1. Introduction

Many definitions and illustrations about Business Networks (BN) have emerged from different authors in the latest years. For instance, industrial clusters [

1], e-industrial cluster [

2], horizontal business cooperation networks [

3], and an evolved concept to ecological networks [

4,

5]. Their differences would be related to the specificities of the empirical cases analyzed and the highlight given to certain characteristics or advantages.

According to Neto [

6], BN can be defined as a group of companies that perform cooperative actions, such as sharing logistics, inventory and distribution, by-products, machines, equipment or even management processes. Compatibility and congruence among the partners is an essential factor that determines the behavior, the strategy, and structure of a business network [

7]. The characteristic of cooperation is usually common to all different concepts related to the subject. Thus, in this article, we chose to use the typology BN due to its scope that includes industrial cluster and service networks.

According to some authors [

8,

9], the concept of Circular Economy (CE), which includes recycling and reuse, becomes a guideline for a promising and facilitating path of the current situation.

The circular economy strategy is widely used as an effective way to achieve a low carbon transition [

8] of cities through waste recycling and Industrial Symbiosis (IS) improvements [

10], and transition to ecological networks [

5,

6,

7,

8,

9]. In the context of sustainability and regional interactions, and under the CE coverage, IS can be pointed out as an important practice that involves industries through geographical proximity [

11]. Usually, developing competitive advantages in a BN involves three spheres: exchange of materials and/or by-products, sharing of utilities and services and cooperation in management [

12]. Therefore, there is an important linkage of IS to BN.

The goal of IS is to benefit all the members involved in the BN. However, each participant will receive a different magnitude of benefits from this flow. That is, each one can define what to share and receive [

4]. Thus, IS is defined as a synergy of byproducts and waste between companies [

13], a key concept of circular economy and industrial ecology, which studies the physical flows of materials and energy in local industrial systems [

2]. Establishing these systems is seen as a hope for industrialized and developing nations to achieve sustainable development goals [

14], interdisciplinary combined with what Circular Economy has an eye for.

For some authors [

15,

16], the main characteristic of IS are sharing material resources, such as energy, water and also by-products among nearby companies. Therefore, IS refers to a collaborative strategy of exchanging physical resources and sharing services among industrial actors, which enhances the resource efficiency and reduces the environmental impacts of industrial operations within the BN [

17].

Although physical exchange between collaborating companies is the main attribute of IS [

18], and also for BN [

7], aspects such as the establishment of agreements between companies that lead to resource efficiency should also be considered as IS [

16,

17,

18,

19].

Brazil has advantages in location and regional aspects enabling a favorable environment to promote sustainability in its various aspects. While there are several BNs in Brazil, no self-organized IS practices are known in those networks. This may be due to the fact that in developing countries the concept of IS is still recent and of little knowledge among small companies, which can make it difficult to draft the emergence of these practices. Here comes a challenge: digging on the opportunity to identify those practices.

Saraceni et al. developed a conceptual qualitative and quantitative model to uncover IS in BN [

20]. It helps to identify, even if initial, the potential of IS. This model was selected due to its successes in integrating IS and BN. It is a model combined by a method and a tool for assessing the existence of IS taking into account the comprehensiveness of the three spheres and five domains. In addition, the conceptual model uses fuzzy logic as a Multicriteria Decision Analysis Method (MCDA) to assign the importance of the variables. Hence, it can be empirically applied to evaluate the presence of IS practices and/or aspects. Supported by the tool, the model can help to action-driven on cases of the early stages of IS.

Identifying early stages is of great importance, considering that IS is a possibility for companies to promote the circular economy to significantly reduce the use of energy, water, and material resources related to environmental impacts. Furthermore, it is an initiative that has been increasingly pointed as a way to minimize the environmental impact due to industrial production [

21]. The model to uncover IS (Method for the evaluation of IS) creates a starting point for new studies that seek to identify the potential of IS and to studies that work on the analysis of ecological networks [

20]. The objective of this work is to perform a temporal comparative analysis of IS in a network in the furniture sector, in southern Brazil, and to present drivers through circular economy modeling.

This article is structured as follows: this first section introduces the topics presented and the objectives of the study; the second section approaches the theoretical background discussing the main authors on the topics; the third section details the methodology used to build this article; fourth section presents results of the comparative analysis of IS in a business network in Brazil; finally, the fifth and last section concludes the paper presenting a compilation of the results obtained, contributions of this research makes, limitations and suggestions for future works.

3. Materials and Methods

For the analysis of industrial symbiosis (IS), applied to a BN of Concórdia, Santa Catarina, in southern Brazil [

20]. The network is characterized by a set of eight companies located in three cities (Piritiba, Concórdia and Seara) with a differential geographical impact. This network presents “a good cooperative performance, with mature and complex actions of both interrelationship and internal competences” [

56].

The selection of the network studied was due to the networking history, which has been operating for over 15 years, and because it is a recognized sector core in the region where it operates. In addition, the productive specialization of the network meets the specificities of this work, since it has the characteristic for the progressive development of IS practices and, consequently, the adoption of the concepts of CE. Factors of maturity of the interrelationship, as well as the accessibility to the companies, also motivated the selection of the network.

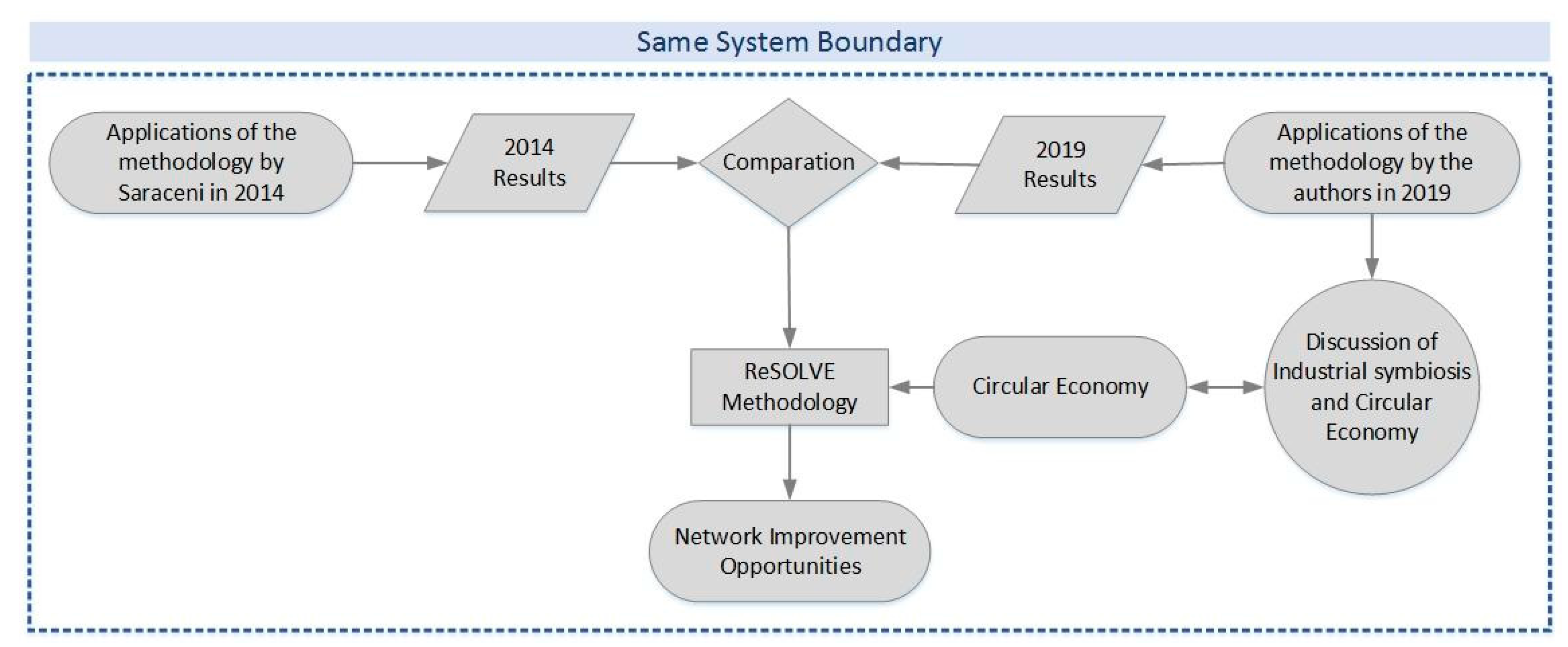

The flow chart in

Figure 1 illustrates the methodological steps that involve the application of this research.

The model (

Figure 2) diagnoses the presence of IS practices in the business network, working on five scientific domain variables: Technical Factor (TF), Economic Factor (FE), Political Factor (PF), Informative Factor (IF) and Organizational Factor (OF) [

20]. These variables are interrelated with three spheres: by-product exchange, sharing of public services and/or services, and cooperation in management.

The IS phenomenon occurs within the black box that cannot be opened. However, it is possible to observe the z phenomenon, IS, and speculate its invisible causation mechanism (black box). We observe the phenomenon by discovering that some phenomena such as exchange of by-products, sharing of utilities and/or services, management cooperation, technical aspects, economic aspects, incentive policies, informational structure, organizational and institutional structure; are related to IS. Some of these phenomena can be controlled by the business network, but others are the result of the individual behavior of each company, or even influenced by the national and international macroeconomic environment [

20].

The observation of the consolidated phenomena in the model shows that correlations between endogenous and exogenous variables influences how IS operates. Some of these phenomena require greater control from companies, such as cooperative management. Others suffer the influence of several external factors, such as those resulting from the behavior of individuals or from the national and international macroeconomic environment [

20,

21,

22,

23,

24,

25,

26,

27,

28,

29]. This model has as its differential the mathematical approach by the Fuzzy tool elaborated by the mathematician Lofti Zadeh and the foundations of the theory were published in 1965 in the Journal Information and Control. Fuzzy sets help researchers conceptualize social and political phenomena assets of inaccurate boundaries that range from “complete relevance” to “total exclusion” [

57].

Hence, the tool reflecting the model is a quiz format with 159 questions divided into the three spheres, and with a subdivision of questions that characterize each domain. The questions use answers of the binary format of “yes” or “no” that is converted to 1 or 0 and, consequently, generate the graphs for analysis of the IS diagnosis.

The comparative analysis of verification of IS was performed comparing the results obtained with results collected in 2019 [

29]. Data collection happened by sending the questionnaires in electronic format to the managers of the companies in Concordia and those responsible for passing the survey to the other managers. Answers got through the electronic format questionnaire are automatically converted into a spreadsheet, facilitating the maneuver graph representation. The validation of the questionnaire used in the research, comprising the variables of the main relationships of IS, had been made in collaboration with researchers and members of ISIE - International Society for Industrial Ecology, through support and adjustment rounds [

29].

The sample consists of 5 of the 8 companies that compose the business network, representing a remarkable response rate of 62.5%, all convex and consistent, therefore, resulting in the 5 valid questionnaires. The 3 non-respondent companies also act as companies in the furniture production segment. However, it was difficult to contact the business owner or partner to authorize the research. Based on Brazilian Law (Brazilian Micro and Small Business Support Service - SEBRAE, 2019), all interviewed companies are classified as small companies, ie, companies with annual revenues between 360,000 and 4,800,000 BRL (approximately 90,000 and 1,190,000 USD, respectively, considering the December 2019 exchange rate). The 5 interviewed companies linked to the Concordia furniture network are engaged in the production of bespoke and high standard furniture. These companies are associated with ACIC (Concordia Commercial and Industrial Association), Santa Catarina, and governed by a particular bylaws of the network, where the managers of the companies themselves manage the cooperative actions.

With the interest among the managers of the business network to promote the improvement in the efficiency of material and energy flows, aiming at the environmental and economic development of organizations. The study raises opportunities, through a literary discussion, that can leverage network synergy by utilizing circular economics, exploring techniques and technologies for the network to achieve restorative services for economic and environmental gains.

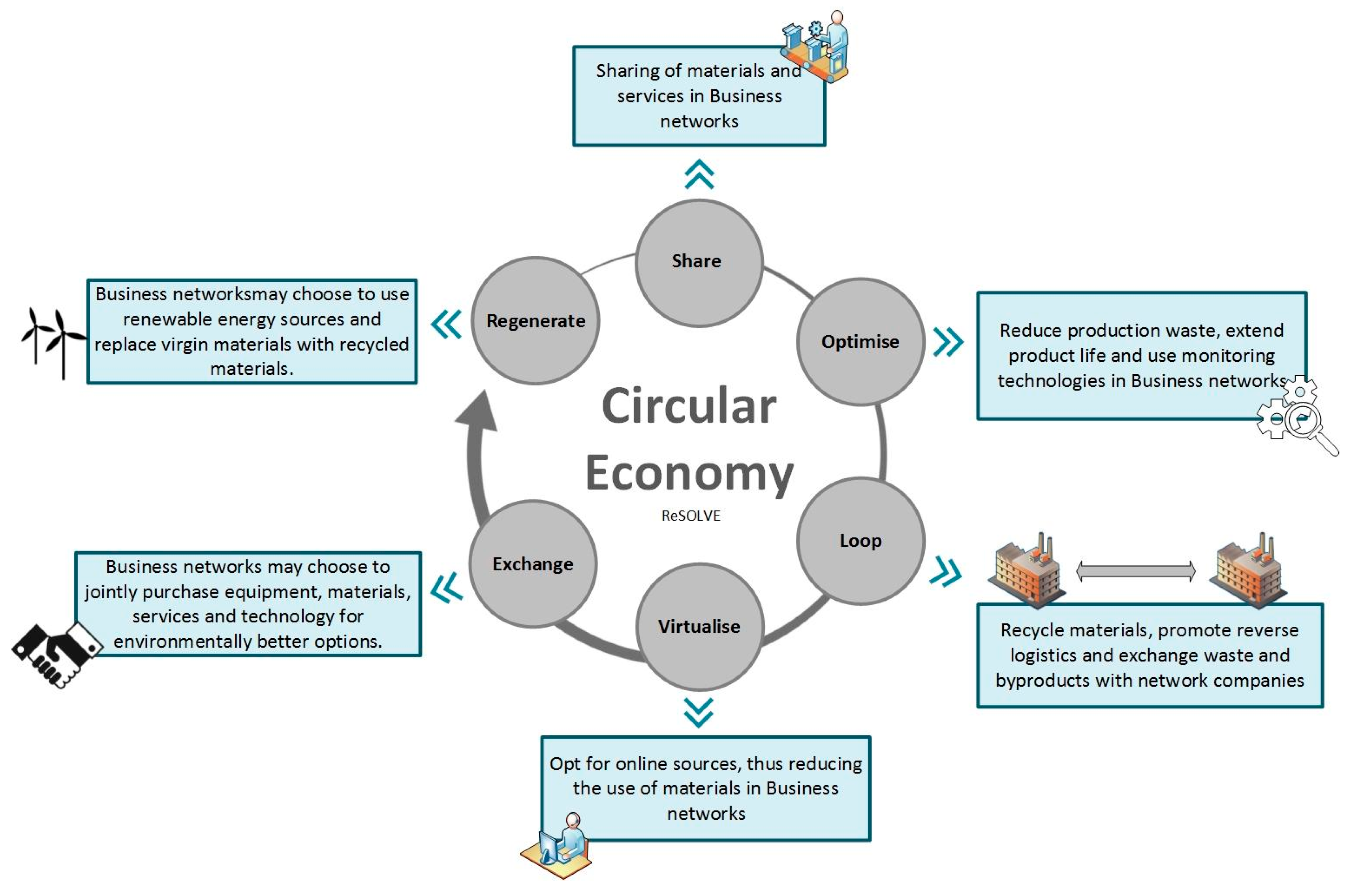

The survey of opportunities was conducted using the ReSOLVE methodology - Regenerate, Share, Optimize, Loop, Virtualise and Exchange - proposed by the Ellen McArthur Foundation [

50]. The methodology addresses the promotion of improvements and innovation through six actions:

Regenerate: involves actions that seek the transition from finite fossil fuels to renewable energy.

Share: aims to achieve maximum use of goods and eliminates waste.

Optimize: seeks waste reduction in manufacturing processes as well as waste energy and the use of materials in processes.

Loop: seeks circularity through recycling, reuse, sharing of materials.

Virtualise: use of community sources for equipment and materials to reduce extraction from non-renewable sources.

Exchange: Exchange on new technologies, upgrading or replacing older forms, seeking to acquire more sustainable sources than before.

4. Results

Results will be presented in three subsections:

Section 4.1 Results from the application in 2014;

Section 4.2 Results from the application in 2019; and

Section 4.3 Comparison of the results from 2014 and 2019.

4.1. Results from the Application in 2014

The application of the IS tool in 2014 in each domain, obtained the results observed in

Figure 3.

In the sphere Byproduct Exchange, the domain that presented characteristics closest to IS was the PF, which involves norms and laws. In the sphere Sharing, the domain that approached the minimum IS indicator was the TF, a domain that involves physical structure, waste logistics, and labor.

Finally, Cooperation in Management was the sphere that presented the most closely related domains to the minimum indicators for IS diagnosis, indicating that the closest aspect for IS in the network would be cooperation between companies. Based on the analysis of the indicators of each domain, it was possible to make the final diagnosis for IS evaluation to the business network.

According to the parameters established by the model to diagnosis IS,

Figure 2 shows that no sphere presented minimum IS indicators in the Concordia Furniture Center. There is a need for actions that can increase the synergistic relationship between the companies of this network to build a balance in economic, environmental and operational spheres.

4.2. Results from the Application in 2019

The application of the IS tool in 2019, in each domain, brought the results observed in

Figure 4.

As observed in

Figure 5 the sphere Byproduct Exchange results do not indicate characterization of IS, but there is a significant number for the PF, demonstrating that there is an importance on the part of the network to develop practices according to the regulations and legislations.

Still, in the sphere Sharing, it is observed that, according to the parameters of the model used, there are no results to IS evidence, but the TF is the one that presented the closest result to the minimum to indicate IS, showing perform well for physical structure, labor and logistics operations for waste. In this sphere, the result indicated by the IF indicates the need for improvements in information management and availability within the network.

Finally, the sphere Cooperation in Management is the one that has results closer to the minimum to characterize IS in all domains, and in the PF the result exceeded the minimum, giving evidence of the realization of possible IS for this sphere.

Figure 6 shows the diagnosis of IS in the application of the tool in 2019.

Looking, it can be concluded that in 2019 there were also no minimum indicators for a result of IS in the Concórdia Furniture Center. However, it is possible to observe that the spheres Cooperation in Management and Sharing of By-products present indicators closer to the minimum to be considered a case of IS. Therefore, this proximity denotes an extremely important character for the delineation of new actions aimed at advancing IS to this business network.

4.3. Comparison of the Results from 2014 and 2019

In 2014, the sphere Cooperation in Management presents closer results of IS practices, as shown in

Figure 7. In 2019, two spheres stand out: Cooperation in Management and the Exchange of By-Products, and in both spheres, the domain of PF presented the closest results for IS.

These changes show a better performance for the physical structure, involving skilled labor and better logistics operations aimed at sharing waste among companies belonging to the network. It also allows us to observe that there is a good competitive performance, maturity in the interrelationship of companies and their respective internal competences, as well as the best attention is given to compliance with tax regulations. It is noteworthy that the government measures imposed by law contributed to the advance of the network towards IS.

However, it is possible to observe that there is still a need for better information management, involving better access and availability of information within the network, as well as highlighting the economic opportunities related to the sharing of utilities, management, and by products, pointing out advantages and disadvantages in a clear and attractive way to network participants.

The results from 2019 show closer proximity to the minimum indicators to obtain from IS compared to the results from 2014 in two spheres, Cooperation in Management and By-Product Exchange. In the first year of application of the tool, the only sphere most likely to present IS was Management Cooperation, pointing out that the Utility Sharing and By-Product Exchange spheres need improvements to reach the diagnosis of IS, such as a waste exchange. Among companies, viewed as the input of raw materials, waste treatment, and sharing of technologies and materials, are examples of opportunities for improvement in these spheres.

However, given this analysis, it is important to highlight that the number of participating companies increased in the application of 2019, which may have influenced the results, as well as the results, may have suffered direct consequences due to the difficulties of interpreting the questionnaire.

Figure 5 graphically presents the final result of the IS analysis of the analyzed company network, for 2014 and 2019, allowing the graphical comparison of the results.

As it can be observed in

Figure 5, there was a significant advance from 2014 to 2019 towards IS. This result is due to dependence on cooperation and integration between companies, the main character of BN. Also, it was possible to observe that by-law influences in the political variable positively impact on Byproduct sphere. Another influence comes from availability/demand for waste, process management, interrelationships and the desire for cooperation between stakeholders. Even though it is still not considered a consolidated case of IS, the biggest highlight observed from 2014 to 2019 results is that in the last one there was a significant advance towards it. This observation is fundamental for the network and public policy managers of the region to be able to direct corrective actions that will lead this network of companies in a few years to become, perhaps, the first case of symbiosis in Brazil.

In order to achieve the best results for achieving IS, the business network should seek to share human resources, their experiences to achieve joint improvement and development of the organizations that make up the network, exchange information and new technological knowledge. Given these inter-organizational attitudes, better product development, lower costs, process safety and environmental improvements can be achieved, aiming at sustainable network development.

In addition, the network can partner with other industries in different sectors, such as research centers, government agencies and universities, aiming for improvements and new opportunities for technological, environmental and economic development.

5. Approach of the Industrial Symbiosis Benefit Relationship to the Business Network Through the Principles of Circular Economy

This section aims to present possible points of connection between the IS and the circular economy, in order to find a relationship between the themes and opportunities to promote circularity in BN, seeking to contribute to the development of IS in these networks.

By addressing the relationship of IS with the CE focusing on the particularity of business network, it is possible to achieve circularity through the sharing of goods and equipment, the exchange of by-products, prolongation of product life, remanufacturing, or, to make waste disposal an opportunity to enter other companies as raw material.

By considering the circular economy in BN, it is possible to propose, create and deliver value through the new opportunities of innovative business models that are critical to sustaining a competitive advantage toward sustainability by providing opportunities to propose, create and deliver value. Through cost efficiency and strategic management.

There is increasing evidence that companies, government agencies and NGOs around the world are seeking to foster synergy with each other [

58]. One way to achieve this synergy is in the benefits of promoting CE, is focused on the economic and environmental dimensions [

59].

According to Ellen MacArthur Foundation [

50], any model that runs away from the linear model assumes significant gains along the value chain of all processes, allowing for greater economic growth, job creation and process innovation, including technological development, use efficient in labor and energy. Resulting in profit opportunities for companies, such as reducing input costs, and adopting more sustainable decision making throughout production.

Thus,

Figure 6 presents points that can help in the generation of economic and environmental value in the BN.

Authors [

60,

61] highlight that there is a strong interest among industrial park managers in promoting the efficiency of material and energy flows, aiming at the environmental and economic development of organizations, aiming to involve global issues such as climate change, deterioration and scarcity of resources. These opportunities can be leveraged through the use of CE by exploring techniques and technologies for the park to achieve restorative services for economic and environmental gains.

Products and materials circulate in the so-called loops, where they can provide value and reduce material consumption [

33]. These mention help optimize resources and improve productivity [

11] by transforming waste within and between companies, involving equipment sharing, waste reduction, and by-product exchange. For Whalen, the greater the interaction between companies and their products, the greater the resource efficiency potential of the circular business model, which slows the consumption of renewable resources. Thus, there are possibilities for risk/cost reduction involving resource extraction, as natural capital consumption will also be reduced, resulting in optimized productivity and reduced use of finite resources [

36].

Some points, such as the sharing of goods, such as the transportation of goods, reduce fuel consumption and pollutant emissions, sharing warehouses reduces energy use. Extending the shelf life of certain products can reduce the environmental impacts associated with new production and extend the value of the product, such as using recycling for example [

36]. It is also possible and feasible to encourage producer responsibility, involving better maintenance, as well as the reuse of the product by the consumer himself, reuse by the company itself or by companies that make up the network, or by using means such as remanufacturing of products some pieces [

62].

Reverse logistics can be facilitated by providing old product exchange credit for a new product, and companies can arrange return services for customers and by-product exchanges, assisting in the loop, and can be driven by online communication platforms and exchanges of information with customers and the companies that make up the network. Opting for renewable energy sources can get a high investment when buying a single company, which alone has no capital, but becomes a viable option when the network has the common goal, which in the long run will bring economic and environmental benefits. For the organizations involved. Thus, the joint purchase of equipment helps companies to reduce costs, reduce energy consumption and reduce environmental impacts due to the production of new equipment. Also, the sharing of equipment and materials allows organizations to have the opportunity and ease of purchasing more technologically and environmentally better products, since the combination of these factors requires a greater investment to acquire these products.

These actions allow changing the material flow from linear to a closed-circuit, where industrial technology and information technologies enable the creation of new business models focused on circular economy [

63]. In this way, the industrial park will gain better opportunities for collaboration and knowledge sharing, materials tracking, improvements in logistics settings and reverse logistics, thereby increasing the use of renewable energy. It also encourages recycling to make the system increasingly self-sufficient [

64]. These points highlight the high potential of promoting CE among the companies that form a network, indicating a more strategic vision for generating sustainable development [

14].

In general, the approaches presented in the

Figure 6 constitute a business model proposed by adopting CE in a company network, filling gaps between the waste management strategy and its actual operations. The idea also involves creating value for customers through sustainable practices and capturing economic value for the organization and its network, where the CE has different points that can be easily adapted and incorporated into a business network with different types of organization [

65].

Still, with the constant environmental, economic and social concern, the proposal developed by this study also collaborates with the achievement of some of the Sustainable Development Goals (SDGs) presented by the UN [

66], which are SDG 8 (Decent Work and economic growth) by seeking to promote sustainable economic growth; SDG 9 (Industry, Innovation and Infrastructure) for targeting sustainable industrialization and fostering innovation; SDG 11 (Sustainable Cities and Societies) for supporting economic, social and environmental relations in industrial development; and SDG 12 (Sustainable Consumption and Production) for emphasizing sustainable means of production and consumption.

As the focus of research is on small and medium-sized enterprises (SMEs), it is noteworthy that research claims that they are becoming increasingly aware of the benefits of improving resource efficiency, although these findings imply clear benefits in real practice, highlights some barriers [

67]. For example, difficulties in assessing future benefits against current costs, knowledge needs, and market pull and pull factors such as technology availability and consumer demand for green products [

68].

The initial cost level, overhead (time and human resources) and expected payback period are particularly important for SMEs as they are generally more sensitive than large companies to any additional costs resulting from green business [

69].While a multinational corporation can support circular technology development through its research and development activities, small and medium enterprises (SMEs) often depend on the availability of technology in the marketplace [

67,

68,

69,

70]. In addition, although multinationals can determine how circular economy concepts are adopted, an SME, due to its size, is usually restricted to observing the trends in the market value chain in which it operates [

70].

Based on a literature review and case studies carried out among SMEs, concluded that while policies and measures exist to leverage CE in Europe, several significant barriers remain and additional European and national policies are needed [

67].

The section presented ways to break the circularity in the company networks, aiming to help the IS and, consequently, offer opportunities for value creation for the companies that constitute the network. It was observed that actions sharing goods and equipment, exchange of by-products, remanufacturing, extending the life of certain products, use of renewable energy sources, joint purchase of technological equipment aimed at reducing waste and energy use, are actions that promote the circular economy and consequently facilitate IS in corporate networks.

6. Proposed Circularity in Networks of Furniture

Based on actions that promote circular economy, this section seeks to present, clearly and directly, circularity guidelines to assist IS in a business network, according to the ReSOLVE method presented in the previous section.

Thus, some circularity opportunities that allow achieving IS in furniture networks according to the ReSOLVE method were established:

For the Regenerate factor nearby companies may choose to use renewable energy sources such as photovoltaic energy. In relation to Share, it encourages the use of goods, eliminating waste. The Optimize factor is suggested to buy raw material as production requires, and try to use less quantity of products/raw material, for the same amount of furniture to be produced.

The closed loop encourages recycling, reuse, material sharing or encourage environmentally sound disposal when the product reaches its end of life. For Virtualise the best option would be to buy community equipment and new materials. And, finally, Exchange, were looking for new network technologies to acquire more sustainable sources becomes a viable and sustainable option.

Figure 8 illustrates the relationship between circular economy factors, proposed actions, and their directions for IS.

The actions presented in the

Figure 8 allows generating competitive advantage, promotion of sustainability, economic development of the sector, reduction of waste and implementation of circularity, showing that economic growth can be achieved without compromising the environment, achieving greater economic growth, cost reductions, job creation and more process innovation, including technological development, efficient use of labor and energy, resulting in profit opportunities for companies.

The points highlighted in

Figure 8 help to promote IS through a method that allows circularity in a company and, as seen in this study, they also make possible to accomplish industrial circularity and symbiosis in a network where companies have the same market tracking. This dynamic becomes possible through the adoption of the strategies addressed in this study, where all companies that compose the network need to pursue the same ideal to achieve economic and environmental development, by using the circular economy and promoting IS.

7. Conclusions

Industrial Symbiosis has been a research topic for over a decade, and there is a growing perception about the factors that affect the development of symbiotic links between nearby companies [

60] when inserted into an Industrial Cluster of their own. The benefits come from the possibility of mutual growth for various companies in various aspects, focusing on sustainability, fostering circular economy and the growth of ecological networks.

This study was successful in achieving its objective of applying the model to uncover IS in a business network of Brazil in order to evaluate the presence of IS practices and compare them with the results previously obtained in 2014. The tool comprises three main spheres: By-Product Exchange, Utility Sharing and/or Services, and Management Cooperation, across five Business Areas: Technical Factor (TF), Economic Factor (EF), Political Factor (PF), Information Factor (IF) and Organizational Factor (OF). As highlighted, it can be stated that based on the model parameters, from 2014 to 2019 there was a significant advance towards IS.

This observation is fundamental for the network and public policy managers of the region to be able to direct corrective actions.

Thus, the contribution of this paper is to offer results of the business network of Concórdia that shows a progressive potential to IS. With the right driven action, it is possible to lead this network of companies to become in a few years the first case of IS in Brazil.

Since 2014, the network had already an important aspect for IS ties, which was a stronger character of Cooperation in Management. Thus, besides the sphere of Cooperation in Management, this time the Sharing of Byproducts also showed results closer to reaching the minimum to be considered IS, which reveals an optimistic comparison with the results found in 2014, in which only the sphere of Cooperation in Management presented significant results.

The limitation of this study is that not all companies agreed to participate in the survey so the results are based on statistical sampling. For future works it is interesting to apply the Method for the evaluation of IS in order to reach a larger number of companies and thus achieve a IS diagnosis result for the other types of BN. Moreover, according to Afshari, Farel, and Peng [

14], despite the competitive advantages offered by IS, many companies do not believe in the potential benefits it can bring. To this end, the authors bring out the CE concept as a potential opportunity for improvement in results for all companies that adopt it, by seeming how to generate more value and throughout the process. The authors also suggest future studies that perform the empirical application of the model that has the flexibility of adaptations according to the researchers’ needs, aiming at the maturation of the spheres and domains developed in the model.

Notwithstanding, besides contributing to future scientific studies, the results achieved in this research contributes to the development of environmental and industrial policies in Brazil. The significant advance towards IS uncovered by this research can be fundamental for the future of the Concordia business network and public policy managers of the region to foster economic benefits and values that all companies and locals society can get throughout the IS process.