1. Introduction

Bangladesh is an energy-starved country due to rapid industrialization where the natural gas and petroleum products are the primary sources of energy. These sources are extensively used in electricity generation and transportation sector. However, the scarcity of these resources and concerns of environmental pollution lead the researchers to incorporate renewable energy resources in electricity generation [

1,

2,

3]. As petroleum resources are significantly decreasing while increasing their cost throughout the entire world, it is essential to consider highly available renewable resources to meet the energy demand for electricity generation as well as the transportation sector [

4].

As a developing country, people are using electric vehicles in Bangladesh due to several key benefits including reduction of sound pollution, fumes and GHG emission. On the other hand, the abrupt increase in the number of EVs in Bangladesh needs an additional 500 MW power daily from the national grid [

5]. This huge demand creates a burden on the grid and affects the stability & power quality of the grid [

6,

7]. Moreover, almost all the EVs are charging their batteries from the residential connection which creates unknown variability and stability issues for the grid. Furthermore, the EV owner pays the bill as a residential consumer that leads to the failure of the power sector to reach the profitability margin [

8].

Renewable energy-based electricity generation would greatly help to meet up huge energy demand of charging EVs. The EVs charged in renewable-based charging station offers less GHG emission and fewer charging costs than grid-based charging stations [

9,

10]. Bangladesh has enormous potential for renewable energy resources such as solar, biogas/biomass, wind, hydro, and so on. These renewable resources can be used to charge the EVs that can help to reduce pollution [

11]. Currently, a few solar charging stations are established in different cities of Bangladesh. However, these charging stations are not sufficient, and therefore, much of charging stations are required for EV charging by renewables. As it is known, solar energy is available in all over the country to generate electricity effectively for 5–6 h with solar irradiation of 4 to 6.5 kWh/m

2-day [

12]. The solar-based charging stations can only work when solar energy is available. However, during cloudy and foggy weather, solar energy is absent which is a significant drawback.

In Bangladesh, necessary wind speed is limited to only coastal and off-shore areas [

13]. Hence, wind resources integration for electricity generation throughout the country is not feasible. Different institutions are working jointly with the power sector of Bangladesh to use renewable resources. In addition to this, the electricity generation from solar resources is more expensive than biogas-based electricity generation. Besides, the biogas plant provides digestate which can be used in the agriculture sector as fertilizer [

14]. Different research demonstrates that Bangladesh is becoming an oppressive polluted country by making waste on an average of 0.5 kg per day individually [

15,

16]. Due to having more industry and large populations, the rate of spreading waste is more pronounced in the case of urban cities compared to the rural areas.

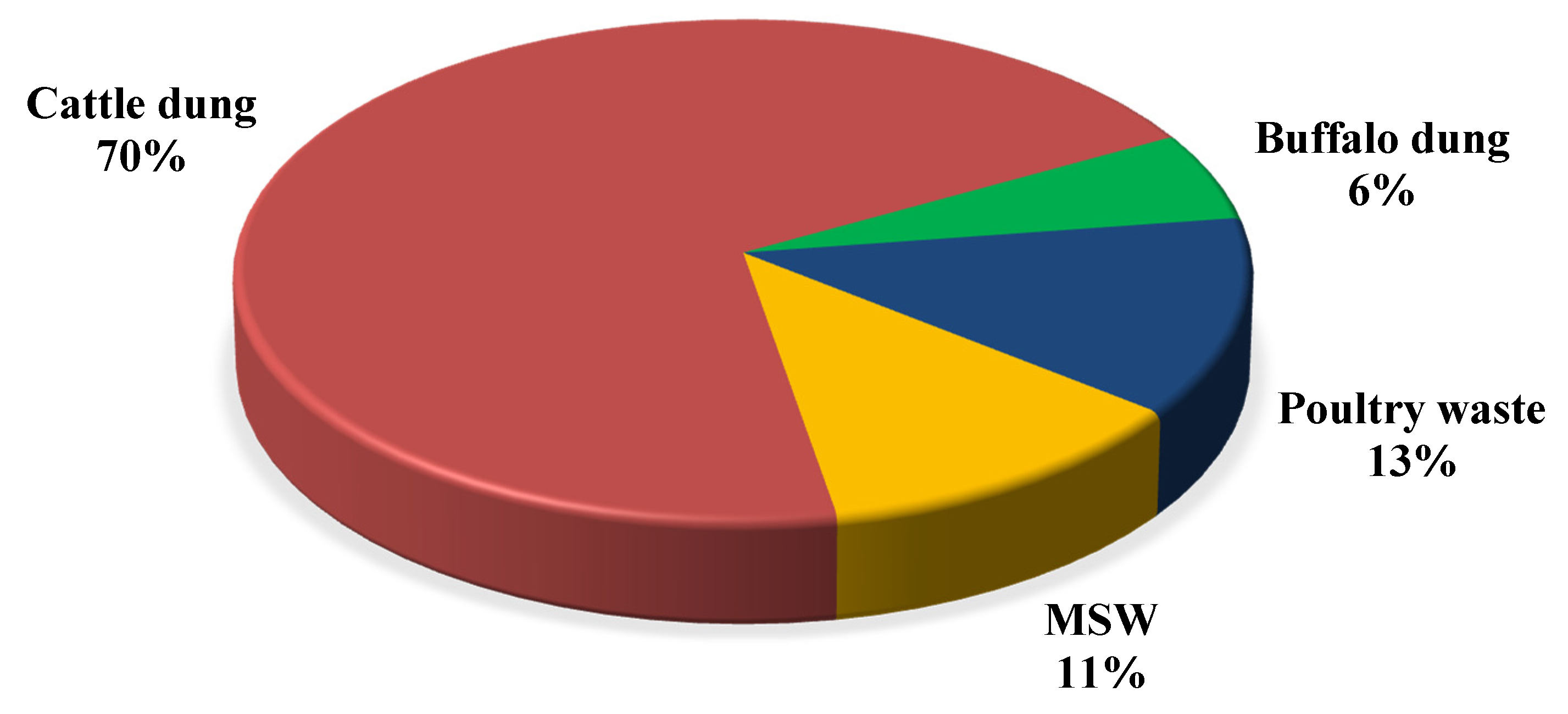

A recent study investigated the biomass potential in Bangladesh, and it explored that the total biomass collected from various wastes and residues can generate more than 3447 Peta joules of energy equivalent to 950 TWh [

17]. According to waste statistics from the Sustainable and Renewable Energy Development Authority (SREDA) and Waste Concern, Bangladesh, it is found that cow dung, poultry waste, Municipal Solid Waste (MSW) could be a potential source of electricity generation in Bangladesh [

18,

19]. A study shows that approximately four million biogas plants could be established in Bangladesh which could meet 20% of the total household demand [

20].

Various factors, such as biogas potential of feedstock, design of digester, inoculum, nature of substrate, pH, temperature, loading rate, hydraulic retention time (HRT), C: N ratio, volatile fatty acids (VFA), etc. influence biogas production [

21,

22]. Bangladesh is suitable for establishing biogas plants due to its climate [

21,

22]. The ideal temperature for anaerobic digestion is 35 °C, where the temperature of Bangladesh varies from 6 °C to 35 °C. The inner temperature of a biogas digester varies from 22 °C to 30 °C which is very close to the optimum requirement [

23]. Moreover, the biogas resources are available throughout the country irrespective of location and time. Thus, the proper use of biogas/biomass resources for electricity generation increases the effective operation hours compared to solar and wind potential [

24,

25]. In this situation, this type of wastes can contribute heavily to produce biogas and further processed for electricity as well as fertilizer.

Several contemporary kinds of research have been made on the issues regarding biogas use in transportation showing better performance than the conventional systems. Furthermore, as EVs need power to charge at any time of the day, it is essential to use available biogas resources for EV charging to increase the effective hour and management of wastes correctly [

26]. The design of EVCS using solar and biogas resources can make the system cost-effective and reduces environment pollution significantly [

27]. A study in the context of Denmark shows that biogas used for EV charging reduces fuel consumption and GHG emission [

28,

29]. Biogas can be converted into bio-CNG which is further used for vehicles. Biogas applications in EV charging can be good hope for reducing the use of fossil fuel and GHG emission from the transport sector remarkably [

30,

31,

32].

To the best of the author’s knowledge, no initiative up to date has been taken place to determine the feasibility of biogas/biomass incorporation in EV charging stations in Bangladesh. Therefore, this study carried out to open a new research platform for using available biogas/biomass resources in EV charging. Furthermore, eco-friendly, cheapest, and effective waste management facilities grow up our interest in performing this research on the use of biogas resources for EV charging.

In this paper, the prospects and potentials of biogas/biomass resources are analyzed using the available real data detailed in

Section 2. Based on the potentiality of biogas resources, a novel model for the EV charging scheme is proposed in

Section 3 which includes system components, mathematical modeling and analysis of the proposed EVCS using solar and biogas resources.

Section 4 presents the schematic arrangement of the proposed EVCS. The technological, financial and environmental analysis using HOMER model is presented in

Section 5 which also includes the socio-economic benefits of the proposed EV charging station. Finally,

Section 6 demonstrates the conclusion with future research directions for sustainable development through the integration of biogas resources for EV charging.

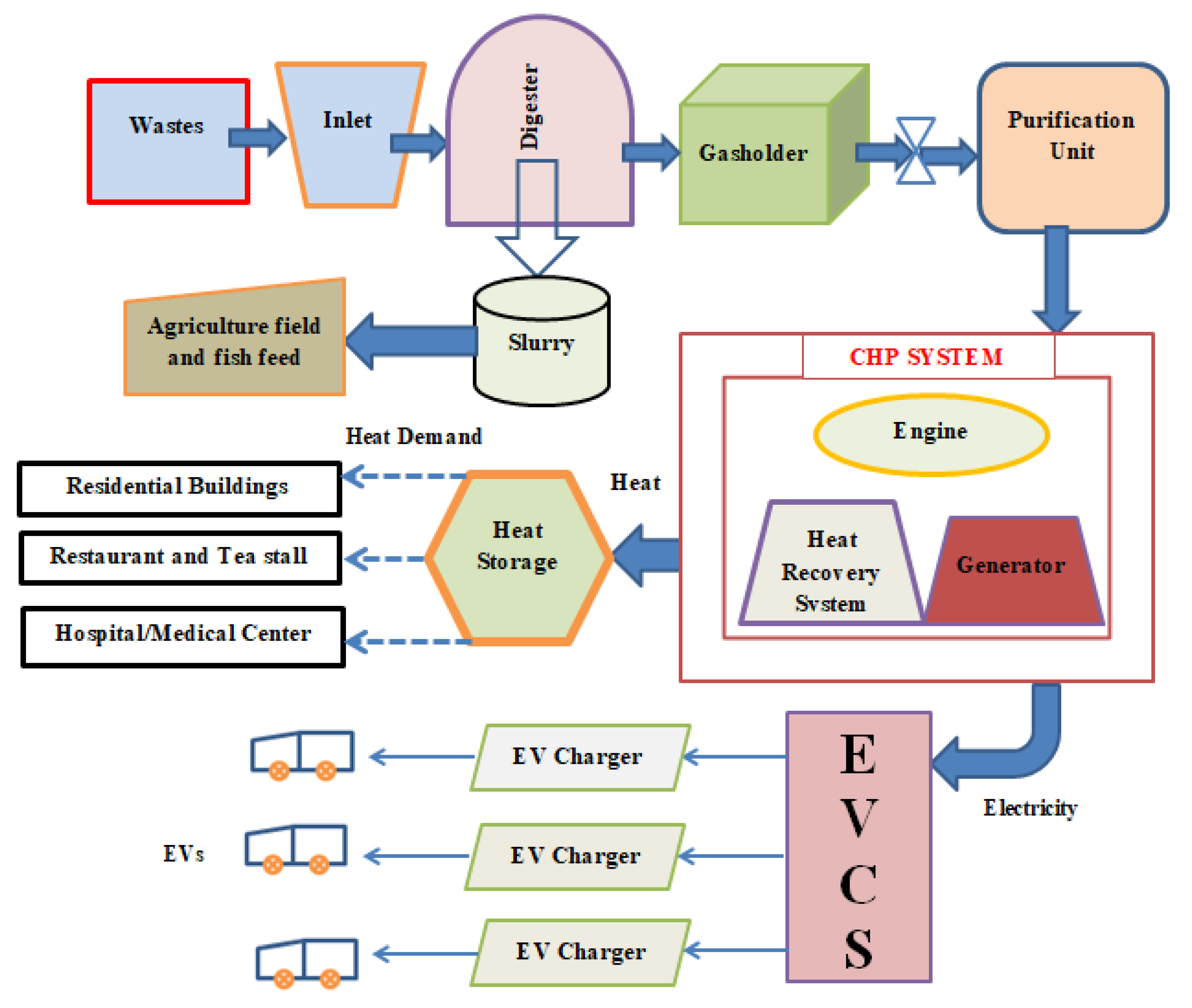

4. Design of the Proposed EVCS

The conceptual design of the proposed biogas-based EVCS where animal and other wastes are collected and processed to recover the energy content is discussed in this section. Animal wastes and MSW are mixed together in order to achieve co-digestion which improves the efficiency of the biogas generation process [

39]. The mixer is used to mixing up the slurry which is made by a combination of processed waste and water. The anaerobic digestion depends upon the waste material and temperature in the digester. The biogas generation rate increases with the increase of temperature. In the proposed plant, thermophilic process is chosen due to its benefits over mesophilic and psychrophilic process. The major advantages of thermophilic process over mesophilic are lowering retention time and improving digestion efficiency. In Bangladesh, temperature is suitable for mesophilic operation; however, a thermophilic process can be adopted using the heat produced by the biogas engine itself. After the completion of anaerobic digestion using available fixed dome type digester, biogas is produced. The biogas is stored in a gasholder at the low consumption period which is designed to store 60% of the daily biogas production. The size of the digester is determined by the retention time and daily feedstock/substrate input. The produced biogas is warm and it contains a large amount of water vapor. The gas purification plant mainly removes the H

2S content because it is corrosive with the CO

2 and water. After completion of purification process, the biogas yield goes to the combined heat and power (CHP) system which has an engine, heat recovery system and generator. A biogas generator is coupled with the engine that finally converts mechanical energy into electrical energy. Only 35% of biogas energy is converted into electricity where 55% is converted into heat and 10% becomes system losses. Using CHP unit, the energy efficiency will be increased due to the use of recovered heat as well as fewer environmental pollutions. The heat produced from this plant can be used for many purposes, including domestic use, restaurant hot water supply, and in hospital/medical centers. As the heat demand is not constant, heat storage is used for storing excess heat. On the other hand, the electrical energy produced from the generator can be linked together with EV charger that is responsible for charging EV batteries [

51]. In addition, digestate slurry can be used to land and ponds as fertilizer and fish feed. It is important to choose appropriate location for establishing biogas plant based on the availability of the waste materials and water, sufficient area, and so on. With the above discussed features, a conceptual design of the proposed biogas-based EVCS is developed and is shown in

Figure 2.

5. Results and Discussion

The load curve in

Figure 3 is obtained from the local private EV charging station in Gazipur district, Bangladesh which shows the EV load variation with time.

It is seen from

Figure 3 that in the evening period, load gradually increases and at the morning hour load is relatively lower than other times. The scenario of the EVCS is similar to the other EVCS in Bangladesh. The EV demand is almost constant throughout the year for a specific EVCS. However, in case of newly joined EV in the transportation sector causes extra burden to the power system.

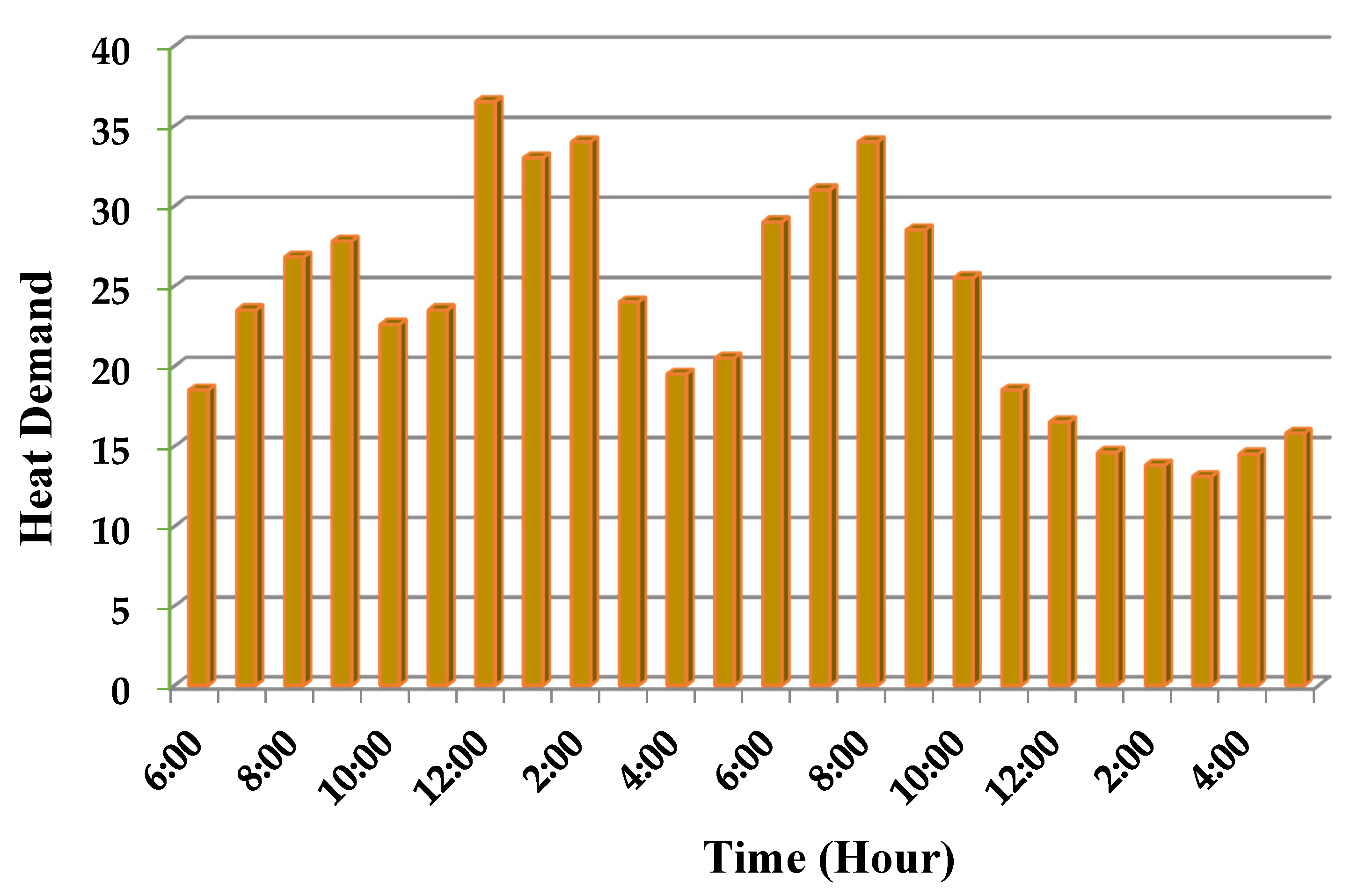

In addition to the electricity demand, the proposed biogas plant will be effective for meeting heat demand of the nearby users such as residential buildings, restaurant, tea stall, and hospital/medical center. The heating demand profile is shown in

Figure 4 which is derived from the village of Gazipur district in Bangladesh where the planned biogas plant will be established. The maximum heat demand is seen at noon and evening period. However, after the midnight to early morning, the heat demand declines and remains approximately constant.

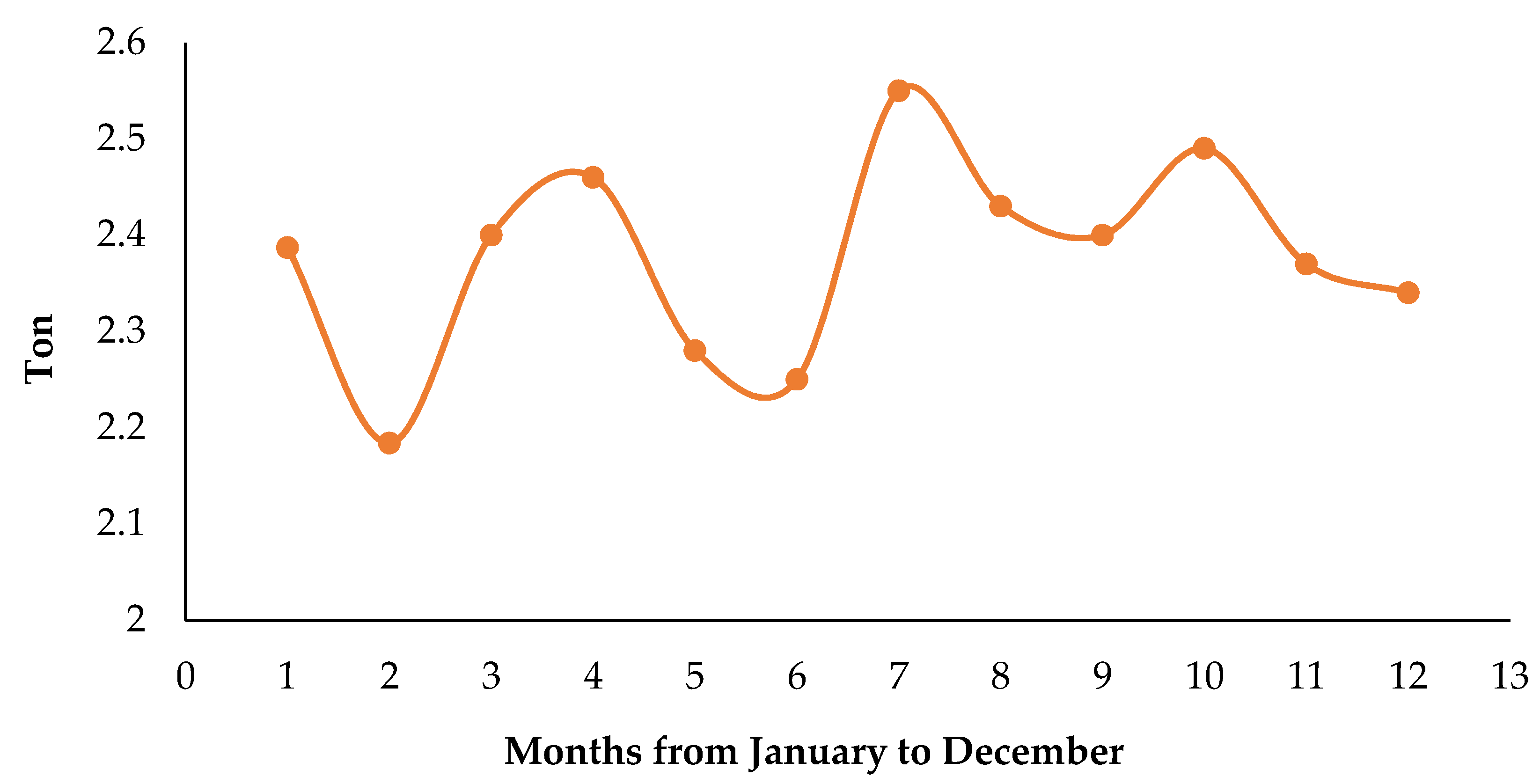

Figure 5 shows the monthly collection of biomass from the nearby cattle farm, poultry farm, and urban areas of Gazipur district, Bangladesh. All types of wastes are collected from the same village where the proposed EVCS aim to be established. Therefore, the transportation cost for the waste material will be much lower.

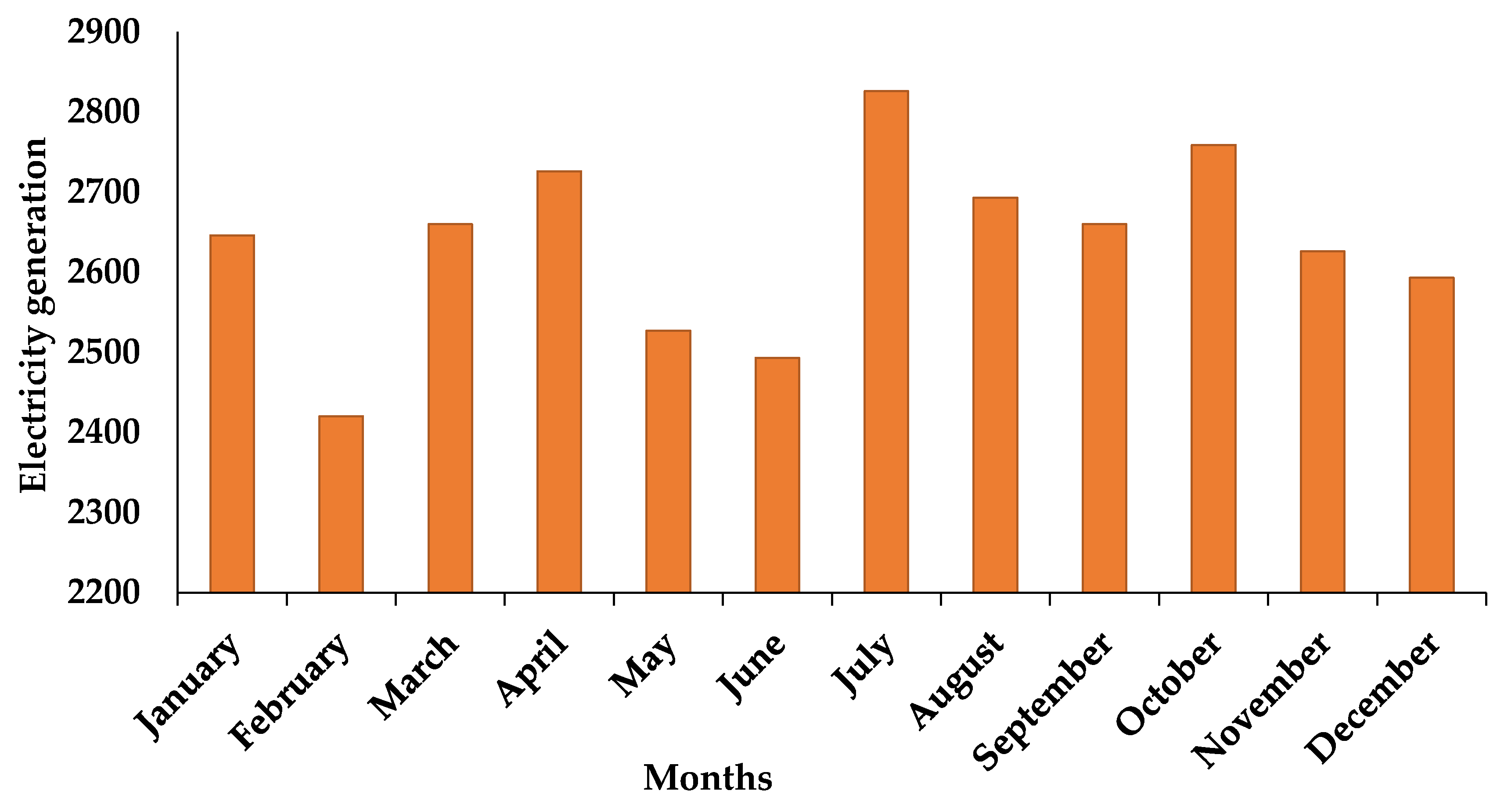

The proposed EVCS is designed for generating electricity for charging EVs according to the battery SOC. The monthly power generation from the proposed EVCS is shown in

Figure 6 where the maximum generation is in July and the minimum in February. It depends upon the biomass collection. The processed biomass is ready for anaerobic digestion in the fixed dome type or floating dome type digester. In accordance with the calorific value of the waste materials, the biogas produces, and thus, electricity is generated.

It is worth mentioning that outputs of a biogas plant are in the form of heat and biogas. Only 35% of the biogas is used for generating electricity but 65% of the output energy is used for mechanical losses and heat [

52]. Of the produced heat, 20–30% goes toward heating the slurry of the digester. The heat produced from this plant can be a good source for cooking. One biogas stove requires approximately 19 MJ/hr for daily cooking of a family [

53]. In that case, the proposed 70 m

3 biogas plant produces 565 MJ/day which can supply heat water to many places such as residential buildings, restaurant, tea stall, and hospital/medical center. In most of the cases, residential building requires heat to cook foods during morning, noon, and evening period. Besides, hot water is required in restaurants, tea stalls, as well as health care centers.

In a biogas plant, the production of biogas is not only the output parameter, but digestate produces from the anaerobic digestion is also carries importance. Digestate can be formed as an excellent fertilizer, and selling this bi-product at a minimum rate to the farmer’s, the EVCS developer can minimize the running cost of the plant.

The daily electricity required for 15–20 EVs is approximately 100 kWh based on their battery capacity, SOC, and duration of charging. However, if the electricity generation exceeds the demand, then the excess power is transferred to the nearby residential areas for light load applications. This excess power is taken into consideration when calculating economic parameters.

5.1. Cost Analysis of the Proposed EVCS

The economic parameters related to the proposed EVCS consist of initial capital cost, O & M cost, replacement cost, cost of energy, and payback period. These parameters play a vital role in the accomplishment and desired success of the project.

Table 7 shows the economic parameters of the proposed EVCS using biogas resources. The O & M cost includes waste transportation cost along with all of the running costs of the plant. It can be minimized by selling slurry as fertilizer at a minimum rate. The HOMER analysis helps to determine the COE, benefit-cost ratio, annual cash flow, payback period and profitability index.

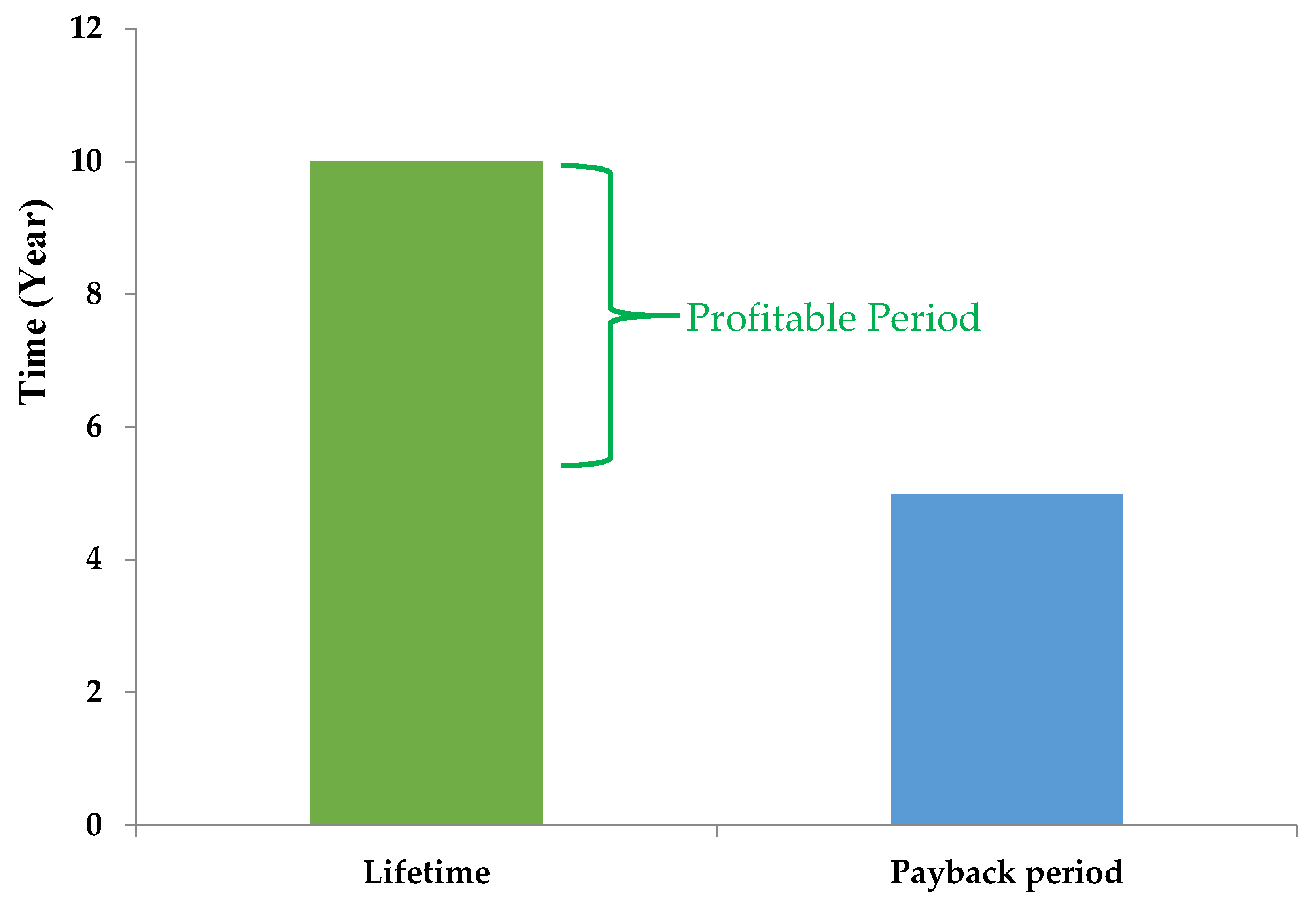

Figure 7 shows the profitable period and payback period of the proposed EVCS where it is observed that after 4.99 years, the project will be profitable. The Benefit-Cost Ratio and profitability index are found to be 1.17 and 2.002 which indicates the proposed project would be economically viable.

5.2. Environmental Aspects of the Proposed EVCS

Electric Vehicles are becoming popular day by day due to their eco-friendly nature. The greenhouse gases (GHG) emission and other pollutants which are noxious to the environment are reduced by using EV. In Bangladesh, the CO

2 emissions are per unit of electricity generation is approximately equal to 640 g [

54]. The primary sources of electricity generation in Bangladesh are natural gas and coal. These two resources are limited and producing a large amount of CO

2 emissions. As compared to these resources, renewable resources such as biogas/biomass have more significant advantages of reducing CO

2 penetration from electricity generation purposes.

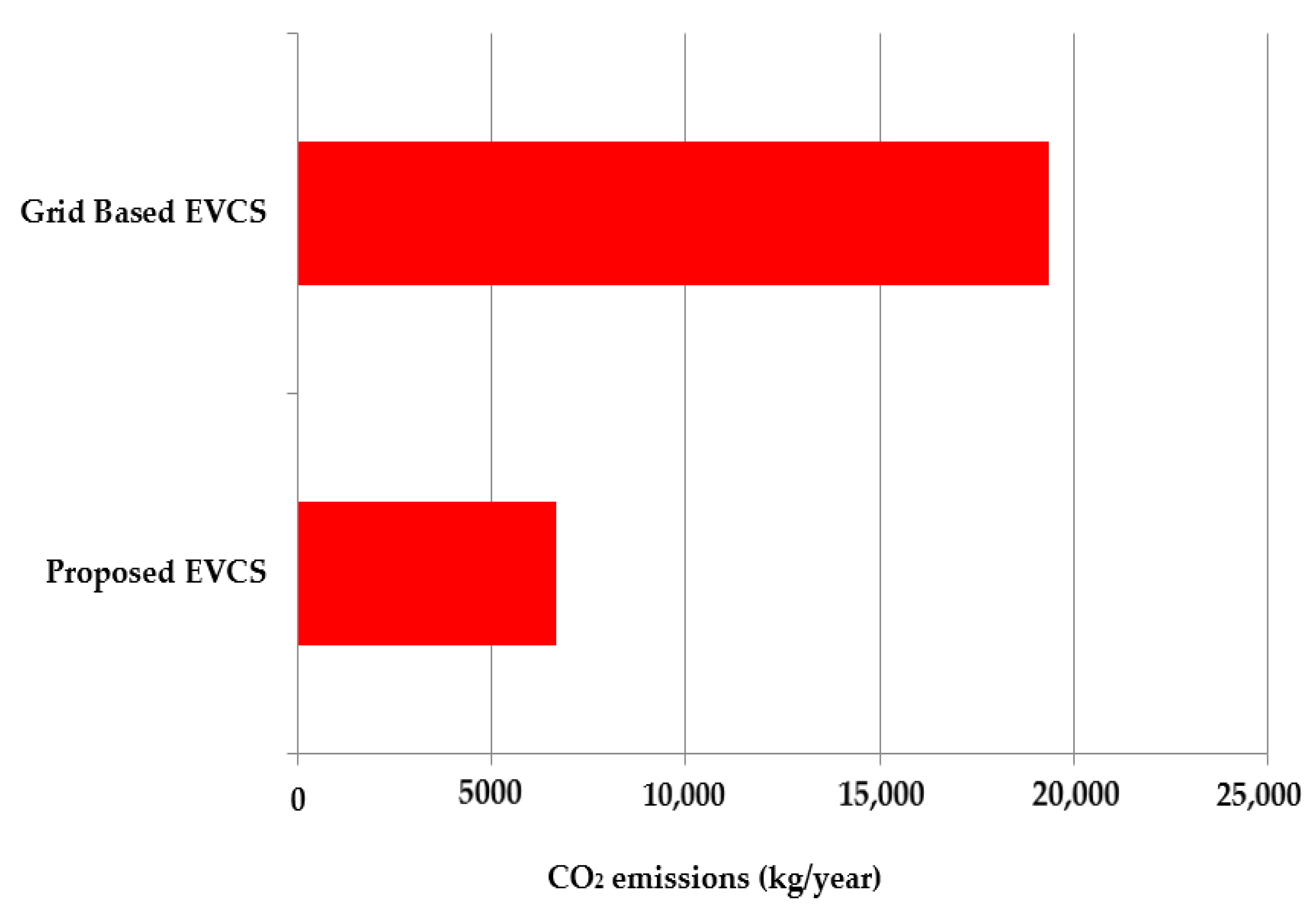

In this proposed charging station, biogas and biomass are used to generate electricity which will further charge the EVs. Thus, the CO2 emissions are reduced significantly by using biogas resources.

Figure 8 illustrates the comparison of the CO

2 emissions from the grid-based EVCS and biogas-based EVCS. In the proposed EVCS, yearly CO

2 emissions is about 6653 kg whereas the same demand grid-based charging station produces 19,350 kg of CO

2. Thus, the CO

2 emissions are reduced to 65.61% from the grid-based charging station. This is because the utility grid in Bangladesh mostly depends on fossil fuel which generates more GHG emissions than renewables [

55].

Hence, the EV charging from renewables such as biogas energy would be very much promising as it enhances waste management capability as well as reduces environmental pollution with cost. The waste material pollutes the environment and scatters the acrid lousy smell to the atmosphere. Use of this waste saves the environment from pollution and bad smell. Another advantage is that there is much slurry production, which can be used as fertilizer and it makes the atmosphere fresh and clean. The application of slurry improves the physical, chemical, and biological characters of the soil.

5.3. Comparison of Results Between Mathematical Analysis and HOMER Analysis

HOMER analysis provides the result based on inputted renewable resources such as biomass, where the losses associated with the EV charging accessories are not taken into consideration. In the analysis, several other factors, such as variation of biomass collection, uncertainties of weather, and breakdown of charging accessories should be considered when calculating more accurate technological, economic, and environmental parameters.

While economic parameters, such as COE, Net Present Cost (NPC), operating cost, payback period and profitability index are analyzed using the HOMER model to present advantages of power generation from the input resources, the mathematical analysis considers the charging equipment cost and infrastructures for charging five EVs simultaneously. As a result, the economic parameter obtained from mathematical analysis varies from the HOMER results.

GHG emission from biogas-based EVCS is calculated in HOMER software which is only considering the power generation process. However, the GHG emission from EV charging depends on GHG emission from EV charger and battery [

56,

57].

Furthermore, the EV battery manufacturing process is also responsible for GHG emission. Therefore, the results of HOMER analysis are different from the mathematical calculation.

In mathematical analysis, the loss associated with the EV charging process is taken into consideration. Thus, the kWh generation in mathematical analysis is less than HOMER result. The operating cost in HOMER analysis is greater than the mathematical analysis because the selling digestate minimizes the cost of waste transportation.

Table 8 shows the comparison between HOMER results and mathematical analysis.

5.4. Socio-Economic Benefits of the Proposed EVCS

Electric vehicle charging infrastructure opens a newly lucrative area of research and application in Bangladesh. Environmental and socio-economic factors are working behind the popularity of electric vehicles. Electric vehicles such as Easy Bikes, Auto-rickshaws and electric rickshaw vans have a high potential of reducing emissions, improving air quality in both urban and rural areas.

An Easy Bike driver in Bangladesh can easily earn approximately $18–$25 where the energy consumption cost of this car is only $1–$1.25 daily which can be a lucrative income option for many as it cuts the physical labor and saves transportation time. The charging cost of an Easy Bike is around $53 per month. It will be lower than the present cost if the proposed charging station charges the EVs.

Table 9 shows the summary of the charging cost in a grid-based system and the proposed EVCS-based system. In addition to the charging cost comparison, the monthly savings by using this EVCS for an EV driver are given in

Table 9. The savings are more or less considered as the monthly income for the EV drivers.

In a biogas plant, the production of biogas is not only the output parameter, but the digestate produces from the anaerobic digestion is also importance. The digestate can be formed as good fertilizer and selling this bi-product at a minimum rate to the farmers to further minimize the running cost of the proposed EVCS plant.

In this research, the digestate price per kg is taken only in BDT. 1.50 which will inspire the farmers to cultivate using green waste-based composite fertilizer. The

Figure 9 illustrates monthly digestate production of the proposed EVCS biogas plant.

6. Conclusions

In Bangladesh, almost all the electric vehicle charging infrastructure is operated by grid electricity, leading to rising power demand, cost, and carbon emission. Although few solar charging stations are established by the government but variable duration of solar radiation and high capital cost, it is important to evaluate use of alternative energy resources to establish sustainable energy development. In this context, it would be beneficial to incorporate available renewable energy resources such as biogas to charge electric vehicles. The concept of using biogas/biomass resources for charging battery-driven electric vehicles opens a promising area of research and application in Bangladesh. In this paper, the proposed EVCS is found economically feasible and the investment will be returned after five years. Mathematical analysis provides results of technological, economic, and environmental parameters which are different from HOMER analysis due to the variation in biomass collection, changes in weather and loss associated with the EV charging process. The proposed EVCS saves $16.31–$29.46 per month than grid-based EVCS. In the case of the environmental aspect, the proposed EVCS can reduce GHG emissions remarkably. The efficient use of locally available wastes in the proposed EVCS ensures continuous power supply, stability, and reliability of the charging infrastructure with proper waste management. Besides, strengthening the national grid by reducing extra burdens of electric vehicle charging, the proposed EVCS may also improve reliability and quality service of the energy sector toward sustainable development.