Numerical Simulation on the Influence of the Longitudinal Fins on the Enhancement of a Shell-and-Tube Ice Storage Device

Abstract

1. Introduction

2. Mathematical Model

- (1)

- Only laminar flow is considered in this simulation;

- (2)

- The materials of the equipment, including water, ice, shell, tube and fin are isotropic;

- (3)

- The physical parameters, except density of the water, are constant throughout this work;

- (4)

- There is considered to be a local equilibrium of temperature and heat flux between water and fins [37].

2.1. Governing Equations

2.2. Numerical Solutions

2.3. Model Validation

3. Results and Discussion

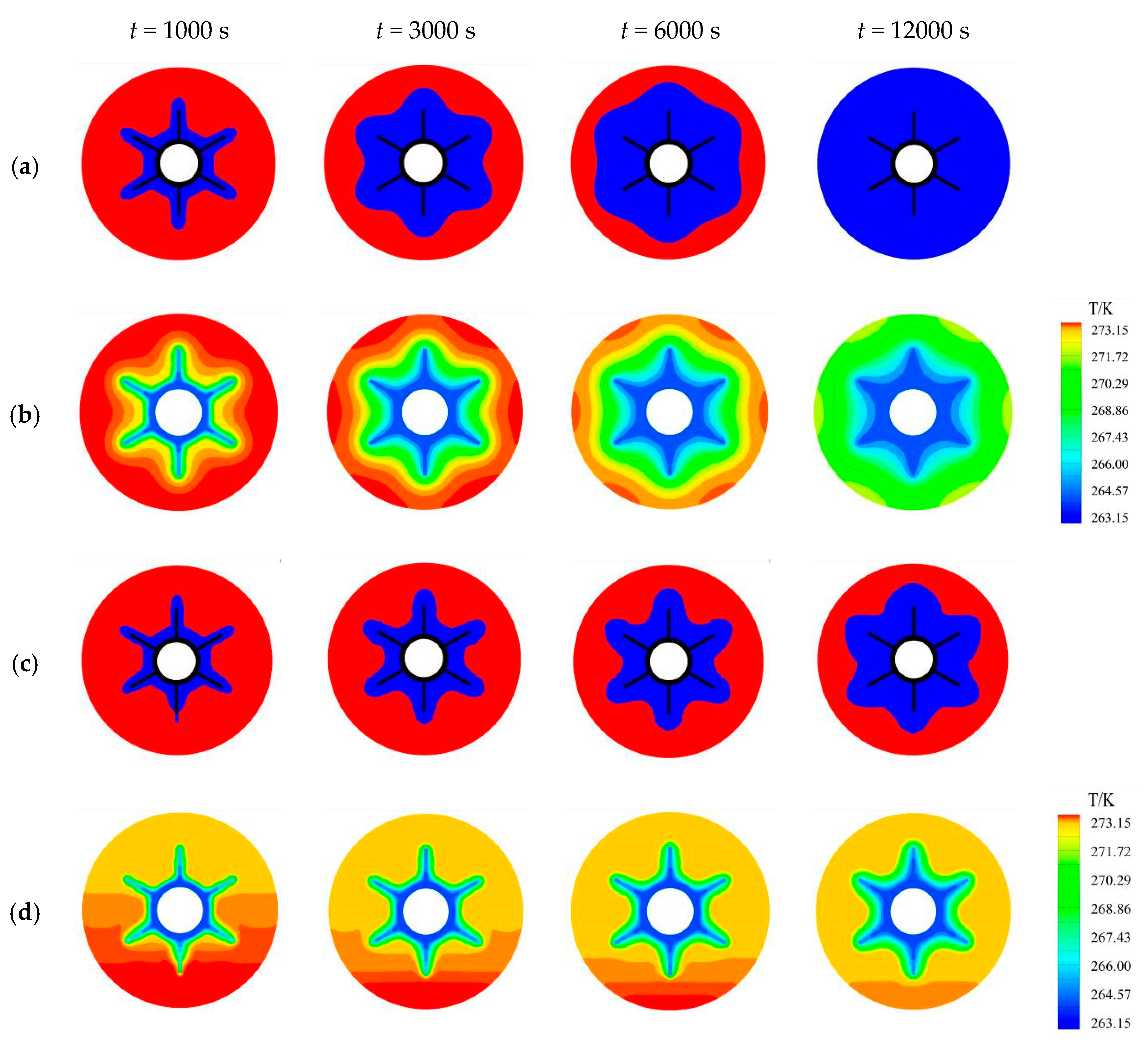

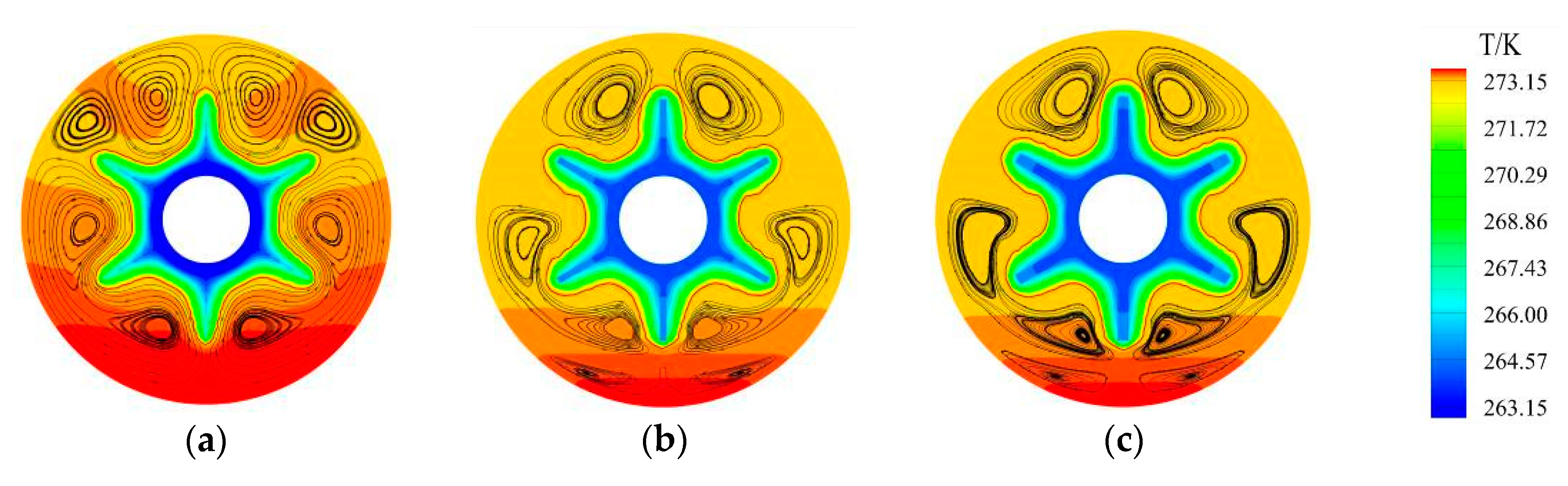

3.1. Solidification Process

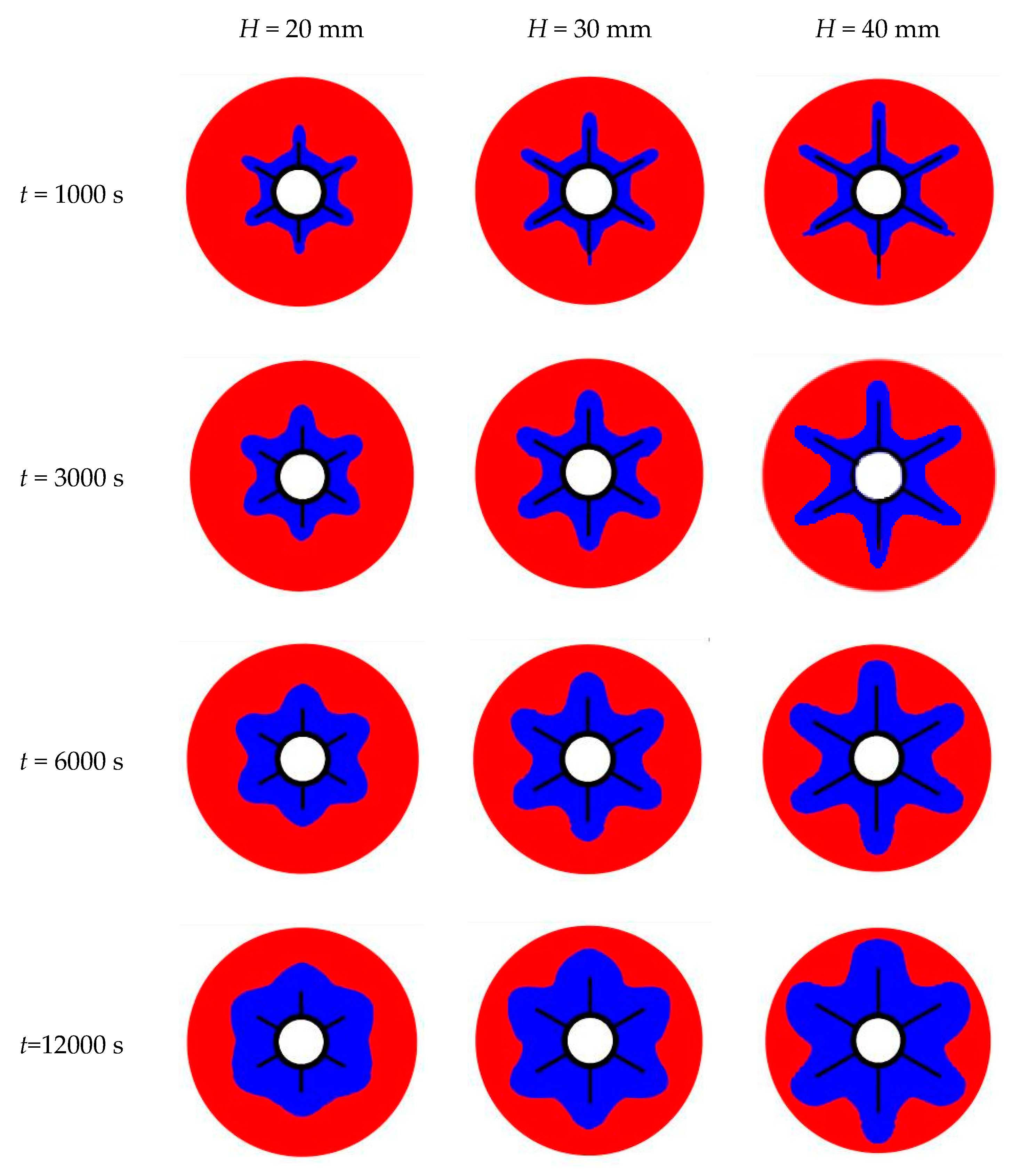

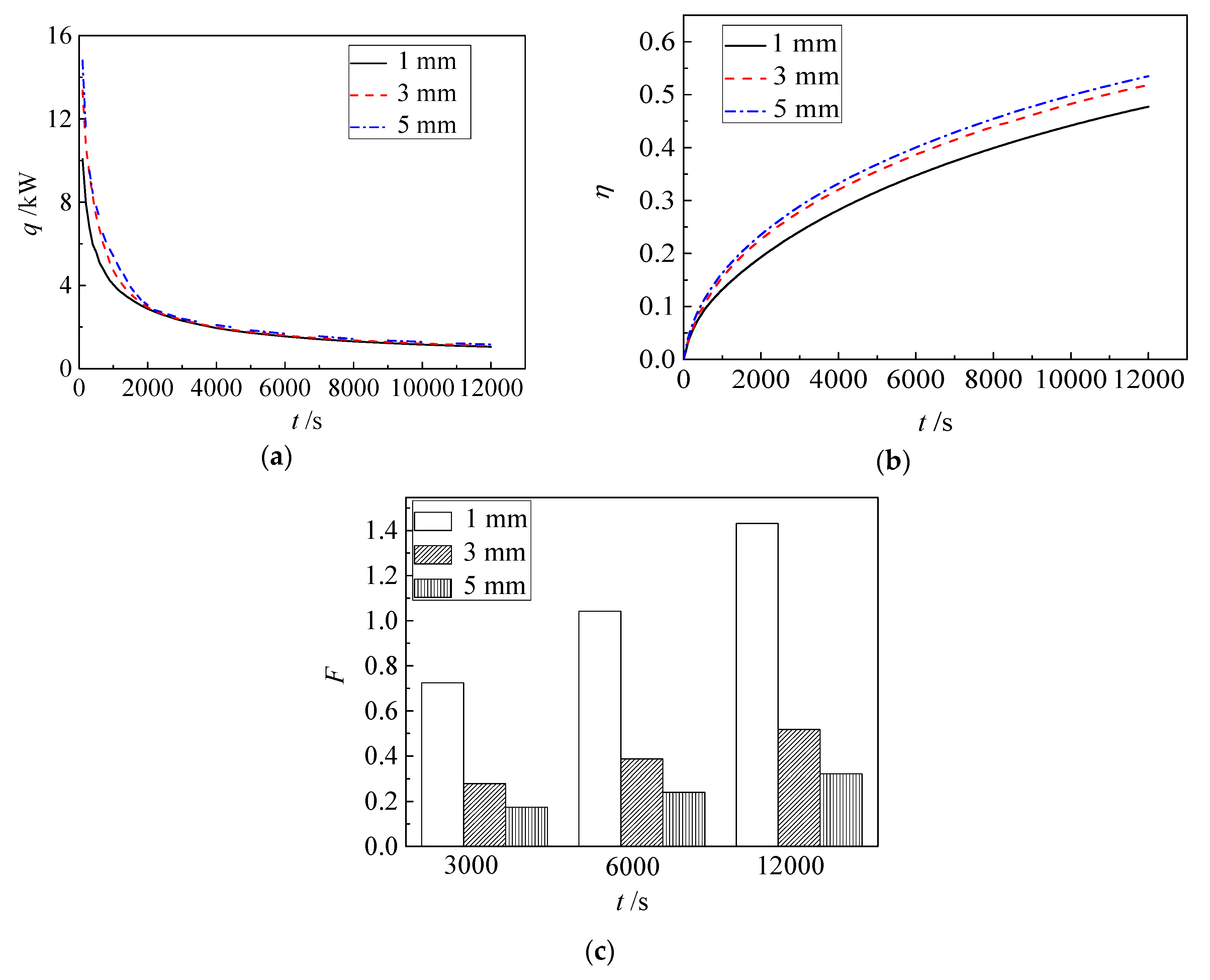

3.2. Influence of the Fin Height

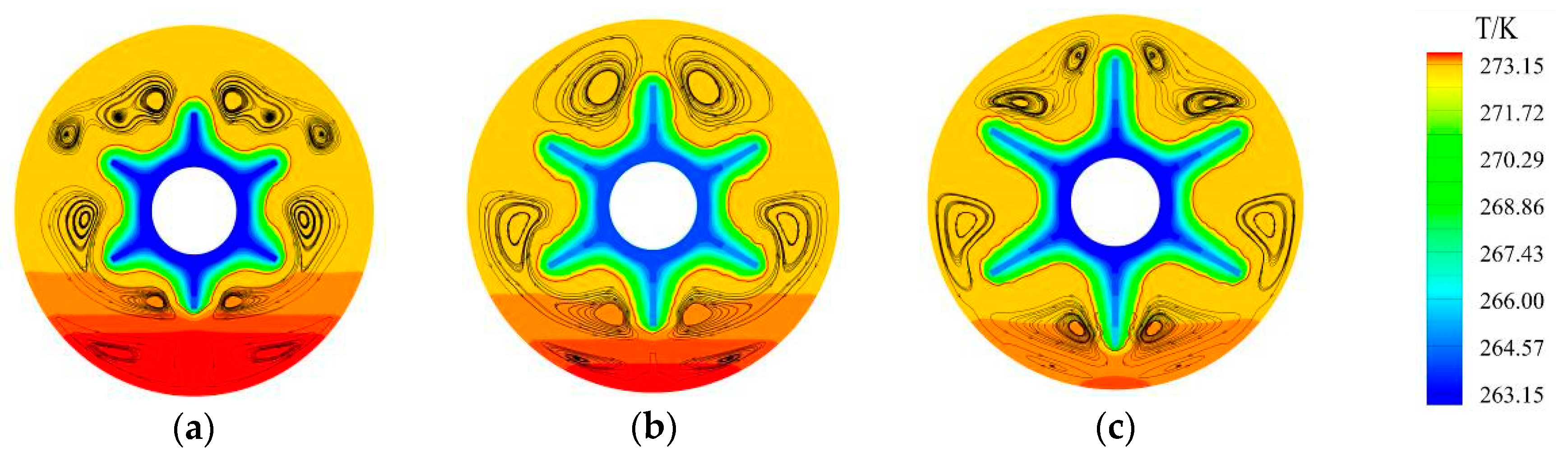

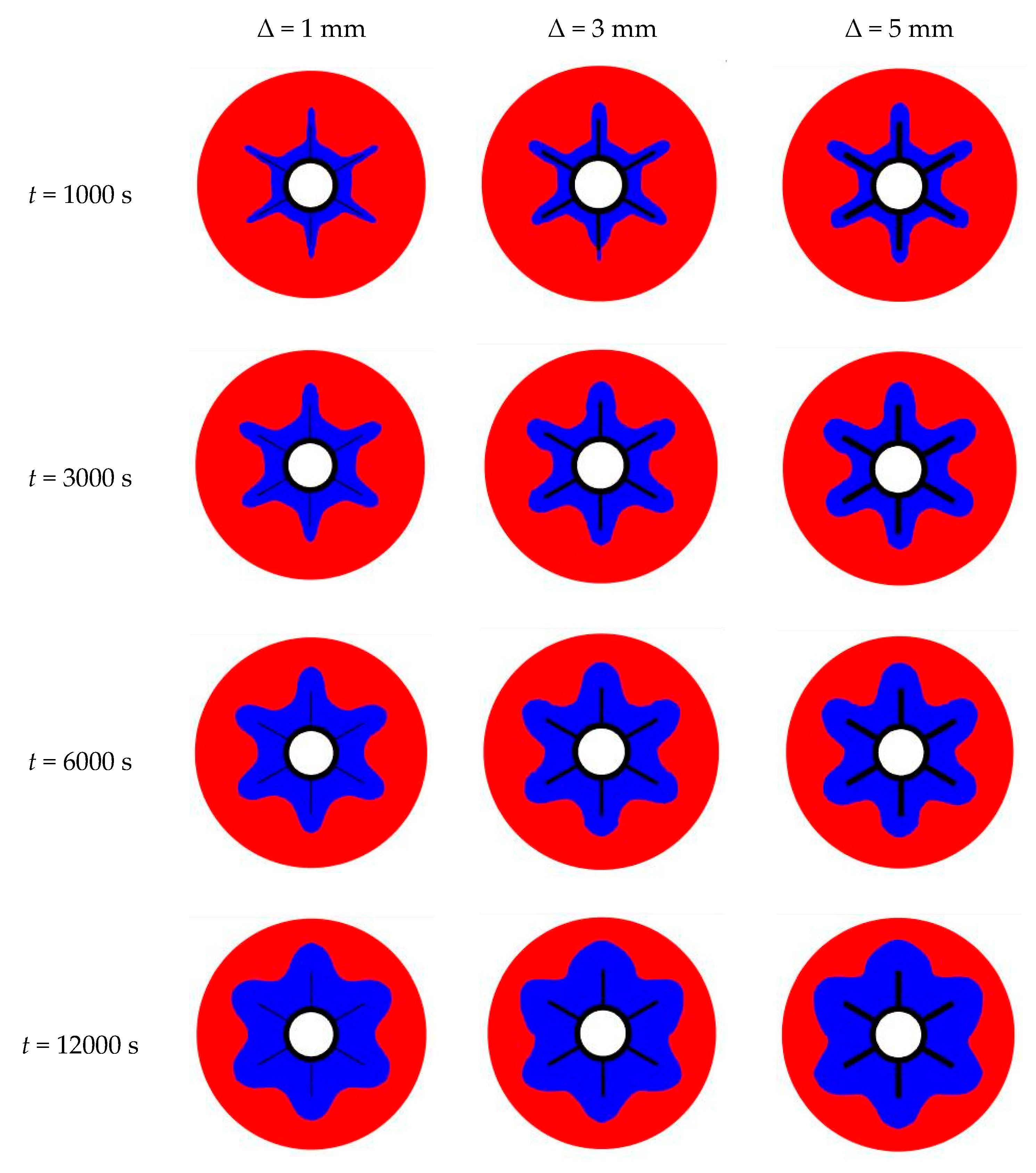

3.3. Influence of Fin Thickness

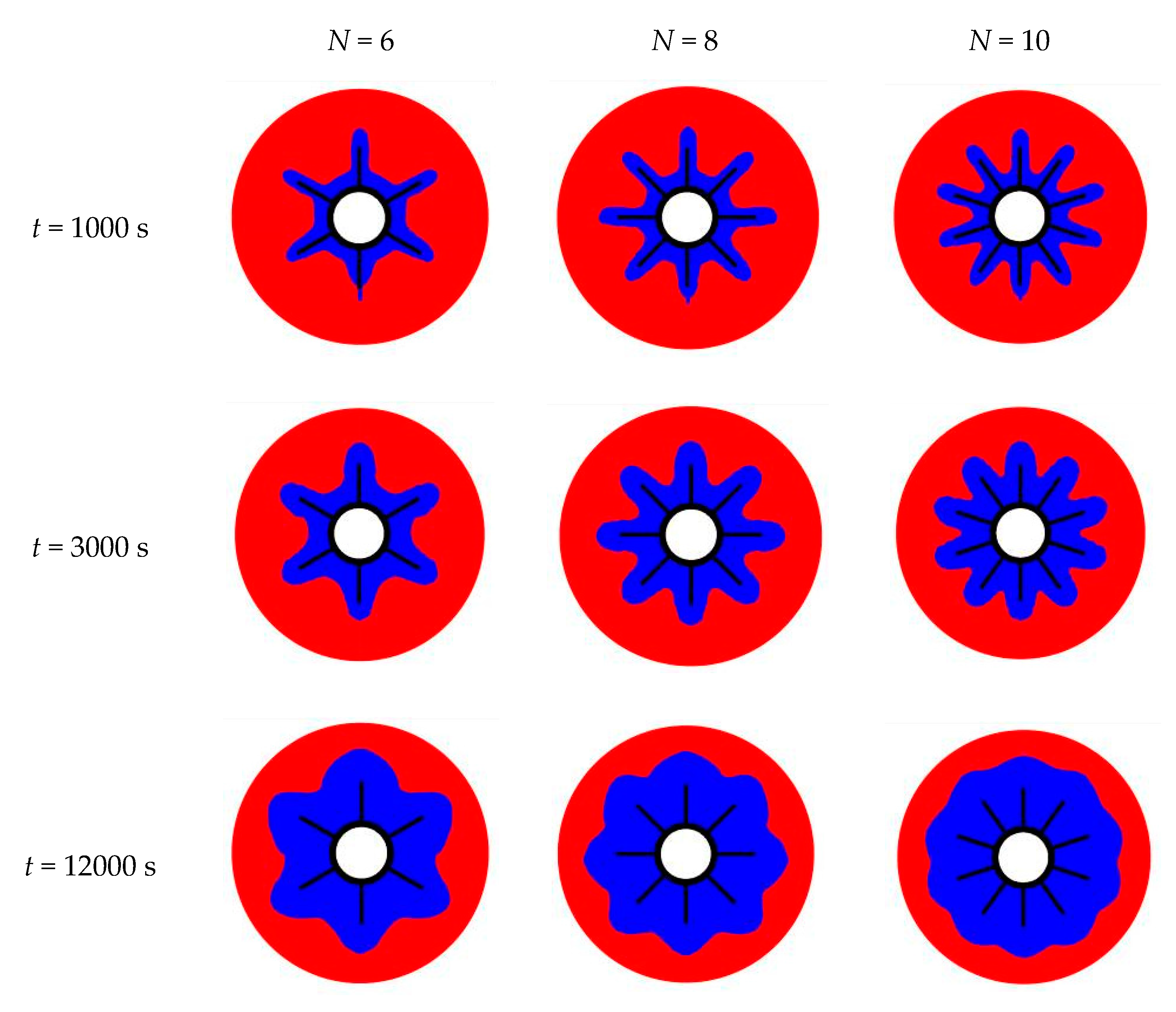

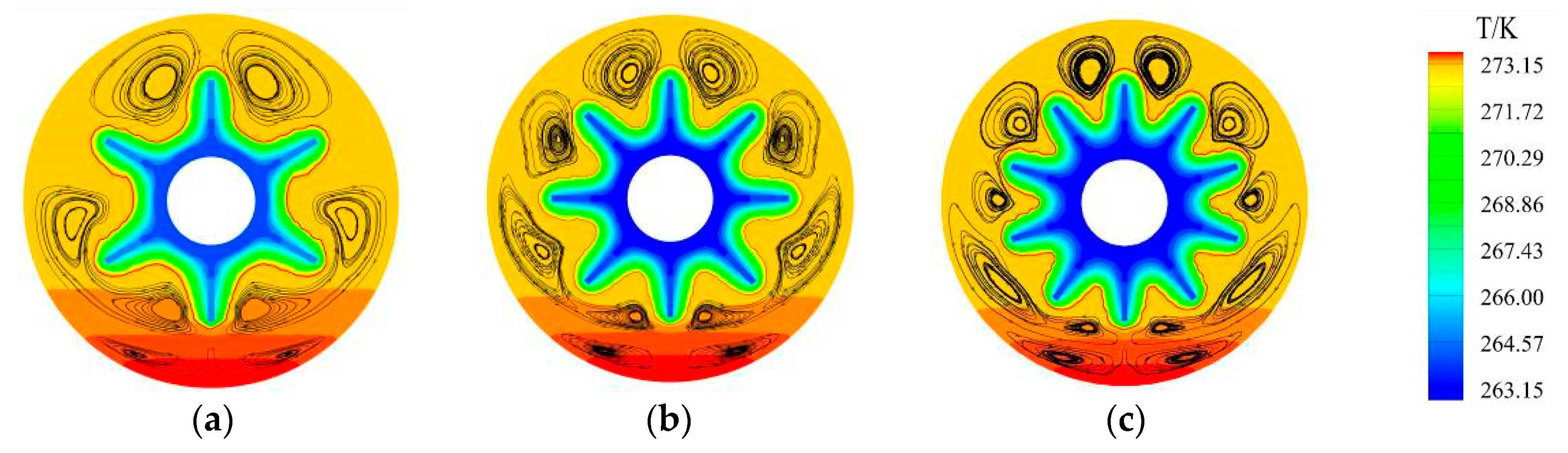

3.4. Influence of the Fin Number

4. Conclusions

- (1)

- The solidification process is fast at the initial stage and slows down due to the increasing thickness of the ice. The dominating factor of the ice freezing process is the heat transfer via the fins at the beginning, and then the heat transfer at the water–ice interface.

- (2)

- The ice storage is negatively affected by the NC, because the water with a higher temperature stays in the lower part of the STIS device and the temperature gradient at the water–ice interface is small.

- (3)

- With longitudinal fins, the ice storage area is divided into several parts, resulting in the restriction of the flow and weaker vortex flow. Therefore, the NC can be weakened by the fins.

- (4)

- The ice storage performance can be enhanced by increasing the fin structure parameters, including the height, the thickness and the number. Among these methods, increasing the fin height is the most effective on weakening the NC, which can last for a longer time. The enhancement by increasing the thickness or the number of the fins is obvious at the beginning. Considering the fin area, the increase of fin number is highly recommended for the enhancement of the ice storage performance.

Author Contributions

Funding

Conflicts of Interest

References

- Yan, C.; Shi, W.; Li, X.; Zhao, Y. Optimal design and application of a compound cold storage system combining seasonal ice storage and chilled water storage. Appl. Energy 2016, 171, 1–11. [Google Scholar] [CrossRef]

- Song, X.; Zhu, T.; Liu, L.; Cao, Z. Study on optimal ice storage capacity of ice thermal storage system and its influence factors. Energ Convers. Manag. 2018, 164, 288–300. [Google Scholar] [CrossRef]

- Mousavi Ajarostaghi, S.S.; Poncet, S.; Sedighi, K.; Aghajani Delavar, M. Numerical modeling of the melting process in a shell and coil tube ice storage system for air-conditioning application. Appl. Sci. 2019, 9, 2726. [Google Scholar] [CrossRef]

- Pathak, S.; Jain, K.; Kumar, P.; Wang, X.; Pant, R.P. Improved thermal performance of annular fin-shell tube storage system using magnetic fluid. Appl. Energy 2019, 239, 1524–1535. [Google Scholar] [CrossRef]

- Mammoli, A.; Robinson, M. Numerical analysis of heat transfer processes in a low-cost, high-performance ice storage device for residential applications. Appl. Therm. Eng. 2018, 128, 453–463. [Google Scholar] [CrossRef]

- Sun, L.; Li, G.; Hua, Q.S.; Jin, Y. A hybrid paradigm combining model-based and data-driven methods for fuel cell stack cooling control. Renew. Energy 2020, 147, 1642–1652. [Google Scholar] [CrossRef]

- Song, X.; Liu, L.; Zhu, T.; Chen, S.; Cao, Z. Study of economic feasibility of a compound cool thermal storage system combining chilled water storage and ice storage. Appl. Therm. Eng. 2018, 133, 613–621. [Google Scholar] [CrossRef]

- Li, Y.; Yan, Z.; Yang, C.; Guo, B.; Yuan, H.; Zhao, J.; Mei, N. Study of a coil heat exchanger with an ice storage system. Energies 2017, 10, 1982. [Google Scholar]

- Sun, L.; Shen, J.; Hua, Q.S.; Lee, K.Y. Data-driven oxygen excess ratio control for proton exchange membrane fuel cell. Appl. Energ 2018, 231, 866–875. [Google Scholar] [CrossRef]

- Ma, X.; Sheikholeslami, M.; Jafaryar, M.; Shafee, A.; Nguyen-Thoi, T.; Li, Z. Solidification inside a clean energy storage unit utilizing phase change material with copper oxide nanoparticles. J. Clean. Prod. 2020, 245, 118888. [Google Scholar] [CrossRef]

- Xu, Y.; Ren, Q.; Zheng, Z.-J.; He, Y.-L. Evaluation and optimization of melting performance for a latent heat thermal energy storage unit partially filled with porous media. Appl. Energy 2017, 193, 84–95. [Google Scholar] [CrossRef]

- Zhang, C.B.; Yu, C.; Liu, X.D.; Jin, O.; Chen, Y.P. Steady deformation characteristics of double emulsion droplet in shear flow. Acta Phys. Sin. 2016, 65, 204704. [Google Scholar]

- Lan, K.; Liu, J.; Li, Z.; Xie, X.; Huo, W.; Chen, Y.; Ren, G.; Zheng, C.; Yang, D.; Li, S.; et al. Progress in octahedral spherical hohlraum study. Matter Radiat. Extrem. 2016, 1, 8–27. [Google Scholar] [CrossRef]

- Ndraha, N.; Hsiao, H.-I.; Vlajic, J.; Yang, M.-F.; Lin, H.-T.V. Time-temperature abuse in the food cold chain: Review of issues, challenges, and recommendations. Food Control 2018, 89, 12–21. [Google Scholar] [CrossRef]

- Lo, C.-C.; Tsai, S.-H.; Lin, B.-S. Ice storage air-conditioning system simulation with dynamic electricity pricing: A demand response study. Energies 2016, 9, 113. [Google Scholar] [CrossRef]

- Hoseini Rahdar, M.; Emamzadeh, A.; Ataei, A. A comparative study on pcm and ice thermal energy storage tank for air-conditioning systems in office buildings. Appl. Therm. Eng. 2016, 96, 391–399. [Google Scholar] [CrossRef]

- Wang, J.; Gao, W.; Zhang, H.; Zou, M.H.; Chen, Y.P.; Zhao, Y.J. Programmable wettability on photocontrolled graphene film. Sci. Adv. 2018, 4, eaat7392. [Google Scholar] [CrossRef]

- Al-Shannaq, R.; Young, B.; Farid, M. Cold energy storage in a packed bed of novel graphite/pcm composite spheres. Energy 2019, 171, 296–305. [Google Scholar] [CrossRef]

- Zhang, C.; Li, J.; Chen, Y. Improving the energy discharging performance of a latent heat storage (lhs) unit using fractal-tree-shaped fins. Appl. Energy 2019, 259, 114102. [Google Scholar] [CrossRef]

- Yang, X.; Niu, Z.; Bai, Q.; Li, H.; Cui, X.; He, Y.-L. Experimental study on the solidification process of fluid saturated in fin-foam composites for cold storage. Appl. Therm. Eng. 2019, 161, 114163. [Google Scholar] [CrossRef]

- Li, S.; Dong, B.; Wang, J.; Li, J.; Shen, T.; Peng, H.; Ling, X. Synthesis and characterization of mixed alkanes microcapsules with phase change temperature below ice point for cryogenic thermal energy storage. Energy 2019, 187, 115898. [Google Scholar] [CrossRef]

- Chen, Y.; Gao, W.; Zhang, C.; Zhao, Y. Three-dimensional splitting microfluidics. Lab. Chip 2016, 16, 1332–1339. [Google Scholar] [CrossRef] [PubMed]

- Lohrasbi, S.; Sheikholeslami, M.; Ganji, D.D. Multi-objective rsm optimization of fin assisted latent heat thermal energy storage system based on solidification process of phase change material in presence of copper nanoparticles. Appl. Therm. Eng. 2017, 118, 430–447. [Google Scholar] [CrossRef]

- Yan, C.; Shi, W.; Li, X.; Wang, S. A seasonal cold storage system based on separate type heat pipe for sustainable building cooling. Renew. Energy 2016, 85, 880–889. [Google Scholar] [CrossRef]

- Liu, X.; Chen, Y.; Shi, M. Dynamic performance analysis on start-up of closed-loop pulsating heat pipes (clphps). Int. J. Therm. Sci. 2013, 65, 224–233. [Google Scholar] [CrossRef]

- Zhao, D.; Tan, G. Numerical analysis of a shell-and-tube latent heat storage unit with fins for air-conditioning application. Appl. Energy 2015, 138, 381–392. [Google Scholar] [CrossRef]

- Hosseini, M.J.; Ranjbar, A.A.; Rahimi, M.; Bahrampoury, R. Experimental and numerical evaluation of longitudinally finned latent heat thermal storage systems. Energ Build. 2015, 99, 263–272. [Google Scholar] [CrossRef]

- Pandiyarajan, V.; Chinna Pandian, M.; Malan, E.; Velraj, R.; Seeniraj, R.V. Experimental investigation on heat recovery from diesel engine exhaust using finned shell and tube heat exchanger and thermal storage system. Appl. Energy 2011, 88, 77–87. [Google Scholar] [CrossRef]

- Mosaffa, A.H.; Talati, F.; Basirat Tabrizi, H.; Rosen, M.A. Analytical modeling of pcm solidification in a shell and tube finned thermal storage for air conditioning systems. Energ Build. 2012, 49, 356–361. [Google Scholar] [CrossRef]

- Longeon, M.; Soupart, A.; Fourmigué, J.-F.; Bruch, A.; Marty, P. Experimental and numerical study of annular pcm storage in the presence of natural convection. Appl. Energy 2013, 112, 175–184. [Google Scholar] [CrossRef]

- Seddegh, S.; Joybari, M.M.; Wang, X.; Haghighat, F. Experimental and numerical characterization of natural convection in a vertical shell-and-tube latent thermal energy storage system. Sustain. Cities Soc. 2017, 35, 13–24. [Google Scholar] [CrossRef]

- Bo, L.; Zhanwen, Z.; Zhibing, H.; Dangzhong, G.; Sufen, C.; Xiaoshan, H.; Xuesen, Z.; Xiaobo, Q.; Yiyang, L.; Zongwei, W.; et al. Preparation and characterization of inertial confinement fusion capsules. High Power Laser Part. Beams 2015, 27, 032024. [Google Scholar]

- Zhao, C.Y.; Lu, W.; Tian, Y. Heat transfer enhancement for thermal energy storage using metal foams embedded within phase change materials (pcms). Sol. Energy 2010, 84, 1402–1412. [Google Scholar] [CrossRef]

- Zhao, C.Y.; Wu, Z.G. Heat transfer enhancement of high temperature thermal energy storage using metal foams and expanded graphite. Sol. Energ Mater. Sol. Cells 2011, 95, 636–643. [Google Scholar] [CrossRef]

- Agyenim, F.; Eames, P.; Smyth, M. Heat transfer enhancement in medium temperature thermal energy storage system using a multitube heat transfer array. Renew. Energy 2010, 35, 198–207. [Google Scholar] [CrossRef]

- Jmal, I.; Baccar, M. Numerical study of pcm solidification in a finned tube thermal storage including natural convection. Appl. Therm. Eng. 2015, 84, 320–330. [Google Scholar] [CrossRef]

- Zheng, J.; Yu, C.; Chen, T.; Yu, Y.; Wang, F. Optimization of the melting performance of a thermal energy storage unit with fractal net fins. Processes 2019, 7, 42. [Google Scholar] [CrossRef]

- Brent, A.D.; Voller, V.R.; Reid, K.J. Enthalpy-porosity technique for modeling convection-diffusion phase change: Application to the melting of a pure metal. Numer. Heat Transf. 1988, 13, 297–318. [Google Scholar] [CrossRef]

- Liu, X.; Zhang, C.; Yu, W.; Deng, Z.; Chen, Y. Bubble breakup in a microfluidic t-junction. Sci. Bull. 2016, 61, 811–824. [Google Scholar] [CrossRef]

- Shmueli, H.; Ziskind, G.; Letan, R. Melting in a vertical cylindrical tube: Numerical investigation and comparison with experiments. Int. J. Heat Mass Transf. 2010, 53, 4082–4091. [Google Scholar] [CrossRef]

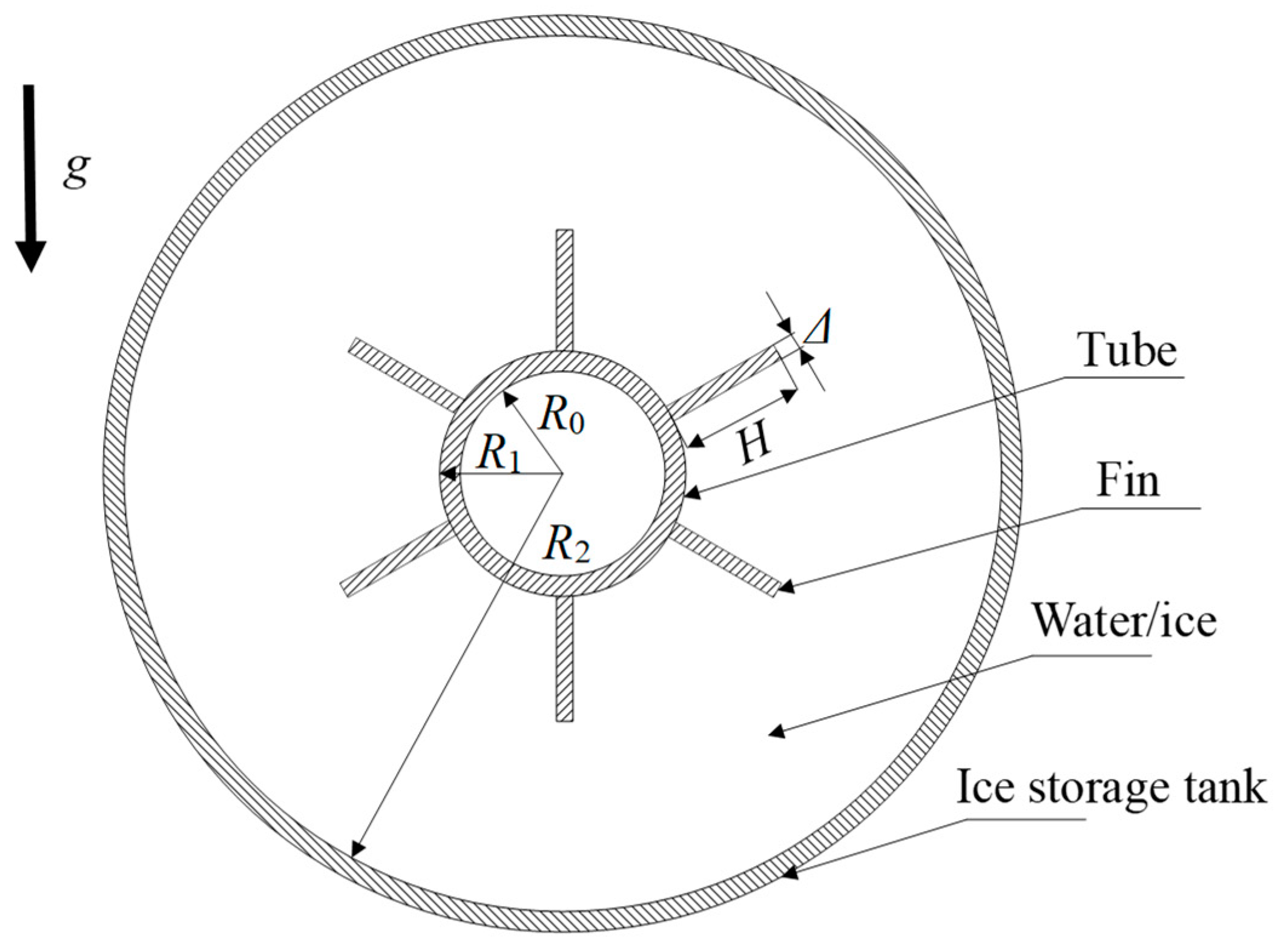

| Parameter | Description | Dimensions |

|---|---|---|

| R0 (mm) | Tube inner radius | 20 |

| R1 (mm) | Tube outer radius | 25 |

| R2 (mm) | Shell radius | 85 |

| H (mm) | Fin height | 20, 30, 40 |

| Δ (mm) | Fin thickness | 1, 3, 5 |

| N | Fin number | 6, 8, 10 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cai, P.; Jiang, Y.; Wang, H.; Wu, L.; Cao, P.; Zhang, Y.; Yao, F. Numerical Simulation on the Influence of the Longitudinal Fins on the Enhancement of a Shell-and-Tube Ice Storage Device. Sustainability 2020, 12, 2292. https://doi.org/10.3390/su12062292

Cai P, Jiang Y, Wang H, Wu L, Cao P, Zhang Y, Yao F. Numerical Simulation on the Influence of the Longitudinal Fins on the Enhancement of a Shell-and-Tube Ice Storage Device. Sustainability. 2020; 12(6):2292. https://doi.org/10.3390/su12062292

Chicago/Turabian StyleCai, Pei, Youxue Jiang, He Wang, Liangyu Wu, Peng Cao, Yulong Zhang, and Feng Yao. 2020. "Numerical Simulation on the Influence of the Longitudinal Fins on the Enhancement of a Shell-and-Tube Ice Storage Device" Sustainability 12, no. 6: 2292. https://doi.org/10.3390/su12062292

APA StyleCai, P., Jiang, Y., Wang, H., Wu, L., Cao, P., Zhang, Y., & Yao, F. (2020). Numerical Simulation on the Influence of the Longitudinal Fins on the Enhancement of a Shell-and-Tube Ice Storage Device. Sustainability, 12(6), 2292. https://doi.org/10.3390/su12062292