The Development of a Decision Support Model for Eco-Friendly Material Selection in Vietnam

Abstract

1. Introduction

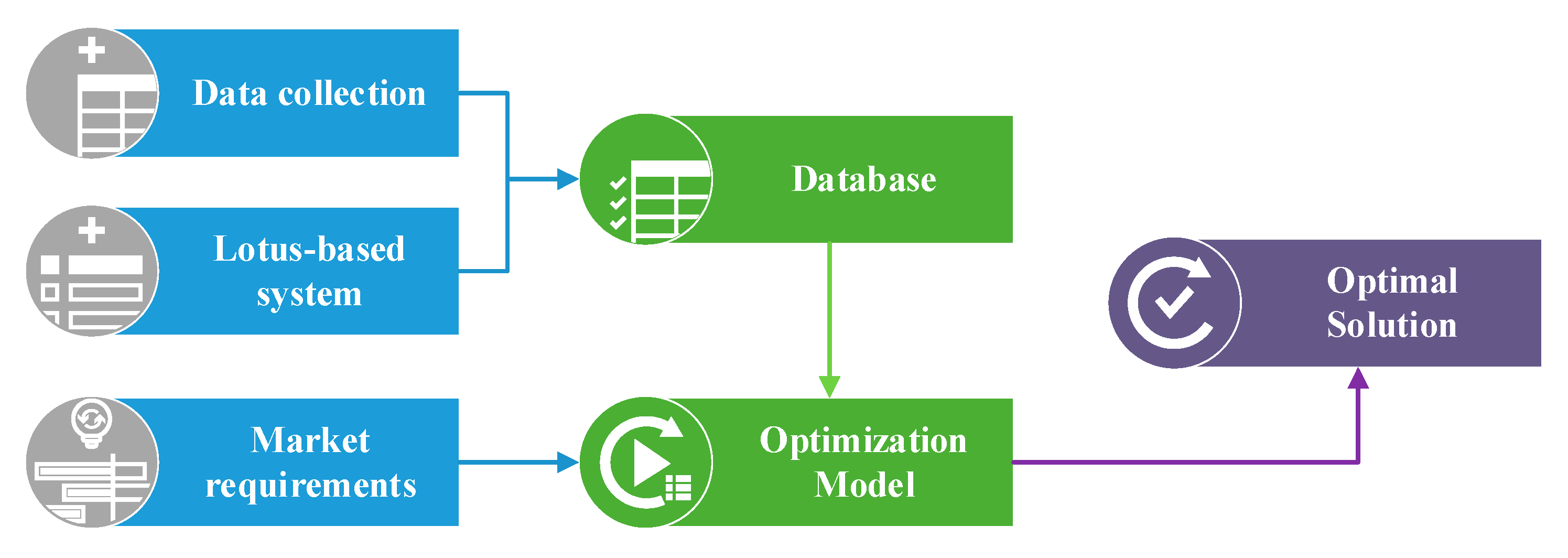

2. Problem Definition

2.1. Definition of the Optimization Problem

| LB: Limited material cost ($) | LP: Total limited labor-working days |

| ci: Unit price of ith material ti | ti: Standard hours to finish ith material |

| dj: Weight of jth category of material | xij: Rate of ith material in jth category |

| zj: The Lotus scores obtained in jth category of the material. | |

| N(j): the maximum number of categories in the system j. | |

| a%: The percentage corresponding to each criterion of the sustainable materials in the Lotus-based system. | |

| lnj: The minimum rate of jth material based on the requirement of the design. | |

| unj: The maximum rate of jth material based on the requirement of the design. | |

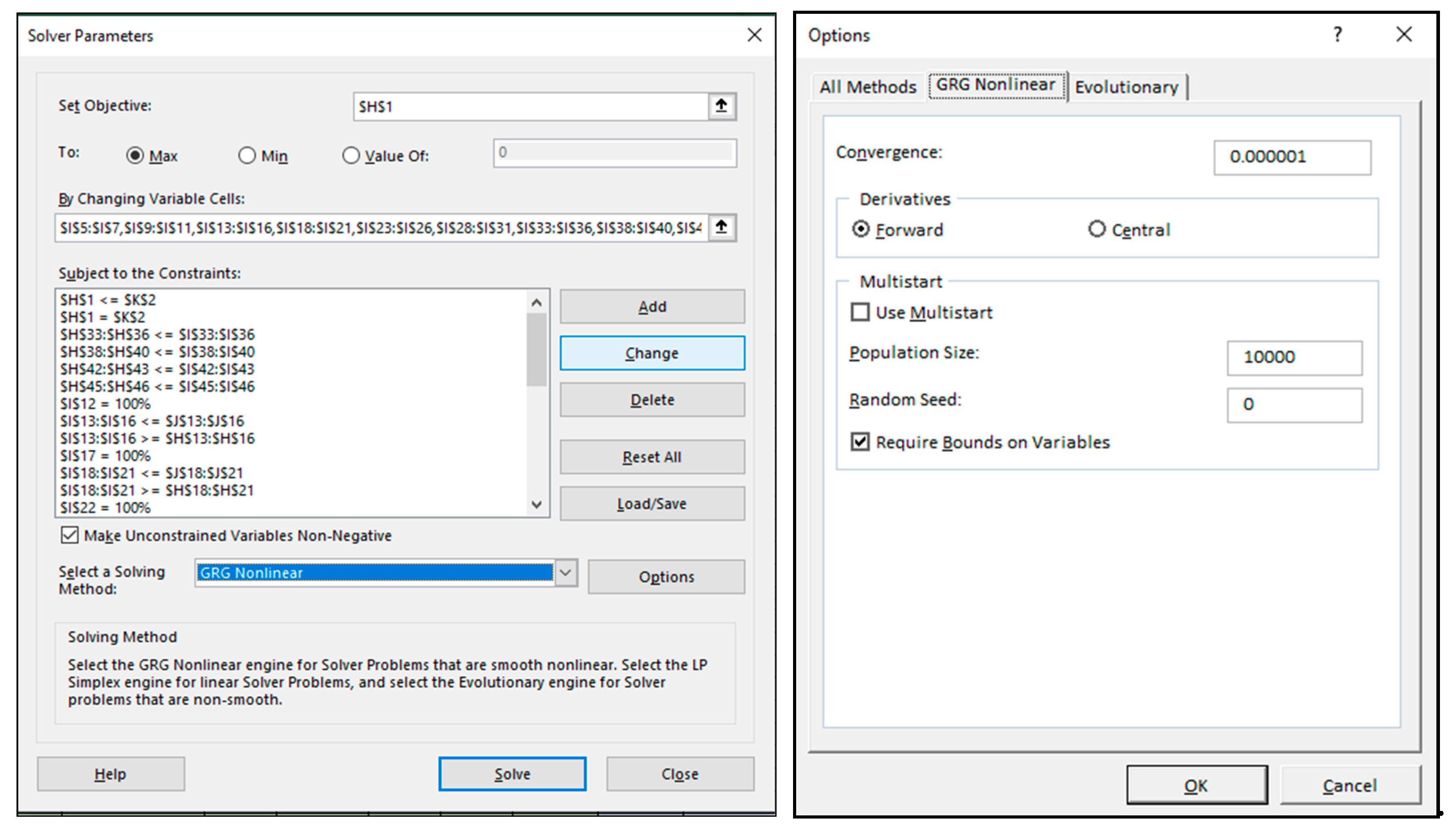

2.2. Generalized Reduced Gradient-Based Nonlinear Optimization Model

3. Case Study

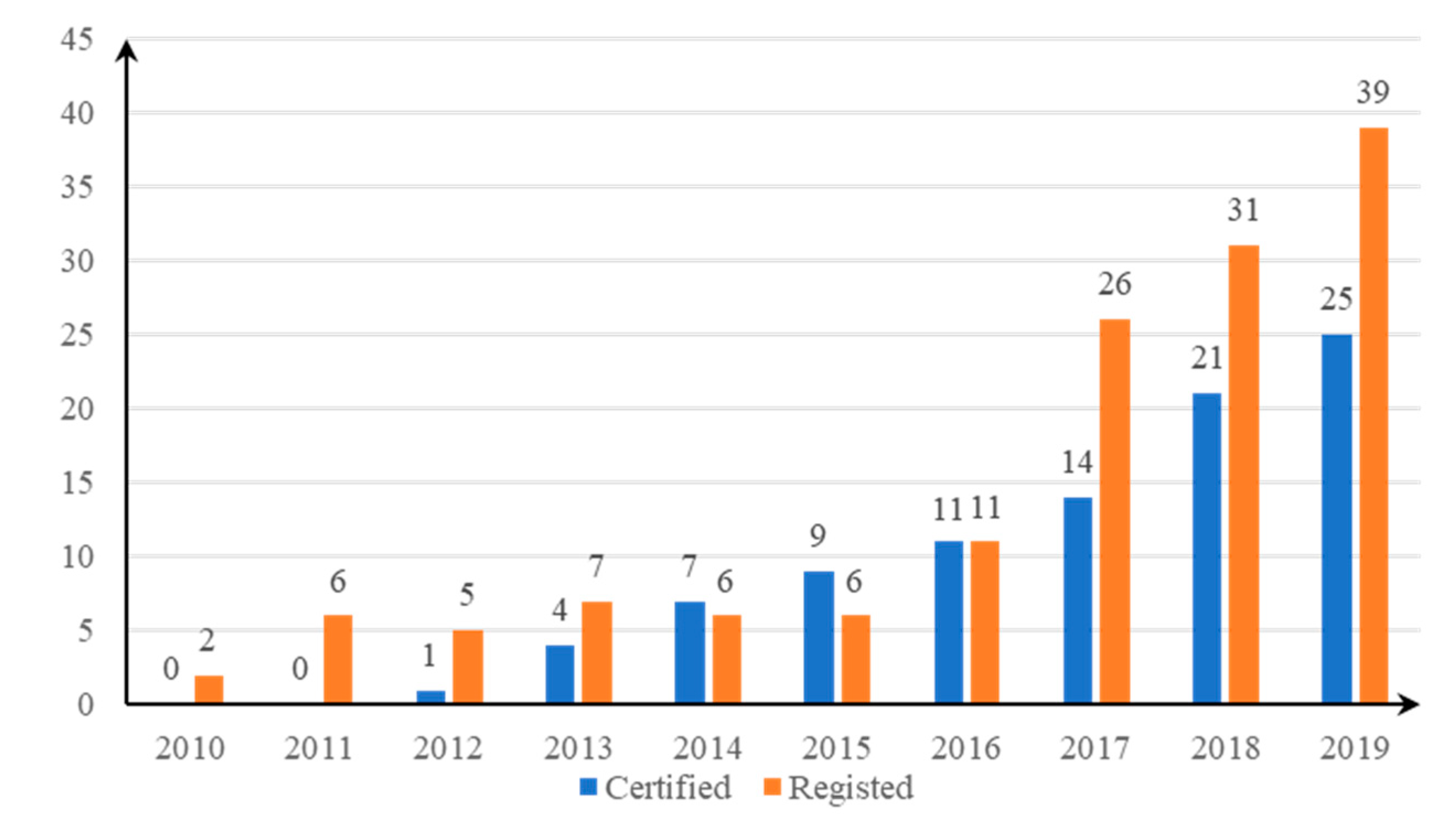

3.1. Lotus-Based Green Building Rating System

3.2. Model Settings

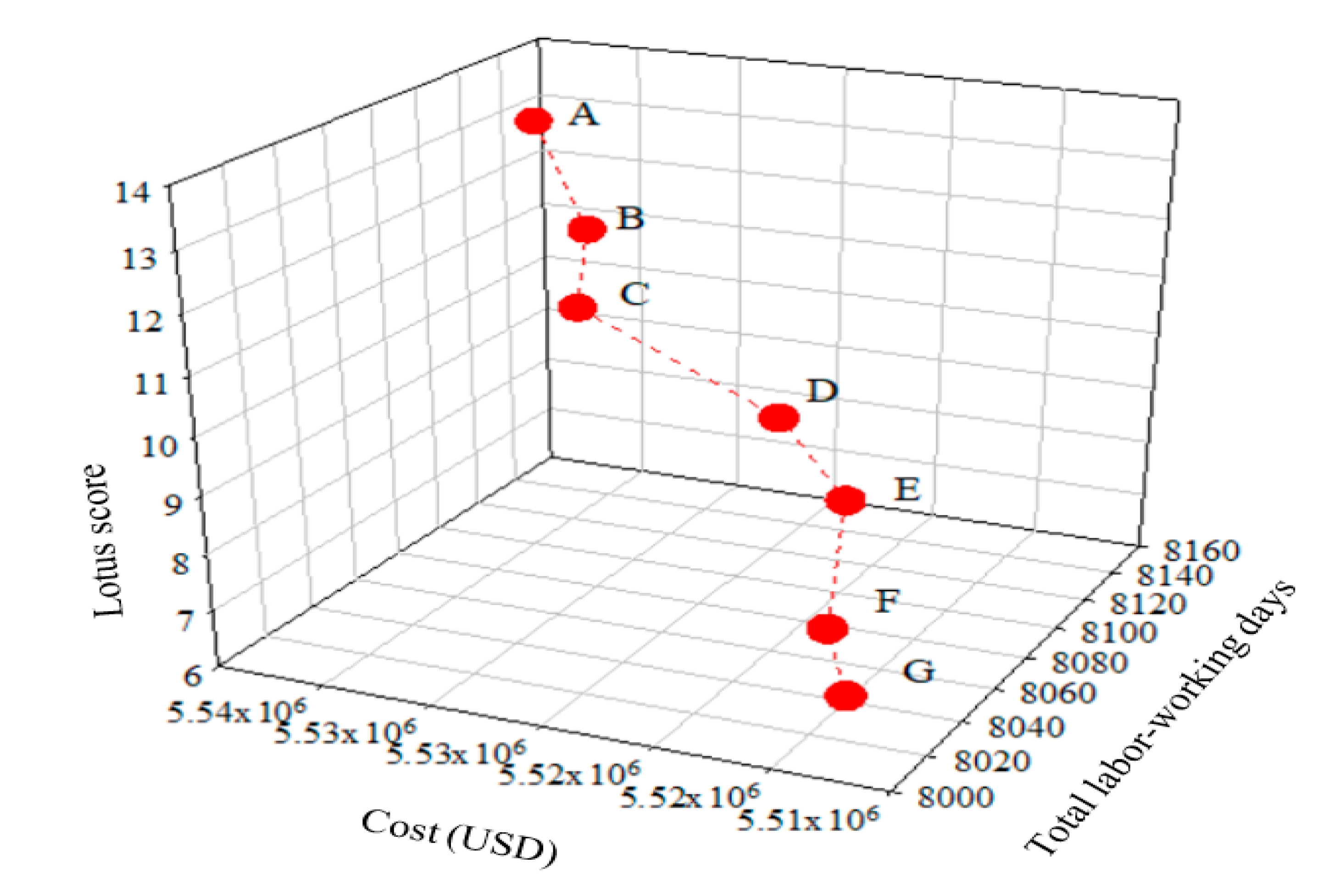

3.3. Analytical Results and Discussion

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Omer, M.A.B.; Noguchi, T. A conceptual framework for understanding the contribution of building materials in the achievement of Sustainable Development Goals (SDGs). Sustain. Cities Soc. 2020, 52, 101869. [Google Scholar] [CrossRef]

- Orsi, A.; Guillén-Guillamón, I.; Pellicer, E. Optimization of Green Building Design Processes: Case Studies within the European Union. Sustainability 2020, 12, 2276. [Google Scholar] [CrossRef]

- Szamosi, Z.; Bodnár, I.; Szepesi, G.L.; Rosas-Casals, M.; Berényi, L. Improved environmental impact in the architecture industry: LCA analysis of an alternative masonry element. Renew. Energy 2020, 147, 1718–1727. [Google Scholar] [CrossRef]

- Pomponi, F.; Moncaster, A. Embodied carbon mitigation and reduction in the built environment—What does the evidence say? J. Environ. Manag. 2016, 181, 687–700. [Google Scholar] [CrossRef]

- Perera, B.A.K.S.; Samarakkody, A.L.; Nandasena, S.R. Managing financial and economic risks associated with high-rise apartment building construction in Sri Lanka. Journal of Financial Management of Property and Construction. J. Financ. Manag. Prop. Constr. 2020, in press. [Google Scholar]

- Madurwar, M.V.; Ralegaonkar, R.V.; Mandavgane, S.A. Application of agro-waste for sustainable construction materials: A review. Constr. Build. Mater. 2013, 38, 872–878. [Google Scholar] [CrossRef]

- Kappenthuler, S.; Seeger, S. From resources to research—A framework for identification and prioritization of materials research for sustainable construction. Mater. Today Sustain. 2020, 7–8, 100009. [Google Scholar] [CrossRef]

- Wahlström, M.; Laine-Yliijoki, J.; Järnström, H.; Kaartinen, T.; Erlandsson, M.; Palm Cousins, A.; Wik, O.; Suer, P.; Oberender, A.; Hjelmar, O.; et al. Environmentally Sustainable Construction Products and Materials—Assessment of Release; Nordic Innovation: Oslo, Norway, 2014. [Google Scholar]

- Kubba, S. (Ed.) Chapter Six—Green Building Materials and Products. In Handbook of Green Building Design and Construction, 2nd ed.; Butterworth-Heinemann: Oxford, UK, 2017; pp. 257–351. [Google Scholar]

- Park, J.; Yoon, J.; Kim, K.-H. Critical Review of the Material Criteria of Building Sustainability Assessment Tools. Sustainability 2017, 9, 186. [Google Scholar] [CrossRef]

- Takano, A.; Pal, S.K.; Kuittinen, M.; Alanne, K.; Hughes, M.; Winter, S. The effect of material selection on life cycle energy balance: A case study on a hypothetical building model in Finland. Build. Environ. 2015, 89, 192–202. [Google Scholar] [CrossRef]

- Sharif, S.A.; Hammad, A. Simulation-Based Multi-Objective Optimization of institutional building renovation considering energy consumption, Life-Cycle Cost and Life-Cycle Assessment. J. Build. Eng. 2019, 21, 429–445. [Google Scholar] [CrossRef]

- Robati, M.; Daly, D.; Kokogiannakis, G. A method of uncertainty analysis for whole-life embodied carbon emissions (CO2-e) of building materials of a net-zero energy building in Australia. J. Clean. Prod. 2019, 225, 541–553. [Google Scholar] [CrossRef]

- Jalaei, F.; Zoghi, M.; Khoshand, A. Life cycle environmental impact assessment to manage and optimize construction waste using Building Information Modeling (BIM). Int. J. Constr. Manag. 2019, 1–18. [Google Scholar] [CrossRef]

- Wang, H.; Chiang, P.-C.; Cai, Y.; Li, C.; Wang, X.; Chen, T.-L.; Wei, S.; Huang, Q. Application of Wall and Insulation Materials on Green Building: A Review. Sustainability 2018, 10, 3331. [Google Scholar] [CrossRef]

- Wang, S.; Tae, S.; Kim, R. Development of a Green Building Materials Integrated Platform Based on Materials and Resources in G-SEED in South Korea. Sustainability 2019, 11, 6532. [Google Scholar] [CrossRef]

- Ruuska, A.; Häkkinen, T. Material Efficiency of Building Construction. Buildings 2014, 4, 266–294. [Google Scholar] [CrossRef]

- Maraveas, C. Production of Sustainable Construction Materials Using Agro-Wastes. Materials 2020, 13, 262. [Google Scholar] [CrossRef]

- Akcay, E.C.; Arditi, D. Desired points at minimum cost in the “Optimize Energy Performance” credit of leed certification. J. Civ. Eng. Manag. 2017, 23, 796–805. [Google Scholar] [CrossRef]

- Akadiri, P.O.; Olomolaiye, P.O.; Chinyio, E.A. Multi-criteria evaluation model for the selection of sustainable materials for building projects. Autom. Constr. 2013, 30, 113–125. [Google Scholar] [CrossRef]

- Takano, A.; Hughes, M.; Winter, S. A multidisciplinary approach to sustainable building material selection: A case study in a Finnish context. Build. Environ. 2014, 82, 526–535. [Google Scholar] [CrossRef]

- Govindan, K.; Shankar, K.M.; Kannan, D. Sustainable material selection for construction industry—A hybrid multi criteria decision making approach. Renew. Sustain. Energy Rev. 2016, 55, 1274–1288. [Google Scholar] [CrossRef]

- Chou, J.-S.; Yeh, K.-C. Life cycle carbon dioxide emissions simulation and environmental cost analysis for building construction. J. Clean. Prod. 2015, 101, 137–147. [Google Scholar] [CrossRef]

- Zolfani, S.H.; Chatterjee, P. Comparative Evaluation of Sustainable Design Based on Step-Wise Weight Assessment Ratio Analysis (SWARA) and Best Worst Method (BWM) Methods: A Perspective on Household Furnishing Materials. Symmetry 2019, 11, 74. [Google Scholar] [CrossRef]

- Doan, D.T.; Ghaffarianhoseini, A.; Naismith, N.; Zhang, T.; Ghaffarianhoseini, A.; Tookey, J. A critical comparison of green building rating systems. Build. Environ. 2017, 123, 243–260. [Google Scholar] [CrossRef]

- Nguyen, H.-T.; Gray, M. A Review on Green Building in Vietnam. Procedia Eng. 2016, 142, 314–321. [Google Scholar] [CrossRef]

- VGBC. Lotus Certification System. Available online: https://vgbc.vn/en/lotus-en/rating-systems/ (accessed on 16 March 2020).

- Kim, H.G.; Kim, S.S. Occupants’ Awareness of and Satisfaction with Green Building Technologies in a Certified Office Building. Sustainability 2020, 12, 2109. [Google Scholar] [CrossRef]

- Rastogi, A.; Choi, J.-K.; Hong, T.; Lee, M. Impact of different LEED versions for green building certification and energy efficiency rating system: A Multifamily Midrise case study. Appl. Energy 2017, 205, 732–740. [Google Scholar] [CrossRef]

- Uğur, L.O.; Leblebici, N. An examination of the LEED green building certification system in terms of construction costs. Renew. Sustain. Energy Rev. 2018, 81, 1476–1483. [Google Scholar] [CrossRef]

- Wu, P.; Song, Y.; Shou, W.; Chi, H.; Chong, H.-Y.; Sutrisna, M. A comprehensive analysis of the credits obtained by LEED 2009 certified green buildings. Renew. Sustain. Energy Rev. 2017, 68, 370–379. [Google Scholar] [CrossRef]

- Awadh, O. Sustainability and green building rating systems: LEED, BREEAM, GSAS and Estidama critical analysis. J. Build. Eng. 2017, 11, 25–29. [Google Scholar] [CrossRef]

- Ferreira, J.; Pinheiro, M.D.; de Brito, J. Portuguese sustainable construction assessment tools benchmarked with BREEAM and LEED: An energy analysis. Energy Build. 2014, 69, 451–463. [Google Scholar] [CrossRef]

- Morris, A.; Zuo, J.; Wang, Y.; Wang, J. Readiness for sustainable community: A case study of Green Star Communities. J. Clean. Prod. 2018, 173, 308–317. [Google Scholar] [CrossRef]

- Illankoon, I.M.C.S.; Tam, V.W.Y.; Le, K.N.; Wang, J.Y. Life cycle costing for obtaining concrete credits in green star rating system in Australia. J. Clean. Prod. 2018, 172, 4212–4219. [Google Scholar] [CrossRef]

- Tham, K.W.; Wargocki, P.; Tan, Y.F. Indoor environmental quality, occupant perception, prevalence of sick building syndrome symptoms, and sick leave in a Green Mark Platinum-rated versus a non-Green Mark-rated building: A case study. Sci. Technol. Built Environ. 2015, 21, 35–44. [Google Scholar] [CrossRef]

- Nguyen, H.-T.; Skitmore, M.; Gray, M.; Zhang, X.; Olanipekun, A.O. Will green building development take off? An exploratory study of barriers to green building in Vietnam. Resour. Conserv. Recycl. 2017, 127, 8–20. [Google Scholar] [CrossRef]

- Zhang, R.-Y.; Liu, Q.; Wang, C.-X. Inventory optimization of building materials under the dual constraints of carbon emissions and stochastic demand. Syst. Sci. Control Eng. 2019, 7, 146–157. [Google Scholar] [CrossRef]

- Baglivo, C.; Congedo, P.M.; Fazio, A. Multi-criteria optimization analysis of external walls according to ITACA protocol for zero energy buildings in the mediterranean climate. Build. Environ. 2014, 82, 467–480. [Google Scholar] [CrossRef]

- Castro-Lacouture, D.; Sefair, J.A.; Flórez, L.; Medaglia, A.L. Optimization model for the selection of materials using a LEED-based green building rating system in Colombia. Build. Environ. 2009, 44, 1162–1170. [Google Scholar] [CrossRef]

- Marzouk, M.; Abdelhamid, M.; Elsheikh, M. Selecting sustainable building materials using system dynamics and ant colony optimization. J. Environ. Eng. Landsc. Manag. 2013, 21, 237–247. [Google Scholar] [CrossRef]

- Park, J.-Y.; Choi, S.-G.; Kim, D.-K.; Jeong, M.-C.; Kong, J.-S. Credit Optimization Algorithm for Calculating LEED Costs. Sustainability 2017, 9, 1607. [Google Scholar] [CrossRef]

- Lasdon, L.S.; Fox, R.L.; Ratner, M.W. Nonlinear optimization using the generalized reduced gradient method. Rev. Française D’automatiqueInform. Rech. Opé Ration. 1974, 8, 73–103. [Google Scholar] [CrossRef]

- Venkataraman, P. Applied Optimization with MATLAB Programming; Wiley Publishing: Hoboken, NJ, USA, 2009. [Google Scholar]

- Frontline Systems Inc. Analytic Solver for Excel. Available online: https://www.solver.com/analytic-solver-platform (accessed on 20 January 2020).

| Countries | Green Building Rating Systems | Sources |

|---|---|---|

| US | Leadership in Energy & Environmental Design (LEED) | [29,30,31] |

| UK | Building Research Establishment Environmental Assessment Method (BREEAM) | [32,33] |

| Australia | Green Star | [34,35] |

| Singapore | Green Mark | [36] |

| Vietnam | Lotus | [26,37] |

| Building Information | Materials | Quanlity | Unit | |

|---|---|---|---|---|

| Type of building | Office building | Steel | 285 | Ton |

| Status | New construction | Cement | 800 | Ton |

| Number of floors | 5 + 1 | Brick | 210 | m3 |

| Number of units | 1 | Wood | 50 | m2 |

| Land area | 950 m2 | Glass | 400 | m2 |

| Gross area (total construction) | 2450 m2 | Wood Flooring | 1715 | m2 |

| Height | 22.2 m | Ceramic Tile Flooring | 490 | m2 |

| Total labor-working days | 9000 days | Roof tile | 125 | m2 |

| Total estimated budget for material | $6,000,000 | Paint | 125 | Lit |

| ID | Materials | Symbol | dj | ci ($) | ti (day) | ri |

|---|---|---|---|---|---|---|

| 1 | Steel 1 | St1 | 285 (T) | 13,380 | 3.2 | 1 |

| Steel 2 | St2 | 13,200 | 3.4 | 1 | ||

| Steel 3 | St3 | 14,500 | 2.8 | 0 | ||

| 2 | Cement 1 | Cm1 | 800 (T) | 1065 | 1.1 | 0 |

| Cement 2 | Cm2 | 1200 | 1.3 | 0 | ||

| Cement 3 | Cm3 | 1460 | 1.5 | 1 | ||

| 3 | Brick 1 | Br1 | 210 (m3) | 600 | 2.4 | 0 |

| Brick 2 | Br2 | 1000 | 3.1 | 1 | ||

| Brick 3 | Br3 | 800 | 3.5 | 1 | ||

| Brick 4 | Br4 | 1200 | 3.2 | 1 | ||

| 4 | Wood 1 | W1 | 50 (m3) | 880 | 1.4 | 1 |

| Wood 2 | W2 | 1650 | 1.6 | 1 | ||

| Wood 3 | W3 | 3000 | 1.25 | 0 | ||

| Wood 4 | W4 | 4500 | 1.3 | 0 | ||

| 5 | Glass 1 | Gl1 | 400 (m2) | 620 | 0.7 | 0 |

| Glass 2 | Gl2 | 1000 | 0.85 | 1 | ||

| Glass 3 | Gl3 | 800 | 1 | 1 | ||

| Glass 4 | Gl4 | 630 | 0.6 | 0 | ||

| 6 | Flooring 1 | Fl1 | 1715 (m2) | 170 | 2.3 | 1 |

| Flooring 2 | Fl2 | 180 | 2.5 | 1 | ||

| Flooring 3 | Fl3 | 230 | 1.8 | 0 | ||

| 7 | Ceramic Brick 1 | GS1 | 490 (m2) | 191 | 1.9 | 0 |

| Green Brick 2 | GS2 | 220 | 2.3 | 1 | ||

| 8 | Tile 1 | T1 | 125 (m2) | 15 | 1.4 | 0 |

| Tile 2 | T2 | 142 | 1.7 | 1 | ||

| 9 | Paint 1 | P1 | 125 (lit) | 212 | 1.5 | 1 |

| Paint 2 | P2 | 221 | 1.4 | 1 | ||

| Paint 3 | P3 | 160 | 1.9 | 0 | ||

| Paint 4 | P4 | 151 | 1.7 | 0 |

| Catalogy | Position | Building Components | Intention | Note | Symbol | Description | Score |

|---|---|---|---|---|---|---|---|

| M1 | Material | Building structure | Rate of structure materials that is sustainable | * Rapidly renewable materials (grown and harvested within 10 years) * Reusable materials * Materials with at least 10% recycled pre-consumer components or 5% post-consumer recycled components * Autoclave materials | M1.1 | 40% of the structure materials are sustainable | 1 |

| M1.2 | 60% of the structure materials are sustainable | 2 | |||||

| M1.3 | 80% of the structure materials are sustainable | 3 | |||||

| M2 | Material | Non-structural walls | Rate of non-structural walls that is sustainable | * Rapidly renewable materials (grown and harvested within 10 years) * Reusable materials * Materials with at least 10% recycled pre-consumer components or 5% post-consumer recycled components * Autoclave materials | M2.1 | 40% of the non-structural walls are sustainable | 1 |

| M2.2 | 60% of the non-structural walls are sustainable | 2 | |||||

| M2.3 | 80% of the non-structural walls are sustainable | 3 | |||||

| M3 | Material | Windows and doors | The ratio of windows and doors made up of sustainable materials | * Rapidly renewable materials (grown and harvested within 10 years) * Reusable materials * Materials with at least 10% recycled pre-consumer components or 5% post-consumer recycled components * Autoclave materials | M3.1 | 40% of windows and doors are made up of sustainable materials | 1 |

| M3.2 | 80% of windows and doors are made up of sustainable materials | 2 | |||||

| M4 | Material | Flooring | Rate of flooring materials that is sustainable | * Flooring materials: Carpets, wood, plastic floors, hard floors * Exterior Concrete | M4.1 | 40% of the flooring materials is sustainable | 1 |

| M4.2 | 80% of the flooring materials is sustainable | 2 | |||||

| M5 | Material | Roofing | Rate of roofing materials that is sustainable | * Rapidly renewable materials (grown and harvested within 10 years) * Reusable materials * Materials with at least 10% recycled pre-consumer components or 5% post-consumer recycled components * Autoclave materials | M5.1 | 40% of the roofing materials is sustainable | 1 |

| M5.2 | 80% of the roofing materials is sustainable | 2 | |||||

| H4 | Limiting VOC emissions | Paint and Overlay | Choose products with low VOC emissions | * Being recognized as a product with low VOC level (Green label, ISO) * Having a VOC level lower than the prescribed level of Vietnamese Standards | H4 | 50% of the material with a low VOC level | 1 |

| Category | Symbols | xij | zj | Category | Symbols | xij | zj |

|---|---|---|---|---|---|---|---|

| M1 | St1 | 30% | 3 | M2 | Br1 | 24% | 3 |

| St2 | 69% | Br2 | 13% | ||||

| St3 | 1% | Br3 | 52% | ||||

| Cm1 | 35% | Br4 | 11% | ||||

| Cm2 | 41% | M4 | Fl1 | 99% | 2 | ||

| Cm3 | 24% | Fl2 | 1% | ||||

| Br1 | 21% | Fl3 | 0% | ||||

| Br2 | 47% | GS1 | 79% | ||||

| Br3 | 15% | GS2 | 21% | ||||

| Br4 | 18% | M5 | T1 | 70% | 2 | ||

| M3 | Gl1 | 40% | 2 | T2 | 30% | ||

| Gl2 | 31% | H4 | P1 | 21% | 1 | ||

| Gl3 | 17% | ||||||

| Gl4 | 12% | P2 | 26% | ||||

| W1 | 61% | ||||||

| W2 | 37% | P3 | 1% | ||||

| W3 | 0% | ||||||

| W4 | 1% | P4 | 51% | ||||

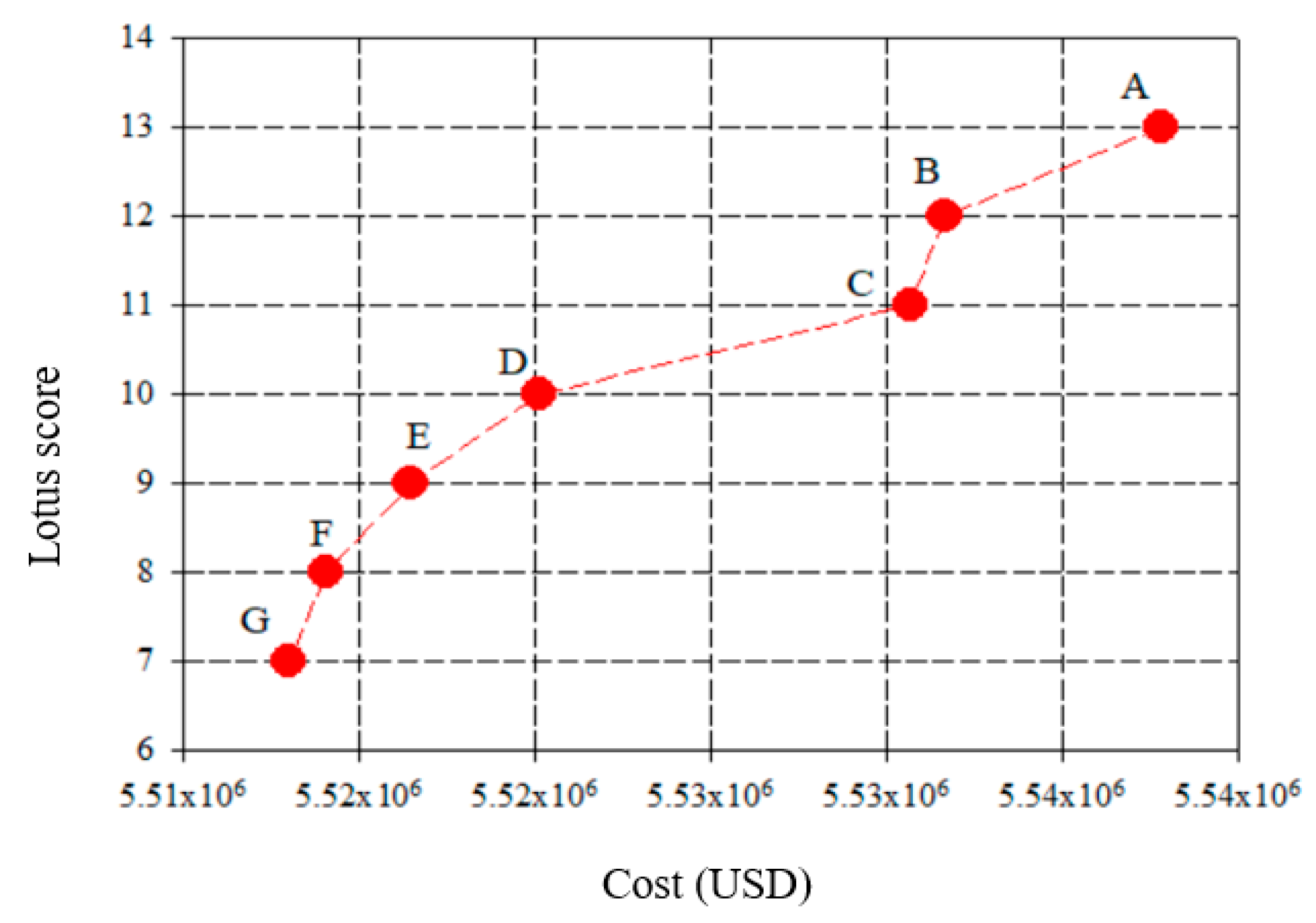

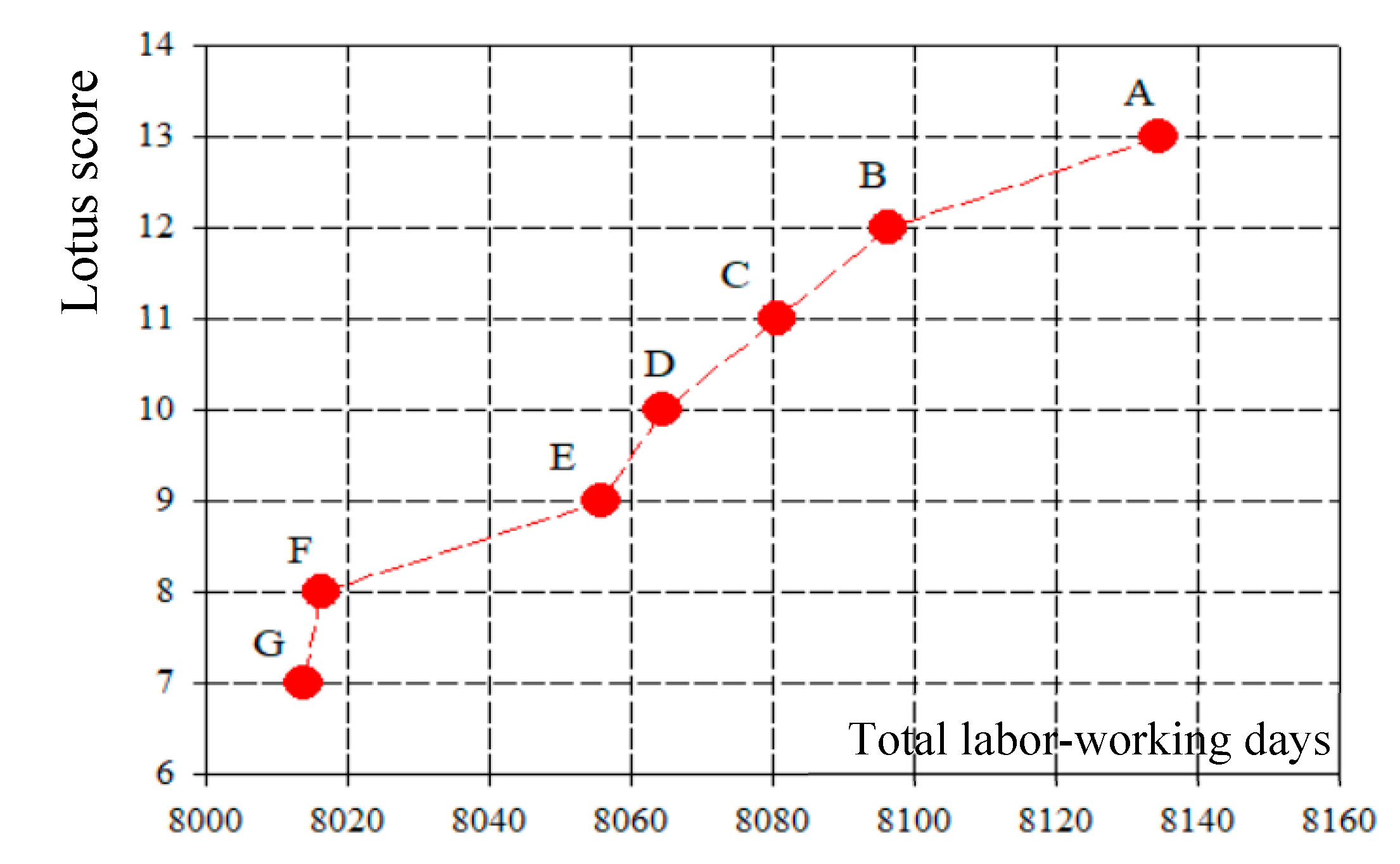

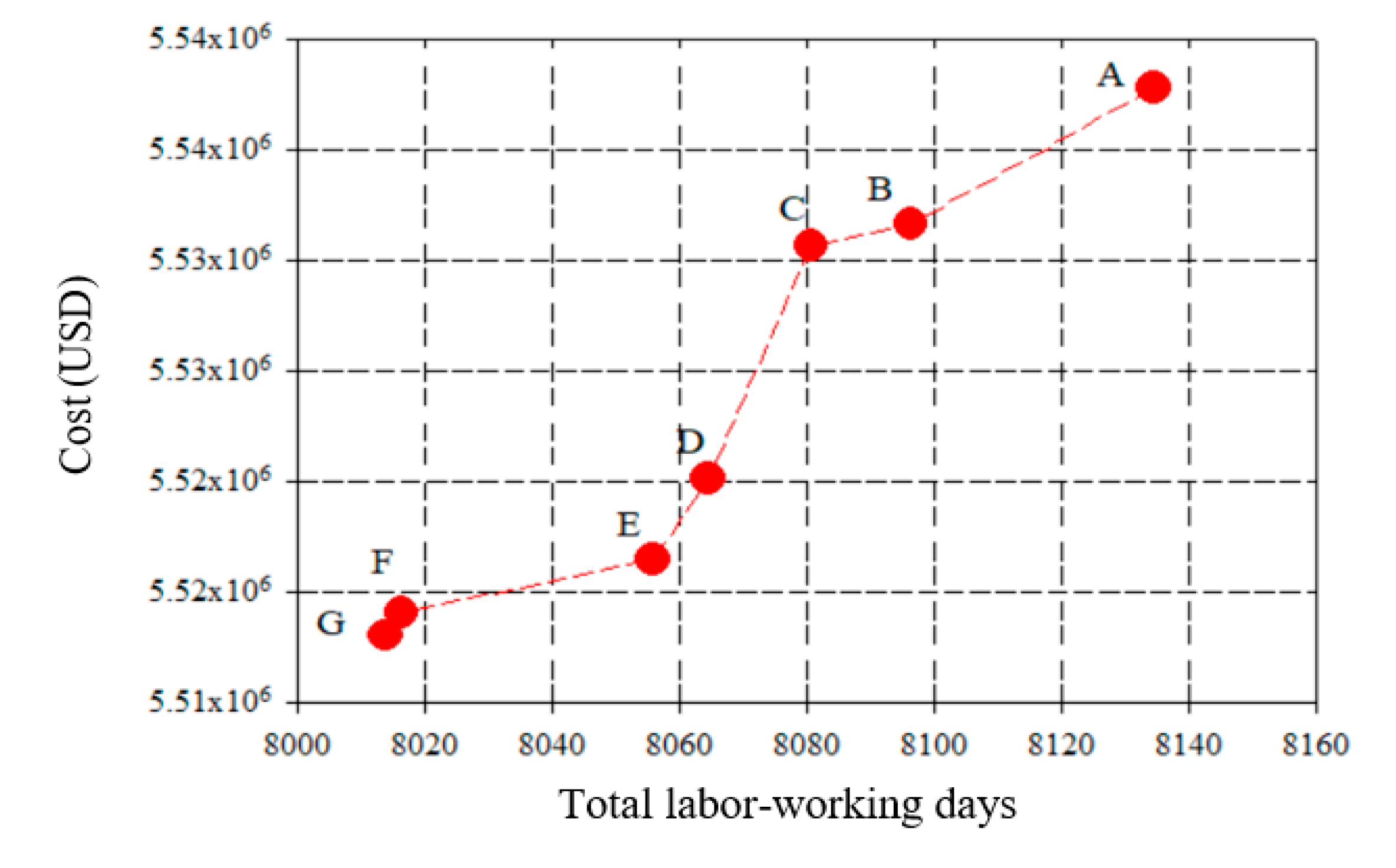

| Lotus score (A) | 13 | ||||||

| Total project cost ($) | 5,537,826 | ||||||

| Total labor-working days | 8135 | ||||||

| Lotus score: 12 points (B) | Lotus score: 11 points (C) | Lotus score: 10 points (D) | |||||||

| Total cost: $5,531,654 | Total cost: $5,530,665 | Total cost: $5,520,122 | |||||||

| Total labor-working days: 8096 | Total labor-working days: 8080 | Total labor-working days: 8064 | |||||||

| Category | Symbols | xij | zj | Symbols | xij | zj | Symbols | xij | zj |

| M1 | St1 | 30% | 3 | St1 | 30% | 3 | St1 | 30% | 3 |

| St2 | 70% | St2 | 70% | St2 | 70% | ||||

| St3 | 1% | St3 | 1% | St3 | 1% | ||||

| Cm1 | 35% | Cm1 | 35% | Cm1 | 35% | ||||

| Cm2 | 41% | Cm2 | 41% | Cm2 | 41% | ||||

| Cm3 | 24% | Cm3 | 24% | Cm3 | 24% | ||||

| Br1 | 21% | Br1 | 21% | Br1 | 21% | ||||

| Br2 | 47% | Br2 | 47% | Br2 | 47% | ||||

| Br3 | 15% | Br3 | 15% | Br3 | 15% | ||||

| Br4 | 18% | Br4 | 18% | Br4 | 18% | ||||

| M2 | Br1 | 50% | 2 | Br1 | 59% | 1 | Br1 | 79% | 0 |

| Br2 | 18% | Br2 | 28% | Br2 | 5% | ||||

| Br3 | 22% | Br3 | 6% | Br3 | 9% | ||||

| Br4 | 10% | Br4 | 7% | Br4 | 7% | ||||

| M3 | Gl1 | 40% | 2 | Gl1 | 40% | 2 | Gl1 | 40% | 2 |

| Gl2 | 31% | Gl2 | 31% | Gl2 | 31% | ||||

| Gl3 | 17% | Gl3 | 17% | Gl3 | 17% | ||||

| Gl4 | 12% | Gl4 | 12% | Gl4 | 12% | ||||

| W1 | 61% | W1 | 61% | W1 | 61% | ||||

| W2 | 37% | W2 | 37% | W2 | 37% | ||||

| W3 | 0% | W3 | 0% | W3 | 0% | ||||

| W4 | 1% | W4 | 1% | W4 | 1% | ||||

| M4 | Fl1 | 99% | 2 | Fl1 | 99% | 2 | Fl1 | 99% | 2 |

| Fl2 | 1% | Fl2 | 1% | Fl2 | 1% | ||||

| Fl3 | 0% | Fl3 | 0% | Fl3 | 0% | ||||

| GS1 | 79% | GS1 | 79% | GS1 | 79% | ||||

| GS2 | 21% | GS2 | 21% | GS2 | 21% | ||||

| M5 | T1 | 70% | 2 | T1 | 70% | 2 | T1 | 70% | 2 |

| T2 | 30% | T2 | 30% | T2 | 30% | ||||

| H4 | P1 | 21% | 1 | P1 | 21% | 1 | P1 | 21% | 1 |

| P2 | 26% | P2 | 26% | P2 | 26% | ||||

| P3 | 1% | P3 | 1% | P3 | 1% | ||||

| P4 | 51% | P4 | 51% | P4 | 51% | ||||

| Lotus score: 9 points (E) | Lotus score: 8 points (F) | Lotus score: 7 points (G) | |||||||

| Total cost: $5,516,463 | Total cost: $5,514,052 | Total cost: $5,513,011 | |||||||

| Total labor-working days: 8055 | Total labor-working days: 8016 | Total labor-working days: 8013 | |||||||

| Category | Symbols | xij | zj | Symbols | xij | zj | Symbols | xij | zj |

| M1 | St1 | 30% | 3 | St1 | 30% | 3 | St1 | 30% | 3 |

| St2 | 70% | St2 | 70% | St2 | 70% | ||||

| St3 | 1% | St3 | 1% | St3 | 1% | ||||

| Cm1 | 35% | Cm1 | 35% | Cm1 | 35% | ||||

| Cm2 | 41% | Cm2 | 41% | Cm2 | 41% | ||||

| Cm3 | 24% | Cm3 | 24% | Cm3 | 24% | ||||

| Br1 | 21% | Br1 | 21% | Br1 | 21% | ||||

| Br2 | 47% | Br2 | 47% | Br2 | 47% | ||||

| Br3 | 15% | Br3 | 15% | Br3 | 15% | ||||

| Br4 | 18% | Br4 | 18% | Br4 | 18% | ||||

| M2 | Br1 | 79% | 0 | Br1 | 79% | 0 | Br1 | 79% | 0 |

| Br2 | 5% | Br2 | 5% | Br2 | 5% | ||||

| Br3 | 9% | Br3 | 9% | Br3 | 9% | ||||

| Br4 | 7% | Br4 | 7% | Br4 | 7% | ||||

| M3 | Gl1 | 40% | 2 | Gl1 | 40% | 2 | Gl1 | 40% | 2 |

| Gl2 | 31% | Gl2 | 31% | Gl2 | 31% | ||||

| Gl3 | 17% | Gl3 | 17% | Gl3 | 17% | ||||

| Gl4 | 12% | Gl4 | 12% | Gl4 | 12% | ||||

| W1 | 61% | W1 | 61% | W1 | 61% | ||||

| W2 | 37% | W2 | 37% | W2 | 37% | ||||

| W3 | 0% | W3 | 0% | W3 | 0% | ||||

| W4 | 1% | W4 | 1% | W4 | 1% | ||||

| M4 | Fl1 | 99% | 2 | Fl1 | 99% | 1 | Fl1 | 99% | 1 |

| Fl2 | 1% | Fl2 | 1% | Fl2 | 1% | ||||

| Fl3 | 0% | Fl3 | 0% | Fl3 | 0% | ||||

| GS1 | 79% | GS1 | 99% | GS1 | 99% | ||||

| GS2 | 21% | GS2 | 1% | GS2 | 1% | ||||

| M5 | T1 | 93% | 1 | T1 | 93% | 1 | T1 | 100% | 0 |

| T2 | 7% | T2 | 7% | T2 | 0% | ||||

| H4 | P1 | 21% | 1 | P1 | 21% | 1 | P1 | 21% | 1 |

| P2 | 26% | P2 | 26% | P2 | 26% | ||||

| P3 | 1% | P3 | 1% | P3 | 1% | ||||

| P4 | 51% | P4 | 51% | P4 | 51% | ||||

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pham, A.-D.; Nguyen, Q.T.; Luong, D.L.; Truong, Q.C. The Development of a Decision Support Model for Eco-Friendly Material Selection in Vietnam. Sustainability 2020, 12, 2769. https://doi.org/10.3390/su12072769

Pham A-D, Nguyen QT, Luong DL, Truong QC. The Development of a Decision Support Model for Eco-Friendly Material Selection in Vietnam. Sustainability. 2020; 12(7):2769. https://doi.org/10.3390/su12072769

Chicago/Turabian StylePham, Anh-Duc, Quang Trung Nguyen, Duc Long Luong, and Quynh Chau Truong. 2020. "The Development of a Decision Support Model for Eco-Friendly Material Selection in Vietnam" Sustainability 12, no. 7: 2769. https://doi.org/10.3390/su12072769

APA StylePham, A.-D., Nguyen, Q. T., Luong, D. L., & Truong, Q. C. (2020). The Development of a Decision Support Model for Eco-Friendly Material Selection in Vietnam. Sustainability, 12(7), 2769. https://doi.org/10.3390/su12072769