3.1. Raw Materials and Generations

Regarding first generation biofuels, having a high sugar or starch content is the most important factor for ethanol, while a high oil content is necessary for biodiesel fuel. Due to this, there is a conflict of interest with human nutritional needs, as mostly grains are used for production. What is essential is to determine the allocation of resources either for eating or travelling. Therefore, it is vital to find other raw materials for biofuel production in order to not jeopardize food security. The competition between biofuels and food security has been deeply analyzed by Koizumi [

11,

12]. One of his major findings was that even cellulosic-based biofuel production competes with food-related demand; therefore, this affects food security.

A common characteristic of the latest biofuel generations is that their raw materials can hardly be used for food industry purposes (e.g., straw, liquid manure or lignocellulose). However, this generates competition with other industries, e.g., cellulose is an important component for the textile and paper industries. The use of waste materials or by-products is an acceptable solution, because they provide an alternative method for biofuel production and help deal with waste management [

13].

The fundamental problem with further biofuel generations is that they are immature and therefore more expensive than first generation production at this moment. This includes algae-based production which requires no land; therefore, it could be an ideal solution for biofuel production.

Table 1 gives an overview of the biofuel generations; it includes possible feedstocks, conversion processes, and carbon balance.

For the first and the second generations, the conversion processes are fermentation for ethanol and transesterification for biodiesel, all with positive carbon balance outcomes. Beginning with the 3rd generation, synthesis is the main conversion process, and the carbon balance may become negative which means that these processes are at least CO2 free.

3.2. Biofuel Markets

Although the production of biofuels is continuously growing, it should be noted that they compose only 2.3%–2.5% of the global oil use on average [

16]. This percentage would be higher if only fuels are considered; however, this is limited by the blending rates. Seventy-one million hectares of land are allocated to biofuel production worldwide, where ethanol represents 62% of it while biodiesel raw materials account for 24% [

17].

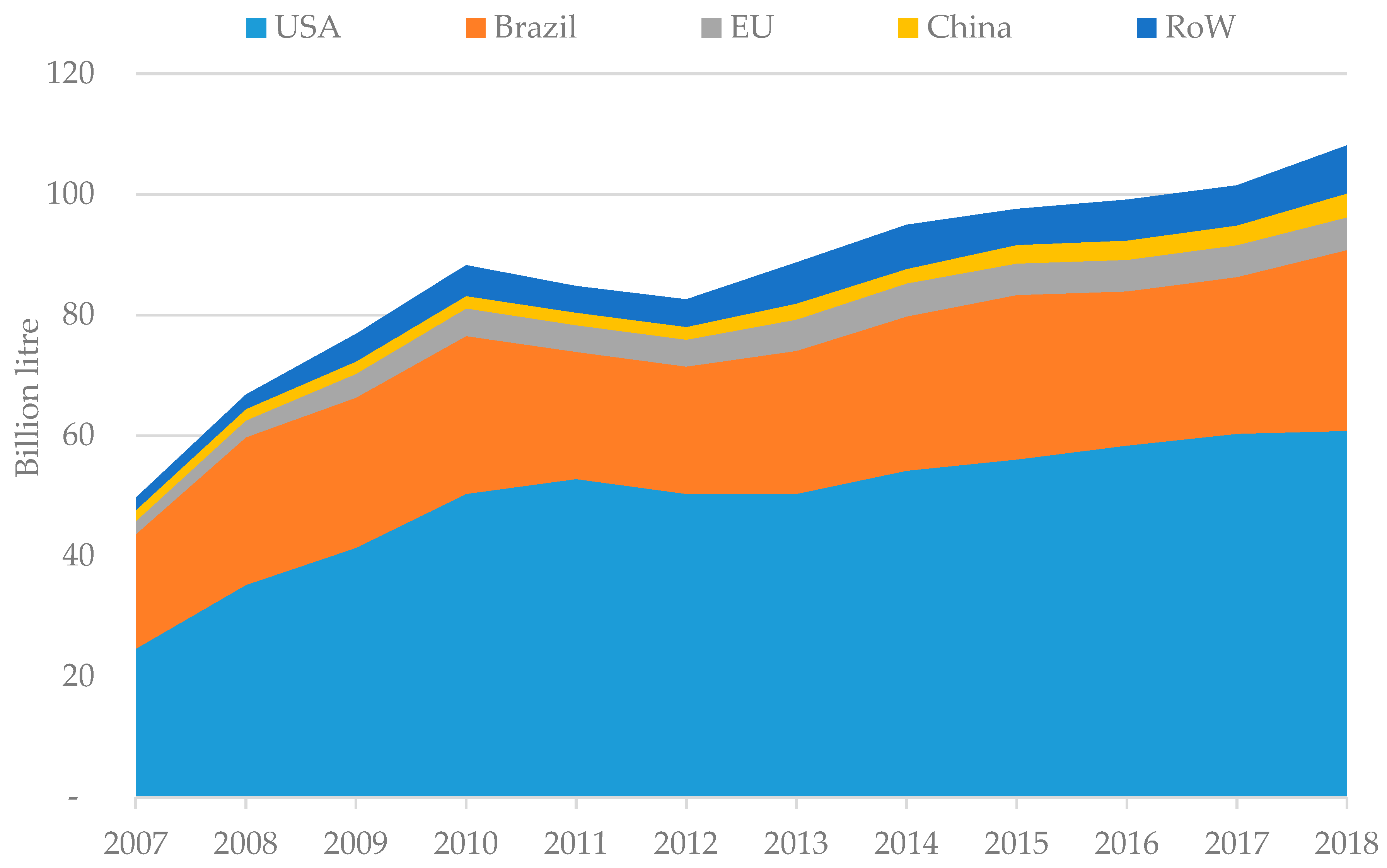

There was only one decrease in the production of ethanol during the analyzed period, from 2010 to 2012 due basically to the poor sugarcane harvest in Brazil as well as the high world sugar prices [

18]. The Brazilian production started to recover only after 2012 (

Figure 1). The major ethanol producer in the world is the USA, followed by Brazil, the EU, and China. All the other producers are represented by the rest of the world (RoW).

According to the RFA database, the share of the USA varied between 50% (2007) and 62% (2012), while it was between 84% (2013) and 89% (2008) when combined with Brazil. The EU had only a 5% share, while the Chinese production accounted for 3%. Based on the projections of the OECD and the FAO, the major producers will be the same and the following changes can be anticipated on the global ethanol market by 2027 [

6]:

The USA will remain the major producer; however, its market share will decrease to 46%;

Brazil will not only keep its second position, but also strengthen it (25% market share);

The EU’s production will not remarkably change, resulting in a bit lower market share;

China is going to increase its production and reach 8% market share by 2027;

Otherwise, Thailand and India are going to increase their ethanol production and claim 2% global market share.

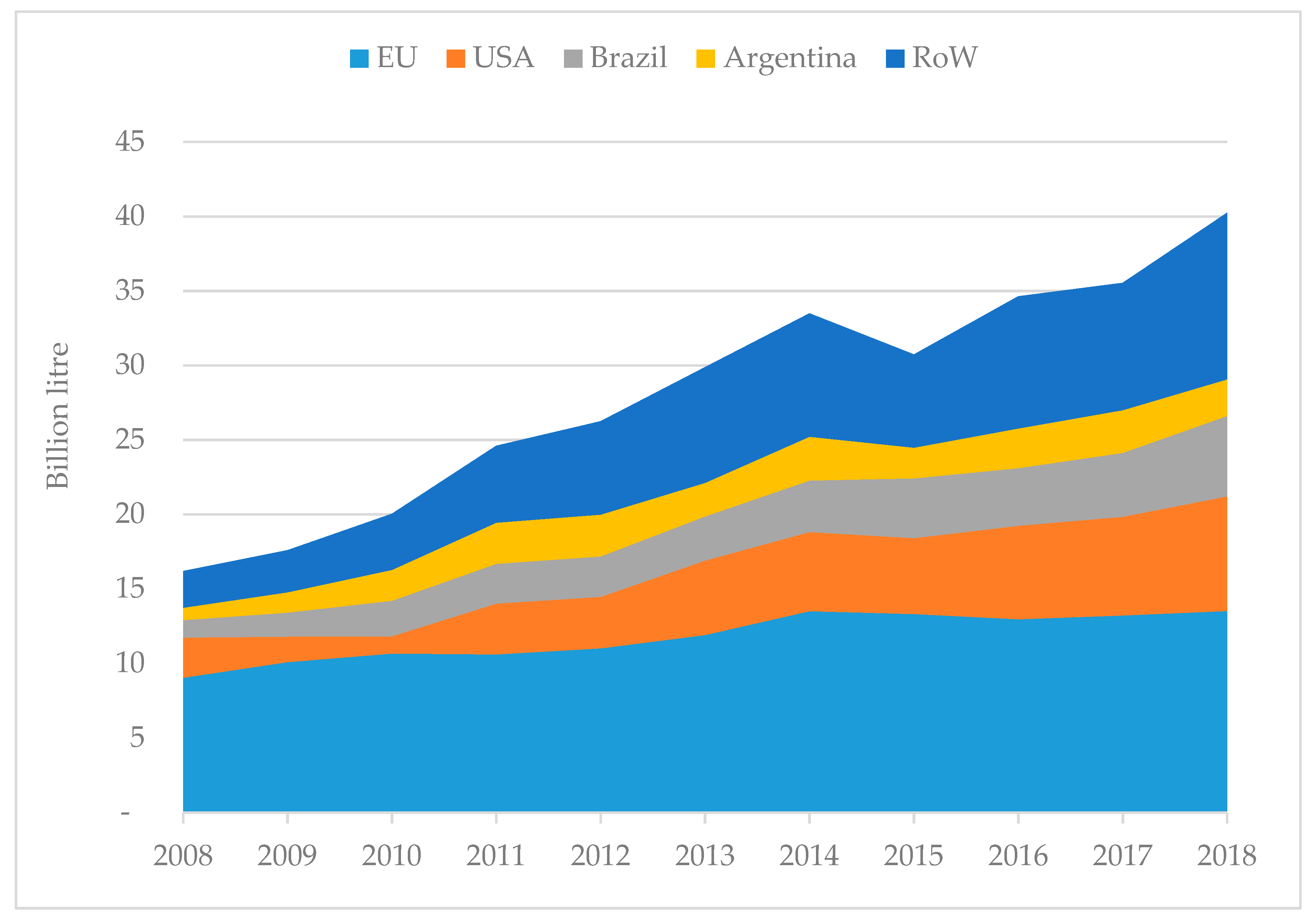

Compared to the ethanol market, the biodiesel market is smaller in terms of production and less concentrated (

Figure 2). The EU is the leading producer with a continuously decreasing market share which went down from 56% to 34% during the analyzed period. The EU is followed by the USA with a market share of 19% in 2018. Brazil and Argentina were able to produce significantly more which resulted in higher market share (13% and 6%, respectively).

According to the OECD and the FAO, even the rank of major producers will change by 2027. The main elements of the anticipated transformation of the global biodiesel market are [

6]:

The EU will keep its leading position but with a decreasing share (34% in 2027);

The EU will still be followed by the USA (17%) and Brazil (14%);

Indonesia is going to take 4th place with an 11% market share;

Argentina and Thailand will have a perceptible production difference from the rest of the world (8% and 5%, respectively).

3.3. Biofuel Production

3.1.1. Ethanol Production

As a matter of first-generation techniques, ethanol can be produced by dry- and wet-milling processes.

Table 2 gives a comparison of them.

As seen in the table above, dry-milling process results in a 10% higher ethanol yield, and the major co-product is DDGS (distiller’s dried grains with solubles). This can be produced out of the highly perishable DGS (distiller’s grains with solubles) by drying. However, drying DGS requires a huge amount of energy, but it extends its tenability; therefore, there is no need for it to be used strictly locally. DDGS is a popular feedstock in the USA, having a well-developed market. The DDGS price is closely correlated with the price of corn, fluctuating around 90% of the price of corn [

22].

The wet-milling process results in lower ethanol yields, but co-products are more valuable. Corn gluten meal and corn gluten feed can be used for feeding. They have a 48%–60% and 18%–22% dry content, respectively. Corn germ oil is used by the food and cosmetics industry. But it should be noted that the continuous development of the processing techniques (optimized temperature, more efficient yeast, IT controlled processes) increases the ethanol yields at the expense of the co-products. Technically, this means smaller amounts of DDGS in the dry-milling process; however, its protein content becomes higher therefore becoming more valuable.

The major economic question of ethanol production (or biofuel production in general) is whether it is profitable to produce it or not. As it is the main substitute of normal gasoline, ethanol production prices should be compared to oil prices.

Table 3 shows the production cost of ethanol in the major producer countries.

Based on production costs, Brazil can produce the cheapest ethanol. This is strengthened by the flexible production of the plants, as they can either produce ethanol or sugar, depending on which is more profitable. China and the USA use mostly corn, while in the European Union, other cereals (e.g., wheat) are also used. According to the latest oil prices (Brent oil is around 59 USD/barrel), ethanol production can be profitable under approximately 37 cents/liter production, giving around 37% more room for the Brazilian production. Under the current oil prices, the Chinese, US, and EU’s production are not price competitive after the weighting.

The majority of the cost for ethanol production comes from the price of raw materials. According to the CARD data [

27]; its share was an average of 59% of the total ethanol production cost (corn-based ethanol, dry-milling process for a representative Iowa corn ethanol plant) in the last 13 years (2007–2019). Therefore, it is important to be aware of how much corn can be harvested on a hectare.

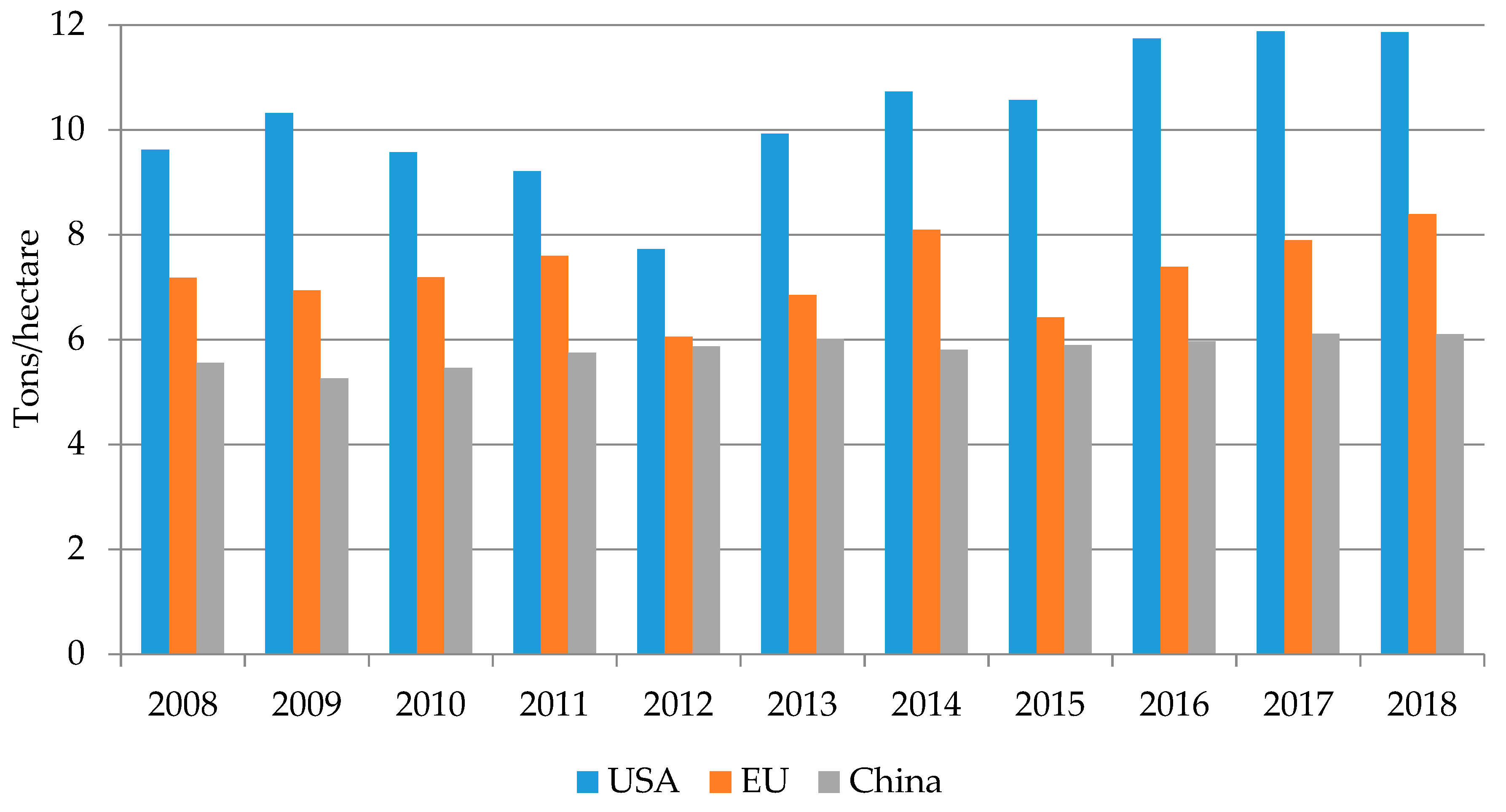

Figure 3 shows corn yields in China, the EU, and the USA from 2008 to 2018.

As seen in the figure above, the USA enjoys extremely high corn yields which is on average 94% higher than the Chinese values and 41% higher than the yields in the EU. This, ceteris paribus, may result in American cost competitiveness over the major corn-based ethanol producers. Overall, commodity yields show an increasing trend; therefore, ethanol production costs are expected to be lower in the future. This is further strengthened by the fact that the maize production area increased by 20% during the analyzed period [

7]. However, ethanol is only one pillar of the total demand besides the food and feed purposes.

3.1.2. Biodiesel Production

In the case of biodiesel production, oil can be extracted by cold and hot press extraction and additional transesterification processes. Large-scale production uses only the latter due to the much higher amount of oil. The efficiency of cold crushers is about 80% while hot press extraction (hexane crusher process) is 99% [

28]. The remaining seed parts can be used for feeding, and their oil content depends on which extraction method was used. The meal has almost no oil content in the case of the hot extraction.

Production costs vary among the countries. Brazil is again the most cost-efficient producer in the world based on the lower boundary; however, the gap between the biodiesel production costs is narrower compared to ethanol. Despite its lower oil content (only 18%), soybeans are mostly used for biodiesel production in Brazil, because the remaining meal can be easily exported or used for feeding purposes [

29]. Soybean is also the major raw material of biodiesel production in the USA, where significant genetic engineering occurred, in order to increase both the yields and oil content. In order to comply with biodiesel standards, rapeseed mostly is used in Europe.

Table 4 contains the production costs of biodiesel in the major producer countries.

Biodiesel production costs are much higher than that of ethanol, neither Brazil nor the USA can produce biodiesel at a lower cost than oil. This means that without additional support, tax credit or blending mandate, it would not be profitable to produce biodiesel. The high cost of biodiesel production relates to low reactor efficiency and material/energy loss during the process [

31]. According to the CARD [

32] data from the last 13 years (2007–2019), its share was an average of 75% of the total biodiesel production cost (soybean oil).This is the reason why biodiesel from used vegetable oil can be cheaper, as the raw material costs less than either soybean or rapeseed.

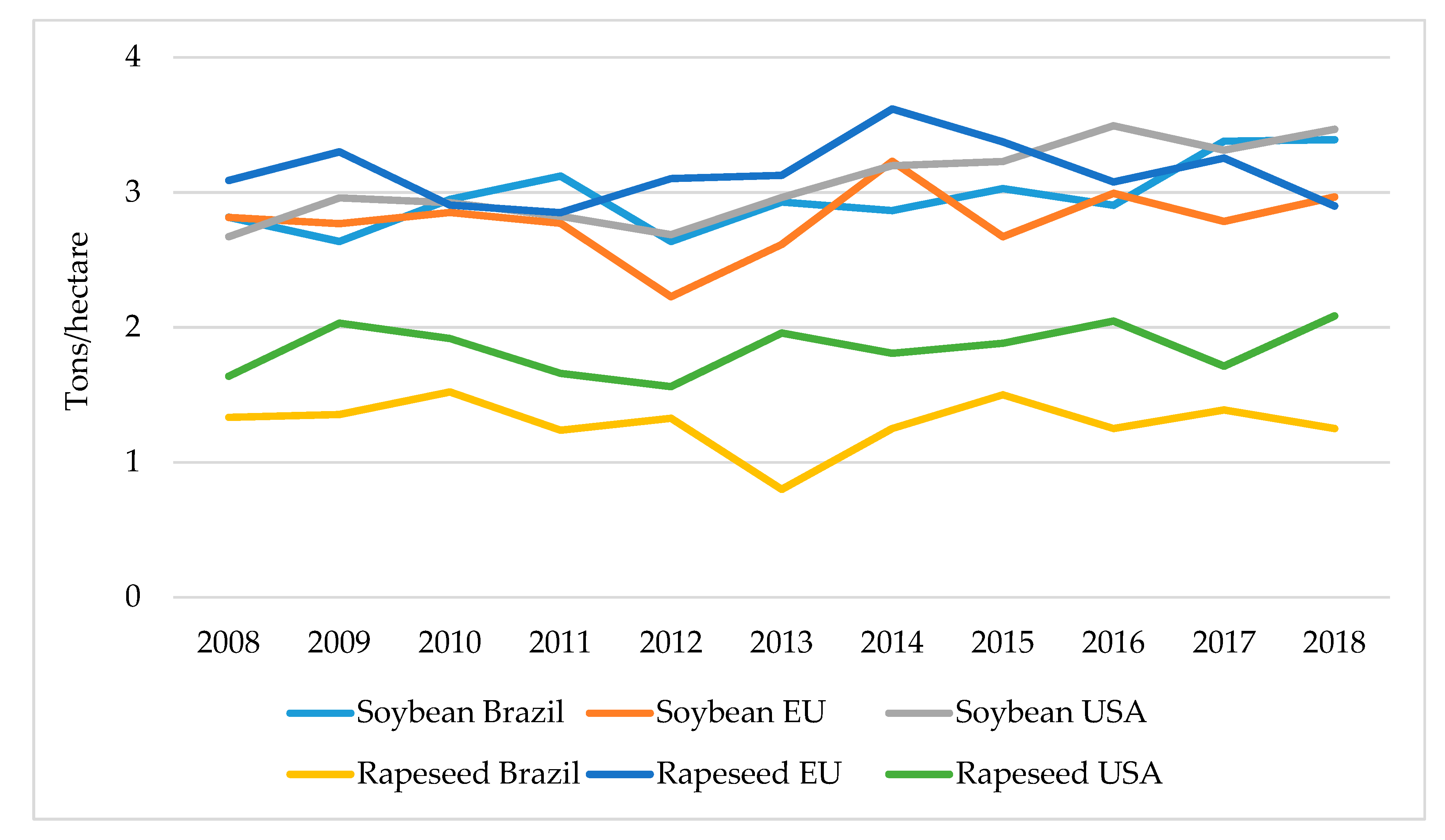

Figure 4 explains why soybean is used on the American continents and why rapeseed is a more common raw material in the EU.

The EU is not self-sufficient in soybean production; it experiences slightly lower yields (e.g., an average of 10.2% compared to the USA). However, rapeseed production is more efficient in the EU compared to either Brazil or the USA, as the EU enjoyed 149.8% and 72.0% higher average yields over the analyzed period, respectively. The yields of biodiesel raw materials also show an increasing trend resulting in lower productions costs. Regarding biodiesel, the cost of raw materials is the most important concern; higher yields result in lower production costs compared to the ethanol production.

3.4. Biofuel Regulations and Their Implications

Pure biofuels are rarely used, they are mostly blended with conventional fuels. There is no doubt that policy measures are the major drivers of both production and the use of biofuels [

33]. The blending mandates have the most significant impact on the use of biofuels, higher percentages of blending mandates result in the higher use of biofuels. In most cases, mandates are strengthened by different tax incentives, such as tax credits or tax exemptions.

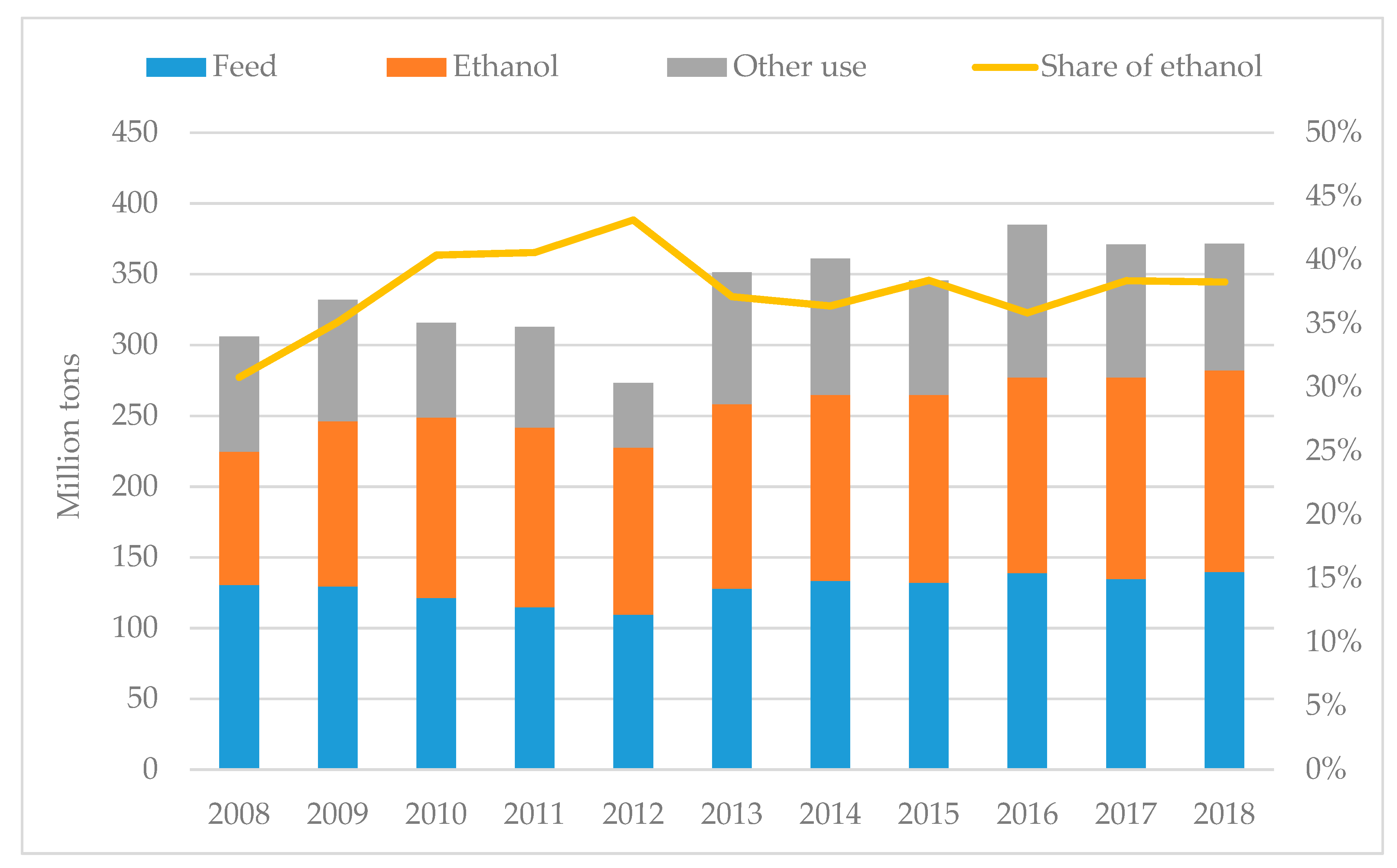

As it was already demonstrated, the USA is the major producer in the ethanol market. Although the country has not signed the Kyoto Protocol, it pays attention to the use of renewable energy. The Renewable Fuel Standard (RFS) program was introduced in 2006 and provides a stable raw material basis for the ethanol blending mandates. This has had a significant impact on the maize market, as almost 40% of the national production is used for ethanol production, even over the last couple of years (

Figure 5).

The use of corn to produce ethanol had its highest share in 2012, when it reached 43% of the total corn use, mostly at the expense of feed use. In the past years, ethanol and feed use had approximately an equal share in the maize utilization.

Blending rates vary across countries. However, it is generally accepted that ethanol can be blended with fuel up to a 10% ratio [

34]. Ethanol use is significantly supported in Brazil. It has the highest blending rate at 18% to 27.5%, tax incentives for ethanol-flex fuel vehicles and a 16% average tax for ethanol, compared to that of 26.8% on gasoline [

35]. In the United States, the use of E10 is common; however, E15 has already been approved and introduced in some states. The expanded version of the renewable fuel standard increased the blending mandate to 36 billion gallons annually by 2022, of which 15 billion gallons will consist of corn-based ethanol [

36]. This results in ethanol taking an important role in the development of US biofuel use. Higher mandates of the RFS directly contributed to lower farm price volatility. This also encouraged further investments because of higher and predictable demand. Higher ethanol content is planned for (e.g., E20 or E30), but this requires further actions from the automobile industry. Production of non-first generation ethanol is subsidized by higher tax incentives which is up to 1.01 USD/gallon compared to the 0.46 USD/gallon of the alcohol fuel tax credits [

37]. In the European Union, Directive 2009/28/EC regulates the promotion of renewable energies with a target of 10% for transportation (EU 2020 strategy). Seven percent of the target can be first-generation biofuels while taking into account that the GHG savings should be at least 35% [

23]. Clearly, this target cannot be achieved without biofuels. This explains why E5 has already replaced E0, but E10 is also available in some EU member states (e.g., Belgium, France, Germany). The introduction of E10 needs to be carefully planned and communicated, as many consumers opposed its use in Germany, mostly due to the food versus fuel debate and engine compatibility concerns [

38]. There are significant differences among the member states regarding this debate. Larger states like Germany, France, and Italy had an average of 6.5%, 7.5%, and 7% maximum cap on crop-based ethanol, respectively, in 2018 [

39].

Regarding biodiesel, blending mandates are also in use. Brazil has continuously increased the blending rates, up to 10% in 2019. Further research is aimed at testing the impacts of B15 [

35]. As the share of diesel vehicles is almost negligible therefore blending mandates are regulated at the state level and, generally, B5 is in use [

40]. The EU, with its share of diesel automobiles being the highest globally, is lagging behind with values similar to 6.5%, 7.7%, and 7% in Germany, France, and Italy, respectively [

39]. The other countries, which this study did not analyze, normally have lower blending mandates. For example, in China, the blending rate was only 2.2% for ethanol and 0.6% for biodiesel in 2015 [

41]. However, it should be noted that the majority of the biofuel producing countries have a scarcity of fossil energies; therefore, this substitution results in lower energy dependency. Eight percent of global cereal production and 12% of the total vegetable oil production were used to produce biofuels in 2012 [

42].

The EU’s regulation is based on the greenhouse gas emission savings which was set to a minimum of 35% until 2017 and increased to 50% (for installations starting operation before 5 October 2015 from 1 January 2018) and 60% (for installations starting operation after 5 October 2015) from 2018 (EU, 2015). These values are completely in line with that of the US values for advanced biofuels (50%) and cellulosic biofuels (60%) measured in life cycle GHG emission reduction [

43].

Table 5 shows the default and typical GHG effects of the different biofuels.

As seen in the table above, sugarcane-based ethanol has the highest GHG emission savings among the selected first-generation biofuels. If the ambitious targets of the renewable energy directives (RED) are met, then the production of waste-based biofuels is expected to grow in the short term due to the fact of their high saving values. Cellulose- and algae-based production are possible future options. It can also be anticipated that more member states will follow Italy, where the use of advanced biofuels have been mandated since 2018 [

39]. Nevertheless, even the European countries are lagging behind the USA, where non-first-generation biofuels (cellulosic, biomass-based diesel and advanced) were introduced in the frame of RFS as early as 2009 [

44]. But it can also be observed based on the dataset of the Environmental Protection Agency that conventional (i.e., starch-based) biofuels will compose approximately two-thirds of the total renewable fuel production in the USA in 2022.

Advanced biofuel production technologies are more expensive at this moment. However, there are numerous research projects all over the world working to make these technologies more efficient and therefore cheaper. There are many options at every level of the production chain (raw materials, enzymes, technology, energy use, etc.).