Supplier Selection for Photovoltaic Module Installation Utilizing Fuzzy Inference and the VIKOR Method: A Green Approach

Abstract

1. Introduction

2. Materials and Methods

3. Brief Theoretical Review

3.1. Selection of Suppliers with a Green Approach

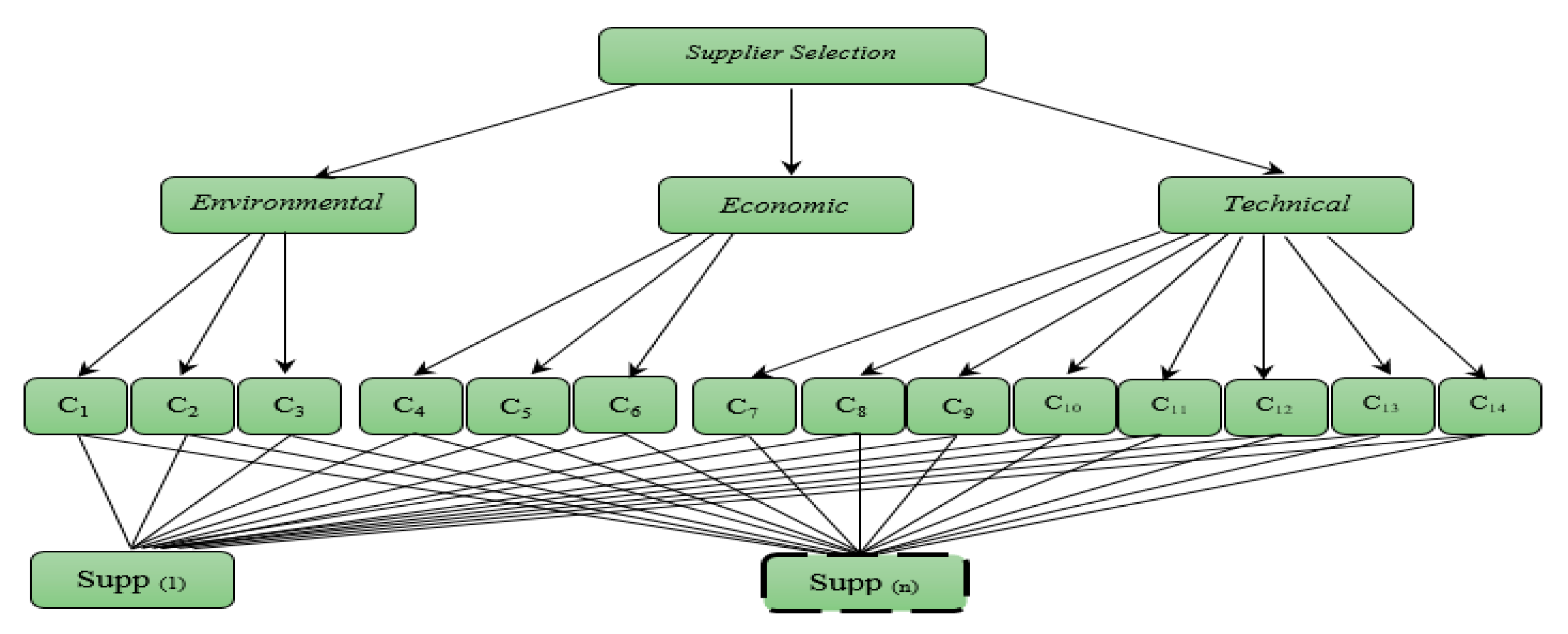

3.2. Dimensions of Analyses for the Selection of Suppliers: Photovoltaic Installation Services Case Study

- What resource can be used to establish a decision matrix that links the indicators to a sample of providers?

- How can the causality between different indicators distributed by the three mentioned dimensions be evaluated?

- What are the conditions in the process of qualifying the indicators according to the different sources selected?

- According to the number of suppliers with valid data, what will be the ranking of selection among them?

3.3. Supplier Selection Techniques and Method to Use

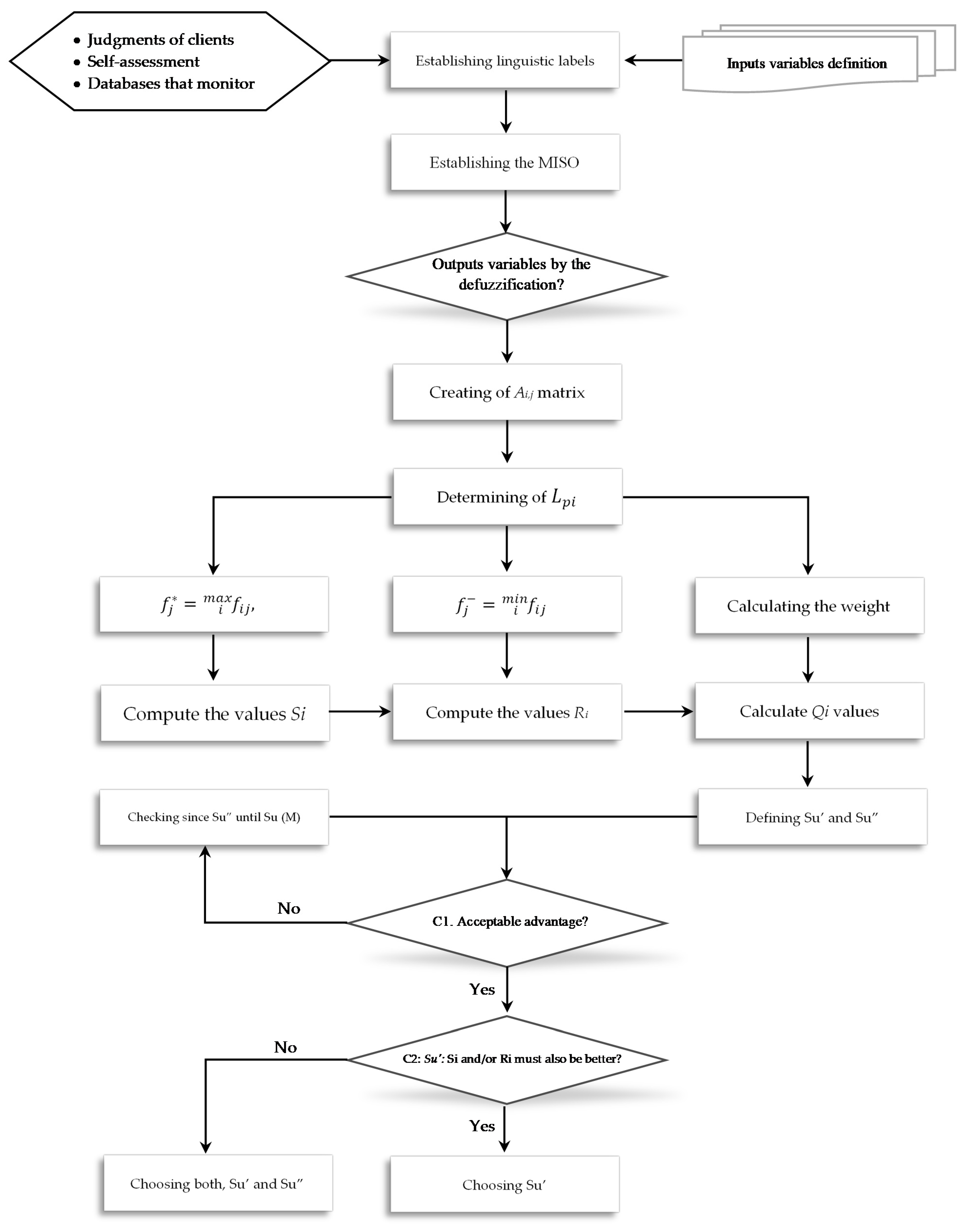

4. Fuzzy Inference Method Integrated with VIKOR

5. Suppliers of Photovoltaic Modules and Installation Services

5.1. Market and Conditions for the Development of Photovoltaic Technology in the Northeast Region

5.2. Application of the Method

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

Appendix A

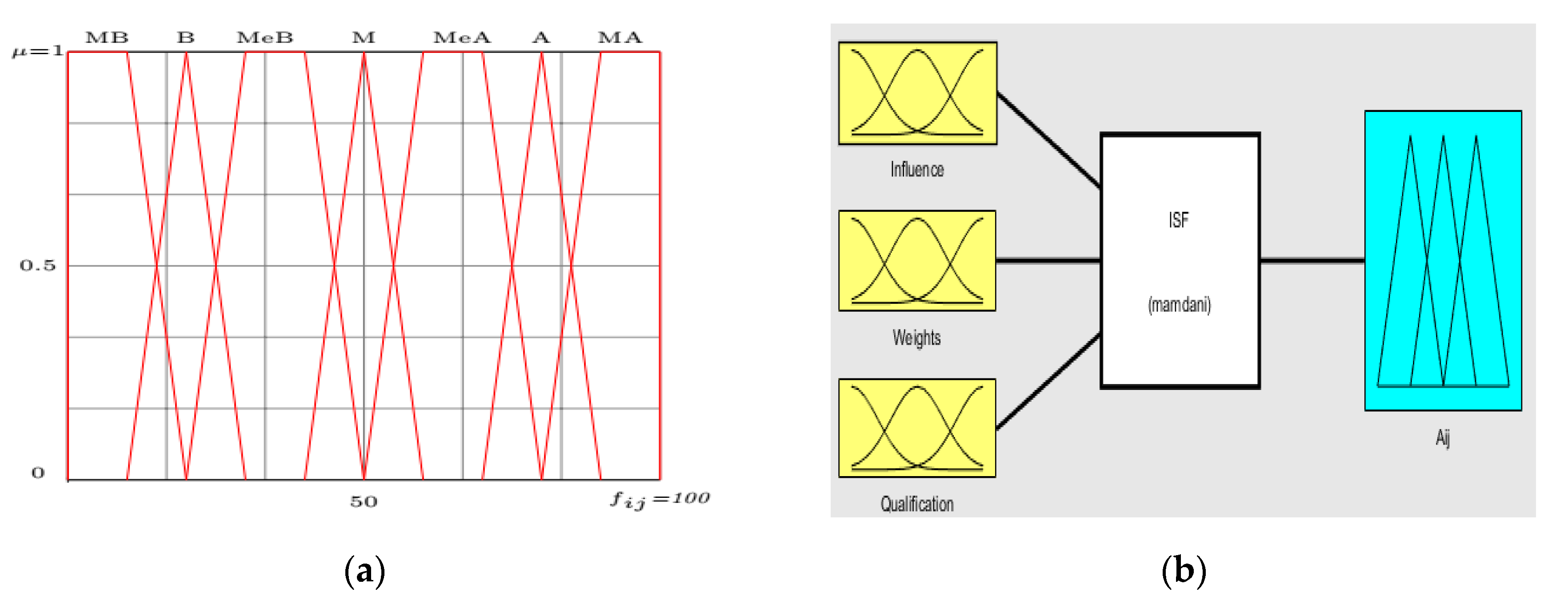

| [System] Name=‘ISF’ Type=‘mamdani’ Version=2.0 NumInputs=3 NumOutputs=1 NumRules=343 AndMethod=‘min’ OrMethod=‘max’ ImpMethod=‘min’ AggMethod=‘max’ DefuzzMethod=‘centroid’ [Input1] Name=‘Influence’ Range=[0 1] NumMFs=7 MF1=‘MB’:‘trapmf’,[0 0 0.1 0.2] MF2=‘B’:‘trapmf’,[0.1 0.2 0.2 0.3] MF3=‘MeB’:‘trapmf’,[0.2 0.3 0.4 0.5] MF4=‘Me’:‘trapmf’,[0.4 0.5 0.5 0.6] MF5=‘MeA’:‘trapmf’,[0.5 0.6 0.7 0.8] MF6=‘A’:‘trapmf’,[0.7 0.8 0.8 0.9] MF7=‘MA’:‘trapmf’,[0.8 0.9 1 1] [Input2] Name=‘Weights’ Range=[0 1] NumMFs=7 MF1=‘MB’:‘trapmf’,[0 0 0.1 0.2] MF2=‘Me’:‘trapmf’,[0.4 0.5 0.5 0.6] MF3=‘A’:‘trapmf’,[0.7 0.8 0.8 0.9] MF4=‘B’:‘trapmf’,[0.1 0.2 0.2 0.3] MF5=‘MeB’:‘trapmf’,[0.2 0.3 0.4 0.5] MF6=‘MeA’:‘trapmf’,[0.5 0.6 0.7 0.8] MF7=‘MA’:‘trapmf’,[0.8 0.9 1 1] [Input3] Name=‘Qualification’ Range=[0 1] NumMFs=7 MF1=‘MB’:‘trapmf’,[0 0 0.1 0.2] MF2=‘B’:‘trapmf’,[0.1 0.2 0.2 0.3] MF3=‘MeB’:‘trapmf’,[0.2 0.3 0.4 0.5] MF4=‘Me’:‘trapmf’,[0.4 0.5 0.5 0.6] MF5=‘MeA’:‘trapmf’,[0.5 0.6 0.7 0.8] MF6=‘A’:‘trapmf’,[0.7 0.8 0.8 0.9] MF7=‘MA’:‘trapmf’,[0.8 0.9 1 1] [Output1] Name=‘Aij’ Range=[0 4] NumMFs=7 MF1=‘MB’:‘trapmf’,[−0.6 −0.0667 0.164021164021164 0.6] MF2=‘B’:‘trapmf’,[0.06668 0.6 0.7332 1.267] MF3=‘MeB’:‘trapmf’,[0.7332 1.267 1.4 1.933] MF4=‘Me’:‘trapmf’,[1.4 1.933 2.067 2.6] MF5=‘MeA’:‘trapmf’,[2.067 2.6 2.733 3.267] MF6=‘A’:‘trapmf’,[2.733 3.267 3.4 3.933] MF7=‘MA’:‘trapmf’,[3.41 3.82539682539683 4.08 4.21] [Rules] | %Source: adapt of [41] close all; clear all; clc; global m n w v mn’ m=7; n=14; v = 0.50; %%%% mn =

rij=sum(mn); vij= mn./rij; lij=log(vij) yij = sum(vij.∗ log(vij)); k= 1./(log(m)); ej = −k.∗ yij; ejj=sum(1− ej); w = (1−ej)./ ejj; Xval=length(mn(:,1)); % extensión total de las alternativas for j= 1:length(mn) if mn(1,j)== 0 fmax(1,j)=min(mn(:,j)); fmin(1,j)= max(mn(:,j)); else fmax(1,j)=max(mn(:,j)); fmin(1,j)= min(mn(:,j)); end end for i=1:Xval for j= 1:length(mn) Xnew(i,j)=(fmax(1,j)−mn(i,j))./(fmax(1,j)−fmin(1,j)); end end for i=1:Xval for j= 1:length(w) WXnew(i,j)=(Xnew(i,j).∗w(j)); end end for i=1:length(mn(:,j)) for j= 1:length(mn) %Si(i,1)=sum(WXnew(i,:)) Ri(i,1)= max(WXnew(i,:)); %Qi(i,1)=(v∗((Si(i,1)−min(Si))/(max(Si)−min(Si))))+((1−v)∗((Ri(i,1)−min(Ri))/(max(Ri)−min(Ri)))) end end Si=sum(WXnew,2); Ri; Qi=(v∗((Si−min(Si))/(max(Si)−min(Si))))+((1−v)∗((Ri−min(Ri))/(max(Ri)−min(Ri)))); DQ=1/(m−1); a1=min(Qi); Q=Qi; Q=sort(Q); a2=Q(2); if a2−a1 >= DQ Condition1=‘TRUE’ elseif a2−a1<DQ Condition1=‘FALSE’ End |

References

- Pinho, J.T.; Galdino, M.A. Manual_de_Engenharia_FV_2014; Rio de Janeiro, Brazil. 2014. Available online: https://docs.google.com/viewer?a=v&pid=sites&srcid=ZGVmYXVsdGRvbWFpbnxnZW9jcmlzcm9kcmlndWVzfGd4OmFmNzViN2VjNzc4ZWVlNA (accessed on 5 March 2020).

- Nascimento, R.L. Energia Solar no Brasil: Situação e Perspectivas; Câmara dos Deputados: Brazilian, Brazil, 2017; p. 46. [Google Scholar]

- Wang, T.; Tsai, S. Solar Panel Supplier Selection for the Photovoltaic System Design by Using Fuzzy Multi-Criteria. Energies 2018, 11, 1989. [Google Scholar] [CrossRef]

- UNFCC. Adoption of the Paris Agreement; United Nations: Le Bourget, France, 2015. [Google Scholar]

- Ramos, C.; Ruiz, E.T.N.F.; Bicalho, F.W.; Barbosa, J.M.; Barros, L.V.; Rabassa, M.M.M. Cadeia De Valor Da Energia Solar Fotovoltaica no Brasil; Sebrae: Brazilian, Brazil, 2018; p. 364. [Google Scholar]

- Akwa, J.V.; Konrad, O.; Kaufmann, G.V.; Machado, C.A. Evaluation of the photovoltaic generation potential and real-time analysis of the photovoltaic panel operation on a building facade in southern Brazil. Energy Build. 2014, 69, 426–433. [Google Scholar] [CrossRef]

- Presidência da República, Lei 13.203: Repactuação Do Risco Hidrológico De Geração De Energia Elétrica; Brazilian, Brazil. 2015; p. 6. Available online: http://www.planalto.gov.br/ccivil_03/_Ato2015–2018/2015/Lei/L13203.htm (accessed on 5 March 2020).

- Konzen, G. (Ministério de Minas e Energia, Rio de Janeiro, Brazil). Geração Fotovoltaica Diagnóstico e Perspectivas. Personal communication, 2018. [Google Scholar]

- Taticchi, P.; Tonelli, F.; Pasqualino, R. Performance measurement of sustainable supply chains. Int. J. Product. Perform. Manag. 2013, 62, 782–804. [Google Scholar] [CrossRef]

- Falcone, P.M.; Sica, E. Assessing the opportunities and challenges of green finance in Italy: An analysis of the biomass production sector. Sustainability 2019, 11, 517. [Google Scholar] [CrossRef]

- BNB. New Line of Credit Finances Mini and Micro Solar Power Generation for Family Farmers, Banco do Nordeste. 2017. Available online: http://www.bnb.gov.br (accessed on 10 February 2020).

- BNDES. BNDES Muda Regra E Pessoas Físicas Podem Investir Em Energia Solar. 2018. Available online: https://www.bndes.gov.br/wps/portal/site/home/imprensa/noticias/ (accessed on 10 February 2020).

- BV. Financiamento Para Energia Solar BV. 2017. Available online: https://www.bv.com.br/financiamento/financiamento-solar (accessed on 10 February 2020).

- Zanetti Neto, G.; da Costa, W.T.; Vasconcelos, V.B. A Resolução Normativa No 482 / 2012 da Aneel: Possibilidades e entraves para a microgeração distribuída. RBENS. 2014, V, 119–127. [Google Scholar]

- Grimm, J.H.; Hofstetter, J.S.; Sarkis, J. Interrelationships amongst factors for sub-supplier corporate sustainability standards compliance: An exploratory field study. J. Clean. Prod. 2018, 203, 240–259. [Google Scholar] [CrossRef]

- Portal Solar. Tudo Sobre Energia Solar Fotovoltaica. Available online: https://www.portalsolar.com.br/ (accessed on 10 July 2019).

- Atanassov, K.T. Intuitionistic fuzzy sets. Fuzzy Sets Syst. 1986, 20, 87–96. [Google Scholar] [CrossRef]

- Opricovic, S. Multicriteria optimization of civil engineering systems. FCE – UB. 1998, 2, 5–21. [Google Scholar]

- Chang, T.H. Fuzzy VIKOR method: A case study of the hospital service evaluation in Taiwan. Inf. Sci. 2014, 271, 196–212. [Google Scholar] [CrossRef]

- Sugeno, M.; Kang, G.T. Structure identification of fuzzy model. Fuzzy Sets Syst. 1988, 28, 15–33. [Google Scholar] [CrossRef]

- Lee, A.H.I.; Kang, H.Y.; Hsu, C.F.; Hung, H.C. A green supplier selection model for high-tech industry. Expert Syst. Appl. 2009, 36, 7917–7927. [Google Scholar] [CrossRef]

- Cucchiella, F.; D’Adamo, I. Issue on supply chain of renewable energy. Energy Convers. Manag. 2013, 76, 774–780. [Google Scholar] [CrossRef]

- Troche-Escobar, J.; Lepikson, H.; Freires, F. A Study of Supply Chain Risk in the Brazilian Wind Power Projects by Interpretive Structural Modeling and MICMAC Analysis. Sustainability 2018, 10, 3442. [Google Scholar] [CrossRef]

- United Nations. Sustainable Development Goals. Website. 2019. Available online: https://www.un.org/sustainabledevelopment/ (accessed on 20 February 2019).

- Govindan, K.; Rajendran, S.; Sarkis, J.; Murugesan, P. Multi criteria decision making approaches for green supplier evaluation and selection: A literature review. J. Clean. Prod. 2015, 98, 66–83. [Google Scholar] [CrossRef]

- Dempsey, W.A. Vendor selection and the buying process. Ind. Mark. Manag. 1978, 7, 257–267. [Google Scholar] [CrossRef]

- Dickson, G.W. An analysis of vendor selection systems and decisions. J. Purch. 1966, 2, 5–17. [Google Scholar] [CrossRef]

- Weber, C.A.; Current, J.R.; Benton, W.C. Vendor selection criteria and methods. Eur. J. Oper. Res. 1991, 50, 2–18. [Google Scholar] [CrossRef]

- Cooper, M.C.; Lambert, D.M.; Pagh, J.D. Supply Chain Management: More Than a New Name for Logistics. Int. J. Logist. Manag. 1997, 8, 1–14. [Google Scholar] [CrossRef]

- Lambert, D.M.; Cooper, M.C.; Pagh, J.D. Supply Chain Management: Implementation Issues and Research Opportunities. Int. J. Logist. Manag. 1998, 9, 1–20. [Google Scholar] [CrossRef]

- Noci, G. Designing green vendor rating systems for the assessment of a supplier’s environmental performance. Eur. J. Purch. Supply Manag. 1997, 3, 103–114. [Google Scholar] [CrossRef]

- Williamson, O.E. The Economic Institutions of Capitalism. Firms, Markets, Relational Contracting; Springer: Gabler, Germany, 2007; pp. 61–75. ISBN 978-3-8349-9320-5. [Google Scholar]

- Tate, W.L.; Dooley, K.J.; Ellram, L.M. Transaction cost and institutional drivers of supplier adoption of environmental practices. J. Bus. Logist. 2011, 32, 6–16. [Google Scholar] [CrossRef]

- Erkul, M.; Kaynak, H.; Montiel, I. Supplier relations and sustainable operations: The roles of codes of conduct and human resource development. Int. J. Integr. Supply Manag. 2015, 9, 225–249. [Google Scholar] [CrossRef]

- Barney, J. Firm Resources and Sustained Competitive Advantage. J. Manage. 1991, 17, 99–120. [Google Scholar] [CrossRef]

- Gavronski, I.; Klassen, R.D.; Vachon, S.; Nascimento, L.F.M.D. A resource-based view of green supply management. Transp. Res. Part E Logist. Transp. Rev. 2011, 47, 872–885. [Google Scholar] [CrossRef]

- Brandon-Jones, E.; Squire, B.; Autry, C.; Petersen, K.J. A Contingent Resource-Based Perspective of Supply Chain Resilience and Robustness. J. Supply Chain Manag. 2014, 50, 55–73. [Google Scholar] [CrossRef]

- Cook, W.D.; Liang, L.; Zhu, J. Measuring performance of two-stage network structures by DEA: A review and future perspective. Omega 2010, 38, 423–430. [Google Scholar] [CrossRef]

- Hervani, A.; Helms, M.M.; Sarkis, J. Performance measurement for green supply chain management. Benchmarking An Int. J. 2005, 12, 330–353. [Google Scholar] [CrossRef]

- Sistemas Da Gestão Ambiental—ISO 14001. Requisitos Com Orientações Para Uso; ABNT NBR: Rio de Janeiro, Brazil, 2005.

- Gestão Ambiental—Avaliação Do Ciclo Devida—Avaliação Do Impacto Do Ciclo De Vida- ISO 14042; ABNT NBR: Rio de Janeiro, Brazil, 2004; pp. 1–16.

- Gestão Ambiental—Avaliação Da Ecoeficiência De Sistemas De Produto-Princípios, Requisitos E Orientações- ISO 14045; ABNT NBR: Rio de Janeiro, Brazil, 2014; p. 49.

- Beamon, B.M. Designing the green supply chain. Logist. Inf. Manag. 1999, 12, 332–342. [Google Scholar] [CrossRef]

- Chiou, C.Y.; Hsu, C.W.; Hwang, W.Y. Comparative Investigation on Green Supplier Selection of the American, Japanese and Taiwanese Electronics Industry in China; IEEE: Piscataway NJ, USA, 2008; pp. 1909–1914. [Google Scholar]

- Chiou, T.-Y.; Chan, H.K.; Lettice, F.; Chung, S.H. The influence of greening the suppliers and green innovation on environmental performance and competitive advantage in Taiwan. Transp. Res. Part E Logist. Transp. Rev. 2011, 47, 822–836. [Google Scholar] [CrossRef]

- Punniyamoorthy, M.; Mathiyalagan, P.; Parthiban, P. A strategic model using structural equation modeling and fuzzy logic in supplier selection. Expert Syst. Appl. 2011, 38, 458–474. [Google Scholar] [CrossRef]

- Yeh, W.-C.; Chuang, M.-C. Using multi-objective genetic algorithm for partner selection in green supply chain problems. Expert Syst. Appl. 2011, 38, 4244–4253. [Google Scholar] [CrossRef]

- Carter, C.R.; Rogers, D.S. A framework of sustainable supply chain management: Moving toward new theory. Int. J. Phys. Distrib. Logist. Manag. 2008, 38, 360–387. [Google Scholar] [CrossRef]

- Carter, C.R.; Easton, P.L. Sustainable supply chain management: Evolution and future directions. Int. J. Phys. Distrib. Logist. Manag. 2011, 41, 46–62. [Google Scholar] [CrossRef]

- Carter, C.R.; Carter, J.R. Interorganizational Determinants of Environmental Purchasing: Initial Evidence from the Consumer Products Industries. Decis. Sci. 1998, 29, 659–684. [Google Scholar] [CrossRef]

- Brink, S.; Diehl, J.C.; Stevels, A. ECO-QUEST, an Ecodesign Self Audit Tool for Suppliers of the Electronics Industry; IEEE: Oak Brook, IL, USA, 1998; pp. 129–132. [Google Scholar]

- Li, S.; Huang, Y. Research on Impact of Supplier Innovativeness on Manufactures’ New Product Development; ICIII: Xi’an, China, 2013; pp. 362–365. [Google Scholar]

- Büyüközkan, G.; Çifçi, G. A novel fuzzy multi-criteria decision framework for sustainable supplier selection with incomplete information. Comput. Ind. 2011, 62, 164–174. [Google Scholar] [CrossRef]

- Amindoust, A.; Ahmed, S.; Saghafinia, A.; Bahreininejad, A. Sustainable supplier selection: A ranking model based on fuzzy inference system. Appl. Soft Comput. J. 2012, 12, 1668–1677. [Google Scholar] [CrossRef]

- Hashemi, S.H.; Karimi, A.; Aghakhani, N.; Kalantar, P. A Grey-Based Carbon Management Model for Green Supplier Selection; GSIS: Macao, China, 2013; pp. 402–405. [Google Scholar]

- Mavi, R.K. Green supplier selection: A fuzzy AHP and fuzzy ARAS approach. Int. J. Serv. Oper. Manag. 2015, 22, 165–188. [Google Scholar] [CrossRef]

- Zadeh, L.A. The Concept of a Linguistic Variable and its Application to Approximate Reasoning. In Learning Systems and Intelligent Robots; Springer: Berkeley CA, USA, 1974; pp. 1–10. [Google Scholar]

- Leyva Vázquez, M.Y.; Pérez Teruel, K.; Febles Estrada, A.; Gulín González, J. Mapas cognitivos difusos para la selección de proyectos de tecnologías de la información. CYA. 2013, 58, 95–117. [Google Scholar] [CrossRef][Green Version]

- Rajaram, T.; Das, A. Modeling of interactions among sustainability components of an agro-ecosystem using local knowledge through cognitive mapping and fuzzy inference system. Expert Syst. Appl. 2010, 37, 1734–1744. [Google Scholar] [CrossRef]

- Ferreira, F.A.F.; Jalali, M.S.; Ferreira, J.J.M.; Stankevičienė, J.; Marques, C.S.E. Understanding the dynamics behind bank branch service quality in Portugal: Pursuing a holistic view using fuzzy cognitive mapping. Serv. Bus. 2016, 10, 469–487. [Google Scholar] [CrossRef]

- Devisscher, T.; Boyd, E.; Malhi, Y. Anticipating future risk in social-ecological systems using fuzzy cognitive mapping: The case of wildfire in the Chiquitania, Bolivia. Ecol. Soc. 2016, 21, 4. [Google Scholar] [CrossRef]

- Pandari, A.R.; Azar, A. A fuzzy cognitive mapping model for service supply chains performance. Meas. Bus. Excell. 2017, 21, 388–404. [Google Scholar] [CrossRef]

- Misthos, L.M.; Messaris, G.; Damigos, D.; Menegaki, M. Exploring the perceived intrusion of mining into the landscape using the fuzzy cognitive mapping approach. Ecol. Eng. 2017, 101, 60–74. [Google Scholar] [CrossRef]

- Branco, J.M.P.; Ferreira, F.A.F.; Meidutė-Kavaliauskienė, I.; Banaitis, A.; Falcão, P.F. Analysing determinants of small and medium-sized enterprise resilience using fuzzy cognitive mapping. J. Multi-Criteria Decis. Anal. 2019, 26, 252–264. [Google Scholar] [CrossRef]

- Pluchinotta, I.; Esposito, D.; Camarda, D. Fuzzy cognitive mapping to support multi-agent decisions in development of urban policymaking. Sustain. Cities Soc. 2019, 46, 101402. [Google Scholar] [CrossRef]

- Azevedo, A.R.S.C.; Ferreira, F.A.F. Analyzing the dynamics behind ethical banking practices using fuzzy cognitive mapping. Oper. Res. 2019, 19, 679–700. [Google Scholar] [CrossRef]

- Mehregan, M.R.; Hashemi, S.H.; Karimi, A.; Merikhi, B. Analysis of interactions among sustainability supplier selection criteria using ISM and fuzzy DEMATEL. Int. J. Appl. Decis. Sci. 2014, 7, 270. [Google Scholar] [CrossRef]

- Aghajani Mir, M.; Taherei Ghazvinei, P.; Sulaiman, N.M.N.; Basri, N.E.A.; Saheri, S.; Mahmood, N.Z.; Jahan, A.; Begum, R.A.; Aghamohammadi, N. Application of TOPSIS and VIKOR improved versions in a multi criteria decision analysis to develop an optimized municipal solid waste management model. J. Environ. Manage. 2016, 166, 109–115. [Google Scholar] [CrossRef]

- Govindan, K.; Khodaverdi, R.; Vafadarnikjoo, A. Intuitionistic fuzzy based DEMATEL method for developing green practices and performances in a green supply chain. Expert Syst. Appl. 2015, 42, 7207–7220. [Google Scholar] [CrossRef]

- Nikjoo, A.V.; Saeedpoor, M. An intuitionistic fuzzy DEMATEL methodology for prioritising the components of SWOT matrix in the Iranian insurance industry. Int. J. Oper. Res. 2014, 20, 439. [Google Scholar] [CrossRef]

- Li, M.; Wu, C. Green Supplier Selection Based on Improved Intuitionistic Fuzzy TOPSIS Model; Metallurgical & Mining Industry: Guangxi, China, 2015; pp. 193–205. [Google Scholar]

- Opricovic, S.; Tzeng, G. Compromise Solution by MCDM Methods: A Comparative Analysis of VIKOR and TOPSIS; Elsevier: Amsterdam, The Netherlands, 2004. [Google Scholar]

- Sayadi, M.K.; Heydari, M.; Shahanaghi, K. Extension of VIKOR method for decision making problem with interval numbers. Appl. Math. Model. 2009, 33, 2257–2262. [Google Scholar] [CrossRef]

- Szmidt, E.; Kacprzyk, J. Entropy for intuitionistic fuzzy sets. Fuzzy Sets Syst. 2001, 118, 467–477. [Google Scholar] [CrossRef]

- Mathew, M. Multi Criteria Decision Making Approach for. 2019. Available online: https://mathewmanoj.wordpress.com/multi-criteria-decision-making/ (accessed on 13 October 2019).

- Avaliação Da Conformidade—Requisitos Gerais Para Ensaios De Proficiência ISO 17043; ABNT NBR: Rio de Janeiro, Brazil, 2017; p. 46.

| Theories | Argument | Exponents |

|---|---|---|

| Transaction cost economics (TCE) | Economic exchange (transaction) dictates the main determinants of the TCE theory, which are: (1) frequency, (2) specificity, (3) bounded rationality and (4) uncertainty and opportunistic behavior. The application of this theory underlies the quantification of the exchange of material resources and energy. In this case, it is a determinant for specifying and identifying assets by the following classification: the specificity of human capital and the specificity of physical assets and specifications in situ. | [32,33,34] |

| Resource-based view | The resources of a company must have four attributes to have the potential for sustained competitive advantage: (1) resources must create value that improves a company’s profits or reduces costs; (2) the appeal must not be perfectly imitable; (3) the value creation strategy is not implemented simultaneously by the economic agents and (4) this feature cannot be replaced. The resources of an enterprise may consist of human or nonhuman and both tangible and intangible resources, as long as these resources produce distinct competencies for a company. | [34,35,36,37] |

| Dimensions | Indicators | Label | Data Source |

|---|---|---|---|

| Provides environmental licenses for projects | C1 | DQ and IQ | |

| Environmental | ISO 14000- ISO 9000- SA 8000 Management System | C2 | DQ and CDB |

| Environmental commitment expressed by supplier reputation | C3 | DQ and IQ | |

| Sales price of components or installation service | C4 | CDB and IQ | |

| Economics | Related logistics costs | C5 | CDB and IQ |

| Credit and advisory channel availability | C6 | CDB and IQ | |

| Photoelectric conversion efficiency | C7 | CDB | |

| Degradation rate of installed components | C8 | CDB | |

| Adaptability to use environment | C9 | CDB | |

| Technical | Product defect rate | C10 | CDB |

| Delivery time | C11 | CDB and IQ | |

| Service warranty period | C12 | CDB | |

| Advice on after-sales service of components | C13 | CDB and IQ | |

| Installed technological capacity | C14 | CDB and DQ |

| Degree of Influence | Weights | Qualification | Label | Fuzzy Numbers |

|---|---|---|---|---|

| Does not influence | Irrelevance | Very low | VL | (0; 0; 0,1; 0,2) |

| Very low influence | Very low relevance | Low | L | (0,1; 0,2; 0,2; 0,3) |

| Low influence | Low relevance | Moderate low | ML | (0,2; 0,3; 0,4; 0,5) |

| Moderate influence | Moderate relevance | Moderate | M | (0,4; 0,5; 0,5; 0,6) |

| Influence | Relevance | Moderate high | MH | (0,5; 0,6; 0,7; 0,8) |

| High influence | High relevance | High | H | (0,7; 0,8; 0,8; 0,9) |

| Very high influence | Very high relevance | Very high | VH | (0,8; 0,9; 1; 1) |

| States | Quantity |

|---|---|

| Bahia | 40 |

| Sergipe | 5 |

| Ceará | 26 |

| Piauí | 10 |

| Alagoas | 6 |

| Pernambuco | 19 |

| Paraíba | 9 |

| Rio Grande do Norte | 9 |

| Maranhão | 15 |

| Northeast Brazil | 139 |

| Sui\Cj | C1 | C2 | C3 | C4 | C5 | C6 | C7 | C8 | C9 | C10 | C11 | C12 | C13 | C14 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Su1 | I P C | MeB MA MA | B A MB | MeB MeB MeA | A MeB MeA | MeA MeA MB | MA MB MB | MB B Me | MB B MA | Me MeB B | Me MeA MeA | MeB Me MA | A MA B | MB MeB MeA | MeB MB MA |

| Su2 | I P C | MB B MB | MA B Me | MeA A MA | B MeB A | B A Me | A B MA | MB A MeA | Me MB MeA | MeA MeA B | Me MB Me | B MB A | MA Me MeB | MeA A MA | MB B MeA |

| Su3 | I P C | MA Me MeA | MB Me MeB | MA MeB MeA | MA MB B | MeB B MeB | A B MA | Me A Me | Me Me Me | MA B MA | B B MeA | A MeA MeA | B MeA MA | MeA MeA MA | MA MeA MeB |

| Su4 | I P C | A B Me | Me MA MA | B MA B | B MA MeB | MA Me MA | MB B B | MB Me MeA | A MB Me | MeB MA Me | B MeB A | MA A MA | MeA B MB | MB MA A | MA MB A |

| Su5 | I P C | B MB MeB | Me MA A | B MeA MB | MeA MB A | Me MeA MA | B MB MA | MeA MB MB | MA Me A | MeA Me A | B A Me | MA A MB | MA MA MeB | Me A A | Me Me B |

| Su6 | I P C | MB Me B | MB MB MeA | A MeA MeA | MB Me A | B MeA MeA | Me Me B | MeA Me Me | MeA B MA | Me MeB MeB | MA B B | Me B MA | B MB A | MeA Me Me | MeA A MeB |

| Su7 | I P C | MeB MB MeA | MA B Me | B Me MeB | MeB MeB A | A MA MA | MeA B MA | A MeB B | MeA MeB Me | B MB MeB | MB Me MA | MeB MA MA | MB MB MeB | MB B MB | Me MeB MB |

| Sui\Cj | C1 | C2 | C3 | C4 | C5 | C6 | C7 | C8 | C9 | C10 | C11 | C12 | C13 | C14 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Su1 | 3.80 | 1.87 | 2.67 | 3.22 | 2.67 | 2.29 | 2.29 | 2.96 | 2.31 | 3.23 | 3.17 | 3.47 | 2.07 | 2.60 |

| Su2 | 1.50 | 3.55 | 3.47 | 2.83 | 2.73 | 3.77 | 2.67 | 2.60 | 3.05 | 2.60 | 2.61 | 3.17 | 3.47 | 2.29 |

| Su3 | 3.55 | 1.73 | 3.55 | 2.60 | 2.21 | 3.77 | 2.87 | 2.86 | 3.79 | 2.67 | 3.60 | 3.22 | 3.65 | 3.25 |

| Su4 | 3.47 | 3.78 | 2.55 | 2.88 | 3.55 | 1.86 | 2.29 | 2.74 | 3.33 | 2.83 | 3.77 | 2.29 | 3.33 | 3.42 |

| Su5 | 1.50 | 3.77 | 1.67 | 2.98 | 3.63 | 2.60 | 1.76 | 3.52 | 3.22 | 2.73 | 2.73 | 3.80 | 3.22 | 2.71 |

| Su6 | 1.49 | 1.76 | 3.60 | 2.80 | 3.05 | 2.71 | 2.88 | 3.65 | 2.67 | 2.55 | 3.55 | 2.61 | 2.88 | 2.75 |

| Su7 | 2.43 | 3.55 | 2.20 | 2.83 | 3.77 | 3.65 | 2.83 | 2.86 | 1.50 | 2.84 | 3.78 | 1.27 | 1.50 | 2.07 |

| Criteria | C1 | C2 | C3 | C4 | C5 | C6 | C7 | C8 | C9 | C10 | C11 | C12 | C13 | C14 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Wj | 0.206 | 0.151 | 0.085 | 0.005 | 0.042 | 0.082 | 0.034 | 0.020 | 0.089 | 0.007 | 0.026 | 0.118 | 0.098 | 0.036 |

| Sui\Cj | C1 | C2 | C3 | C4 | C5 | C6 | C7 | C8 | C9 | C10 | C11 | C12 | C13 | C14 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Su1 | 0.000 | 0.067 | 0.034 | 0.000 | 0.050 | 0.055 | 0.038 | 0.047 | 0.046 | 0.000 | 0.037 | 0.009 | 0.052 | 0.043 |

| Su2 | 0.071 | 0.008 | 0.005 | 0.045 | 0.048 | 0.000 | 0.013 | 0.071 | 0.023 | 0.066 | 0.071 | 0.018 | 0.006 | 0.060 |

| Su3 | 0.008 | 0.071 | 0.002 | 0.071 | 0.071 | 0.000 | 0.001 | 0.054 | 0.000 | 0.059 | 0.011 | 0.016 | 0.000 | 0.009 |

| Su4 | 0.010 | 0.000 | 0.039 | 0.039 | 0.010 | 0.071 | 0.038 | 0.062 | 0.014 | 0.042 | 0.001 | 0.043 | 0.011 | 0.000 |

| Su5 | 0.071 | 0.000 | 0.071 | 0.028 | 0.006 | 0.044 | 0.071 | 0.009 | 0.018 | 0.053 | 0.064 | 0.000 | 0.014 | 0.038 |

| Su6 | 0.071 | 0.070 | 0.000 | 0.048 | 0.033 | 0.040 | 0.000 | 0.000 | 0.035 | 0.071 | 0.014 | 0.034 | 0.026 | 0.035 |

| Su7 | 0.042 | 0.008 | 0.052 | 0.045 | 0.000 | 0.004 | 0.003 | 0.054 | 0.071 | 0.041 | 0.000 | 0.071 | 0.071 | 0.071 |

| Alternatives | Si | Ri | Qi |

|---|---|---|---|

| Su1 | 0.486 | 0.141 | 0.569 |

| Su2 | 0.415 | 0.205 | 0.715 |

| Su3 | 0.279 | 0.151 | 0.277 |

| Su4 | 0.309 | 0.082 | 0.048 |

| Su5 | 0.473 | 0.206 | 0.809 |

| Su6 | 0.588 | 0.207 | 1.000 |

| Su7 | 0.571 | 0.123 | 0.634 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pérez-Velázquez, A.; Oro-Carralero, L.L.; Moya-Rodríguez, J.L. Supplier Selection for Photovoltaic Module Installation Utilizing Fuzzy Inference and the VIKOR Method: A Green Approach. Sustainability 2020, 12, 2242. https://doi.org/10.3390/su12062242

Pérez-Velázquez A, Oro-Carralero LL, Moya-Rodríguez JL. Supplier Selection for Photovoltaic Module Installation Utilizing Fuzzy Inference and the VIKOR Method: A Green Approach. Sustainability. 2020; 12(6):2242. https://doi.org/10.3390/su12062242

Chicago/Turabian StylePérez-Velázquez, Alexei, Leandro Leysdian Oro-Carralero, and Jorge Laureano Moya-Rodríguez. 2020. "Supplier Selection for Photovoltaic Module Installation Utilizing Fuzzy Inference and the VIKOR Method: A Green Approach" Sustainability 12, no. 6: 2242. https://doi.org/10.3390/su12062242

APA StylePérez-Velázquez, A., Oro-Carralero, L. L., & Moya-Rodríguez, J. L. (2020). Supplier Selection for Photovoltaic Module Installation Utilizing Fuzzy Inference and the VIKOR Method: A Green Approach. Sustainability, 12(6), 2242. https://doi.org/10.3390/su12062242