1. Introduction

The implementation of sustainability requires strategic attention from any organisation, which has emerged out as an integrated business concept today [

1]. Any organisation which tends to make its manufacturing sustainable, seeks to integrate the triple bottom line (economic, environmental and social) strategy into their manufacturing life-cycle decisions [

2,

3]. This also involves the consideration of the entire life cycle of a product ranging from product conceptualization, design, manufacturing, its by-products, product life extension, end-of-life recycling, to product recovery and reuse, and these activities are now considered as a part of core supply chain activities [

4].

Sustainable manufacturing has emerged as one of the most significant aspects of a sustainable supply chain (SSC), both among researchers and practitioners. A SSC has been defined as the “transformation of materials into finished goods by developing and utilising practices and technologies, which aim at minimising energy consumption, greenhouse gases (GHG), waste generation and utilisation of non-renewable/toxic resources” [

5]. Conventionally, a large number of manufacturing organisations mostly depend on non-renewable resources and hence generate waste and emissions. However, amid increased concern about such practices, organisations have started to deploy measures required in order to enhance their sustainability performance [

6]. It is now essential for manufacturing organisations to pursue activities in a way that yields economic and social benefits while minimising negative environmental impacts [

7]. It is important to note that the sustainability of an organisation needs to be assessed from economic, environmental and social perspectives [

8]. Therefore, sustainable manufacturing practice entails preserving humans by continuously striking the balance between the triple bottom line (i.e., environmental, social and economic) conditions [

9]. Although many researchers have outlined how to successfully implement sustainable manufacturing, organisations still face challenges and are consistently facing pressures from stakeholders including customers, governments and society [

10,

11].

For manufacturing organisations to implement sustainability, they must take into account critical indicators. These indicators inform organisations about which areas are critical to achieve sustainable manufacturing. There is abundant literature on sustainable manufacturing indicators, commonly also referred to as critical success factors, critical indicators and performance indicators of sustainable manufacturing. Given the concept of the lifecycle of a product, it would be challenging for manufacturing organisations to improve their sustainability performance by merely knowing critical indicators that span across various dimensions. Indeed, it is necessary to explore contextual relationships between critical indicators, which gives managers a deep cause-and-effect understanding of critical indicators and how they relate to each other. This can also help organisations to prioritise and focus on the most important critical indicators that have the biggest impact on other indicators. Moreover, in order to comprehend the comprehensive nature of relationships among critical indicators, the perspectives of both researchers and industry practitioners should be taken into account. As the two groups (researchers and industry practitioners) have different working environments [

12], there is a need to bridge the gap by considering the difference of opinions between the two groups.

This paper is among one of the first such studies, which investigates the causal relationships among critical indicators in between both the groups to evaluate their understanding of how sustainable manufacturing is implemented in the context of India. Through this work the objective is to identify the inter-relationships between critical indicators using the DEMATEL (decision-making trial and evaluation laboratory) technique. Furthermore, we utilised the MMDE (maximum mean de-entropy) methodology to select the threshold, which then facilitates the ISM (interpretive structural modelling) method to project a hierarchical structure of critical indicators. Moreover, prior to deploying the ISM method, the validation of all derived relations was done by utilising the SEM (structural equation modelling) approach in order to identify the imperative and causal relationships of indicators for both groups. The final causality models for each of the respondent groups, developed through ISM techniques, were further validated through the opinions from a researcher and industry professional for each indicator.

The main contribution of this study is twofold. First, the study makes a methodological contribution by proposing a robust and statistically validated causal-and-effect framework based on four integrated approaches. The proposed integrated approach has been uniquely applied to surface out the indicators of sustainable manufacturing practices. Second, the study provides practical implications to policymakers by comparing the responses of both academics and industry experts alike to implement sustainability initiatives in the manufacturing sector. To the best of the authors’ knowledge, this study is first of its kind, which highlights probable issues wherein both the groups agree and differ from one another. This inclusive approach facilitates the policy makers to design suitable mechanisms, which can minimize the differences and harnesses the combined effort from both the groups for effective implementation of sustainability practices in the manufacturing sector.

This paper is organized as follows: an introduction and the background of the study is presented in

Section 1;

Section 2 presents the relevant literature and reveals the existing research gaps, which are addressed in this study;

Section 3 highlights critical indicators of sustainable manufacturing;

Section 4 outlines the approach used to analyse the results in the study;

Section 5 presents a detailed discussion of the indicators of sustainable manufacturing using the inputs of research and industry experts;

Section 6 validates our final models for each respondent group by considering the viewpoints of a researcher and an industry professional expert; and

Section 7 concludes, issues recommendations and suggests future research areas.

2. Literature Survey

This section explores extant literature to have focused on implementing sustainability initiatives in manufacturing organisations. The section covers recently published works on theoretical models, frameworks and empirical findings, which facilitate manufacturing organisations to implement sustainability. Moreover, the review also includes studies that have proposed decision and contextual relationship models aiding manufacturing organisations to make sustainable decisions. The section further identifies existing research gaps, which are addressed in subsequent sections of the paper.

Thirupathi et al. [

11] developed a modeling framework based on system dynamics to implement sustainable manufacturing in the context of an automotive manufacturing organisation. They also analysed factors influencing sustainable initiatives using the proposed model. A list of appropriate performance indicators was identified and utilised for further analysis. Similarly, Smith and Ball [

13] proposed guidelines for a process pertaining to material, energy, and waste (MEW) in the domain of manufacturing sustainability. They highlighted further research avenues towards developing effective metrics to monitor improvement. Furthermore, they also pointed out a pressing need for efforts to establish suitable modeling tools for the selection of appropriate solutions among available set of sustainability-related practices.

Some authors have identified key drivers, enablers and barriers that facilitate or impede the implementation of sustainable initiatives in manufacturing. Moktadir et al. [

10] identified the main drivers and their sub-drivers of sustainability-related manufacturing practices in the leather industry of Bangladesh. They assessed, prioritised and ranked the drivers of sustainability-related manufacturing practices using an integrated graph theory and matrix-based method. Similarly, Habidin et al. [

14] examined the critical success factors in ongoing manufacturing practices to improve the sustainability of the automotive sector in Malaysia. Moreover, Bhanot et al. [

15] proposed a comprehensive framework for manufacturing sustainability by identifying the contextual relationship for each of the enablers and barriers relating to sustainable manufacturing by employing the DEMATEL and ISM techniques. Meanwhile, numerous researchers have assessed the implementation of sustainability as a pure decision-making problem and utilised multi-attribute decision-making approaches to address the issue. Shukla et al. [

16] considered product and process design, lean concept, eco-design and product recovery as key factors in the implementation of sustainability in manufacturing. They prioritised these factors through analysing their importance using the analytic hierarchy process (AHP) in a study carried out in the Indian automobile sector. Similarly, Shankar et al. [

17] utilised the AHP to prioritise key factors assisting organisations to successfully implement sustainability in advanced manufacturing environments considering agile, computer-integrated and cellular manufacturing. The application of these multi-attribute decision-making (MADM) methods was further extended to prioritise green manufacturing initiatives [

18] and to select an appropriate sustainable manufacturing strategy [

19].

It has also been observed that numerous studies have focused on specific dimensions or sub-dimensions of sustainability rather than taking a holistic approach. Sellitto et al. [

20] developed a qualitative model to analyse activities, which may contribute to eco-efficiency within green supply-chain management (GSCM). They found 21 green practices from the literature that were primarily concerned with environmental impacts. Sun et al. [

21] proposed an electricity demand response technique for integrated manufacturing and heating, venting and air-conditioning (HVAC) systems taking into account electricity pricing, reducing power demand, production capability and ambient temperature to investigate the optimal electricity demand response strategy considering both production schedule and HVAC control using a numerical case study. Similarly, Wang and Li [

22] attempted to increase the energy efficiency and cost-effectiveness of manufacturing systems by proposing a framework for time-of-use based electricity demand while considering the production target constraints. Scur and Barbosa [

23] identified and analysed GSCM practices followed by home appliance manufacturers in Brazil. They considered certain aspects of the environmental domain, namely green purchasing and manufacturing, internal environmental management, life-cycle assessment, reverse logistics, eco-design and waste management. The social dimension is usually ignored in the manufacturing context. For example, Abdul Zubar et al. [

24] analysed the occupational health and safety of manufacturing industries in southern India. They examined data on managing health and safety, accident statistics, welfare facilities, leadership and training, motivation and other social indicators. Fu et al. [

25] studied the impact of participatory training on the occupational health improvement of workers in small and medium manufacturing enterprises of China. They found that training led to significant increase in staff attitude, technical knowledge, and practice scores.

It is clear from this review that the studies aiming to aid manufacturing companies to successfully implement sustainability have been abundant. However, a close assessment of the literature reveals certain research gaps. The literature is rich in terms of critical or key indicators of sustainable manufacturing, however the insights into the contextual relationships between them are limited. The contextual, or cause-and-effect, relationships between critical indicators can increase the knowledge of manufacturing organisations towards identifying root indicators that affect all others. This would enable manufacturing companies to make more informed decisions. Moreover, the extant literature has mainly focused on a particular sector, such as automobiles and leather manufacturing, rather than taking a more holistic view, while particular sustainability aspects have not been covered comprehensively. Therefore, there is a need to study a set of holistic critical indicators for sustainable manufacturing, which can be used by any manufacturing organisation in any sector. It is commonly observed in the literature that previously conducted studies aggregate the opinions of both academic and industry experts to produce final set of critical factors, enablers or barriers. There is a need to conduct the study separately based on the opinions of the two groups, which would further open up research avenues to study the differences between their opinions and to close the gap between theory and practice. This paper attempts to address the aforementioned gaps in the literature by proposing a comprehensive framework of contextual relationships between critical indicators of sustainable manufacturing. The next section proposes a set of critical indicators to be used for further analysis.

3. Sustainable Manufacturing Indicators

Manufacturing companies have predominantly been measuring their performance based on a set of financial (i.e., economic) indicators for a long time. However, in the wake of rising concerns about sustainability, various studies have now attempted to consider numerous environmental and social indicators, besides economic ones, to develop comprehensive metrics to measure the value of sustainability [

26,

27,

28,

29]. It has also been revealed that most of the sustainability-related frameworks in the manufacturing literature were primarily focused on product levels [

30,

31,

32] with limited attention to processes [

33,

34]. Therefore, it is necessary to broaden the discussion to include both product and processes. Thus, putting together a comprehensive list of sustainable manufacturing indicators, which can be considered for various processes, would be beneficial. In a recent study, all sustainable manufacturing indicators found in the literature were collected and divided into various categories [

35]. These indicators are classified under one of the following three sustainability dimensions (all of which have sub-indicators):

Economic Dimension: a summary of economic indicators identified from the literature were found to cover four main themes, namely manufacturing cost, production efficiency, machining performance and process improvement. The economic critical indicators used for the purpose of this study are presented below:

- (A)

Cost of Production (PC): the overall cost of production includes various aspects such as actual machining, idle machining, cutting/lubrication fluid, by-product treatment, machine tool usage and governmental policies.

- (B)

Cutting Quality (CQ): this includes surface roughness, variations induced during machining and cutting temperature.

- (C)

Production Rate (PR): this mainly involves power consumption during cutting and the material removal rate.

- (D)

Process Management (PM): this takes into account improvement initiatives in existing processes, material/energy consumption and performance measurement on a continuous basis leading to improved customer service and satisfaction.

Environmental Dimension: a summary of environmental indicators identified from the literature were found to cover five main themes, namely water consumption, energy consumption, types of material, types of waste, and government regulations. The environmental critical indicators used for the purpose of this study are presented below:

- (A)

Water Intensity (WI): this encompasses different types of water sources (such as, recycled or fresh water supply) and water consumed/unit output for the process.

- (B)

Energy Intensity (EI): similarly, EI refers to different types of energy sources (such as renewable or non-renewable) as well as energy consumed/unit output for the process.

- (C)

Material aspects (ML): this includes hazardous materials per unit product, different sources of raw materials per unit product, chemicals usage per unit product, composition of materials; re-usability and recyclability aspects of packaging materials and distance travelled by materials to and from supply and source market respectively.

- (D)

Waste Management (WM): this deals with managing weight of releases into air i.e., greenhouse gases emissions, surface water and land from production process. This also includes weight of transfers into disposal (consumables, chips, scraps), treatment before disposal, recycling (chips and scraps) and energy recovery from the production process. Besides this, reusing consumables, transfers to sewage, wastage and spill-over, impact on ozone depletion are also posing significant impacts while determining waste-management issues for organisations.

- (E)

Environmental Regulations (ER): manufacturing companies are consistently facing challenges to adhere to strict environmental regulations and ongoing government sustainability policies. One of the major concerns for manufacturing industries is the rising cost of implementing sustainability in their products and manufacturing processes. Given such circumstances, it is quite difficult for manufacturing industries to survive, especially small and medium-sized enterprises.

Social Dimension: similarly, a summary of social indicators identified from the literature were found to cover four themes, namely health issues, safety issues, labour issues, and workforce training. The social critical indicators used for the purpose of this study are presented below:

- (A)

Worker Health (WH): this includes contamination of job floor environment due to chemicals, mist, dust and noise levels. It also reflects a physical load index as well as absenteeism due to ill health, adherence to regulatory requirements of the industry and permissible waste and emission levels.

- (B)

Worker Safety (WS): this deals with measures to protect workers from toxic chemicals and high-energy working environments. This also considers frequency of workplace accidents, near misses, workers’ level of risk, and ergonomic workplace design.

- (C)

Labour Relations (LR): this considers duration of working hours, appropriate wages, amount of workload, engagement with community and local hiring.

- (D)

Training and Education (TR): this plays a critical role taking into account training hours imparted per operator on an average as well as emphasizing acquiring a desired level of skills.

Taking a step forward, it is paramount to investigate the interaction effects between the aforementioned critical indicators in order to visualise the effective implementation of sustainable manufacturing. Concurrently, it is also necessary to understand the difference of views between researchers and industry practitioners’ groups so that efforts can be made to work collectively towards sustainability enhancement. Hence, an integrated decision-making approach is needed to investigate the causality relationships between critical indicators of sustainable manufacturing and this is explained in the next section.

4. Methodology

In this paper, an integrated and rigorous framework of various methodologies, namely the DEMATEL, MMDE, ISM and SEM, as explained in detail by Bhanot et al. [

15], is innovatively applied to present a robust and statistically validated causal relationships between critical indicators of sustainable manufacturing using information on the level of interaction between them. The causal relationships between indicators of sustainable manufacturing are built on the inputs received from researchers and industry practitioners. The underlying rationale for the selected methodology needs to be understood, as DEMATEL offers flexibility in identifying the interaction level between any two variables on a 0–4 scale. Subsequent to the identification of interrelationship, ISM then assists towards developing structures in a hierarchical manner. In order to integrate the DEMATEL results as input for ISM, conventional hit and trial techniques have been usually employed by many researchers to obtain cut-off value [

36,

37]. This approach is not only time consuming due to taking experts’ opinions, but may also induce bias due to human intervention, which poses risk of inclusion or exclusion of a significant relation between two factors. Therefore, MMDE, based on entropy calculations, proves to be the only scientific method to provide threshold value without human judgement [

38] and has been utilised by several researchers in different domains [

35,

39,

40]. Furthermore, statistically validated models of critical indicators are then obtained by employing the SEM approach for both groups. This provides insight into the difference of opinion between both groups and further lays the foundation of working together towards sustainability implementation. The methodology for identifying the most critical indicators of sustainable manufacturing is depicted in

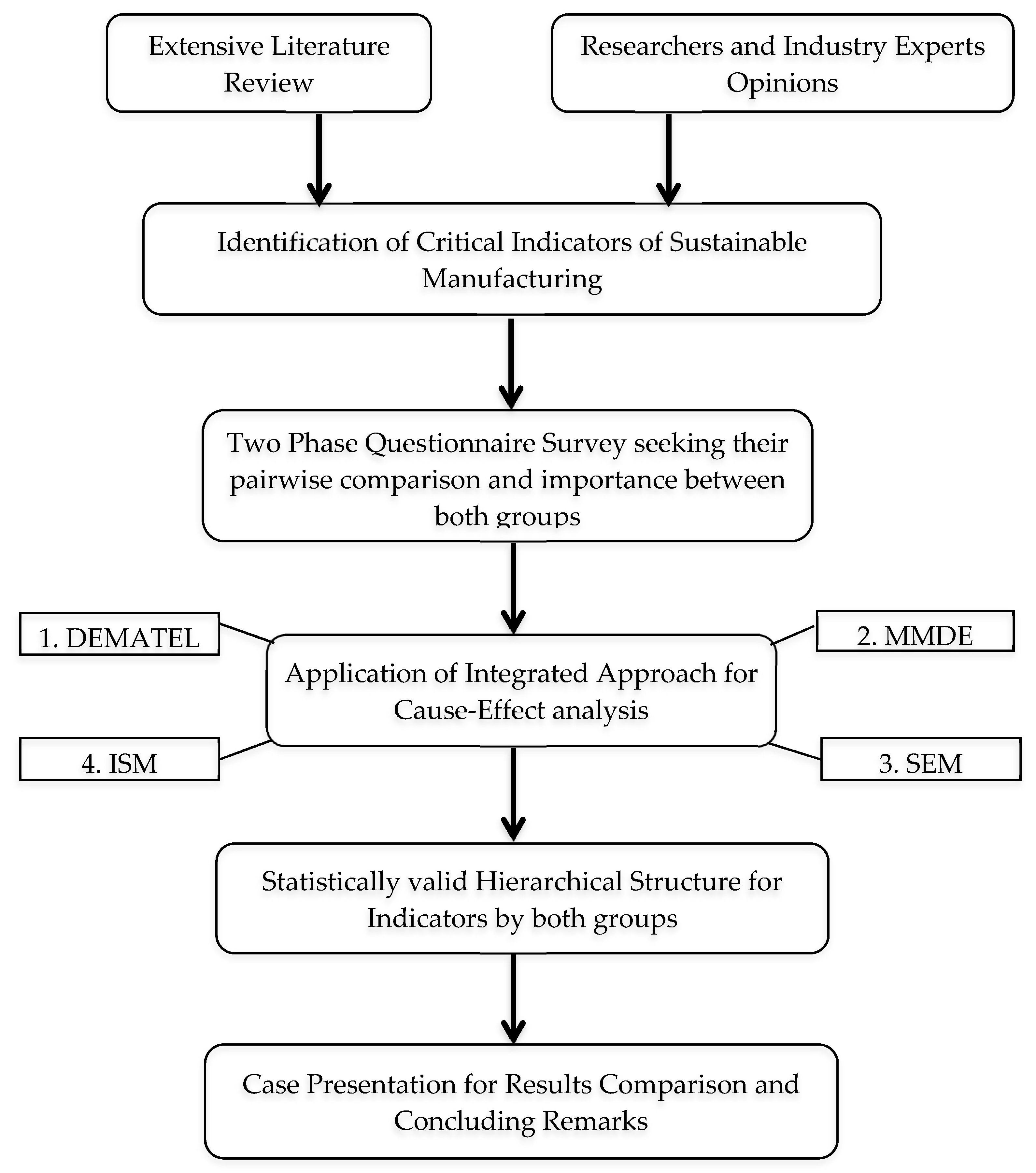

Figure 1.

However, the initial list of sustainable manufacturing indicators was taken from the findings of Bhanot et al. [

35]. The first quantitative method of the proposed integrated approach is DEMATEL as detailed below.

4.1. The DEMATEL (Decision-Making Trial and Evaluation Laboratory) Method

The DEMATEL method, which uses graph theory, is applied to prepare a structural model between complex factors based on causal relationships [

41]. The method has the advantage of being able to quantify the extent to which each indicator is related to others, and thus, provides the intensity between different indicators [

42]. The stepwise process of the DEMATEL method is given below:

Step I: Design questionnaire for data collection: in the first step, a set of survey questions was designed and e-mailed to a total of 15 researchers and industry practitioners. Following 7 days of initial email, a gentle reminder was also sent to those whose responses were awaited. At the end of the survey, we received 10 responses out of which five were from industry practitioners and five from researchers.

Step II: Compute the average matrix (

A) using the response from survey: the survey asked respondents to mention the degree with which each indicator in row “

i” affects other indicator in column “j”. In other words, the respondents meant to indicate the extent (on a scale of 0–4) to which indicators in each row influence other indicators in each column. Based on the data, an average matrix was prepared for each of the two groups as follows:

where,

is the pairwise comparison between any two factors

i and

j by respondent

k, and

b is the total number of respondents.

Step III: Compute the direct influence matrix: this step involves calculation of a normalized initial direct-relation matrix “

D”, which was carried out by normalizing matrix “

A” calculated in Step II as follows:

Step IV: Calculate the total relation matrix (

T): the total relation matrix “

T” was then calculated based on the matrix “

D” obtained in Step III as follows:

where,

I is

n ×

n Identity matrix.

Step V: Calculate sum of individual rows “

U” and individual columns “

V” of matrix “

T”, which leads to the preparation of a causal diagram.

4.2. MMDE (Maximum Mean De-Entropy) Algorithm

The total relational matrix “T” was then utilised by ISM for obtaining hierarchical structure. However, the ISM needs the threshold value of relationships to have already been established, which was achieved by utilising the MMDE approach. The following steps were taken to apply the MMDE approach:

Step I: The matrix “T” was converted into an ordered set in order to arrange the elements in descending order.

Step II: A set of ordered dispatch-node was prepared by taking second element from the ordered triplets of set T*.

Step III: The probabilities of different elements were assigned considering the first t elements of

TDi as new set

TtDi, and the

HD of the set

TtDi was calculated to determine the mean de-entropy value (MD) as follows:

Step IV: The maximum mean de-entropy was picked along with its corresponding TtDi from C (TDi) mean de-entropy values and was designated as TmaxDi.

Step V: A set of ordered receive-node Tre was prepared by taking third element from the ordered triplets of set T*. The step also calculated a maximum mean de-entropy receive-node set TmaxRe following steps III and IV.

Step VI: Finally, the threshold value was calculated based on the minimum influence value in

Tth as follows:

4.3. SEM (Structural Equation Modelling) Application

SEM is one of the most superior approaches [

43] and has been employed for analysing the multiple causality in relationships among interacting parameters of the system. In order to facilitate SEM application, a total of 106 and 99 responses were obtained from researchers and industry practitioners respectively using a five-point Likert scale. Mathematically, SEM can be explained as being comprised of two elements, namely the structural model and the measurement model.

Structural equations can be expressed as:

Measurement equations can be expressed as:

where,

X denotes exogenous observed parameters.

Z denotes dependent parameters.

S denotes latent dependent parameters.

β denotes coefficients of the S parameters.

λ stands for errors in the structural relationship between S and X

η stands for coefficients of the X variables in the structural relationship

πy stands for coefficients of y on S

The steps taken for applying SEM are described as follows [

44]:

Step I: Specification of Model

This step involves specifying a model by converting “T” into binary matrix (i.e., 0 and 1), based on threshold values obtained from MMDE method, and is then illustrated diagrammatically.

Step II: Estimation of Coefficients

This involves path analysis of the model in focus by running specific significance tests and estimating the coefficients. Estimation techniques, for example, iterative maximum likelihood or the generalized least squares method, were mainly considered as tests for significance, being commonly used in the literature [

15].

Step III: Evaluation of Goodness-of-Fit Statistics

This step assists in identifying the degree of fitness of the specified statistical model. In other words, it shows how good the data is at fitting the model. In this paper, different fit indices were considered, namely: chi-square/degrees of freedom, comparative fit index (CFI), Tucker–Lewis index (TLI), standardized root mean squared residual (SRMR) and root mean square error of approximation (RMSEA).

4.4. ISM (Interpretive Structural Modelling) Application

Following model validation, ISM approach was then employed to determine causal relationships between critical indicators for both respondent groups. The ISM technique helps in decomposing an intricate system into various sub-systems and constructs a multilevel structural model and thus helps in transforming to well-defined models from roughly visualized models [

45]. The ISM technique was applied as follows:

Step I: The matrix “T” obtained from the DEMATEL technique was initially converted into a binary matrix (i.e., 0 and 1) based on the MMDE technique. The obtained matrix was then statistically validated using SEM technique with improved goodness-of-fit in order to be utilised as initial reachability (IR) matrix for the ISM approach.

Step II: The transitivity was then checked for modified initial reachability matrix and all transition links were incorporated in order to obtain the final reachability matrix.

Step III: In this step, a hierarchical structure was then prepared in the finalised ISM model by partitioning it into different levels.

Step IV: A digraph was then constructed on the basis of the relationship found in step III. The transition links were removed too.

Step V: The variable nodes were then replaced with statements in the resultant digraph in order to convert it into the ISM model.

5. Results and Discussion

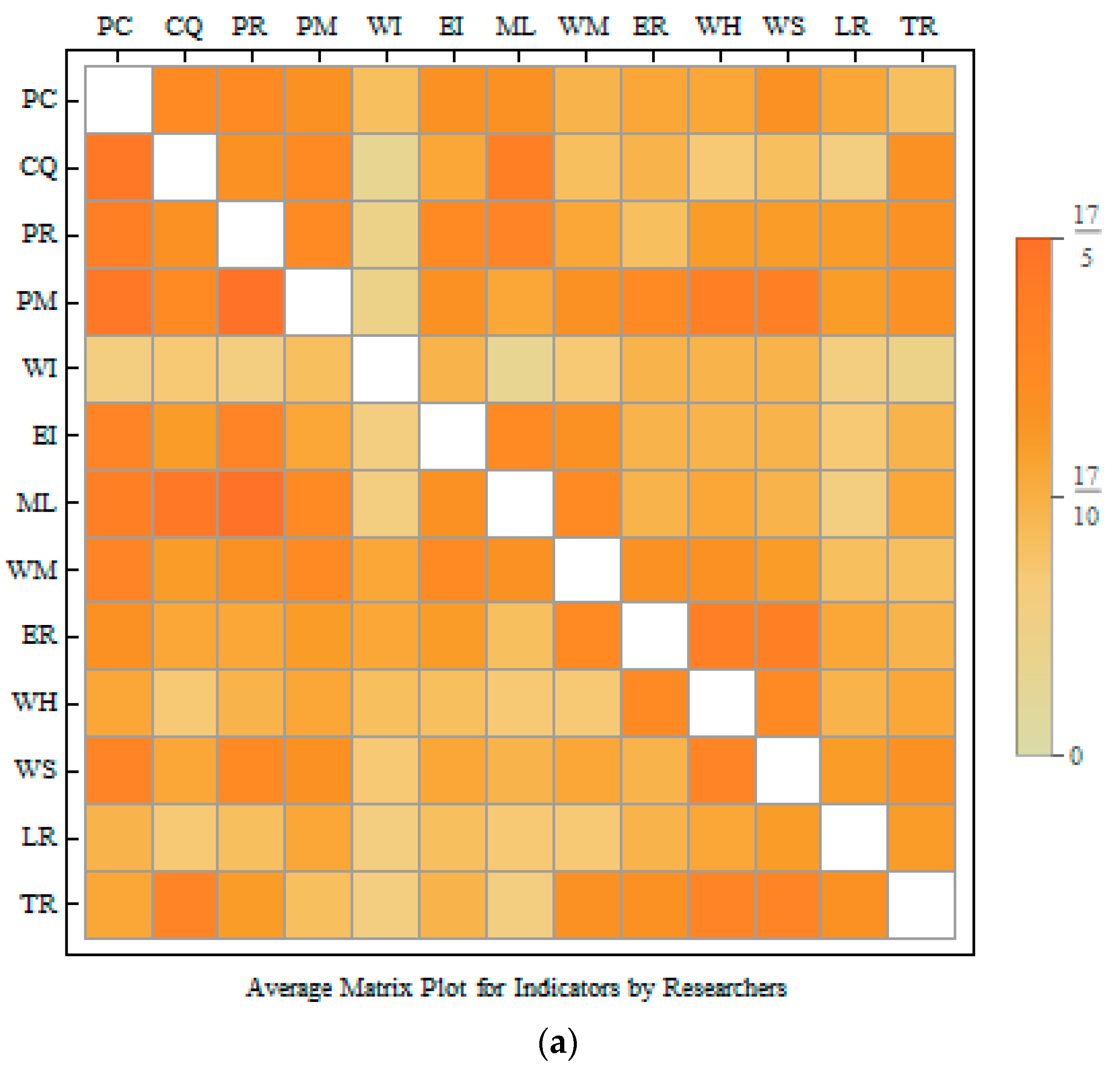

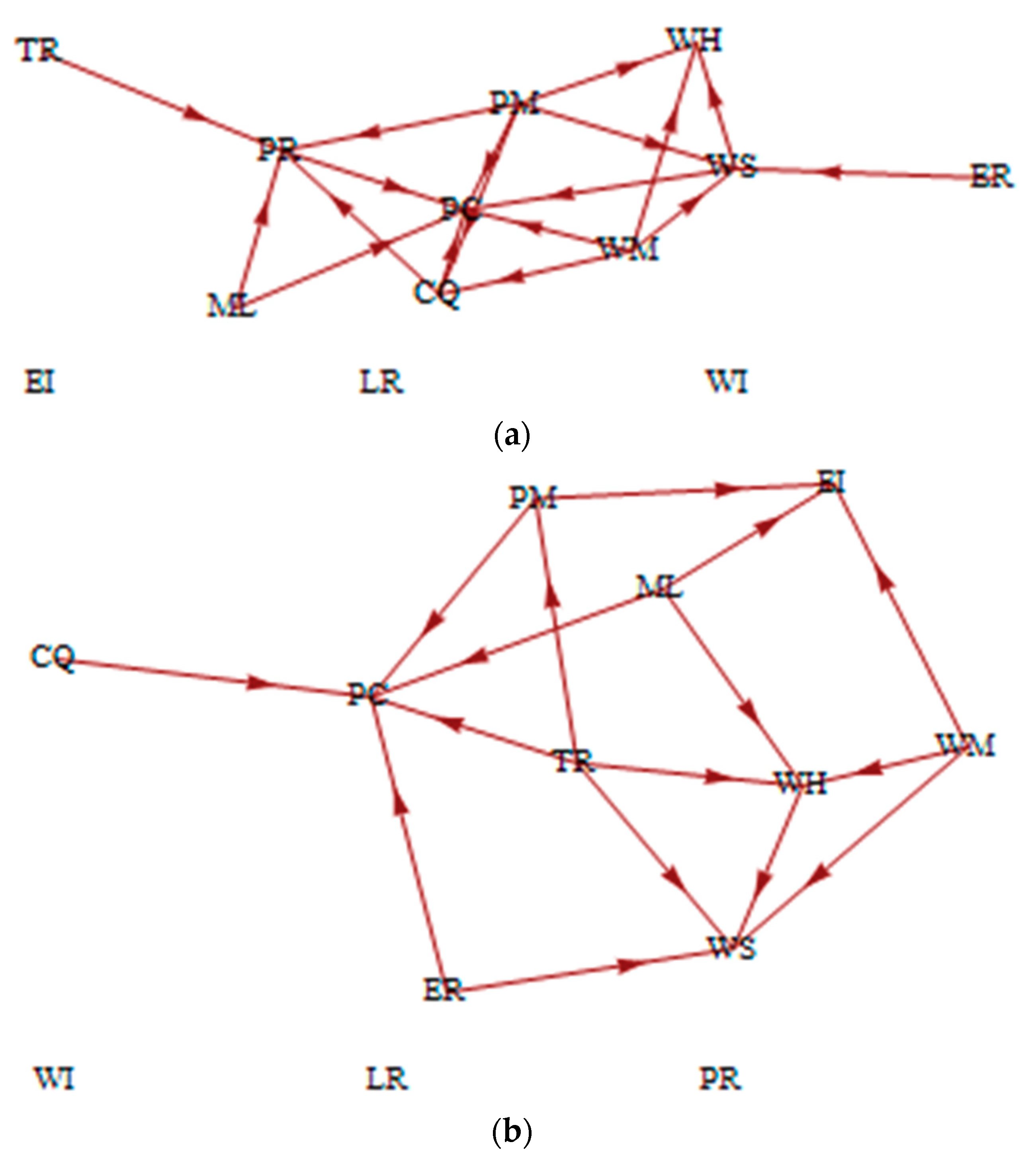

The differences between researchers and industry practitioners’ opinions were analysed to investigate the interrelationships between indicators of sustainable manufacturing. The average matrix plots for indicators in both groups are shown in

Figure 2 using Mathematica [

46]. The plots were designed on the basis of pair-wise comparison among indicators (0–4 scale).

The darkness of shades in the figure reflects the degree of impact that each row member has on each column member. The degree of impact is demonstrated through a colour scale presented in

Figure 2, from which it should be inferred that the darker the shade, the greater the impact. For the researchers’ case, PM was observed to have high influence on PR (mean of 3.4). It was similar in the case of CQ and PM on PC (mean of 3.2), and ML on CQ (mean of 3.2). Meanwhile, for practitioners, ML was observed to be the highest impact on PC, and TR on CQ and WS (mean of 3.4).

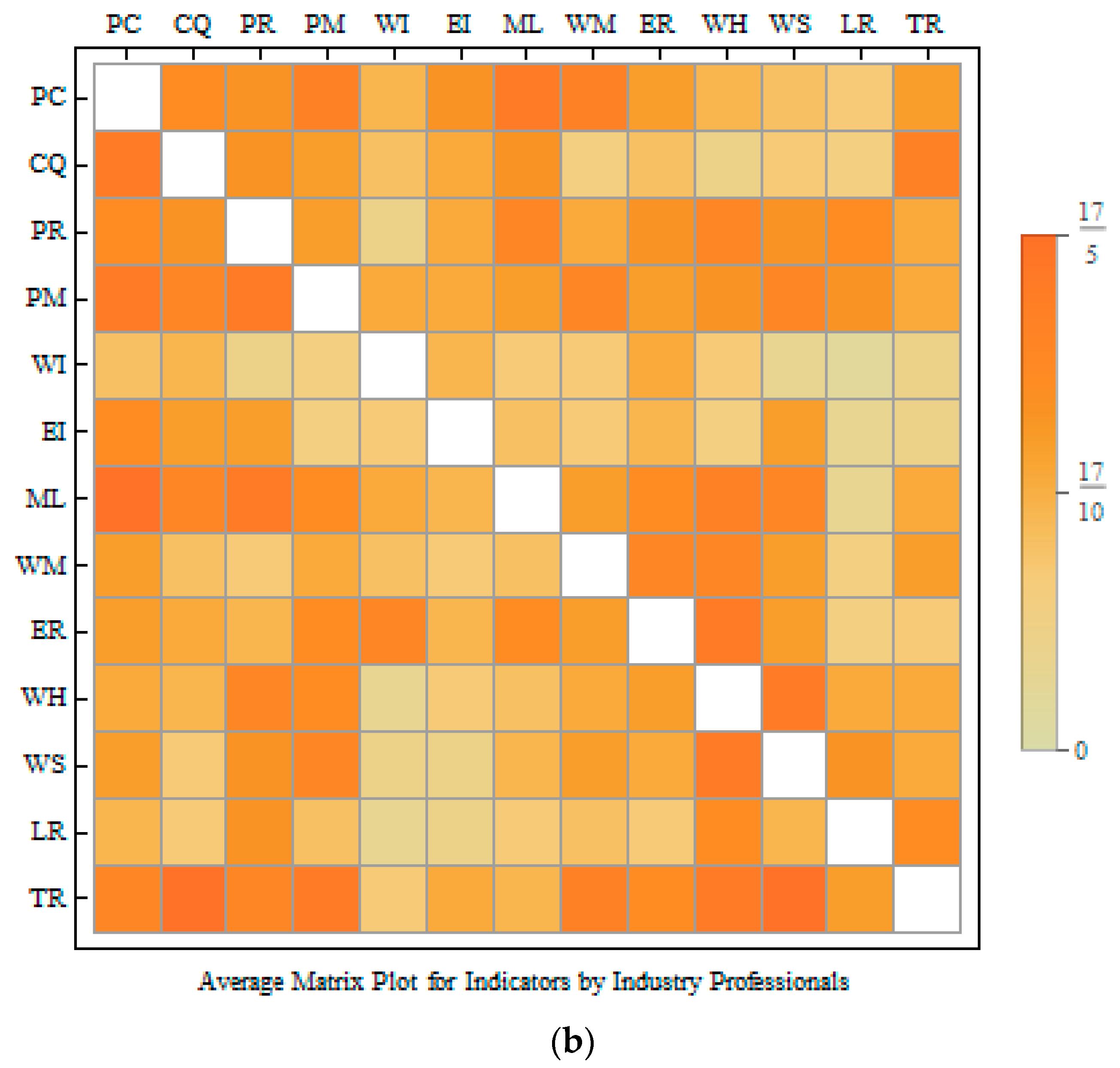

Figure 3a,b graphically represent indicators for both respondent groups in which X-axis denotes degree of prominence (R + C) i.e., the intensity of relations, while Y-axis represents Causal Degree (R-C), which reflects the degree of being influenced. The (R + C) values of various indicators for the researchers’ group in descending order were identified as PM, PC, PR, WS, ML, WM, ER, CQ, EI, WH, TR, LR and WI evidently showing that PM holds maximum influential potential for the required change in other indicators. For R-C values, the indicators belonging to the causal group are ER, ML, PM, TR, WI and WM; whereas the indicators belonging to the effect group are CQ, EI, LR, PC, PR, WH and WS. The R + C value trend for the practitioners’ group is presented in descending order as PC, PM, TR, PR, ML, WH, WS, ER, CQ, WM, EI, LR and WI evidently showing that PC poses maximum influence on other indicators. For the R-C values, indicators for the casual group were LR, ML, PM and TR. Indicators for the effect group were CQ, ER, EI, PC, PR, WH, WI, WM and WS.

Interestingly ML, TR and PM fall in causal category, whereas, PC, WH, EI, WS, CQ, PR and EI pertain to the effect category in case of both respondent groups, demonstrating a high level of similarity between groups. It clearly reflects the acceptability in both groups towards these indicators which can act as change agents to implement sustainability in manufacturing domain, while at the same time it raises the need to analyse those indicators for which both groups differ in their opinion so that efforts can be made to take a joint call towards enhancing sustainability.

Following the DEMATEL approach, the MMDE technique was then applied on matrix “

T” for both the respondent groups. As mentioned, the cut-off values to obtain I.R. matrix from MMDE, facilitated the use of the ISM technique. Then, the SEM technique was utilised at this stage to check the fitness of the finalised model. Subsequently, based on survey responses, SEM-based modifications were carried out to incorporate additional paths in the IR matrix to increase the goodness-of-fit for both the groups. The threshold values obtained through the MMDE for both respondent groups, based on which the “

T” matrix was converted into the required input matrix, to facilitate the ISM application (

Table 1). The table demonstrates SEM-based new paths incorporated in the IR matrix of indicators. However, SEM results depicting fitness statistics are provided immediately after the ISM model.

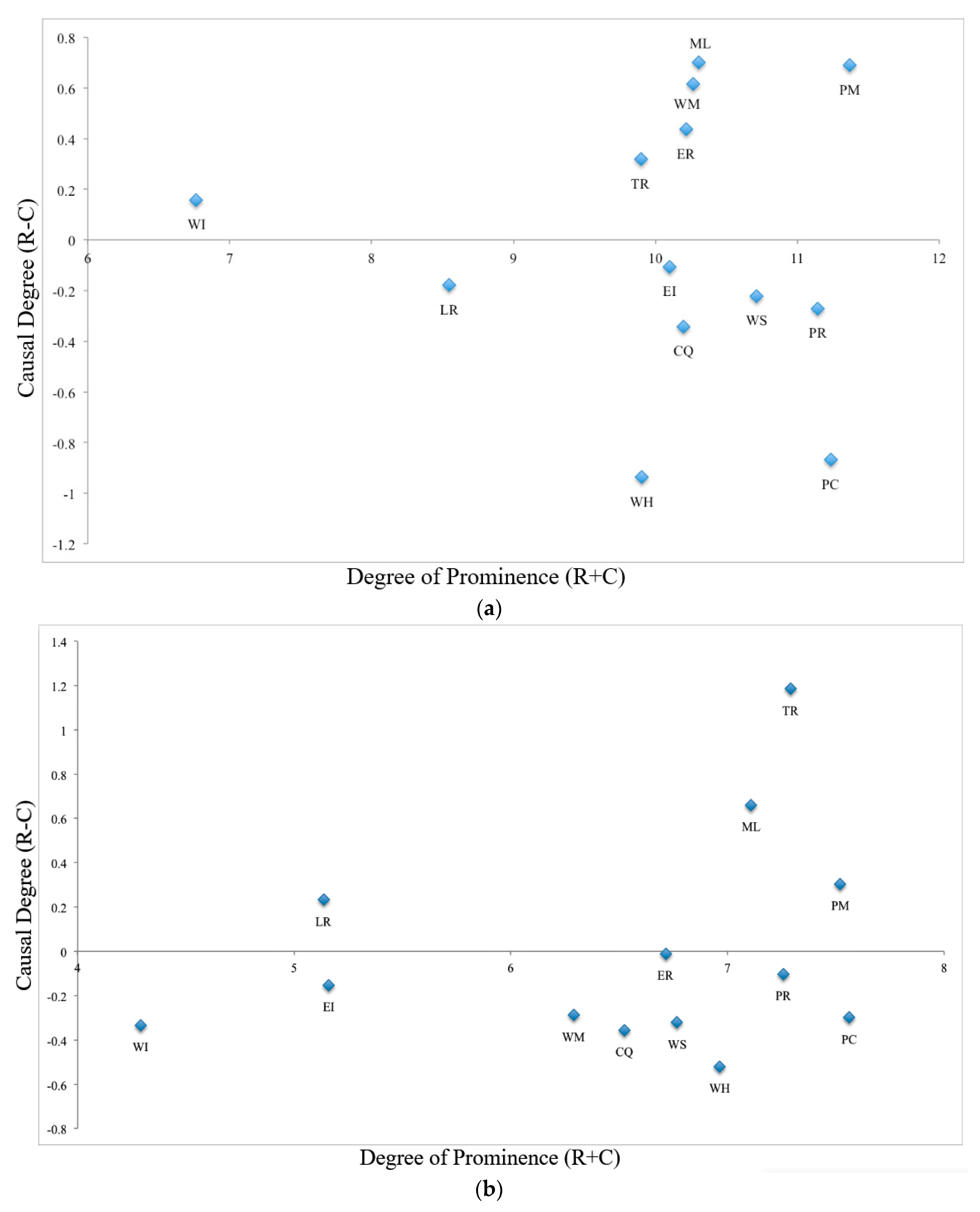

Figure 4 shows digraph plot, for both researchers and practitioners, developed from the I.R. matrix. Looking at the digraph plot of researchers, it shows that WM and PM possess maximum causal power relative to other indicators whilst indicator PC is most impacted by other indicators. Importantly, LR, WI and EI bear no significant relationship in either direction with other indicators and hence were not considered in the final model. In contrast, when considering the practitioner plot it was revealed that other indicators significantly influence PC and WS while TR, WM and ML possess maximum causal influence. Similarly, no cause-and-effect relationships were found for WI, PR and LR and were, therefore, omitted in the final model.

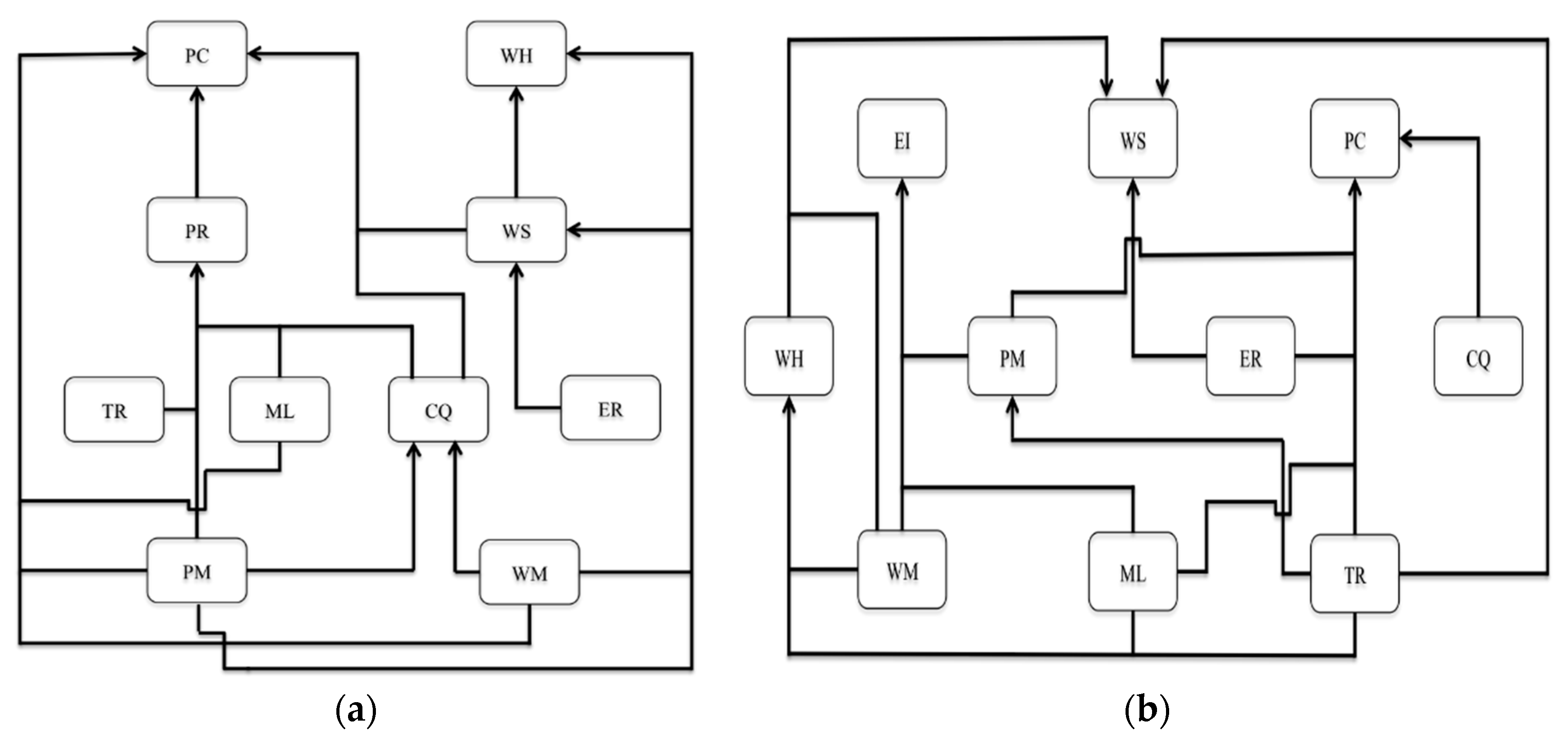

Using the SEM technique based on values assigned to different indicators, a statistically valid structural model is developed for researchers and practitioners. This model is depicted in

Figure 5a,b respectively.

Referring to

Figure 5, the positioning of PM and WM in the hierarchy shows them to be the most critical indicators according to researchers. As such, the critical position of these indicators leads to their effect on other indicators. Waste-management policies are essential to managing environmental aspects. Again, for the practitioner case WM is a critical indicator alongside TR and ML, with the final indicator emphasizing the need to develop workers’ skills to facilitate effective adoption of sustainability measures.

Table 2 highlights fitness statistics of models for both respondent groups before and after path modifications. The results for the preliminary fit indices show the original model is a poor fit for researchers and industry professionals. After incorporating additional paths as suggested by the MMDE, the fitness statistics shows significant improvement in case of both the groups, making the models more suitable to be considered for interpretation of the interrelationships among the indicators of sustainable manufacturing.

The goodness-of-fit measures for researchers (original) and practitioners (original) were based on the original model presented before additional pathways were added as suggested by the SEM technique. Whereas, the fitness statistics for researchers (modified) and practitioners (modified) were based on the modified I.R. matrices of the two groups.

5.1. Significant Relationships between Indicators Identified by Both Groups

This subsection throws light on significant relationships between indicators commonly found in models of both the groups and is illustrated in

Figure 5.

Production Cost (PC) is significantly affected by Process Management (PM) and Cutting Quality (CQ). It is noted that CQ is proportional to PC and the product quality being manufactured. This increases the production cost, however, by effectively deploying techniques to manage the process, reduction can be achieved in terms of production cost. Thus, a suitable strategy should be devised to help achieve better quality product along with reduced production costs.

Workers Safety (WS) is significantly affected by Waste Management (WM) and Environmental Regulations (ER). WS can be ensured by providing a safe working environment by regulating various hazardous activities under strict environmental rules and regulations. In addition, techniques for disposal of waste should follow prescribed safety standards while carrying out routine tasks under different manufacturing environments. For example, safety guards in turning operations ensure proper disposal of chips as well as reducing the risk of accidents on the shop floor.

5.2. Differences between Groups on Significant Relationships of Indicators

This sub-section elucidates the differences between groups in terms of their identification of significant relationships between indicators, which are presented in the causal models of each respondent group. It further tends to identify the underlying reasons of the significant interrelationships in both models to provide further insights about the issues regarding implementation of sustainable manufacturing initiatives.

5.2.1. Significant Relationships Identified by Researchers Only

A discussion of the significant relationships found in the researchers’ group is presented as follows:

Cutting Quality (CQ) is significantly affected by Waste Management (WM) and Process Management (PM) wherein PM directly affects CQ. For example, referring to turning process, better quality of the manufactured product can be ensured by efficient utilisation of coolants and cutting inserts. In addition to this, manufacturing organisations can utilise advanced technological practices to reduce the waste generated as well as improve the quality of goods being manufactured.

Production Rate (PR) is also significantly affected by Cutting Quality (CQ), Training and Education (TR) and Material Aspects (ML). Higher cutting quality comes at the expense of lower production rates, as it takes longer to achieve acceptable quality, which leads to increased production cost. Moreover, material properties play a crucial part in the machining process as more energy is generally required to machine harder materials, thus resulting in low production rates. Hence, in order to increase production rates, different heat treatment applications are employed to achieve desired material properties. Moreover, well-trained workers equipped with required skills are more capable of achieving the required production rates.

Worker Health (WH) is significantly affected by Worker Safety (WS). The implementation of safety precautions in different industries is carried out to provide a safe working environment. The chances of injury and fatal accidents during work performance can thus be lowered by implementing improved safety initiatives and by providing recommended safety equipments.

5.2.2. Significant Relationships Identified by Practitioners Only

A discussion on the significant relationships found in the practitioners’ group is presented as follows:

Production Cost (PC) is significantly affected by Environmental Regulations (ER). ER have adverse effects on PC since they reduce the productivity of any organisation. When employing pollution control measures, it is necessary to make changes in the production processes. However, ER also have a proven record of helping to improve air and water quality.

Process Management (PM) is significantly affected by Training and Education (TR). Employee training can suitably enhance the organisational productivity. It also assists in developing desired skills regardless of any manufacturing operations in the workforce. It improves process management capabilities thus boosting the overall development of the organisation as well as its workers. Thus, the process management techniques helps in reducing lead-time and improve the quality of processes to enhance the sustainability of operations.

Energy Intensity (EI) is significantly affected by Material Aspects (ML), Process Management (PM) and Waste Management (WM). It is always desirable for energy consumption in manufacturing operations to be kept to a minimum, and this can mainly be achieved by appropriate selection of process management techniques, taking into account various energy optimisation models. Meanwhile, material aspects also significantly affect energy consumption. For example, hard materials may consume more energy. Therefore, there is a need to identify alternative materials that can still provide the same level of quality but consume less energy. Lastly, organisations can also achieve a desired energy efficiency through a suitable waste-management policy to minimise different undesired losses from the system. Moreover, there is a pressing need to achieve reduced carbon emissions and to minimise non-renewable energy consumption by producing energy through waste recycling or by harnessing renewable energy.

Worker Health (WH) is significantly affected by Training & Education (TR), Waste Management (WM) and Material Aspects (ML). In the manufacturing sector, certain hazardous materials can negatively affect the health of workers. Hence, it becomes essential to adhere to the safety guidelines defined by organisations in order to protect workers’ health. In addition, if there is non-compliance with waste-management procedures, workers can suffer injuries that render them incapable of working again. Imparting relevant training and education may aware employees on adverse effect of various operations and enables them to safely perform their jobs while minimising the risks.

Worker Safety (WS) is significantly affected by Worker Health (WH). The health and safety of workers are interrelated terms and must complement each other to keep workers mentally and physically healthy in a safe working environment. However, workers need to follow suitable guidelines responsibly while carrying out their jobs in an efficient and safe manner.

In view of above interpretations of graphical results, the following conclusions can be drawn:

The researchers’ group highlighted the significance of waste and process management in relation to other indicators, specifically in reducing production costs along with enhancing environmental regulations compliance.

The practitioners’ group were concerned about the economic-related aspects of machining processes along with achieving the required quality of products being manufactured. They also highlighted the need for suitable training and educational facilities to enhance their workers’ skills and to fully benefit from good waste management practices pursuant to sustainability.

6. Validation of Causality Models

Following the development of the causality models, an attempt has been made to validate the models by yielding the opinions of a relevant researcher and industry practitioner for each indicator. It was observed that the researchers placed more emphasis on human-centric issues, especially worker health and safety as a part of process management. Moreover, the researchers focused on production cost indirectly through production rate, process management and machining quality and highlighted economies of scale approach. Finally, the researchers also mentioned the impact of waste management practices on production cost, worker health and machining quality.

However, from the industry professionals’ perspective, the need to enhance the workforce’s skills through proper training was the most important concern. Though the main focus within the industry is to maintain a competitive edge in the market with minimum production cost and good product quality. The industry professionals added that the most significant factors affecting production cost were cost of raw materials, machining quality, process management and labour training. However, proper management of resources can help to reduce production cost. Finally, effective waste-management practices can certainly improve worker health and safety, thus leading to enhanced manufacturing performance.

Briefly put, researchers tend to focus on the health and safety of workers while the industry professionals seek to strengthen worker’s skills through training and education. Researchers focus on process management as a basic tool to control all associated processes related to waste management, worker safety and environmental regulations while the industry professionals’ focus is primarily on training to enhance the skills of their workforce. Meanwhile, both groups expressed a desire for government actions. Such governmental initiatives could take the form of devising policies or rolling out relevant projects in order to channel resources and to exploit researchers’ efforts to grow the manufacturing industry.

7. Conclusions and Future Research

This study has analysed the contextual relationships between critical indicators of sustainable manufacturing while taking into account both researchers’ and practitioners’ opinions. The study also compared and contrasted the views of both respondent groups. It was found that researchers emphasised the influence of waste and process management on relevant indicators with respect to enhancing sustainability, whereas, practitioners highlighted the requirement of improved training and education facilities, which enables a workforce to follow sustainability-oriented measures. They also emphasised to create better understanding about positive outcomes of waste-management practices to enhance sustainability.

This research has focused on manufacturing organisations seeking ways to improve their sustainability prospects. This study identified critical indicators after a detailed analysis of the literature and conducting surveys with both researchers and practitioners. This study has highlighted differences in the opinions of researchers and practitioners through research models that have been validated by employing statistical techniques for both the groups to understand interrelationships among different indicators. Because it is not practically feasible to simultaneously focus on all the indicators, this study should help manufacturing companies and relevant government agencies to establish appropriate procedures and strategies considering critical indicators in order to improve sustainability in the manufacturing domain.

This study paves the way for future research to validate the relationships between critical indicators of sustainable manufacturing in the context of developing countries. Besides that, more research is required to analyse the mediating factors affecting relationships between critical indicators. Such research would further aid manufacturing organisations to take control of the factors enabling or hindering the desired relationship outcomes.