Bibliometric Analysis of Supplier Management: The Theme and Cluster Perspectives

Abstract

1. Introduction

- Q1: what are the hot research themes in the field of supplier management?

- Q2: what is the relationship between these hot research themes?

- Q3: What are the evolution trends in the field of supplier management?

- Q4: What are the main future research directions in the field of supplier management?

2. Materials and Methodology

2.1. Bibliometric Analysis Method

2.2. Data Collection

3. Results of Co-Word Analysis: From the Theme Perspective

3.1. The Establishment of Word Database

3.2. The Establishment of Co-Occurrence Matrix

3.3. Visualization of Hot Research Themes

3.4. Results of Theme Analysis

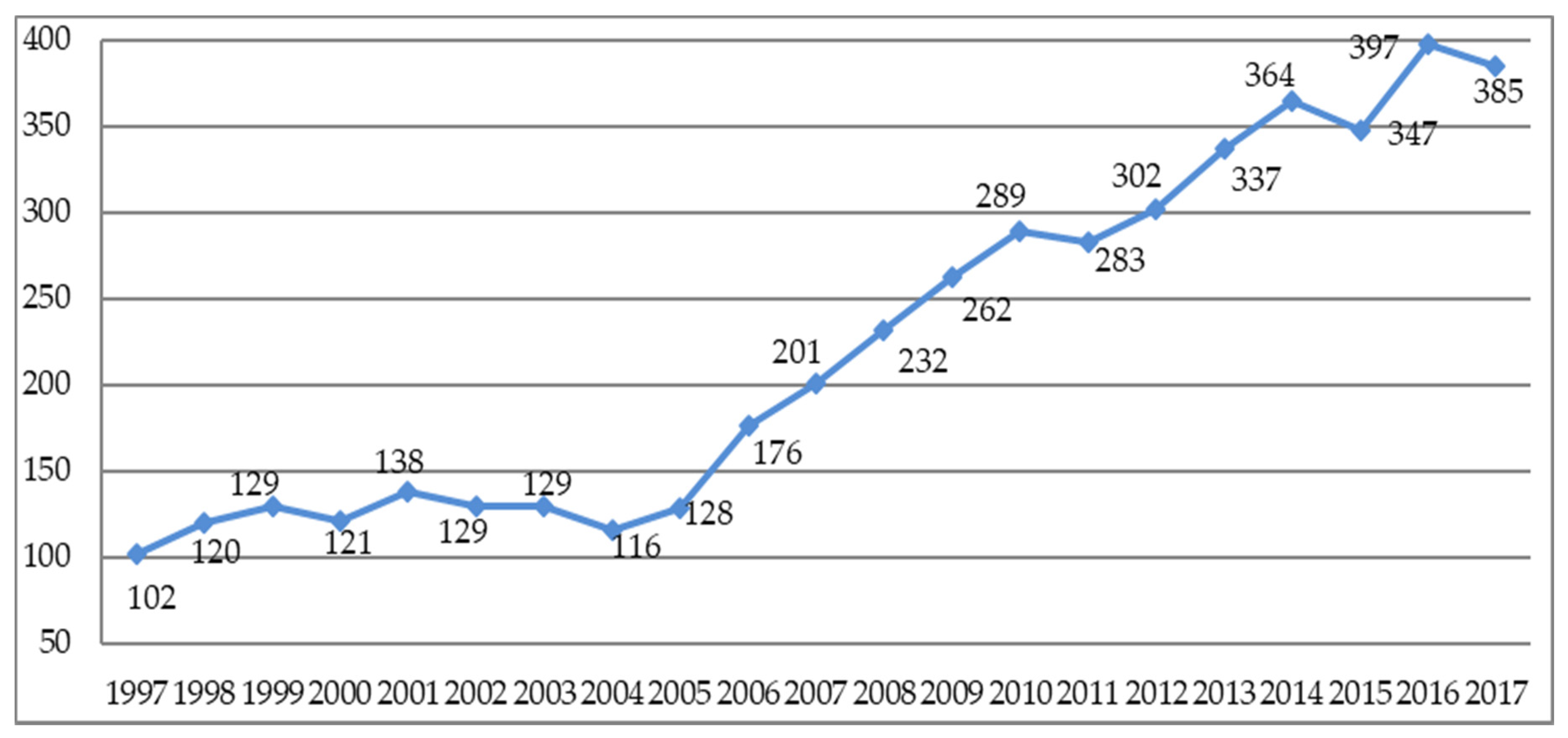

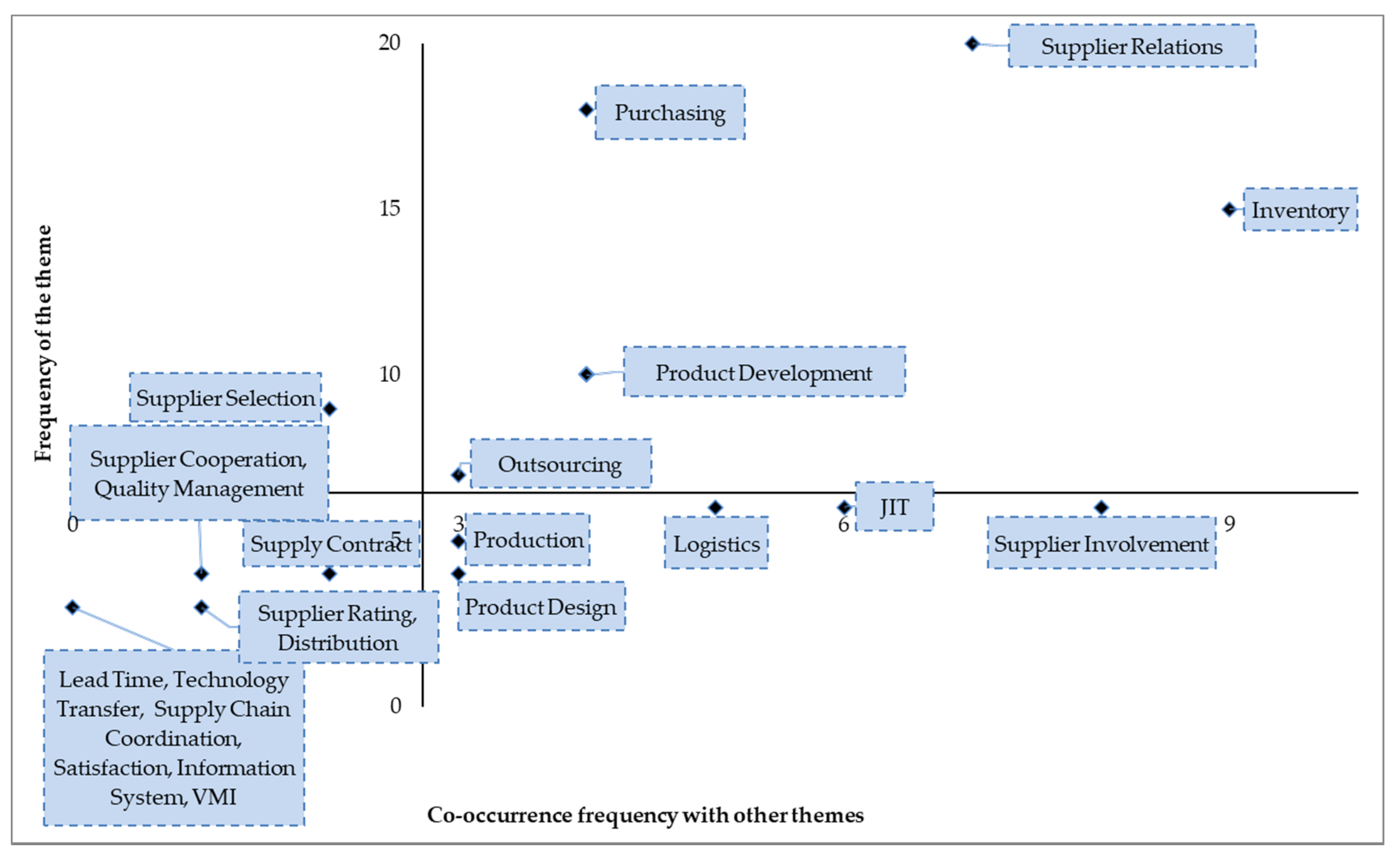

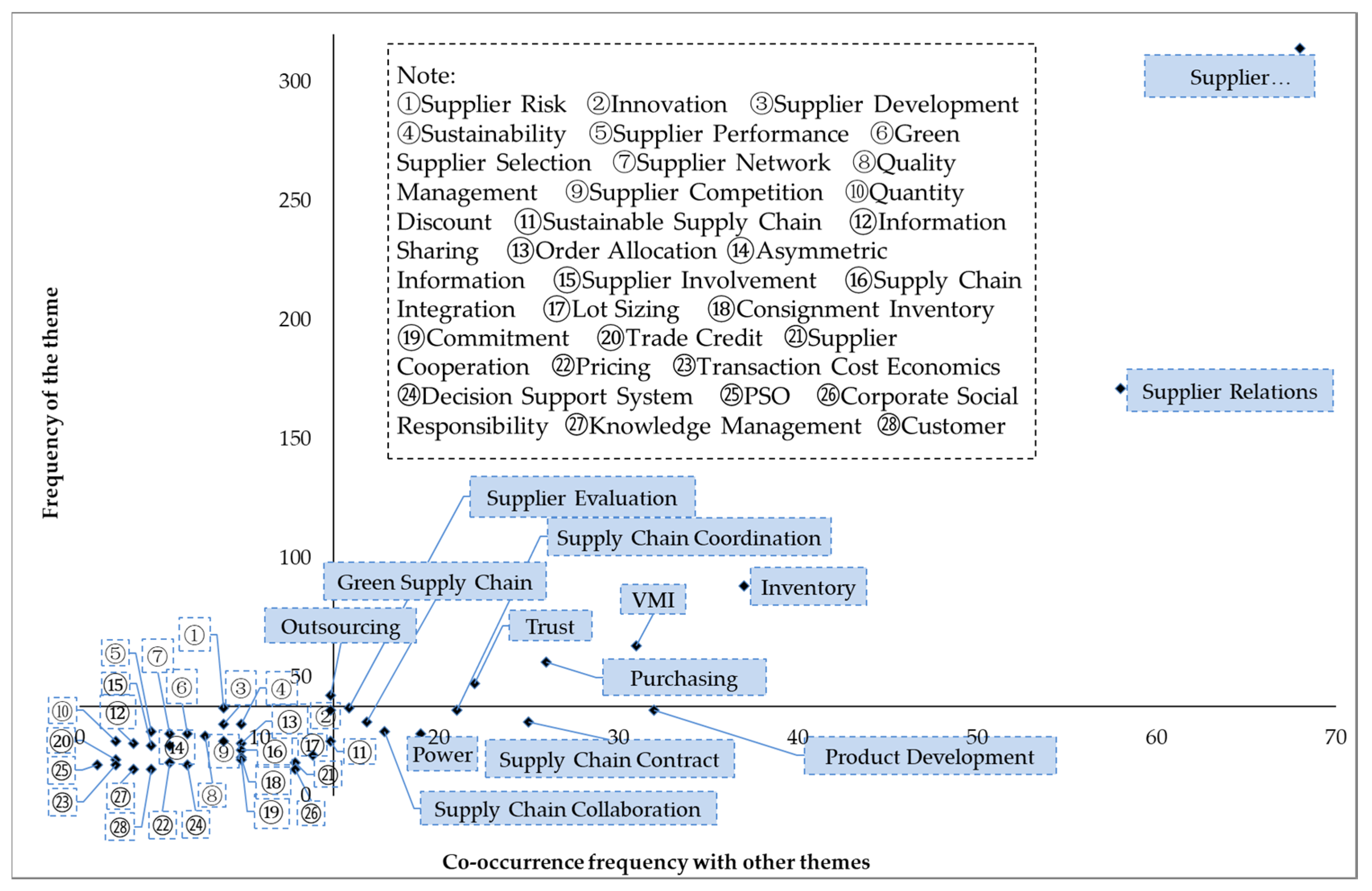

- The research on supplier management has made breakthroughs in both breadth and depth. As can be seen from Figure 2, Figure 3, Figure 4 and Figure 5, representative research themes, such as, “sustainability”, “corporate social responsibility”, “knowledge management”, etc., have gradually penetrated into the field of supplier management. In addition, it can be seen from Table 4 that the self-frequency and co-occurrence frequency of most hot research themes show an increasing trend, which to some extent indicates that these hot research topics continue to make breakthroughs in depth.

- Researchers have always been very enthusiastic about the research themes, such as “supplier selection”, “supplier relations” and “inventory”, which are always in the first quadrant of the quadrant diagrams for the four stages, see Figure 2, Figure 3, Figure 4 and Figure 5. This conclusion can also be confirmed in Table 4, from which it can be found that the frequency of these three themes has been always in the top three.

- The research themes of “VMI” and “trust” are attracting more and more researchers’ attention. As can be seen from Figure 3 and Figure 4, the theme “VMI” moved from the third quadrant to the first quadrant, and “Trust” from the fourth quadrant to the first quadrant, indicating that the number of studies on these two themes increased significantly. Figure 5 shows that these two themes are still in the first quadrant at stage 4, indicating that these two themes are of great strategic importance in the field of supplier management.

- It can be predicted from the trends that research themes, such as “green supply chain”, “supply chain collaboration”, will become more and more important in the field of supplier management. “Supply chain collaboration” appears in the word database at stage 3, and “green supply chain” appears in the word database at stage 4. It can be found in Figure 5 that they are all in the fourth quadrant and are very close to the first quadrant. According to the calculation results in Table 4, the self-frequency and co-occurrence frequency of these two themes are of great potential, and it can be predicted that they will likely move to the first quadrant in the future.

4. Results of Cluster Analysis: From the Cluster Perspective

4.1. The Establishment of Similarity Matrix

4.2. Cluster Analysis of the Research Themes

4.3. Visualization of Theme Clusters

4.4. Evolution Analysis of Theme Clusters

4.5. Results of Cluster Analysis

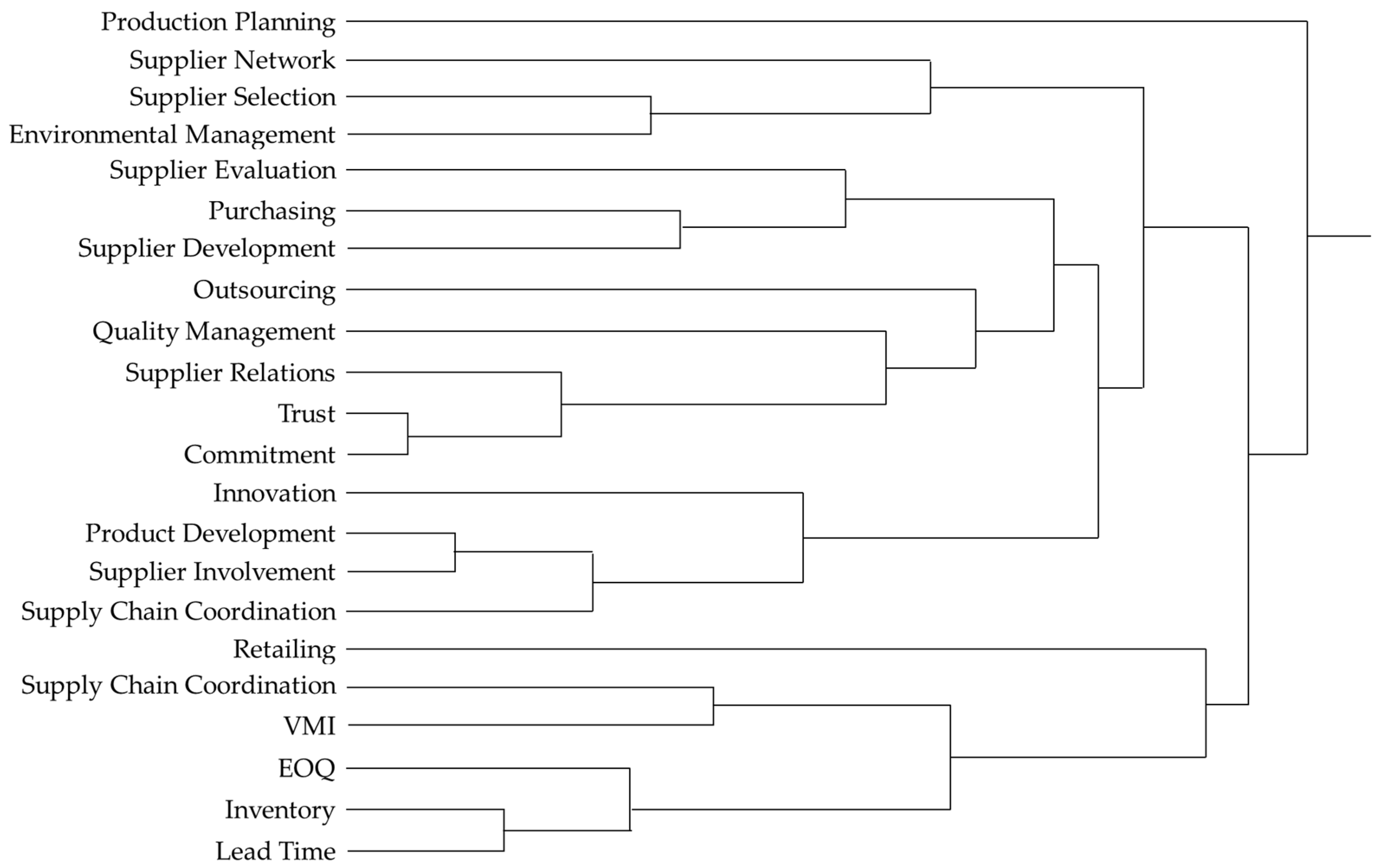

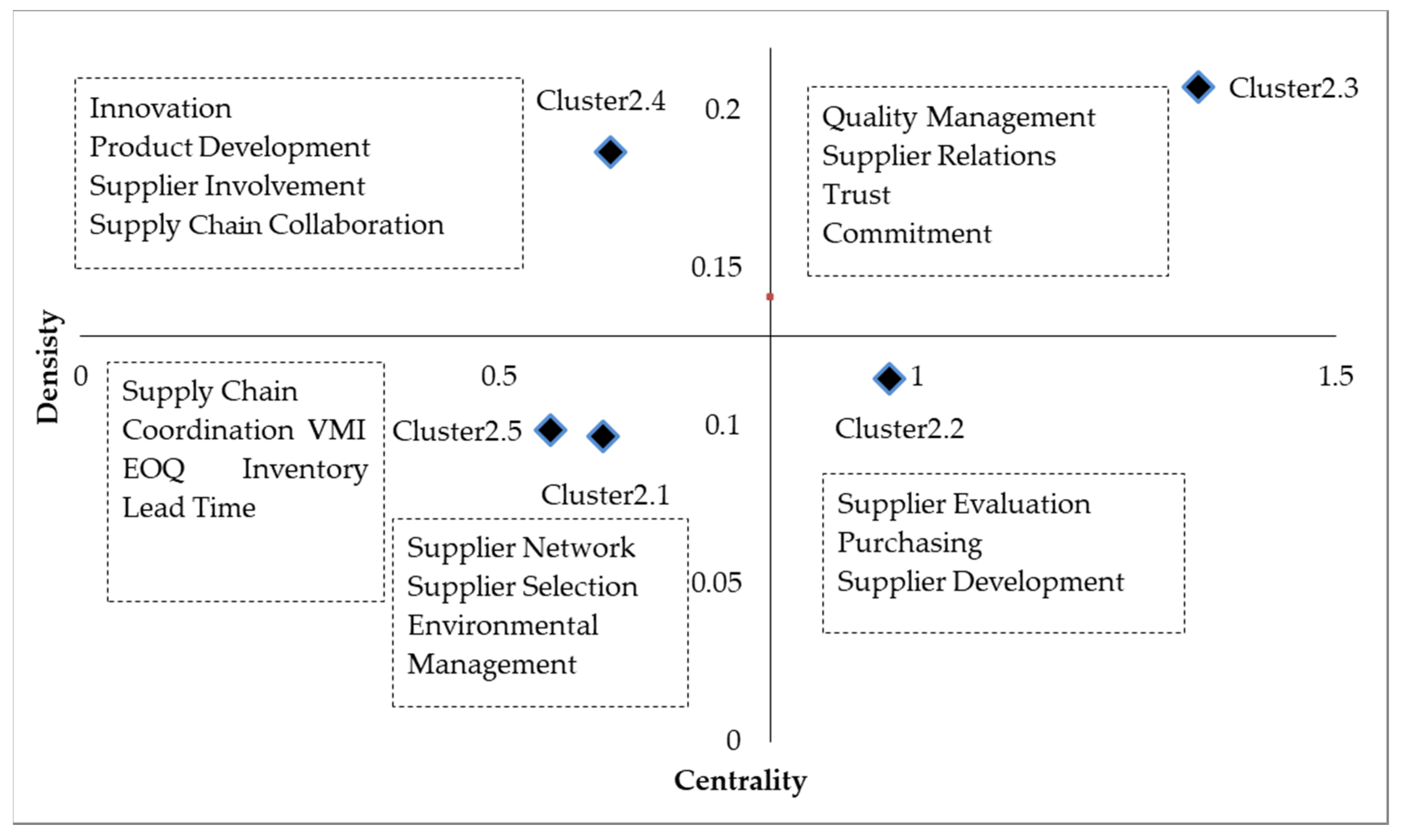

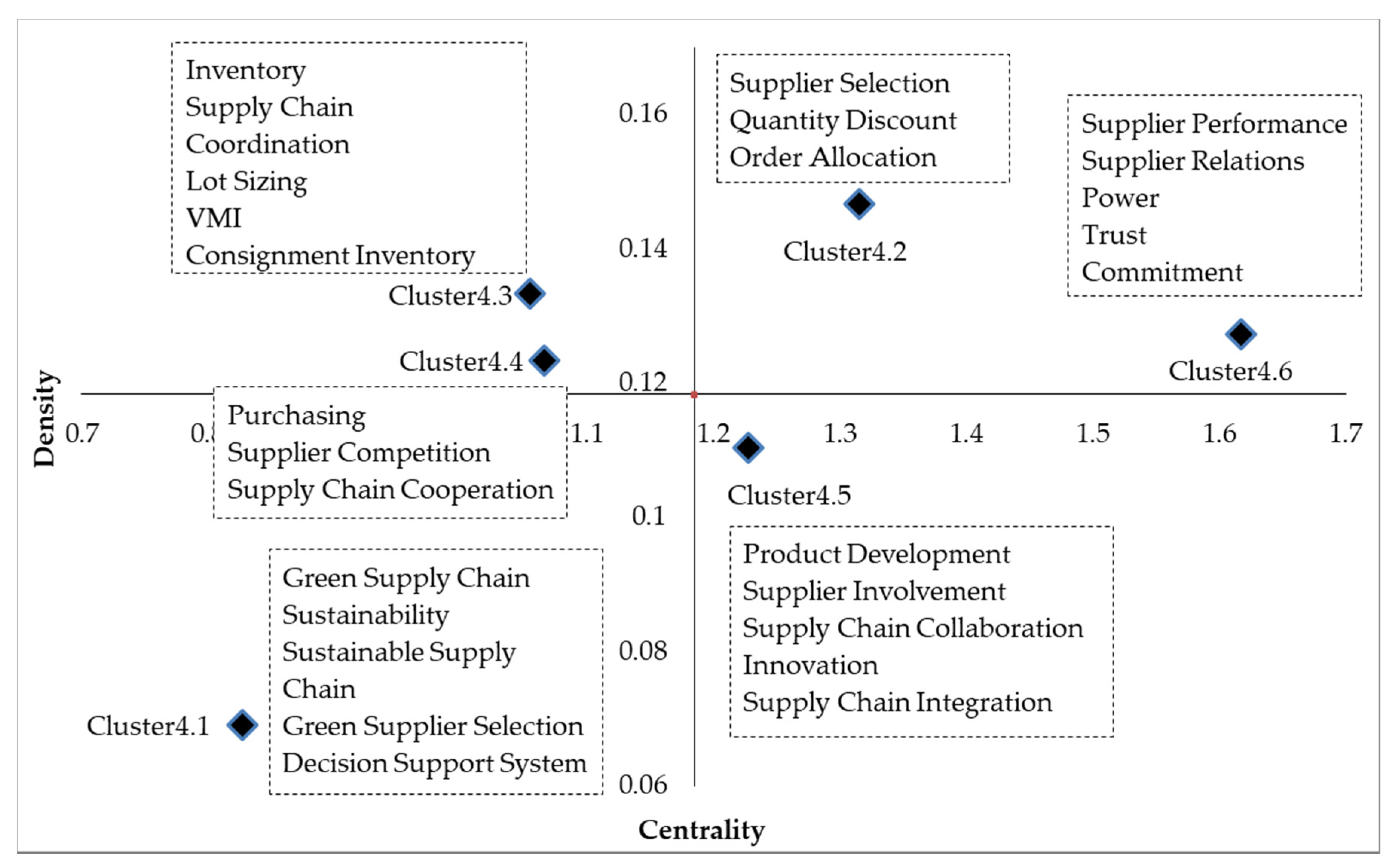

- As can be seen from the strategic diagram for stage 4 (Figure 13), the “supplier relations” cluster (cluster 4.6), is in the first quadrant, indicating its high strategic importance in the field of supplier management. In addition, from the comparative analysis of theme clusters for the four stages, it can be found that the centrality of “supplier relations” cluster at different stage is always high, which indicates that “supplier relations” clusters have always been playing a significant role in the field of supplier management. These results are consistent with the results of co-word analysis, which show that the self-frequency and co-occurrence frequency of theme members in the “supplier relations” cluster is always high, and present a rapid growth trend during the research period.

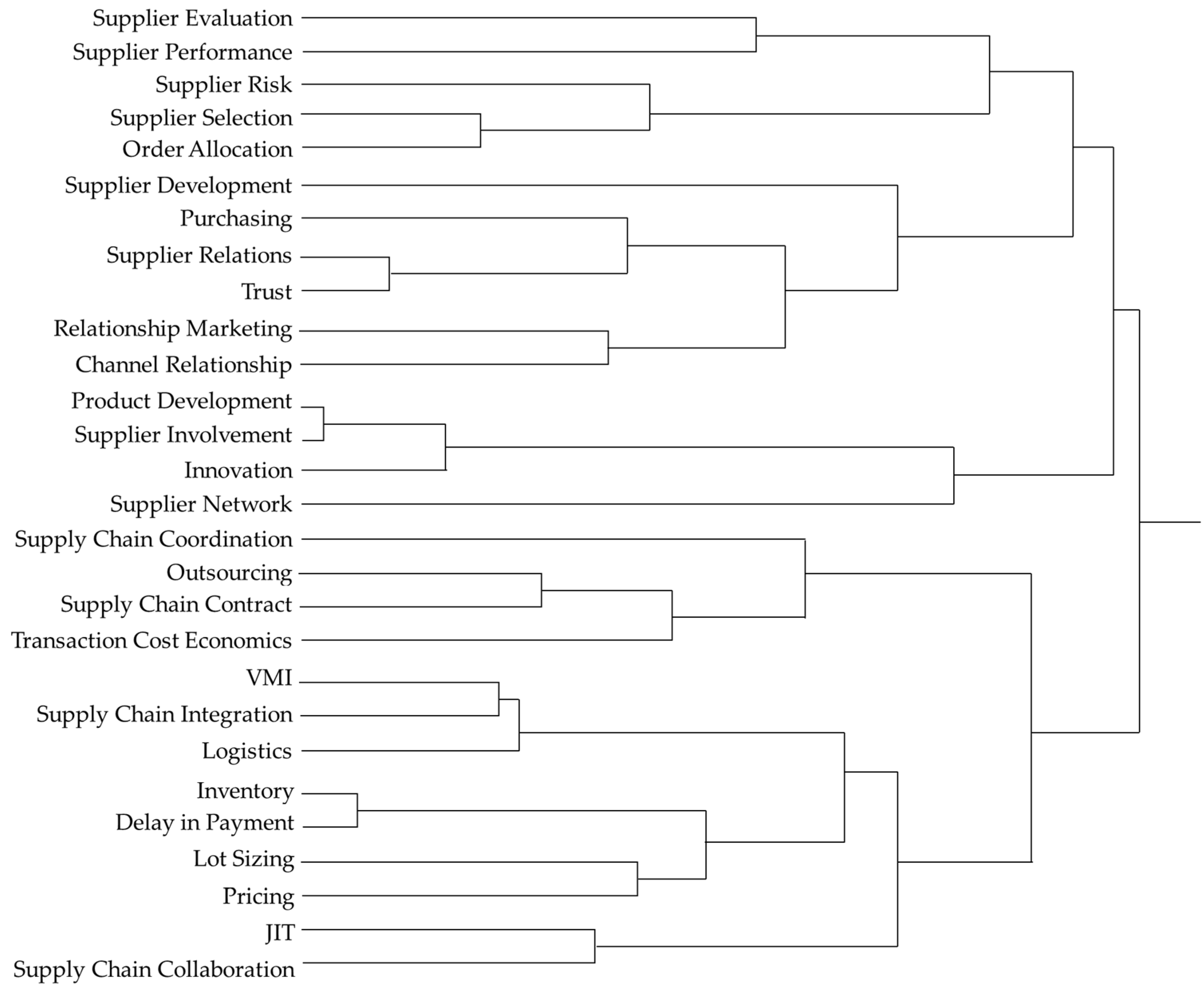

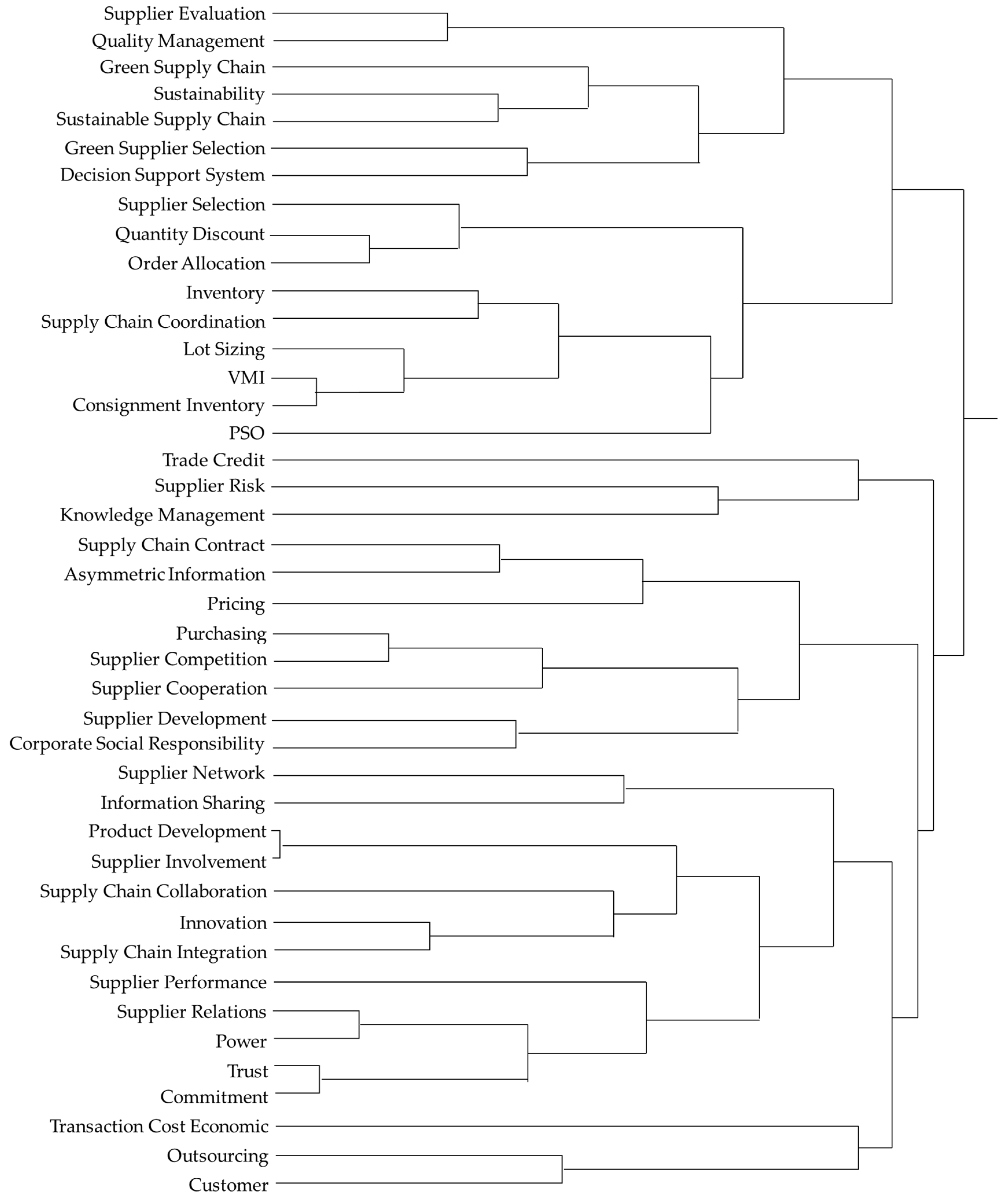

- The “supplier selection” cluster is also in the first quadrant of strategic diagram for stage 4 (Figure 13), indicating its importance in the field of supplier management. It should be noted that the “supplier selection” cluster is not stable because its theme members are always changing. As can be seen from Figure 6, Figure 7, Figure 8 and Figure 9, there are only two theme members at stage 1, “supplier selection” and “quality management”; three members at stage 2, “supplier network”, “supplier selection” and “environmental management”; five members at stage 3, “supplier evaluation”, “supplier performance”, “supplier risk”, “supplier selection and “order allocation”; and three members at stage 4, “supplier selection”, “quantity discount” and “order allocation”. This shows that the “supplier” selection cluster is not focused on a specific topic, and the theme of “supplier selection” is not very closely related to other themes.

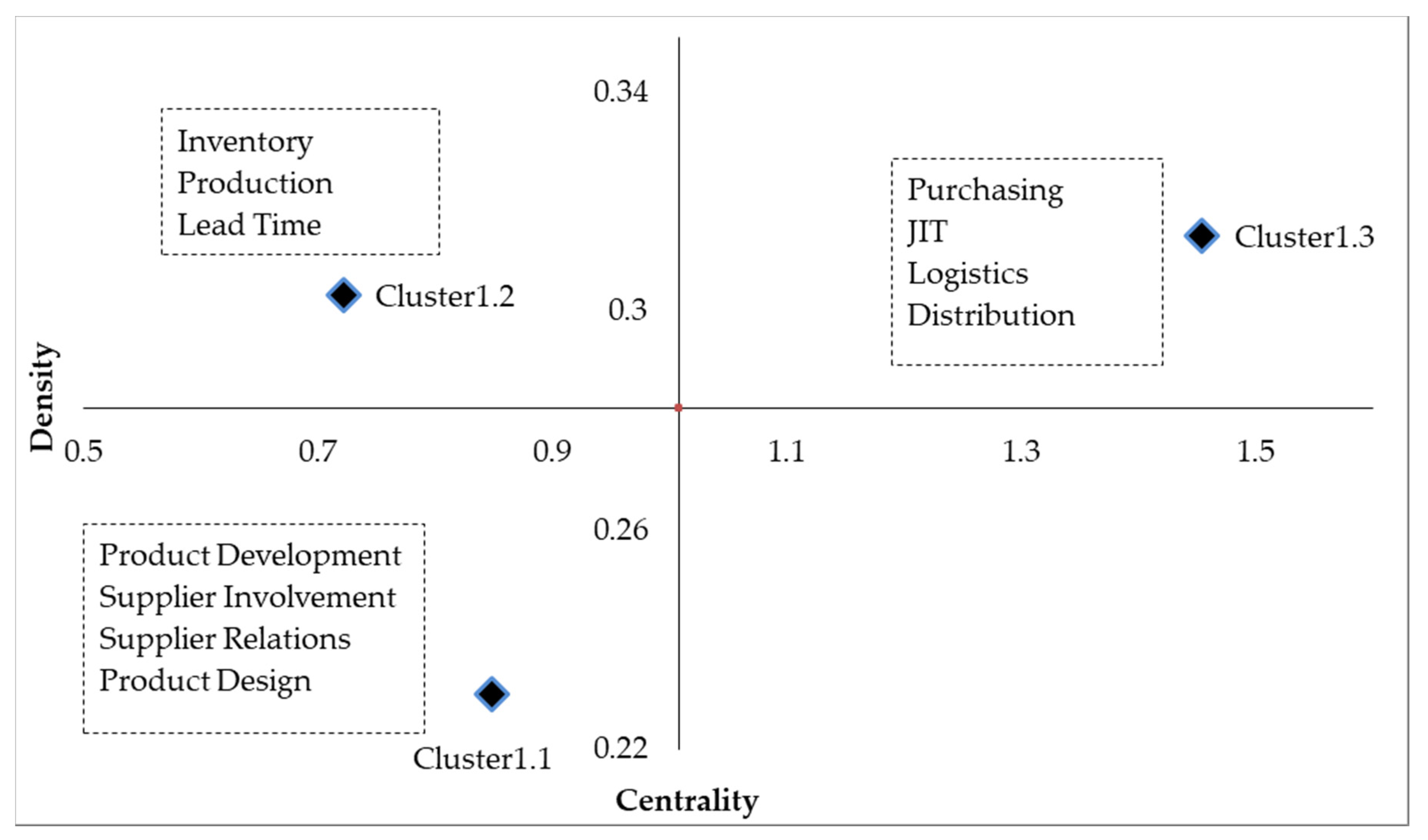

- As can be seen from Table 7, the evolution path of the “inventory” cluster is: cluster 1.2→cluster 2.5→cluster 3.5→cluster 4.3, and the quadrant changes of these clusters in the strategic diagram are: 2nd→3rd→4th→2nd. It can be summarized from Table 6 that the density of “inventory” cluster shows a trend of decreasing first and then increasing. Due to the addition of new theme members, such as “VMI” and “EOQ”, the density of “inventory” clusters decreased significantly from stage 1 to stage 2. However, the density increased significantly from stage 2 to stage 4, indicating that the strength of the linkages between themes within the cluster has been increasing, and the structural stability and maturity of the cluster have gradually improved.

- It can be seen from Table 7 that the quadrant changes of the “innovation” clusters (cluster 1.1→cluster 2.4→cluster 3.1→cluster 4.5) in the strategic diagram are: 3rd→3rd→2nd→4th, indicating that the strategic importance of “innovation” cluster in the study of supplier management is gradually increasing. It can also be summarized from Table 6 that the density of “innovation” cluster has gradually decreased during the research period, while the centrality has increased significantly from stages 2 to 4, indicating that the cluster is a relatively “open” cluster, and its impact on the entire research filed of supplier management has been gradually increasing.

- As can be seen from the strategic diagram for stage 4 (Figure 13), the “sustainability” cluster has become the new favorite of researchers, which is consistent with co-word analysis results. The “sustainability” cluster at stage 4 mainly includes five research themes: “green supply chain”, “sustainability”, “sustainable supply chain”, “green supplier selection”, and “decision support system”. However, it is worth noting that the density of “sustainability” cluster is relatively low, indicating that the relationship between themes within the cluster is relatively weak, and the stability and maturity of the structure need to be further improved.

5. Discussion

6. Conclusions

6.1. Theoretical Contributions and Management Implications

- Knowledge management in supply chain, such as key factors affecting knowledge management practices, obstacles to implementing knowledge management practices, and the impact of knowledge management practices on supply chain performance.

- Sustainable, green and strategic-oriented supplier selection.

- Supply chain innovation in industries other than manufacturing, such as healthcare, hospitality, construction, retail, etc.

- Quantitative research on sustainable supply chain and corporate social responsibility in supplier management.

- Social considerations in sustainable supply chain research.

- Cross-research on sustainability and other research themes, such as integration of corporate social responsibility and sustainability in the supply chain, sustainable supply chain innovation, supply chain cooperation and sustainability, green/sustainable/low-carbon supplier selection, etc.

6.2. Limitations

Author Contributions

Funding

Conflicts of Interest

References

- Soosay, C.A.; Hyland, P. A decade of supply chain collaboration and directions for future research. Supply Chain Manag. 2015, 20, 613–630. [Google Scholar] [CrossRef]

- Ahmad, M.T.; Mondal, S. Dynamic supplier selection model under two-echelon supply network. Expert Syst. Appl. 2016, 65, 255–270. [Google Scholar] [CrossRef]

- Simic, D.; Kovacevic, I.; Svircevic, V.; Simic, S. 50 years of fuzzy set theory and models for supplier assessment and selection: A literature review. J. Appl. Log. 2017, 24, 85–96. [Google Scholar] [CrossRef]

- Craighead, C.W.; Blackhurst, J.; Rungtusanatham, M.J.; Handfield, R.B. The severity of supply chain disruptions: Design characteristics and mitigation capabilities. Dec. Sci. 2007, 38, 131–156. [Google Scholar] [CrossRef]

- Kehr, T.W.; Proctor, M.D. People Pillars: Re-structuring the Toyota Production System (TPS) House Based on Inadequacies Revealed During the Automotive Recall Crisis. Qual. Reliab. Eng. Int. 2017, 33, 921–930. [Google Scholar] [CrossRef]

- Martins, C.L.; Pato, M.V. Supply chain sustainability: A tertiary literature review. J. Clean. Prod. 2019, 225, 995–1016. [Google Scholar] [CrossRef]

- Ahi, P.; Searcy, C. A comparative literature analysis of definitions for green and sustainable supply chain management. J. Clean. Prod. 2013, 52, 329–341. [Google Scholar] [CrossRef]

- Ansari, Z.N.; Kant, R. Exploring the Framework Development Status for Sustainability in Supply Chain Management: A Systematic Literature Synthesis and Future Research Directions. Bus. Strateg. Environ. 2017, 26, 873–892. [Google Scholar] [CrossRef]

- Roy, V.; Schoenherr, T.; Charan, P. The thematic landscape of literature in sustainable supply chain management (SSCM): A review of the principal facets in SSCM development. Int. J. Oper. Prod. Manag. 2018, 38, 1091–1124. [Google Scholar] [CrossRef]

- Das, C.; Jharkharia, S. Low carbon supply chain: A state-of-the-art literature review. J. Manuf. Technol. Manag. 2018, 29, 398–428. [Google Scholar] [CrossRef]

- De Oliveira, U.R.; Espindola, L.S.; da Silva, I.R.; da Silva, L.N.; Rocha, H.M. A systematic literature review on green supply chain management: Research implications and future perspectives. J. Clean. Prod. 2018, 187, 537–561. [Google Scholar] [CrossRef]

- Barbosa-Povoa, A.P.; da Silva, C.; Carvalho, A. Opportunities and challenges in sustainable supply chain: An operations research perspective. Eur. J. Oper. Res. 2018, 268, 299–431. [Google Scholar] [CrossRef]

- Alexander, A.; Walker, H.; Naim, M. Decision theory in sustainable supply chain management: A literature review. Supply Chain Manag. 2014, 19, 504–522. [Google Scholar] [CrossRef]

- Ansari, Z.N.; Kant, R. A state-of-art literature review reflecting 15 years of focus on sustainable supply chain management. J. Clean. Prod. 2017, 142, 2524–2543. [Google Scholar] [CrossRef]

- Tseng, M.L.; Islam, M.S.; Karia, N.; Fauzi, F.A.; Afrin, S. A literature review on green supply chain management: Trends and future challenges. Resour. Conserv. Recycl. 2019, 141, 145–162. [Google Scholar] [CrossRef]

- Luthra, S.; Garg, D.; Haleem, A. Critical success factors of green supply chain management for achieving sustainability in Indian automobile industry. Prod. Plan. Control 2015, 26, 339–362. [Google Scholar]

- Maditati, D.R.; Munim, Z.H.; Schramm, H.J.; Kummer, S. A review of green supply chain management: From bibliometric analysis to a conceptual framework and future research directions. Resour. Conserv. Recycl. 2018, 139, 150–162. [Google Scholar] [CrossRef]

- Saeed, M.A.; Kersten, W. Drivers of Sustainable Supply Chain Management: Identification and Classification. Sustainability 2019, 11, 1137. [Google Scholar] [CrossRef]

- Koberg, E.; Longoni, A. A systematic review of sustainable supply chain management in global supply chains. J. Clean. Prod. 2019, 207, 1094–1098. [Google Scholar] [CrossRef]

- Tebaldi, L.; Bigliardi, B.; Bottani, E. Sustainable Supply Chain and Innovation: A Review of the Recent Literature. Sustainability 2018, 10, 3946. [Google Scholar] [CrossRef]

- Zimmer, K.; Frohling, M.; Schultmann, F. Sustainable supplier management—A review of models supporting sustainable supplier selection, monitoring and development. Int. J. Prod. Res. 2016, 54, 1412–1442. [Google Scholar] [CrossRef]

- Mishra, D.; Gunasekaran, A.; Papadopoulos, T.; Hazen, B. Green supply chain performance measures: A review and bibliometric analysis. Sustain. Prod. Consump. 2017, 10, 85–99. [Google Scholar] [CrossRef]

- Liu, J.J.; Feng, Y.T.; Zhu, Q.H.; Sarkis, J. Green supply chain management and the circular economy: Reviewing theory for advancement of both fields. Int. J. Phys. Distrib. Logist. Manag. 2018, 48, 794–817. [Google Scholar] [CrossRef]

- Ho, W.; Zheng, T.; Yildiz, H.; Talluri, S. Supply chain risk management: A literature review. Int. J. Prod. Res. 2015, 53, 5031–5069. [Google Scholar] [CrossRef]

- Fan, Y.Y.; Stevenson, M. A review of supply chain risk management: Definition, theory, and research agenda. Int. J. Phys. Distrib. Logist. Manag. 2018, 48, 205–230. [Google Scholar] [CrossRef]

- Zhu, Q.; Krikke, H.; Caniels, M.C.J. Integrated supply chain risk management: A systematic review. Int. J. Logist. Manag. 2017, 28, 1123–1141. [Google Scholar] [CrossRef]

- Cunha, L.; Ceryno, P.; Leiras, A. Social supply chain risk management: A taxonomy, a framework and a research agenda. J. Clean. Prod. 2019, 220, 995–1016. [Google Scholar] [CrossRef]

- Wetzstein, A.; Hartmann, E.; Benton, W.C.; Hohenstein, N.O. A systematic assessment of supplier selection literature—State-of-the-art and future scope. Int. J. Prod. Econ. 2016, 182, 304–323. [Google Scholar] [CrossRef]

- Ho, D.; Kumar, A.; Shiwakoti, N. A Literature Review of Supply Chain Collaboration Mechanisms and Their Impact on Performance. Eng. Manag. J. 2019, 31, 47–68. [Google Scholar] [CrossRef]

- Ralston, P.M.; Richey, R.G.; Grawe, S.J. The past and future of supply chain collaboration: A literature synthesis and call for research. Int. J. Logist. Manag. 2017, 28, 508–530. [Google Scholar] [CrossRef]

- Adams, F.G.; Richey, R.G.; Autry, C.W.; Morgan, T.R.; Gabler, C.B. Supply Chain Collaboration, Integration, and Relational Technology: How Complex Operant Resources Increase Performance Outcomes. J. Bus. Logist. 2014, 35, 299–317. [Google Scholar] [CrossRef]

- Ma, K.; Pal, R.; Gustafsson, E. What modelling research on supply chain collaboration informs us? Identifying key themes and future directions through a literature review. Int. J. Prod. Res. 2019, 57, 2179–2202. [Google Scholar] [CrossRef]

- Addo-Tenkorang, R.; Helo, P.T. Big data applications in operations/supply-chain management: A literature review. Comput. Ind. Eng. 2016, 101, 528–543. [Google Scholar] [CrossRef]

- Nguyen, T.; Zhou, L.; Spiegler, V.; Ieromonachou, P.; Lin, Y. Big data analytics in supply chain management: A state-of-the-art literature review. Comput. Oper. Res. 2018, 98, 254–264. [Google Scholar]

- Ben-Daya, M.; Hassini, E.; Bahroun, Z. Internet of things and supply chain management: A literature review. Int. J. Prod. Res. 2019, 57, 4719–4742. [Google Scholar] [CrossRef]

- Queiroz, M.M.; Telles, R.; Bonilla, S.H. Blockchain and supply chain management integration: A systematic review of the literature. Supply Chain Manag. 2019, 25, 241–254. [Google Scholar] [CrossRef]

- Cipriani, A.; Geddes, J. Comparison of systematic and narrative reviews: The example of the atypical antipsychotics. Epidemiol. Psichiatr. Soc. 2003, 12, 146–154. [Google Scholar] [CrossRef]

- Zhu, W.W.; Wang, Z.Q. The Collaborative Networks and Thematic Trends of Research on Purchasing and Supply Management for Environmental Sustainability: A Bibliometric Review. Sustainability 2018, 10, 1510. [Google Scholar] [CrossRef]

- Munoz-Leiva, F.; Veidma-del-Jesus, M.I.; Sanchez-Fernandez, J.; Lopez-Herrera, A.G. An application of co-word analysis and bibliometric maps for detecting the most highlighting themes in consumer behavior research from a longitudinal perspective. Qual. Quant. 2012, 46, 1077–1095. [Google Scholar] [CrossRef]

- Callon, M.; Courtial, J.P.; Laville, F. Co-word analysis as a tool for describing the network of interactions between basic and technological research: The case of polymer chemistry. Scientornetrics 1991, 22, 155–205. [Google Scholar] [CrossRef]

- Feng, Y.T.; Zhu, Q.H.; Lai, K.H. Corporate social responsibility for supply chain management: A literature review and bibliometric analysis. J. Clean. Prod. 2017, 158, 296–307. [Google Scholar] [CrossRef]

- Cerchione, R.; Esposito, E. A systematic review of supply chain knowledge management research: State of the art and research opportunities. Int. J. Prod. Econ. 2016, 182, 276–292. [Google Scholar] [CrossRef]

- Chao, C.M.; Cheng, B.W. Factors influencing the future relationship of hospital procurement staff with medical device suppliers. Soc. Behav. Pers. 2012, 40, 945–957. [Google Scholar] [CrossRef]

- Deng, C.P.; Mao, J.Y.; Wang, G.S. An empirical study on the source of vendors’ relational performance in offshore information systems outsourcing. Int. J. Inf. Manag. 2013, 33, 10–19. [Google Scholar] [CrossRef]

- Jain, M.; Khalil, S.; Johnston, W.J.; Cheng, J.M.S. The performance implications of power-trust relationship: The moderating role of commitment in the supplier-retailer relationship. Ind. Mark. Manag. 2014, 43, 312–321. [Google Scholar] [CrossRef]

- Jiang, Z.Z.; Henneberg, S.C.; Naude, P. Supplier relationship management in the construction industry: The effects of trust and dependence. J. Bus. Ind. Mark. 2012, 27, 3–15. [Google Scholar] [CrossRef]

- Chao, C.M.; Yu, C.T.; Cheng, B.W.; Chuang, P.C. Trust and commitment in relationships among medical equipment suppliers: Transaction cost and social exchange theories. Soc. Behav. Pers. 2013, 41, 1057–1069. [Google Scholar] [CrossRef]

- Cao, M.; Zhang, Q.Y. Supply chain collaboration: Impact on collaborative advantage and firm performance. J. Oper. Manag. 2011, 29, 163–180. [Google Scholar] [CrossRef]

- Gimenez, C.; Tachizawa, E.M. Extending sustainability to suppliers: A systematic literature review. Supply Chain Manag. 2012, 17, 531–543. [Google Scholar] [CrossRef]

- Wong, D.T.W.; Ngai, E.W.T. Critical review of supply chain innovation research (1999–2016). Ind. Mark. Manag. 2019, 82, 158–187. [Google Scholar] [CrossRef]

- Fahimnia, B.; Sarkis, J.; Davarzani, H. Green supply chain management: A review and bibliometric analysis. Int. J. Prod. Econ. 2015, 162, 101–114. [Google Scholar] [CrossRef]

- Ashby, A.; Leat, M.; Hudson-Smith, M. Making connections: A review of supply chain management and sustainability literature. Supply Chain Manag. 2012, 17, 497–516. [Google Scholar] [CrossRef]

| Rule | Example | |

|---|---|---|

| Before | After | |

| 1. Unify the singular and plural forms of keywords | supplier, suppliers | supplier |

| 2. Unify the different expressions of the same word | supplier, vendor | supplier |

| 3. Unify the abbreviation and full writing of the same word | VMI, Vendor managed inventory EOQ, Economic Order Quantity JIT, Just in Time PSO, Particle Swarm Optimization | VMI EOQ JIT PSO |

| 4. Unify different expressions of the same meaning | supplier selection, supplier selection problem | supplier selection |

| 5. Delete keywords that cannot represent the research theme | keywords representing regions, countries, industries, etc. | deleted |

| Stage 1 | Stage 2 | Stage 3 | Stage 4 |

|---|---|---|---|

| Supplier Relations Purchasing Inventory Product Development Supplier Selection Outsourcing Logistics JIT Supplier Involvement Production Supplier Cooperation Supply Contract Product Design Quality Management Lead Time Technology Transfer Supplier Rating Supply Chain Coordination Satisfaction Distribution Information System VMI | Supplier Relations Inventory Supplier Selection Purchasing Quality Management Product Development Supplier Evaluation Trust Supply Chain Coordination Supplier Network VMI Supplier Development Supplier Involvement Outsourcing Innovation Retailing Commitment EOQ Production Planning Environmental Management Supply Chain Collaboration Lead Time | Supplier Selection Supplier Relations Inventory Purchasing VMI Trust Supply Chain Coordination Supplier Evaluation Supplier Risk Outsourcing Supply Chain Integration Product Development Supplier Development Supplier Involvement Innovation Supplier Performance Delay in Payment Supply Chain Contract Order Allocation Logistics Lot Sizing Pricing Relationship Marketing Channel Relationship JIT Transaction Cost Economics Supplier Network Supply Chain Collaboration | Supplier Selection Supplier Relations Inventory VMI Purchasing Trust Outsourcing Supplier Risk Supplier Evaluation Supply Chain Coordination Product Development Innovation Green Supply Chain Supply Chain Contract Supplier Development Sustainability Supplier Performance Supply Chain Collaboration Green Supplier Selection Supplier Network Power Quality Management Supplier Competition Quantity Discount Sustainable Supply Chain Information Sharing Order Allocation Asymmetric Information Supplier Involvement Supply Chain Integration Lot Sizing Consignment Inventory Commitment Trade Credit Supplier Cooperation Pricing Transaction Cost Economics Decision Support System PSO Corporate Social Responsibility Knowledge Management Customer |

| Supplier Selection | Supplier Relations | Inventory | VMI | Purchasing | Trust | … | |

|---|---|---|---|---|---|---|---|

| Supplier Selection | 314 | 2 | 10 | 0 | 8 | 0 | … |

| Supplier Relations | 2 | 171 | 0 | 0 | 7 | 12 | … |

| Inventory | 10 | 0 | 88 | 11 | 2 | 0 | … |

| VMI | 0 | 0 | 11 | 63 | 0 | 0 | … |

| Purchasing | 8 | 7 | 2 | 0 | 56 | 1 | … |

| Trust | 0 | 12 | 0 | 0 | 1 | 47 | … |

| … | … | … | … | … | … | … | … |

| Research Theme | Freq./Year | Co-Occurrence Freq./Year | Quadrant |

|---|---|---|---|

| Stage: 1→2→3→4 | Stage: 1→2→3→4 | Stage: 1→2→3→4 | |

| Supplier Relations | 4.0→12.2→25.0→28.5 | 1.4→5.4→6.6→9.7 | 1st→1st→1st→1st |

| Supplier Selection | 1.8→5.8→35.2→52.3 | 0.4→0.8→3.8→11.3 | 2nd→2nd→1st→1st |

| Inventory | 3.0→7→13.6→14.7 | 1.8→2.0→6.0→6.2 | 1st→1st→1st→1st |

| Purchasing | 3.6→5.6→9.6→9.3 | 0.8→1.8→4.2→4.3 | 1st→1st→1st→1st |

| VMI | 0.6→1.6→8.4→10.5 | NA→0.4→2.8→5.2 | 3rd→3rd→1st→1st |

| Trust | NA→2.0→8.0→7.8 | NA→1.4→2.0→3.7 | NA→4th→1st→1st |

| Outsourcing | 1.4→1.4→4.6→7.0 | 0.6→0.6→1.6→2.3 | 1st→4th→4th→2nd |

| Product Development | 2.0→3.4→4.2→6.0 | 0.8→2.6→3.4→5.3 | 1st→1st→4th→4th |

| Supply Chain Coordination | 0.6→1.8→5.8→6.0 | NA→0.2→2.2→3.5 | 3rd→3rd→4th→4th |

| Supplier Evaluation | NA→2.4→5.6→6.2 | NA→0.6→1.4→2.5 | NA→3rd→3rd→4th |

| Supply Chain Collaboration | NA→1.0→1.6→4.5 | NA→0.2→1.0→2.8 | NA→3rd→3rd→4th |

| Green Supply Chain | NA→NA→NA→5.2 | NA→NA→NA→2.7 | NA→NA→NA→4th |

| Supplier Selection | Supplier Relations | Inventory | VMI | Purchasing | Trust | … | |

|---|---|---|---|---|---|---|---|

| Supplier Selection | 1 | 0.008631 | 0.060158 | 0 | 0.06033 | 0 | … |

| Supplier Relations | 0.008631 | 1 | 0 | 0 | 0.071533 | 0.133855 | … |

| Inventory | 0.060158 | 0 | 1 | 0.147734 | 0.02849 | 0 | … |

| VMI | 0 | 0 | 0.147734 | 1 | 0 | 0 | … |

| Purchasing | 0.06033 | 0.071533 | 0.02849 | 0 | 1 | 0.019492 | … |

| Trust | 0 | 0.133855 | 0 | 0 | 0.019492 | 1 | … |

| … | … | … | … | … | … | … | … |

| Cluster | Theme | Adhesion | External Linkage |

|---|---|---|---|

| Cluster 1.1 | Product Development | 0.219273 | 0.074536 |

| Supplier Involvement | 0.338644 | 0.192450 | |

| Supplier Relations | 0.152105 | 0.345719 | |

| Product Design | 0.210618 | 0.235702 | |

| Cluster 1.2 | Inventory | 0.454547 | 0.539341 |

| Production | 0.230940 | 0.182574 | |

| Lead Time | 0.223607 | 0.000000 | |

| Cluster 1.3 | Purchasing | 0.308604 | 0.729813 |

| JIT | 0.345522 | 0.393393 | |

| Logistics | 0.297410 | 0.182574 | |

| Distribution | 0.303744 | 0.149071 | |

| Cluster 2.1 | Supplier Network | 0.061898 | 0.085358 |

| Supplier Selection | 0.144944 | 0.353582 | |

| Environmental Management | 0.083045 | 0.186359 | |

| Cluster 2.2 | Supplier Evaluation | 0.105586 | 0.299069 |

| Purchasing | 0.121370 | 0.576599 | |

| Supplier Development | 0.117846 | 0.090536 | |

| Cluster 2.3 | Quality Management | 0.066949 | 0.256129 |

| Supplier Relations | 0.170502 | 0.604400 | |

| Trust | 0.296143 | 0.240828 | |

| Commitment | 0.297132 | 0.235098 | |

| Cluster 2.4 | Innovation | 0.105657 | 0.118580 |

| Product Development | 0.276339 | 0.429758 | |

| Supplier Involvement | 0.240164 | 0.000000 | |

| Supply Chain Collaboration | 0.125015 | 0.084515 | |

| Cluster 2.5 | Supply Chain Coordination | 0.057635 | 0.303391 |

| VMI | 0.074284 | 0.000000 | |

| EOQ | 0.087796 | 0.000000 | |

| Inventory | 0.167484 | 0.174544 | |

| Lead Time | 0.106695 | 0.084515 | |

| Cluster 3.1 | Product Development | 0.247634 | 0.232191 |

| Supplier Involvement | 0.238317 | 0.122865 | |

| Innovation | 0.137446 | 0.212236 | |

| Supplier Network | 0.025717 | 0.031623 | |

| Cluster 3.2 | Supplier Evaluation | 0.051980 | 0.171947 |

| Supplier Performance | 0.013639 | 0.119126 | |

| Supplier Risk | 0.053074 | 0.246429 | |

| Supplier Selection | 0.072960 | 0.401387 | |

| Order Allocation | 0.089662 | 0.036564 | |

| Cluster 3.3 | Supplier Development | 0.030548 | 0.107676 |

| Purchasing | 0.043002 | 0.561042 | |

| Supplier Relations | 0.138244 | 0.586022 | |

| Trust | 0.068073 | 0.217986 | |

| Relationship Marketing | 0.061193 | 0.061898 | |

| Channel Relationship | 0.046074 | 0.000000 | |

| Cluster 3.4 | Supply Chain Coordination | 0.050233 | 0.447835 |

| Outsourcing | 0.077988 | 0.338943 | |

| Supply Chain Contract | 0.112740 | 0.129612 | |

| Transaction Cost Economics | 0.056670 | 0.280984 | |

| Cluster 3.5 | VMI | 0.075304 | 0.258587 |

| Supply Chain Integration | 0.064856 | 0.139876 | |

| Logistics | 0.054955 | 0.229620 | |

| Inventory | 0.106196 | 0.275574 | |

| Delay in Payment | 0.041134 | 0.000000 | |

| Lot Sizing | 0.065394 | 0.106395 | |

| Pricing | 0.040385 | 0.000000 | |

| JIT | 0.047106 | 0.103053 | |

| Supply Chain Collaboration | 0.036554 | 0.241484 | |

| Cluster 4.1 | Green Supply Chain | 0.083354 | 0.173655 |

| Sustainability | 0.053899 | 0.187043 | |

| Sustainable Supply Chain | 0.081321 | 0.124722 | |

| Green Supplier Selection | 0.072789 | 0.104530 | |

| Decision Support System | 0.054108 | 0.237223 | |

| Cluster 4.2 | Supplier Selection | 0.131158 | 0.642830 |

| Quantity Discount | 0.141863 | 0.344860 | |

| Order Allocation | 0.167116 | 0.327421 | |

| Cluster 4.3 | Inventory | 0.100741 | 0.213843 |

| Supply Chain Coordination | 0.109194 | 0.390706 | |

| Lot Sizing | 0.113048 | 0.340296 | |

| VMI | 0.167466 | 0.109706 | |

| Consignment Inventory | 0.176077 | 0.000000 | |

| Cluster 4.4 | Purchasing | 0.101449 | 0.444194 |

| Supplier Competition | 0.167184 | 0.224176 | |

| Supply Chain Cooperation | 0.101449 | 0.397488 | |

| Cluster 4.5 | Product Development | 0.184216 | 0.233889 |

| Supplier Involvement | 0.119608 | 0.108746 | |

| Supply Chain Collaboration | 0.069649 | 0.466321 | |

| Innovation | 0.091144 | 0.305743 | |

| Supply Chain Integration | 0.087510 | 0.112703 | |

| Cluster 4.6 | Supplier Performance | 0.067757 | 0.298894 |

| Supplier Relations | 0.119160 | 0.654365 | |

| Power | 0.136367 | 0.125993 | |

| Trust | 0.191583 | 0.245327 | |

| Commitment | 0.121623 | 0.293105 |

| Group | Evolution Path | Quadrant |

|---|---|---|

| Inventory | Cluster 1.2→Cluster 2.5→Cluster 3.5→Cluster 4.3 | 2nd→3rd→4th→2nd |

| Innovation | Cluster 1.1→Cluster 2.4→Cluster 3.1→Cluster 4.5 | 3rd→3rd→2nd→4th |

| Supplier Relations | Cluster 2.3→Cluster 3.3→Cluster 4.6 | 1st→4th→1st |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wen, D.; Sun, X.; Liu, Y. Bibliometric Analysis of Supplier Management: The Theme and Cluster Perspectives. Sustainability 2020, 12, 2572. https://doi.org/10.3390/su12062572

Wen D, Sun X, Liu Y. Bibliometric Analysis of Supplier Management: The Theme and Cluster Perspectives. Sustainability. 2020; 12(6):2572. https://doi.org/10.3390/su12062572

Chicago/Turabian StyleWen, Decheng, Xiaojing Sun, and Yuying Liu. 2020. "Bibliometric Analysis of Supplier Management: The Theme and Cluster Perspectives" Sustainability 12, no. 6: 2572. https://doi.org/10.3390/su12062572

APA StyleWen, D., Sun, X., & Liu, Y. (2020). Bibliometric Analysis of Supplier Management: The Theme and Cluster Perspectives. Sustainability, 12(6), 2572. https://doi.org/10.3390/su12062572