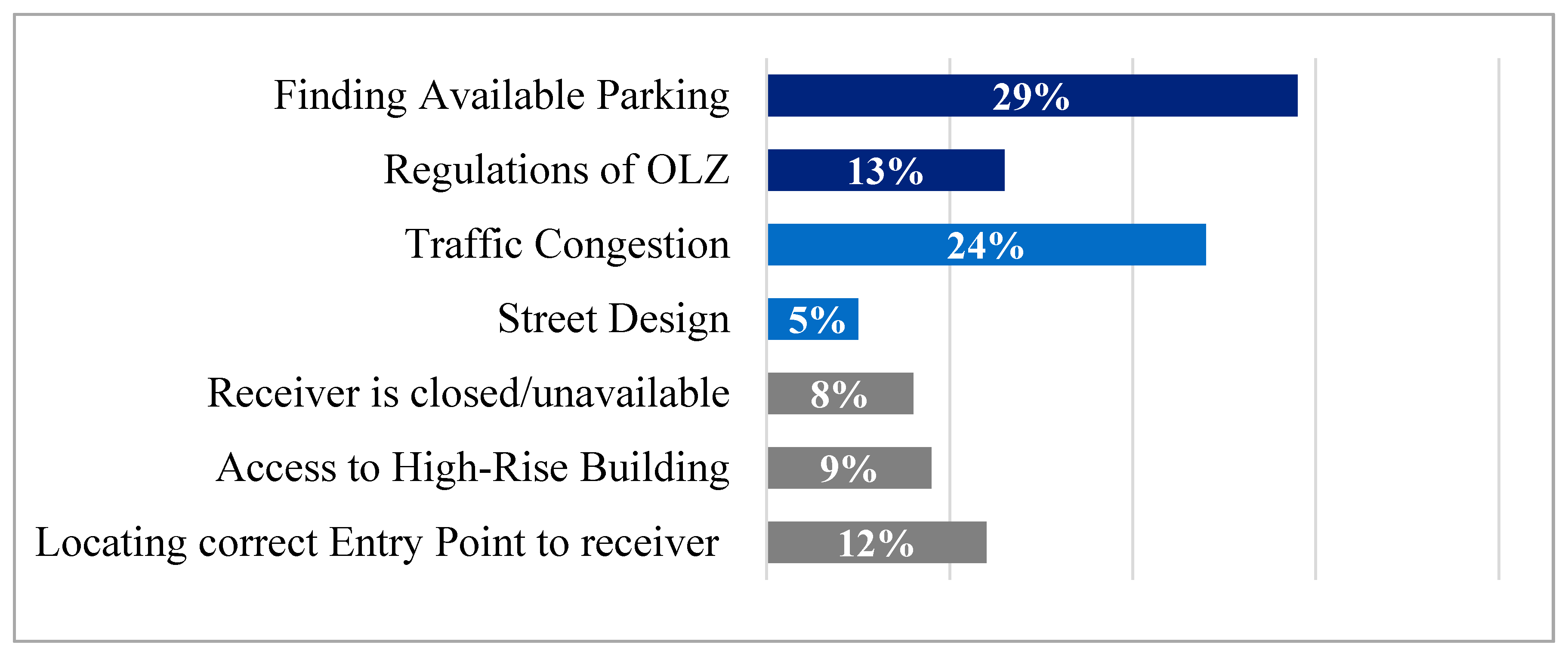

- finding available parking

- traffic congestion

- regulations of on-street loading zones

- receiver’s availability

- access to high-rise buildings

- finding the correct entry point to the receiver

- street design

- 1st Stage: out of the possible 5 clusters in Greater Melbourne, all 5 clusters were selected. Number of selected clusters: 5

- 2nd Stage: out of the possible 4 TPW sub-industries in each cluster, all 4 TPW sub-industries were selected. Number of subclusters: 20

- 3rd Stage: 10 businesses from the 4 TPW sub-industries were selected by simple random sampling in each cluster. Total sample: 200 delivery companies.

4. Results and Analysis

4.1. Analysis of the Last Mile Delivery Network of CEP Service Providers (Responses of the Semistructured Interviews)

4.2. Delivery Practices for Freight Carriers in the Inner-City Area (Survey Responses)

4.2.1. Descriptive Analysis of the Delivery Trips and Operational Issues for the Freight Carriers

4.2.2. Inferential Analysis of the Relationships between the Characteristics of Delivery Trips and Operational Issues

- LCVs have a significantly higher fill rate than LTs (p = 0.068, r = 0.5) and MTs (p < 0.001, r = 0.59). LCV drivers reported a fill rate between 60% to 70%, whereas LT and MT drivers stated a fill rate of 50–60% and less than 40%, respectively.

- LCVs perform a significantly higher number of drops than MTs (p < 0.001, r = 0.66). LCV drivers made 40 to 60 drops, while MT drivers made 20 to 40 drops.

- MTs deliver a significantly higher number of parcels per drop than LCVs (p = 0.026, r = −0.40). MT drivers deliver 8–10 parcels per drop, whereas LCV drivers deliver between 1 to 3 parcels per drop.

- MT drivers reported significantly higher difficulty in finding available parking than LCV drivers and somewhat higher than LT drivers (MT vs. LCV: p = 0.006, r = 0.47; MT vs. LT: p = 0.030, r = 0.56). MT drivers had a rating higher than 30% for the influence of this issue, whereas LCV/LT drivers stated a rating of 25%.

- LCV drivers have significantly higher difficulty in accessing high-rise buildings than MT drivers (p = 0.033, r = 0.39). LCV drivers reported a rating of 12.5%, whereas MT drivers stated a rating of 0%.

- LT and MT drivers have significantly higher difficulty than LCV drivers as to street design (LT vs. LCV: p = 0.001, r = −0.54; MT vs. LCV: p < 0.001, r = −0.90). LCV drivers reported a rating of 0%, while LT and MT drivers stated a rating of 10% and 20%, respectively.

5. Discussion

5.1. The Delivery Practices and Operational Challenges of Freight Deliveries to Business Receivers in the Inner City

5.2. Policy Implications for Local Authorities and the Urban Freight Industry

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Lehrer, U.; Keil, R.; Kipfer, S. Reurbanization in Toronto: Condominium boom and social housing revitalization. disP Plan. Rev. 2010, 46, 81–90. [Google Scholar] [CrossRef]

- Williams, P. Class constitution through spatial reconstruction? A re-evaluation of gentrification in Australia, Britain, and the United States. In Gentrification of the City; Smith, N., Williams, P., Eds.; Routledge: Oxfordshire, UK, 2013; pp. 72–93. [Google Scholar]

- Verlinde, S.; Kin, B.; Strale, M.; Macharis, C. Sustainable freight deliveries in the pedestrian zone: Facilitating the necessity. Portfolio 2016, 1, 97–109. [Google Scholar]

- Aljohani, K.; Thompson, R. Receivers-led delivery consolidation policy: Estimating the characteristics of the most interested businesses to participate. Res. Transp. Econ. 2019, 100808. [Google Scholar] [CrossRef]

- Aljohani, K.; Thompson, R. Impacts of logistics sprawl on the urban environment and logistics: Taxonomy and review of literature. J. Transp. Geogr. 2016, 57, 255–263. [Google Scholar] [CrossRef]

- Allen, J.; Bektaş, T.; Cherrett, T.; Bates, O.; Friday, A.; McLeod, F.; Piecyk, M.; Piotrowska, M.; Nguyen, T.; Wise, S. The Scope for Pavement Porters: Addressing the Challenges of Last-Mile Parcel Delivery in London. Transp. Res. Rec. J. Transp. Res. Board 2018, 2672, 184–193. [Google Scholar] [CrossRef]

- Ducret, R. Parcel deliveries and urban logistics: Changes and challenges in the courier express and parcel sector in Europe—The French case. Res. Transp. Bus. Manag. 2014, 11, 15–22. [Google Scholar] [CrossRef]

- Rai, H.B.; Verlinde, S.; Macharis, C. The “next day, free delivery” myth unravelled Possibilities for sustainable last mile transport in an omnichannel environment. Int. J. Retail Distrib. Manag. 2019, 47, 39–54. [Google Scholar]

- Juhász, J.; Bányai, T. Last mile logistics: An integrated view. IOP Conf. Ser. Mater. Sci. Eng. 2018, 448, 012026. [Google Scholar] [CrossRef]

- Kin, B.; Ambra, T.; Verlinde, S.; Macharis, C. Tackling Fragmented Last Mile Deliveries to Nanostores by Utilizing Spare Transportation Capacity—A Simulation Study. Sustainability 2018, 10, 653. [Google Scholar] [CrossRef]

- Fransoo, J.C.; Zhao, L.; Martinelli, J.L. Omnichannel and Traditional Retail: Platforms to Seamlessly Connect Retail, Service, and Delivery. In Operations in an Omnichannel World; Gallino, S., Moreno-Garcia, A., Eds.; Springer International Publishing: Cham, Switzerland, 2019; pp. 341–353. [Google Scholar]

- Hounwanou, S.; Gonzalez-Feliu, J.; Comi, A.; Gondran, N. Inner city versus urban-periphery retailing: Retail-store movement and shopping trip behaviours. Indications from Saint-Etienne. 2018 EURO Mini Conference on Advances in Freight Transportation and Logistics, Padoue, Italy, 2018. Elsevier Transp. Res. Procedia 2018, 30, 363–372. [Google Scholar] [CrossRef]

- Butrina, P.; Giron-Valderrama, G.D.C.; MachadoLeón, J.L.; Goodchild, A.; Ayyalasomayajula, P.C. From the Last Mile to the Last 800 Feet: Key Factors in Urban Pick-up and Delivery of Goods. Transp. Res. Rec. J. Transp. Res. Board 2017, 2609, 85–92. [Google Scholar] [CrossRef]

- Olsson, J.; Hellström, D.; Pålsson, H. Framework of Last Mile Logistics Research: A Systematic Review of the Literature. Sustainability 2019, 11, 7131. [Google Scholar] [CrossRef]

- Combes, F. A theoretical analysis of the cost structure of urban logistics. In Proceedings of the 6th International Conference in Informations Systems, Logistics and Supply Chain, Bordeaux, France, 1–4 June 2016. [Google Scholar]

- Aljohani, K.; Thompson, R. A Stakeholder-Based Evaluation of the Most Suitable and Sustainable Delivery Fleet for Freight Consolidation Policies in the Inner-City Area. Sustainability 2018, 11, 124. [Google Scholar] [CrossRef]

- Dablanc, L.; Rodrigue, J.P. City logistics: Towards a global typology. In Proceedings of the Transport Research Arena, Paris, France, 14–17 April 2014. [Google Scholar]

- Park, H.; Park, D.; Jeong, I.-J. An effects analysis of logistics collaboration in last-mile networks for CEP delivery services. Transp. Policy 2016, 50, 115–125. [Google Scholar] [CrossRef]

- Behrends, S. Recent developments in urban logistics research—A review of the proceedings of the international conference on city logistics 2009–2013. Transp. Res. Procedia 2016, 12, 278–287. [Google Scholar] [CrossRef]

- Allen, J.; Piecyk, M.; Piotrowska, M.; McLeod, F.; Cherrett, T.; Ghali, K.; Nguyen, T.; Bektaş, T.; Bates, O.; Friday, A.; et al. Understanding the impact of e-commerce on last-mile light goods vehicle activity in urban areas: The case of London. Transp. Res. Part D Transp. Environ. 2018, 61, 325–338. [Google Scholar] [CrossRef]

- Scherr, Y.; Saavedra, B.A.N.; Hewitt, M.; Mattfeld, D. Service network design with mixed autonomous fleets. Transp. Res. Part E Logist. Transp. Rev. 2019, 124, 40–55. [Google Scholar] [CrossRef]

- Suksri, J.; Raicu, R. Developing a Conceptual Framework for the Evaluation of Urban Freight Distribution Initiatives. Procedia Soc. Behav. Sci. 2012, 39, 321–332. [Google Scholar] [CrossRef]

- Danielis, R.; Rotaris, L.; Marcucci, E. Urban freight policies and distribution channels. Eur. Transp. 2010, 46, 114–146. [Google Scholar]

- Eidhammer, O.; Johansen, B.G.; Andersen, J. Comparing Deliveries to On-street Consignees and Consignees Located at Shopping Centers. Transp. Res. Procedia 2016, 14, 1221–1229. [Google Scholar] [CrossRef]

- Kijewska, K.; Iwan, S.; Konicki, W.; Kijewski, D. Assessment of freight transport flows in the city centre based on the Szczecin example—Methodological approach and results. Res. Transp. Bus. Manag. 2017, 24, 59–72. [Google Scholar] [CrossRef]

- Tozzi, M.; Corazza, M.V.; Musso, A. Recurring Patterns of Commercial Vehicles Movements in Urban Areas: The Parma Case Study. Procedia Soc. Behav. Sci. 2013, 87, 306–320. [Google Scholar] [CrossRef]

- Thompson, R.; Flores, G. Understanding Deliveries to Towers in Melbourne. Transp. Res. Procedia 2016, 16, 510–516. [Google Scholar] [CrossRef]

- Jaller, M.; Wang, X.; Holguín-Veras, J. Large urban freight traffic generators: Opportunities for city logistics initiatives. J. Transp. Land Use 2015, 8, 51. [Google Scholar] [CrossRef]

- Casey, N.; Rao, D.; Thompson, R.G. Understanding Last Mile Freight Delivery in Melbourne’s Central Business District. Procedia-Soc. Behav. Sci. 2014, 125, 326–333. [Google Scholar] [CrossRef]

- Litman, T. London Congestion Pricing: Implications for Other Cities; Victoria Transport Policy Institute: Victroia, BC, Canada, 2012. [Google Scholar]

- Stokoe, M. Space for Freight–Managing capacity for freight in Sydney–a CBD undergoing transformation. Transp. Res. Procedia 2019, 39, 488–501. [Google Scholar] [CrossRef]

- Zou, W.; Wang, X.; Conway, A.; Chen, Q. Empirical Analysis of Delivery Vehicle On-Street Parking Pattern in Manhattan Area. J. Urban Plan. Dev. 2016, 142, 04015017. [Google Scholar] [CrossRef]

- Holguín-Veras, J.; Lawson, C.; Wang, C.; Jaller, M.; González-Calderón, C.; Campbell, S.; Kalahashti, L.; Wojtowicz, J.; Ramirez, D.; National Cooperative Freight Research Program; et al. Using Commodity Flow Survey Microdata and Other Establishment Data to Estimate the Generation of Freight, Freight Trips, and Service Trips: Guidebook; Transport Research Board: Washington, DC, USA, 2016. [Google Scholar]

- Pronello, C.; Camusso, C.; Valentina, R. Last mile freight distribution and transport operators’ needs: Which targets and challenges? Transp. Res. Procedia 2017, 25, 888–899. [Google Scholar] [CrossRef]

- VicRoads. Truck Gen Mass and Dimension Limits; Department of Transport, State Government of Victoria: Melbourne, Australia, 2016. [Google Scholar]

- Muñuzuri, J.; Cortés, P.; Grosso, R.; Guadix, J. Selecting the location of minihubs for freight delivery in congested downtown areas. J. Comput. Sci. 2012, 3, 228–237. [Google Scholar] [CrossRef]

- Verlinde, S.; Macharis, C.; Milan, L.; Kin, B. Does a Mobile Depot Make Urban Deliveries Faster, More Sustainable and More Economically Viable: Results of a Pilot Test in Brussels. Transp. Res. Procedia 2014, 4, 361–373. [Google Scholar] [CrossRef]

- Aljohani, K.; Thompson, R.G. Optimizing the Establishment of a Central City Transshipment Facility to Ameliorate Last-Mile Delivery: A Case Study in Melbourne CBD. In City Logistics 3; Wiley: Hoboken, NJ, USA, 2018; pp. 23–46. ISBN 9781119425472. [Google Scholar]

- Broaddus, A.; Browne, M.; Allen, J. Sustainable Freight: Impacts of the London Congestion Charge and Low Emissions Zones. Transp. Res. Rec. J. Transp. Res. Board 2015, 2478, 1–11. [Google Scholar] [CrossRef]

- Holguín-Veras, J.; Amaya-Leal, J.; Wojtowicz, J.; Jaller, M.; González-Calderón, C.; Sanchez-Díaz, I.; Wang, X.; Haake, D.G.; Rhodes, S.S.; Frazier, R.J.; et al. Improving Freight System Performance in Metropolitan Areas: A Planning Guide; Transport Research Board: Washington, DC, USA, 2015. [Google Scholar]

- Bates, O.; Wise, S.; Davies, N.; Friday, A.; Allen, J.; Cherrett, T.; McLeod, F.; Bektaş, T.; Nguyen, T.; Piecyk, M.; et al. Transforming Last-mile Logistics. In Proceedings of the 2018 CHI Conference on Human Factors in Computing Systems—CHI ’18, Montreal, QC, Canada, 21–26 April 2018; Association for Computing Machinery (ACM): New York, NY, USA, 2018; p. 526. [Google Scholar]

- Thompson, R.G.; Zhang, L. Optimising courier routes in inner-city areas. Transp. Res. Part C Emerg. Technol. 2018, 93, 1–12. [Google Scholar] [CrossRef]

- UW Supply Chain Transportation & Logistics Center. The Final 50 Feet Urban Goods Delivery System—Research Scan and Data Collection Project, Report Submitted to Seattle Department of Transportation. 2018. Available online: https://depts.washington.edu/sctlctr/sites/default/files/SCTL_Final_50_full_report.pdf (accessed on 15 May 2018).

- Holguín-Veras, J.; Jaller, M. Comprehensive Freight Demand Data Collection Framework for Large Urban Areas. In Biotechnology Business—Concept to Delivery; Saxena, A., Ed.; Springer: Cham, Switzerland, 2013; pp. 91–112. [Google Scholar]

- Allen, J.; Browne, M.; Cherrett, T. Survey Techniques in Urban Freight Transport Studies. Transp. Rev. 2012, 32, 287–311. [Google Scholar] [CrossRef]

- Richardson, A.J.; Ampt, E.S.; Meyburg, A.H. Survey Methods for Transport Planning; Eucalyptus Press: Parkville, Australia, 1995. [Google Scholar]

- Leedy, P.D.; Ormrod, J.E. Practical Research: Planning and Design, 8th ed.; Pearson Prentice-Hall: Upper Saddle River, NJ, USA, 2005. [Google Scholar]

- Washington, S.P.; Karlaftis, M.G.; Mannering, F. Statistical and Econometric Methods for Transportation Data Analysis; CRC Press: Boca Raton, FL, USA, 2010. [Google Scholar]

- Kim, H.; Boyle, L.N.; Goodchild, A. Delivery Process for an Office Building in the Seattle Central Business District. Transp. Res. Rec. J. Transp. Res. Board 2018, 2672, 173–183. [Google Scholar] [CrossRef]

- Bányai, T. Real-Time Decision Making in First Mile and Last Mile Logistics: How Smart Scheduling Affects Energy Efficiency of Hyperconnected Supply Chain Solutions. Energies 2018, 11, 1833. [Google Scholar] [CrossRef]

| Variables | Vehicle Type vs. Fill Rate | Vehicle Type vs. Number of Drops | Vehicle Type vs. Number of Parcels/Stop |

|---|---|---|---|

| Hscore | 15.28 | 19.63 | 9.13 |

| df | 2 | 2 | 2 |

| P | <0.01 | <0.01 | 0.017 |

| χ2 | 10.597 | 10.597 | 7.824 |

| Variables | Vehicle Type vs. Finding Parking | Vehicle Type vs. Access to High-Rise Building | Vehicle Type vs. Street Design |

|---|---|---|---|

| Hscore | 11.03 | 13.59 | 40.25 |

| df | 2 | 2 | 2 |

| P | 0.007 | 0.037 | <0.001 |

| χ2 | 9.210 | 5.991 | 13.816 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Aljohani, K.; Thompson, R.G. An Examination of Last Mile Delivery Practices of Freight Carriers Servicing Business Receivers in Inner-City Areas. Sustainability 2020, 12, 2837. https://doi.org/10.3390/su12072837

Aljohani K, Thompson RG. An Examination of Last Mile Delivery Practices of Freight Carriers Servicing Business Receivers in Inner-City Areas. Sustainability. 2020; 12(7):2837. https://doi.org/10.3390/su12072837

Chicago/Turabian StyleAljohani, Khalid, and Russell G. Thompson. 2020. "An Examination of Last Mile Delivery Practices of Freight Carriers Servicing Business Receivers in Inner-City Areas" Sustainability 12, no. 7: 2837. https://doi.org/10.3390/su12072837

APA StyleAljohani, K., & Thompson, R. G. (2020). An Examination of Last Mile Delivery Practices of Freight Carriers Servicing Business Receivers in Inner-City Areas. Sustainability, 12(7), 2837. https://doi.org/10.3390/su12072837