Life Cycle Assessment of Nile Tilapia (Oreochromis niloticus) Farming in Kenyir Lake, Terengganu

Abstract

1. Introduction

2. Methodologies

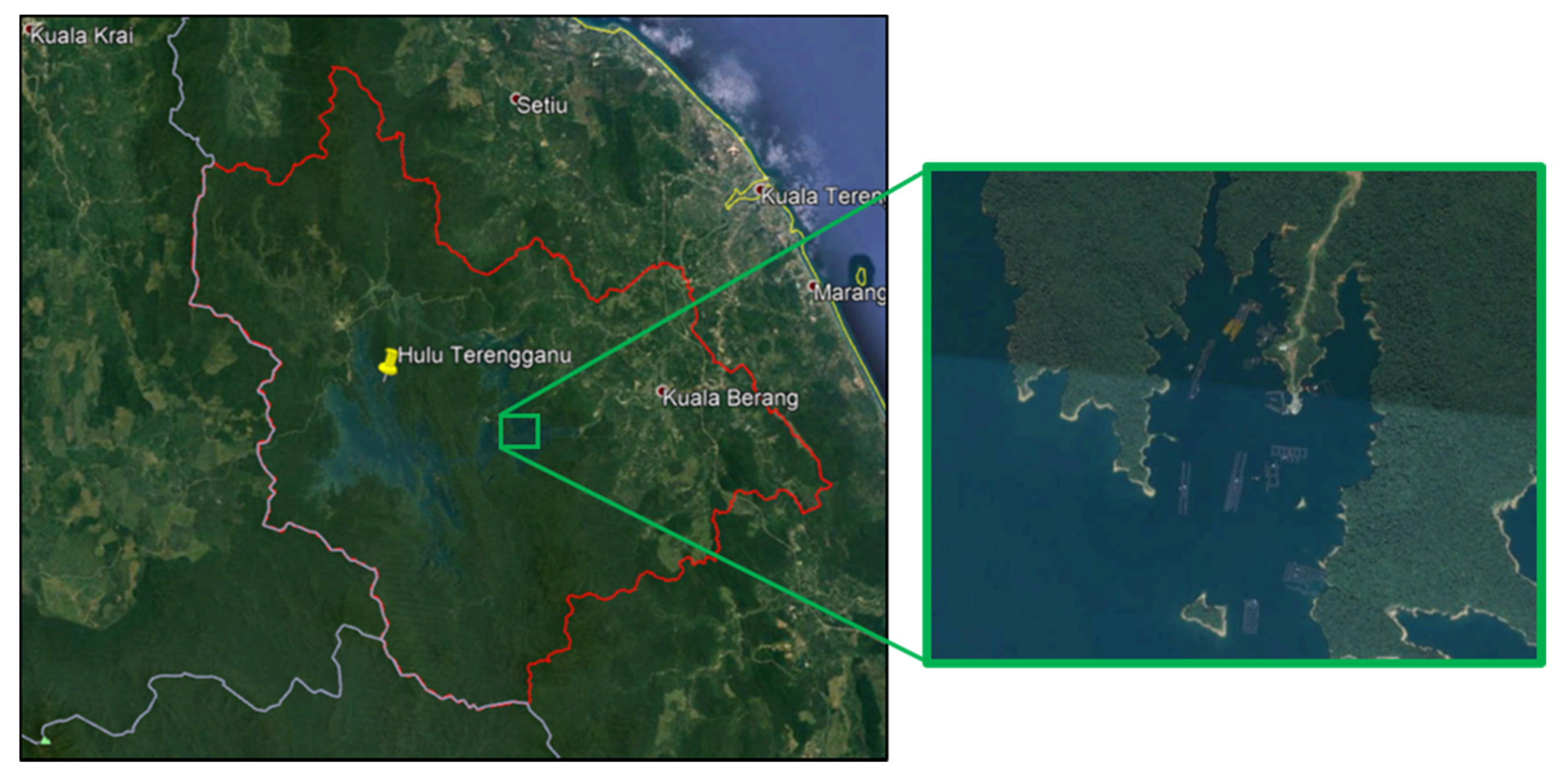

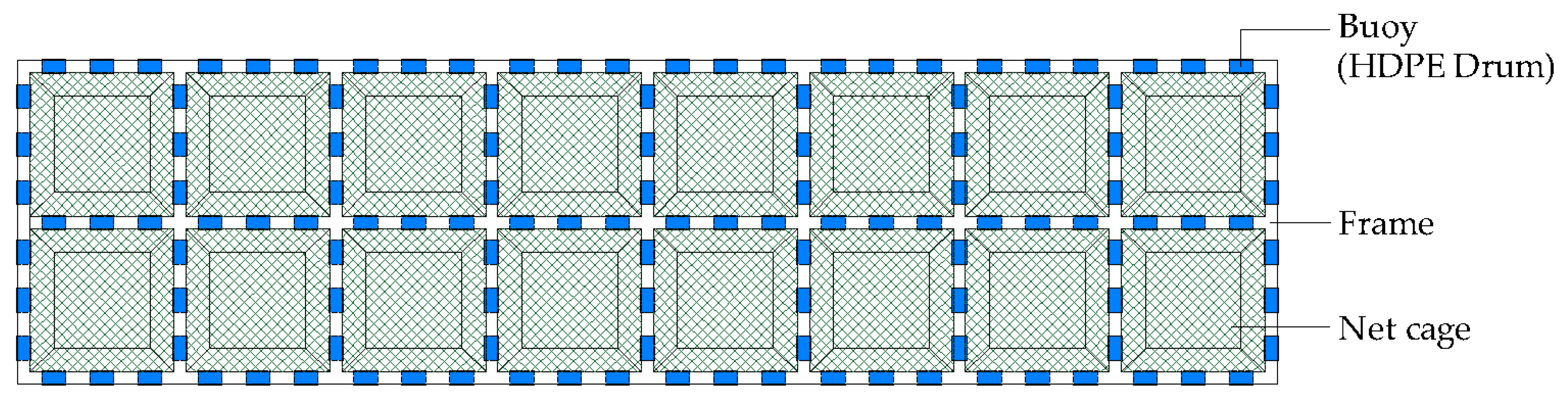

2.1. Study Area and System Description

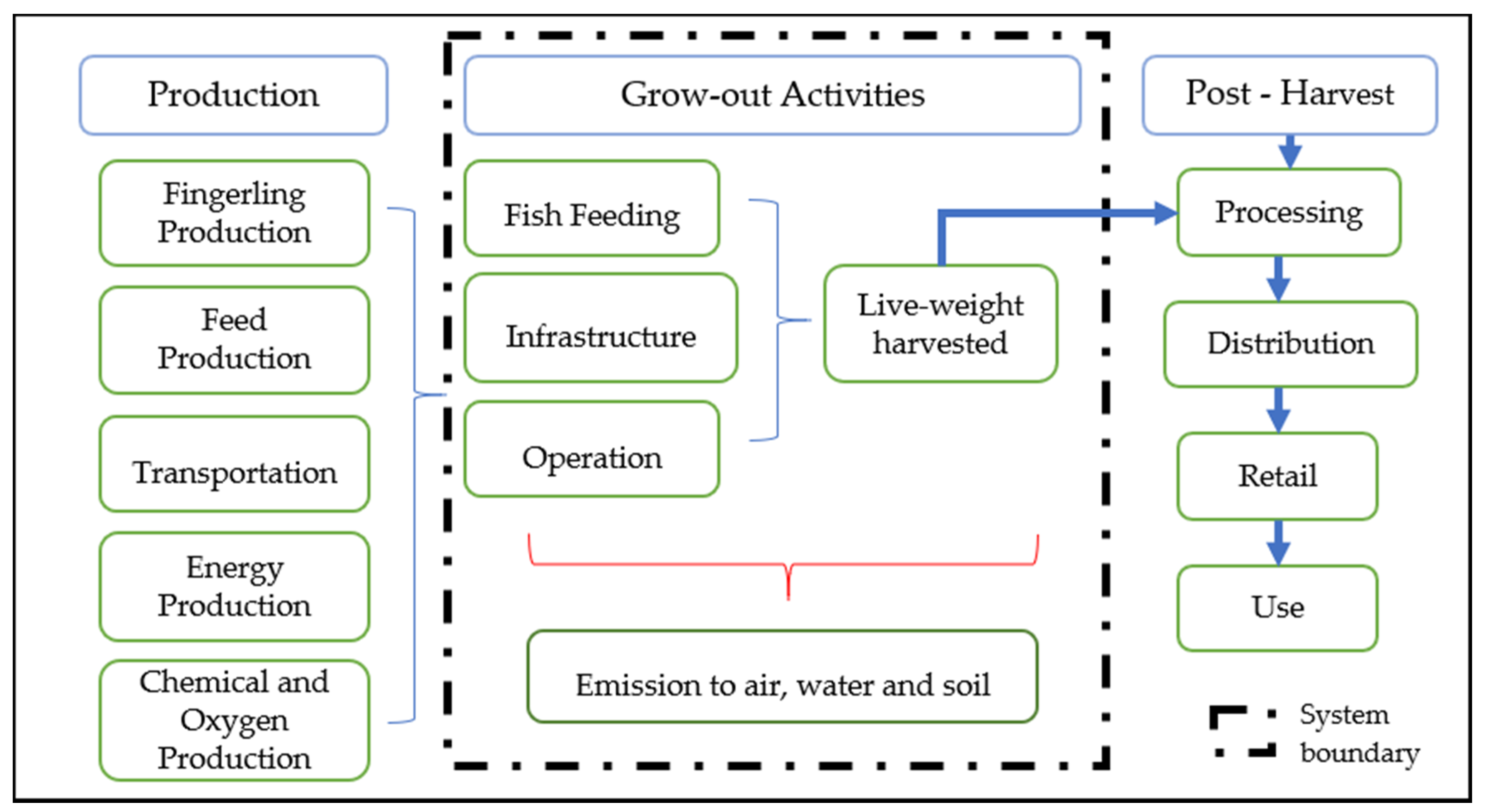

2.2. Goal, Scope and System Boundary

2.2.1. System Boundary

2.2.2. Functional Unit

3. Results

3.1. Life Cycle Inventory (LCI)

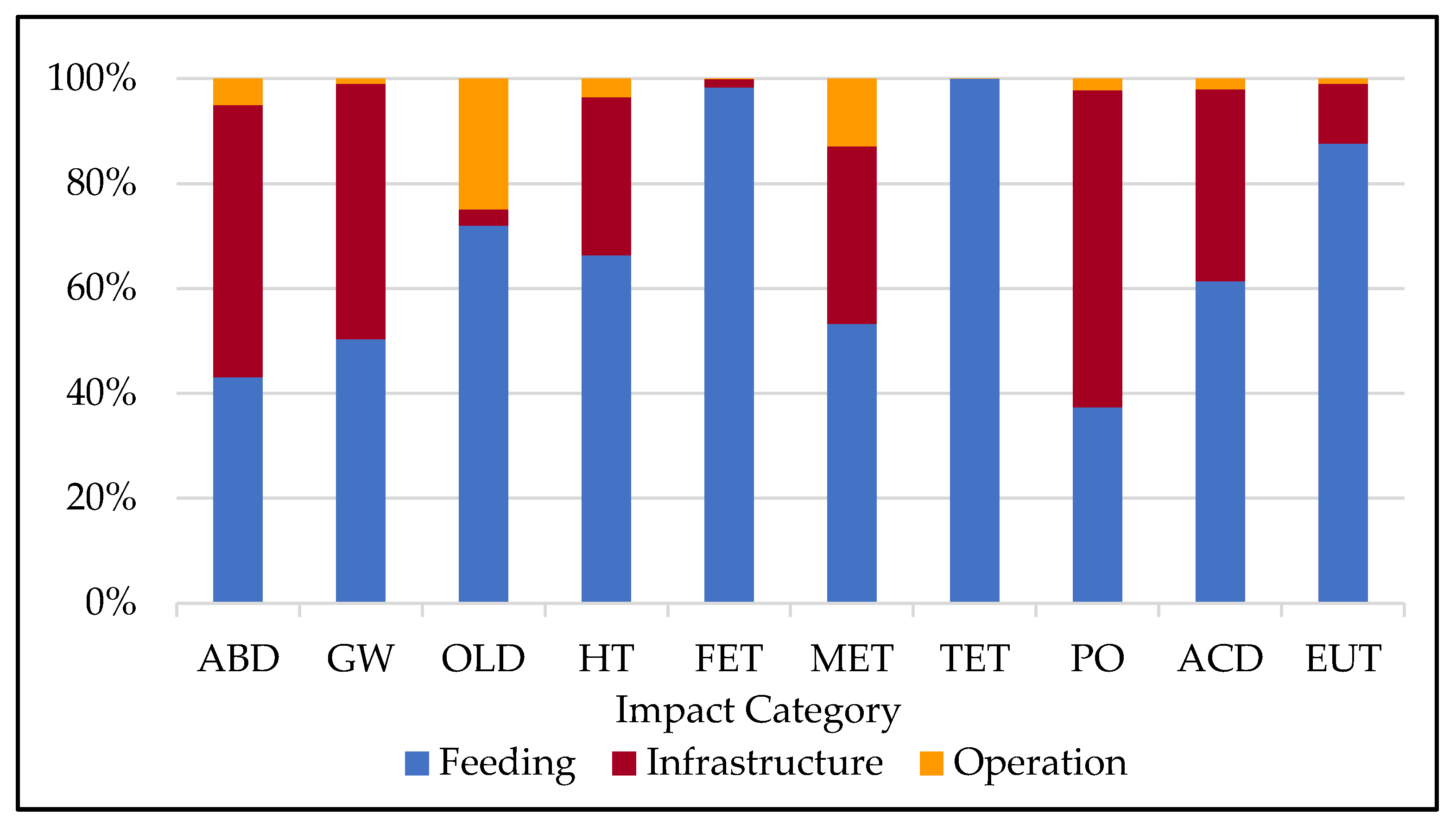

3.2. Effect on Various Environmental Impact Categories

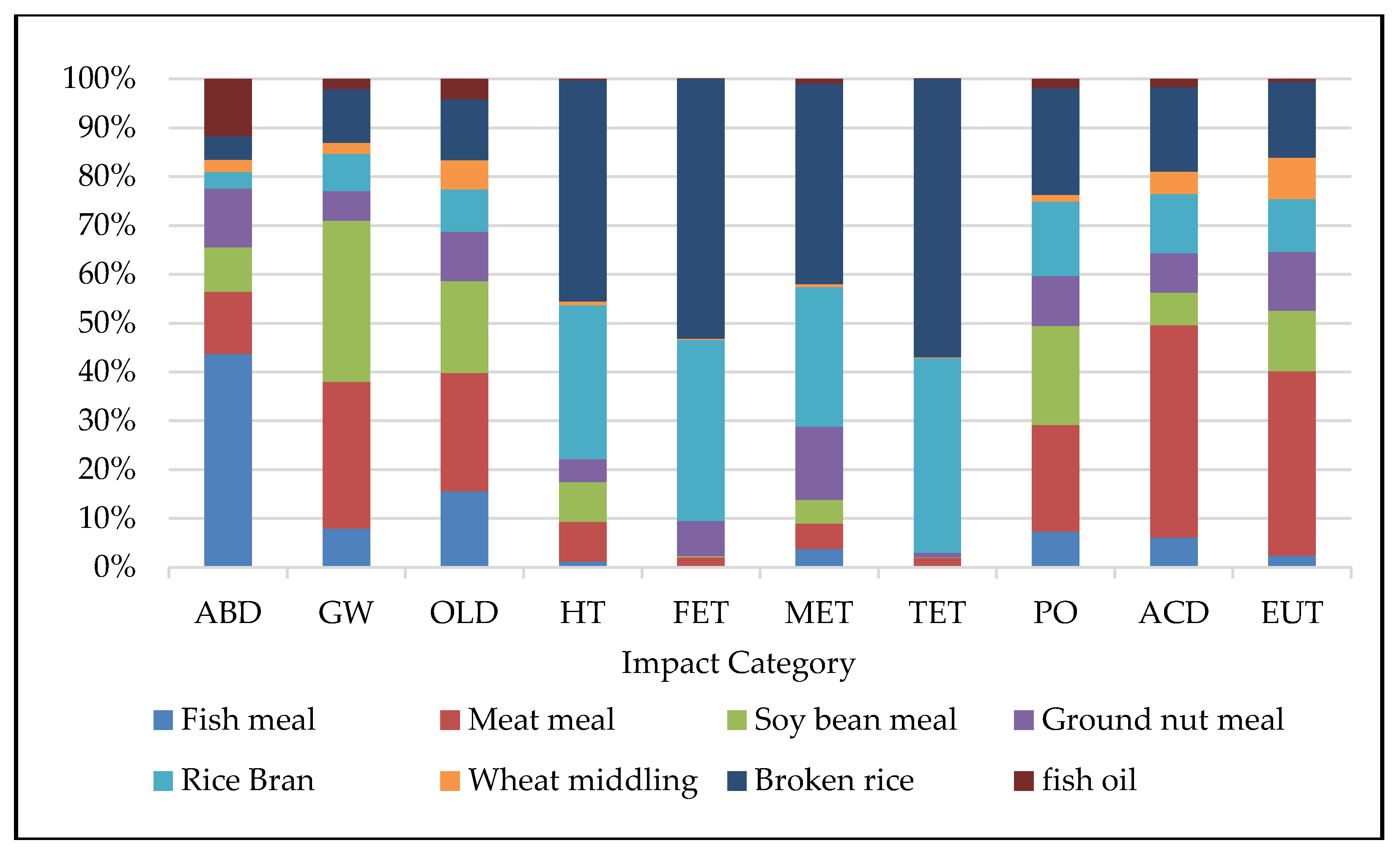

3.2.1. Fish Feed

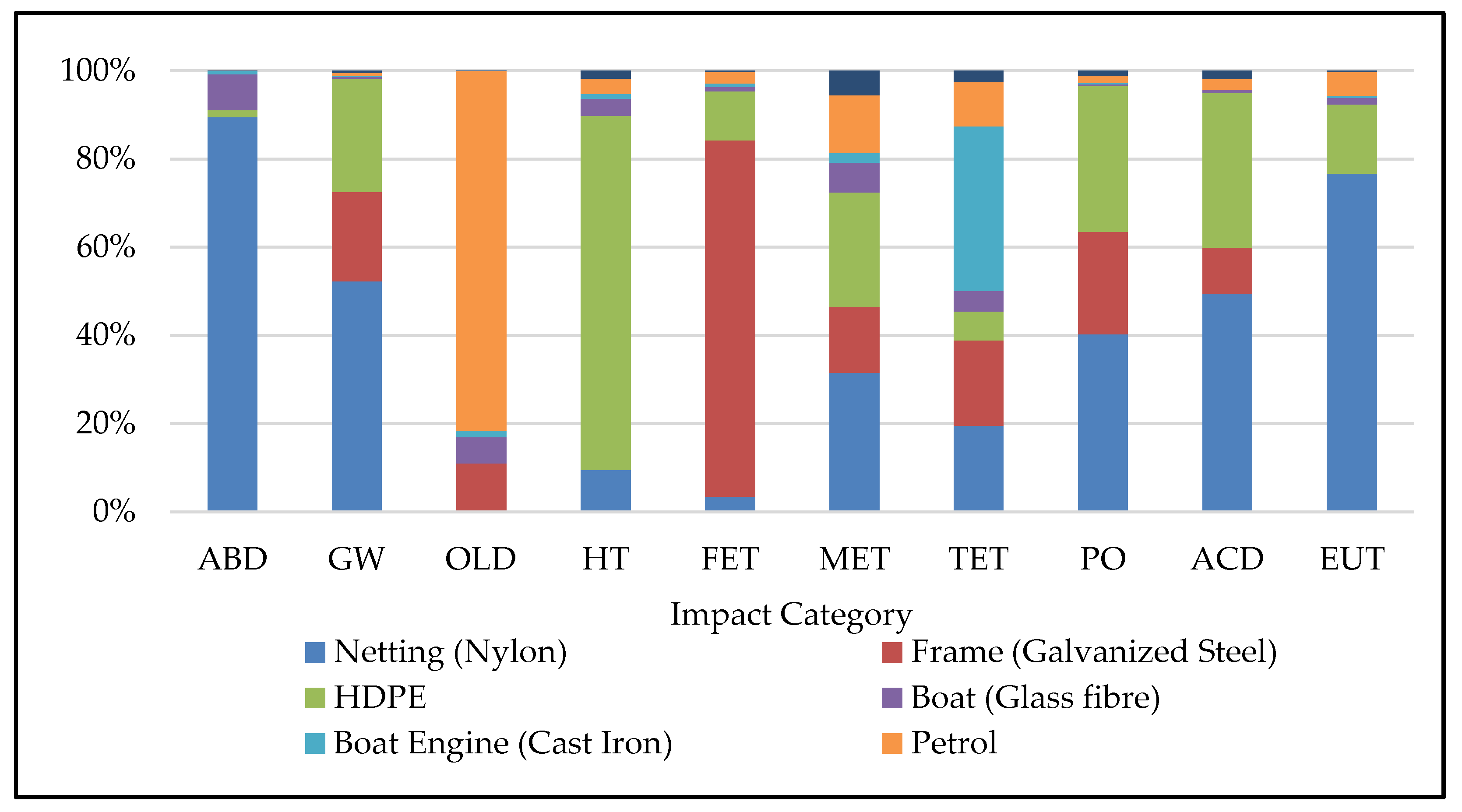

3.2.2. Infrastructure

3.2.3. Operation

3.3. Analysis on Feeding Ingredients

3.4. Analysis on Infrastructure and Operation

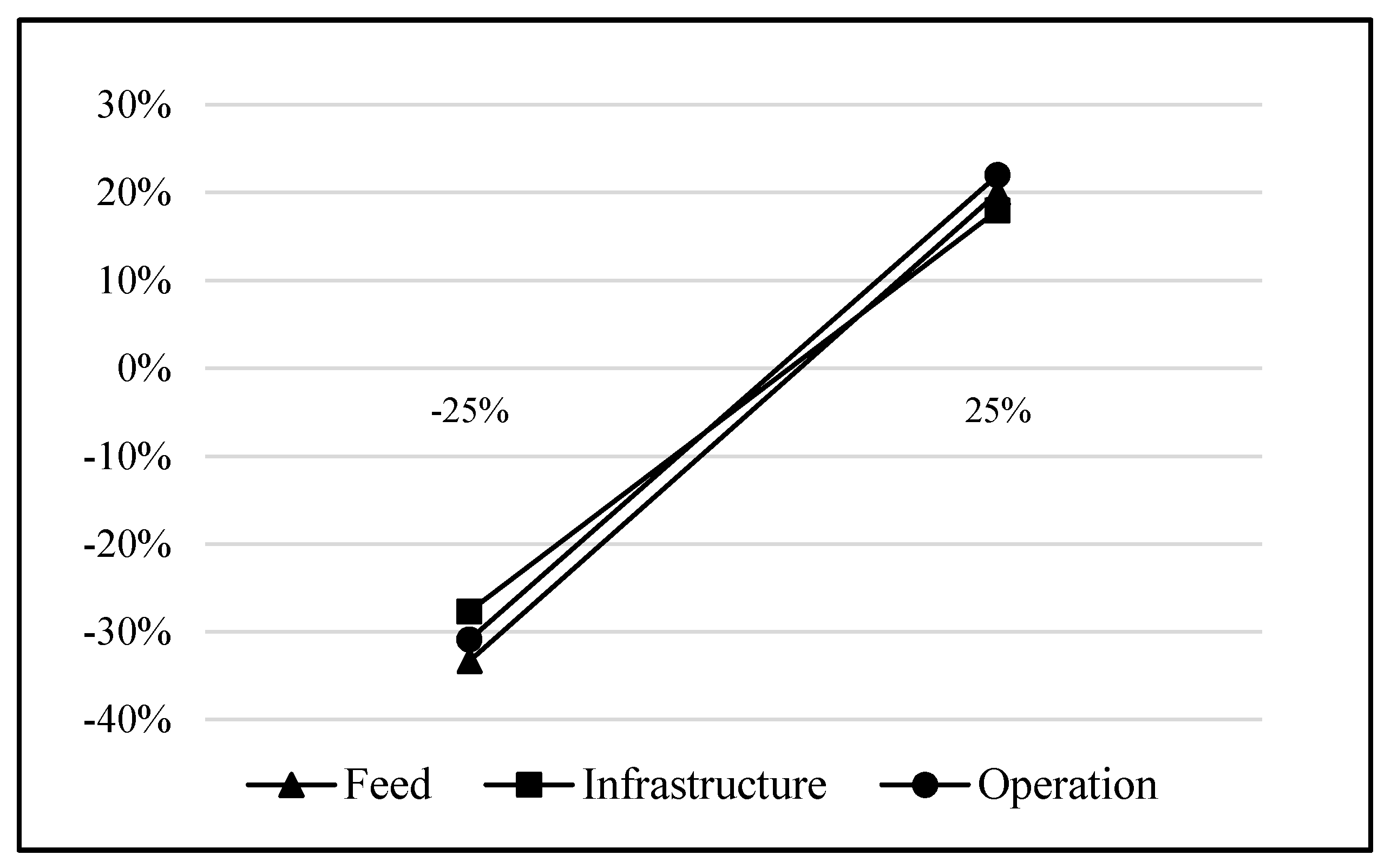

4. Sensitivity Analysis

5. Conclusions and Recommendation

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Zon Industri Akuakultur: Department of Fisheries. 2014. Available online: https://www.dof.gov.my/index.php/pages/view/78 (accessed on 30 March 2019).

- FAO. The State of World Fisheries and Aquaculture 2018—Meeting the Sustainable Development Goals; FAO: Djerba Island, Tunisia, 2018. [Google Scholar]

- Avadí, A.; Henriksson, P.J.G.; Vázquez-Rowe, I.; Ziegler, F. Towards improved practices in Life Cycle Assessment of seafood and other aquatic products. Int. J. Life Cycle Assess. 2018, 23, 979–981. [Google Scholar] [CrossRef]

- Pelletier, N.; Tyedmers, P. Feeding farmed salmon: Is organic better? Aquaculture 2007, 272, 399–416. [Google Scholar] [CrossRef]

- Yazdi, S.; Shakouri, B. The Effects of Climate Change on Aquaculture. Int. J. Environ. Sci. Dev. 2010, 1, 378–382. [Google Scholar] [CrossRef]

- Froehlich, H.E.; Gentry, R.R.; Halpern, B.S. Potential under climate change. Nat. Ecol. Evol. 2018, 2, 1745–1752. [Google Scholar] [CrossRef] [PubMed]

- Brugere, C.; Soto, D.; Bartley, D.M. Comparative environmental costs of aquaculture and other food production sectors: Environmental and economic factors conditioning the global development of responsible aquaculture. FAO Fish. Proc. 2007, 26–36. [Google Scholar]

- Hamzah, A.; Nguyen, N.H.; Ponzani, R.W.; Kamaruzzaman, B.N.; Subha, B. Performance and survival of three red tilapia strains (Oreochromis spp.) in pond environment in Kedah state, Malaysia. In Proceedings of the 8th International Symposium on Tilapia in Aquaculture, Cairo, Egypt, 12–14 October 2008; pp. 199–211. [Google Scholar]

- Cao, L.; Wang, W.; Yang, Y.; Yang, C.; Yuan, Z.; Xiong, S.; Diana, J. Aquaculture Pollution in China Subject Area 5.1: Microbial studies and technologies supporting waste disposal, management, and remediation of municipal and industrial hazardous wastes Environmental Impact of Aquaculture and Countermeasures to Aquaculture. Environ. Sci. Pollut. Res. 2007, 14, 452–462. [Google Scholar]

- Costopoulou, D.; Vassiliadou, I.; Leondiadis, L. PCDDs, PCDFs and PCBs in farmed fish produced in Greece: Levels and human population exposure assessment. Chemosphere 2016, 146, 511–518. [Google Scholar] [CrossRef]

- Pahri, S.D.R.; Mohamed, A.F.; Samat, A. LCA for open systems: A review of the influence of natural and anthropogenic factors on aquaculture systems. Int. J. Life Cycle Assess. 2015, 20, 1324–1337. [Google Scholar] [CrossRef]

- Henriksson, P.J.G.; Guinée, J.B.; Kleijn, R.; de Snoo, G.R. Life cycle assessment of aquaculture systems—A review of methodologies. Int. J. Life Cycle Assess. 2012, 17, 304–313. [Google Scholar] [CrossRef]

- Bohnes, F.A.; Hauschild, M.Z.; Schlundt, J.; Laurent, A. Life cycle assessments of aquaculture systems: A critical review of reported findings with recommendations for policy and system development. Rev. Aquac. 2018, 11, 1–19. [Google Scholar] [CrossRef]

- ISO 14044, Environmental Management—Life Cycle Assessment—Requirements and Guidelines; International Organization for Standardization: Geneva, Switzerland, 2006.

- Abdou, K.; Lasram, F.B.R.; Romdhane, M.S.; le Loc’h, F.; Aubin, J. Rearing performances and environmental assessment of sea cage farming in Tunisia using life cycle assessment (LCA) combined with PCA and HCPC. Int. J. Life Cycle Assess. 2018, 23, 1049–1062. [Google Scholar] [CrossRef]

- Parker, R. Implications of high animal by-product feed inputs in life cycle assessments of farmed Atlantic salmon. Int. J. Life Cycle Assess. 2018, 23, 982–994. [Google Scholar] [CrossRef]

- Yacout, D.M.M.; Soliman, N.F.; Yacout, M.M. Comparative life cycle assessment (LCA) of Tilapia in two production systems: Semi-intensive and intensive. Int. J. Life Cycle Assess. 2016, 21, 806–819. [Google Scholar] [CrossRef]

- Pahri, S.D.R.; Mohamed, A.F.; Samat, A. Life Cycle Assessment of Cockles (Anadara granosa) Farming: A Case Study in Malaysia. EnvironmentAsia 2016, 9, 80–90. [Google Scholar]

- García, B.G.; Jiménez, C.R.; Aguado-Giménez, F.; García, J.G. Life cycle assessment of gilthead seabream (Sparus aurata) production in offshore fish farms. Sustainability 2016, 8, 1228. [Google Scholar] [CrossRef]

- Ayer, N.; Martin, S.; Dwyer, R.L.; Gace, L.; Laurin, L. Environmental performance of copper-alloy Net-pens: Life cycle assessment of Atlantic salmon grow-out in copper-alloy and nylon net-pens. Aquaculture 2016, 453, 93–103. [Google Scholar]

- Aubin, J.; Baruthio, A.; Mungkung, R.; Lazard, J. Environmental performance of brackish water polyculture system from a life cycle perspective: A Filipino case study. Aquaculture 2015, 435, 217–227. [Google Scholar] [CrossRef]

- Dekamin, M.; Veisi, H.; Safari, E.; Liaghati, H.; Khoshbakht, K.; Dekamin, M.G. Life cycle assessment for rainbow trout (Oncorhynchus mykiss) production systems: A case study for Iran. J. Clean. Prod. 2015, 91, 43–55. [Google Scholar] [CrossRef]

- Pongpat, P.; Tongpool, R. Life Cycle Assessment of Fish Culture in Thailand: Case Study of Nile Tilapia and Striped Catfish. Int. J. Environ. Sci. Dev. 2013, 4, 608–612. [Google Scholar] [CrossRef]

- Mungkung, R.; Aubin, J.; Prihadi, T.H.; Slembrouck, J.; van der Werf, H.M.G.; Legendre, M. Life cycle assessment for environmentally sustainable aquaculture management: A case study of combined aquaculture systems for carp and tilapia. J. Clean. Prod. 2013, 57, 249–256. [Google Scholar] [CrossRef]

- Nyhus, O.J. Life Cycle Assessment of Farmed Salmon, Comparing a Closed with an Open Sea Cage System. Master’s Thesis, Norwegian University of Science and Technology, Trondheim, Norway, 2014. [Google Scholar]

- Bonton, A.; Bouchard, C.; Barbeau, B.; Jedrzejak, S. Comparative life cycle assessment of water treatment plants. DES 2012, 284, 42–54. [Google Scholar] [CrossRef]

- ISO 14041, Environmental Management—Life Cycle Assessment—Goal and Scope Definition and Inventory Analysis; International Organization for Standardization: Geneva, Switzerland, 1998.

- Abdou, K.; Gascuel, D.; Aubin, J.; Romdhane, M.S.; Lasram, F.B.R.; le Loc’h, F. Environmental life cycle assessment of seafood production: A case study of trawler catches in Tunisia. Sci. Total Environ. 2018, 610, 298–307. [Google Scholar] [CrossRef] [PubMed]

- Henriksson, P.J.G.; Belton, B.; Murshed-e- Jahan, K.; Rico, A. Measuring the potential for sustainable intensification of aquaculture in Bangladesh using life cycle assessment. Proc. Natl. Acad. Sci. USA 2018, 115, 201716530. [Google Scholar] [CrossRef] [PubMed]

- IPCC. 2013 Supplement to the 2006 IPCC Guidelines for National Greenhouse Gas Inventories: Wetlands; IPCC Guildelines Natl. Greenh. Gas Invent; IPCC: Genève, Switzerland, 2013; pp. 1–354. [Google Scholar]

- Pelletier, N.; Tyedmers, P.; Sonesson, U.; Scholz, A.; Ziegler, F.; Flysjo, A.; Kruse, S.; Cancino, B.; Silverman, H. Not all salmon are created equal: Life cycle assessment (LCA) of global salmon farming systems. Environ. Sci. Technol. 2009, 43, 8730–8736. [Google Scholar] [CrossRef] [PubMed]

- Aubin, J.; Papatryphon, E.; van der Werf, H.M.G.; Chatzifotis, S. Assessment of the environmental impact of carnivorous finfish production systems using life cycle assessment. J. Clean. Prod. 2009, 17, 354–361. [Google Scholar] [CrossRef]

- Boissy, J.; Aubin, J.; Drissi, A.; van der Werf, H.M.G.; Bell, G.J.; Kaushik, S.J. Environmental impacts of plant-based salmonid diets at feed and farm scales. Aquaculture 2011, 321, 61–70. [Google Scholar] [CrossRef]

- Iribarren, D.; Moreira, M.T.; Feijoo, G. Life cycle assessment of aquaculture feed and application to the turbot sector. Int. J. Environ. Res. 2012, 6, 837–848. [Google Scholar]

- Ayer, N.W.; Tyedmers, P.H. Assessing alternative aquaculture technologies: Life cycle assessment of salmonid culture systems in Canada. J. Clean. Prod. 2009, 17, 362–373. [Google Scholar] [CrossRef]

- Silva, C.B.; Valente, L.M.P.; Matos, E.; Brandão, M.; Neto, B. Life cycle assessment of aquafeed ingredients. Int. J. Life Cycle Assess. 2018, 23, 995–1017. [Google Scholar] [CrossRef]

- Bosma, R.; Anh, P.T.; Potting, J. Life cycle assessment of intensive striped catfish farming in the Mekong Delta for screening hotspots as input to environmental policy and research agenda. Int. J. Life Cycle Assess. 2011, 16, 903–915. [Google Scholar] [CrossRef]

- Iribarren, D. Life Cycle Assessment of Mussel and Turbot Aquaculture. Ph.D. Thesis, Universidade De Santiago De Compostela, Santiago, Spain, 2010. [Google Scholar]

- McGrath, K.P.; Pelletier, N.L.; Tyedmers, P.H. Life cycle assessment of a novel closed-containment salmon aquaculture technology. Environ. Sci. Technol. 2015, 49, 5628–5636. [Google Scholar] [CrossRef]

- Philis, G.; Ziegler, F.; Gansel, L.C.; Jansen, M.D.; Gracey, E.O.; Stene, A. Comparing Life Cycle Assessment (LCA) of Salmonid Aquaculture Production Systems: Status and Perspectives. Sustainability 2019, 11, 2517. [Google Scholar] [CrossRef]

- Henriksson, P.J.G.; Zhang, W.; Nahid, S.A.A.; Newton, R.; Phan, L.T.; Dao, H.M.; Zhang, Z.; Jaithiang, J.; Andong, R.; Chaimanuskul, K.; et al. Final LCA Case Study Report; 2014; Available online: https://www.researchgate.net/project/Sustaining-Ethical-Aquaculture-Trade-SEAT-http-seatglobaleu (accessed on 13 March 2020).

- Aziz, N.I.H.A.; Hanafiah, M.M. Life cycle analysis of biogas production from anaerobic digestion of palm oil mill effluent. Renew. Energy 2020, 145, 847–857. [Google Scholar] [CrossRef]

| Authors, Year | Species | Functional Unit | System Boundary | Software | Impact Category |

|---|---|---|---|---|---|

| Abdou et al., (2018) [15] | Seabass and Seabream | 1 tonne of fish | Cradle-to-gate | SimaPro v. 8.0 | ACD, EUT, GW, LOP, NNPU, TCED |

| Parker (2018) [16] | Atlantic Salmon | 1 tonne of salmon | Farm gate | SimaPro v. 8.1 | GW, TCED, PO ACD, EUT, OLD, |

| Yacout et al., (2016) [17] | Tilapia | 1 tonne of tilapia | Cradle-to-farm-gate | SimaPro v. 7.2 | ACD, EUT, GW, TCED |

| Pahri et al., (2016) [18] | Cockles | 70 kg of cockles | Cradle-to-farm-gate | SimaPro v. 8 | ABD, GW, HT, FET, MET, PO, ACD, EUT, OLD, TET |

| (García et al., 2016) [19] | Gilthead seabream | 1000 tonnes | Cradle-to-grave | SimaPro v. 8.04 | ABD, GW, OLD, PO, ACD, EUT, TCED |

| (Ayer et al., 2016) [20] | Atlantic Salmon | 1 tonne of salmon | Market | SimaPro v. 7.3.3 | ACD, EUT, GW, TCED, MET, MD |

| (Aubin et al., 2015) [21] | Black tiger prawn, Mud crabs, Tilapia and Milkfish | 1 tonne of product | Cradle-to-gate | SimaPro v. 7.0 | EUT, ACD, GW, LOP, NNPU, TCED |

| Dekamin et al., (2015) [22] | Rainbow trout | 1 tonne of live fish | Farm Gate | SimaPro 7.1 software | EUT, ACD, GW, ABD, HT, FET, PO, WD |

| Pongpat and Tongpool (2013) [23] | Nile Tilapia and Striped Catfish | 1 kg of fish | Cradle-to-gate | SimaPro v. 7.3 | ABD, ACD, GW |

| Mungkung et al., (2013) [24] | Carp and tilapia | 1 tonne of fish | Cradle-to-farm gate | Not stated | WD, ACD, EUT, GW, LOP, TCED, NPPU |

| Activities (1) | Parameter Input (2) | Feed Ingredients (kg·t−1) (3) | Quantity (4) |

|---|---|---|---|

| Feeding | Formulation | Fish meal (15%) | 309.34 kg |

| Meat meal (5%) | 103.11 kg | ||

| Soybean meal (22%) | 412.46 kg | ||

| Ground nut meal (10%) | 206.23 kg | ||

| Rice Bran (10%) | 206.23 kg | ||

| Wheat middling (16%) | 309.34 kg | ||

| Broken rice (16%) | 309.34 kg | ||

| fish oil (6%) | 82.49 kg | ||

| Materials (kg·t−1) | |||

| Infrastructure | Net Cage | Netting (Nylon) | 406.81 kg |

| Frame (Galvanized Steel) | 409.29 kg | ||

| High-density polyethylene (HDPE) drum | 450.22 kg | ||

| Operation | Materials used | Boat (Glass fibre) | 8.96 kg |

| Boat Engine (Cast Iron) | 4.48 kg | ||

| High-density polyethylene (HDPE) drum | 1.97 kg | ||

| Petrol | 33.07 kg | ||

| Electricity | 24.81 kWh |

| Parameter Output (1) | Amount (kg·t−1) (2) |

|---|---|

| Nitrous Oxide (N2O) | 1.69 |

| Biochemical Oxygen Demand (BOD) | 5.328 |

| Chemical Oxygen Demand (COD) | 5.04 |

| Total Suspended Solid (TSS) | 100.8 |

| Ammonia-Nitrogen (NH3-N) | 0.7344 |

| Phosphorus (P) | 0.72 |

| Nitrogen (N) | 0.36 |

| Parameter | Aquaculture Farm | No Aquaculture Activity |

|---|---|---|

| Biochemical Oxygen Demand (BOD) | 7.4 mg/L | 3.3 mg/L |

| Chemical Oxygen Demand (COD) | 7 mg/L | 6.5 mg/L |

| Total Suspended Solid (TSS) | 140 mg/L | 80 mg/L |

| Ammonia-Nitrogen (NH3-N) | 1.02 mg/L | 4.5 mg/L |

| Phosphorus (P) | 0.9 mg/L | 0.2 mg/L |

| Nitrogen (N) | 1 mg/L | 0.4 mg/L |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dullah, H.; Malek, M.A.; Hanafiah, M.M. Life Cycle Assessment of Nile Tilapia (Oreochromis niloticus) Farming in Kenyir Lake, Terengganu. Sustainability 2020, 12, 2268. https://doi.org/10.3390/su12062268

Dullah H, Malek MA, Hanafiah MM. Life Cycle Assessment of Nile Tilapia (Oreochromis niloticus) Farming in Kenyir Lake, Terengganu. Sustainability. 2020; 12(6):2268. https://doi.org/10.3390/su12062268

Chicago/Turabian StyleDullah, Hayana, M. A. Malek, and Marlia M. Hanafiah. 2020. "Life Cycle Assessment of Nile Tilapia (Oreochromis niloticus) Farming in Kenyir Lake, Terengganu" Sustainability 12, no. 6: 2268. https://doi.org/10.3390/su12062268

APA StyleDullah, H., Malek, M. A., & Hanafiah, M. M. (2020). Life Cycle Assessment of Nile Tilapia (Oreochromis niloticus) Farming in Kenyir Lake, Terengganu. Sustainability, 12(6), 2268. https://doi.org/10.3390/su12062268